Externally-tightening and quick-changing hobbing tool for shafts

An external expansion and gear hobbing technology, applied in gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems affecting the output of the production line, the small range of the outer diameter of the rigid expansion sleeve, the long loading and unloading, and the adjustment time, etc. To achieve the effect of increasing the range and uniform tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

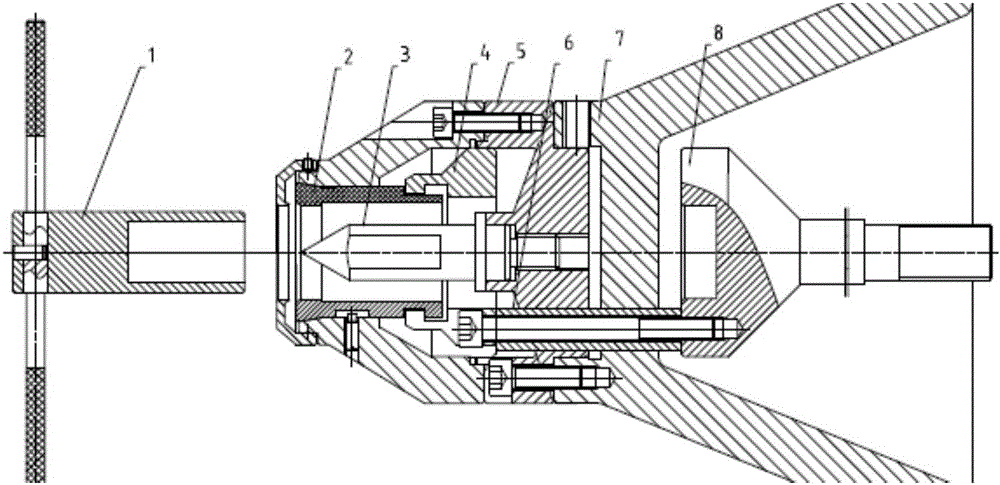

[0023] see figure 1 , the present invention includes a base 7 installed on the working plane of the machine tool, on which a transition support 5, a top 3, a transition pull plate 4 and an adhesive expansion sleeve 2 are sequentially installed on the base 7; in addition, it also includes a top 3 for changing different sizes Auxiliary tool 1 for production replacement; the top 3 adopts a flattened structure, and the part matching the inner hole of the transition support 5 is provided with a platform to ensure that the center line of the top is perpendicular to the plane of the worktable; the tail of the top 3 is provided with a guide and a fixing function thread. The transition puller 4 is connected to the machine tool tie rod 8 through the matching assembly of the screw and the guide sleeve 6, and moves downward or upward under the drive of the machine tool tie rod 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com