Patents

Literature

51results about How to "Avoid uneven tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loop tension control method and device

ActiveCN104907346AAvoid uneven tensionAvoid excessive tension differenceRoll mill control devicesFlexible work arrangmentsStrip steelDrive motor

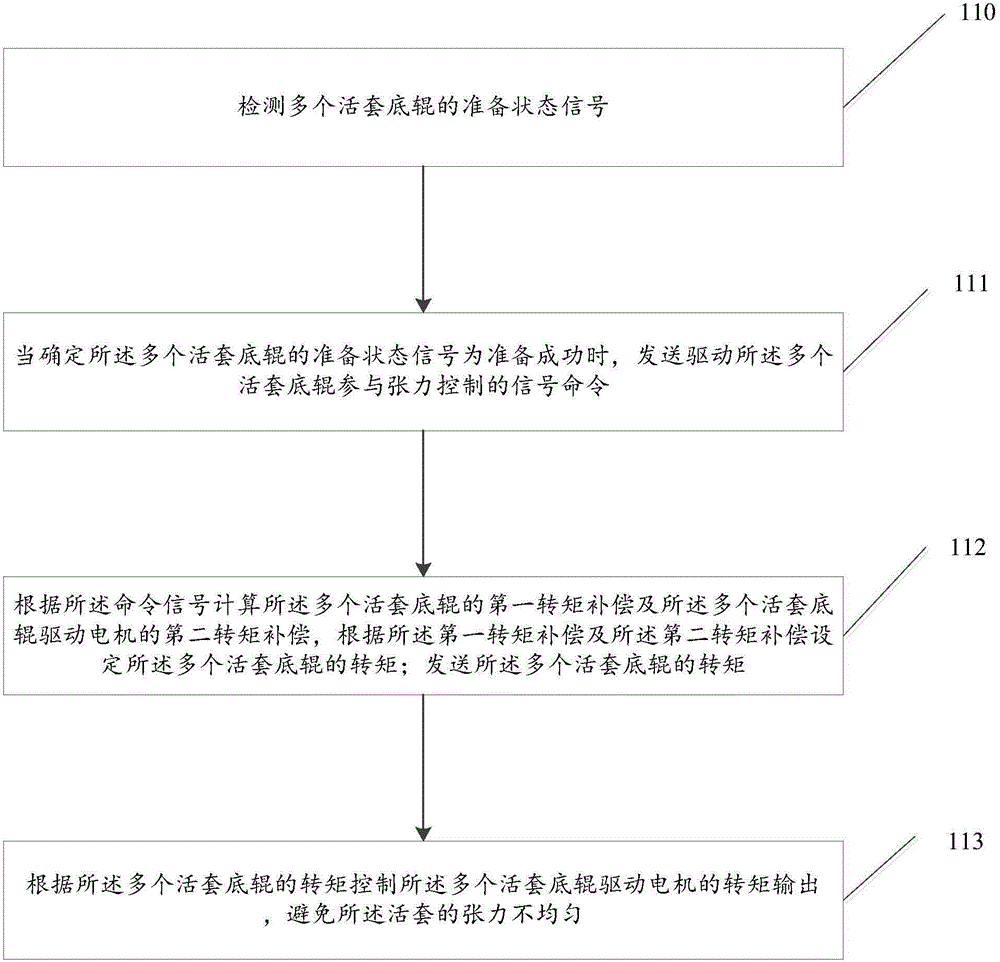

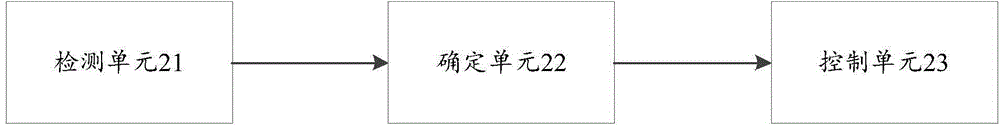

The invention provides a loop tension control method and device. The method includes the steps of detecting preparation state signals of a plurality of loop bottom rollers, generating instruction signals for driving the loop bottom rollers to participate in tension control when determining that the preparation state signals of the loop bottom rollers are successfully prepared, calculating first torque compensation of the loop bottom rollers and second torque compensation of loop bottom roller drive motors according to the instruction signals, setting torques of the loop bottom rollers according to the first torque compensation and the second torque compensation, sending the torques of the loop bottom rollers, and controlling the torque output of the loop bottom roller drive motors according to the torques of the loop bottom rollers so that the tension non-uniformity of loops can be avoided. Thus, the technical problem that in the prior art, due to the fact that the loop double-tower tension difference is too large, strip steel slides and gets loose is solved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

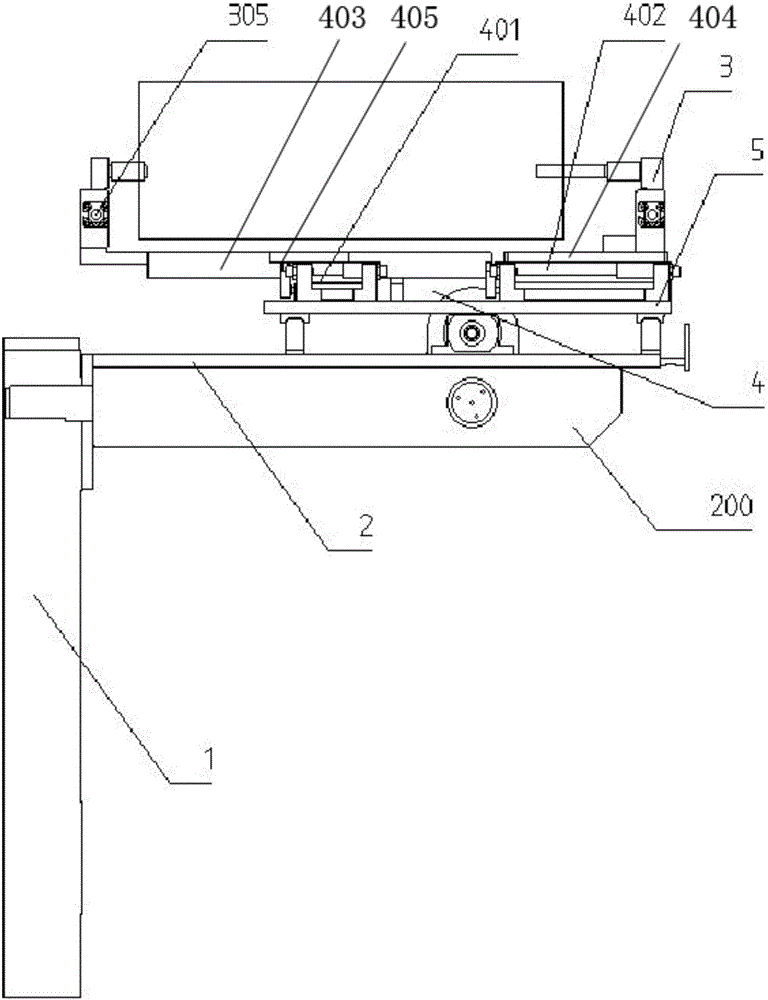

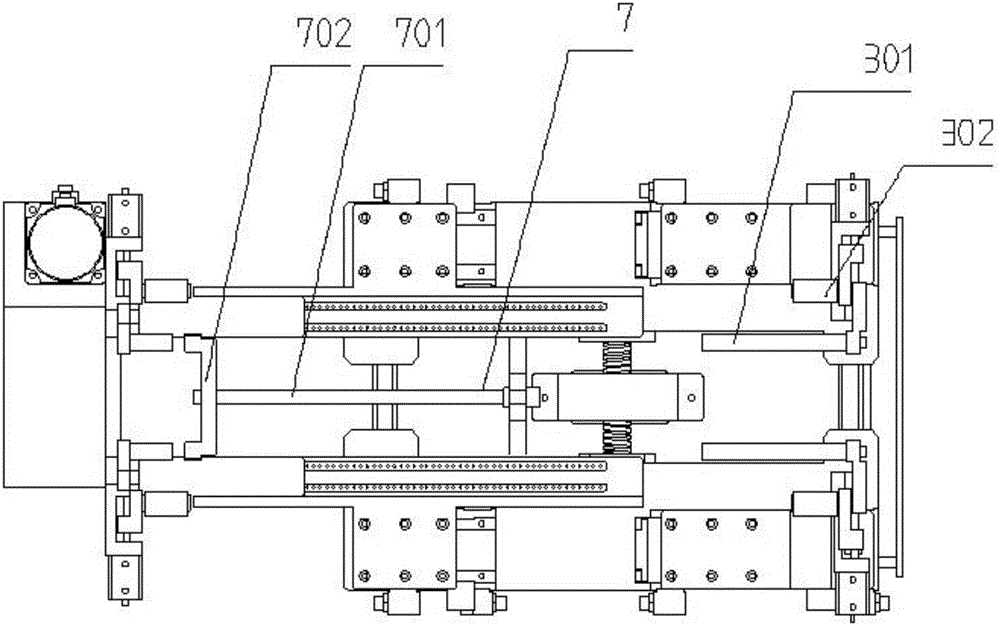

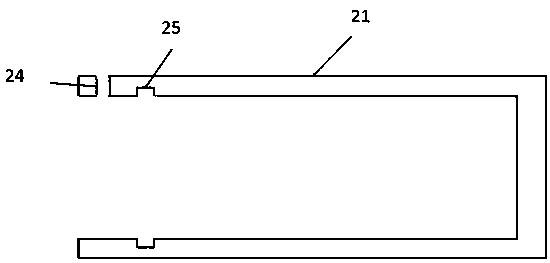

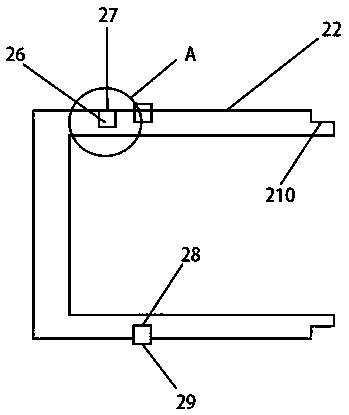

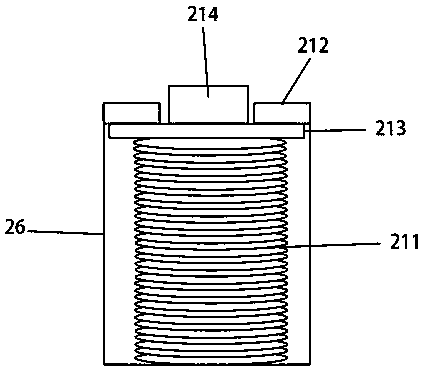

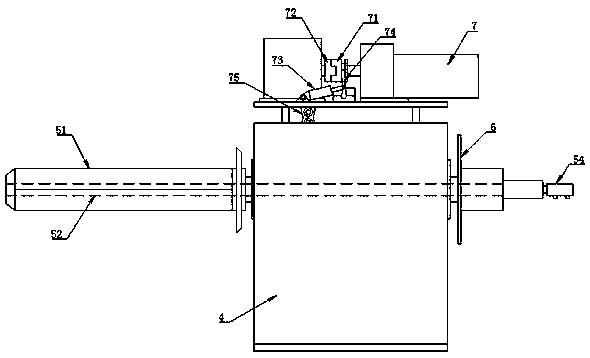

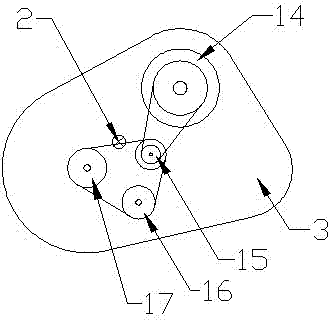

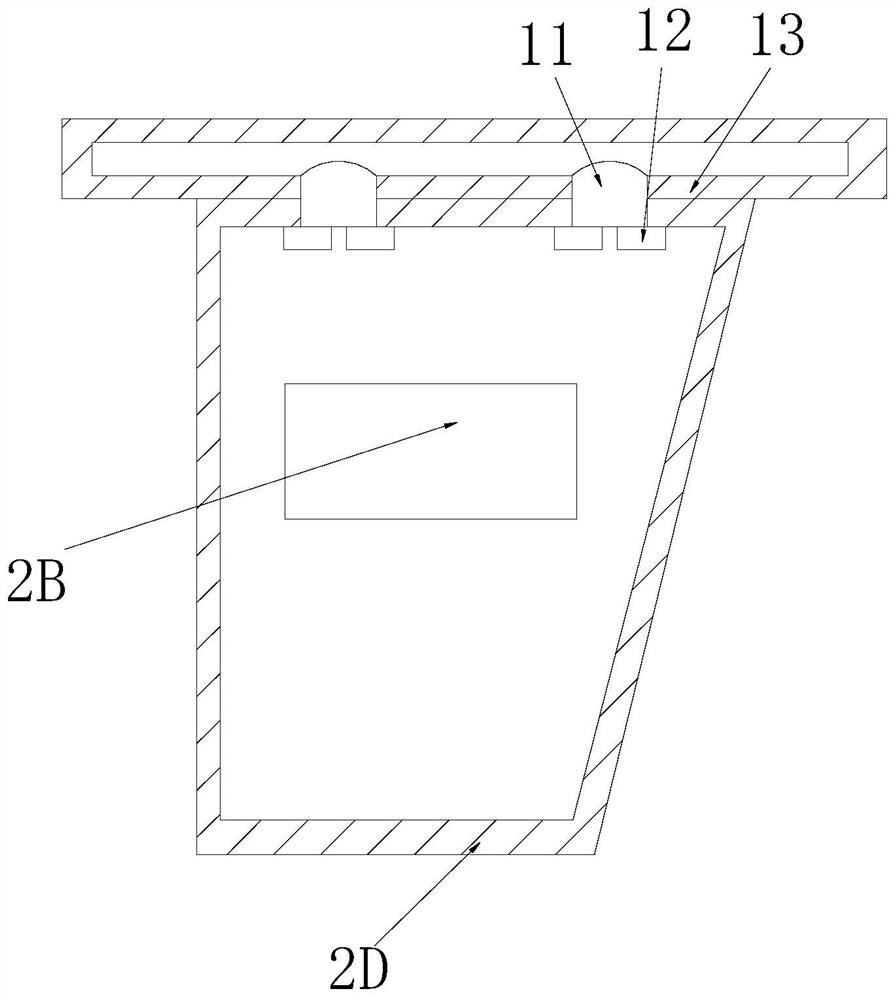

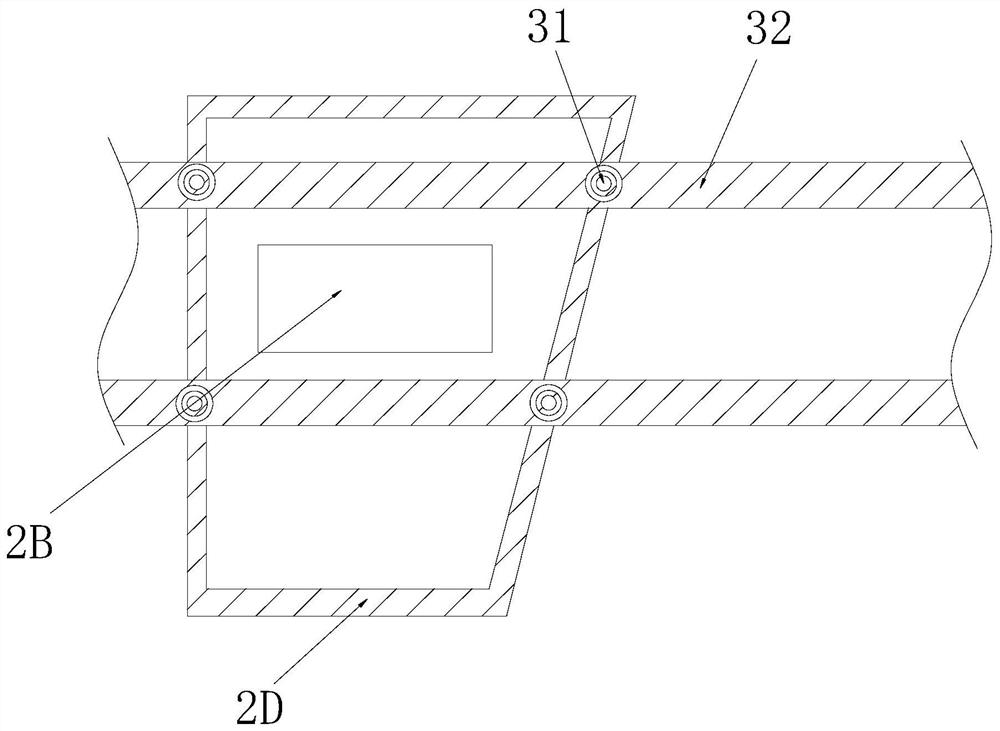

Battery cell clamping and connecting mechanism

ActiveCN106159343AQuality assuranceImprove winding efficiencyFinal product manufactureSecondary cells manufactureEngineeringRelative motion

The invention relates to a battery cell clamping and connecting mechanism. The battery cell clamping and connecting mechanism is characterized by comprising a first bottom plate, a clamping jaw motion mechanism and a stretching motion mechanism, wherein two second bottom plates capable of doing a relative motion are arranged on the first bottom plate in a fore-and-aft symmetry manner; the clamping jaw motion mechanism comprises two clamping jaw motion mechanism units symmetrically arranged on the two second bottom plates; each clamping jaw motion mechanism unit comprises a left clamping jaw and a right clamping jaw that clamp the left and right ends of a battery cell; the stretching motion mechanism comprises a stretching driving apparatus mounted on the first bottom plate; and the power output end of the stretching driving apparatus is connected with the two second bottom plates for enabling the second bottom plates to do the relative motion, so that the two clamping jaw motion mechanism units pull the clamped battery cell to be flat. According to the battery cell clamping and connecting mechanism, the round battery cell is pulled to be flat to obtain a flat battery cell, so that the problems of low winding efficiency of the flat battery cell and non-uniform tension force during winding of the flat battery cell in the prior art are avoided and the battery cell quality is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

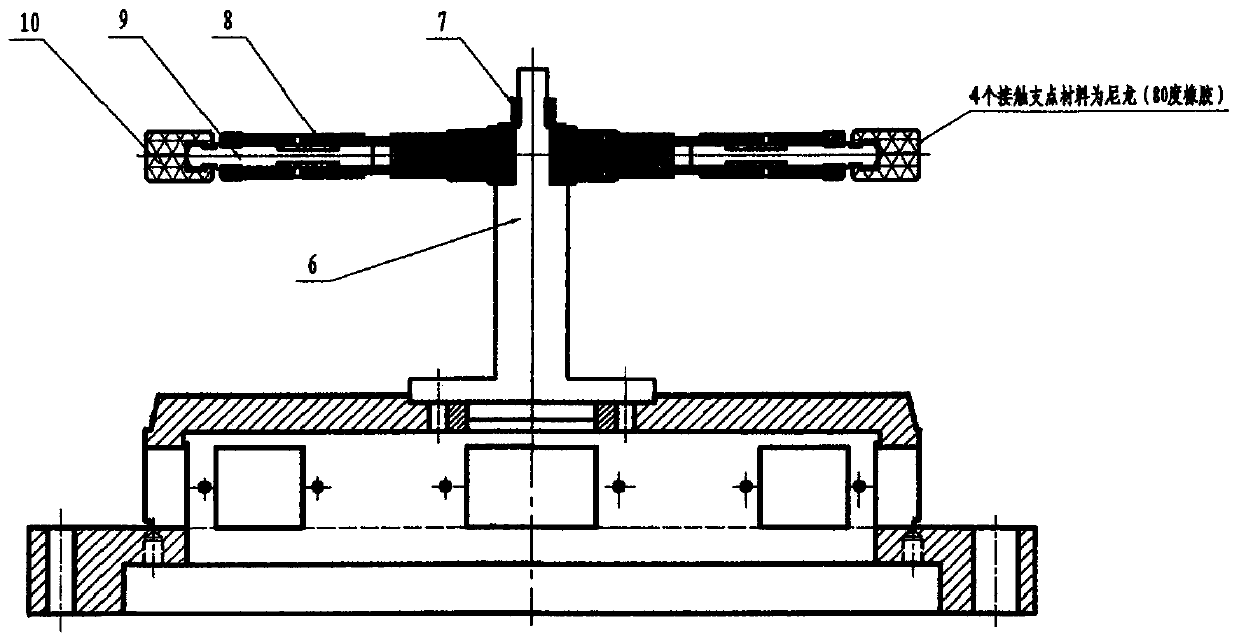

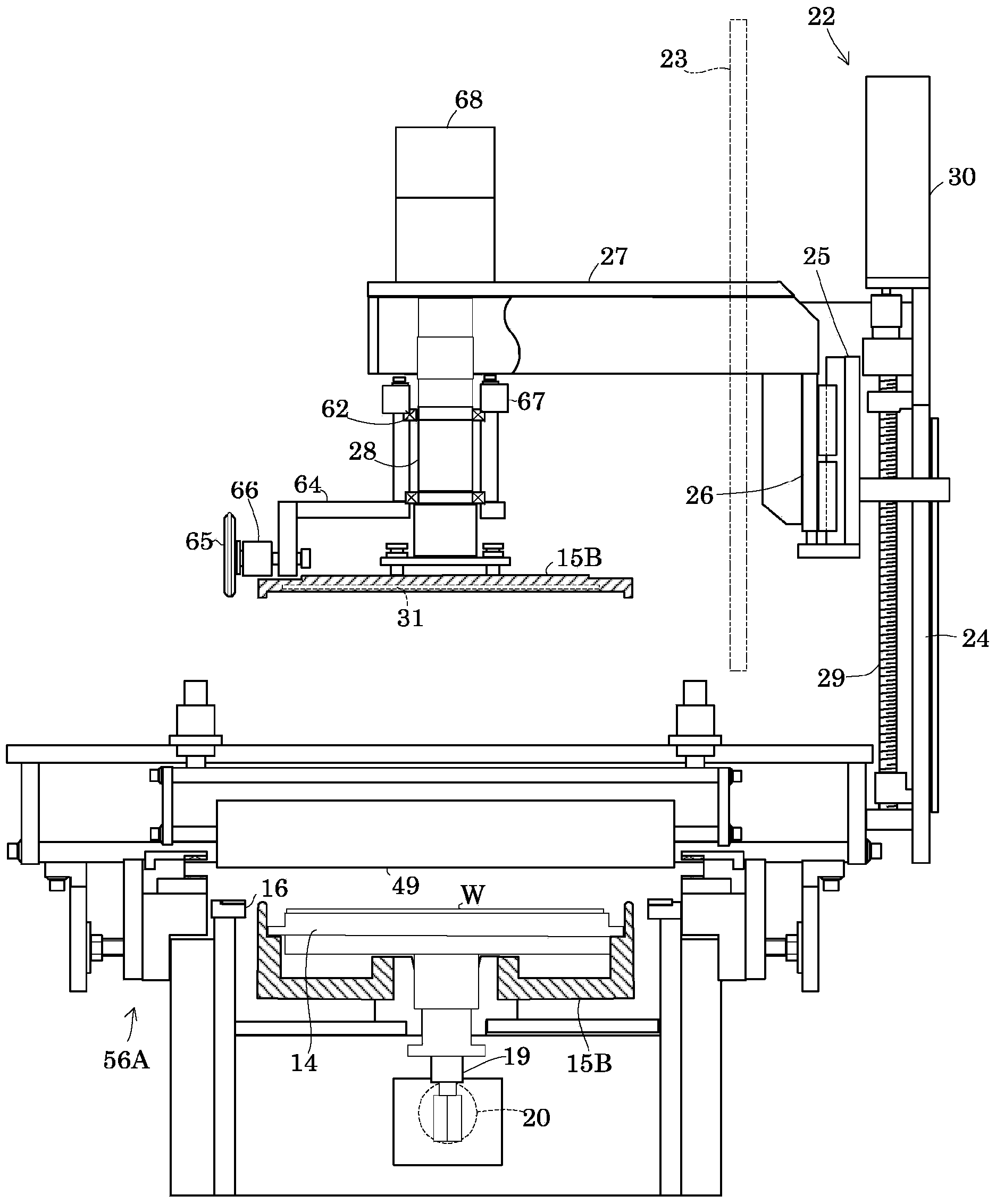

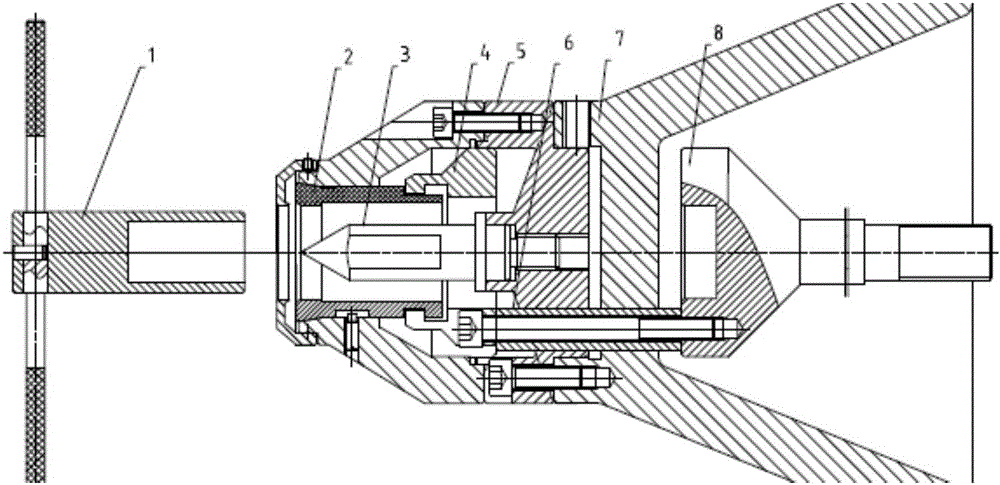

Machining device and method for double-layer casing of aero-engine

InactiveCN110774002ALoading and unloadingReasonable arrangementAircraft componentsOther manufacturing equipments/toolsAviationMechanical engineering

The invention discloses a machining device and method for a double-layer casing of an aero-engine. The device comprises an end surface gland, a shell, an inner sleeve, movable tensioning blocks, an air bag, a supporting rod, supporting arm nuts, supporting arms, a connecting seat, a ball head guiding rod, an inner hole fixing claw, an outer stand column, a transverse top head and a pressing plate.A turning and milling compound machining method is adopted, when an inner hole and an end surface are turned, the mode that an outer supporting is matched with the air bag for tensioning is adopted,and when an outer boss is milled, the mode that an inner supporting is matched with the air bag for tensioning is adopted; and according to the machining device, the high-quality and high-efficiency machining of the similar thin-wall double-layer casing can be achieved, and it is ensured that the circular degree of the casing meets the requirement.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

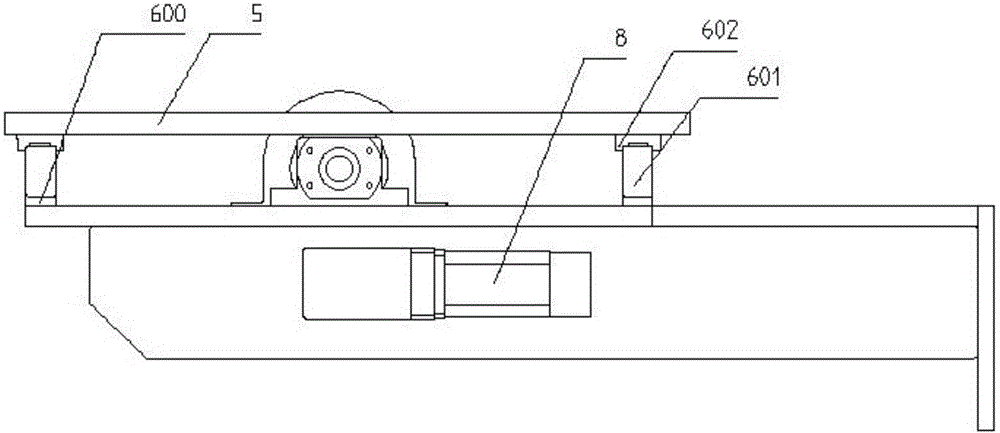

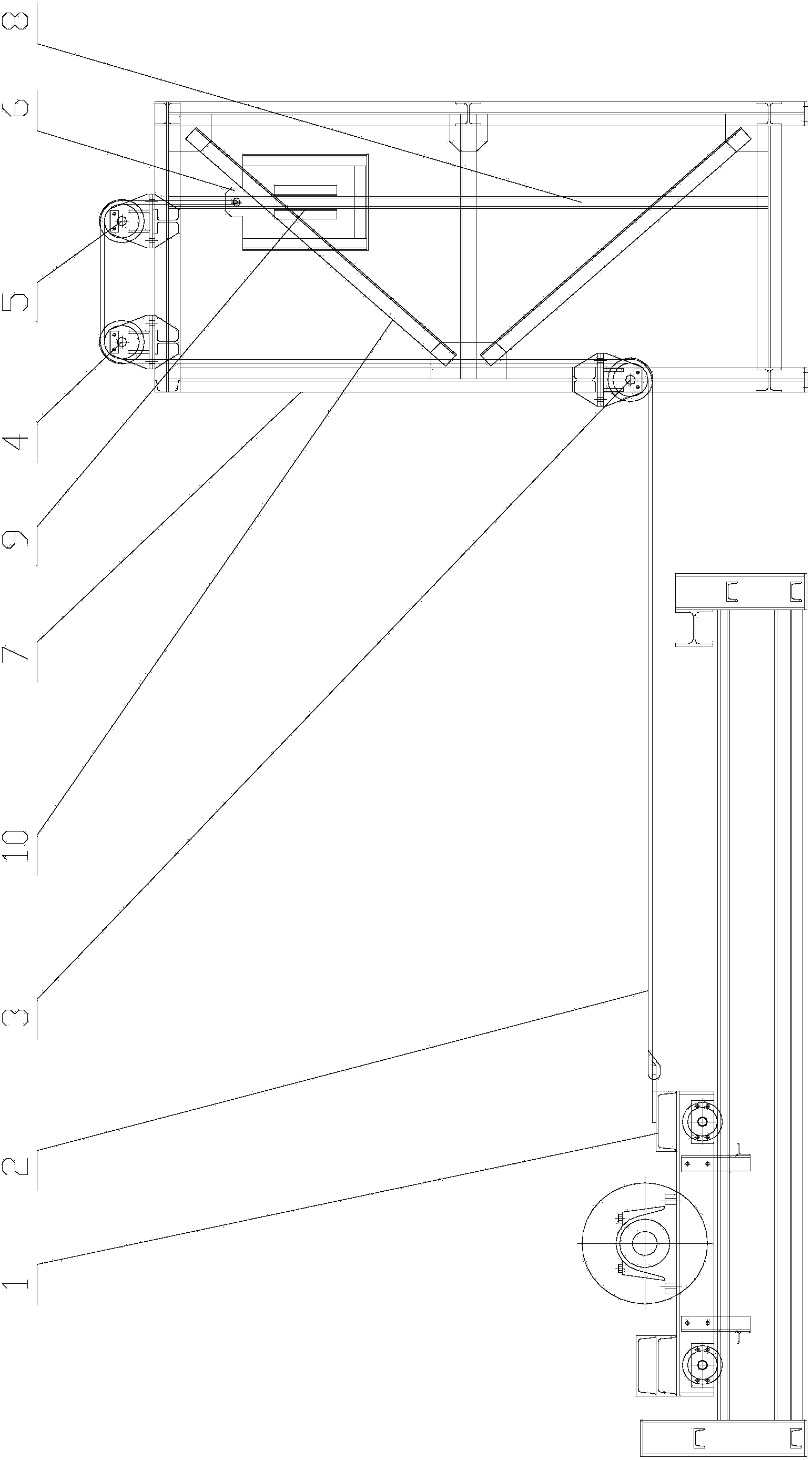

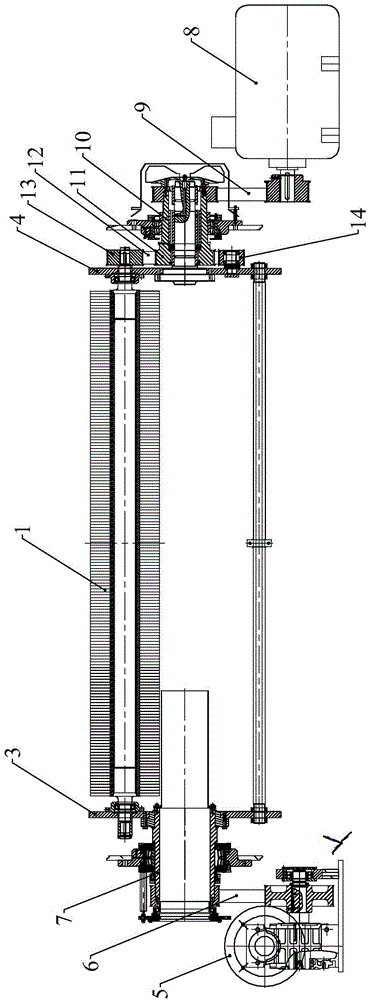

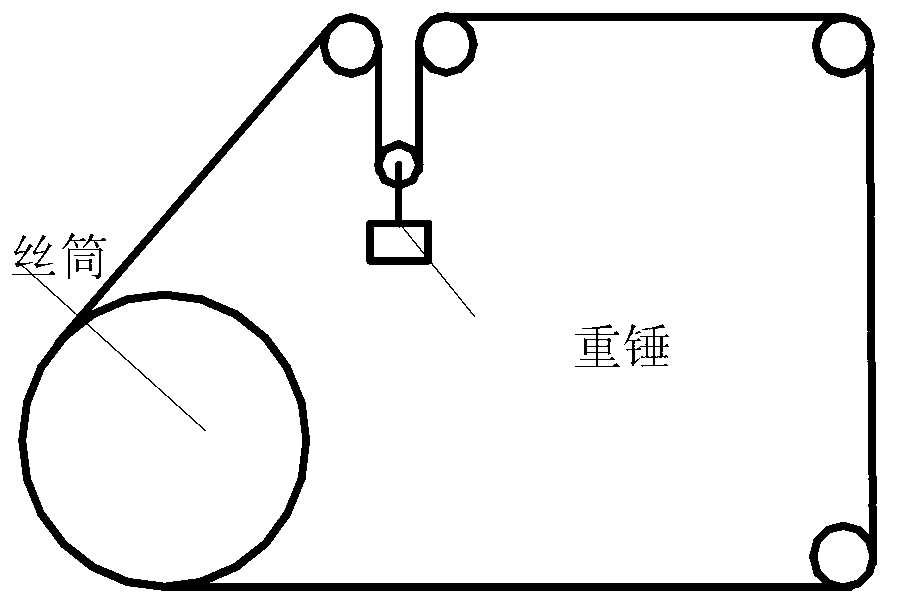

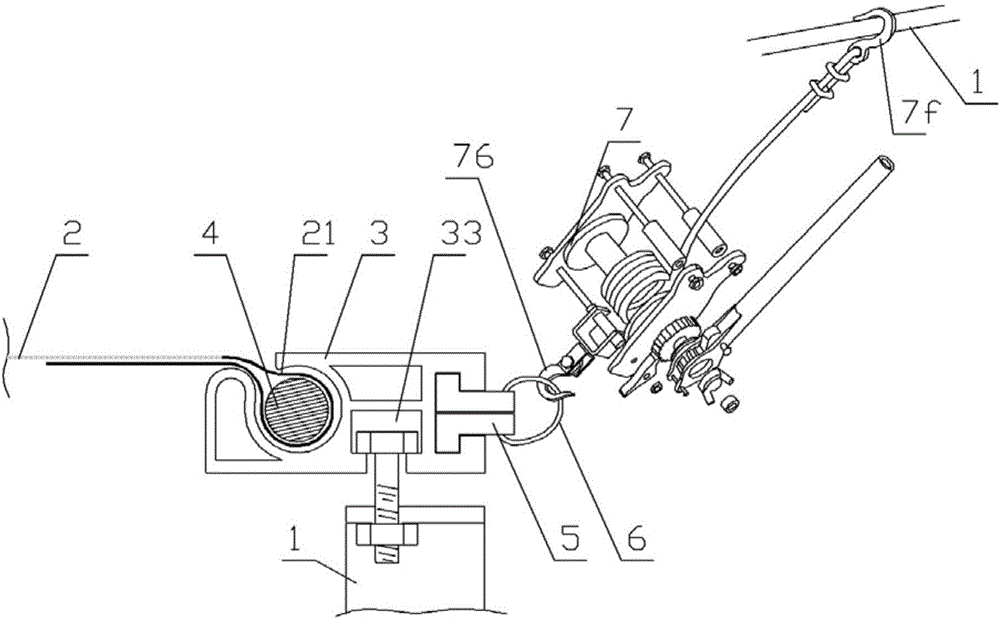

Gravity tensioning device of belt conveyor

The invention discloses a gravity tensioning device of a belt conveyor, and relates to the field of belt conveyors. The gravity tensioning device of the belt conveyor solves the problems that in the using process of the belt conveyor, with an existing tensioning mechanism, a belt of the belt conveyor can not be tensioned all the time, and use of the belt conveyor is seriously influenced because of instability of the tensioning state of the belt. The gravity tensioning device of the belt conveyor comprises a machine frame, a steel wire rope, a first turning pulley, a second turning pulley, a third turning pulley, a weight box, a gravity tensioning frame, a sliding rod and a hollow sliding rail. According to the gravity tensioning device of the belt conveyor, due to the design of the weight box and the turning pulleys, the steel wire rope can have a horizontal tensile force on the machine frame so that the belt of the belt conveyor can be tensioned, meanwhile, the weight box can only slide along the sliding rod, it is avoided that the tensile force is not even because the weight box waggles, and the belt can be tensioned well. The gravity tensioning device of the belt conveyor is suitable for the field of belt conveyors.

Owner:JIANGSU JIANGDA MACHINERY

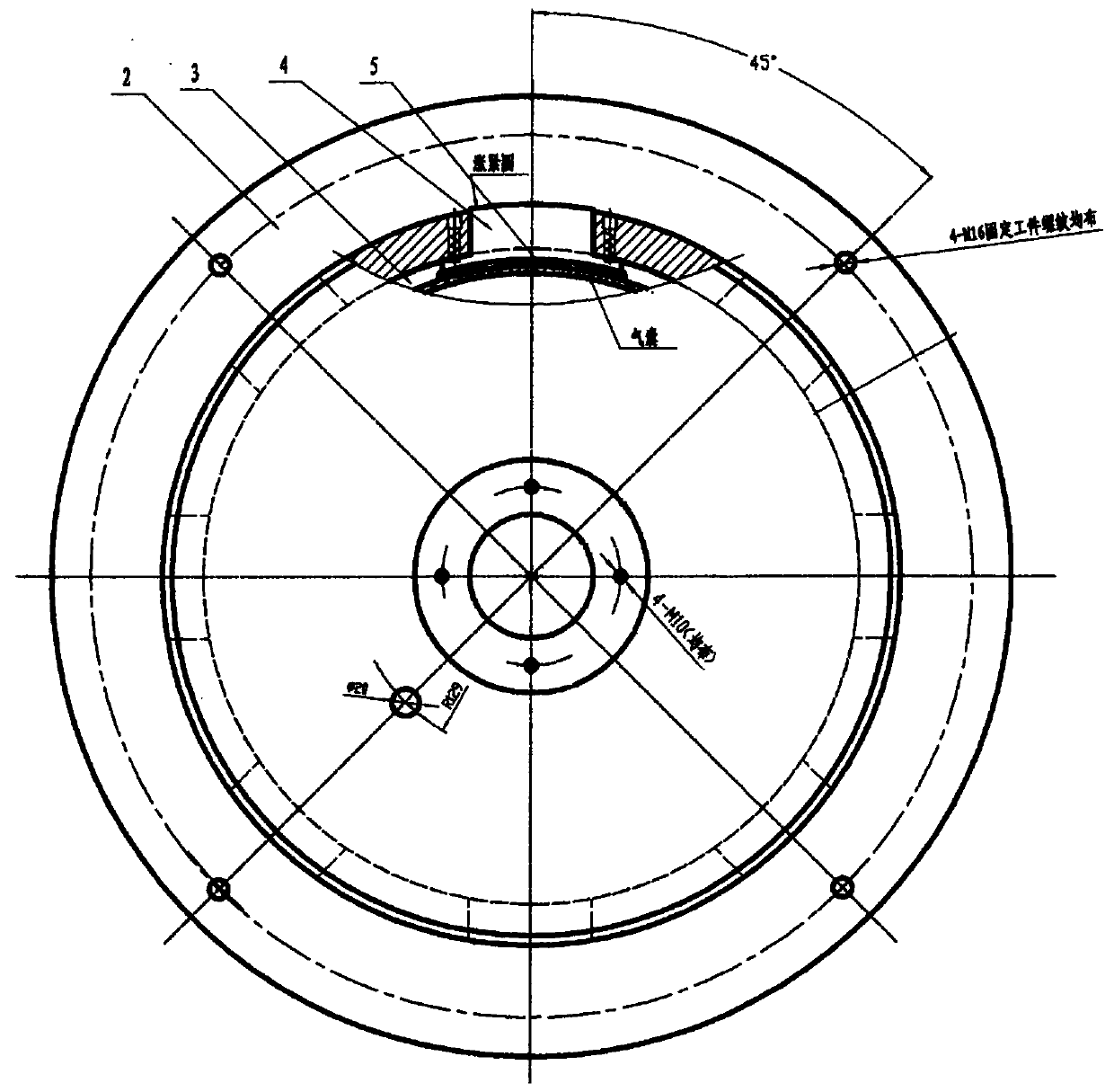

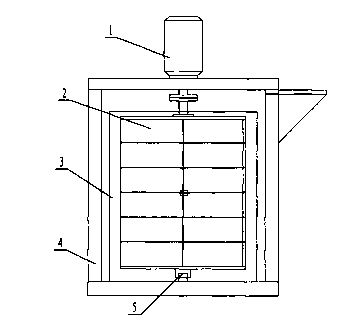

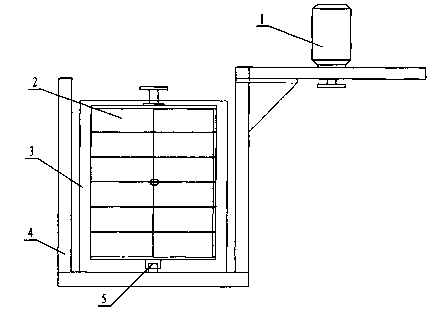

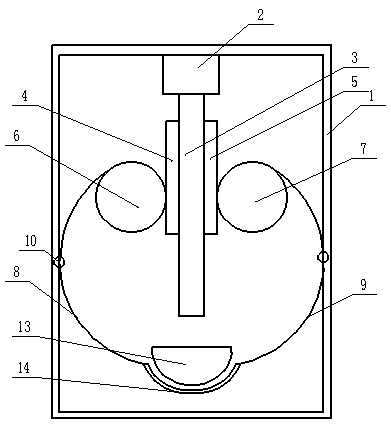

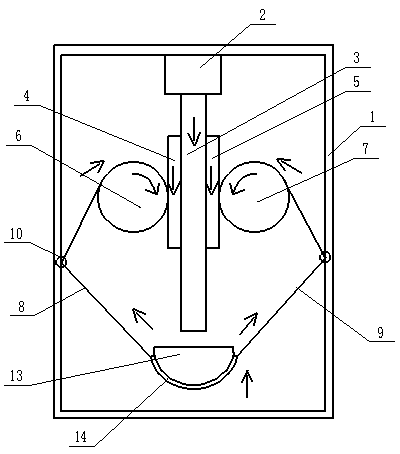

Dyeing vat

InactiveCN102864604AUnified operationAvoid uneven tensionTextile treatment containersYarnEngineering

The invention relates to a dyeing vat. The dyeing vat comprises a vat body (3) and a skein cage (2), the skein cage (2) is located in the vat body (3), the skein cage (2) comprises a circular cage body (8), a frame (4) and a power source (1) are arranged on the outside of the vat body (3), the power source (1) is arranged on the frame (4), a flange (7) is arranged at the upper end of the cage body (8), a locating shaft (5) is arranged in the middle of the bottom portion of the outside of the cage body (8), and the power source (1) is connected with the cage body (8) through the flange (7) at the upper end of the cage body (8). The skein cage can be driven by the power source to rotate around an axis of the locating shaft, yarns and the dyeing vat relatively move in the dyeing vat, dyeing time is greatly saved, dyeing effects are improved, production efficiency is greatly improved, and rotation of the skein cage enables liquid such as dye liquor to be stirred, so that yarn dyeing is even, product quality is unified, problems such as uneven tensile force borne by yarn materials are avoided, and the product quality is good.

Owner:CHANGZHOU POLYACE TEXTILE & YARN

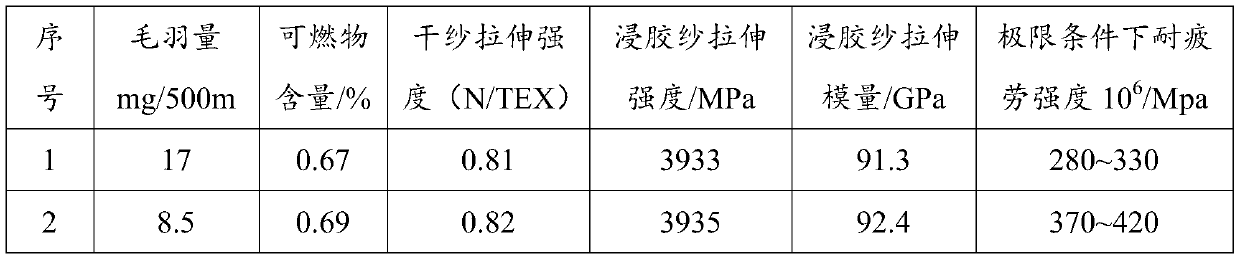

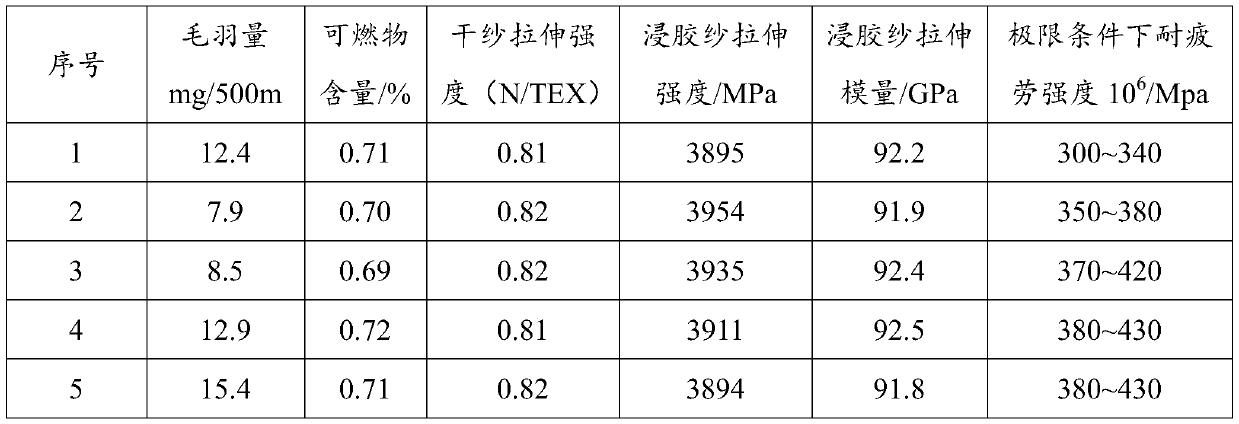

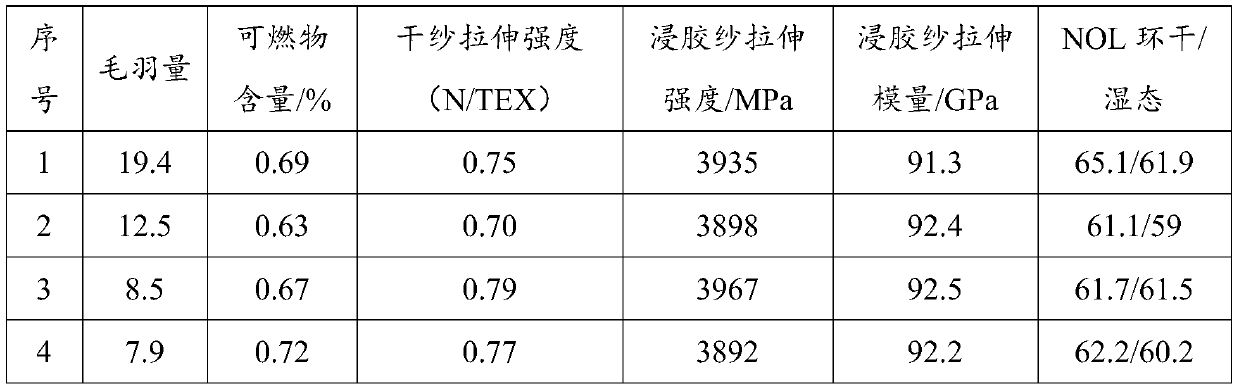

Film forming agent suitable for glass fibers, impregnating agent comprising same, and preparation method and applications of impregnating agent

The invention relates to the technical field of impregnating agents, and discloses a film forming agent suitable for glass fibers, an impregnating agent comprising the same, and a preparation method and applications of the impregnating agent. The film forming agent comprises emulsified bisphenol A type epoxy resin and polyester type polyurethane. Through the emulsification effect of a surfactant, the interfacial energy of a system is reduced, the stability of epoxy resin emulsion is improved, and thus the function of the epoxy resin emulsion can be better exerted. The polyester polyurethane film forming agent has a large molecular weight and a strong yarn-wrapping performance and easily forms a compact film on the surface of glass fibers, thus the glass fibers are isolated from the external environment, water will not enter the cracks of the glass fibers, the elasticity and wear resistant performance of yarns are improved, the anti-fatigue performance of yarns is strengthened, at the same time, the bundling force is high, and the phenomenon of yarns such as natural draping, non-uniform tension force, and the like, is effectively relieved.

Owner:SINOMA SCI & TECH

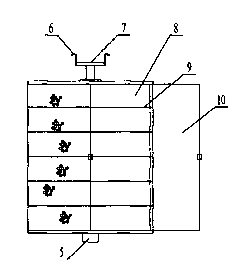

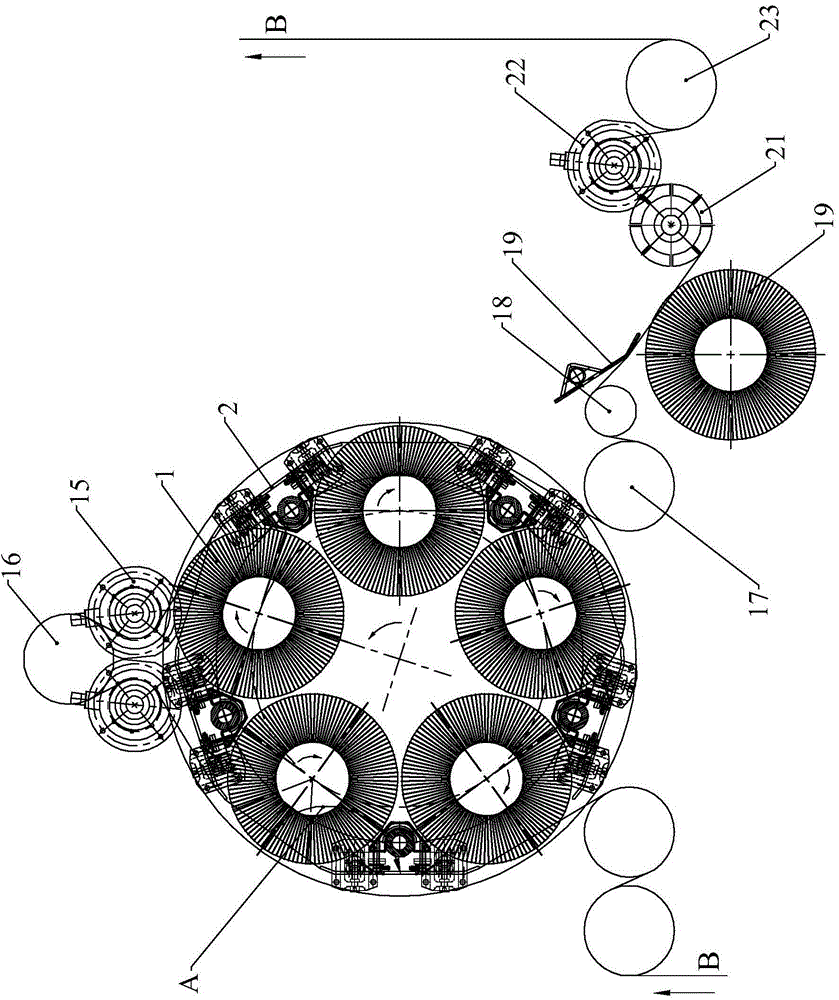

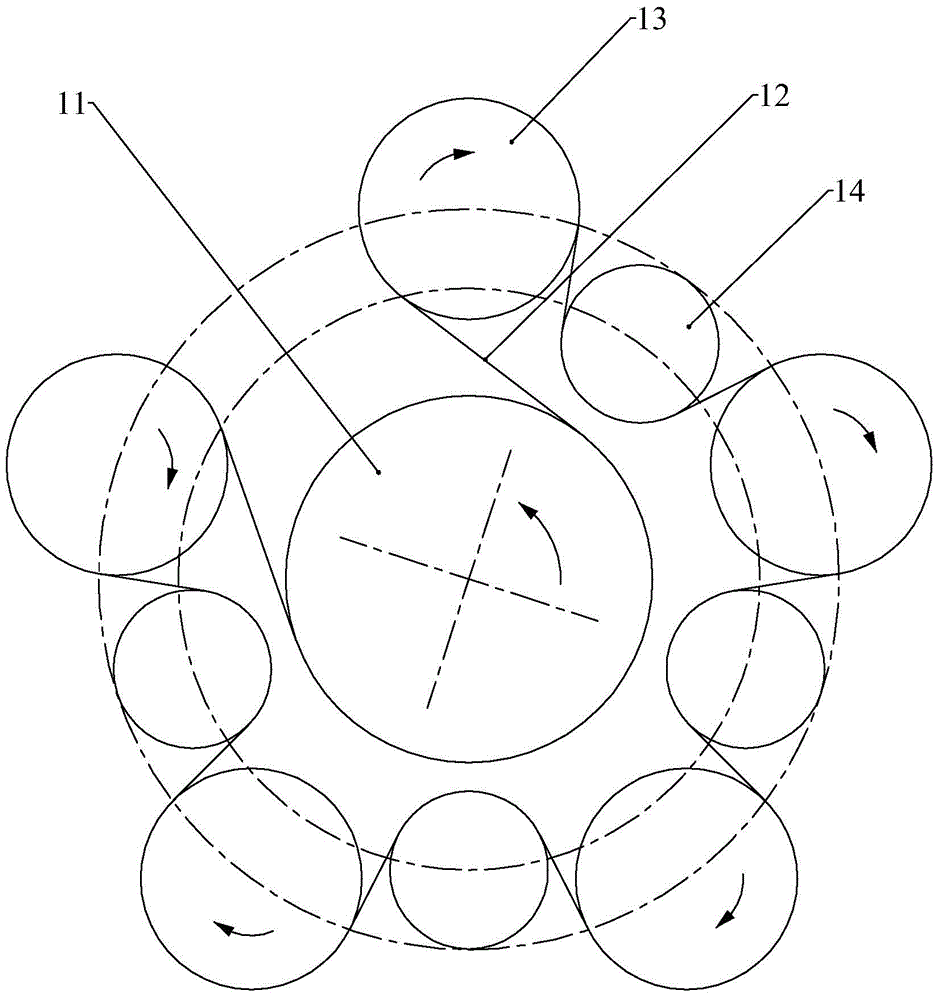

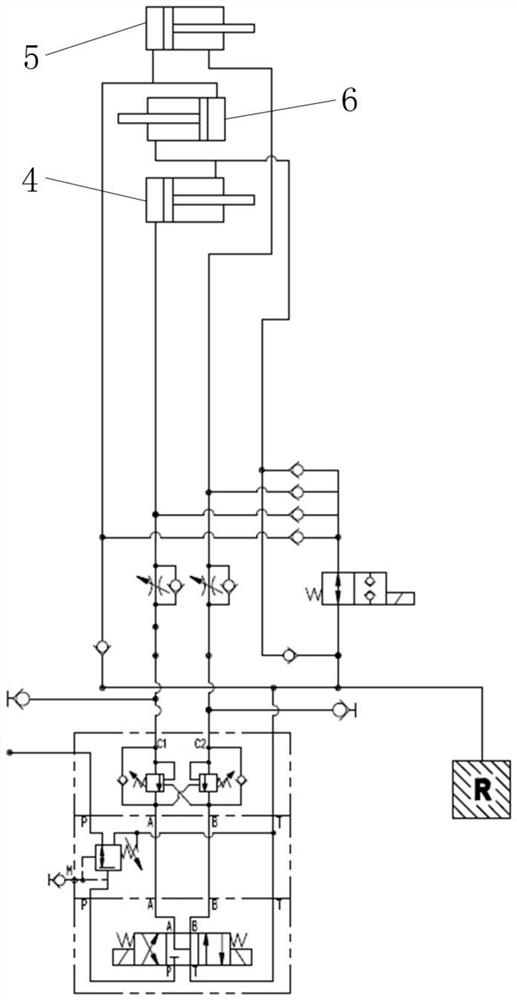

Sanding system of sanding machine

The invention relates to a sanding system of a sanding machine. The sanding system comprises a brush drum, a brush drum drive device, a brush roller drive device, a brush roller synchronous rotation device and a sanding arrangement device. The brush drum comprises five brush rollers and five adjustment plate devices. The five brush rollers are arranged on a left supporting plate and a right supporting plate through even distribution and arrangement frames of planet structures. The adjustment plate devices are arranged between the adjacent brush rollers. A brush drum motor drives a brush drum transmission device to form the brush drum drive device through a brush drum synchronous belt. The brush roller motor drives a brush roller transmission device through a synchronous belt. A main transmission belt wheel of the brush roller synchronous rotation device is driven by the brush roller transmission device. A brush roller double-sided synchronous belt changes the direction through tensioning belt wheels and drives five brush roller transmission belt wheels to synchronously rotate. An outlet drive roller of the sanding arrangement device drives sanding cloth to be subjected to sanding arrangement through the outlet brush roller by means of a cloth guide roller and an adjustment pressing plate. The sanding system has the advantages of being capable of saving energy, convenient to install and detach and good in sanding effect.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

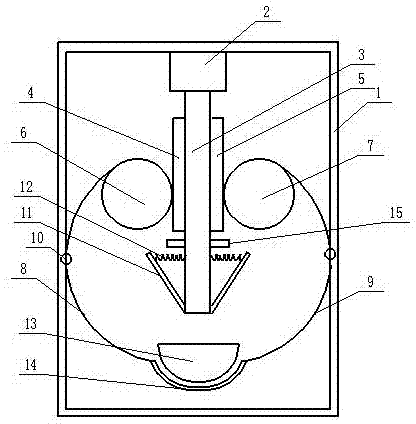

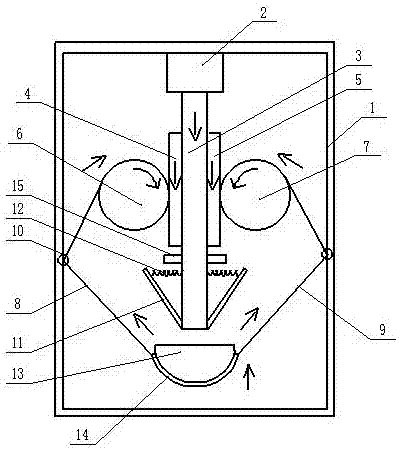

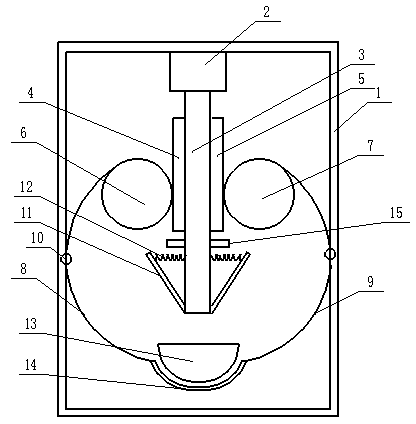

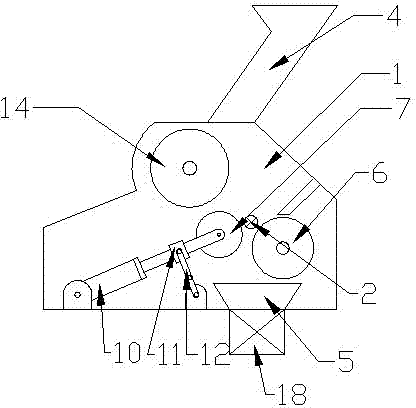

Wood board bending method

ActiveCN107486902AAvoid bending failuresImprove bending effectWood stock bendingHydraulic cylinderLinear motion

The invention relates to the field of wood board bending equipment, in particular to a wood board bending method. The wood board bending method comprises the steps that a wood bending machine is prepared; a wood board is mounted; a hydraulic cylinder is started; a hydraulic cylinder output shaft is controlled to slowly extend and retract within the extension stroke being 2-4cm; the hydraulic cylinder output shaft is controlled to retract 30-50cm at a time; and the bent and formed wood board is taken out. When the hydraulic cylinder output shaft extends, racks make linear motion downwards, gears engaged with the racks rotate towards the racks, one ends of bundled steel wires are fixed to the gears, the other ends of the bundled steel wires are fixed to the wood board, the gears tighten the bundled steel wires when the gears rotate towards the racks, and the bundled steel wires are shortened so that the wood board is attached to a mould till the wood board is stretched and then is subjected to bending forming. With the implementation of the technical scheme, a bending forming failure is avoided due to the fact that the two ends of the wood board are stressed sufficiently, and the wood board is saved.

Owner:重庆市浩源门业有限公司

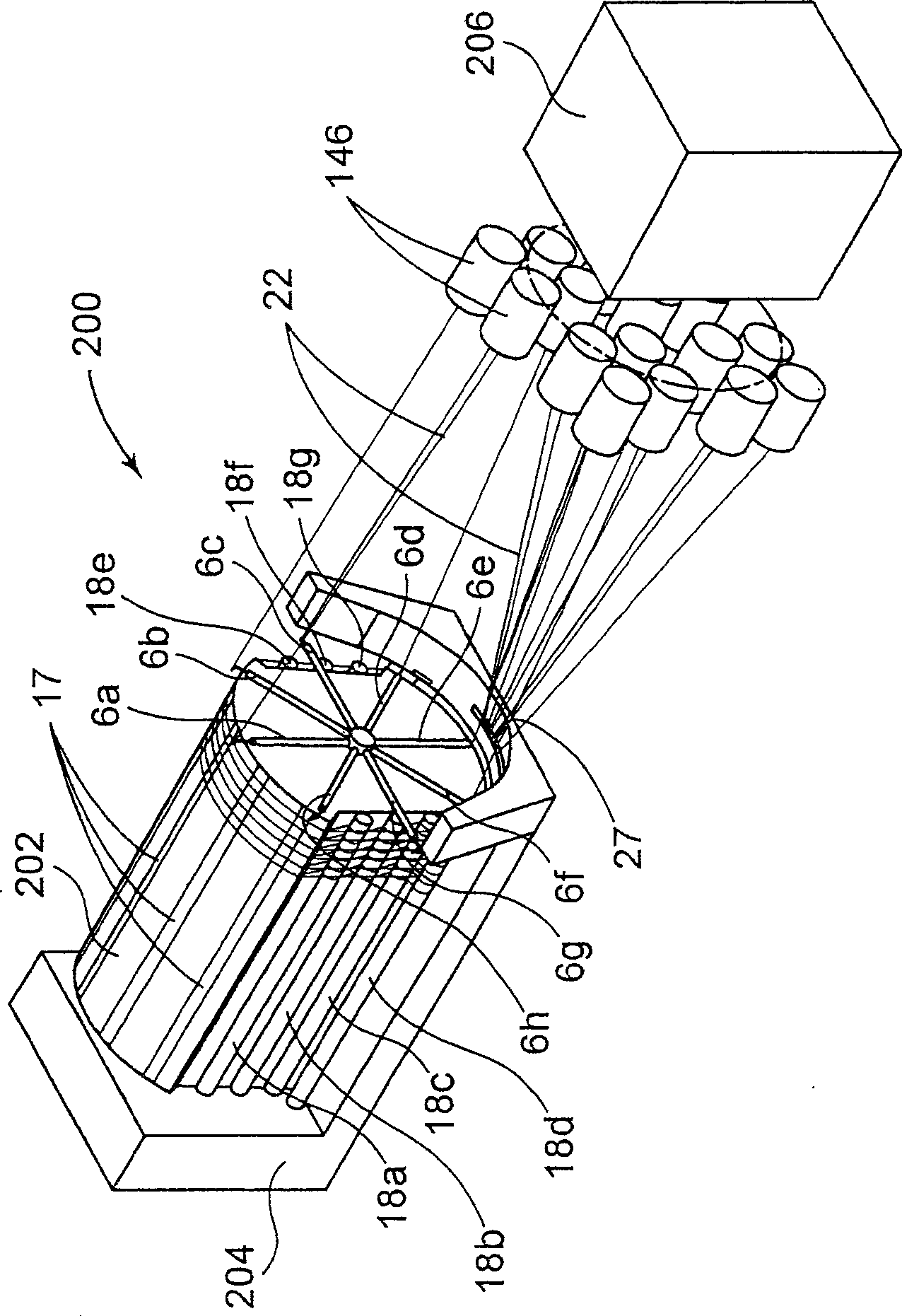

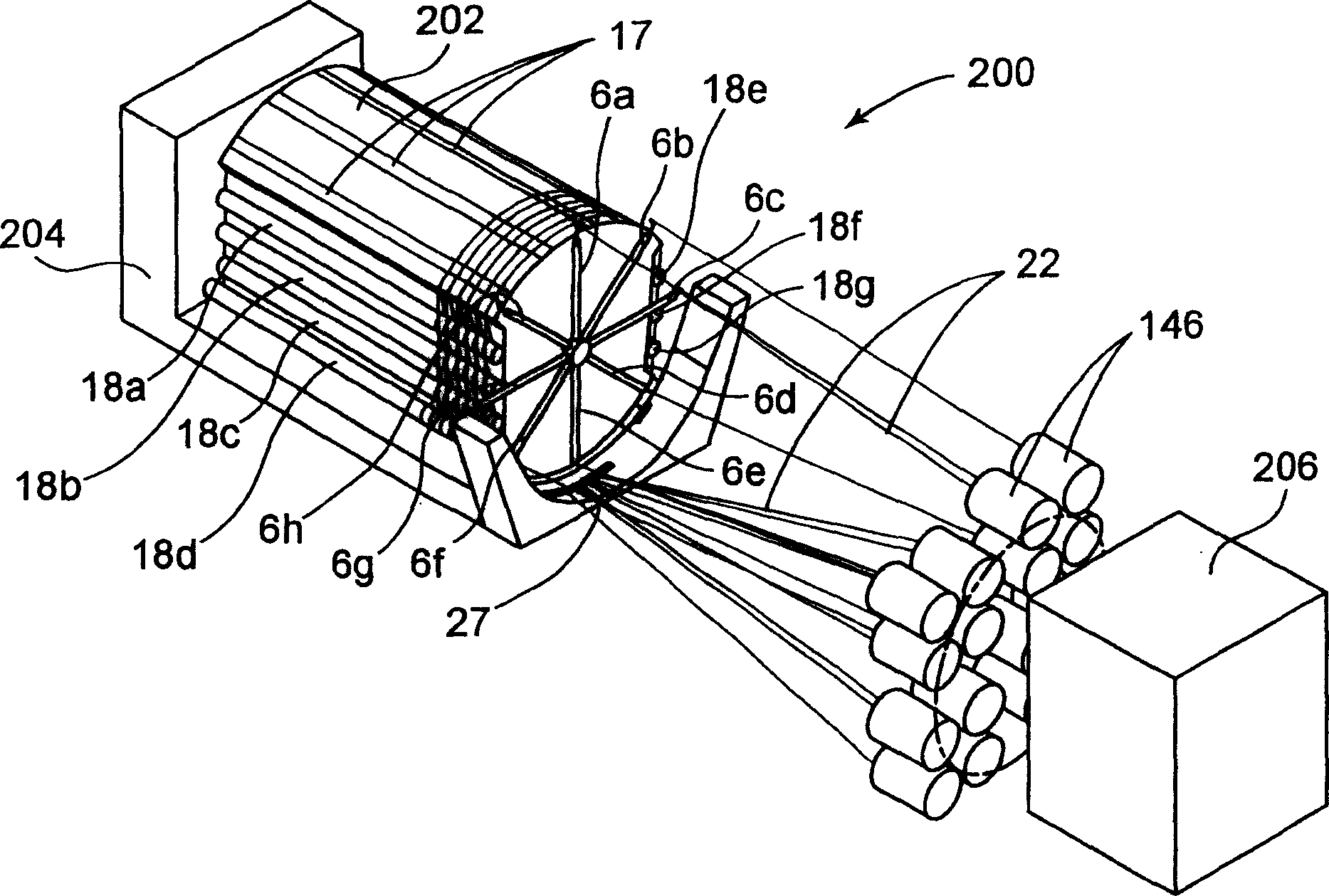

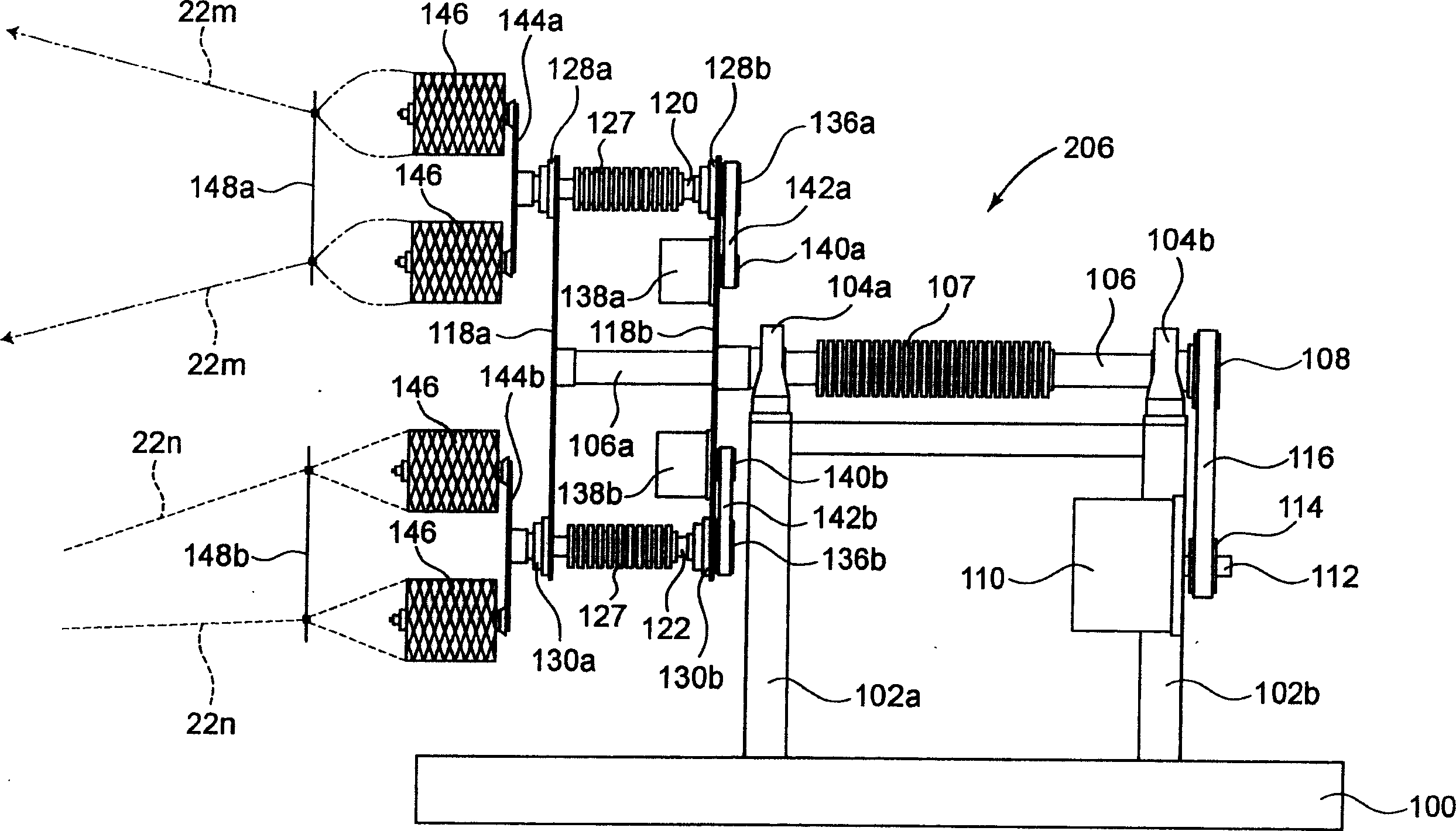

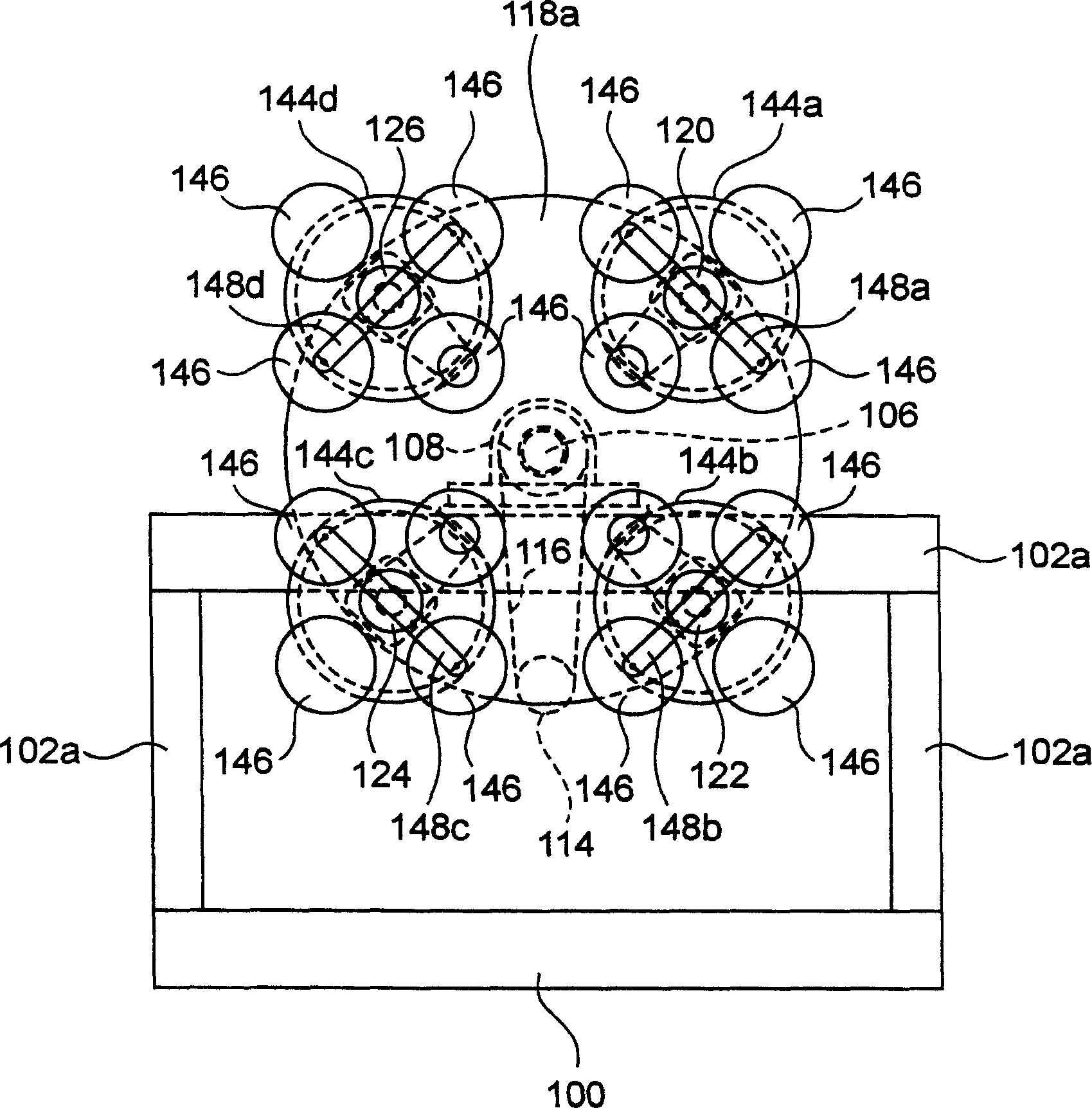

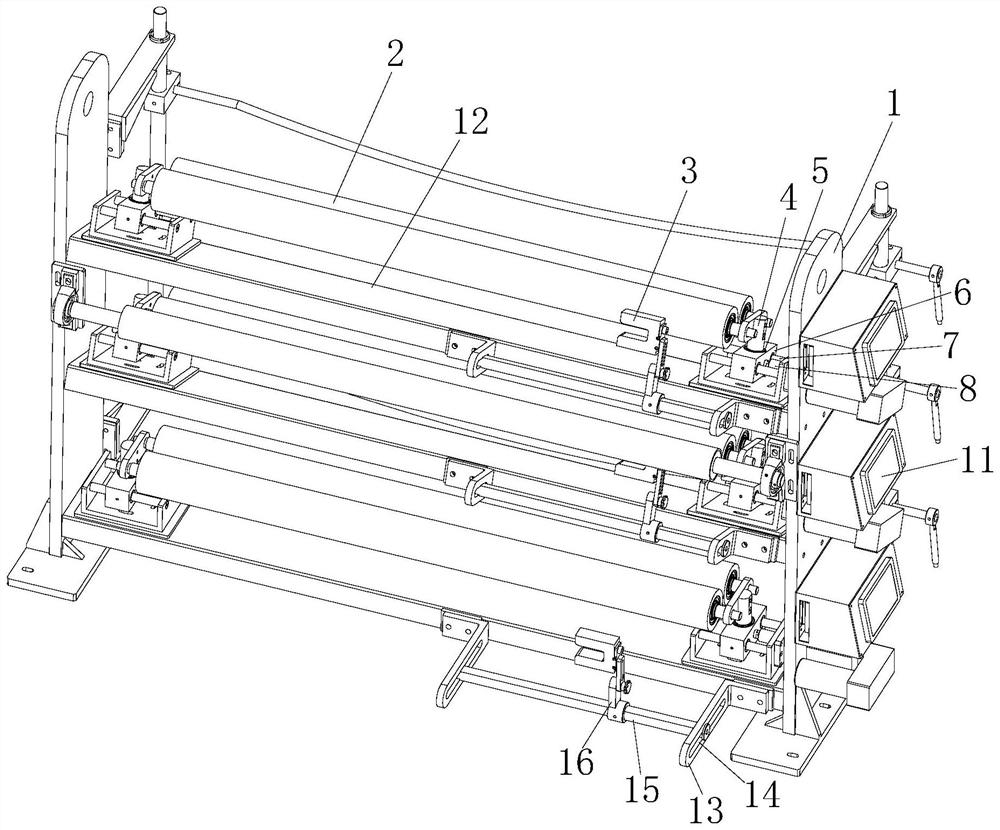

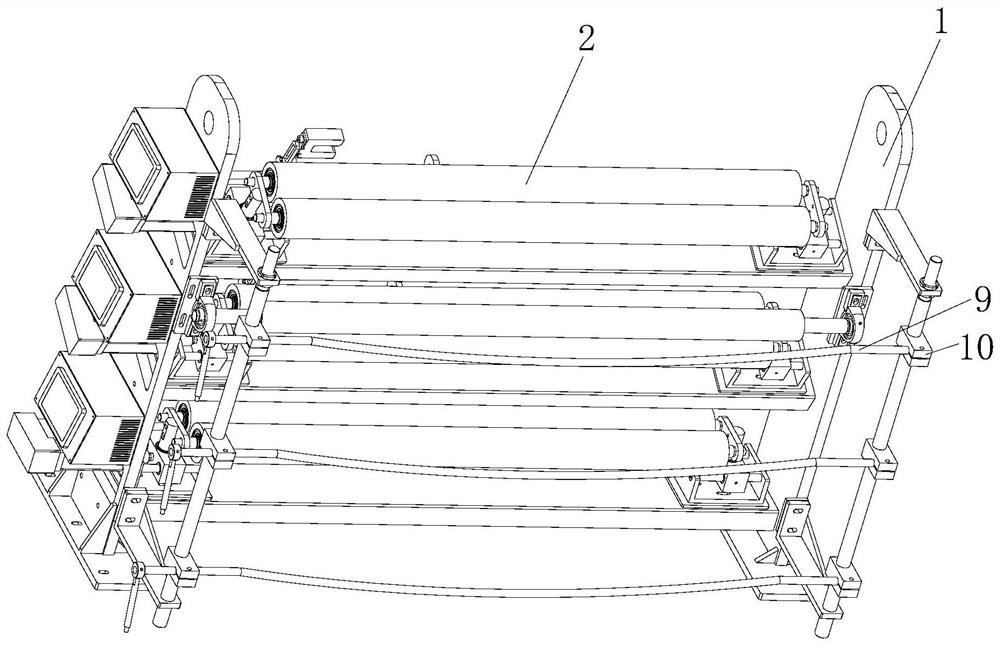

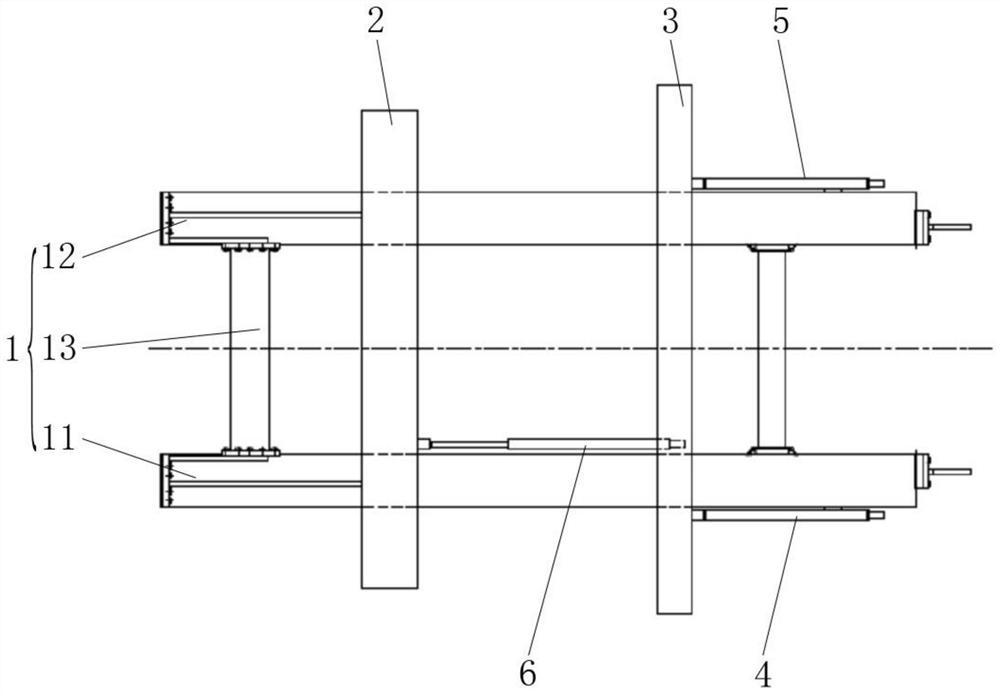

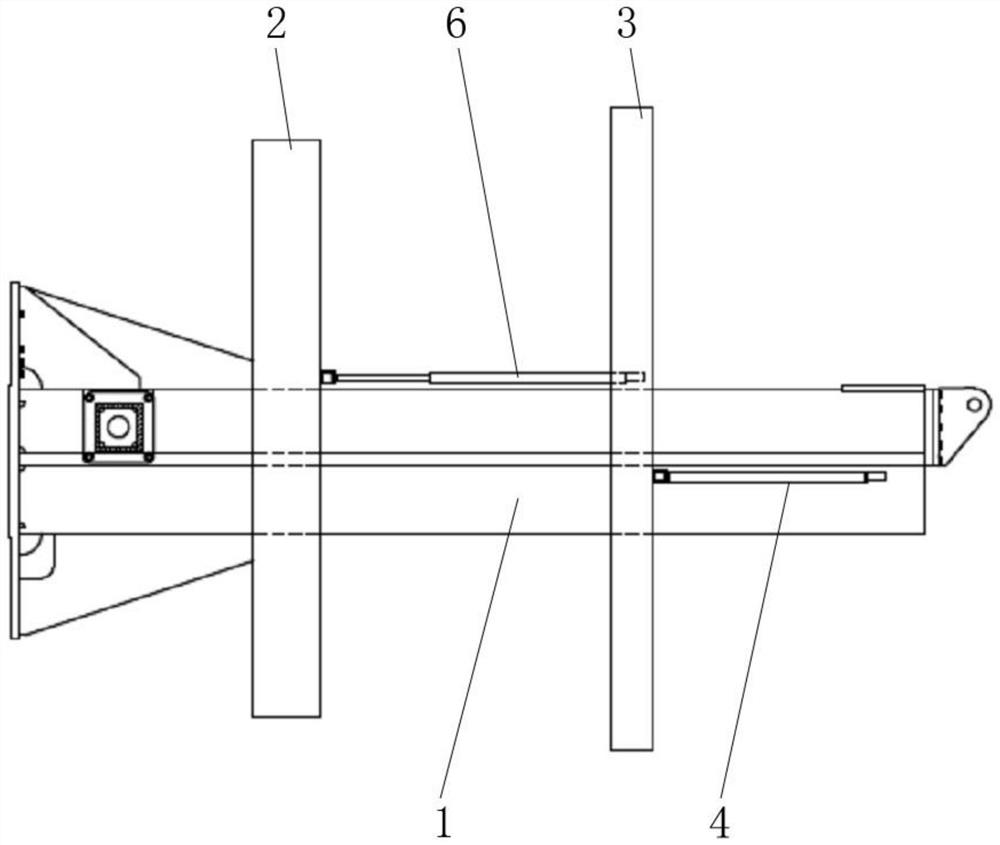

Multi-shaft rotary creel, sample warper and warping method

A multi-axis rotary creel, a sampling warping machine, and a warping method, a multi-axial rotary creel, comprising: a base body; A plurality of fulcrums rotatably arranged on the front protruding portion of the main shaft, and a plurality of bobbins mounted on each of the fulcrums; and arranged opposite to a sampling warping machine with a plurality of yarn guides; The main shaft or each fulcrum rotates in synchronization with the rotation of the yarn guide, while simultaneously warping a plurality of the main shafts or each fulcrum simultaneously with the main shaft. Compared with the conventional single-axis rotary creel, this multi-axis rotary creel can further improve the degree of freedom of warping, and can provide a new multi-axial rotary creel that can prevent uneven tension and is provided with the Multi-axis rotary creel, sampling warping machine for more efficient warping and warping method thereof.

Owner:SUZUKI WARPER LTD

Multi-shaft rotary creel, sample warper and warping method

Owner:SUZUKI WARPER LTD

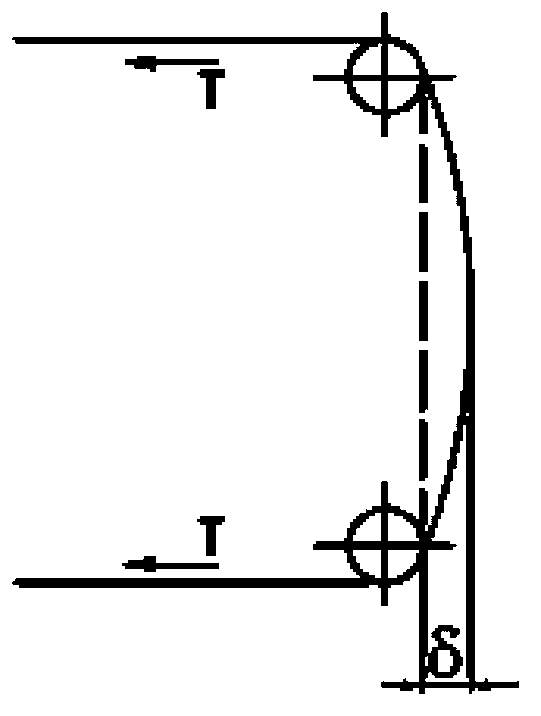

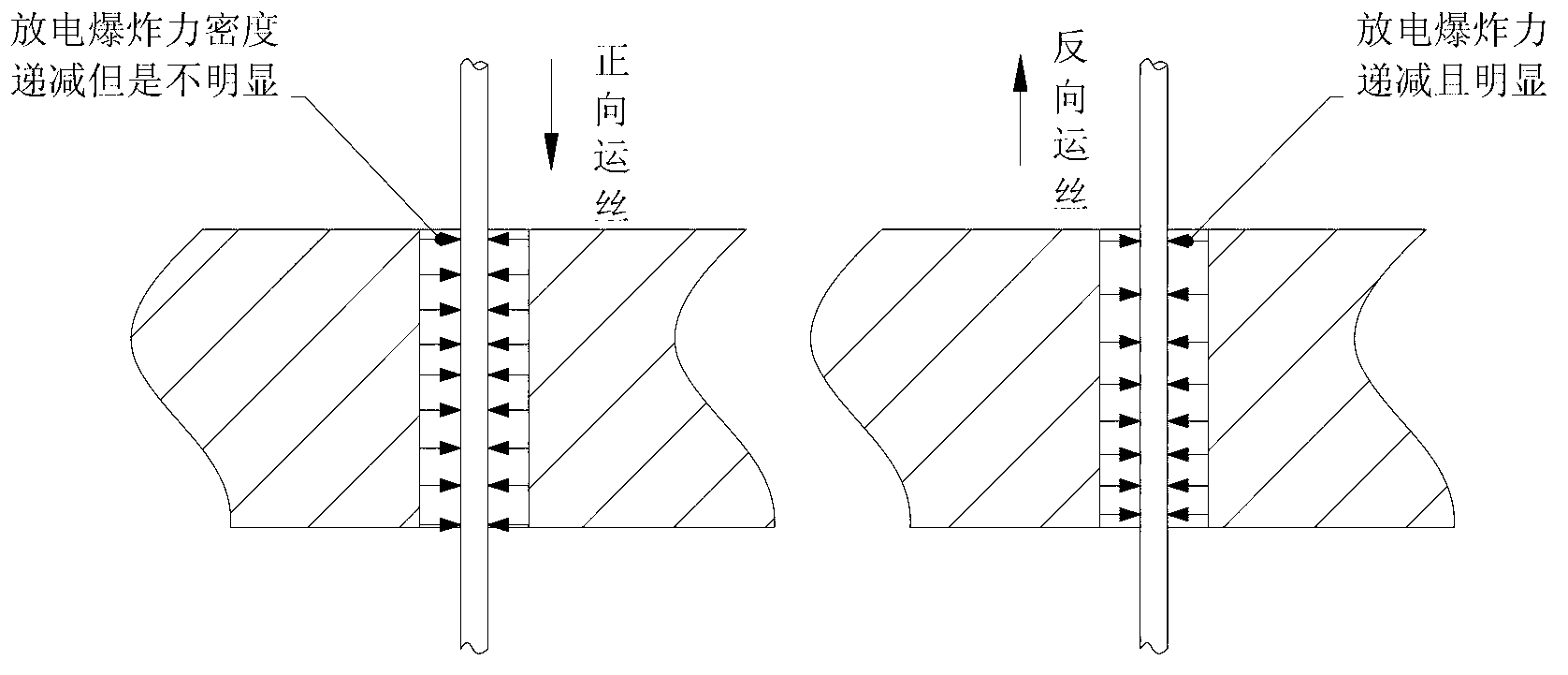

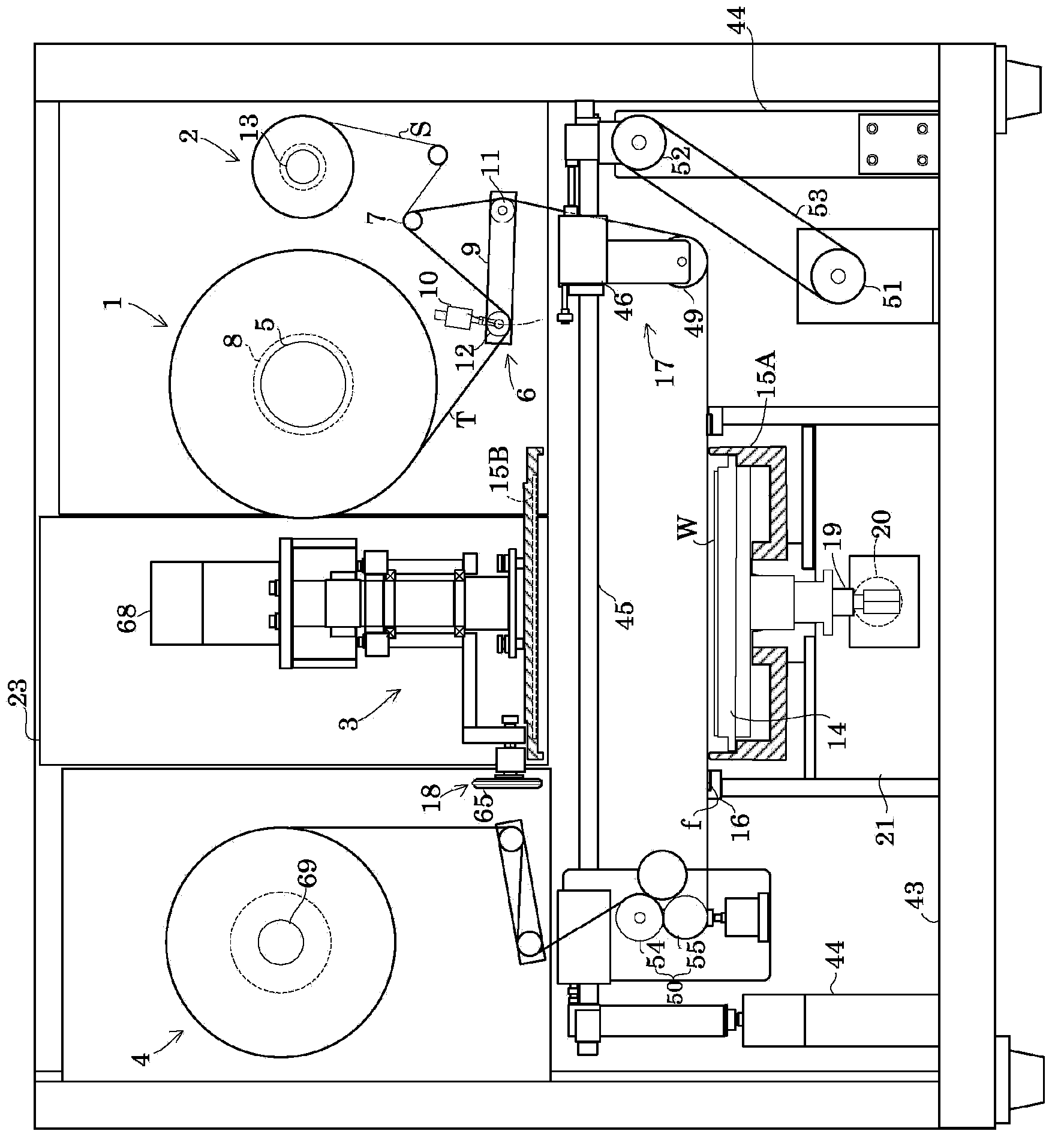

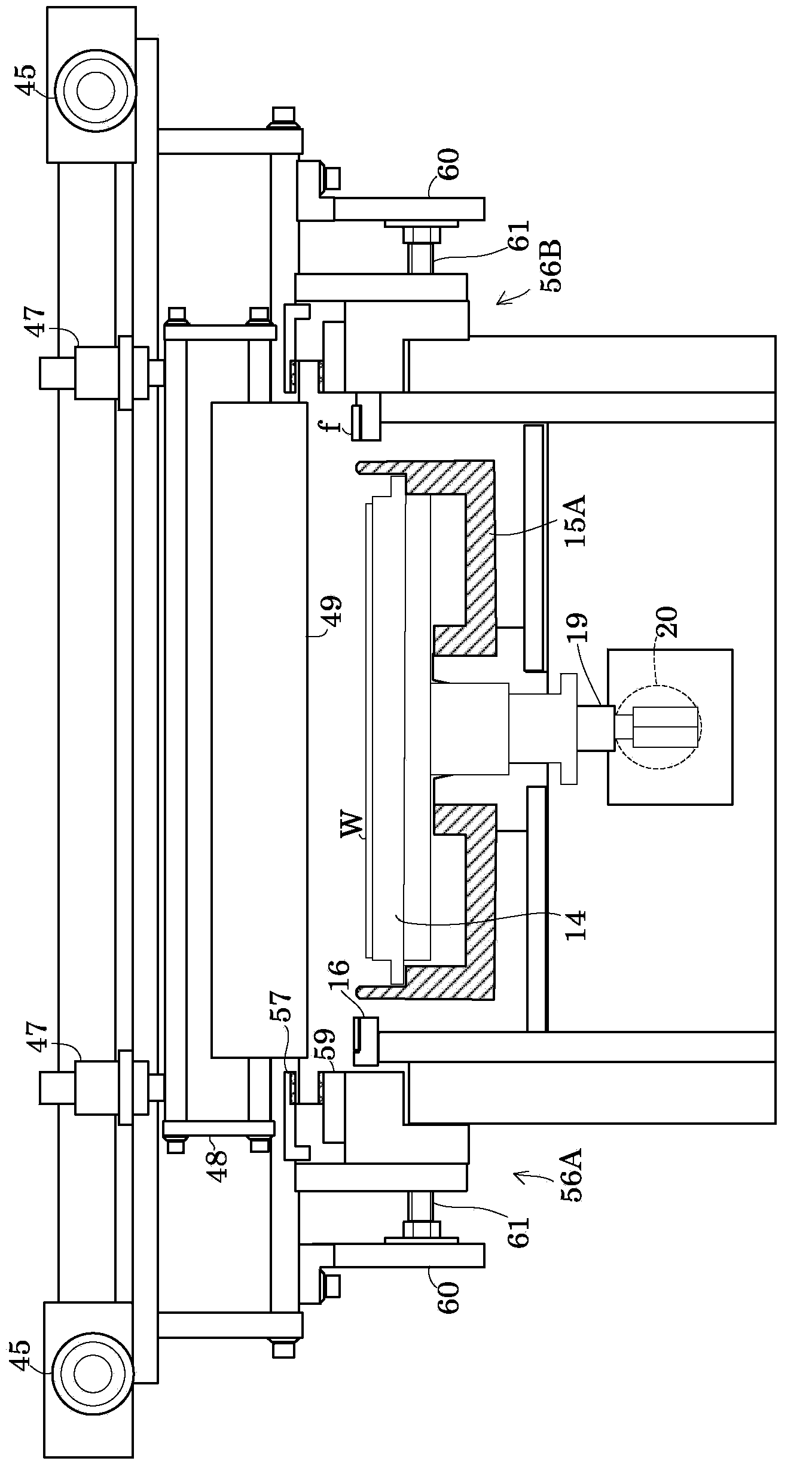

Unilateral wire loosening elimination method of cutting wire electrodes through reciprocating wire moving electrical discharge wires

InactiveCN103157859ASimple measuresSimplify wire structureElectrical-based machining electrodesElimination methodEngineering

Provided is a unilateral wire loosening elimination method of cutting wire electrodes through reciprocating wire moving electrical discharge wires. The unilateral wire loosening elimination method of cutting the wire electrodes through the reciprocating wire moving electrical discharge wires is characterized in that a frequency conversion device is used for controlling forward and reverse rotation speed of a wire storage cylinder, forward and reverse rotation differential rotation of the wire storage cylinder is achieved, tensile difference of forward and reverse moving wire electrodes of the wire electrodes cut by high-speed reciprocating wire moving electrical discharge wires is eliminated, the phenomenon of 'unilateral wire loosening' is eliminated, and therefore machining accuracy and surface roughness are improved, and service life of the wire electrodes is prolonged. The unilateral wire loosening elimination method of cutting the wire electrodes through the reciprocating wire moving electrical discharge wires has the advantages of being easy in implementation method, simple in structure, and strong in practicability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Adhesive tape joining method and adhesive tape joining apparatus

InactiveCN103681229AAvoid uneven tensionUniform tensionSolid-state devicesSemiconductor/solid-state device manufacturingBand shapeEngineering

The invention provides an adhesive tape joining method and an adhesive tape joining apparatus. An adhesive tape is joined onto an annular frame in a state that a tensile force is applied onto the adhesive tape in the length and width directions of the adhesive tape, wherein the adhesive tape is band-shaped and the self-width of the adhesive tape is greater than the outline width of the annular frame. A pair of covers are used to clamp the adhesive tape between the annular frame and a semiconductor wafer, thereby forming a chamber. The pressure of one space formed by separation via the adhesive tape (T) and accommodating the wafer is decreased to be lower than the pressure of the other space, so that the adhesive tape (T) is joined onto an annular convex part formed in the periphery of the wafer and a flat plane in the inner side of the annular convex part.

Owner:NITTO DENKO CORP

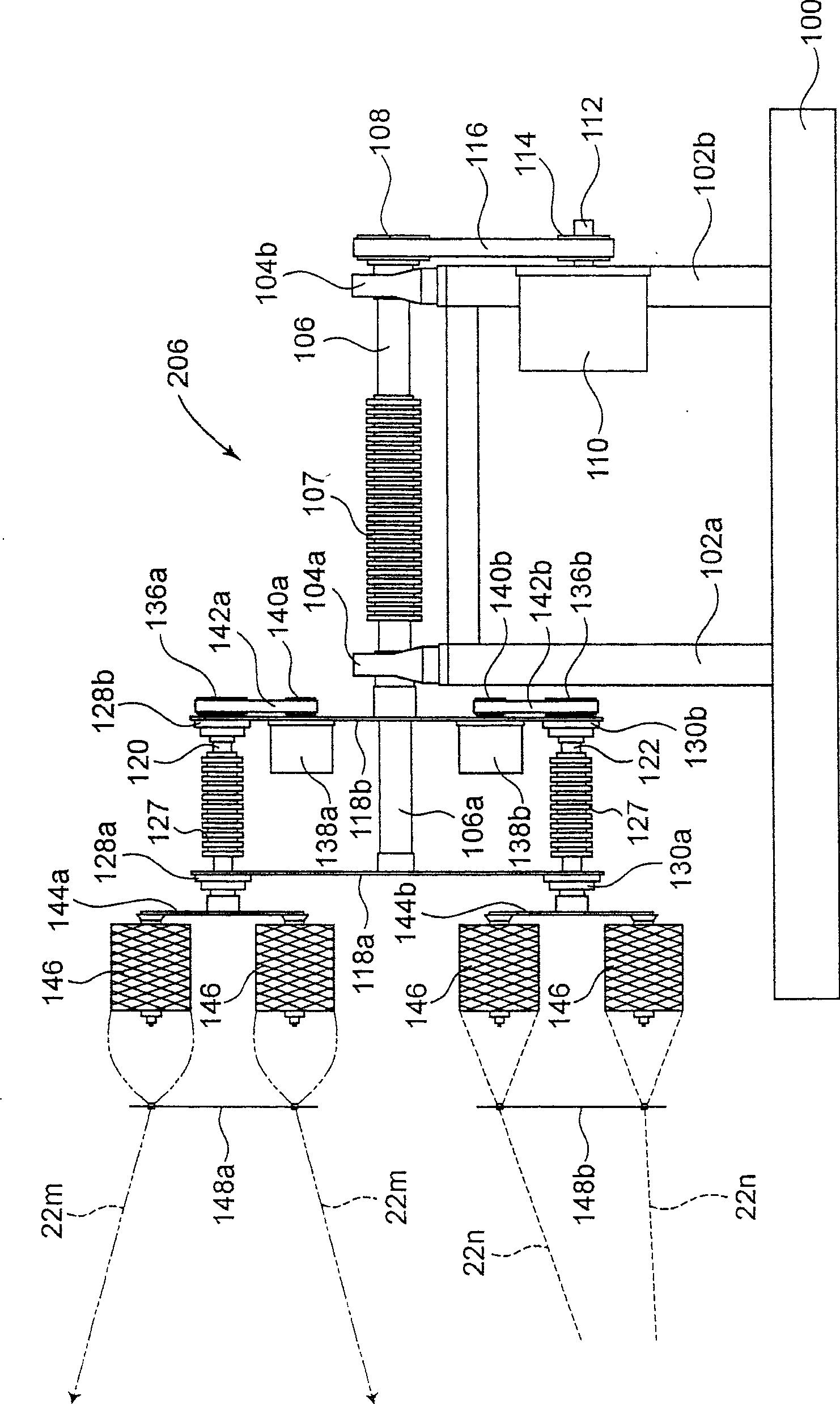

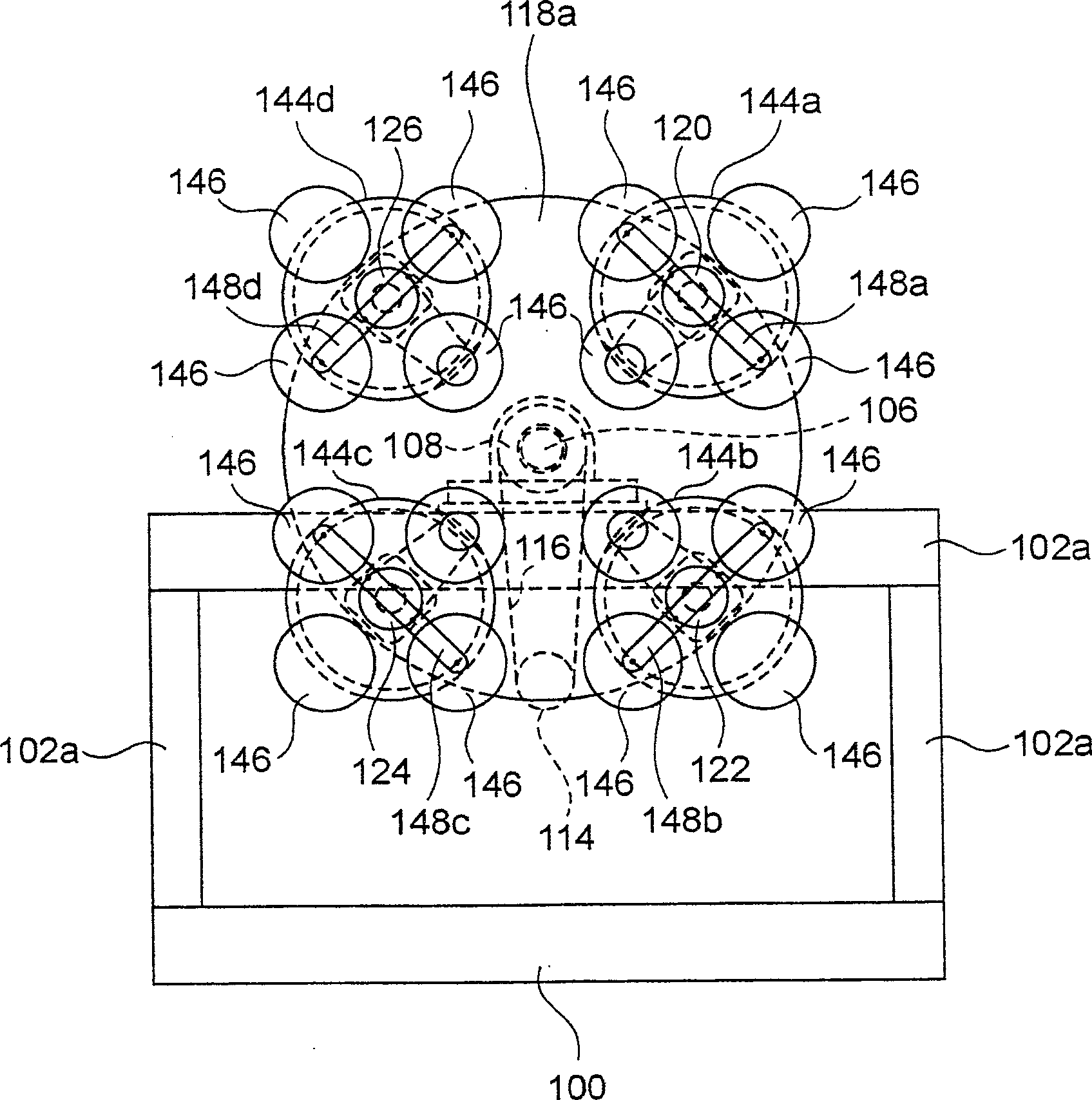

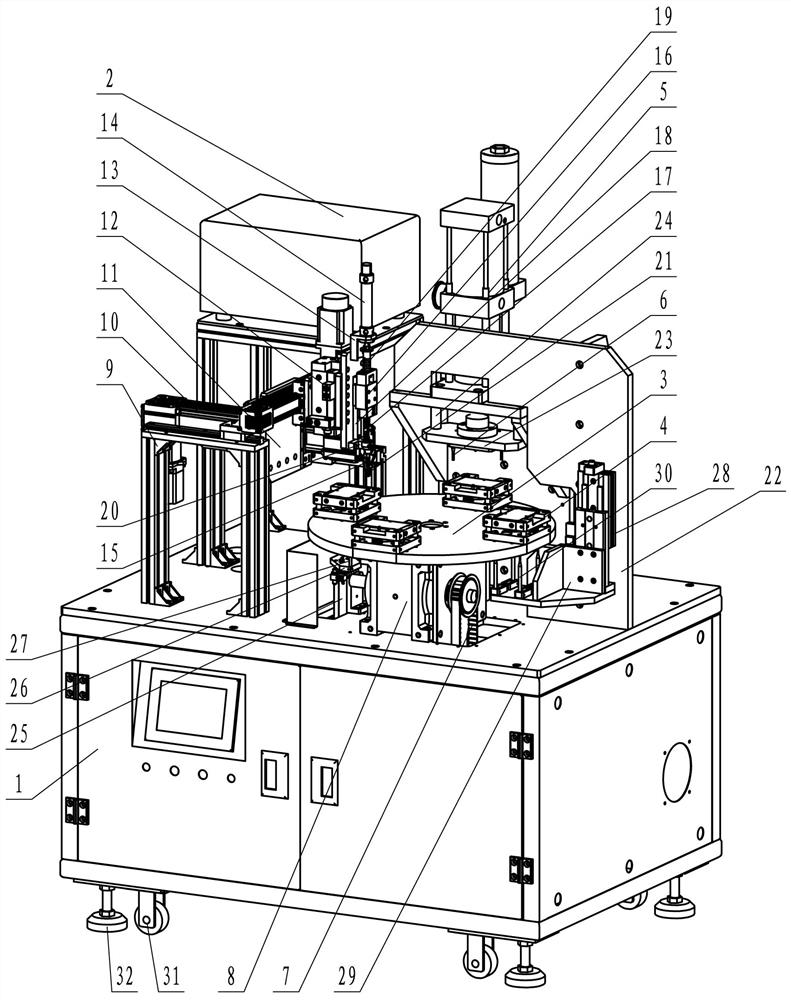

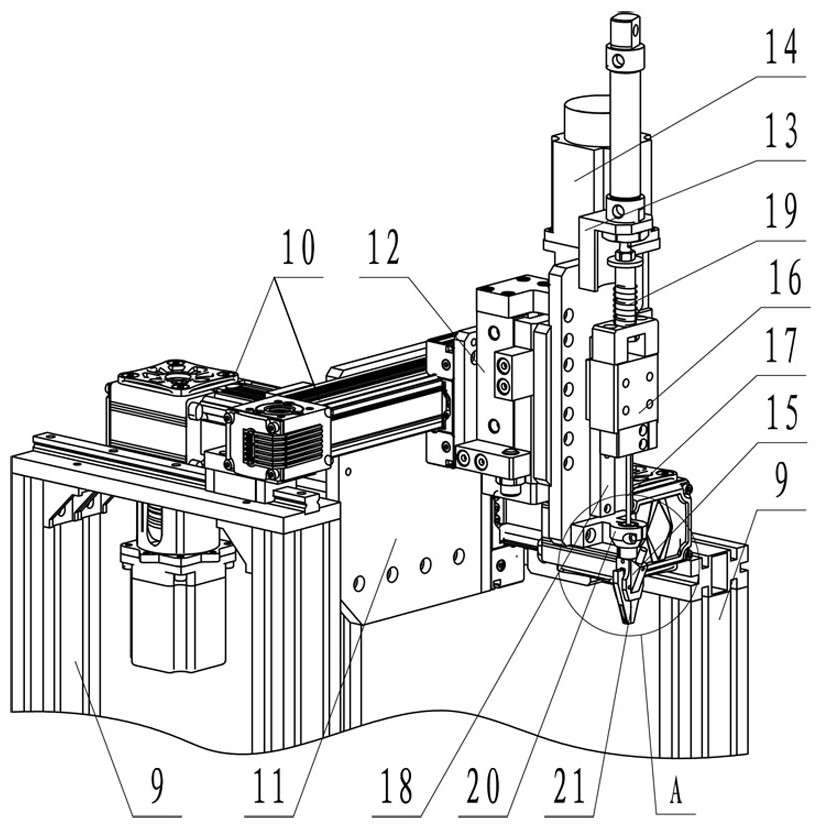

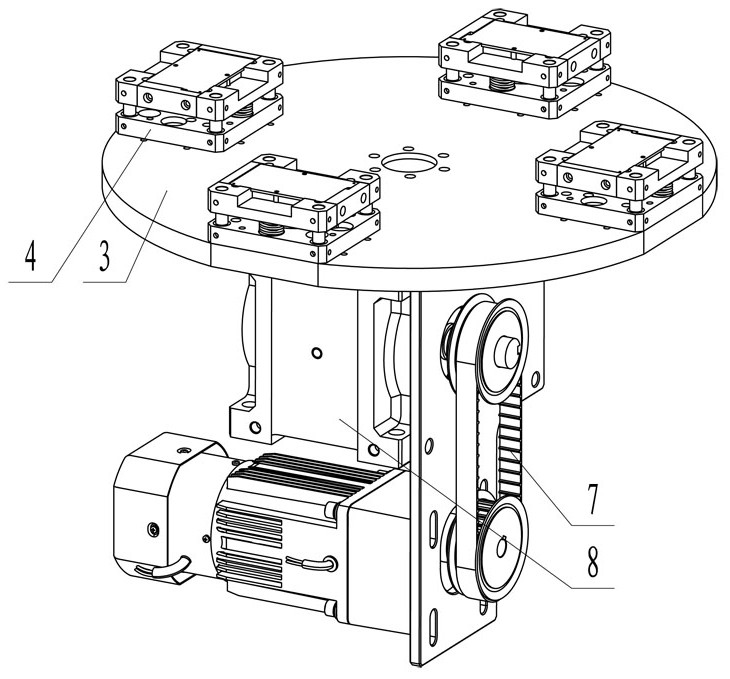

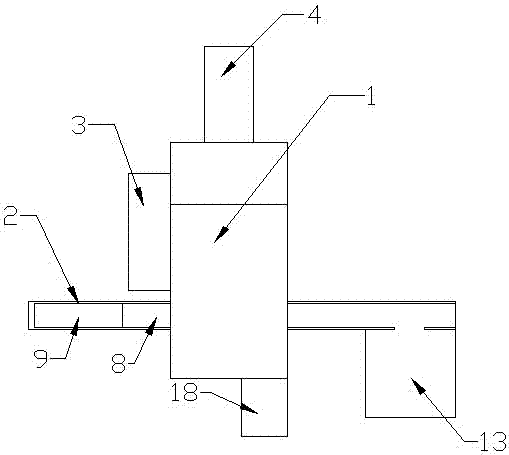

PIN press-fitting device

PendingCN111774846AImprove pressing efficiencyAvoid uneven tensionMetal working apparatusEngineeringMachine

The invention discloses a PIN press-fitting device. The PIN press-fitting device comprises a turnover mechanism and a pin bin which are arranged on a machine table, a pin feeding mechanism and a press-fitting mechanism are sequentially arranged in the rotating direction of the turnover mechanism, the turnover mechanism comprises a rotary disc, a plurality of product jigs carrying cooling fins areevenly distributed on the edge of the rotary disc, and the pin feeding mechanism comprises a working part capable of being converted from the horizontal direction to the vertical direction and a feeding unit arranged on the working part; the press-fitting mechanism comprises a press-fitting air cylinder and a group of press-fitting ejector pins arranged on the press-fitting air cylinder, and an auxiliary positioning mechanism used for assisting in positioning the cooling fins on the product jigs is arranged at the position, corresponding to the pin feeding mechanism, below the rotary disc; andthe PIN press-fitting device further comprises a stripping mechanism used for conveniently separating the press-fitted cooling fins from the product jigs. According to the PIN press-fitting device, automatic implantation and automatic press-fitting of PINs in production of the cooling fins are realized, the automation degree is high, compared with a traditional manual press-fitting mode and PIN press-fitting machine, the technical scheme has the advantages that the press-fitting efficiency of the PINs is greatly improved, and labor force is liberated.

Owner:信阳同裕电子科技有限公司

Underground pipeline measuring device and application method thereof

The invention relates to an underground pipeline measuring device and an application method thereof. The underground pipeline measuring device is used for measuring a pipeline trend in a pipeline, andcomprises a traction machine and a measurement machine, wherein the traction machine comprises a chassis and a traction part; the traction part is arranged on the chassis through a lifting device; the chassis is connected with the traction part through a cable; a power supply module, a power module, a lifting unit, a switch, a speedometer and a positioning module are arranged on the traction machine; an inertia measurement module, a human-computer interaction module, a central processing module and a storage module are arranged in the measurement machine; and the measurement machine comprisesan outer barrel, an inner barrel and an extending barrel. The measuring device provided by the invention is long in measuring range, good in waterproofness, and high in accuracy.

Owner:苏州市测绘院有限责任公司

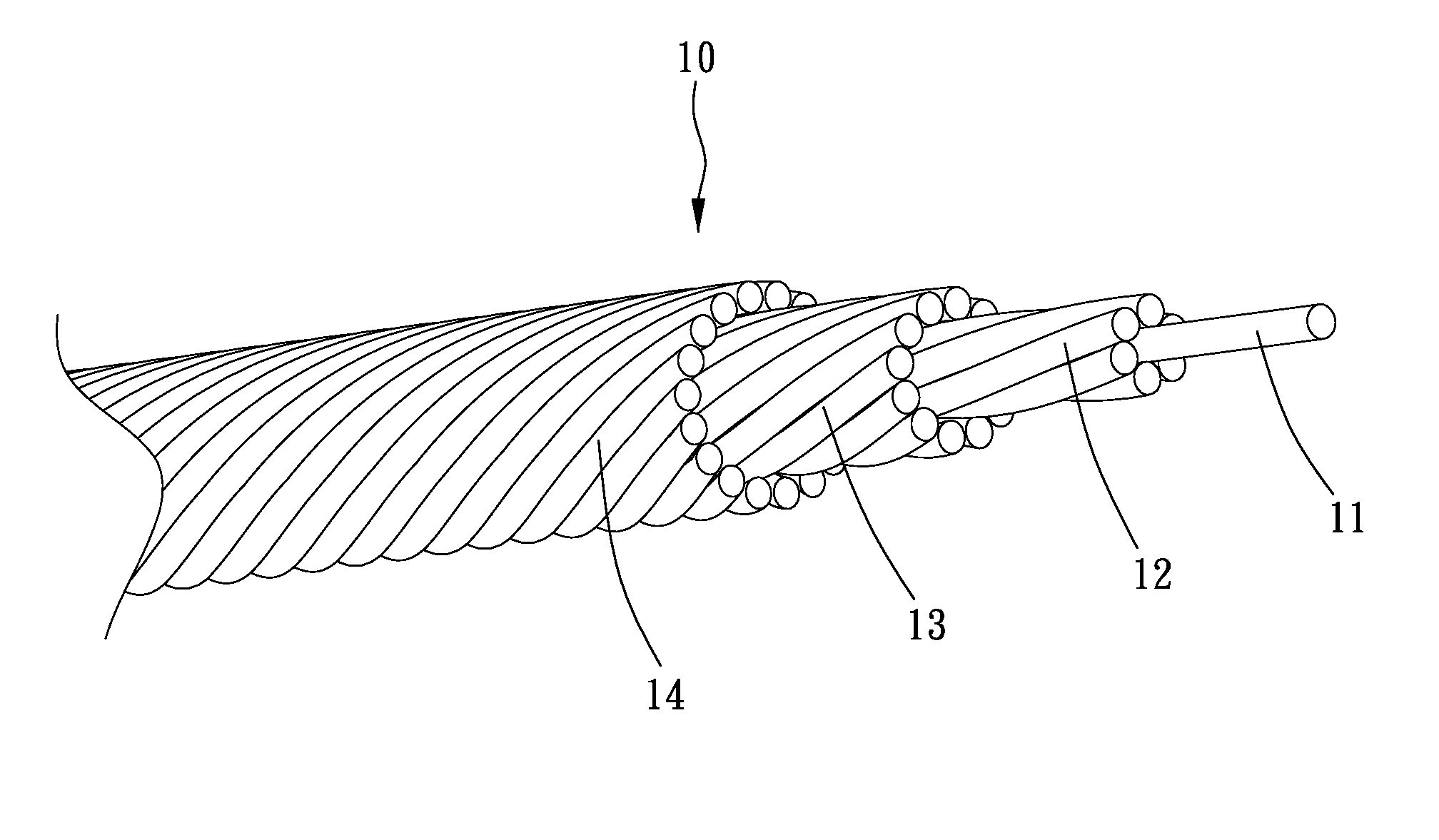

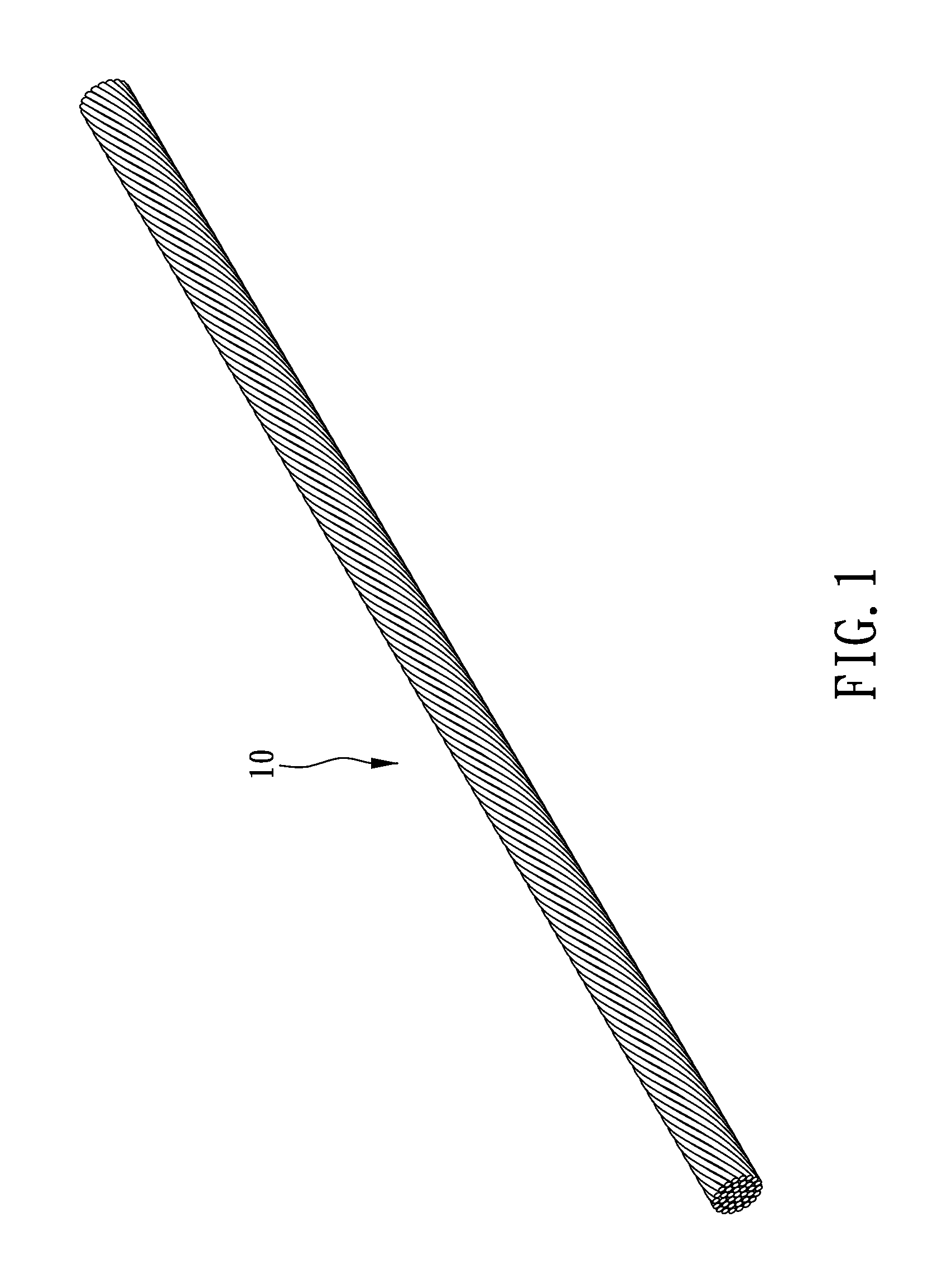

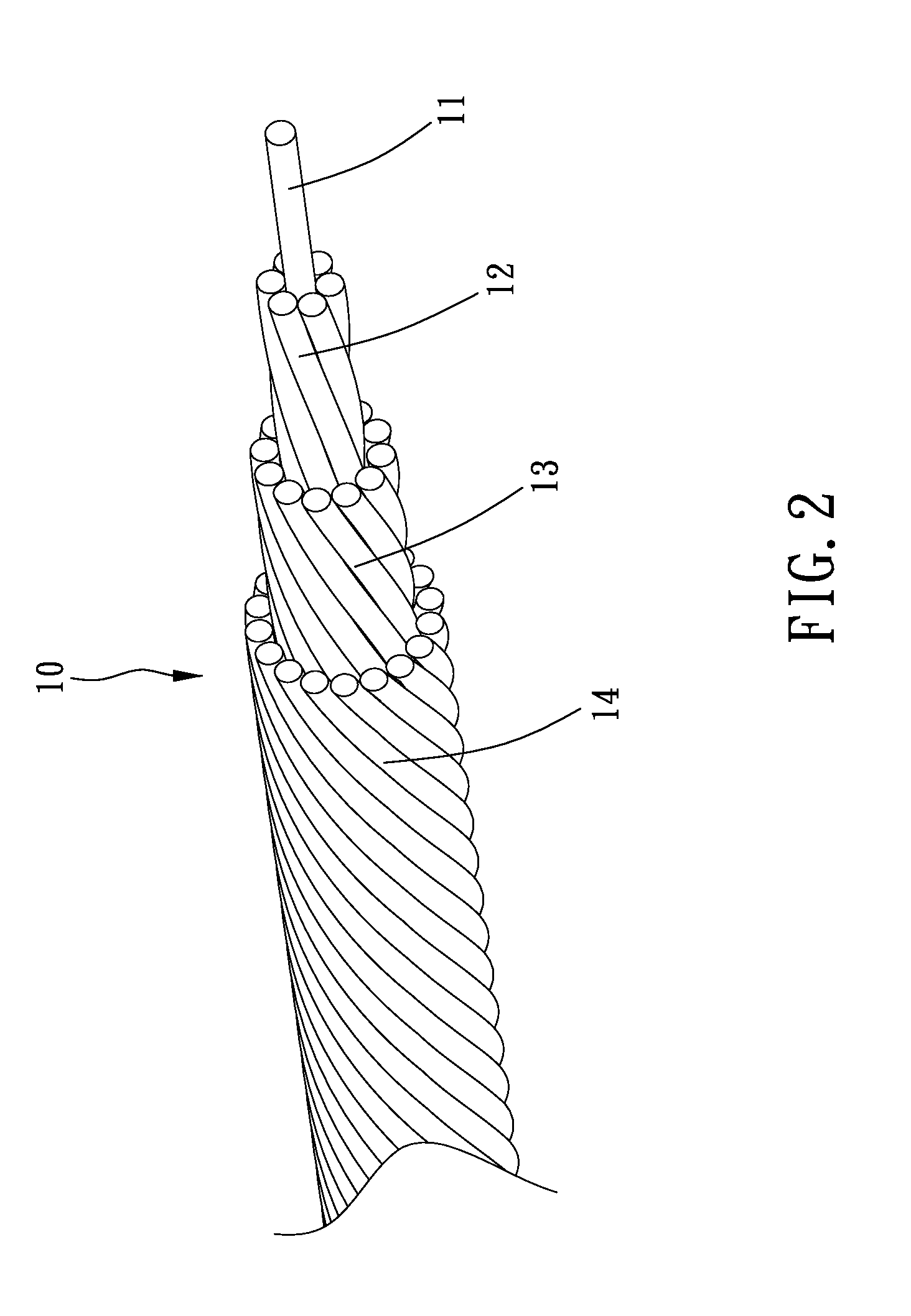

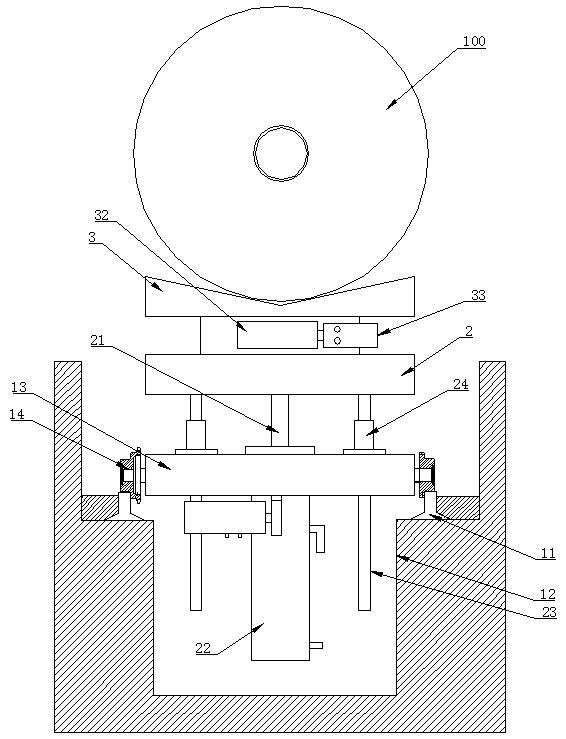

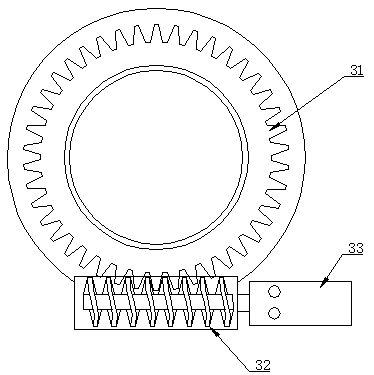

Twisted cable

InactiveUS20140318100A1Improve structural strengthSmall amount of longitudinal deformationYarnTextile cablesEngineeringUltimate tensile strength

A twisted cable includes a main body which includes a central filament and a plurality of twisted filaments. The twisted filaments are arranged around the central filament and include six first filaments, twelve second filaments, and eighteen third filaments from the central filament outward. The cross-section of each first filament is the same with the one of each second filament. The cross-section of each first filament is larger than the one of the third filament but smaller than the one of the central filament. The twisted filaments are twisted around the central filament. As a result, the twisted cable of the present invention has improved structure strength, appropriate toughness, and smaller amount of longitudinal deformation.

Owner:WEN YUAN HUNG

Feeding device of aluminum foil slitting machine

PendingCN110683395AEasy to transportEasy to operateArticle deliveryWebs handlingRotary stageEngineering

The invention relates to a feeding device of an aluminum foil slitting machine. The feeding device comprises a rotary trolley used for transporting raw materials, walking guide rails of the rotary trolley and a feeding machine used for loading the raw materials. The rotary trolley comprises a walking mechanism moving along the walking guide rails, a lifting platform, a hoisting mechanism used fordriving the lifting platform to ascend and descend, a rotary platform used for containing the materials and a rotary mechanism used for driving the rotary platform to rotate. The feeding machine comprises a machine seat and a tension mechanism. The tension mechanism comprises multiple arc plates, an expansion-shrinkage pull rod shaft, a core shaft and a first power device. The first power device drives the expansion-shrinkage pull rod shaft to stretch and shrink, so that the multiple arc plates are expanded outwards or loosened inwards. According to the feeding device, feeding is convenient, the raw materials are fixed stably, operation is coordinated with the aluminum foil slitting procedure in order, and it is guaranteed that the aluminum foil slitting procedure is carried out fast in order; the rotary trolley is arranged, time and labor are saved during feeding, and operation is not limited by sites; and the feeding machine is provided with the tension mechanism, the raw materials are fixed, operation and control are more convenient, and tension force is constant.

Owner:山东富格琳遮阳科技有限公司

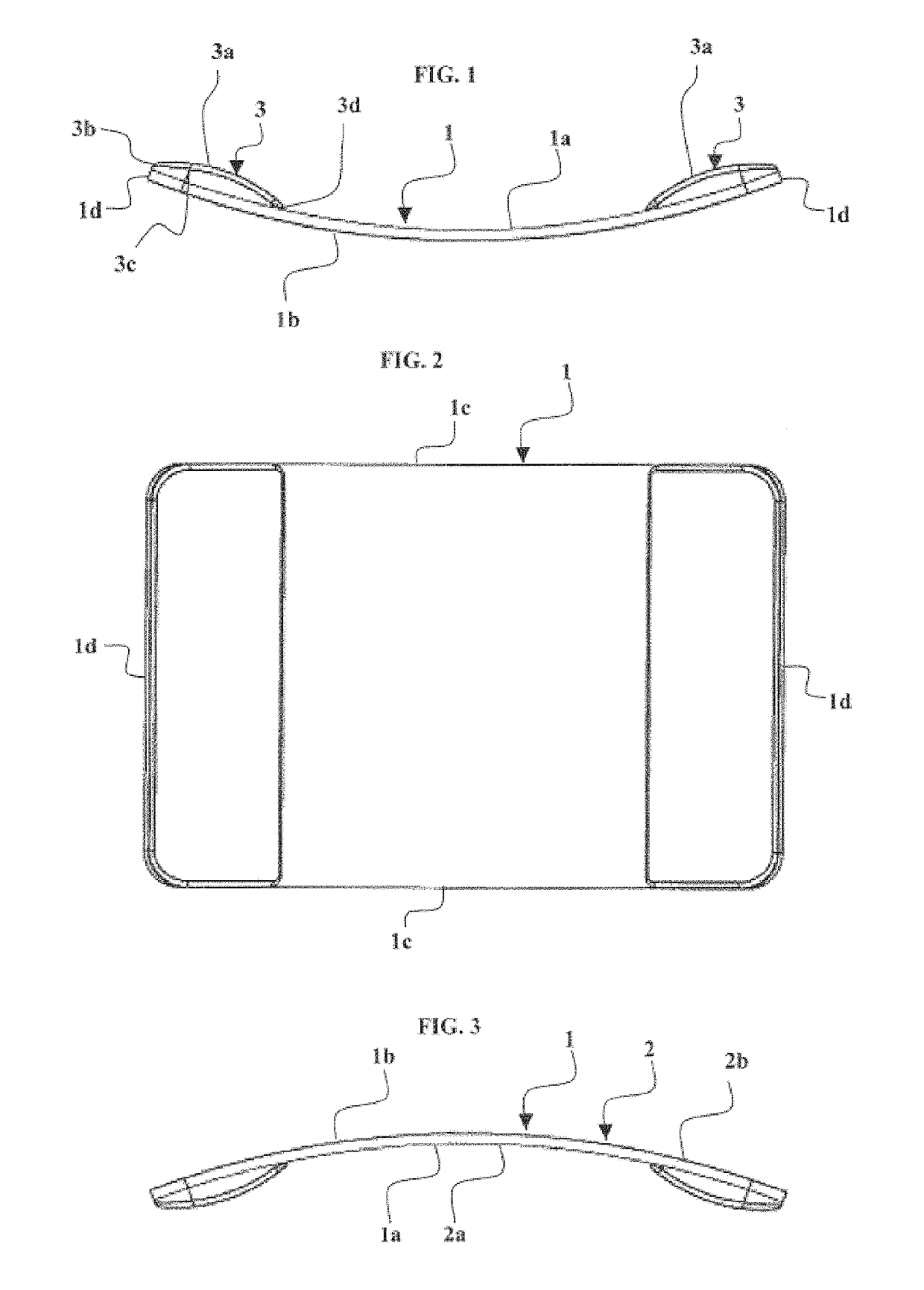

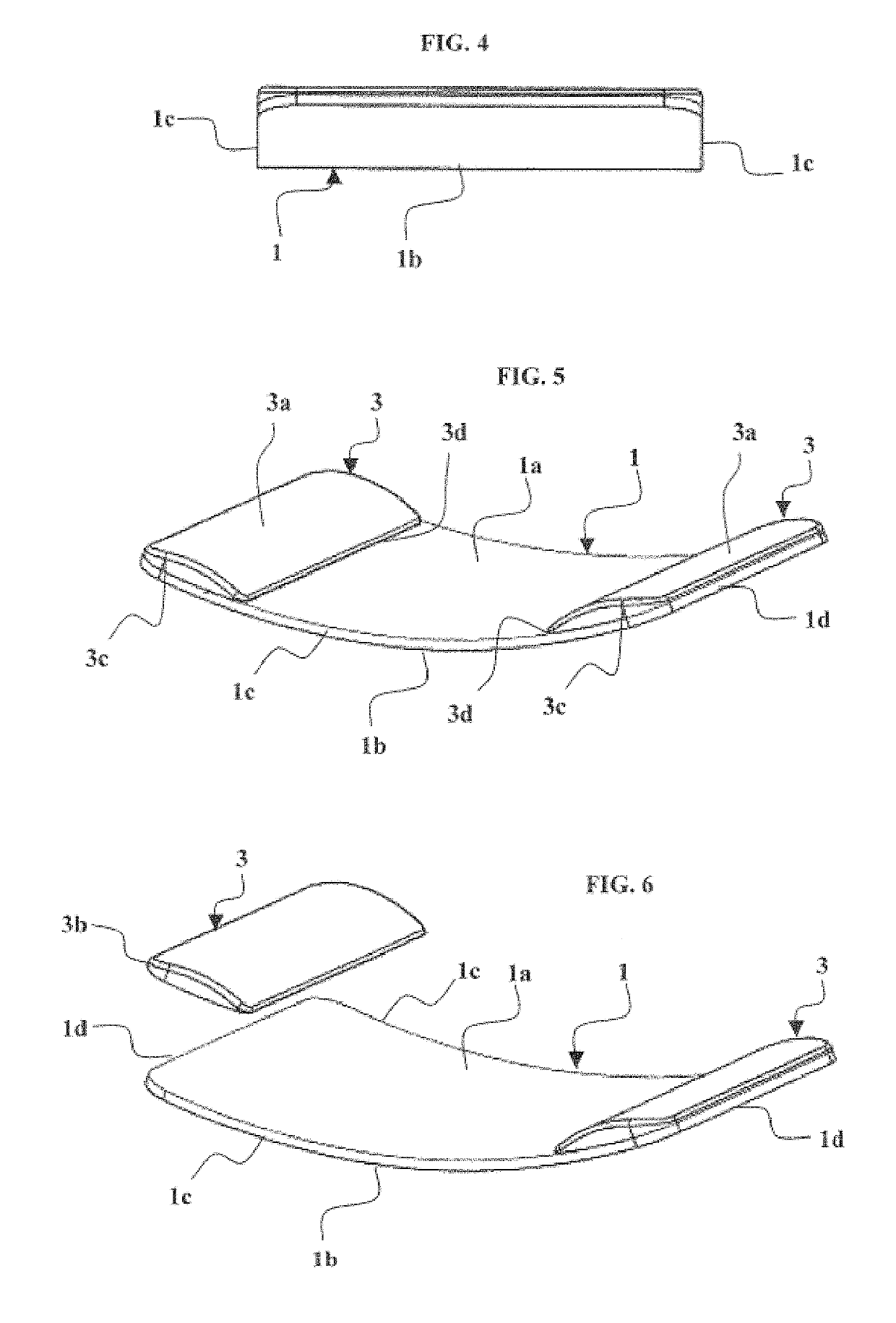

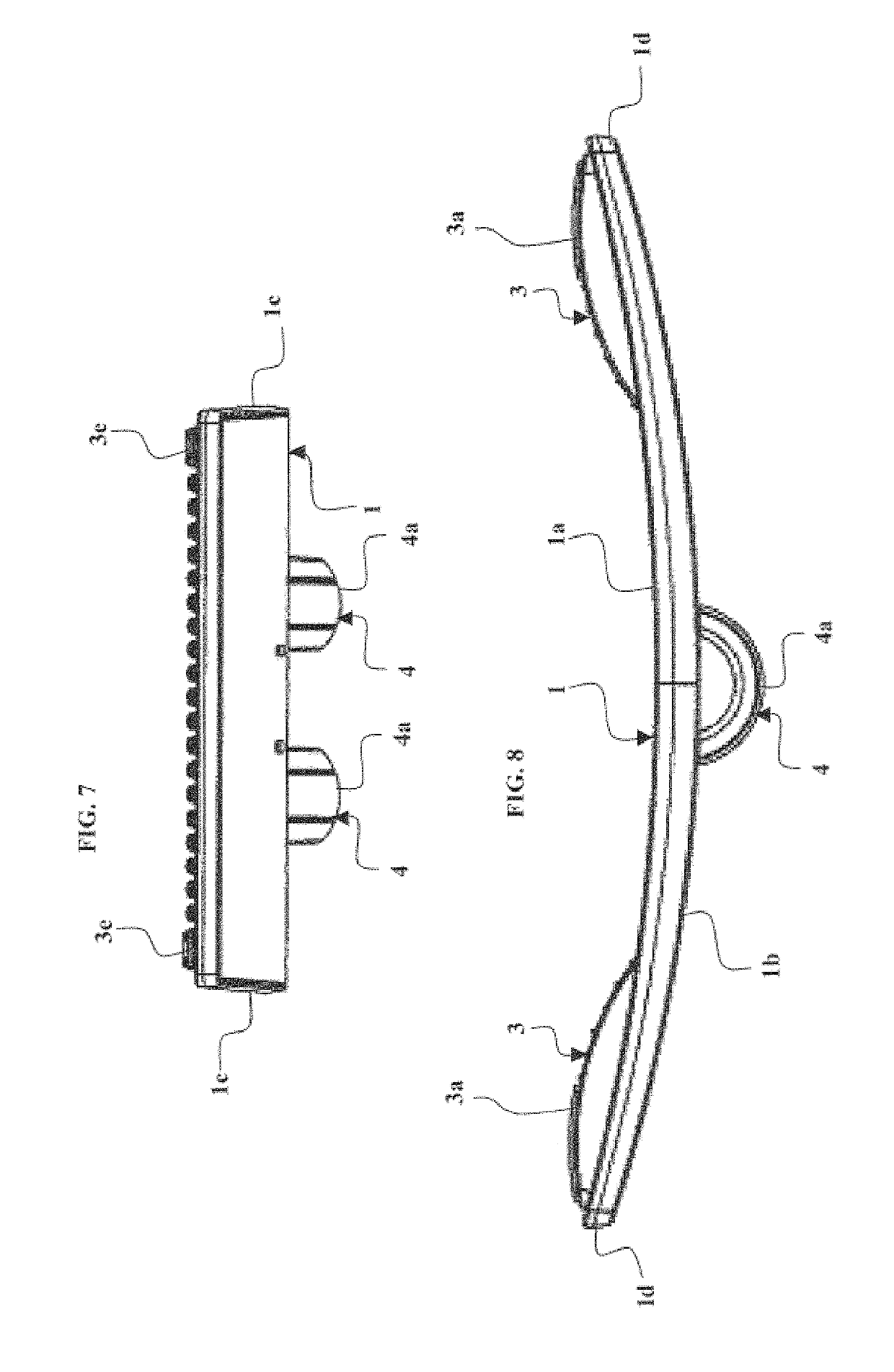

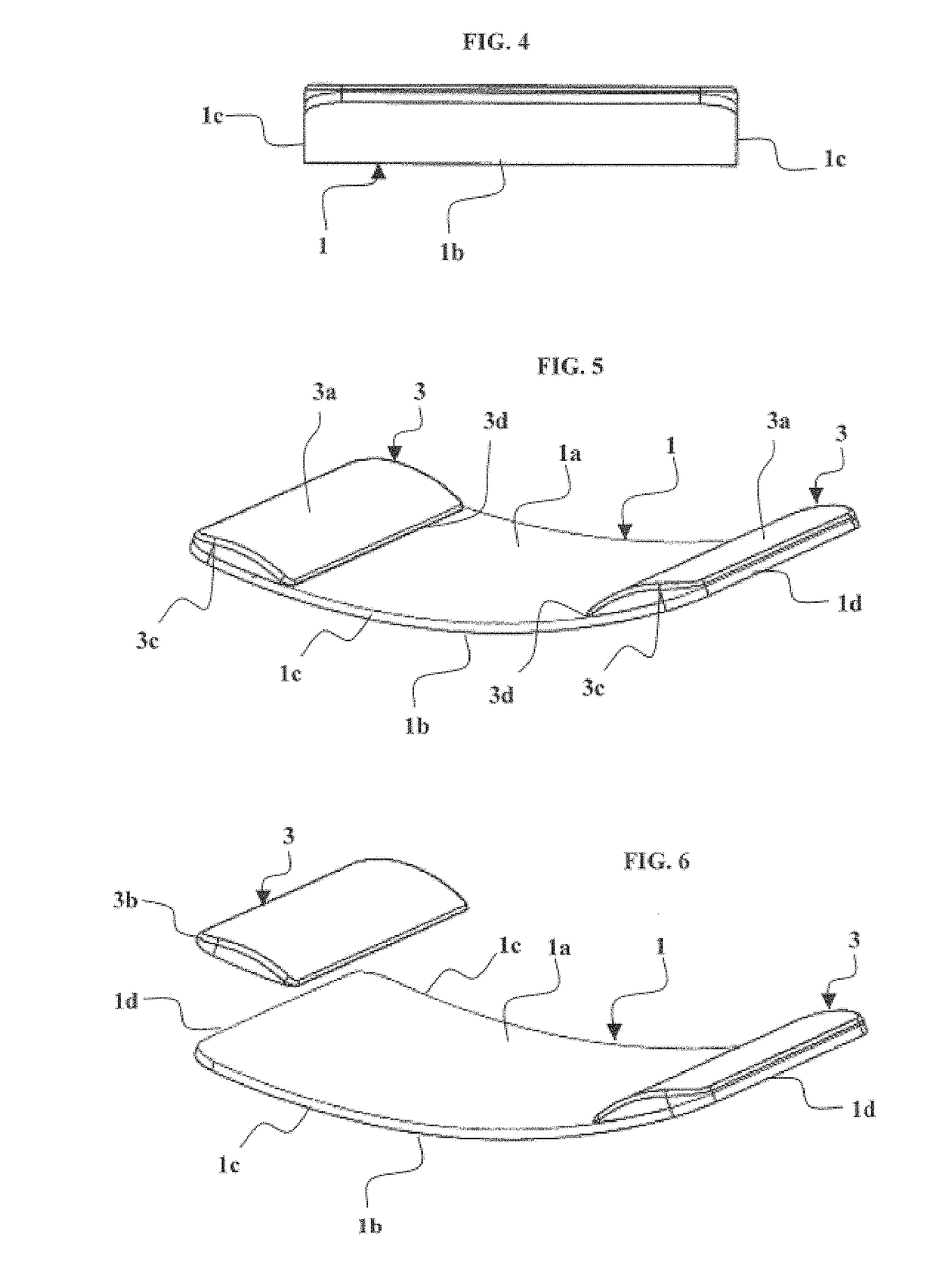

Multifunctional curved board

ActiveUS10363191B2Maintenance savingAvoid uneven tensionChiropractic devicesStiltsMuscle strengthFoot supports

A multi-functional curved board used as a support for legs of a user and for general maintenance of muscle strength, the multi-functional curved board having one or more curved bodies (1) including a radius of curvature, a longitudinal axis, and at least one raised foot support. The multi-functional curved board can be bent in the direction transverse to the radius of curvature to enable the multi-functional curved board to rotate around the longitudinal axis.

Owner:GYMBA OY

Wood bending machine

InactiveCN107650219AImprove bending effectAvoid bending failuresWood stock bendingHydraulic cylinderPulp and paper industry

The invention relates to the field of wood bending equipment, in particular to a wood bending machine. The wood bending machine comprises a machine frame. The top of the machine frame is provided witha hydraulic cylinder. The hydraulic cylinder comprises a vertical-downward hydraulic cylinder output shaft. The lower part of the machine frame is provided with a mold. The curved surface of the moldfaces downwards and forms a wood bending channel with the bottom of the machine frame. Vertical racks are arranged symmetrically and fixedly on the two sides of the hydraulic cylinder output shaft. The machine frame on the two sides of the hydraulic cylinder output shaft is rotationally connected with gears correspondingly. Each gear is engaged with the corresponding rack on the same side. Each gear end face is fixedly connected with a wire bundle which is tightened when the gear rotates toward the corresponding rack. The lower end of each wire bundle is fixed to one end of same side wood. Wire bundle fixing sleeves are arranged symmetrically and fixedly on the machine frame between the mold and the gears. The upper ends of the wire bundles penetrate through the wire bundle fixing sleeves. By using the technical scheme, the two ends of the wood are pulled by the wire bundles, so that the two ends of the wood fails to being bent due to the lack of force, and the wood is saved.

Owner:重庆市浩源门业有限公司

Corn sheller

The invention discloses a corn sheller. A corn is shelled through the rotation of two rotating rolls which rotate in opposite directions and friction force; meanwhile, the corn sheller comprises a compression mechanism which adapts to corns with non-uniform diameters. The corn sheller is provided with a core returning mechanism which can automatically push the shelled corn out of a shelling mechanism automatically, so that an operation process is greatly simplified, and the manpower cost is reduced; meanwhile, the corn sheller has the advantages of simple structure, easiness in part processing and the like, and has wide social benefits and outstanding technical progress.

Owner:WUJIANG LILI JIANXING CASTING FACTORY

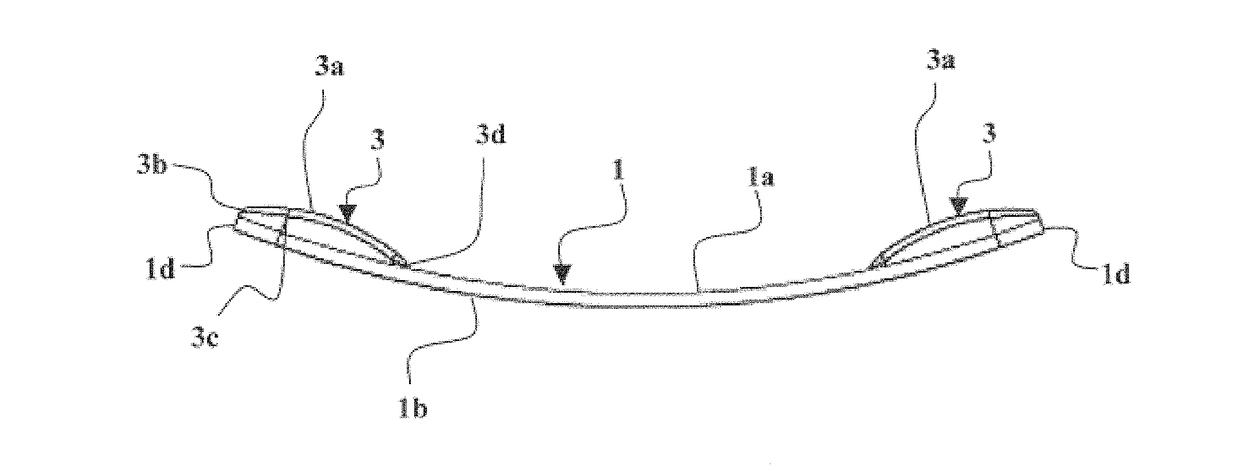

Multifunctional curved board

ActiveUS20170273848A1Maintenance savingEven tension is avoidedChiropractic devicesStiltsMuscle strengthStanding Positions

A multi-functional curved board to be used when working in standing position and for working when sitting down as a support for feet and generally for maintaining muscle strength, the multi-functional curved board having at least one curved body (1). The body (1) comprises at least one counter-curve means (3). One surface (1b) of the body is curved outwards and the counter-curve means are fastened to a surface (1a) opposite this surface (1a) adjacent the end sides (1d) of the body (1) and the counter-curve means are curved outwards from the opposite surface of the body (1).

Owner:GYMBA OY

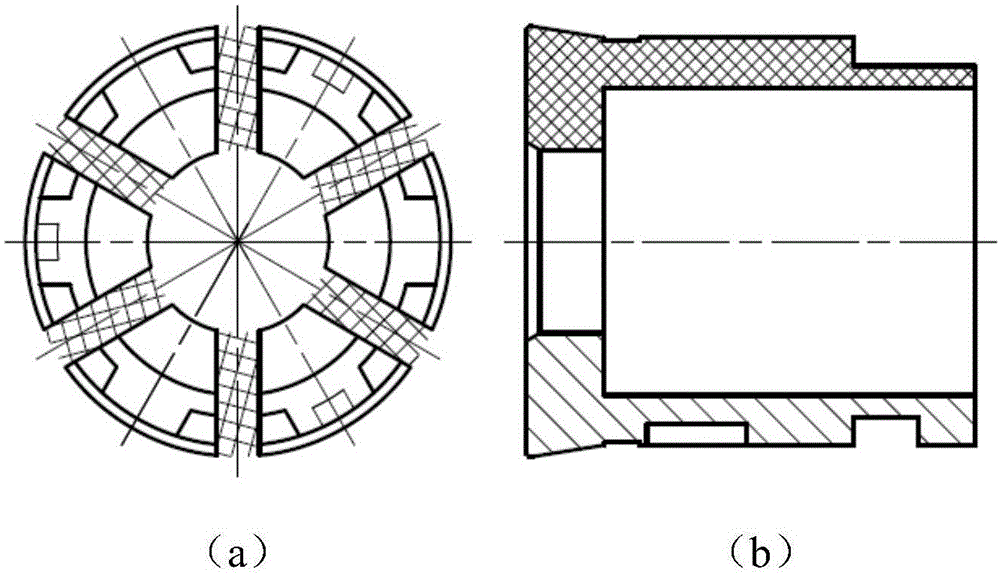

Externally-tightening and quick-changing hobbing tool for shafts

ActiveCN105149703AAvoid uneven tensionEasy to replaceGear-cutting machinesGear teethHobbingEngineering

The invention discloses an externally-tightening and quick-changing hobbing tool for shafts. The externally-tightening and quick-changing hobbing tool comprises a base installed on a work plane of a machine tool. A transition pull plate and an adhesion tightening sleeve are sequentially installed on the base. The transition pull plate is connected to a pull rod of the machine tool and driven by the pull rod of the machine tool to move downwards or upwards. The adhesion tightening sleeve is matched with the transition pull plate to tighten or loosen work-pieces. According to the characteristics that power takeoff shafts are various and production change is frequent, the externally-tightening and quick-changing hobbing tool is designed. According to the tool, serialization design is carried out on the adhesion tightening sleeve and a centre, the adhesion tightening sleeve and the centre are convenient to change, and the design range of clamps for new shaft parts in future can be expanded.

Owner:SHAANXI FAST GEAR CO

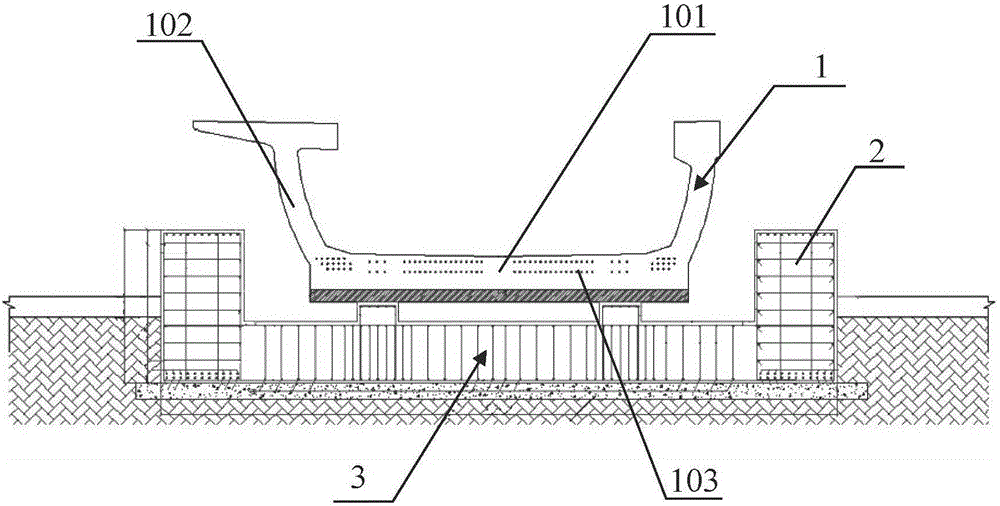

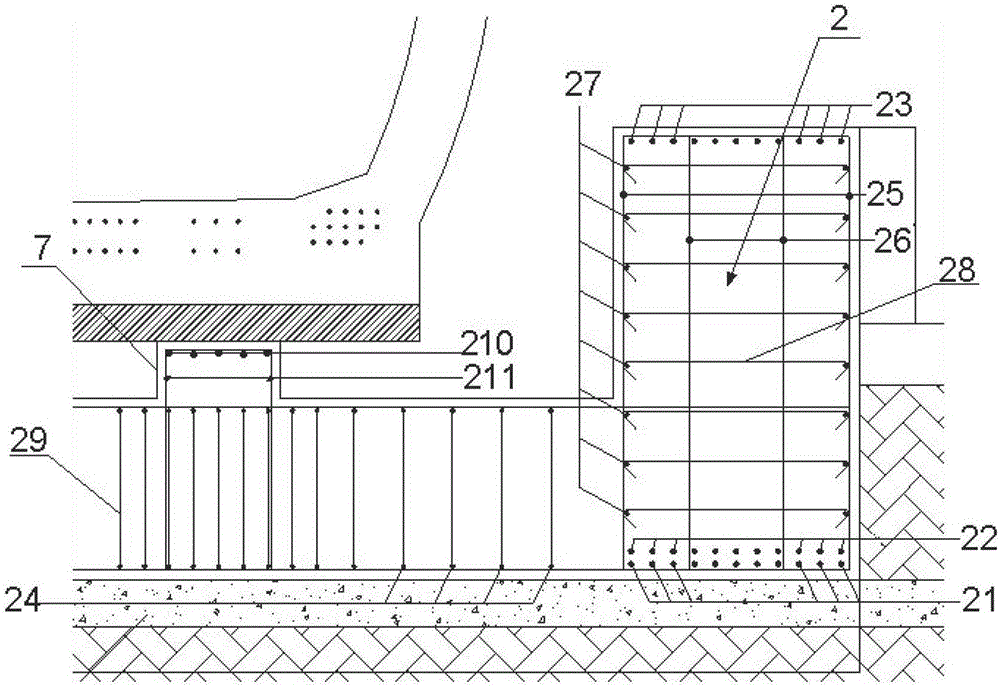

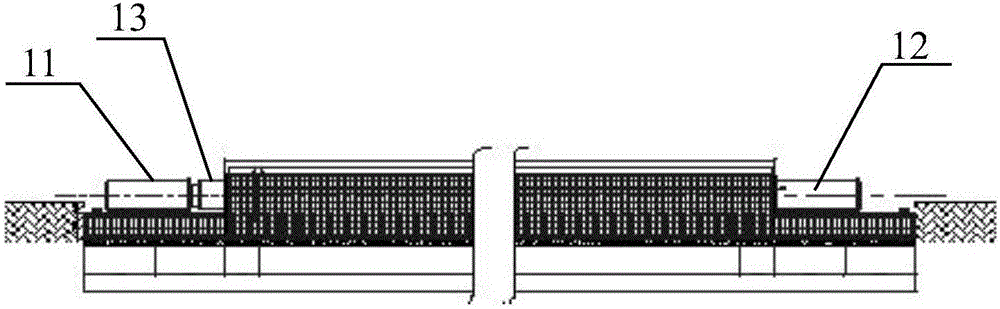

Rail transit large-tonnage pre-tensioning method prestressed concrete U type beam and tensioned bed thereof

ActiveCN106426542AImprove stabilitySimple structureCeramic shaping apparatusBridge materialsPre stressPrestressed concrete

The invention provides a rail transit large-tonnage pre-tensioning method prestressed concrete U type beam and a tensioned bed thereof. The tensioned bed comprises a bottom plate, a strip foundation arranged on the bottom plate and used for supporting the rail transit large-tonnage pre-tensioning method prestressed concrete U type beam, force transmission beams arranged on the two sides of the bottom plate, movable end steel cross beams arranged at one ends of the force transmission beams, fixed end steel cross beams arranged at the other ends of the force transmission beams and a jack arranged between the movable end steel cross beams and the force transmission beams. The tensioned bed has the beneficial effects of being simple in structure, clear in stress, being free of piling, high in construction speed, capable of greatly saving the construction materials and the like.

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD +1

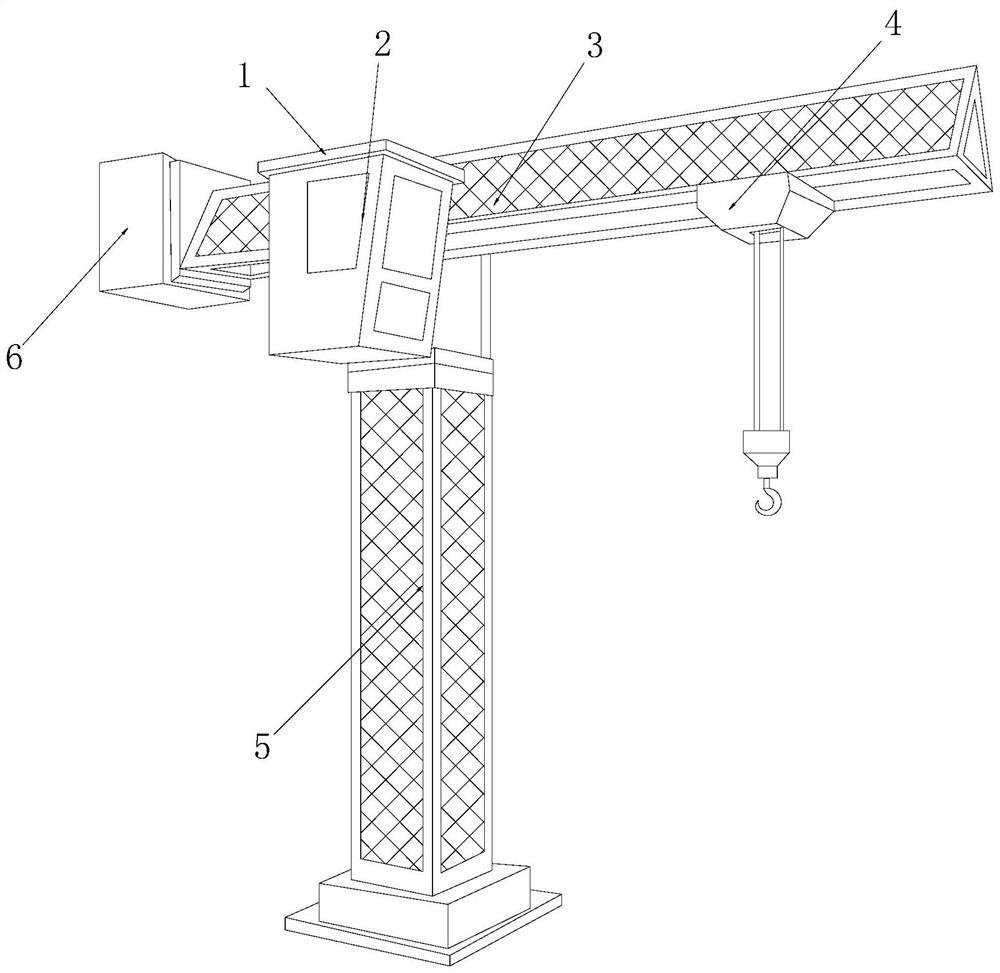

Transverse locking device for heavy tower crane

InactiveCN112374382AStable construction operation effectSolid construction operation effectCranesTower craneControl theory

The invention discloses a transverse locking device for a heavy tower crane. The transverse locking device structurally comprises a top cover plate, a guide rail locking box groove, a transverse framelifting arm, a rope lifting hook frame seat, a rib rod supporting column frame and a balance weight. According to the transverse locking device for the heavy tower crane, the guide rail locking box groove is matched with the transverse frame lifting arm, a transverse balance weight lifting arm frame rod of the tower crane is matched with a machine box groove shell to form one pull buckle mountingeffect through a left wheel buckle disc and roller pad truss plates, and the pad rotation stability of the line distance is guaranteed; and the safety coefficient and the anti-disengaging stability of the transverse frame lifting arm of the whole heavy tower crane are improved through the firmness of flexible disassembly and tightening of a pull buckle pad petal groove, the safety range of groundworkers and the high-altitude hoisting balance framework effect are guaranteed, and the operation effect of uniform regulation and control over the flexibility and the tension degree of subsequent transverse vibration isolation sliding output lifting arm operation is achieved.

Owner:陈以贺

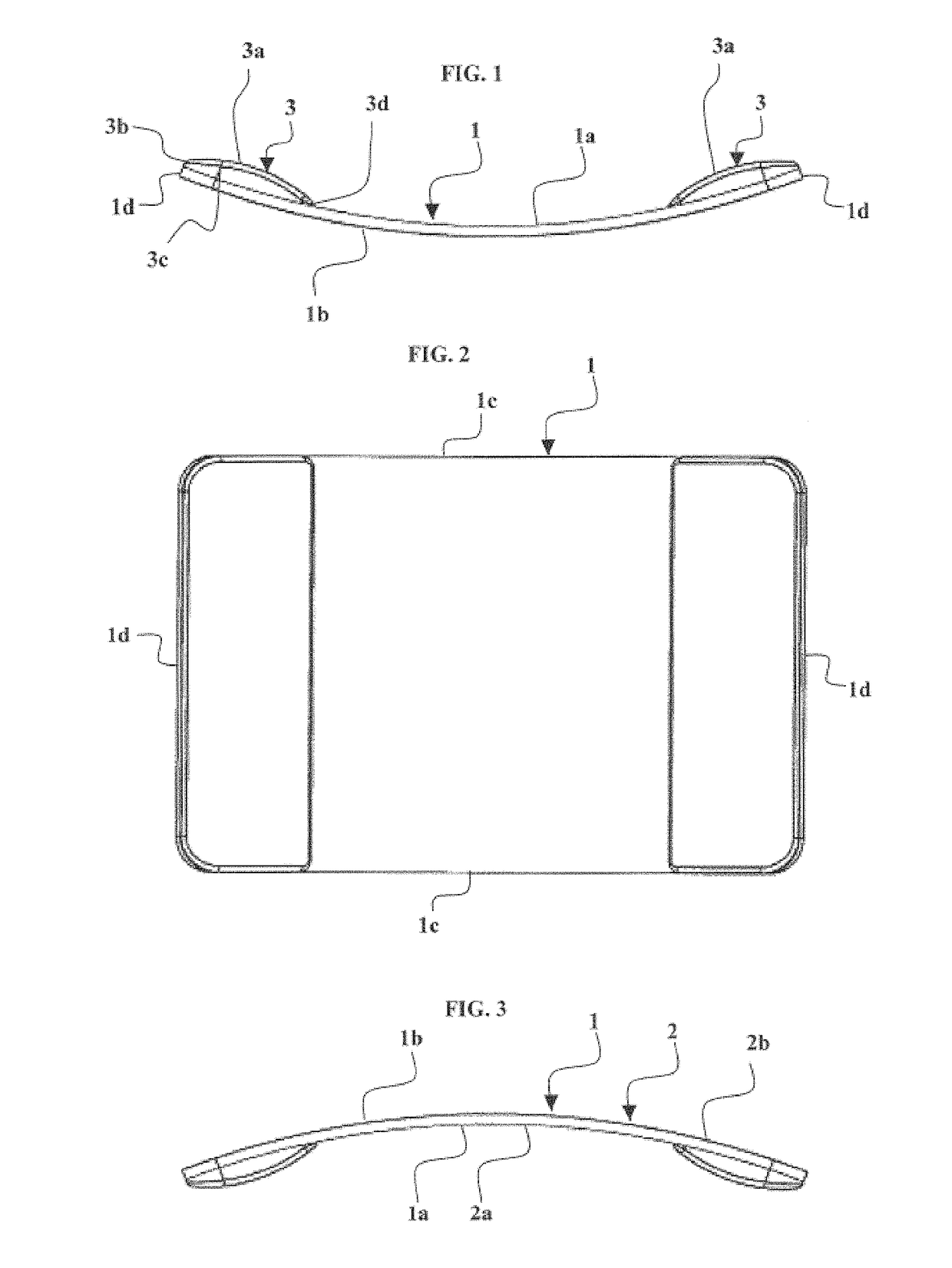

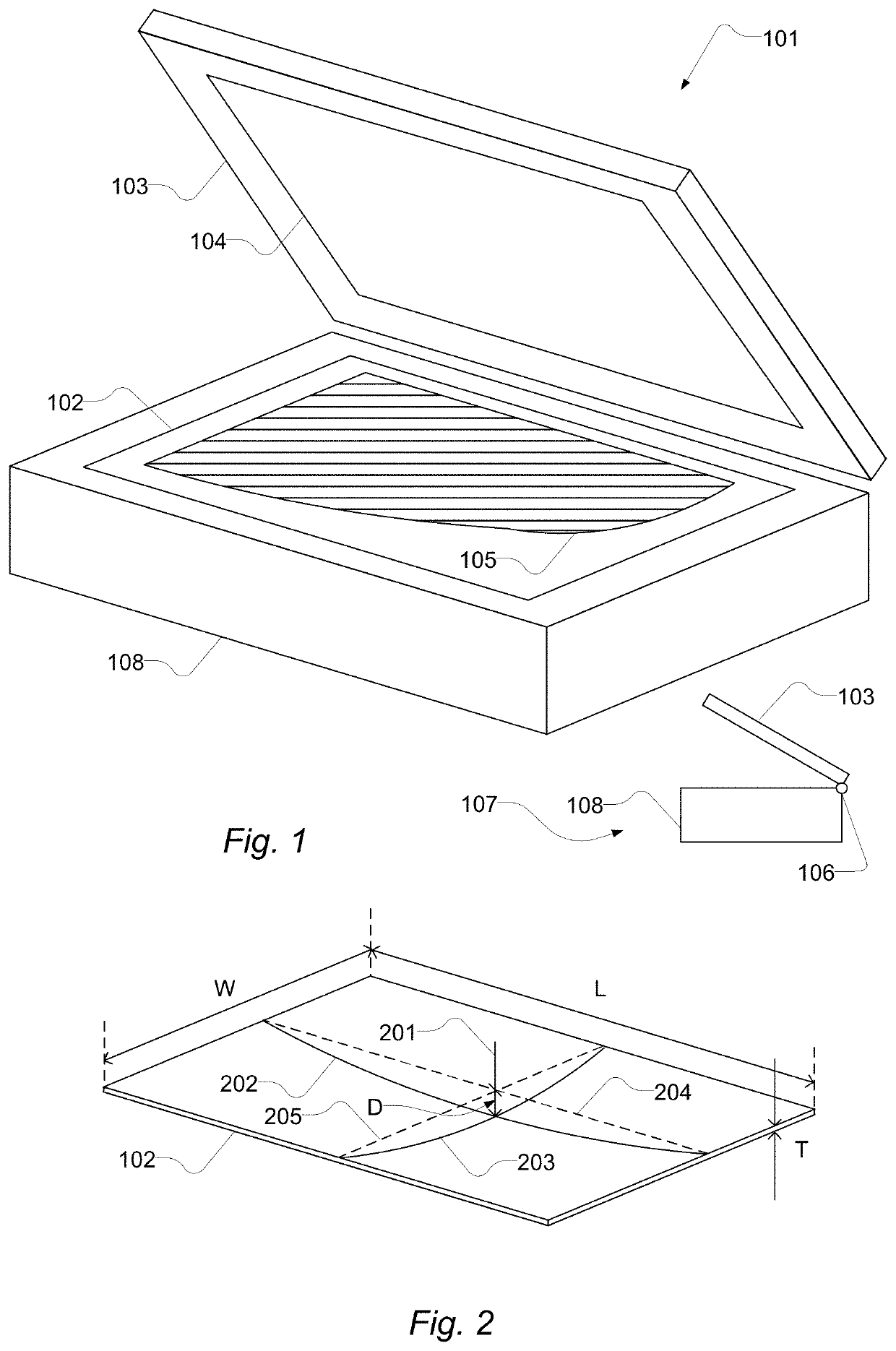

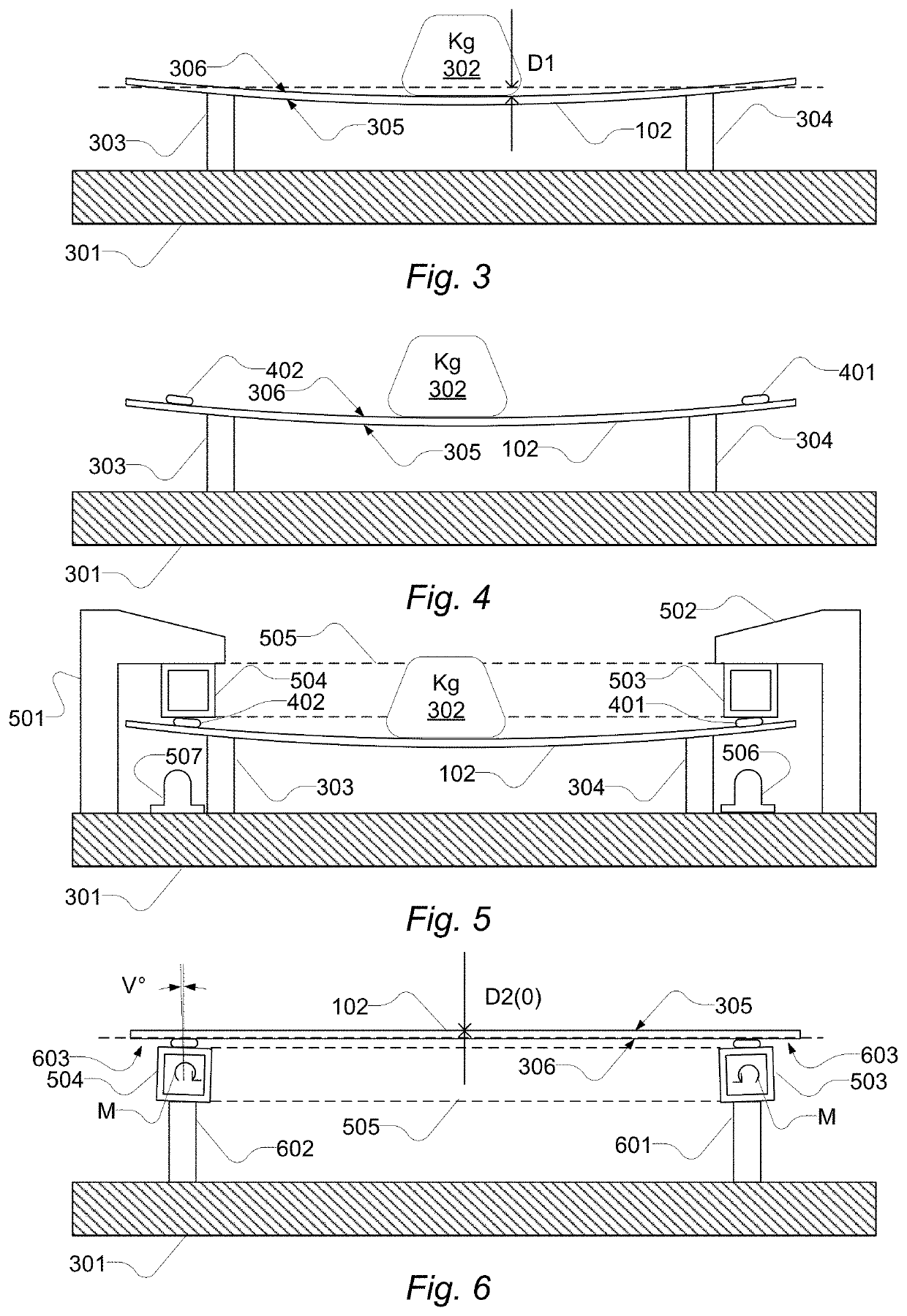

Optical flatbed scanner with rigid transparent plate fixing

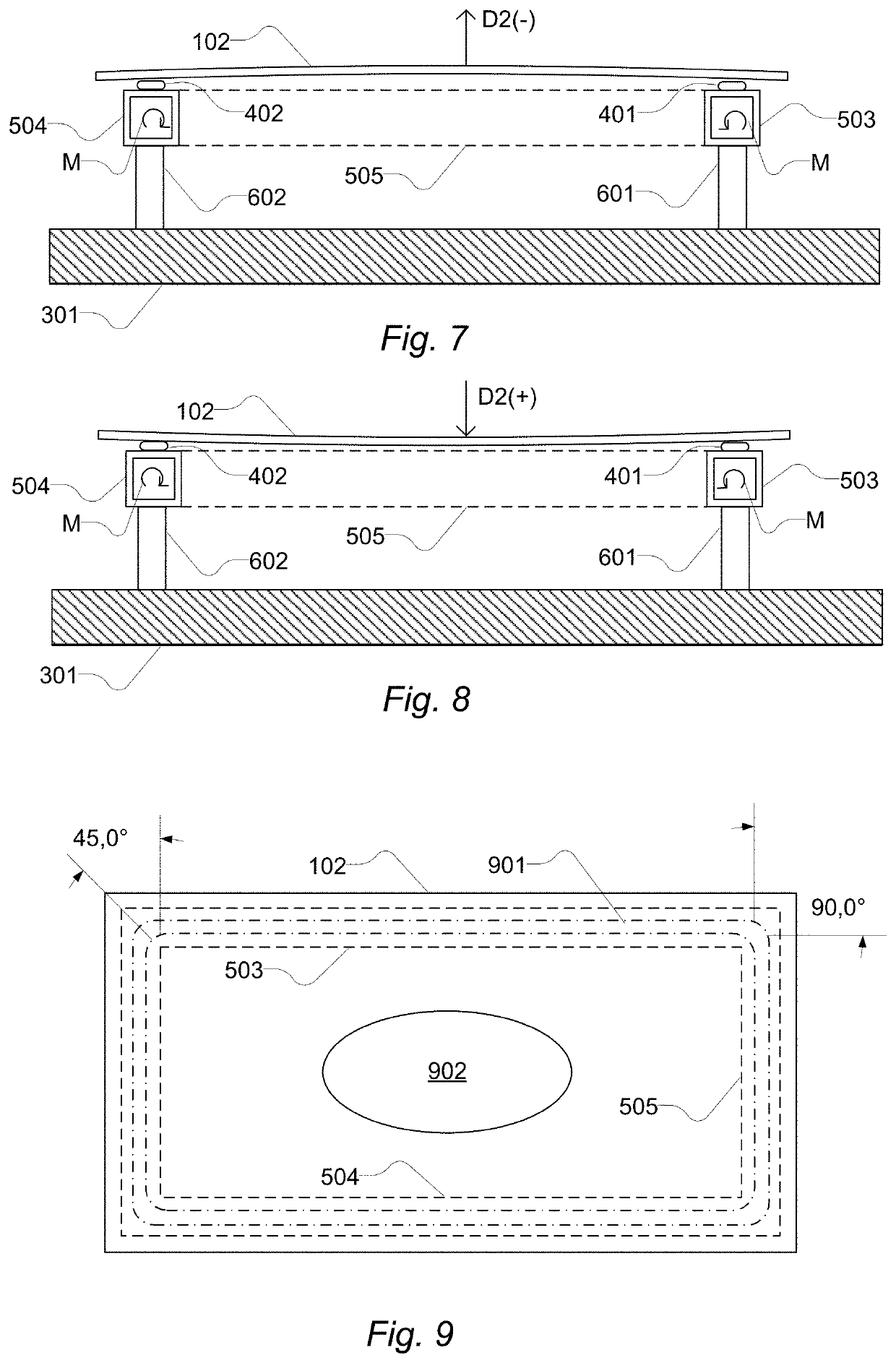

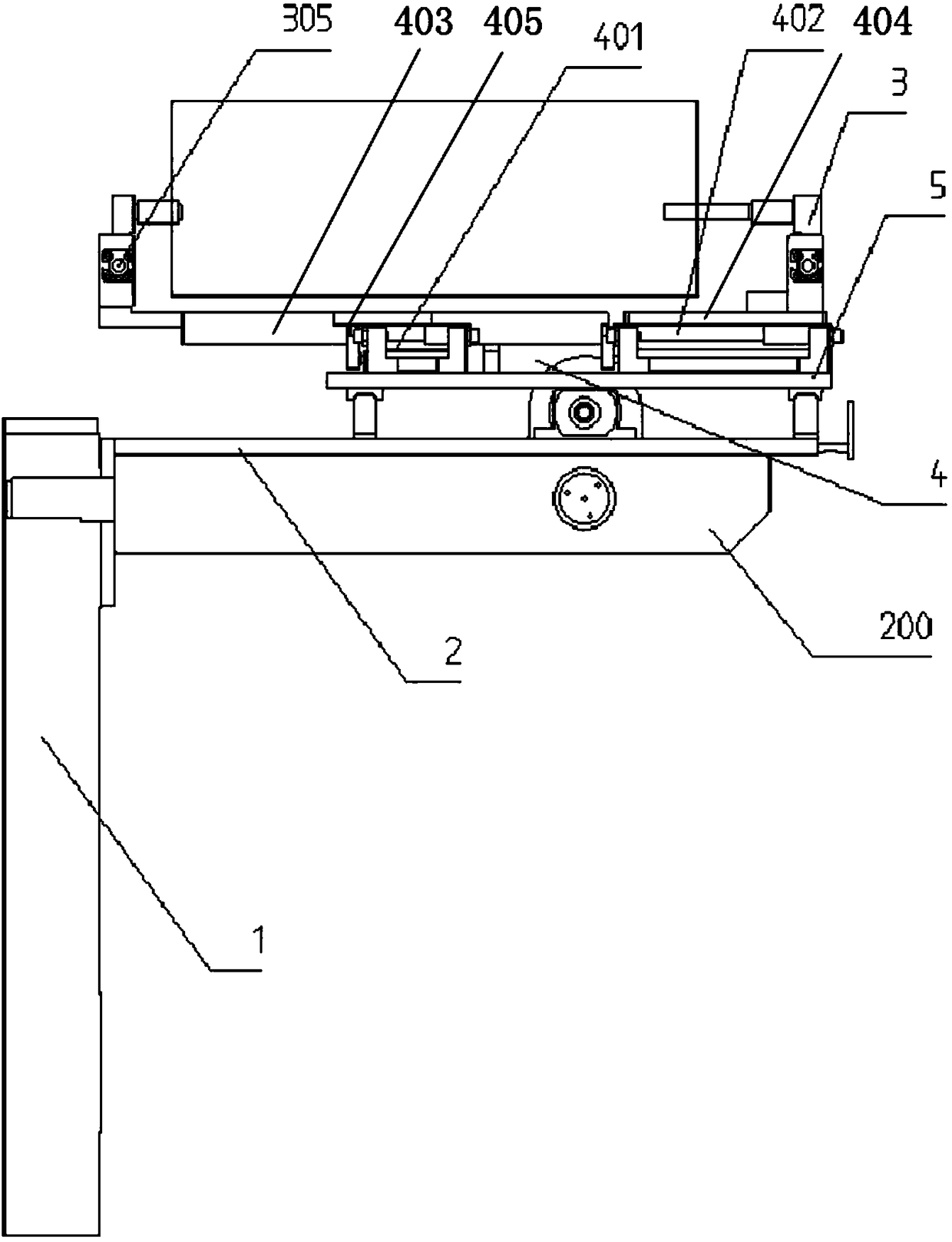

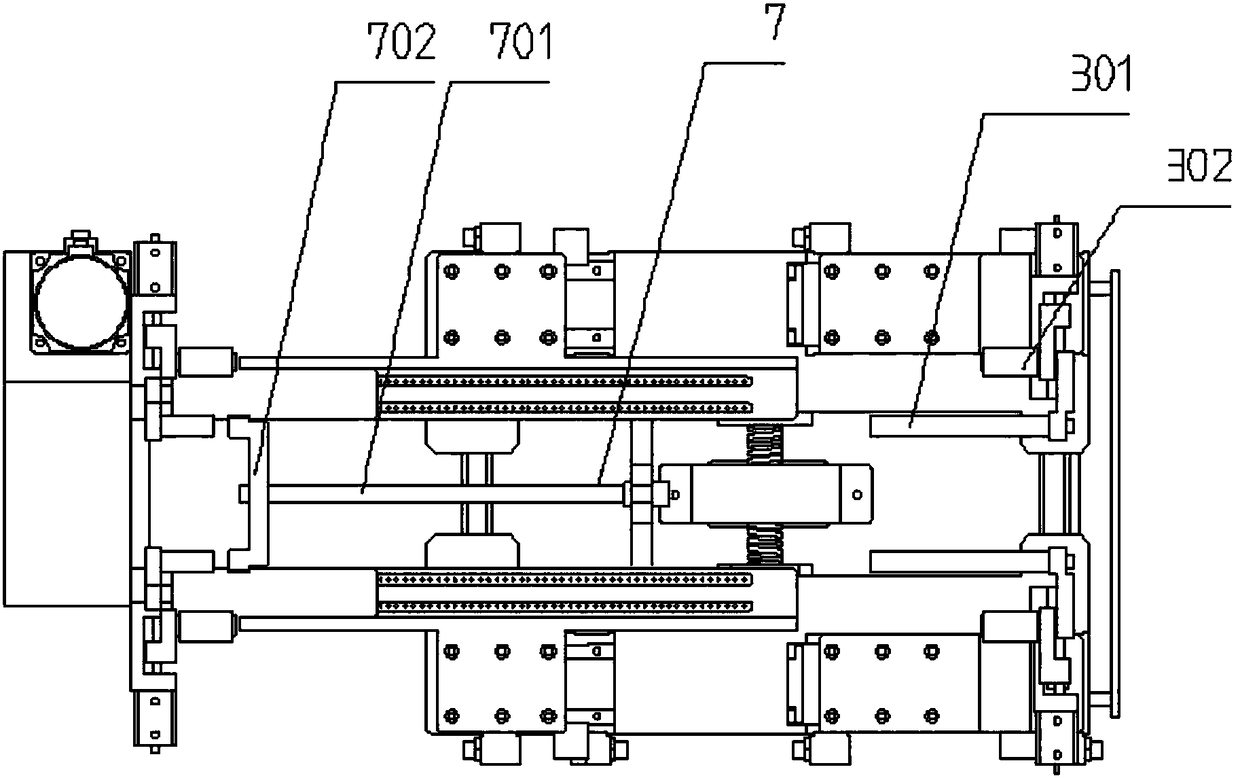

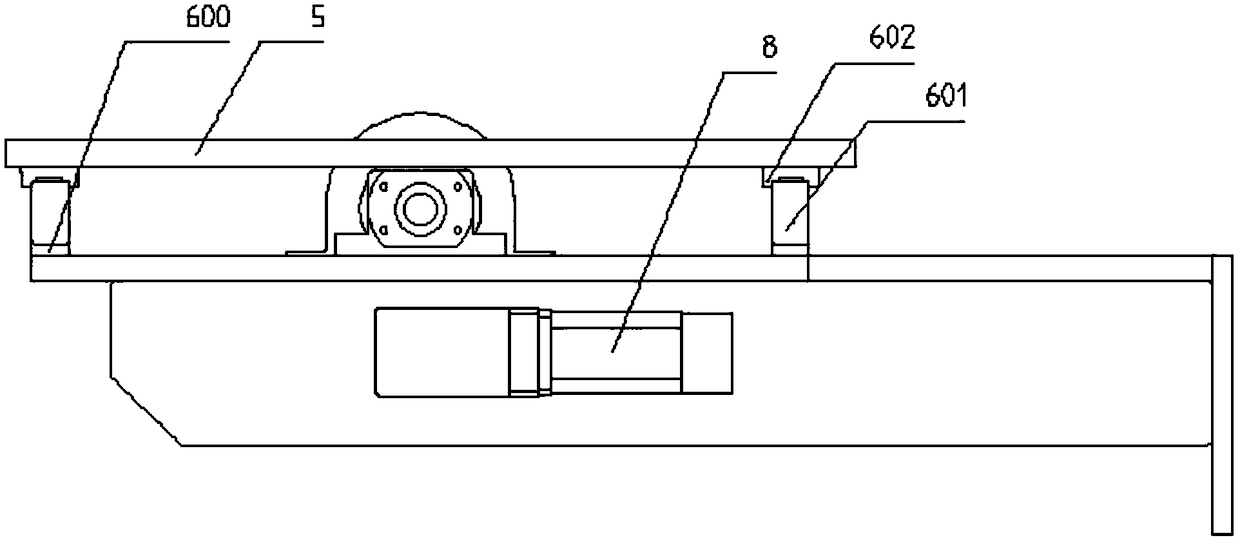

ActiveUS10542174B2Reduce deflectionImprove image qualityPictoral communicationMetal frameworkEngineering

A flatbed scanner document scanner includes a large format document scanner body accommodating a rectangular rigid frame with an upwardly facing plane face and a rectangular transparent plate for supporting a large format document. The rectangular transparent plate overlies the upwardly facing plane face all around the metal frame. The scanner also includes a movable carriage configured to move along and below the rectangular transparent plate and carrying a line camera extending across the rectangular transparent plate. The rectangular transparent plate and the metal frame are bonded together by a hard glue seam that runs on the upwardly facing plane face of the metal frame. A predetermined deflected shape can be formed when the bonded plate and frame are turned upside-down. The rectangular metal frame can deform under its own load to a cambered shape, a flat shape or a less deflected shape when turned upright in a normal position.

Owner:GLOBAL SCANNING DENMARK AS

Cell Clamping Mechanism

ActiveCN106159343BQuality assuranceImprove winding efficiencyFinal product manufactureSecondary cells manufactureEngineeringPower output

The invention relates to a battery clamping mechanism, which is characterized in that it includes a first bottom plate, a clamping jaw movement mechanism and a stretching movement mechanism; two second bottom plates capable of relative movement are symmetrically arranged on the first bottom plate The jaw movement mechanism includes two jaw movement mechanism units symmetrically arranged on the two second bottom plates; the jaw movement mechanism unit includes a left jaw and a right jaw for clamping the left and right ends of the electric core; The stretching motion mechanism includes a stretching drive device installed on the first bottom plate, and the power output end of the stretching drive device is connected to two second bottom plates to make the second bottom plates move relative to each other, so that the two jaw movement mechanism units will clamp The tight battery pulls flat. The invention flattens the circular battery core to obtain a flat battery core, avoids the problems of low winding efficiency of the flat battery core and uneven tension in winding the flat battery core in the prior art, and improves the quality of the battery core.

Owner:CONTEMPORARY AMPEREX TECH CO

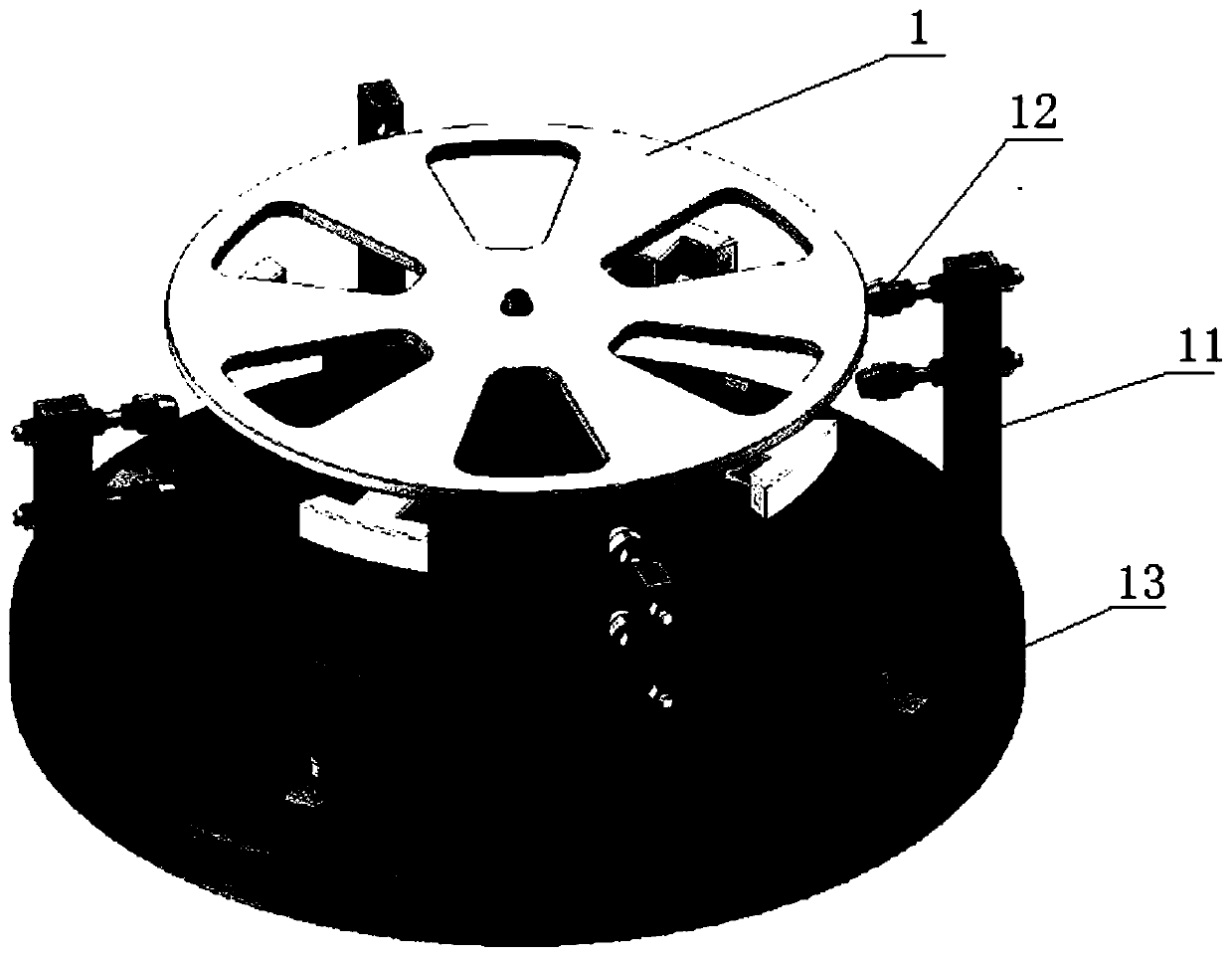

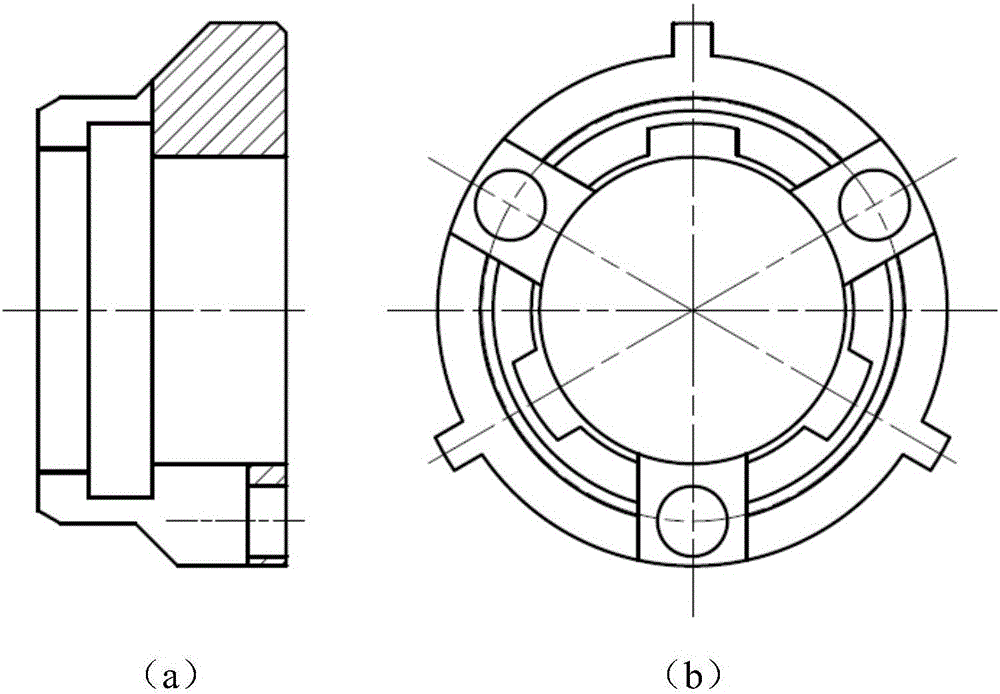

Anti-vibration core expanding tool with locking function

PendingCN113894581AAvoid uneven tensionWith lock functionPositioning apparatusMetal-working holdersStructural engineeringMechanical engineering

Owner:贵州欣宇泰科精密科技有限公司

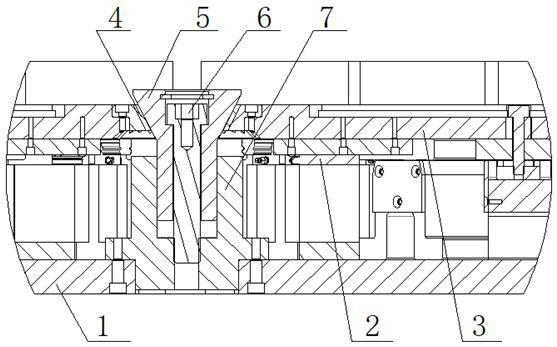

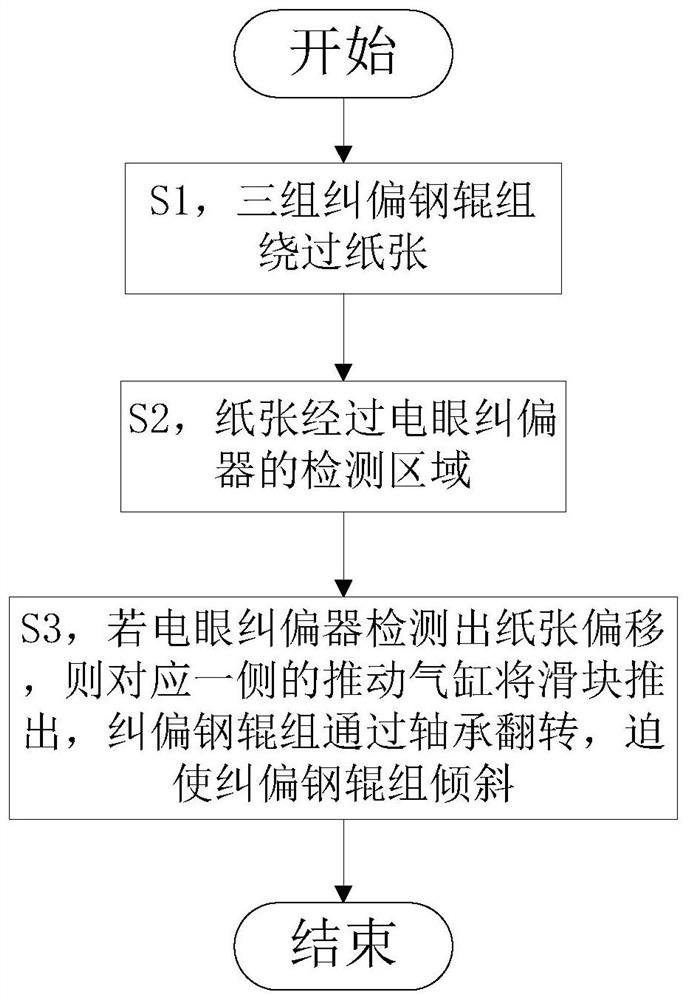

Paper deviation rectifying device and deviation rectifying method

PendingCN112777367AAvoid uneven tensionBag making operationsPaper-makingEngineeringStructural engineering

Owner:佛山市骏联智能装备有限公司

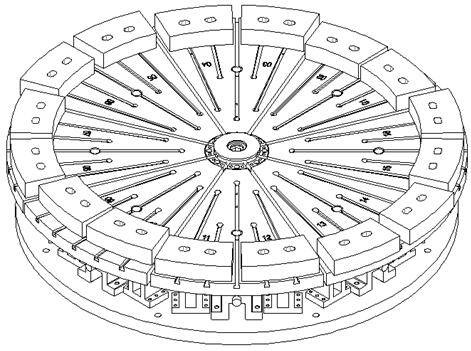

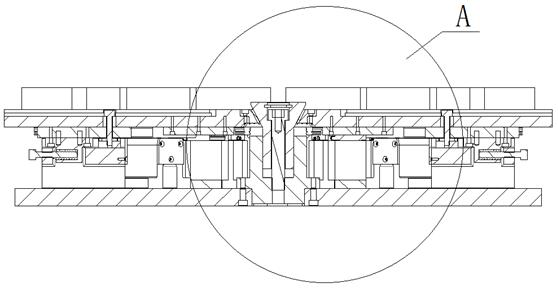

Shield tunneling machine and synchronous translation mechanism of segment rounding device thereof

ActiveCN112814702AAvoid deflectionAvoid uneven tensionUnderground chambersTunnel liningShield machineStructural engineering

The invention discloses a synchronous translation mechanism of a segment rounding device. The synchronous translation mechanism comprises a supporting beam, a segment assembling machine, the segment rounding device, a first driving part and a second driving part, wherein the supporting beam is arranged on a machine body in a transverse translation mode, the segment assembling machine is arranged at one longitudinal end of the supporting beam, the segment rounding device is arranged at the other longitudinal end of the supporting beam, the first driving part is arranged on the transverse left side of the supporting beam, connected with the segment rounding device and used for driving the segment rounding device to move in the longitudinal direction of the supporting beam, the second driving part is arranged on the transverse right side of the supporting beam, connected with the segment rounding device and used for driving the segment rounding device to move in the longitudinal direction of the supporting beam, and the output state of the first driving part and the output state of the second driving part are synchronous. According to the synchronous translation mechanism, the segment rounding device can be prevented from deflecting in the steering process of the shield tunneling machine, the phenomenon that the supporting pressure on segments is not uniform is avoided, and meanwhile abrasion of a base plate of the segment rounding device is reduced. The invention further discloses the shield tunneling machine. The shield tunneling machine has the advantages.

Owner:CHINA RAILWAY CONSTR HEAVY IND

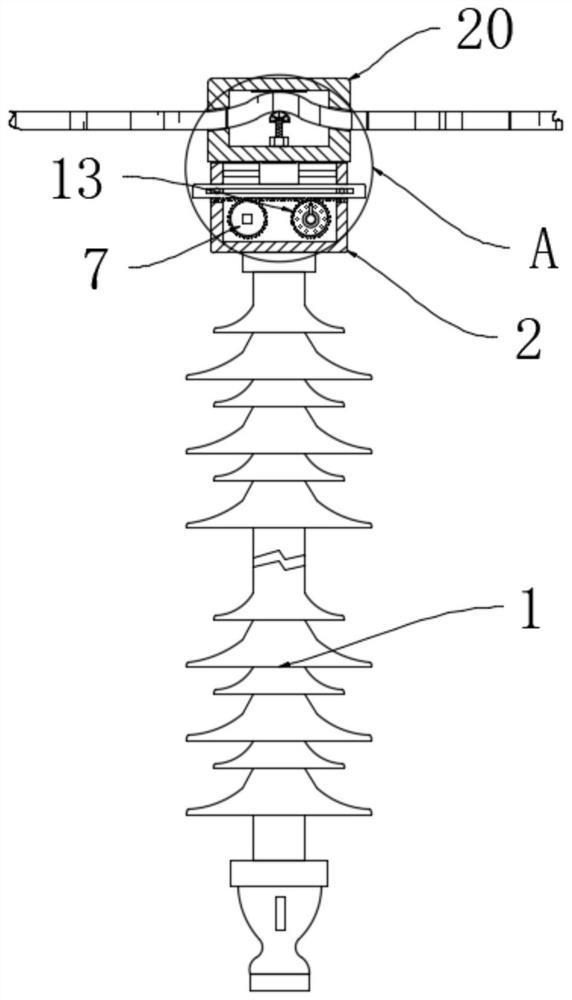

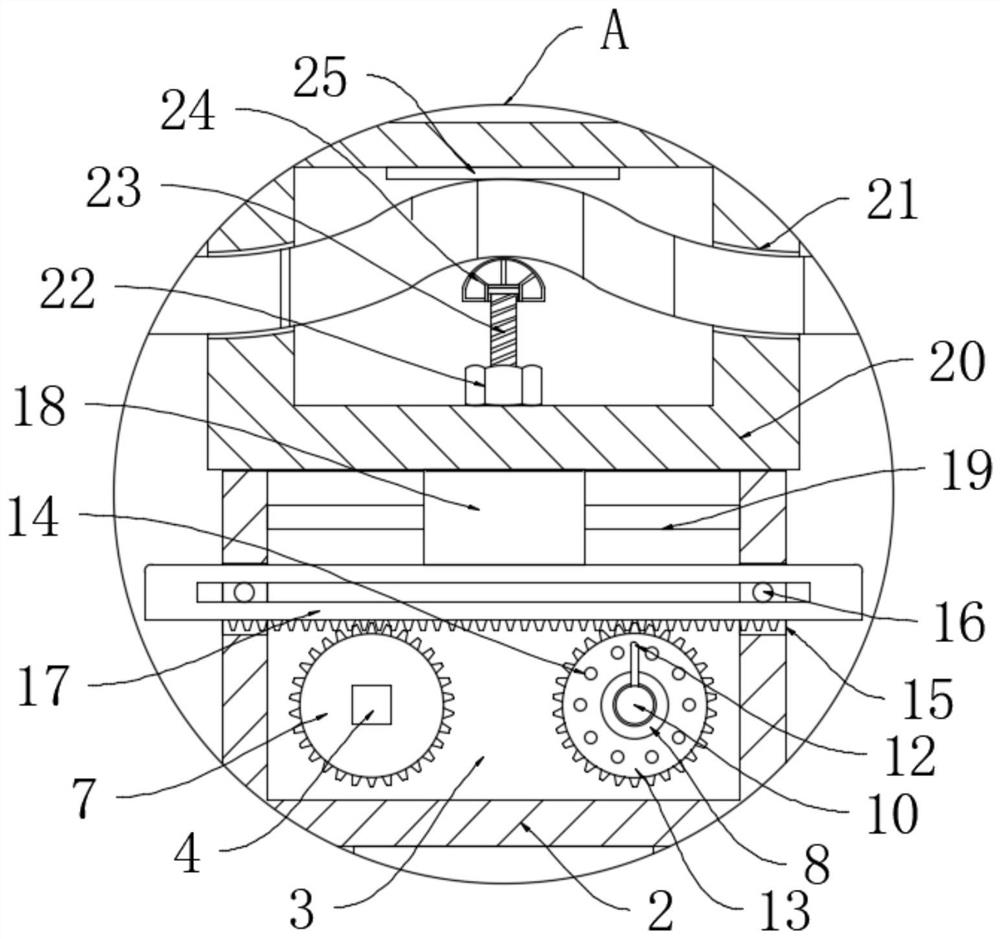

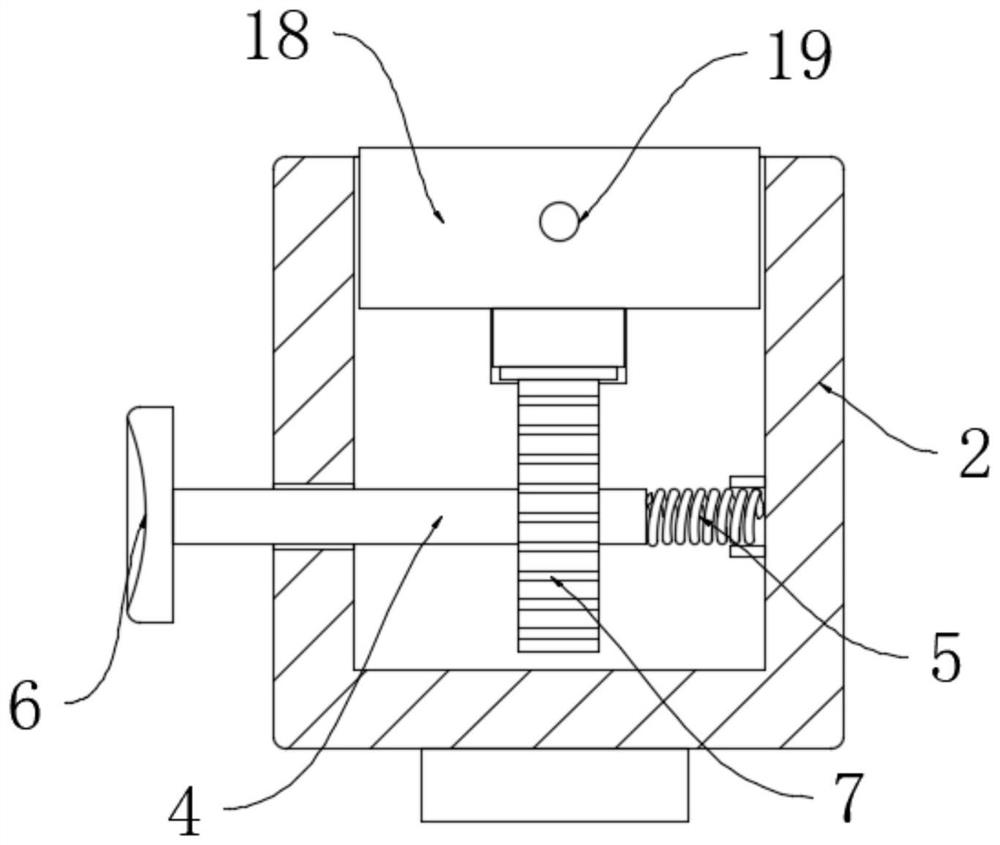

Electric porcelain insulator capable of being quickly connected with cable

The invention relates to the technical field of insulators, in particular to an electric porcelain insulator capable of being quickly connected with a cable, which comprises an insulator body. A limiting block is fixedly mounted on the insulator body, a cavity is formed in the limiting block, a square shaft is mounted in the cavity in a sliding manner, and a first spring is fixedly connected to the square shaft. A pressing block and a limiting gear are fixedly installed on the square shaft, a sleeve is fixedly installed in the cavity, a second spring is fixedly installed in the sleeve, a circular shaft is movably connected into the sleeve, a rotary knob and a push rod are fixedly installed on the circular shaft, a gear ring is rotatably installed on the sleeve, and a clamping column is fixedly installed on the gear ring; a through groove is formed in the limiting block; the cable is installed and fixed through the cable clamp installed on the limiting block at the top of the insulatorbody, a small-range fine adjustment mechanism is arranged in the cable clamp, a large-range coarse adjustment mechanism is installed in the limiting block, and the problem that the tension of the cables on the two sides of the cable clamp is not uniform is effectively solved.

Owner:萍乡百斯特电瓷有限公司

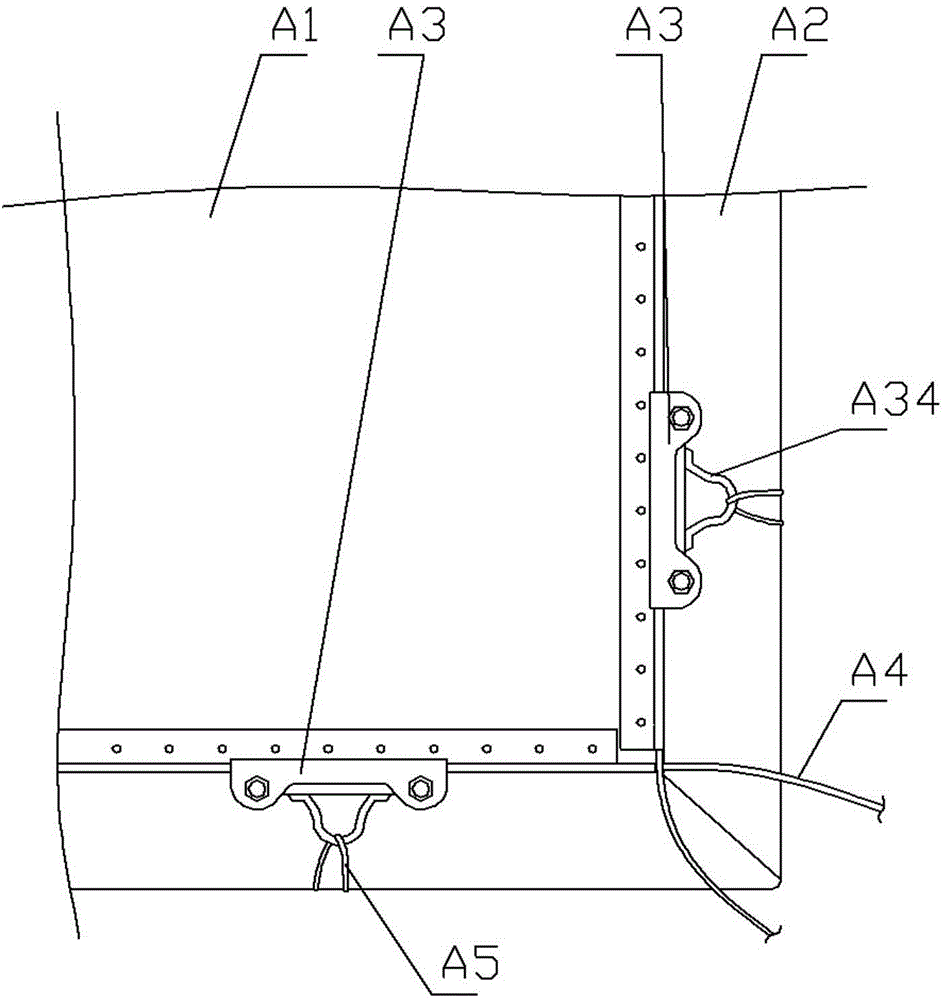

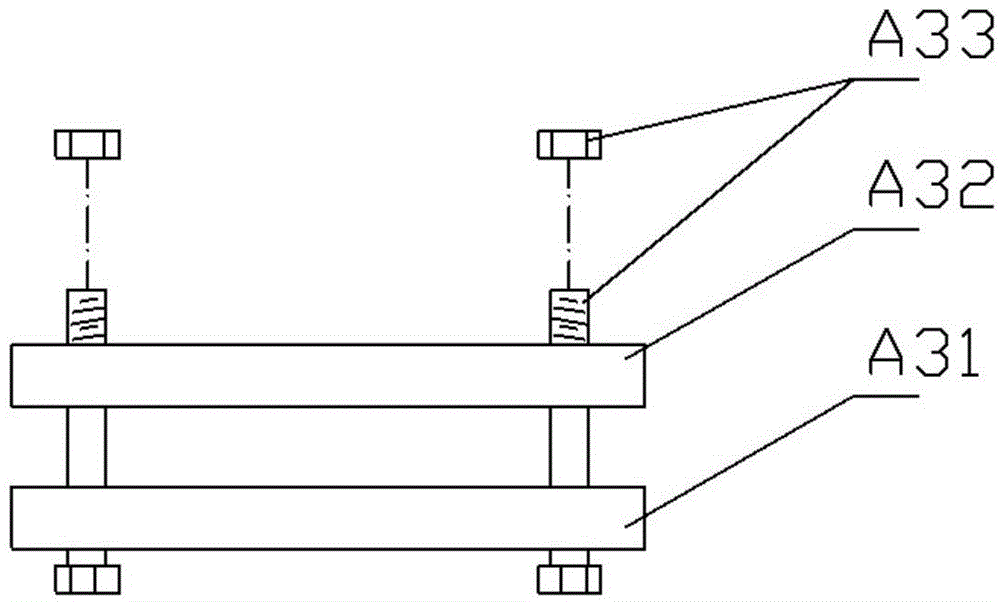

Curtain structure using tensioner

ActiveCN103432753BAvoid uneven tensionImprove mechanical performanceStage arrangementsEngineeringAirflow

The invention discloses a curtain structure using a tensioner. A lock edge pressure strip is structurally characterized in that a round groove with an upper opening, a lower T-shaped groove at the lower part of a plate body and a right T-shaped groove at the right part of the plate body are formed in the plate body, the lower T-shaped groove is provided with a T-shaped cross section and a downward opening, and the right T-shaped groove is provided with a T-shaped cross section and a rightward opening; a curtain is provided with a curtain buckle edge lap, a buckle edge rubber strip is sleeved on the curtain buckle edge lap in a penetration way, the curtain buckle edge lap is inserted and sleeved in the round groove, and the lower T-shaped groove is inserted and sleeved on a curtain structure bracket; each pull block is an L-shaped plate body comprising a short edge and a long edge, a through hole is formed in the long edge, and the height of the short edge is smaller than the width of the opening of the right T-shaped groove; two pull blocks are stacked, inserted and sleeved in the right T-shaped groove, and a pull rope is sleeved in the through holes in the penetration way; a suspension hook is suspended on the curtain structure bracket, and the pull rope is pulled by a pull hook 76. According to the curtain structure, the curtain tension force is balanced, the curtain is smooth, the service life of the curtain structure is prolonged, and the effect of lightly lifting the curtain due to airflow and wind is remarkably reduced.

Owner:ZHEJIANG BAOYE CONSTR GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com