Corn sheller

A peeling machine, corn technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of cumbersome operation, time-consuming, large particle damage, etc., achieve extensive social benefits, improve location, and reduce free side effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

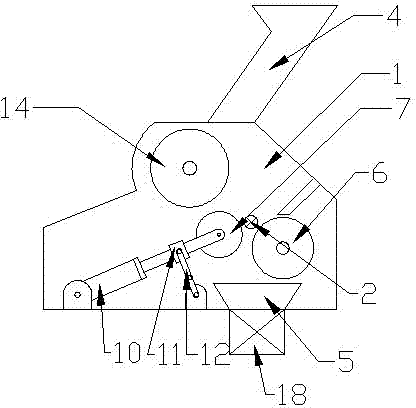

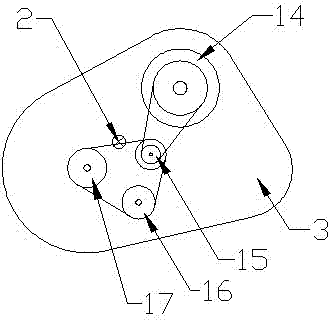

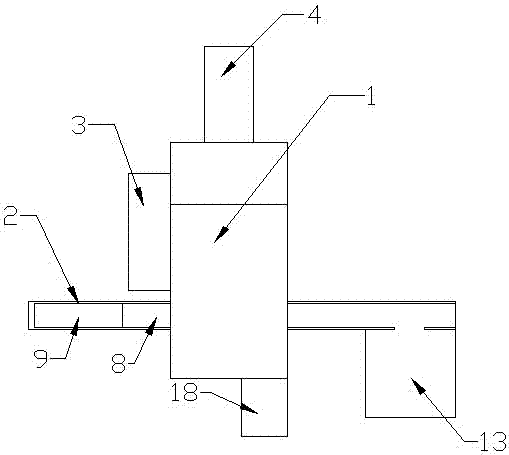

[0037] Do further description below in conjunction with accompanying drawing:

[0038] like Figure 1~3 Shown, a kind of corn peeling machine, described corn peeling machine comprises frame 1, withdrawing core mechanism 2, transmission case 3, peeling mechanism, feed hopper 4, discharge hopper 5;

[0039] The feed hopper 4 is arranged on the top of the frame 1, the discharge hopper 5 is arranged on the bottom of the frame 1, the discharge hopper 5 and the feed hopper 4 communicate with the peeling mechanism, and the core removal mechanism 2 and the transmission box 3. Set on the frame 1 and connect with the core ejection mechanism 2;

[0040] The peeling mechanism includes a pressing wheel 7 and a fixed wheel 6, and the pressing wheel 7 and the fixed wheel 6 are connected to reverse rotation through the transmission box 3, and the fixed wheel 6 is provided with granular protrusions, and the pressing wheel 6 The surface of the pinch wheel 7 is provided with flexible soft rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com