Cell Clamping Mechanism

A battery clip and battery cell technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of low winding efficiency of flat batteries and uneven tension of winding flat batteries. Achieve the effect of avoiding low winding efficiency, avoiding uneven tension, and improving winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

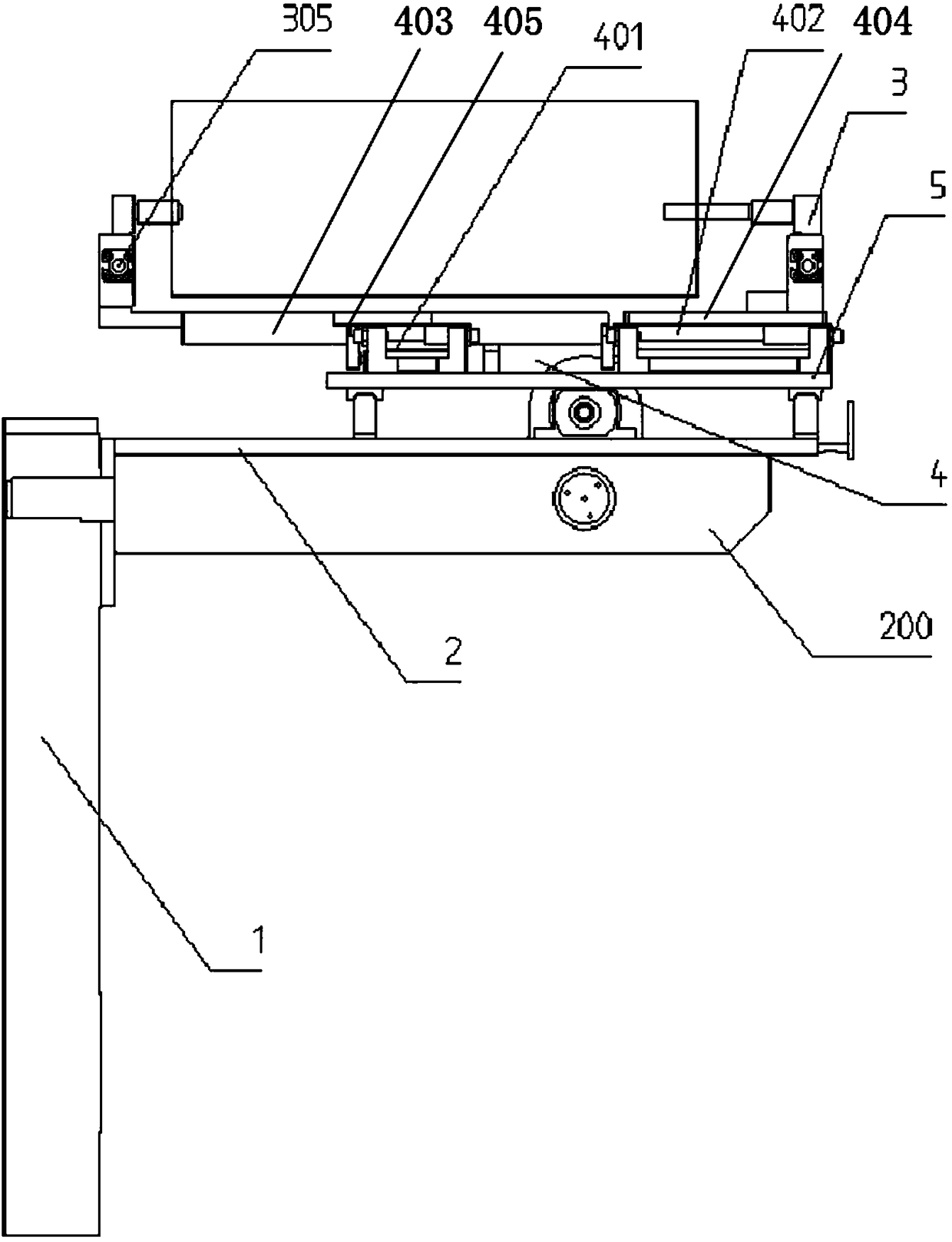

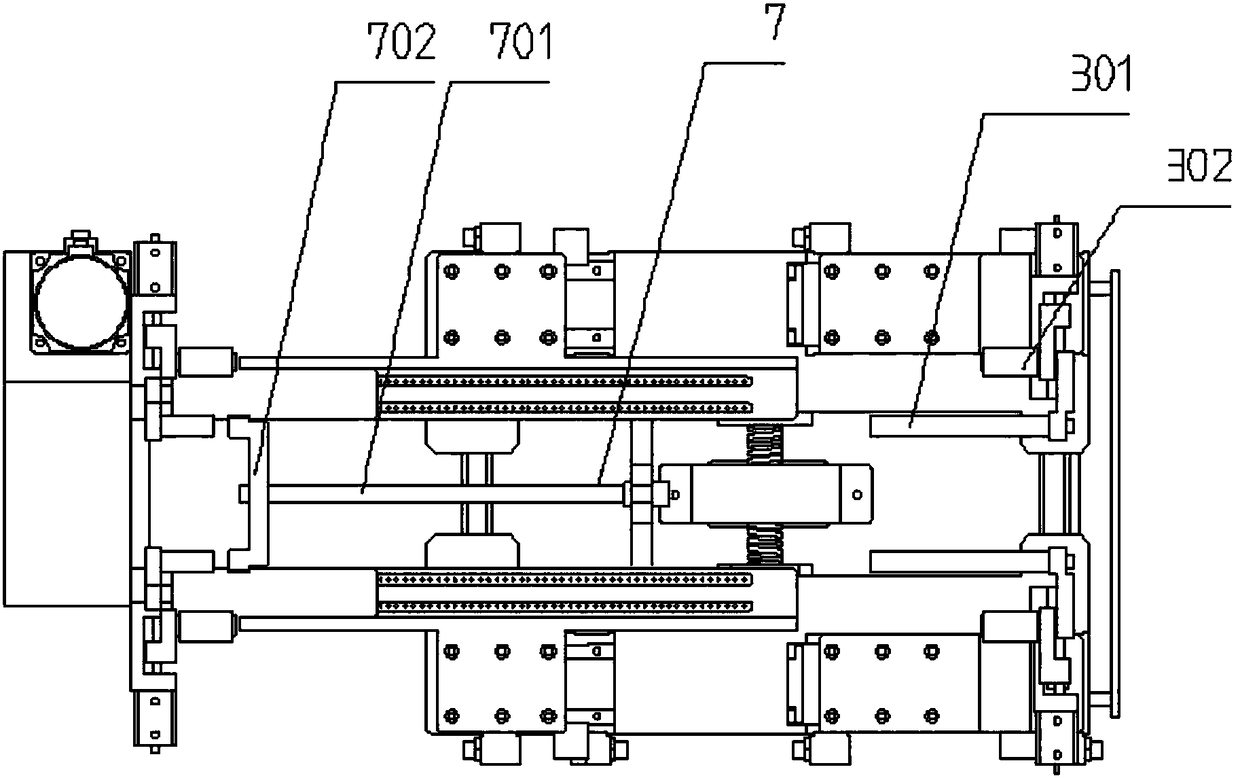

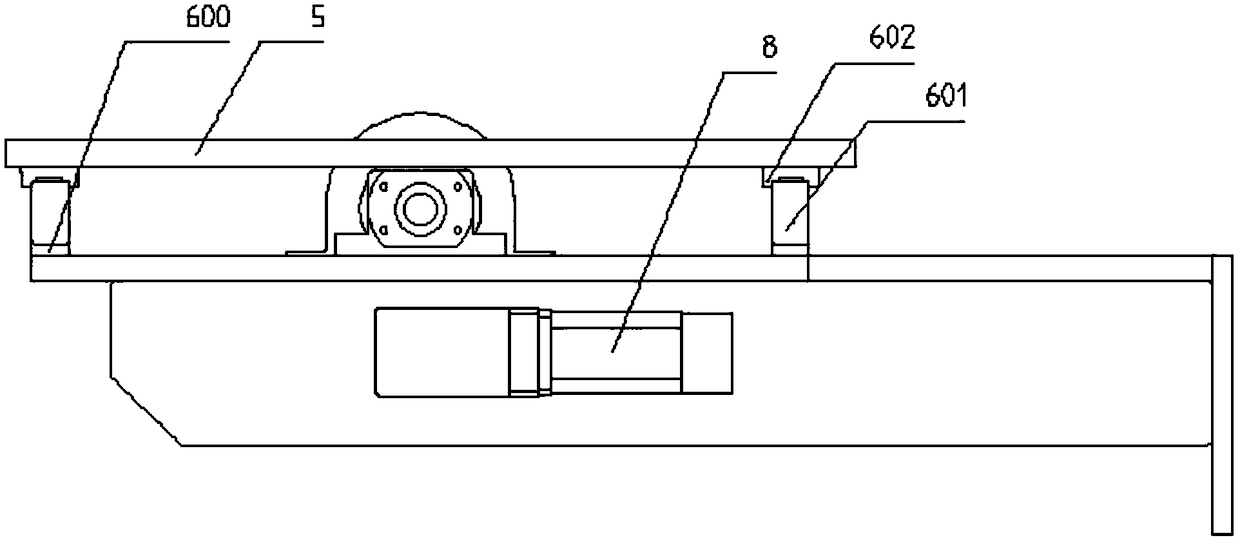

[0026] The present invention will be further described below in conjunction with specific drawings.

[0027] The directions or positional relationships such as "left, right" and "front and back" proposed in the present invention are based on the attached figure 1 The orientation or positional relationship shown, the "left and right" proposed in the present invention refers to the attached figure 1 as a benchmark, figure 1 The left side of is "Left", figure 1 The right side of is "Right", figure 1 The direction facing the paper is "front", and the direction of the back paper is "rear".

[0028] like Figure 1 to Figure 7 As shown: the cell clamping mechanism includes a lifting mechanism 1, a first base plate 2, a jaw movement mechanism unit 3, a jaw adjustment mechanism unit 4, a second base plate 5, a line rail assembly 6, a screw adjustment mechanism 7, and a motor 8. Driving gear 9, driven gear 10, ball screw 11, screw nut 12, connecting block 13, reinforcing rib 200, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com