Transverse locking device for heavy tower crane

A technology of horizontal lock and tower crane, which is applied to cranes and other directions, and can solve problems such as bending deformation, easy swaying of bolts, and inability to guarantee the firmness of tower cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

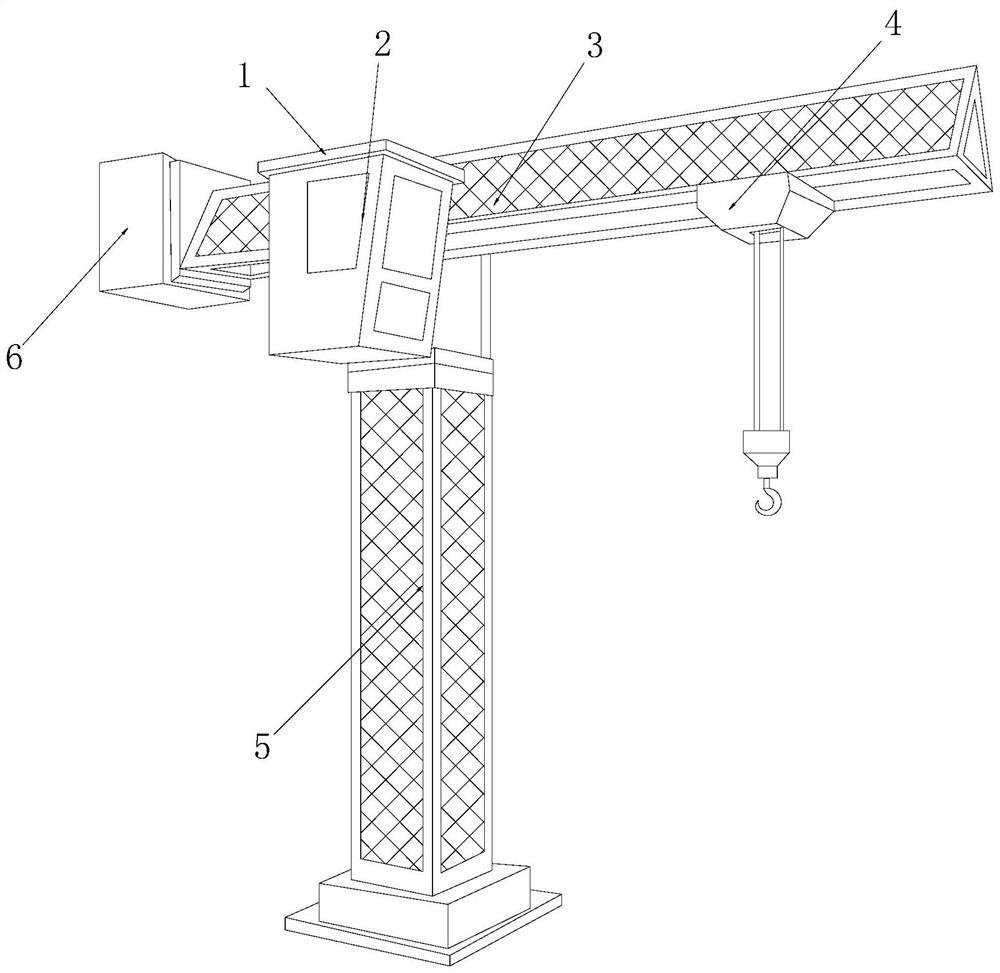

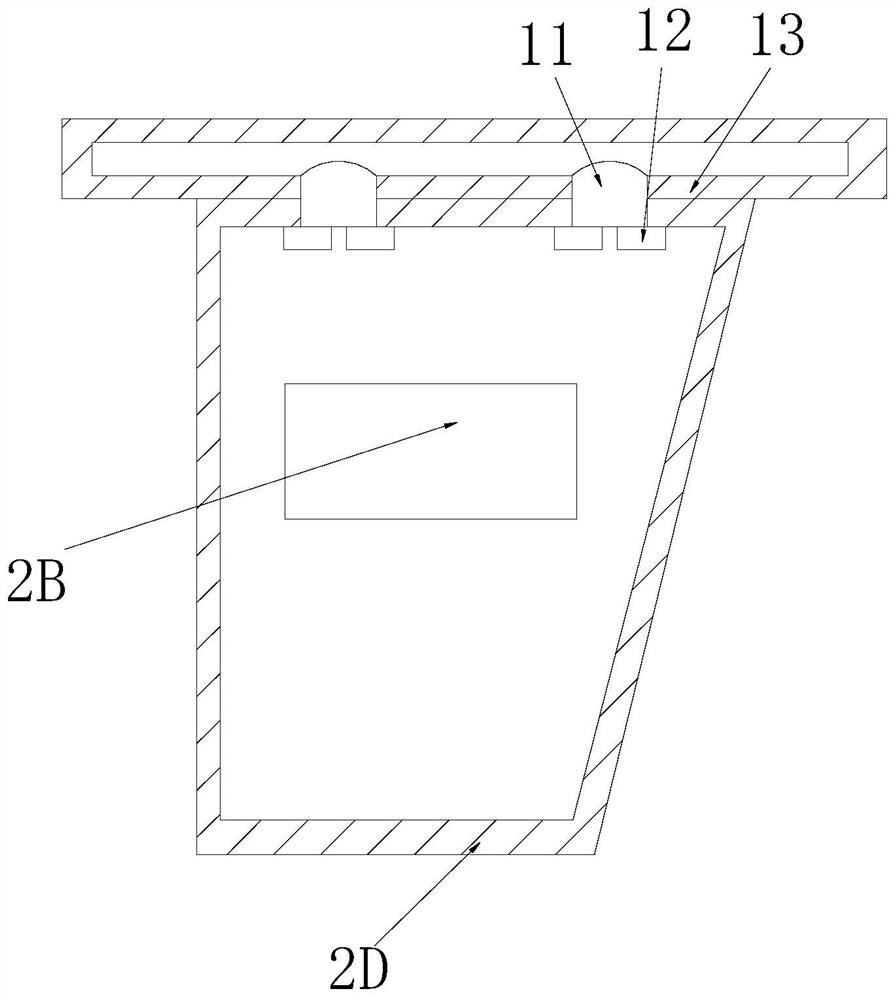

[0035] see Figure 1-Figure 8 , the present invention provides a heavy-duty tower crane horizontal locking device, the structure of which includes: top cover plate 1, guide rail locking box groove 2, horizontal frame boom 3, rope lifting hook frame seat 4, tendon rod support frame 5, counterweight Block 6, the guide rail locking box groove 2 is buckled together with the horizontal frame boom 3, the top cover plate 1 is nested on the top of the guide rail locking box groove 2, and the horizontal frame boom 3 is connected with the lifting arm The rope hook frame base 4 is mechanically connected and perpendicular to each other, the tendon rod support frame 5 is inserted under the bottom of the guide rail lock box groove 2 and is on the same vertical plane, and the counterweight 6 is nested in the horizontal frame hanger On the left side of the arm 3, the guide rail locking box groove 2 is provided with a roller pad truss plate 2A, a buckle pad flap groove 2B, a reed pipe column b...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a heavy-duty tower crane lateral locking device, which is the same as Embodiment 1 in other respects, except that:

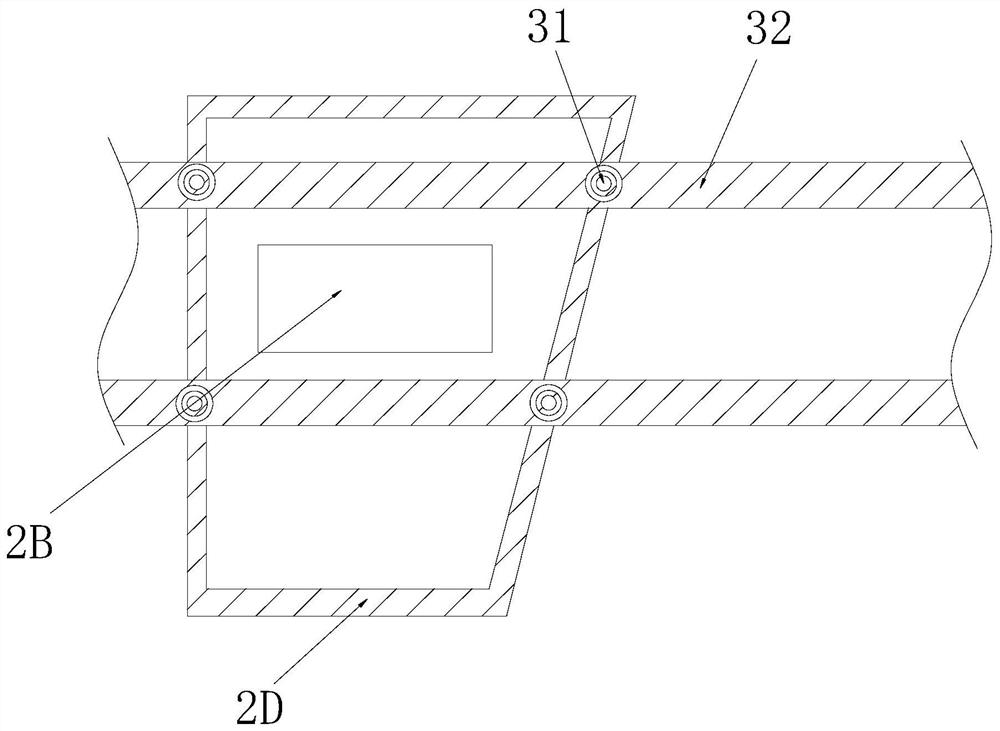

[0044] see image 3 , the cross frame boom 3 is composed of a left wheel buckle 31 and a boom bar 32, the left wheel buckle 31 is installed inside the boom bar 32 and is on the same vertical plane, the left wheel buckle 31 is buckled together with the boom bracket bar 32, and the boom bracket bar 32 is inserted into the boom bracket bar 32 by the left wheel buckle plate 31 to form a lock shaft hoisting interspersed effect.

[0045] see Image 6 , the left wheel buckle plate 31 is composed of a fan pad wheel buckle groove 311 and a frame ring disk groove 312. The fan pad wheel buckle groove 311 is installed inside the frame ring disk groove 312. The ring disc groove 312 is nested into one body and is on the same vertical plane. The fan gasket wheel buckle groove 311 is a wheel groove structure in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com