Curtain structure using tensioner

A technology of tensioner and curtain, which is applied to the devices used in theaters, circuses, etc., entertainment, stage devices, etc. It can solve the problems of short service life of the curtain structure, wrinkles of the curtain A1, water and dust accumulation on the curtain, etc., and achieve waterproof effect Improvement, fast installation speed, and the effect of reducing the gray level of water accumulation on the roof structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

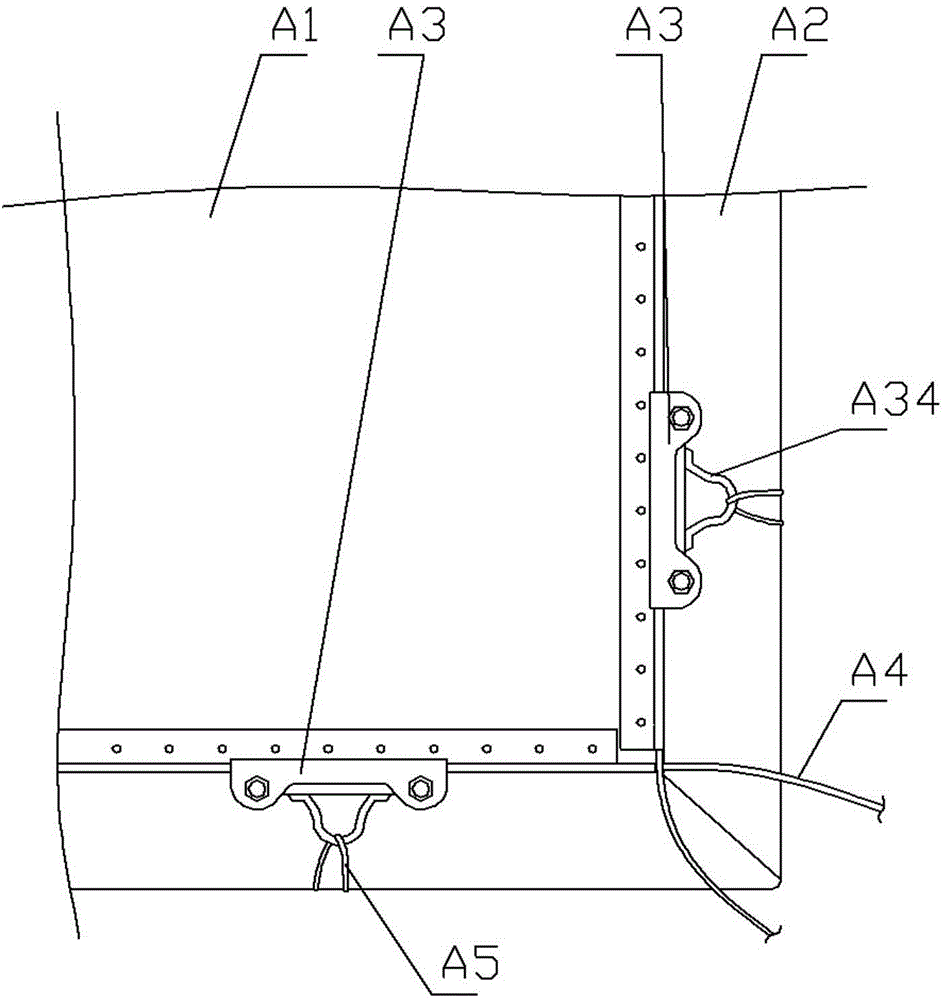

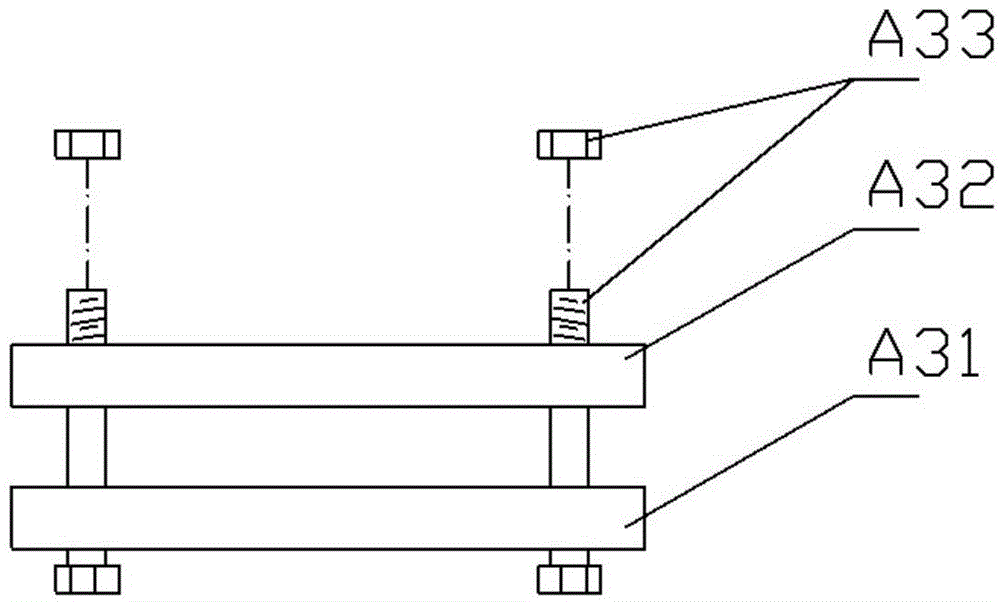

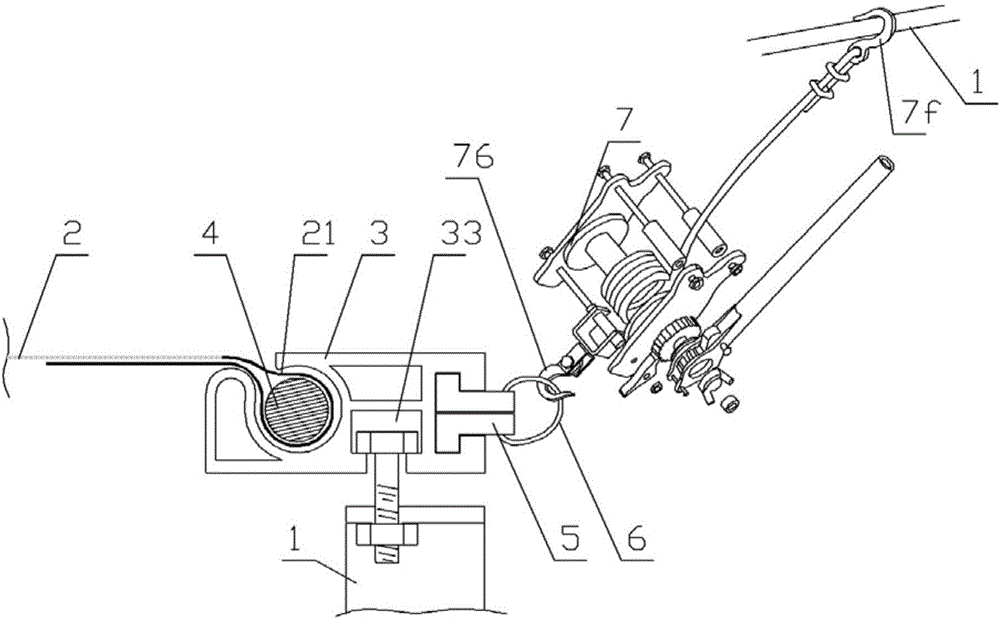

[0025] Example: see Figures 3 to 8 As shown, a curtain structure using a tensioner includes a curtain structure bracket 1 and a curtain 2. The structure of the overlock bead 3 is that a circular groove 32 with an upper opening 321 is formed on the plate body 31, and is located on the plate body 31. The lower T-shaped groove 33 of the bottom and the right T-shaped groove 34 positioned at the right part of the plate body 31, the cross-section of the lower T-shaped groove 33 is "T" and the opening of the groove is downward, and the cross-section of the right T-shaped groove 34 is "T" shape and slot opening to the right;

[0026] The curtain 2 has a curtain buckle lap 21, the buckle rubber strip 4 is put on the curtain buckle lap 21, the curtain buckle lap 21 is inserted into the circular groove 32, and the lower T-shaped groove 33 is inserted into the curtain structure On bracket 1;

[0027] The structure of the pull block 5 is that it is an "L"-shaped plate body composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com