Adhesive tape joining method and adhesive tape joining apparatus

A technology of sticking device and adhesive tape, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., which can solve the problems of chip flying, peeling, and uneven tension of the adhesive tape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

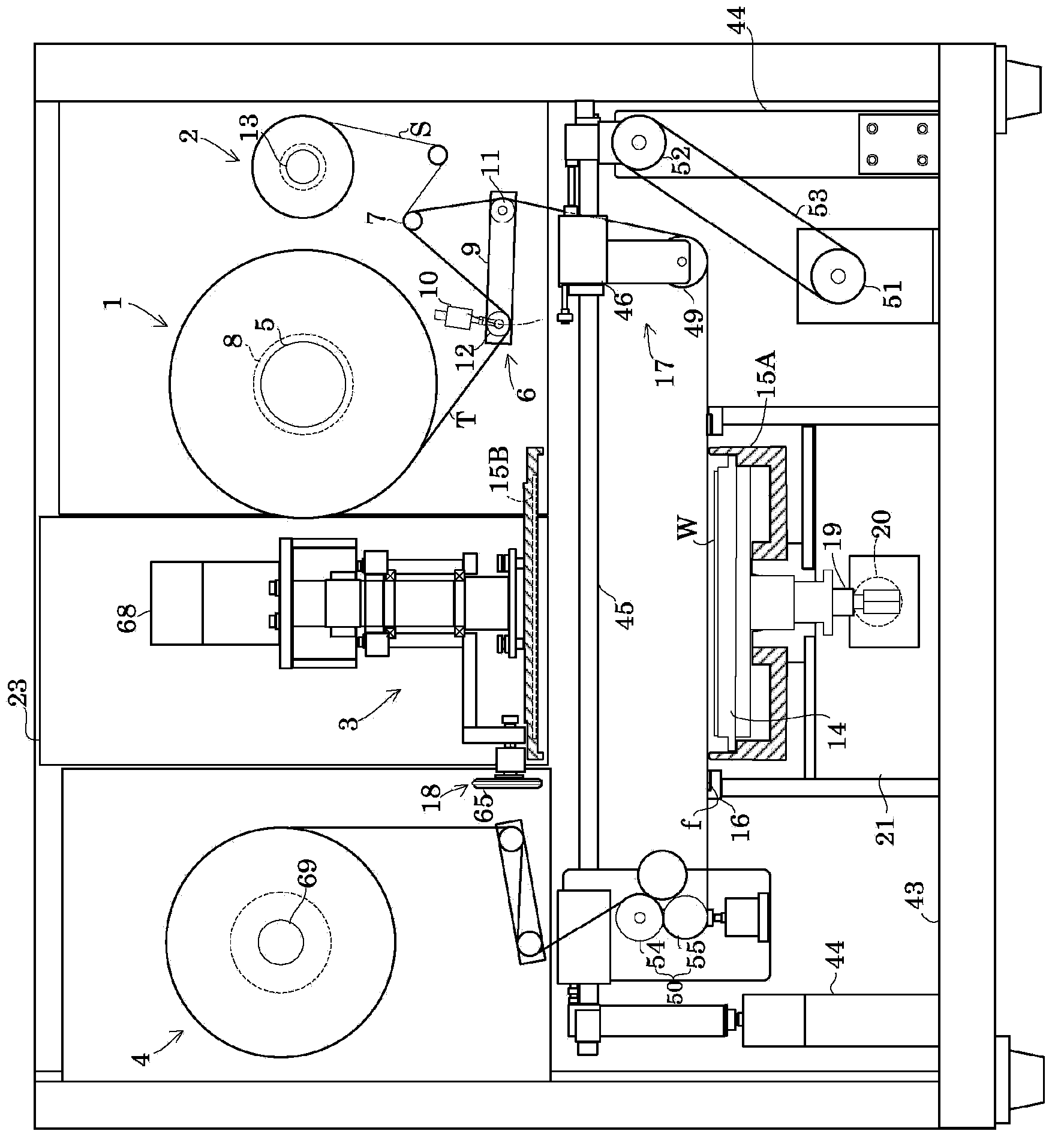

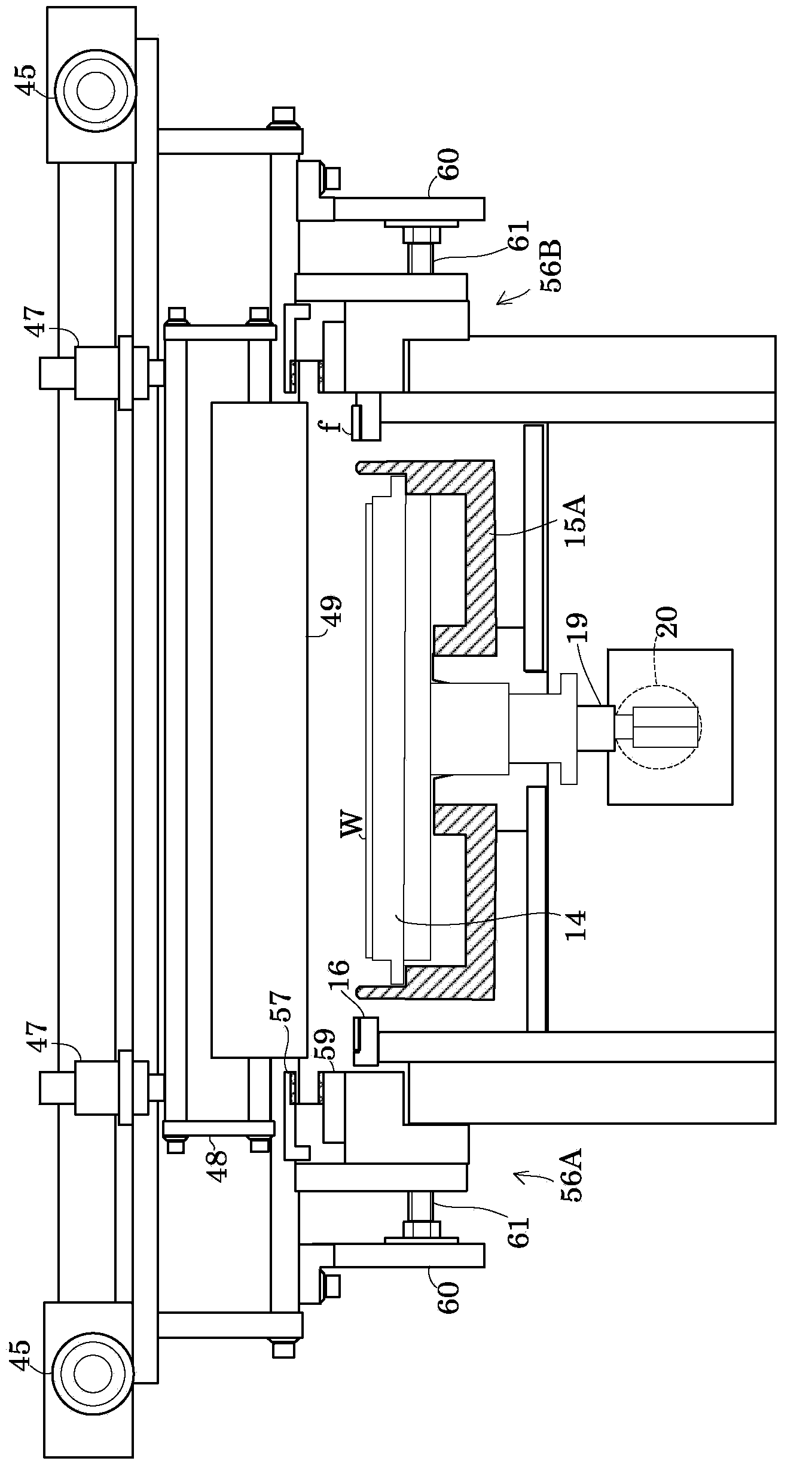

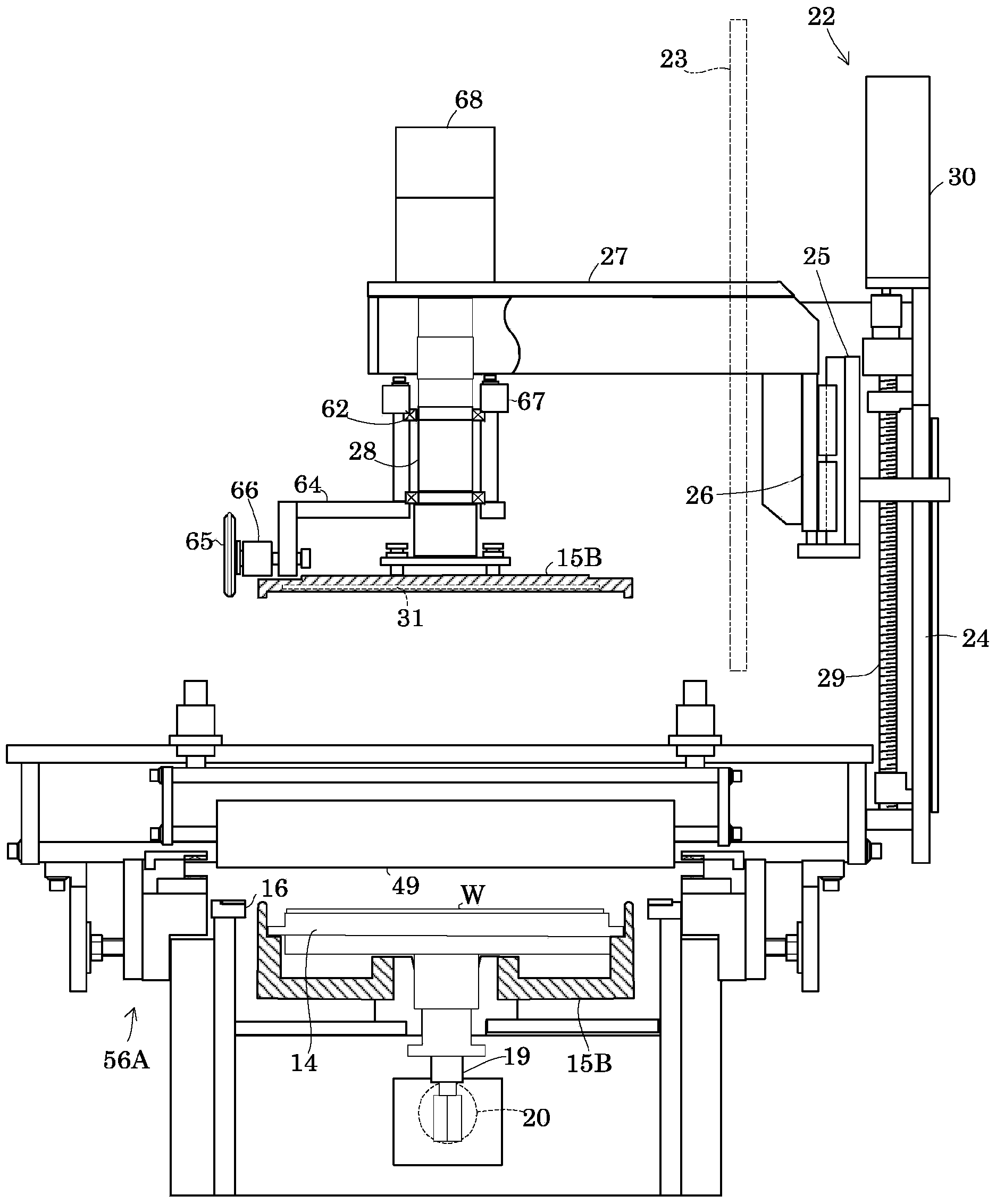

[0031] In order to explain the invention, several embodiments considered to be suitable at present are shown in the drawings, but it is understood that the present invention is not limited to the structures and methods shown in the drawings.

[0032] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. In addition, if Figure 13 ~ Figure 15 As shown, the semiconductor wafer (hereinafter, simply referred to as “wafer”) used in this embodiment is a wafer in which a protective tape PT is pasted on the surface on which the circuit is formed to protect the surface and has undergone backgrinding. Using a wafer processed into a shape in which the back surface of the wafer is ground (background) so that the outer peripheral portion is left about 2 mm in the radial direction, a flat concave portion b is formed on the back surface, and along the back surface The ring-shaped convex part r remains on the outer periphery. For example, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com