Anti-vibration core expanding tool with locking function

A core expanding and tooling technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., to achieve the effects of uniform tightening force, low production cost, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the concept of the present invention, the specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings:

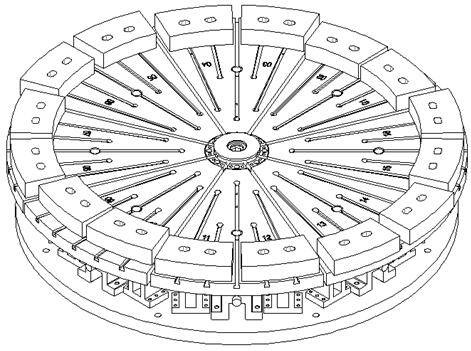

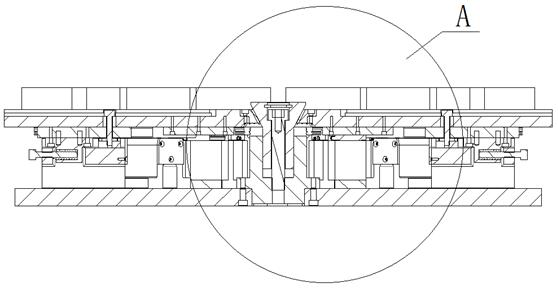

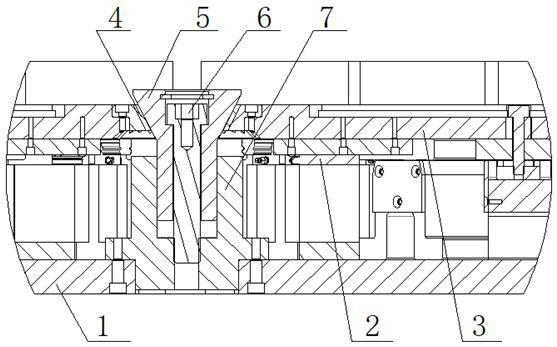

[0019] Such as Figure 1 to Figure 5 As shown, a kind of anti-seismic expansion core tooling with locking function according to the present invention includes a tooling base plate 1, a guide rail mechanism 2 and a core expansion block 3, the guide rail mechanism 2 is arranged on the tooling base plate 1, and the The core expansion block 3 is arranged in the guide rail mechanism 2, and an expansion sleeve mechanism is provided between the tooling base plate 1 and the core expansion block 3. The expansion sleeve mechanism includes a wear-resistant sheet 4, an inclined guide post 5, a positioning Screw 6 and guide sleeve 7, described guide sleeve 7 is arranged on the tooling base plate 1, is provided with the guide hole that matches with described inclined-plane guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com