Patents

Literature

42results about How to "Solve the problem of chip removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

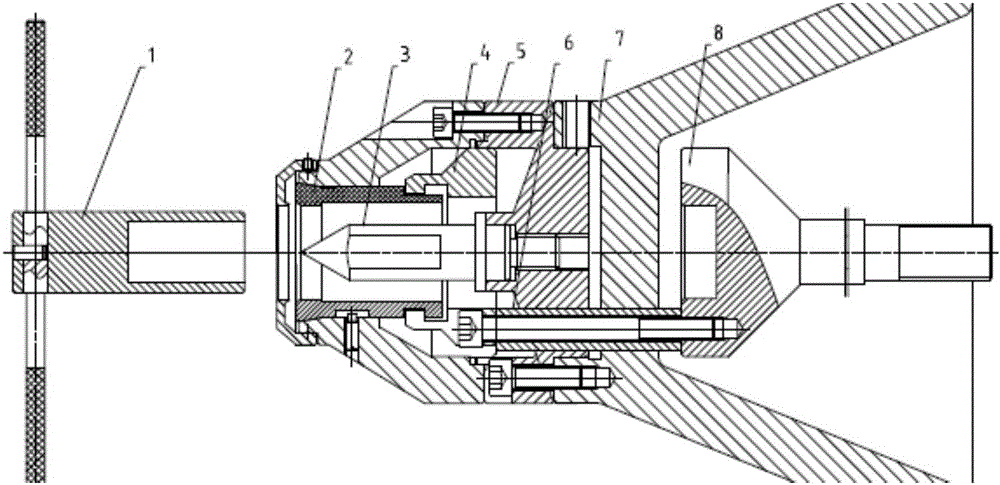

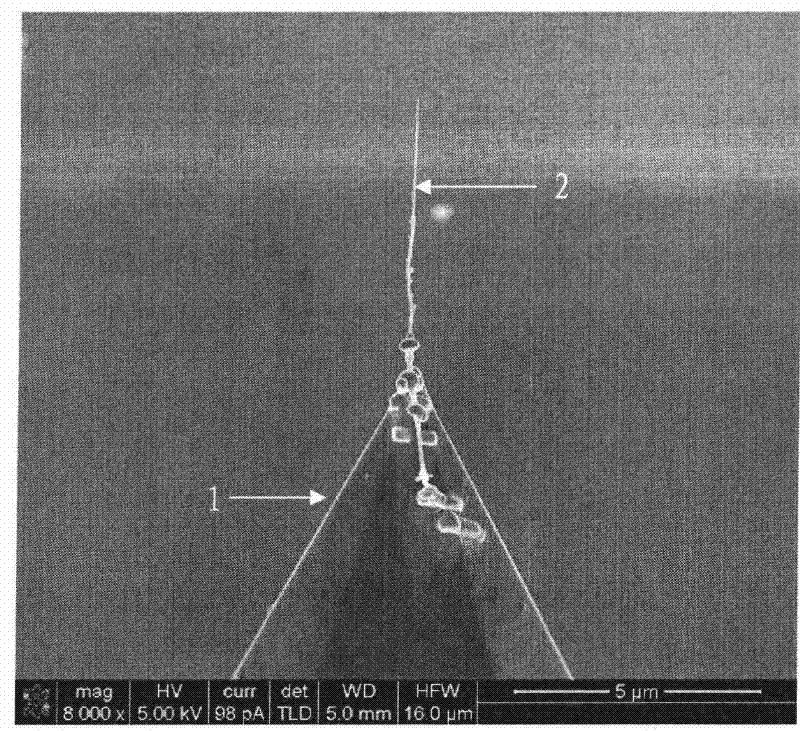

Method and system of micro three-dimensional structure by micro-nano electric discharge machining

InactiveCN101665238ARich technical methodsSolve the problem of chip removalSemi-permeable membranesNanostructure manufactureMicro nanoNanowire

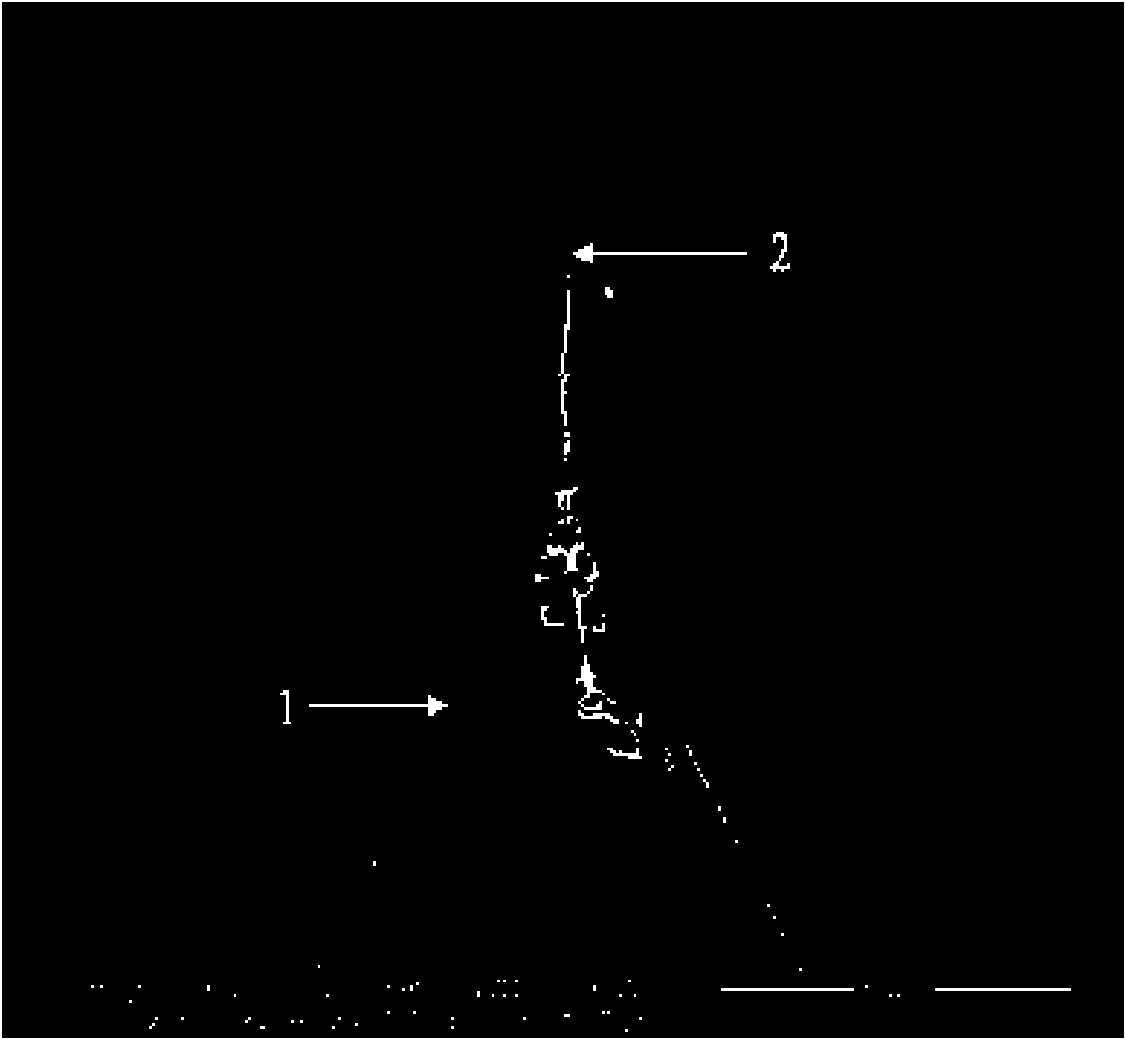

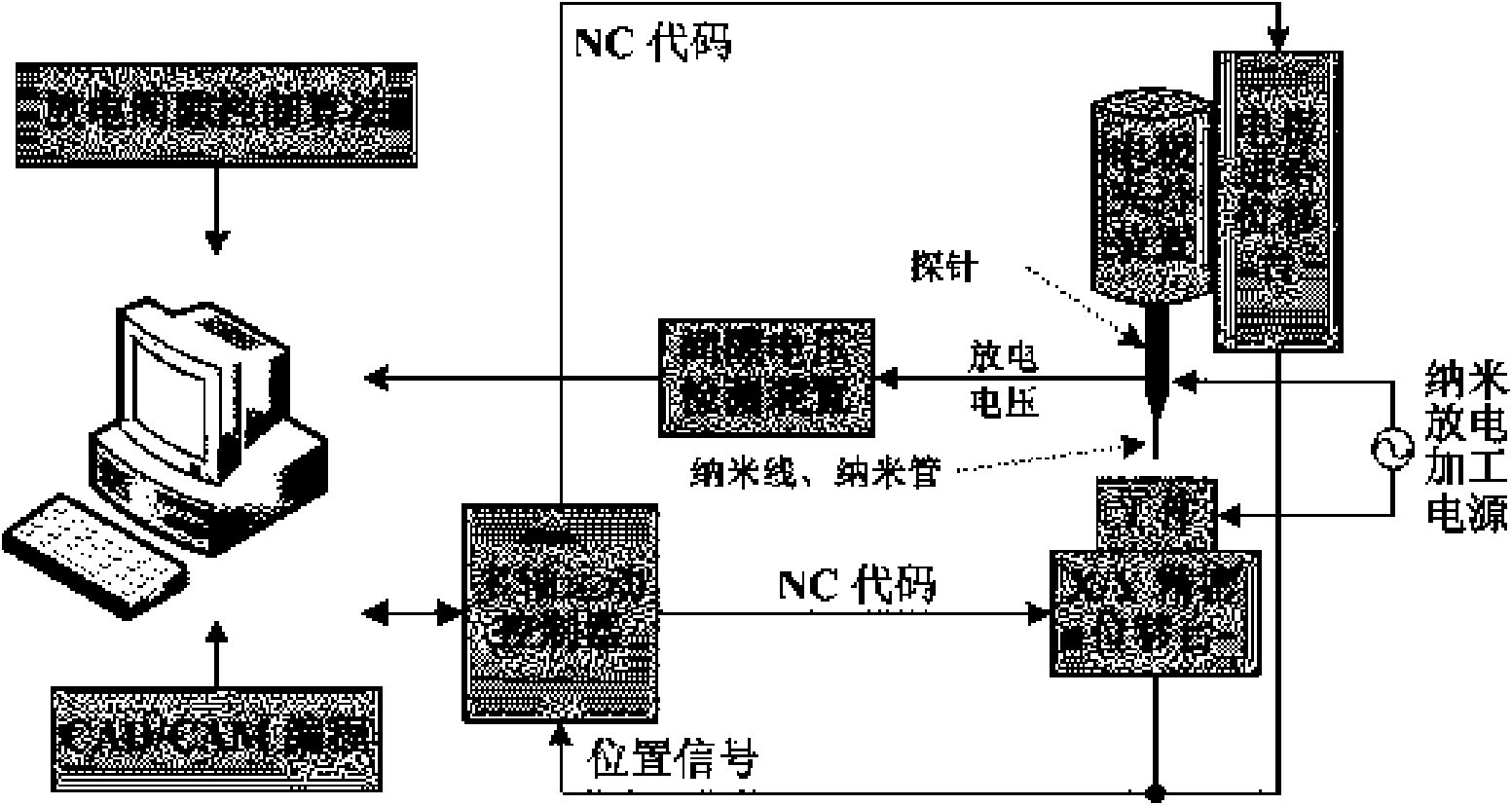

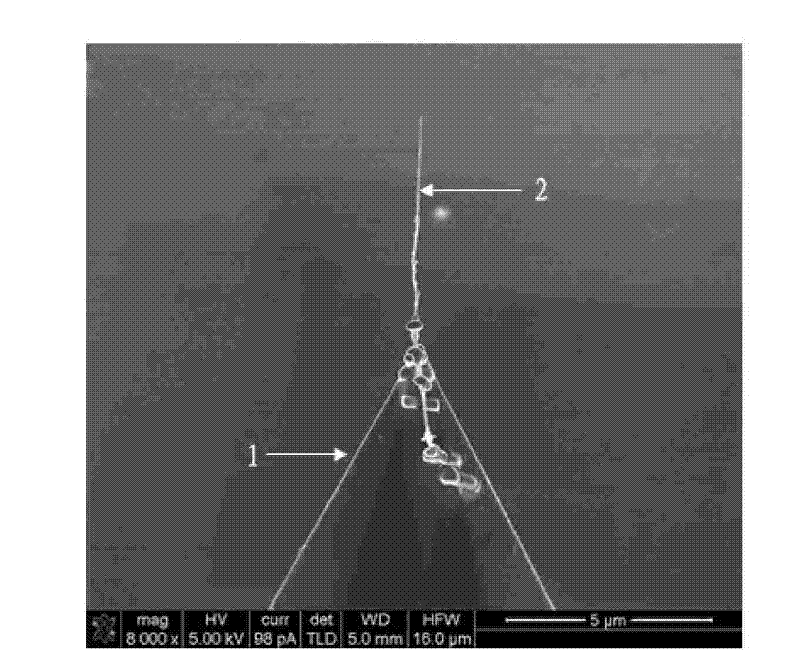

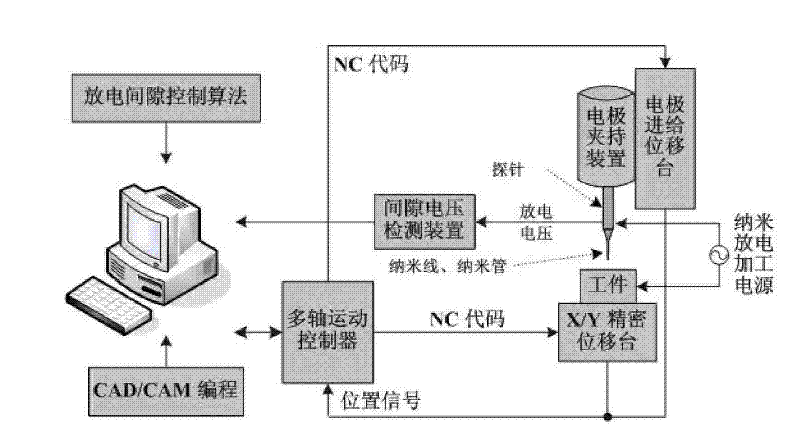

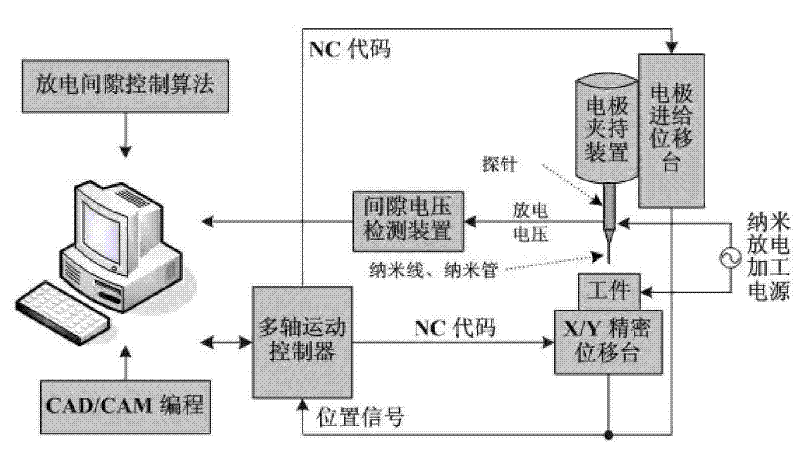

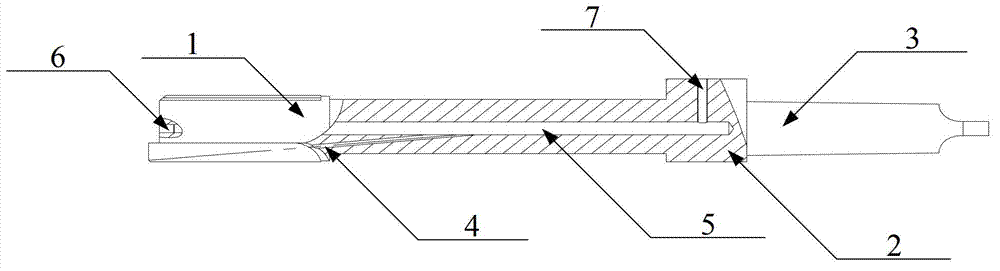

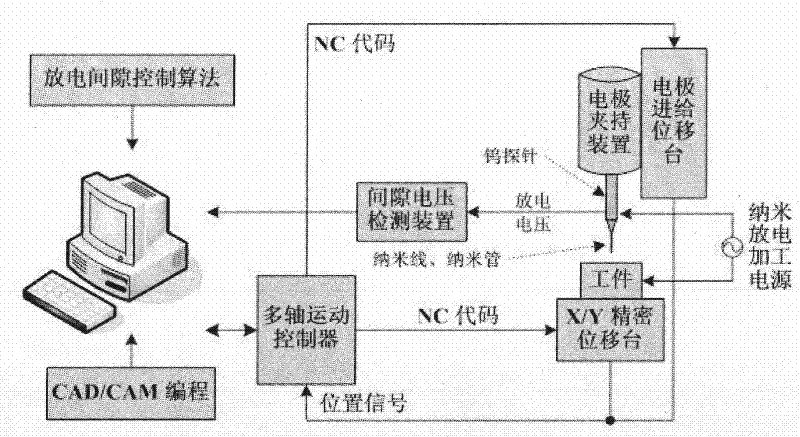

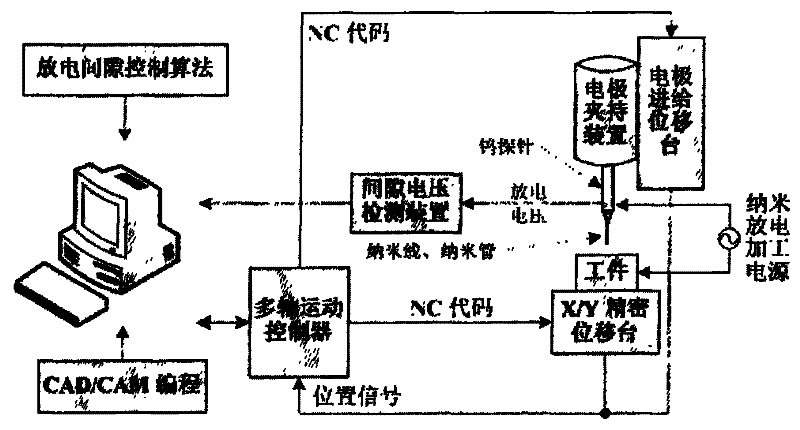

The invention belongs to the field of micro-nano manufacturing technology, and relates to a method of a micro three-dimensional structure by micro-nano electric discharge machining, which comprises the following steps: (1) fixing a nanowire or nanatube with electrical conductivity on the point of a probe made of conductive material as an electrode; (2) placing an electrode clamping device on a displacement platform, and controlling the movement of the displacement platform by a multi-axis motion controller; (3) placing a conductive material workpiece on an X / Y precise displacement platform, and controlling the movement of the X / Y displacement platform by the multi-axis motion controller; (4) connecting the cathode of a pulse power supply to the probe, and connecting the anode thereof to the workpiece; and (5) sending a command to a multi-axis motion control card by an industrial personal computer, controlling the displacement platform placing the electrode clamping device, providing work voltage for electric discharge machining by the pulse power supply, collecting discharge gap voltage by a gap voltage detecting device, and controlling the movement of an electrode feed displacement platform by the industrial personal computer according to the gap voltage. The method leads the size of the electric discharge machining to reach micro and nano level and simultaneously solves the problem of chip removal during the machining process.

Owner:TIANJIN UNIV

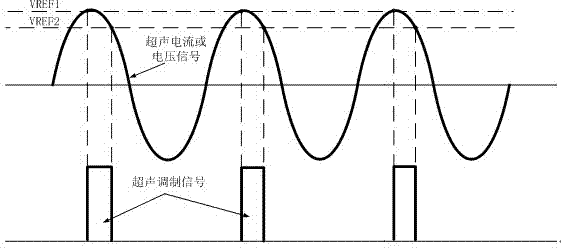

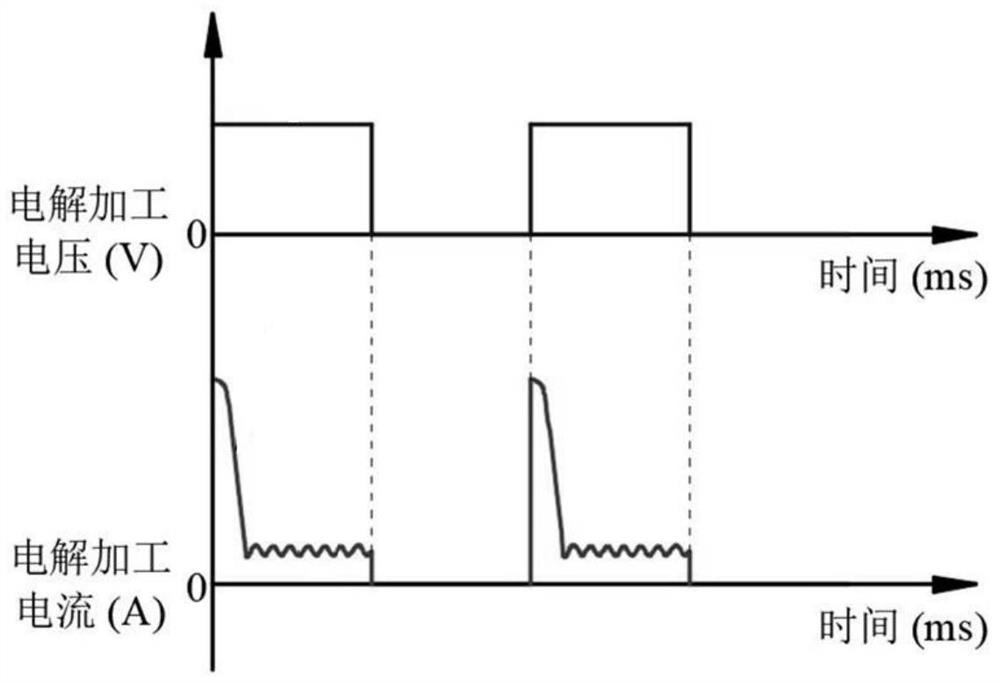

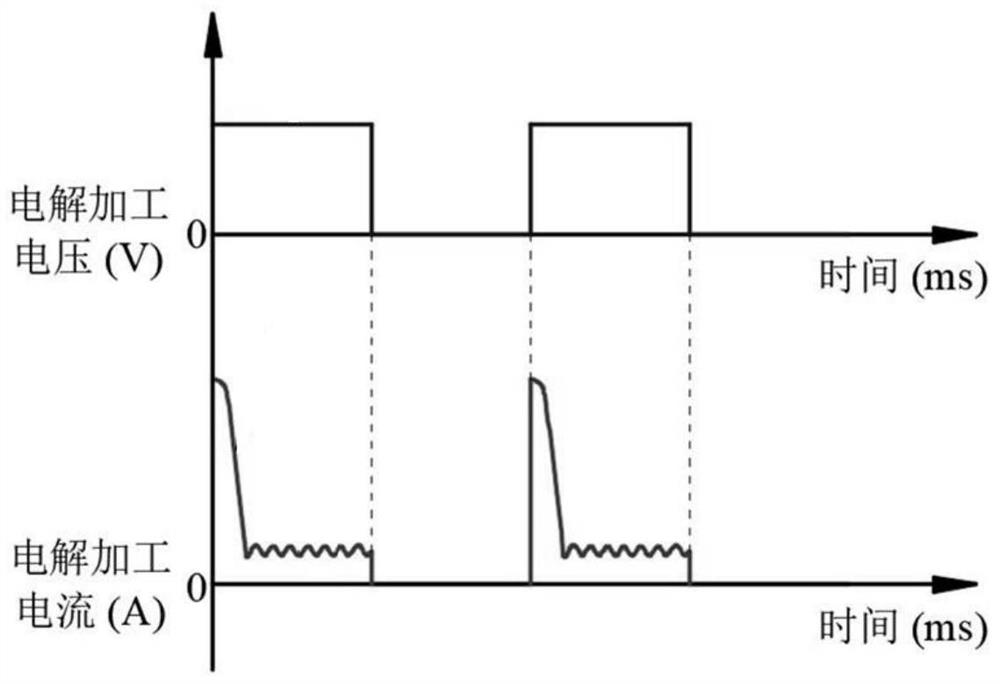

Ultrasonic vibration modulation bidirectional narrow-pulse-width micro-energy pulse power supply

InactiveCN103394778AEffective chip removalRapid deionization treatmentElectric circuitsElectric dischargeEngineering

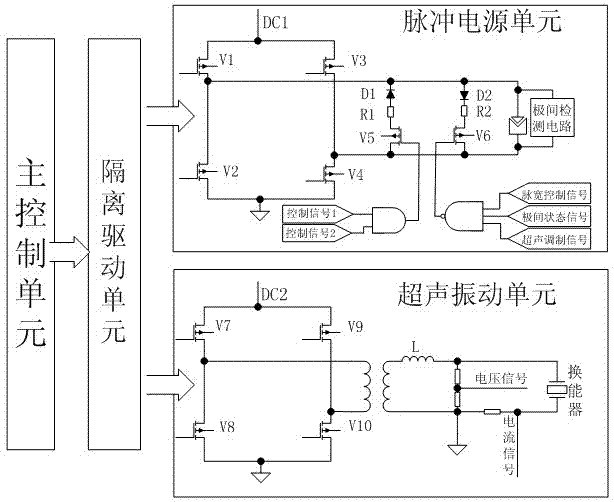

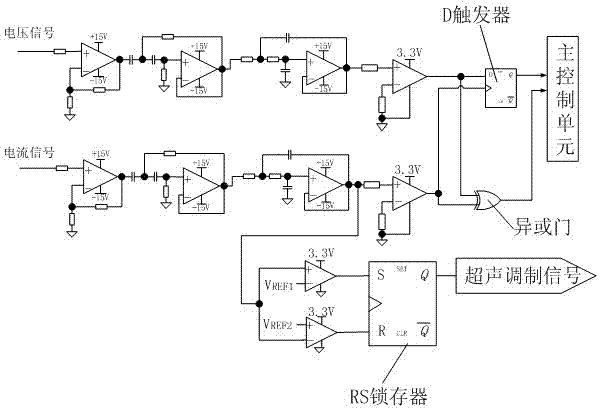

The invention provides an ultrasonic vibration modulation bidirectional narrow-pulse-width micro-energy pulse power supply which aims to improve the micro-electric discharge machining precision and realize an optimal machining effect. A main body portion of the ultrasonic vibration modulation bidirectional narrow-pulse-width micro-energy pulse power supply comprises a pulse power supply and an ultrasonic vibration system. The ultrasonic vibration system drives a tool electrode or workpiece to ultrasonically vibrate. The ultrasonic vibration frequency of the tool electrode or workpiece is identical to the chopping frequency of the pulse power supply, and a precondition foundation can be provided for organically combining ultrasonic vibration with pulse discharge to carry out discharge machining under the control effect of a group of identical signals outputted by a main control unit. The ultrasonic vibration modulation bidirectional narrow-pulse-width micro-energy pulse power supply has the advantages that bidirectional narrow-pulse-width pulses are generated by the aid of ultrasonic vibration modulation, single micro-energy pulses capable of discharging are obtained, discharge channels are stretched, scraps can be effectively removed, quick de-ionization processing can be carried out, gap discharge conditions are improved, the machining speed is increased, the machining precision is enhanced, and the ultrasonic vibration modulation bidirectional narrow-pulse-width micro-energy pulse power supply has important engineering application value.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

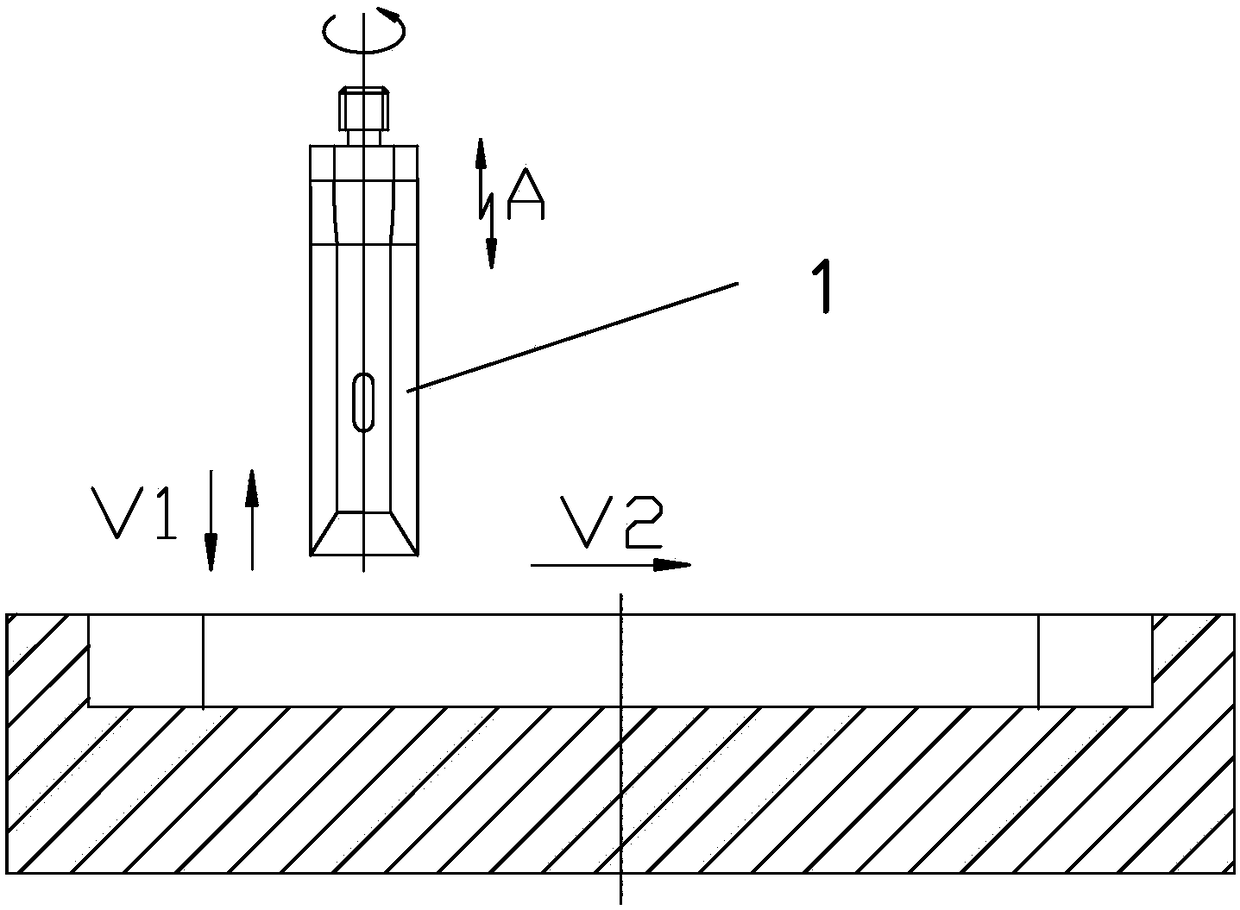

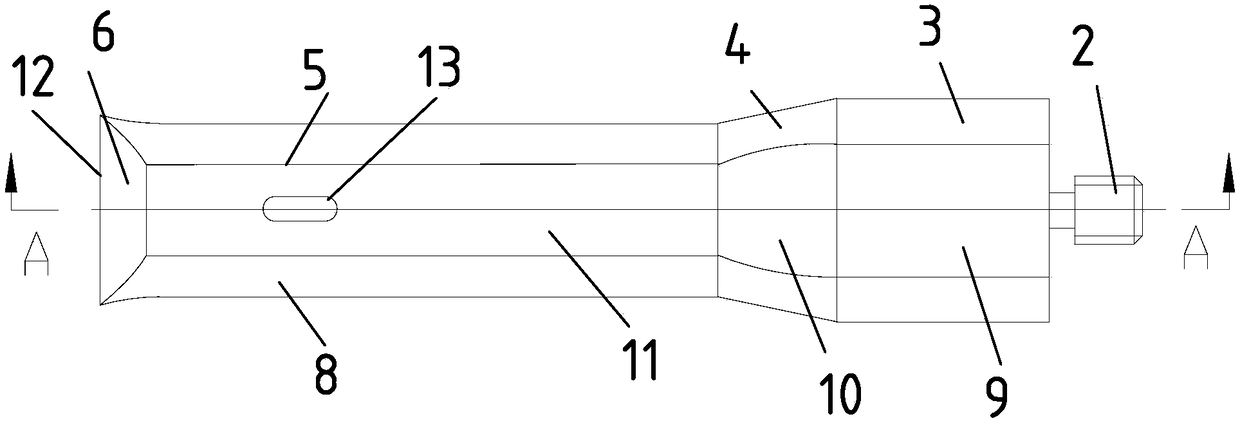

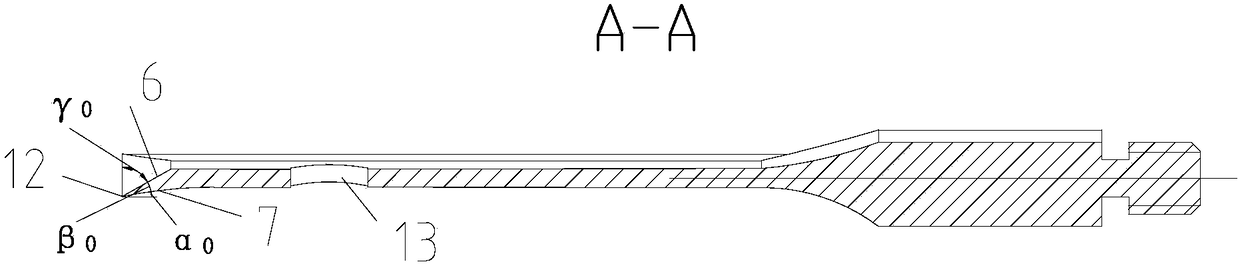

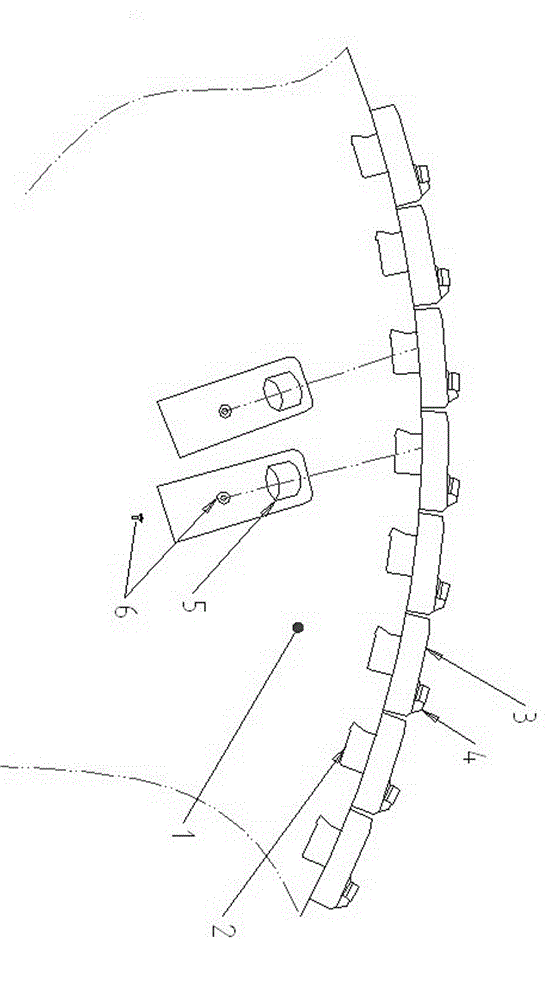

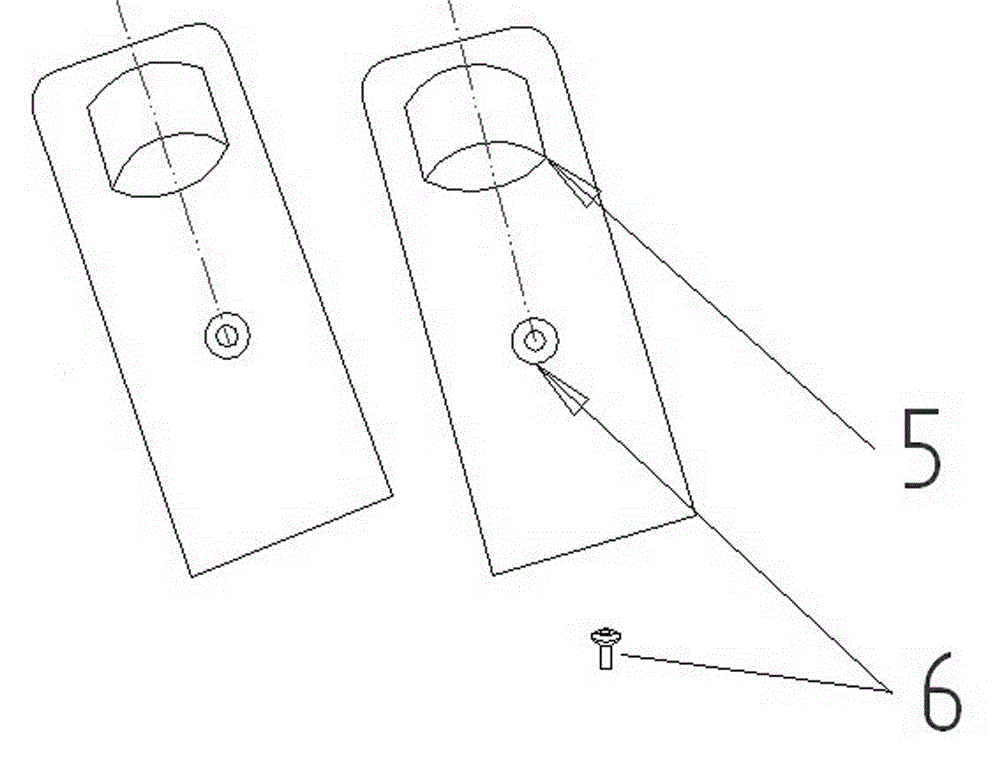

Ultrasonic inserting cutting tool for processing curve outline of honeycomb core

ActiveCN108356299AReduce processing defectsReduce wearPlaning/slotting toolsTurning toolsHoneycombUltrasonic vibration

The invention discloses an ultrasonic inserting cutting tool for processing a curve outline of a honeycomb core. The ultrasonic inserting cutting tool comprises a threaded section, a rigidity improving block, a trapezoid-like shaped platform transition block and a thin-sheet shaped open type tool body, wherein axes of the threaded section, the rigidity improving block, the trapezoid-like shaped platform transition block and the thin-sheet shaped open type tool body are positioned on an axis of the ultrasonic inserting cutting tool for processing the curve outline of the honeycomb core. According to the ultrasonic inserting cutting tool for processing the curve outline of the honeycomb core, the curve outline of the honeycomb core material is inserted and cut under ultrasonic vibration effect; the honeycomb core material can be smoothly cut through a circular arc shaped cutting bottom edge under the ultrasonic effect, thus the damage of the honeycomb core material in processing can be decreased, and the processing rigidity of the rest materials can be improved; in addition, the friction between the circular arc shaped cutting bottom edge and the processing surface of the honeycomb core is reduced by the ultrasonic effect, so that the processing defects of the curve outline of the honeycomb core can be reduced; the abrasion of the tool is reduced, and as a result, the service life of the tool is prolonged; and the curve outline of the honeycomb core is processed with high quality.

Owner:DALIAN UNIV OF TECH

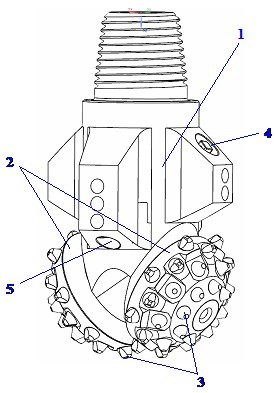

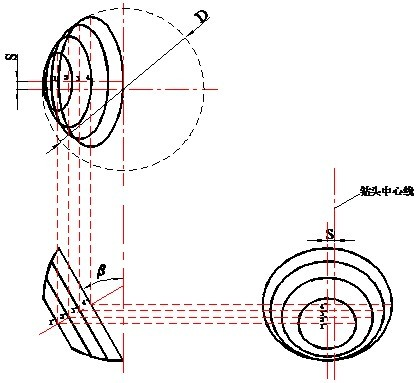

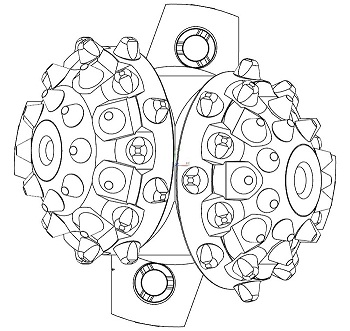

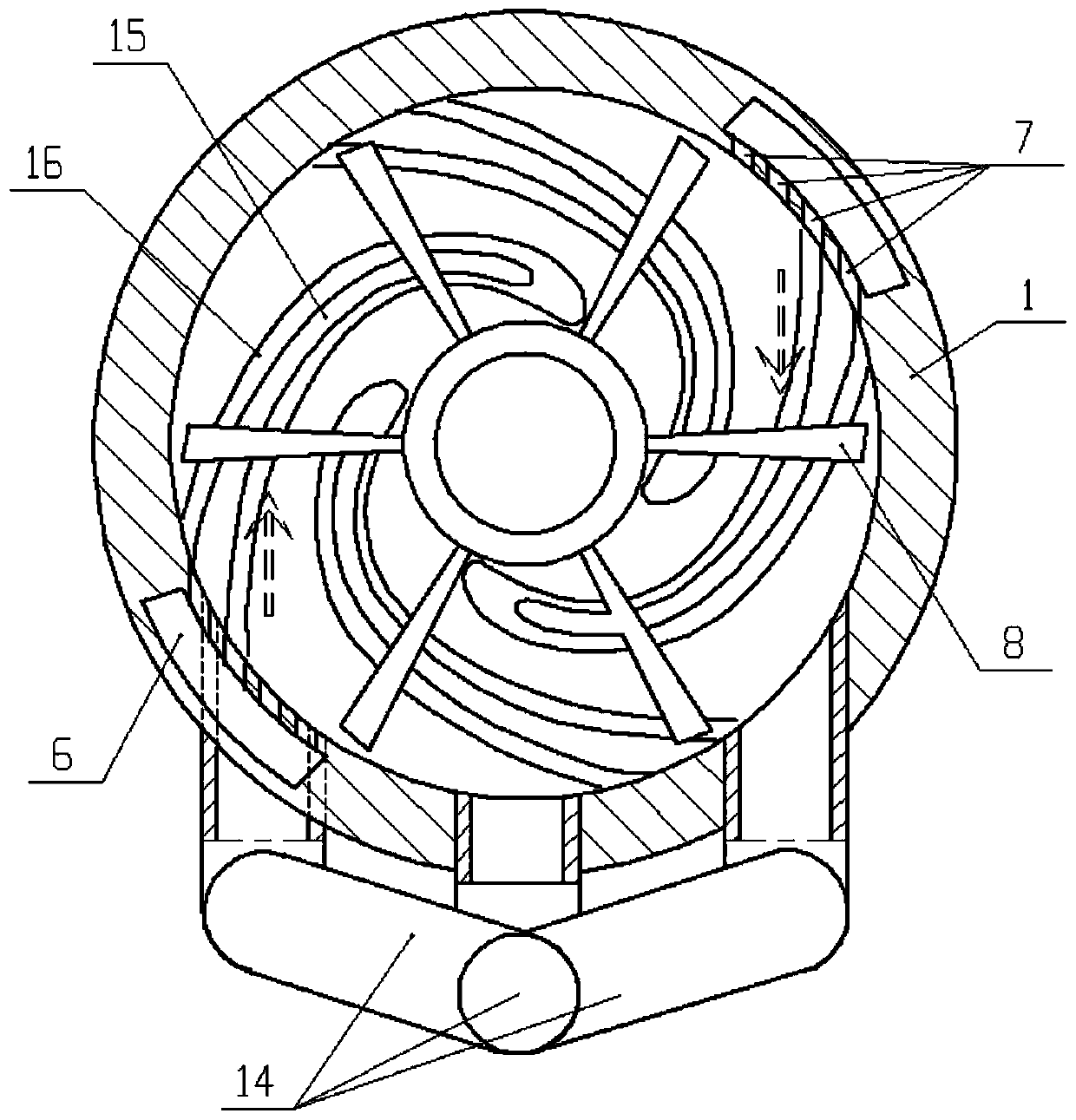

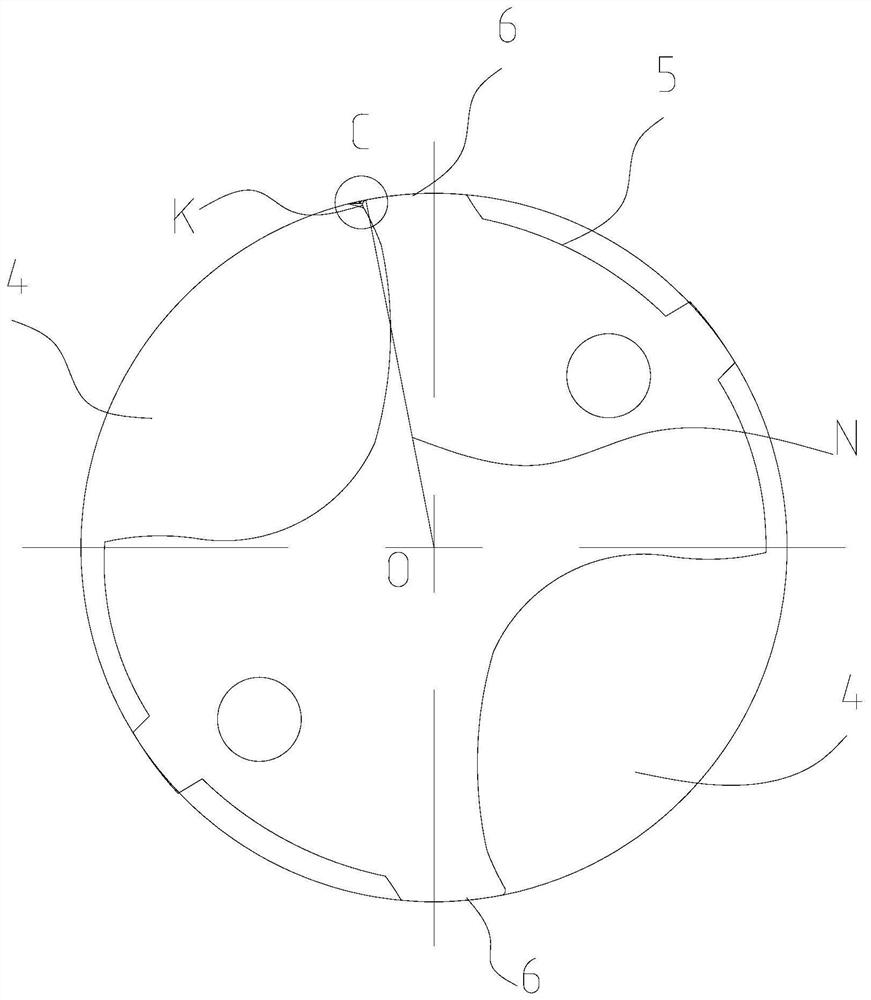

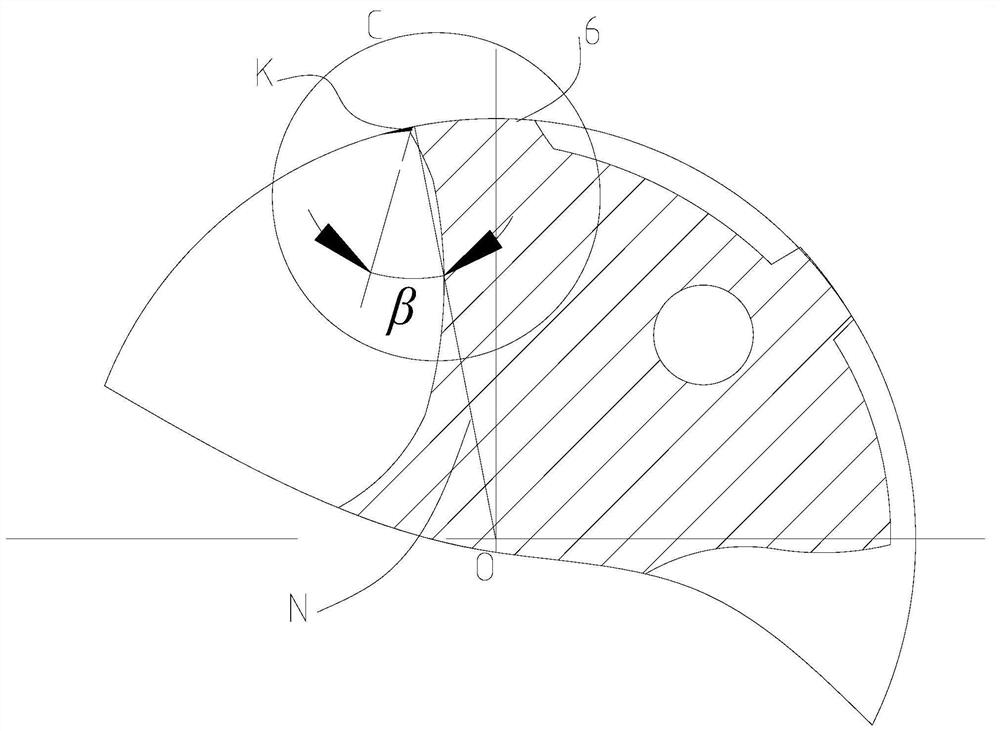

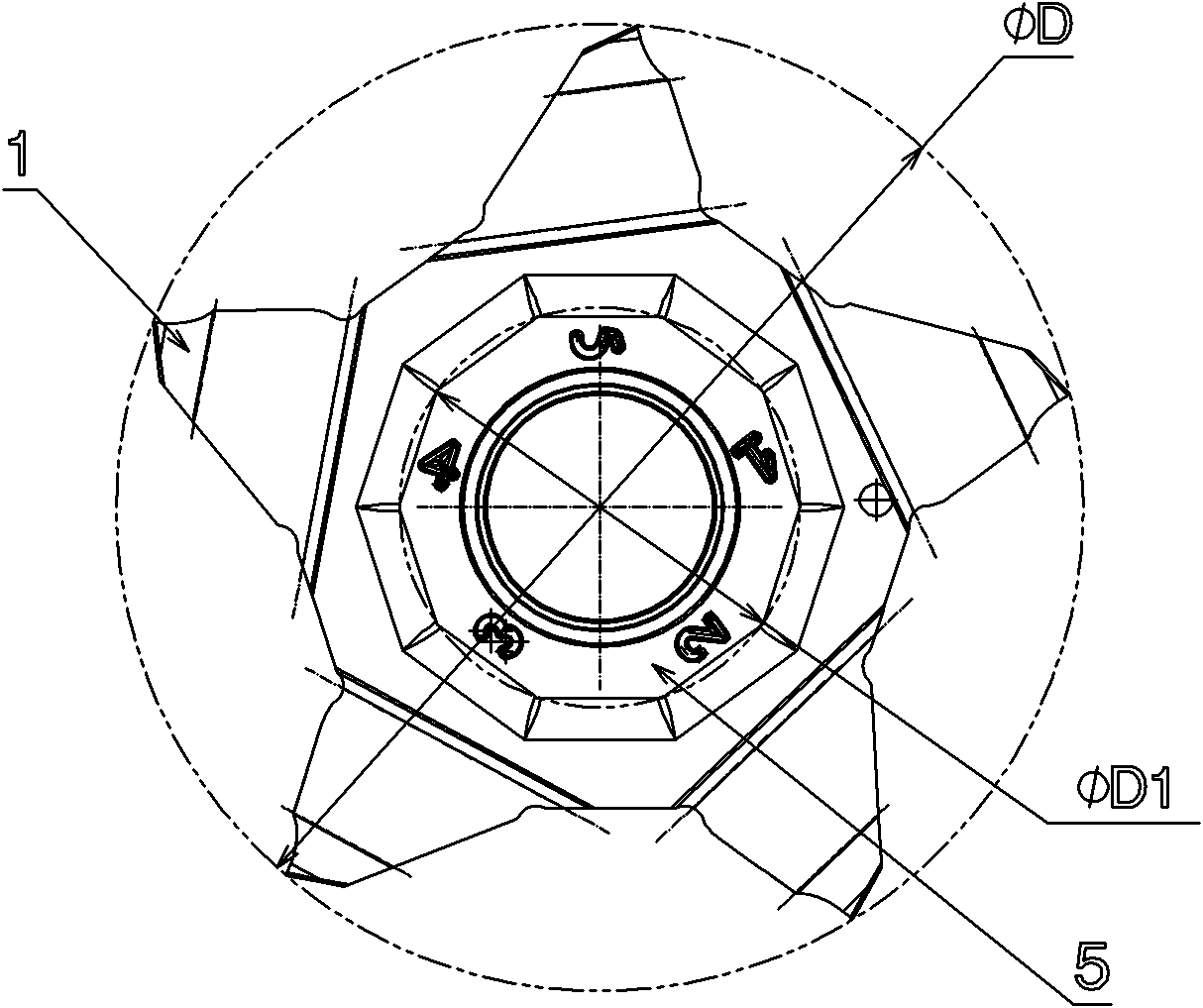

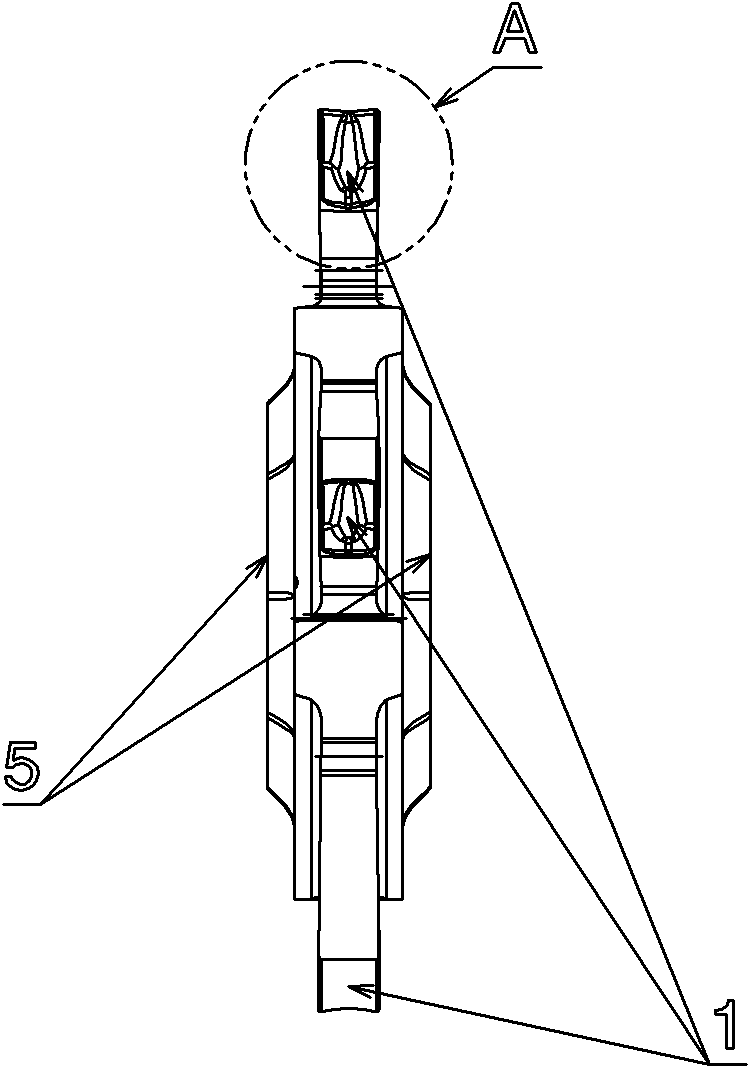

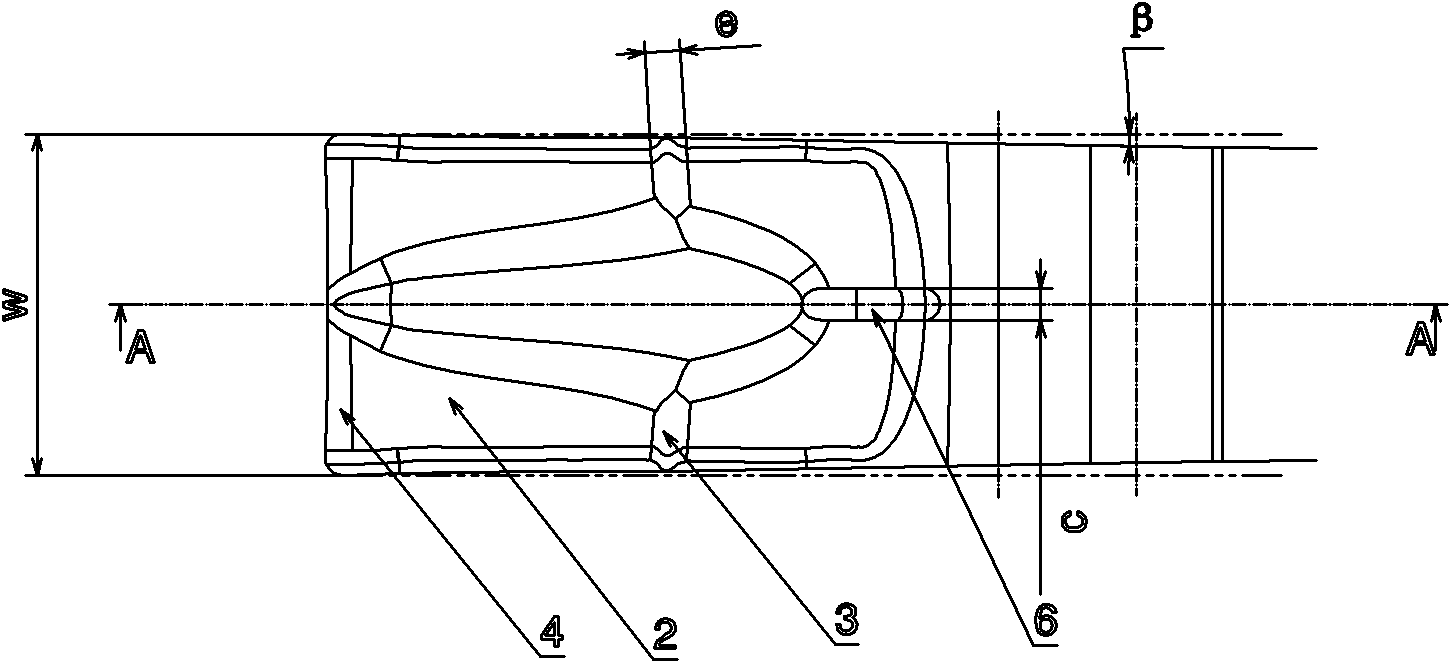

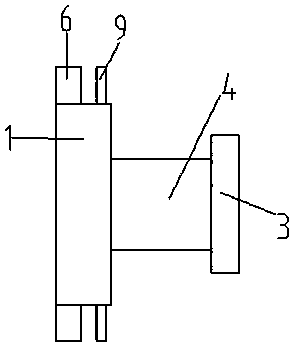

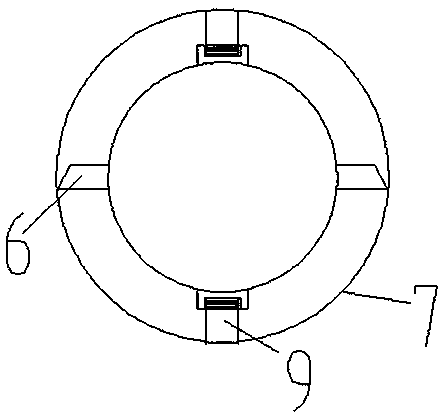

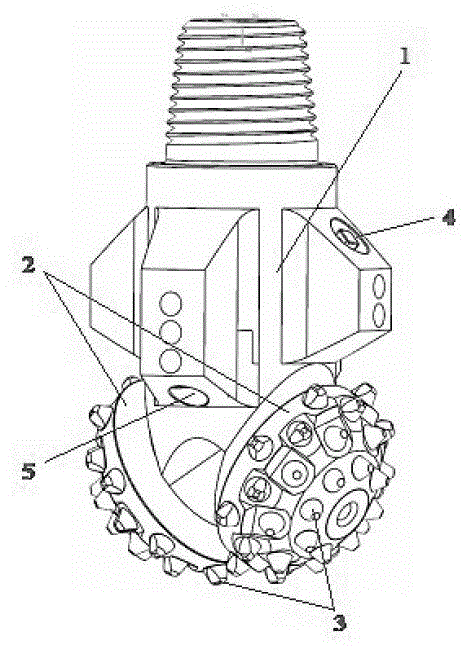

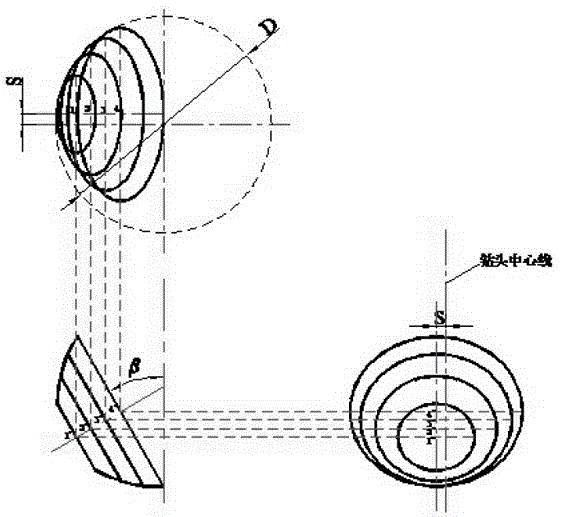

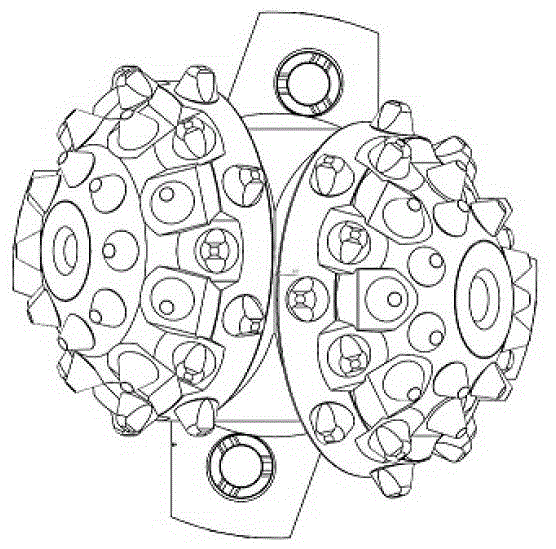

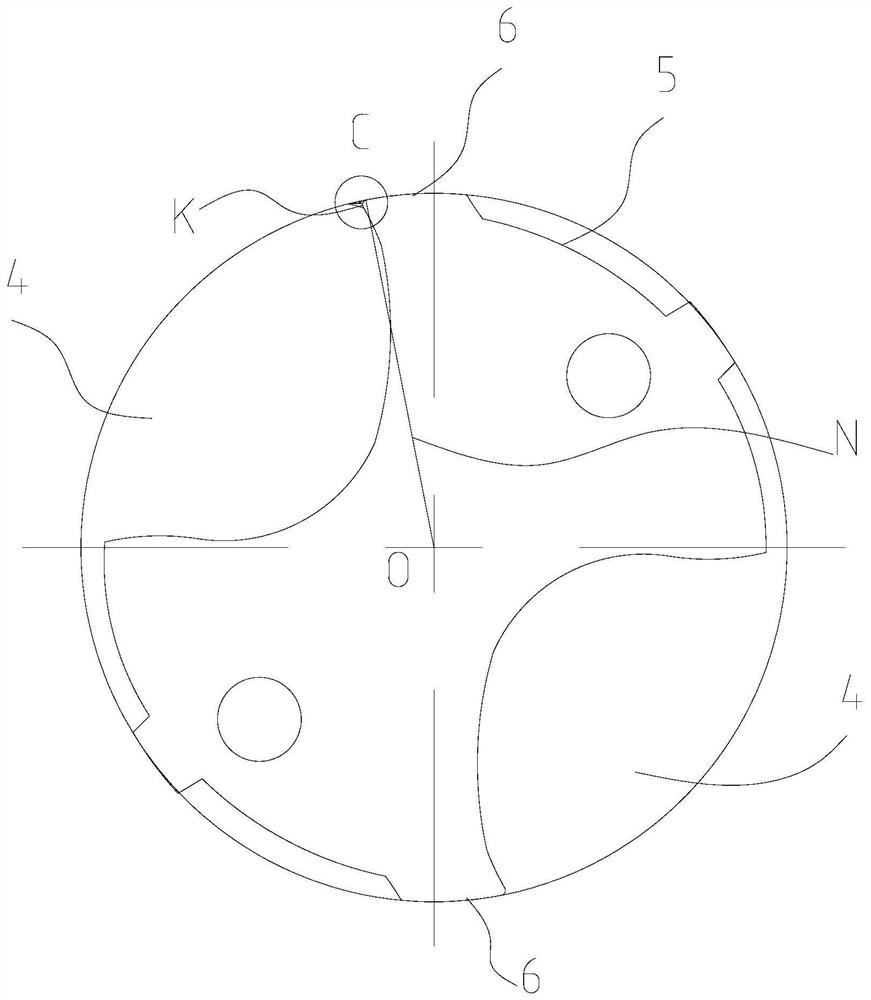

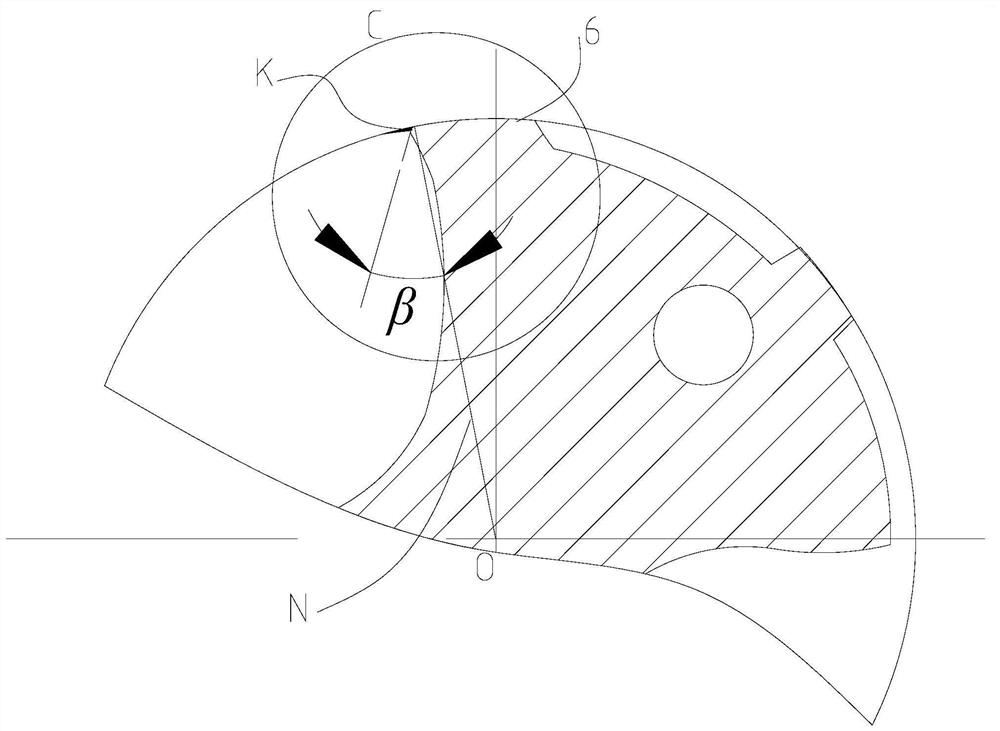

Drill bit for breaking rock by rotary cutting

The invention discloses a drill bit for breaking rock by rotary cutting (a rotary cutting drill bit for short as follows), which comprises a drill bit main body, a roller cone, cutting teeth, an oil storage bag and a spray nozzle, wherein the drill bit main body comprises a roller cone shaft neck, a centralizing block, a high-pressure slurry channel and a connecting screw thread; and the roller cone and the shaft neck on the main body adopt a general bearing and a sealing structure of a tricone drill bit; a plurality of circles of cutting teeth are arranged from the large end to the small end of the roller cone; an included angle beta (an included angle of a cone body for short as follows) between a roller cone shaft neck plane on the main body and an axial line of the drill bit ranges from 0 to 90 degrees (containing beta i=beta(i+1) and beta i is not equal to beta(i+1)); the offset s (containing si=s(i+1) and si is not equal to s(i+1)) of the shaft neck ranges from-D / 2 to D / 2; wherein i (greater than or equal to 1) represents a serial number of the roller cone; the included angle of the cone body corresponding to the cone i is represented by beta i; the offset of the shaft neck corresponding to the cone i is represented by si; and D represents the diameter of the drill bit. According to the drill bit disclosed by the invention, an inner-row large gear ring is used for cutting the center of a shaft bottom and has high rock-breaking efficiency; each circle of cutting teeth can be used for scratching and cutting the shaft wall and has favorable effects for gauge protection and side drilling; the size of the shaft neck is large; the speed ratio of the cone body is smaller than 1; and the bearing has a long service life.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

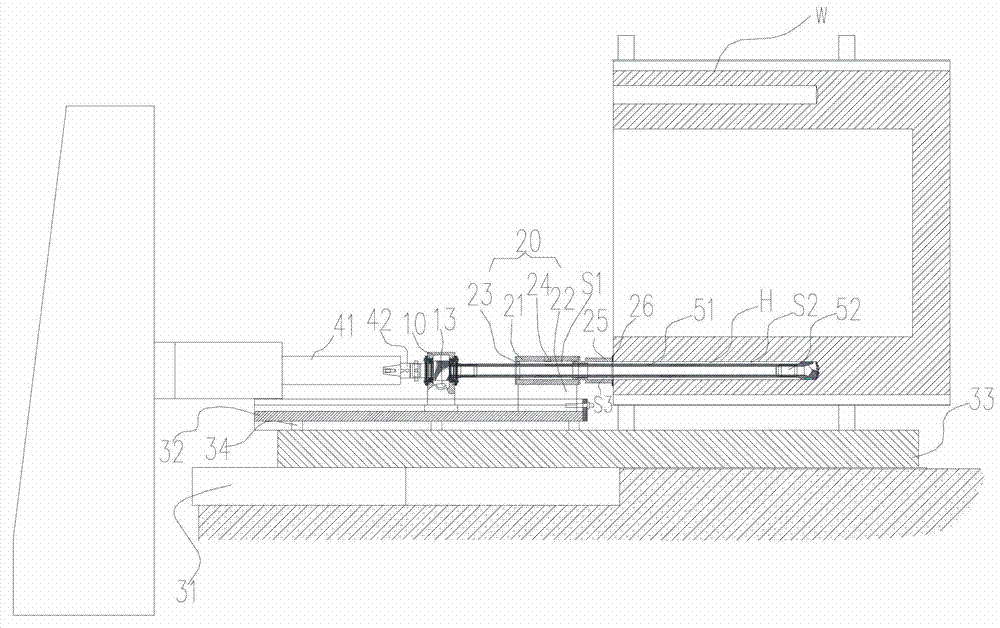

Deep hole drilling device

InactiveCN102814526AImprove cooling effectSolve the cooling effectTransportation and packagingMaintainance and safety accessoriesEngineeringDeep hole

A deep hole drilling device comprises a chip cleaner, an oil feeder and a hole drilling portion. The chip cleaner comprises a body and a connecting shaft, the connecting shaft is provided with a chip removing channel, and a chip removing hole is arranged on the body and is communicated with the chip removing channel; the hole drilling portion comprises an inner chip removing drill stem and an inner chip removing drill bit connected with the inner chip removing drill stem, the inner chip removing drill bit is provided with drill bit chip removing holes, the inner chip removing drill stem is a hollow stem, one end of the inner chip removing drill stem is connected with the connecting shaft, and the inner chip removing drill stem is communicated with the chip removing channel; and the oil feeder is sleeved on the outer portion of the inner chip removing drill stem, a first space is formed between the oil feeder and the inner chip removing drill stem, and an oil inlet is arranged on the oil feeder. When the hole drilling portion is drilled in a processed workpiece, a second space is formed between the outer wall of a drilled portion of the inner chip removing drill stem and the wall of a drilled hole, cooling liquid from the oil inlet sequentially flows through the first space and the second space, flows into the inner chip removing drill stem via the drill bit chip removing holes, and then flows into the chip removing channel, and then the cooling liquid and chips generated during hole drilling are mixed with each other and are drained via the chip removing hole.

Owner:TAIYUAN HEAVY IND

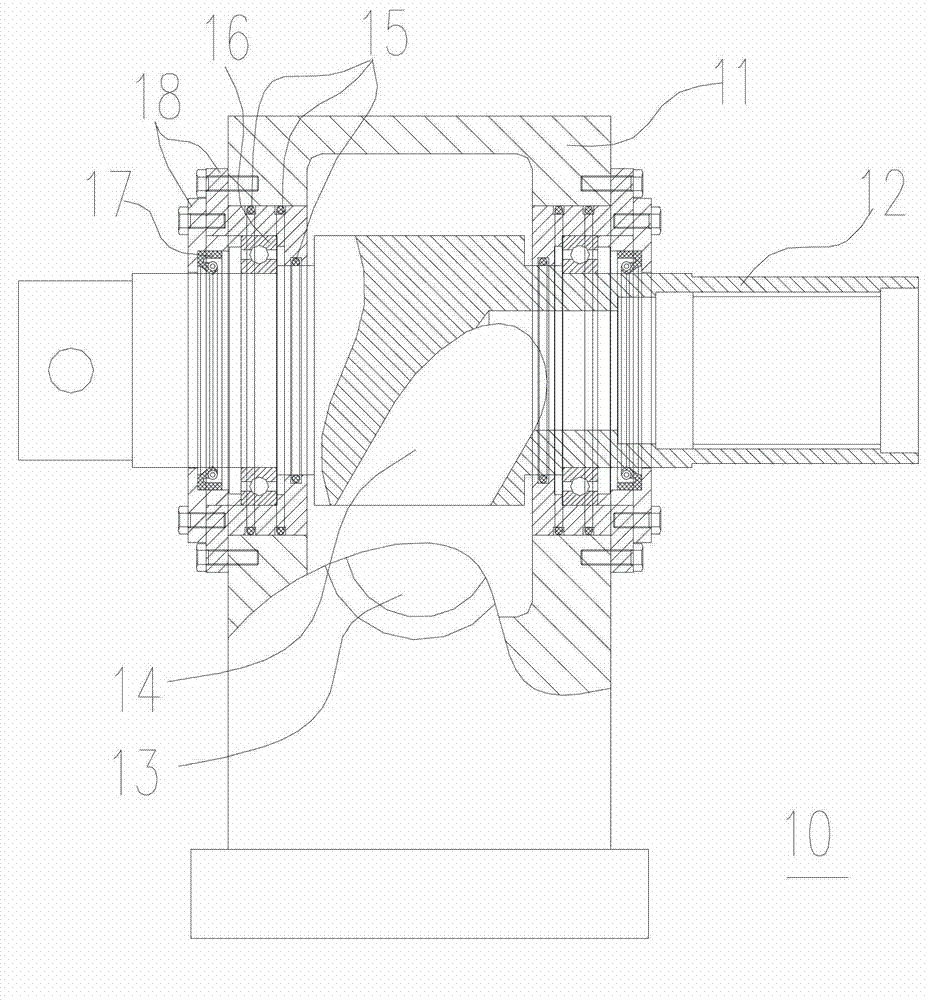

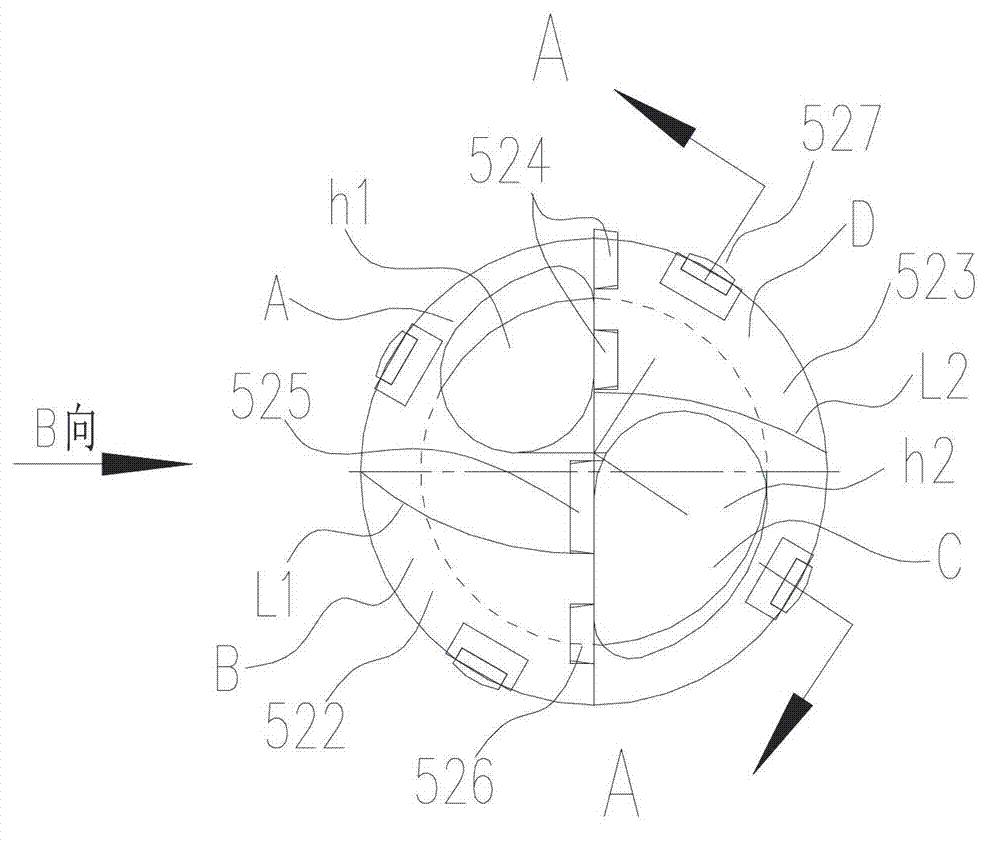

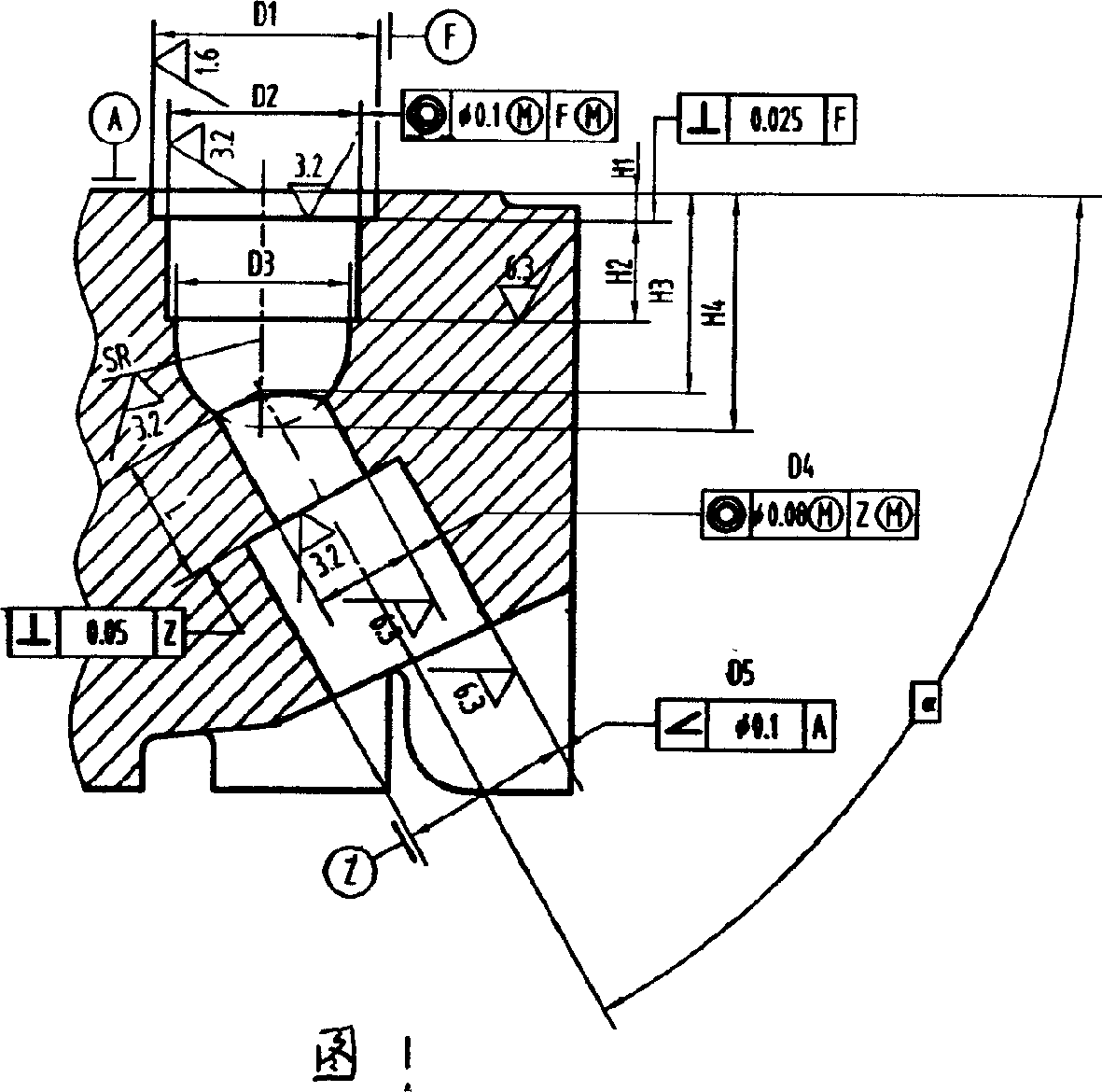

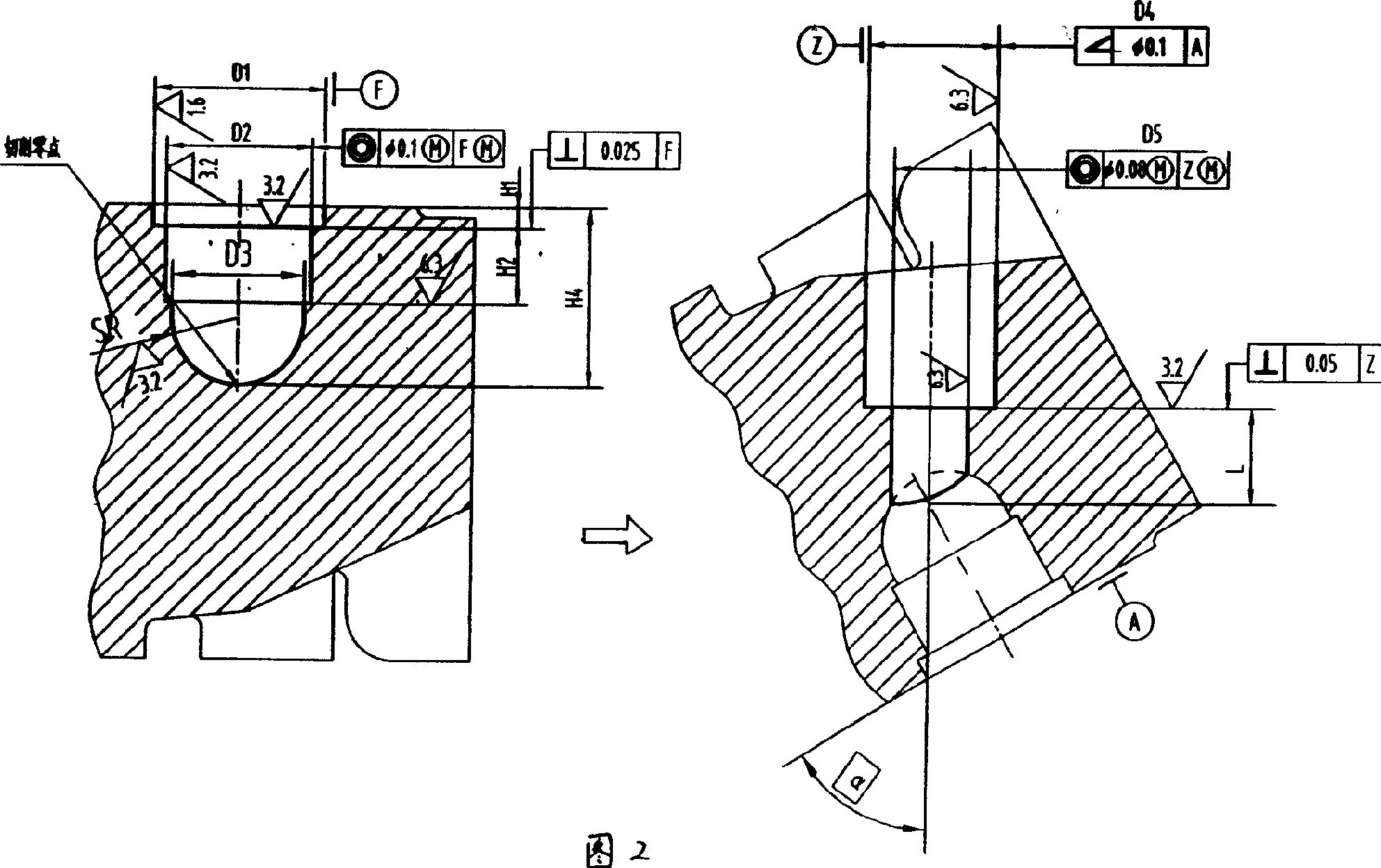

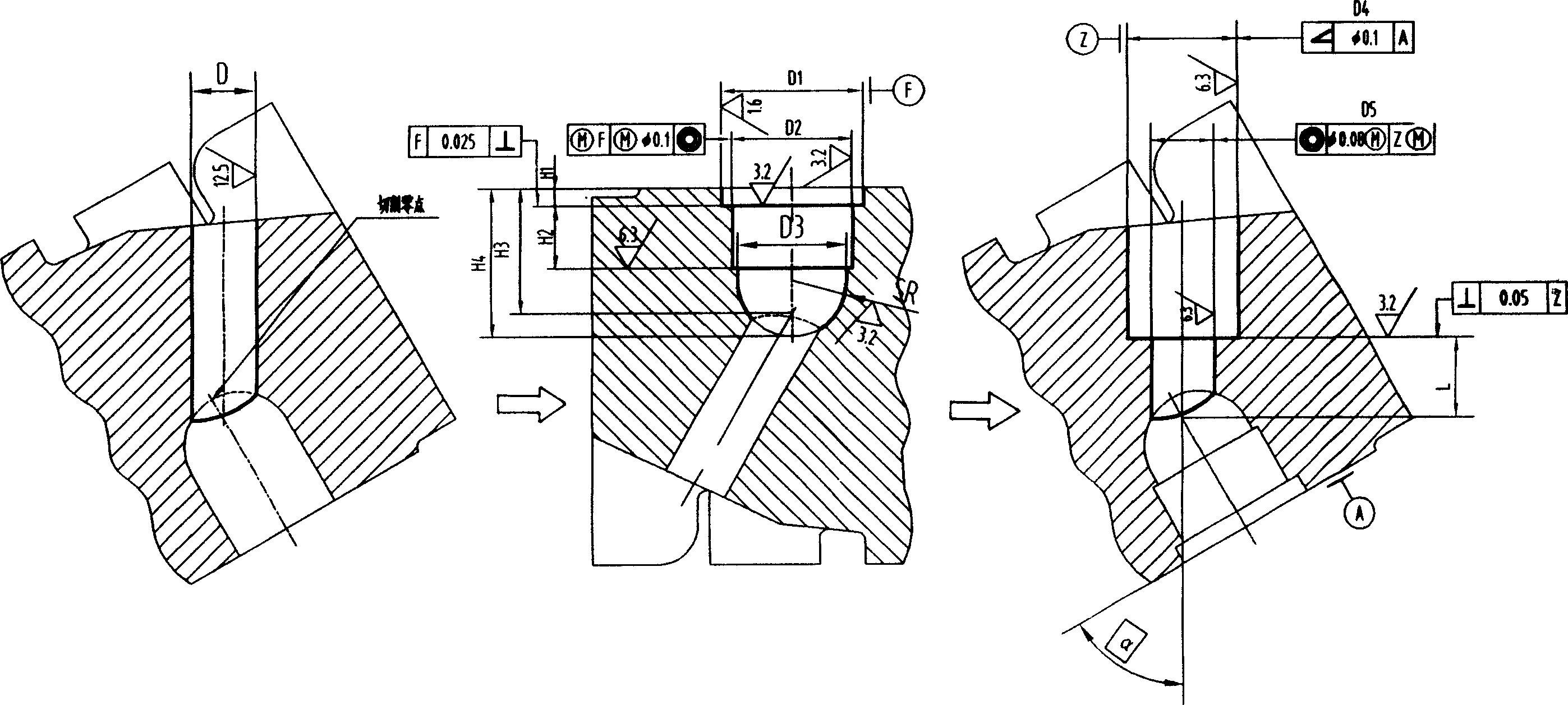

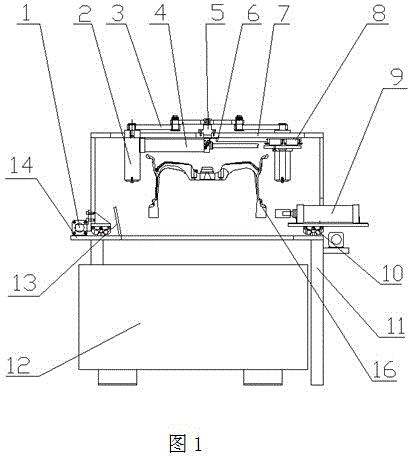

Processing method of special electric power fitting taper sleeve taper hole for carbon fibre compound core wires and special device thereof

InactiveCN101716688AAffect surface accuracySolve the problem of chip removalNumerical controlCarbon fibers

The invention discloses a processing method of a special electric power fitting taper sleeve taper hole for carbon fibre compound core wires and a special device thereof. The processing method comprises the following steps: (1) setting the processing size and the processing procedure of the workpiece for a numerical control machine, and clamping the workpiece to be processed on a clamping chuck of the numerical control machine; (2) starting the numerical control machine, and meanwhile, starting the tooling of the cutter; and milling the workpiece at high speed, wherein the workpiece rotates at the speed of 80-120 rpm, and the cutter rotates at the speed of 1400-2400 rpm. The special device comprises a clamping chuck and a middle backing plate of the numerical control machine, a cutter and a tooling which drives the cutter to rotate, wherein the tooling comprises a rotating shaft and a shell, the rotating shaft is movably connected with the shell through a bearing, and the shell is fixed with the middle backing plate. The invention has the advantages of high machining precision, high production efficiency, long cutter life and low production cost.

Owner:仝明

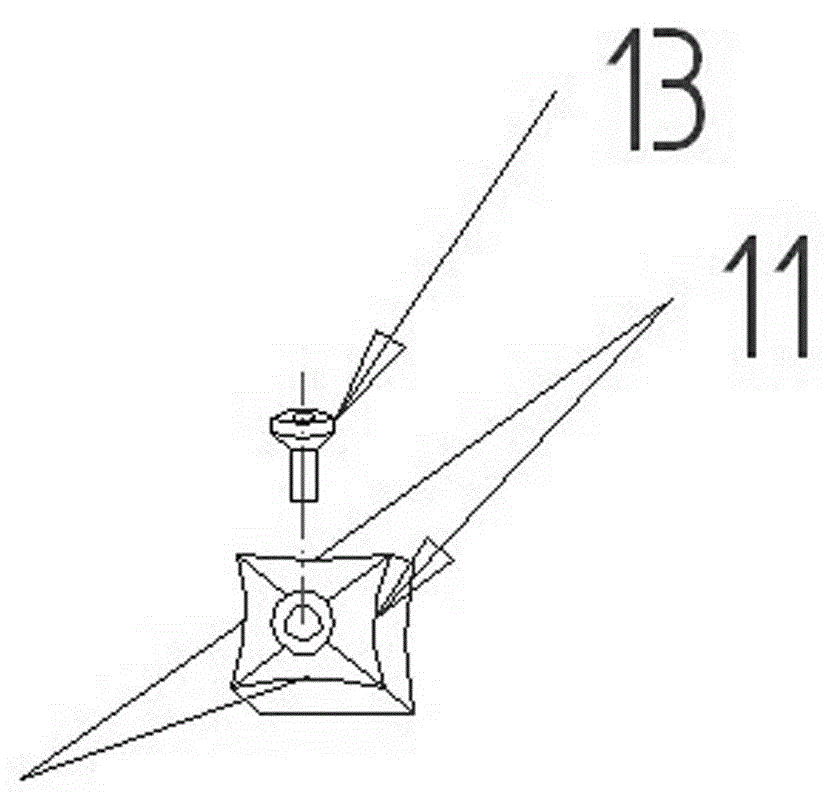

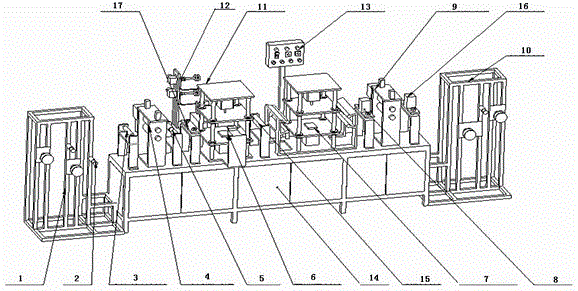

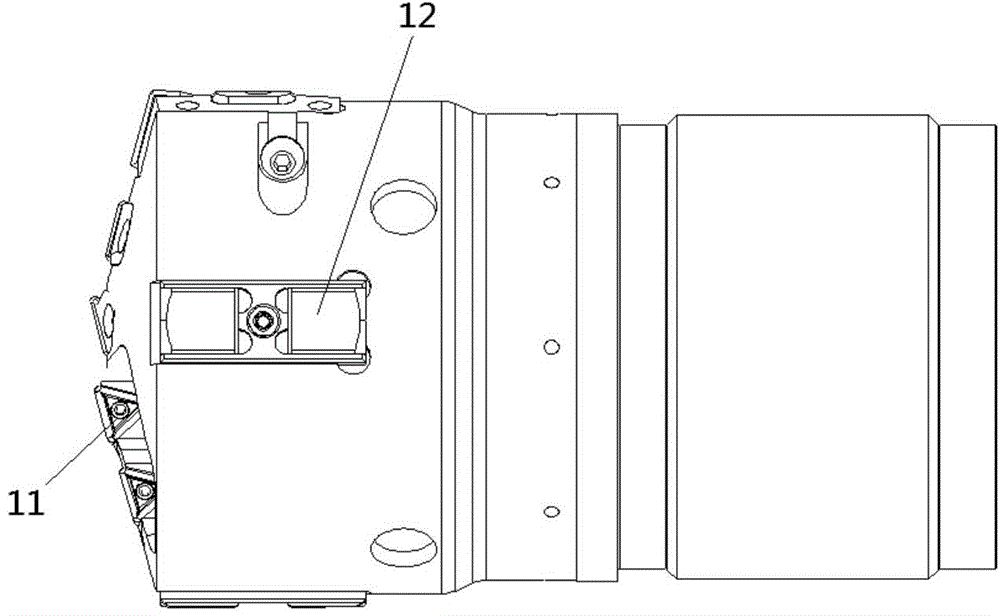

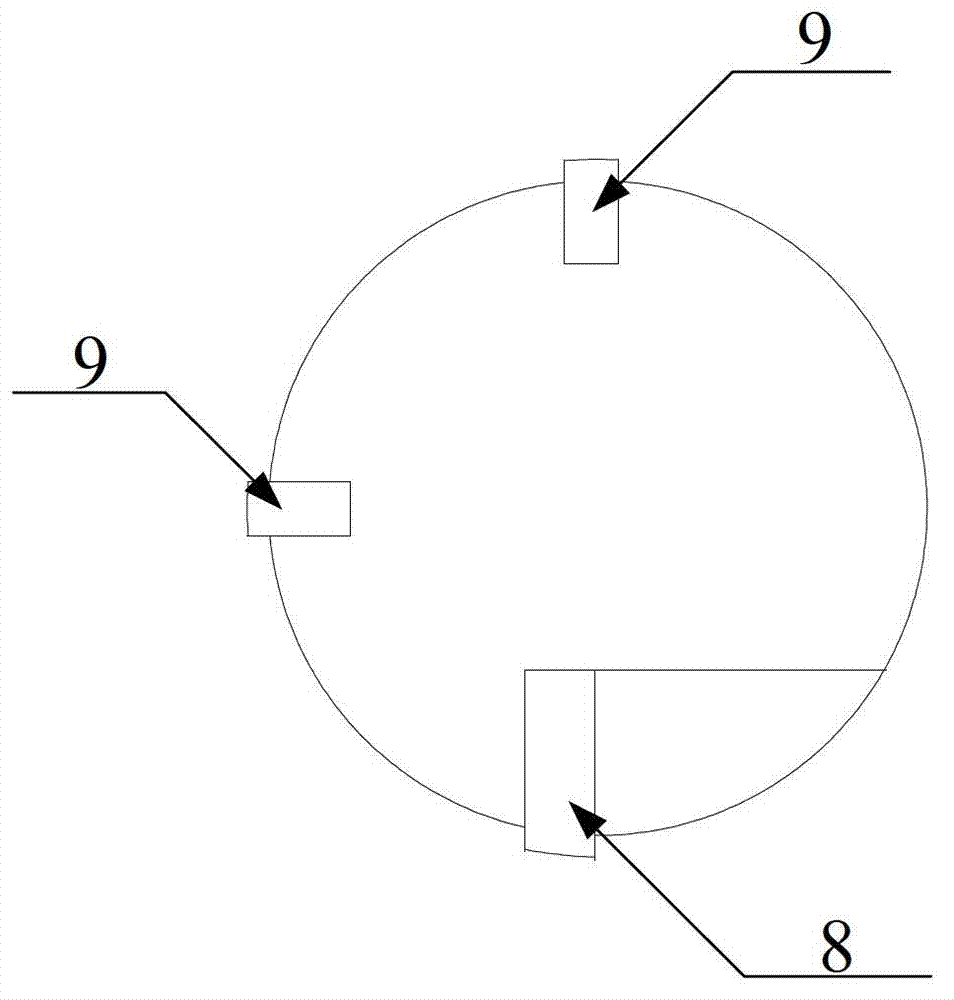

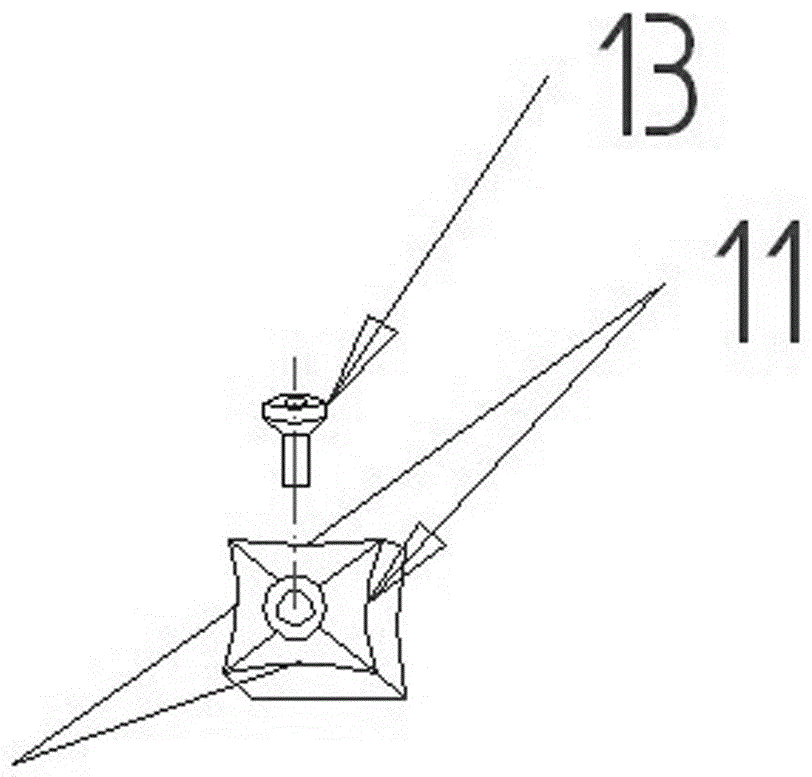

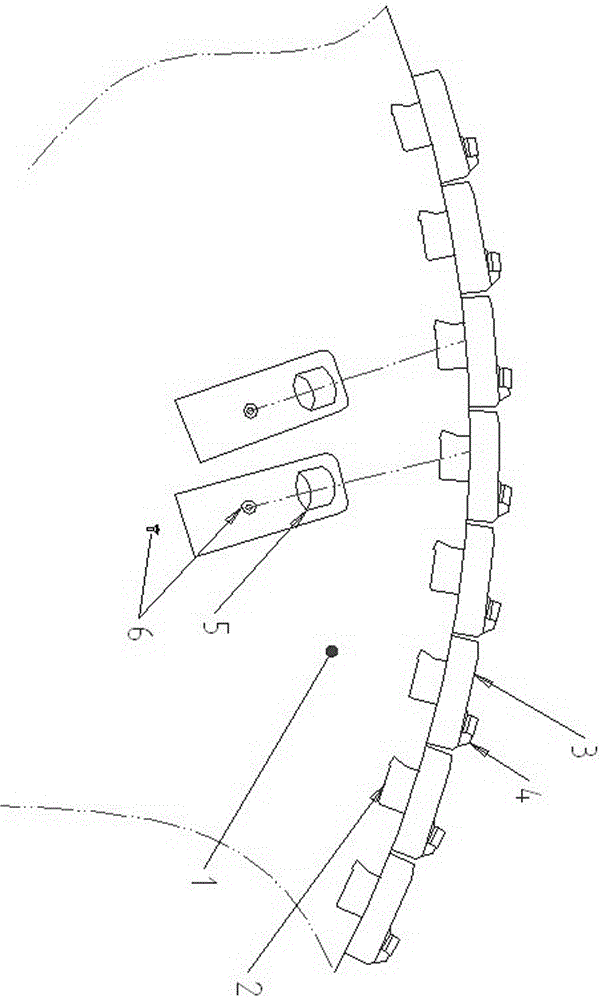

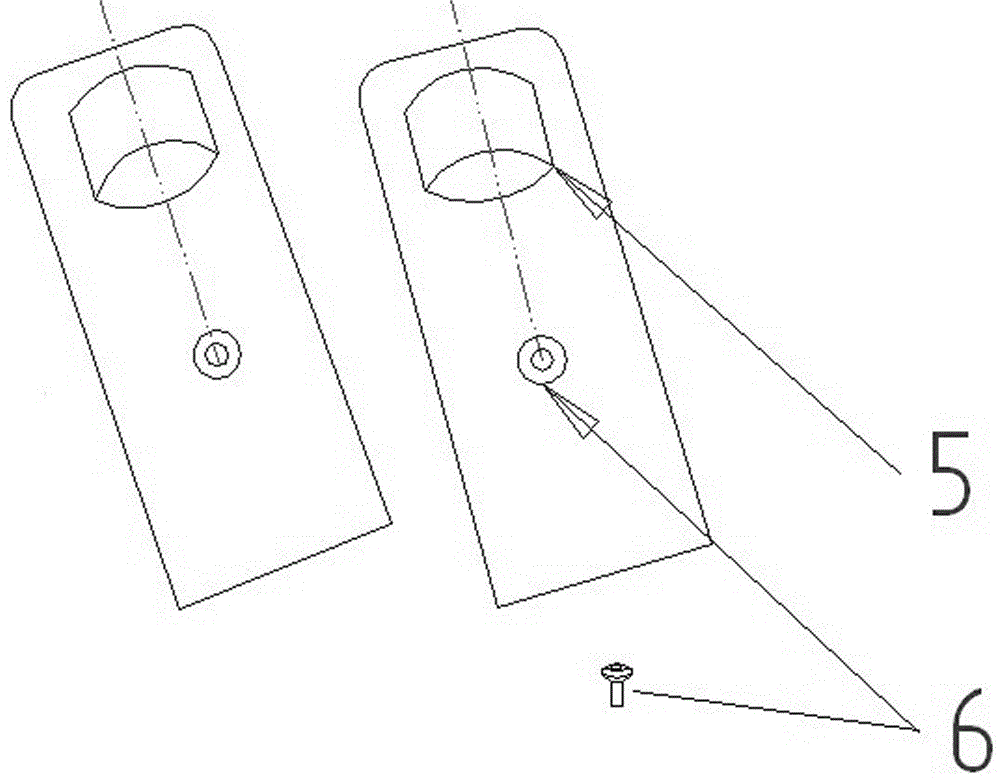

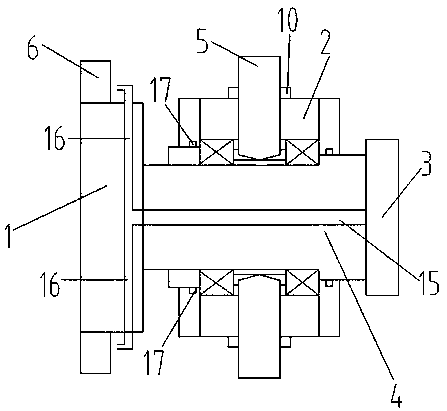

Circular forming knife rest type milling assembly

ActiveCN104439474AEasy maintenanceSmall form factorMilling cuttersMilling equipment detailsEngineeringKnife blades

Owner:CRCC HIGH TECH EQUIP CORP LTD

Full-automatic tab forming machine

InactiveCN105070875AImprove versatilitySolve the problem of chip removalCell electrodesCell component detailsElectrical conductorEngineering

The invention relates to a full-automatic tab forming machine which comprises a discharging mechanism, a main machine, a glue delivery mechanism and a receiving mechanism, wherein a conductor cleaning mechanism, a first servo motor, a heating mechanism, a coating mechanism, a slitting mechanism, a second servo motor and a cutting mechanism are sequentially arranged on the main machine. The full-automatic tab forming machine is high in automation, the production efficiency is higher, and the quality is safer.

Owner:WUXI BAISHIJIE METAL PROD TECH

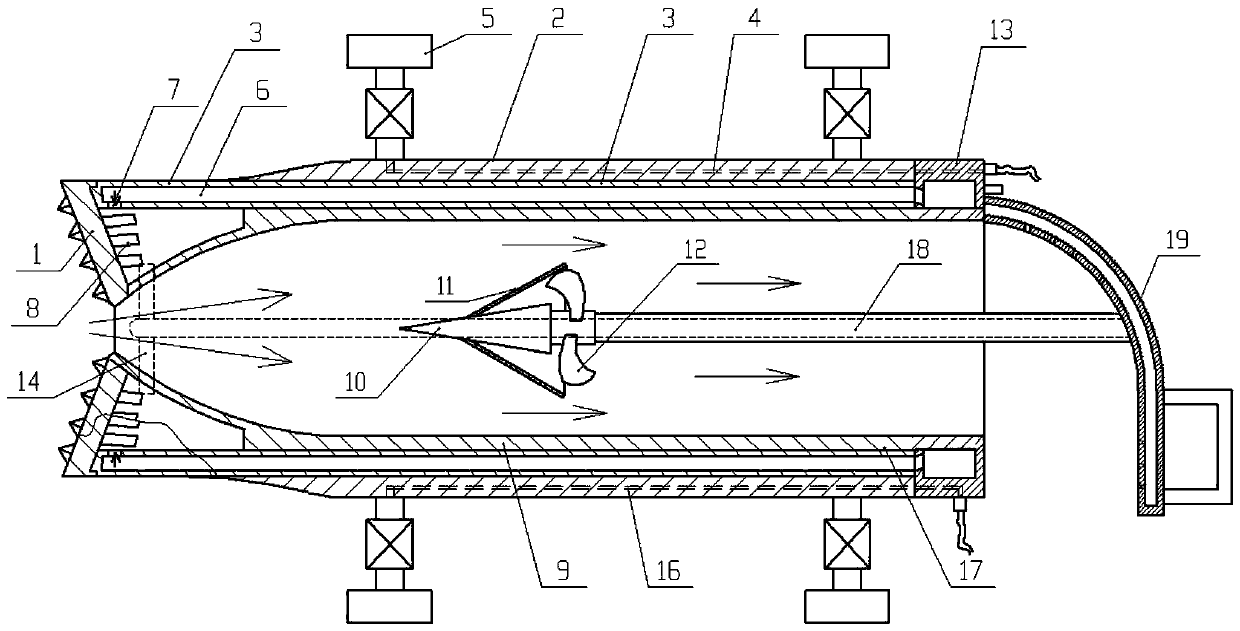

Pipeline dredging and flow guiding tool for water conservancy construction

InactiveCN109894437ASolve the problem of chip removalReduce volumeHollow article cleaningImpellerWater flow

The invention discloses a pipeline dredging and flow guiding tool for water conservancy construction. The pipeline dredging and flow guiding tool for water conservancy construction comprises a rotating head, an outer cylinder, an inner cylinder, a core body part and a back end cover; the rotating head comprises a conical shell-shaped body, the inner side wall of the body is provided with cutter teeth, the outer side wall of the body is provided with blades, and the length of the blades is gradually decreased from the large end of the body to the small end of the body; water outlet pipelines are arranged in a backward extending mode in the length direction of a core cylinder; the portion nearby the cavity bottom of a water injection cavity of the inner cylinder is provided with jetting holes used for jetting out water flow, and the water flow jetted out from the jetting holes exactly impacts the blades to drive the rotating head to conduct rotating cutting; and a conical thrust cone iscoaxially installed in the core cylinder in a hung mode, the cone tip of the thrust cone faces the small end port of the body, and an impeller used for enabling air to quickly flow towards a back portof the core cylinder is coaxially installed on the end face of the thrust cone. The device is high in dredging capability and extremely high in dredging efficiency.

Owner:黄虎

Novel process for processing vertex chamber hole on diesel engine cylinder cover

InactiveCN1607063AImprove processing qualitySolve the problem of chip removalInternal combustion piston enginesCylinder headsSurface roughnessDiesel engine

A novel process for working swirl chamber aperture in cylinder cover of diesel engine is that, the fuel injection hole is preworked before working swirl chamber aperture, then working the swirl chamber aperture and finely working fuel injection hole. Said invention raises the working quality of fuel injection hole.

Owner:YANGDONG CO LTD

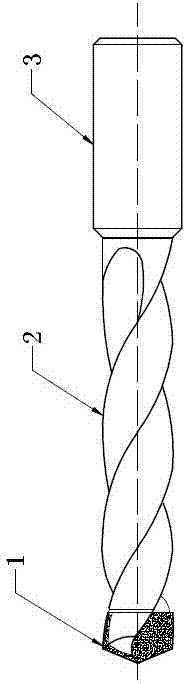

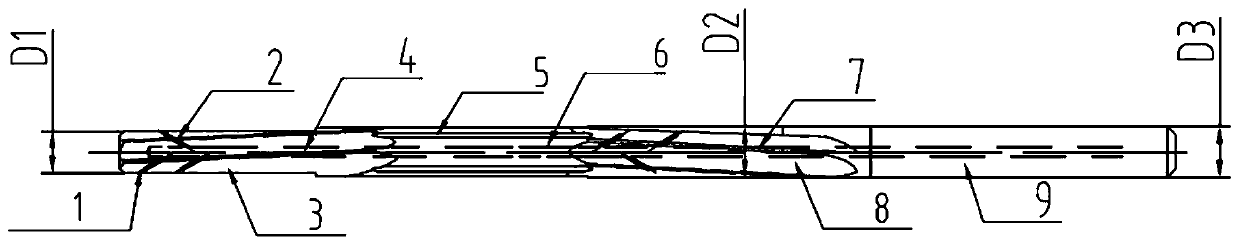

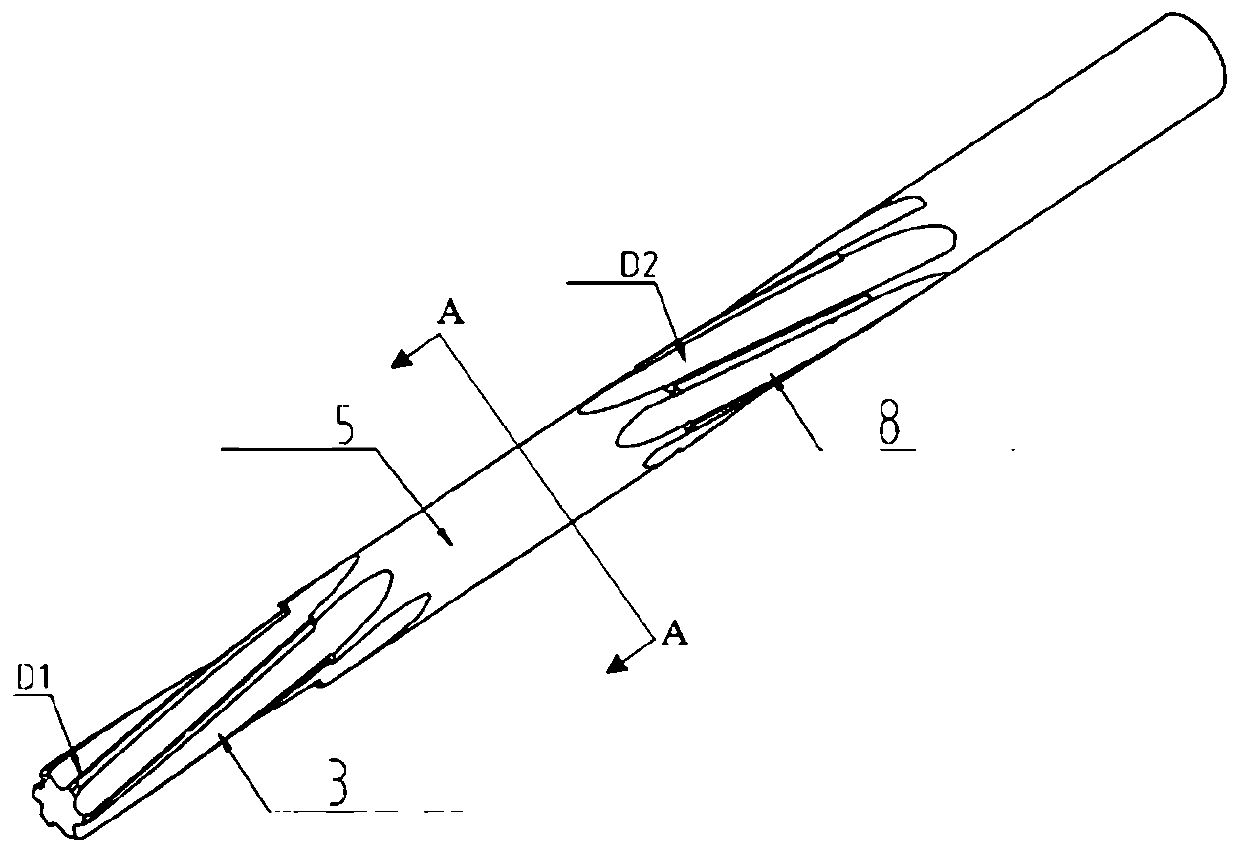

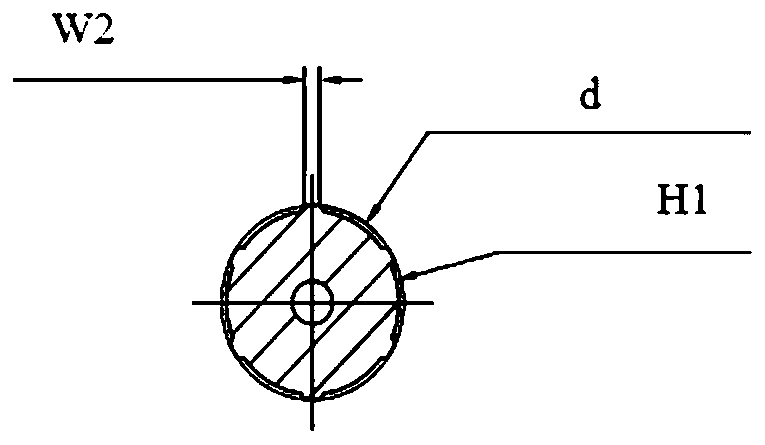

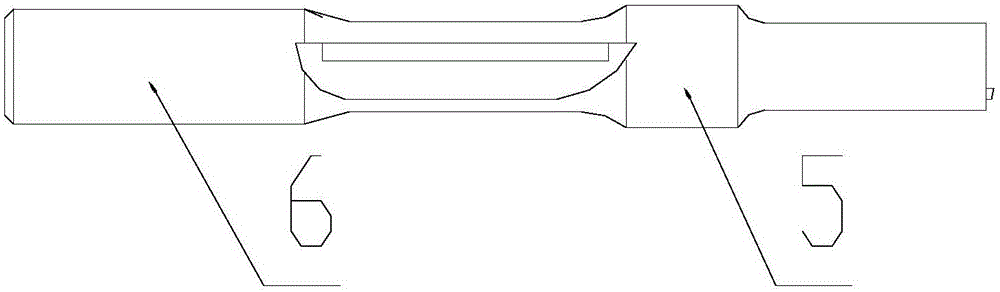

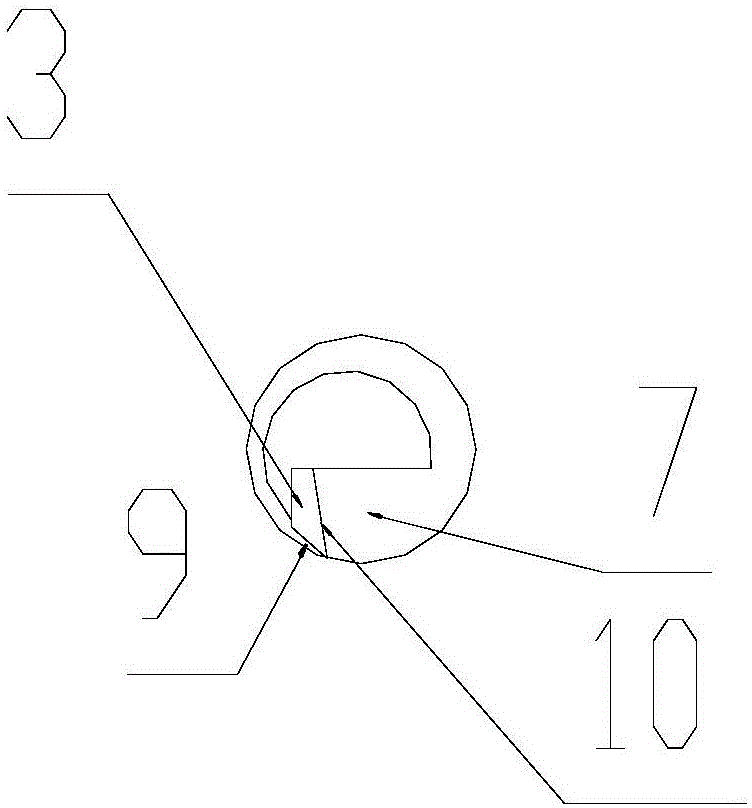

Imbedded carbide drill for steel piece and processing method

The invention relates to an imbedded carbide drill for a steel piece and a processing method, wherein the imbedded carbide drill for the steel piece is structurally a cutter body which is connected between a carbide blade and a shank; the front end part of the cutter body is connected with the carbide blade, a cuttings reeling slot is arranged between the tool nose of the cutter body and an auxiliary chamfered edge of a peripheral blade, the rear part of the cuttings reeling slot is connected with a cuttings-breaking groove, the center of the carbide blade is provided with a blade drilling core, a cutter slot is formed in the top of the cutter body, and a cutter body core is arranged at the center of the cutter slot. The processing method comprises of 1, selecting the blade; 2, cuttings reeling of a blade section and grinding of the cuttings-breaking groove; 3, grooving a steel body; 4, preparing a tool section for the carbide blade; 5, cutting the tool section through wire-electrode cutting; 6, lathing the cutter body through a lathe; 7, milling the cutter body through a milling machine; 8, milling the cutter slot through the milling machine; 9, heat treating; 10, welding; 11, grinding the carbide blade through a tool; and 12, coating TiAlN. The imbedded carbide drill has the advantages that steel piece processing and cuttings are automatically reeled, broken and removed, the material consumption is 1 / 20 of the existing material consumption, the cost performance is greatly increased, and the imbedded carbide drill has great economic and social benefits.

Owner:TAIZHOU X DAKE CUTTING TOOL

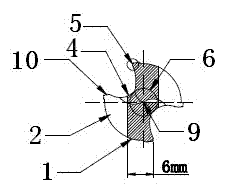

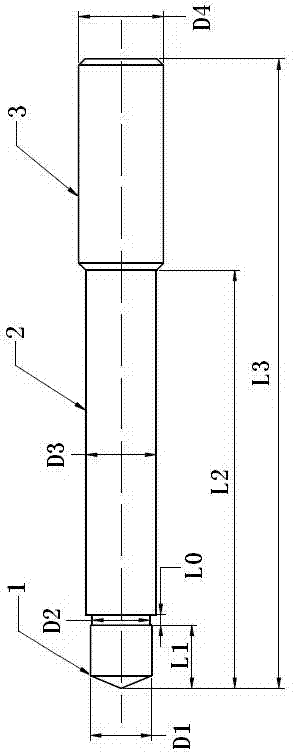

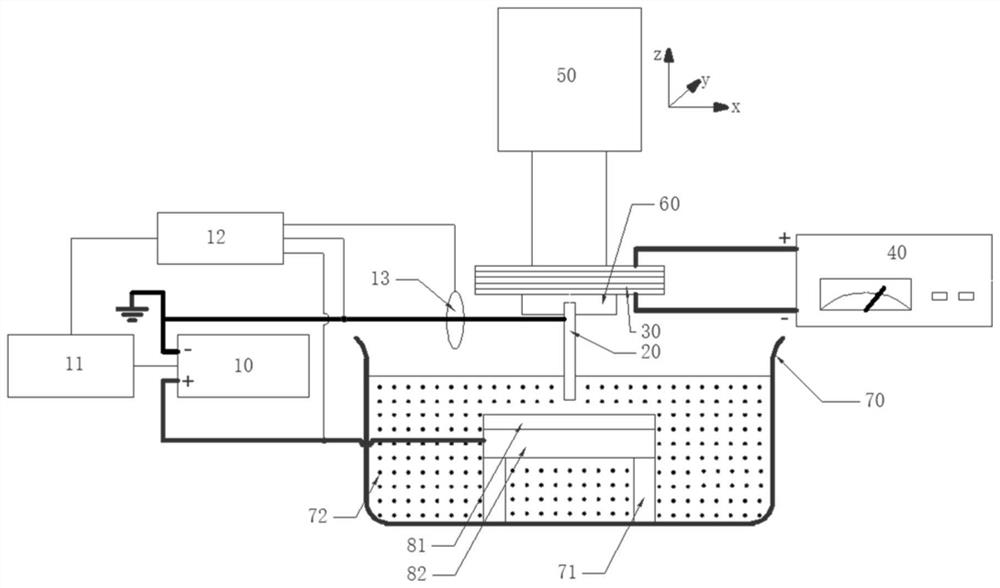

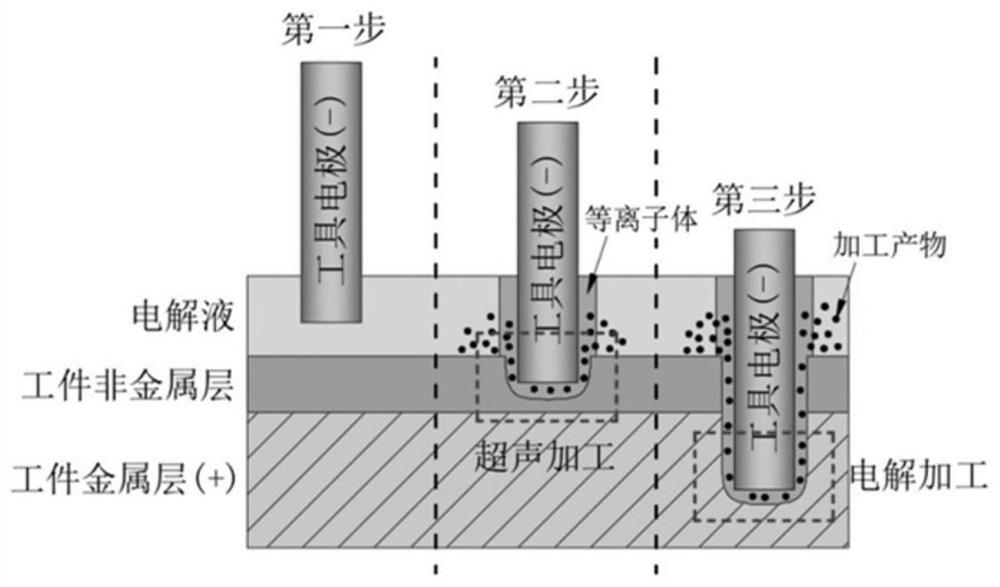

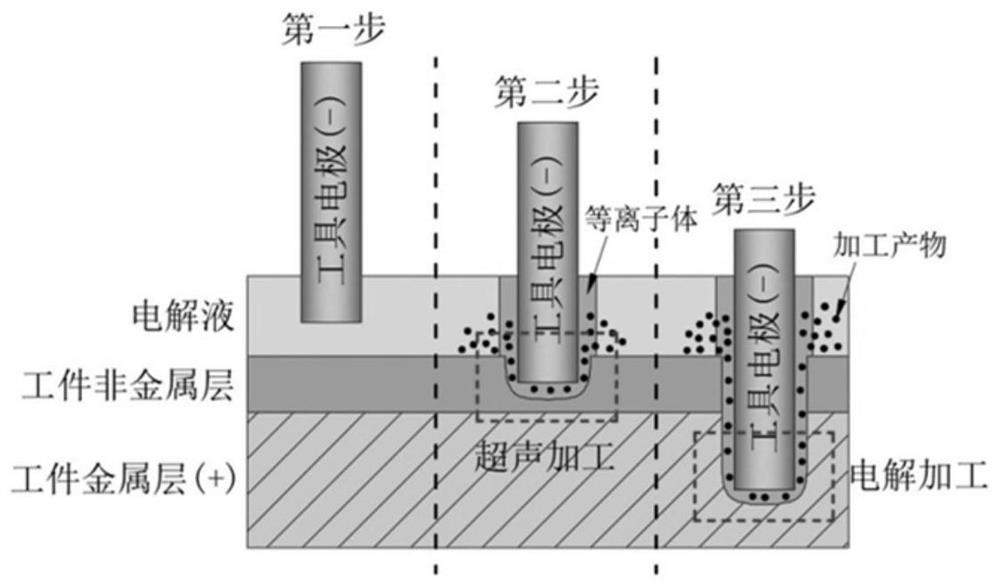

Workpiece ultrasonic-plasma electrolysis combined machining method and machining device

ActiveCN112809111AImprove ECM EfficiencyPromote circulationEfficient propulsion technologiesElectrolytic agentUltrasonic machining

The invention discloses a workpiece ultrasonic-plasma electrolysis combined machining method and a machining device. The machining method comprises the following steps that an electrolyte is provided between a non-metal layer and a tool electrode; a metal layer is connected with the anode of an electrolytic machining power supply, the tool electrode is connected with the cathode of the electrolytic machining power supply, and direct-current voltage is applied between the metal layer and the tool electrode; and the tool electrode moves relative to the non-metal layer from the side, far away from the metal layer, of the non-metal layer, and ultrasonic waves are guided to the non-metal layer. According to the method, firstly, the surface of the non-metal layer is machined through the ultrasonic waves guided to the non-metal layer, and in the ultrasonic machining process, plasma generated through induction can promote solution circulation of ultrasonic machining, so that products of ultrasonic machining are rapidly discharged out of a machining area. And after the non-metal layer is machined, the metal layer is exposed, so that ultrasonic electrolysis parallel processing is carried out on the metal layer.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

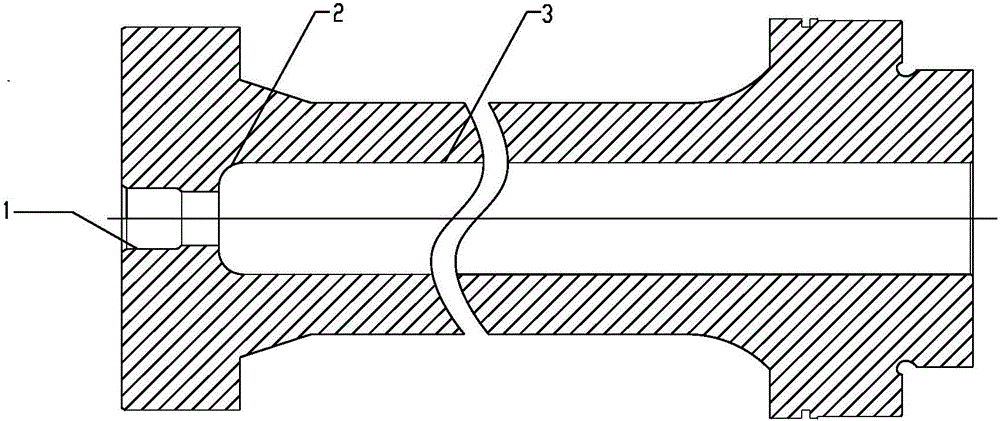

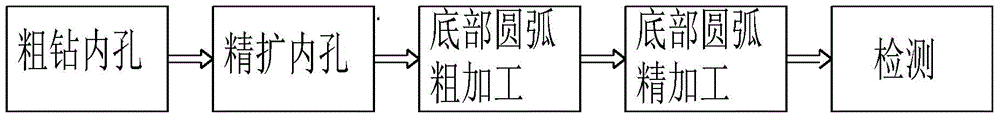

Processing method for diesel oil engine piston rod deep hole

ActiveCN104907596AScientific and reasonable arrangementEasy to implementPistonsBoring/drilling machinesEngineeringCutting force

A processing method for a diesel oil engine piston rod deep hole comprises steps of an inner hole rough drilling step, an inner hole accurate expanding step, a bottom arc rough processing step, a bottom arc fine processing step and a detection step. During drilling process for the deep hole, a work piece rotationally moves, a cutter rotationally moves and conducts feeding motions in an opposite direction; the cutters employs a specific-made serial ejector drill; with the negative pressure produced by the cutter, cutting chips can be easily discharged out and cutter retraction for chip discharging can be avoided; and the cutter is supported by a guide block on a cutter body to balance cutting force during drilling. By the use of the processing method for the diesel oil engine piston rod deep hole, linearity of the deep hole is increased and a problem of large cutter contact between the deep hole bottom arc and the deep hole is solved, so stable product quality and high cutting efficiency can be achieved; and the processing method is suitable for processing deep holes of a large diesel oil engine piston rod, in particular for processing of a deep hole having a large round arc on the bottom and with an aperture 30 times larger than normal deep holes.

Owner:CSSC MES DIESEL

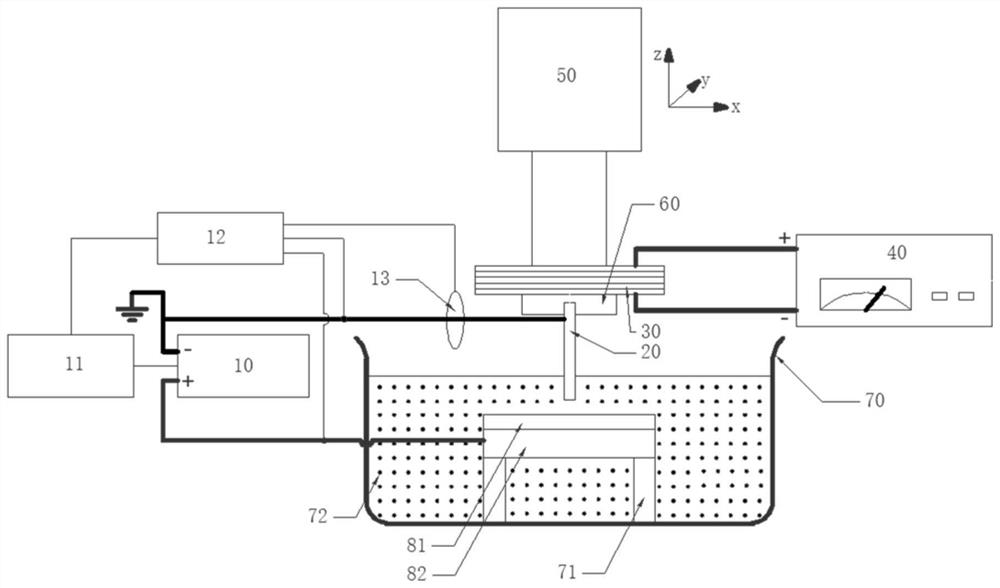

A method and system for micro-nano electrical discharge machining of micro-three-dimensional structures

InactiveCN101665238BRich technical methodsSolve the problem of chip removalSemi-permeable membranesNanostructure manufactureMicro nanoNanowire

The invention belongs to the technical field of micro-nano manufacturing, and relates to a method for micro-nano electric discharge machining of a micro-three-dimensional structure: (1) fixing conductive nanowires or nanotubes on probe tips made of conductive materials as electrodes; (2) ) place the electrode clamping device on the displacement platform, and control the movement of the displacement platform through the multi-axis motion controller; (3) place the conductive material workpiece on the X / Y precision displacement platform, and use the multi-axis motion controller to control the movement of the displacement platform; Control the movement of the X / Y precision translation stage; (4) Connect the negative pole of the pulse power supply to the probe, and its positive pole to the workpiece; (5) Use the industrial computer to send instructions to the multi-axis motion control card to control the placement of electrodes The displacement table of the clamping device is provided with the working voltage of the discharge machining by the pulse power supply, and the discharge gap voltage is collected by the gap voltage detection device, and the industrial computer controls the movement of the electrode feeding displacement table according to the gap voltage. The invention enables the size of electric discharge machining to reach micron and nanometer levels, and simultaneously solves the chip removal problem in the machining process.

Owner:TIANJIN UNIV

Precision deep-hole boring cutter

InactiveCN103111644AEliminate chatterSolve cooling and chip removal problemsTurning toolsBoring/drilling machinesCooling channelEngineering

The invention discloses a precision deep-hole boring cutter which comprises a cutter body, wherein the end of the cutter body is provided with a cutter holder; a cutter handle is connected to the cutter holder; a back taper is arranged on the cutter body; a cooling channel is formed inside the cutter body and passes through the cutter body, and the bottom of the cooling channel extends into the cutter handle; a cooling liquid inlet is formed in the cutter handle and extends from the side face of the cutter handle to be connected with the cooling channel; and at least two guide blocks made from Kenner 2210 superfine crystalline grain hard alloy are fixed with the cutter body to a whole body through welding. According to the precision deep-hole boring cutter, the problems of cooling and chip removal during operation are solved, vibration during operation is eliminated, the abrasive resistance of the cutter is improved, and the loss of the cutter is reduced.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

A kind of peripheral forming tool holder type milling assembly

ActiveCN104439474BEasy maintenanceSmall form factorMilling cuttersMilling equipment detailsEngineeringKnife blades

The invention discloses a circular forming knife rest type milling assembly which comprises a circular forming cutter head base body, wherein a knife rest type milling assembly is arranged on the edge of the base body; at least two columns of cutting blades are arranged on the knife rest type milling assembly; and the two columns of cutting blades are arranged in a staggered mode in a direction perpendicular to the circular cutting direction. According to the knife rest type milling assembly disclosed by the invention, blank parts of various materials can be subjected to circular forming milling, the knife rest type milling assembly is particularly applied to milling the railway rail head profile and has the advantages of convenience in blade maintenance, convenience in knife rest storage, high tool track machining expandability and the like, and the development of the circular forming, particularly the development of the circular forming technology of the railway rail head profile and the tool application, is promoted.

Owner:CRCC HIGH TECH EQUIP CORP LTD

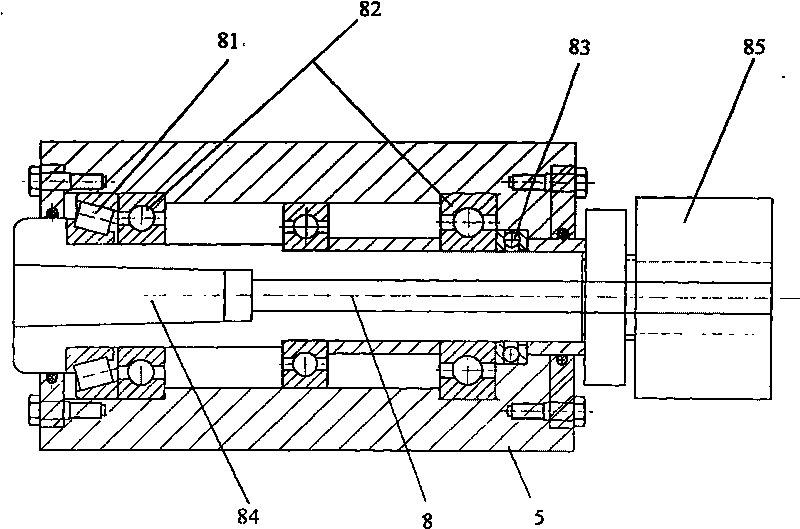

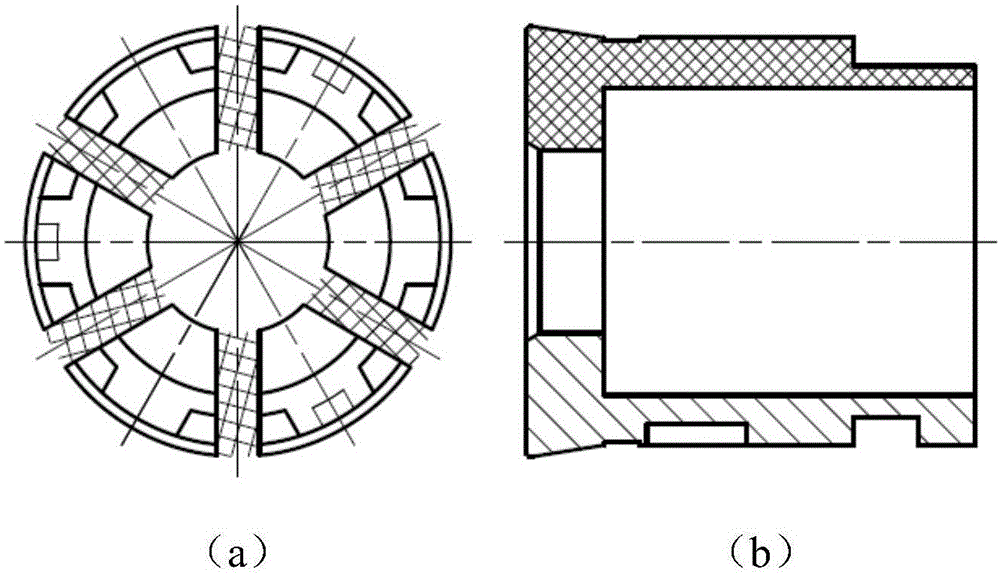

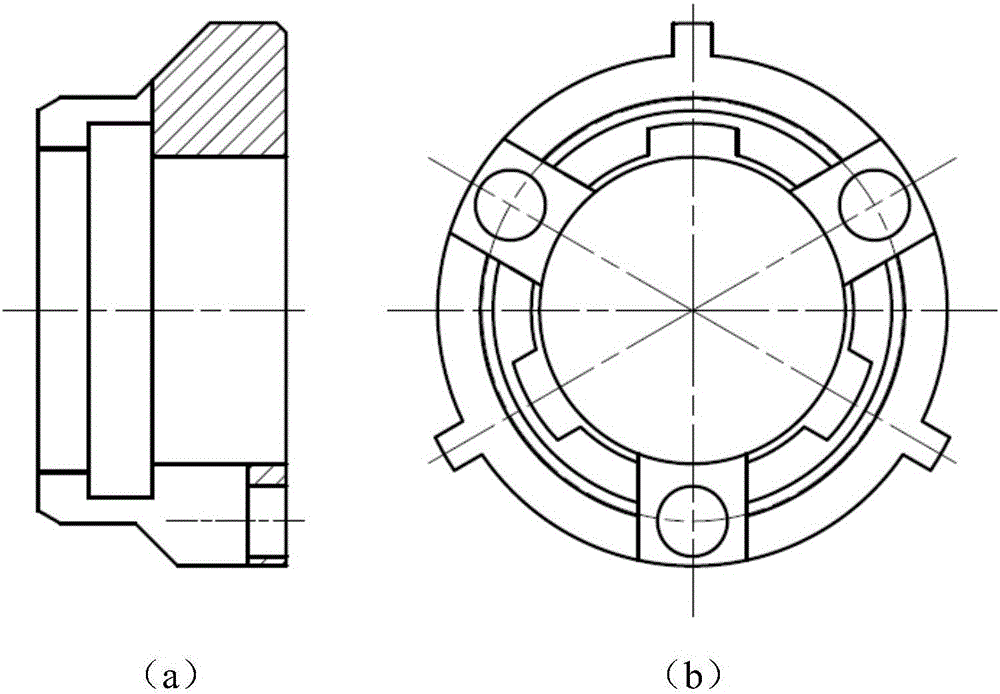

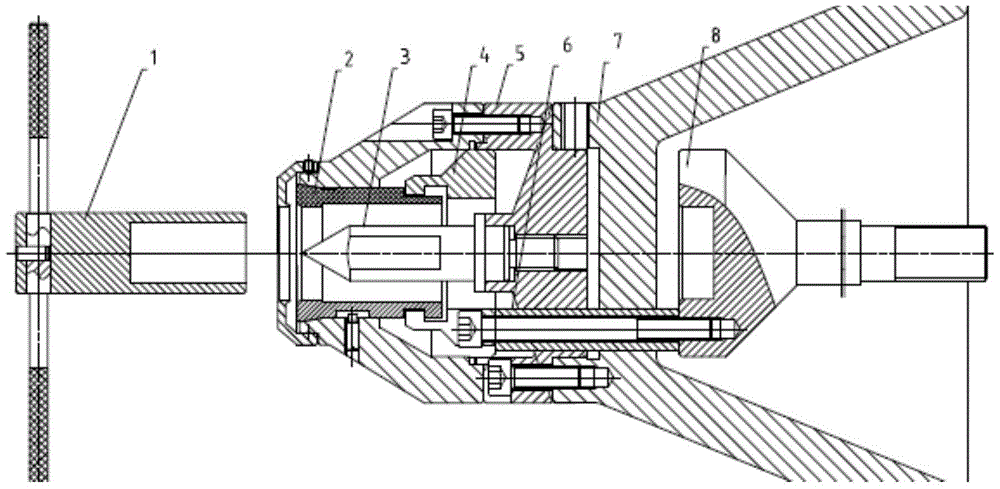

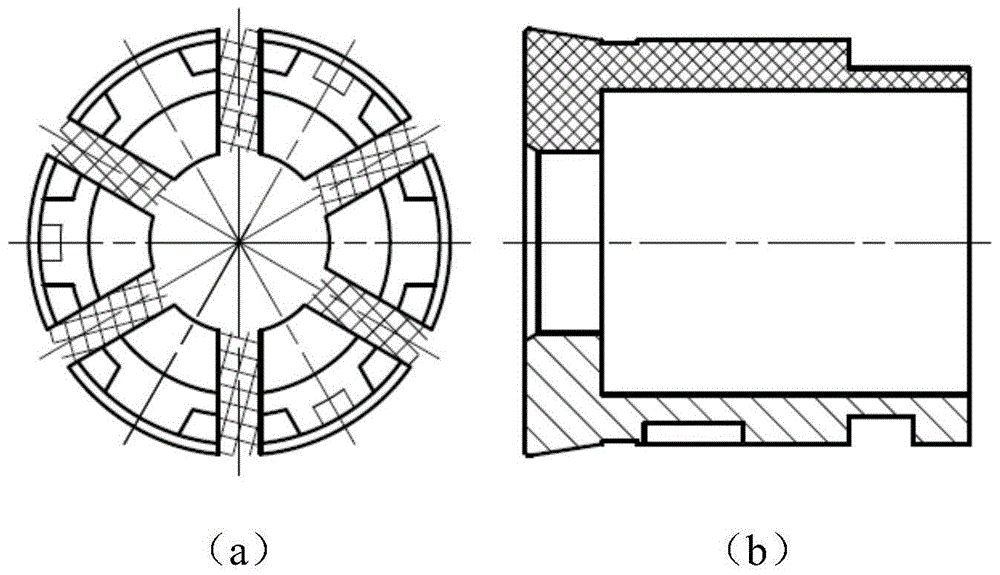

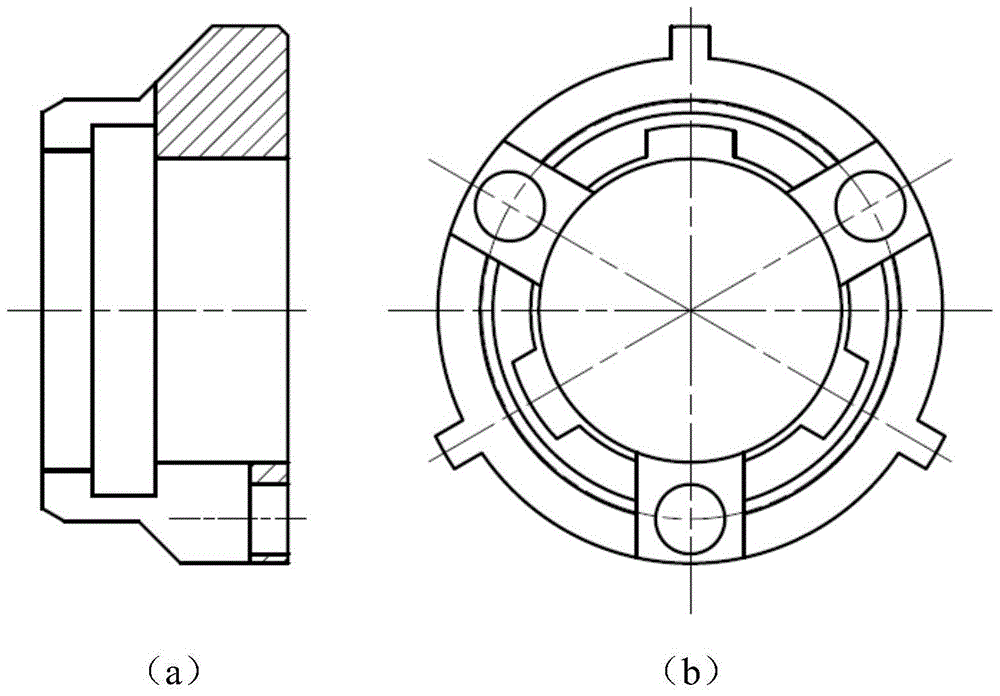

Externally-tightening and quick-changing hobbing tool for shafts

ActiveCN105149703AAvoid uneven tensionEasy to replaceGear-cutting machinesGear teethHobbingEngineering

The invention discloses an externally-tightening and quick-changing hobbing tool for shafts. The externally-tightening and quick-changing hobbing tool comprises a base installed on a work plane of a machine tool. A transition pull plate and an adhesion tightening sleeve are sequentially installed on the base. The transition pull plate is connected to a pull rod of the machine tool and driven by the pull rod of the machine tool to move downwards or upwards. The adhesion tightening sleeve is matched with the transition pull plate to tighten or loosen work-pieces. According to the characteristics that power takeoff shafts are various and production change is frequent, the externally-tightening and quick-changing hobbing tool is designed. According to the tool, serialization design is carried out on the adhesion tightening sleeve and a centre, the adhesion tightening sleeve and the centre are convenient to change, and the design range of clamps for new shaft parts in future can be expanded.

Owner:SHAANXI FAST GEAR CO

Method for electric discharge machining of micronanometer three-dimensional structure of nanowire or nanotube and system thereof

InactiveCN101638217BRich technical methodsSolve the problem of chip removalSemi-permeable membranesNanostructure manufactureElectric dischargeManufacturing technology

The invention belongs to the technical field of micronanometer manufacturing, relating to a method for electric discharge machining of micronanometer three-dimensional structure of a nanowire or a nanotube, comprising: (1) sticking a conductive nanowire or nanotube to a tungsten tip; (2) putting an electrode clamping device onto a displacement table, and controlling the movement of the displacement table via a multi-axis motion controller; (3) putting conductive material workpieces to an X / Y precision displacement table, and controlling the movement of the X / Y precision displacement table by the multi-axis motion controller; (4) connecting the cathode of a pulse power supply to the tungsten tip, and connecting the anode to the workpiece; (5) using an industrial personal computer to send orders to the multi-axis motion controller, controlling the displacement table provided with the electrode clamping device, providing working voltage for electric discharge machining by the pulse powersupply, collecting electric discharge gap voltage by a gap voltage detection device, and controlling the movement of an electrode feeding displacement table by the industrial personal computer according to gap voltage. The invention ensures that the size of electric discharge machining reaches the micrometer level and the nanometer level and simultaneously solves the problem of chip removal in the machining process.

Owner:TIANJIN UNIV

High-precision high-rigidity turning and milling combined center inclined lathe bed

PendingCN111300079AImprove chip removal efficiencyReasonable structureLarge fixed membersMaintainance and safety accessoriesStructural engineeringMachine tool

The invention discloses a high-precision high-rigidity turning and milling combined center inclined lathe bed. The high-precision high-rigidity turning and milling combined center inclined lathe bed comprises a base and a stand column, wherein the stand column is fixed to one side of the top of the base, the outer side wall of the stand column is perpendicularly fixed to the base, the inner side wall of the stand column is obliquely fixed to the base, and the included angle between the inner side wall of the stand column and the top end face of the base ranges from 75 degrees to 85 degrees. According to the turning and milling combined center inclined lathe bed, by means of the inclined side wall of the stand column, chippings generated after a workpiece is machined by a turning and milling combined center can be discharged in time through a lathe bed structure, and the chippings are better and faster discharged by means of the inclination angle of the side wall of the stand column compared with a common vertical angle or a common horizontal angle, therefore, the situation that the chippings are accumulated in a machine tool and then the operation of the machine tool is influencedis avoided, the chipping removal efficiency is improved, moreover, the overall working efficiency of the machine tool is further improved, and high practicability is achieved.

Owner:BEIJING PROSPER PRECISION MACHINE TOOL CO LTD

Multi-section forming reamer for processing automobile valve sleeve

InactiveCN111390281AHigh precisionAvoid the phenomenon of being unable to dischargeReaming toolsCooling effectStructural engineering

The invention discloses a multi-section forming reamer for processing an automobile valve sleeve. A left peripheral blade and a right peripheral blade are sequentially arranged on a knife body; a guide column is arranged between the left peripheral blade and the right peripheral blade; a left knife rotating slot with left helixes is formed in the left peripheral blade; a right knife rotating slotwith right helixes is formed in the right peripheral blade; an internal cold hole which is formed along a center axis is formed inside the knife body; one end, towards the head part of the knife body,of the internal cold hole is sealed; and the head of the knife body is provided with a forming chamfer angle. The multi-section forming reamer for processing the automobile valve sleeve provided by the invention, a left-helix design is adopted for discharging chips downwards, and a right-helix design is adopted for upwards discharging chips, so that a phenomenon that scrap iron cannot be discharged as a chip discharge slot is too long is avoided; a guide column is additionally arranged to raise a supporting column, so that hole precision is improved; a forming chamfer design is adopted, chamfering for connecting a R angle to a transition angle is made after conventional chamfering, so that roughness of hole walls can be improved in a cutting process; and the left knife rotating slot adopts front punching and side cooling, and a right knife rotating slot adopts back punching and side cooling, so that a chip discharge direction is met, chip removal and cutting edge cooling are facilitated better, and therefore, cooling effect is improved.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

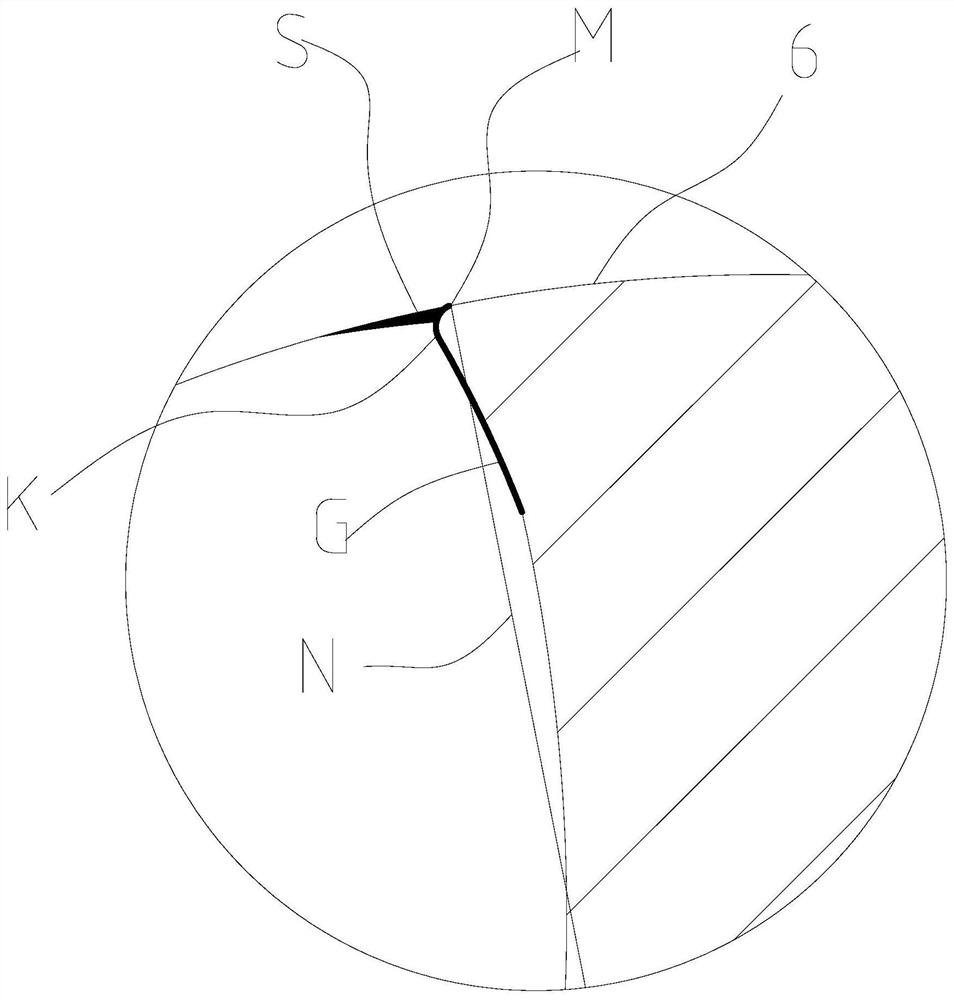

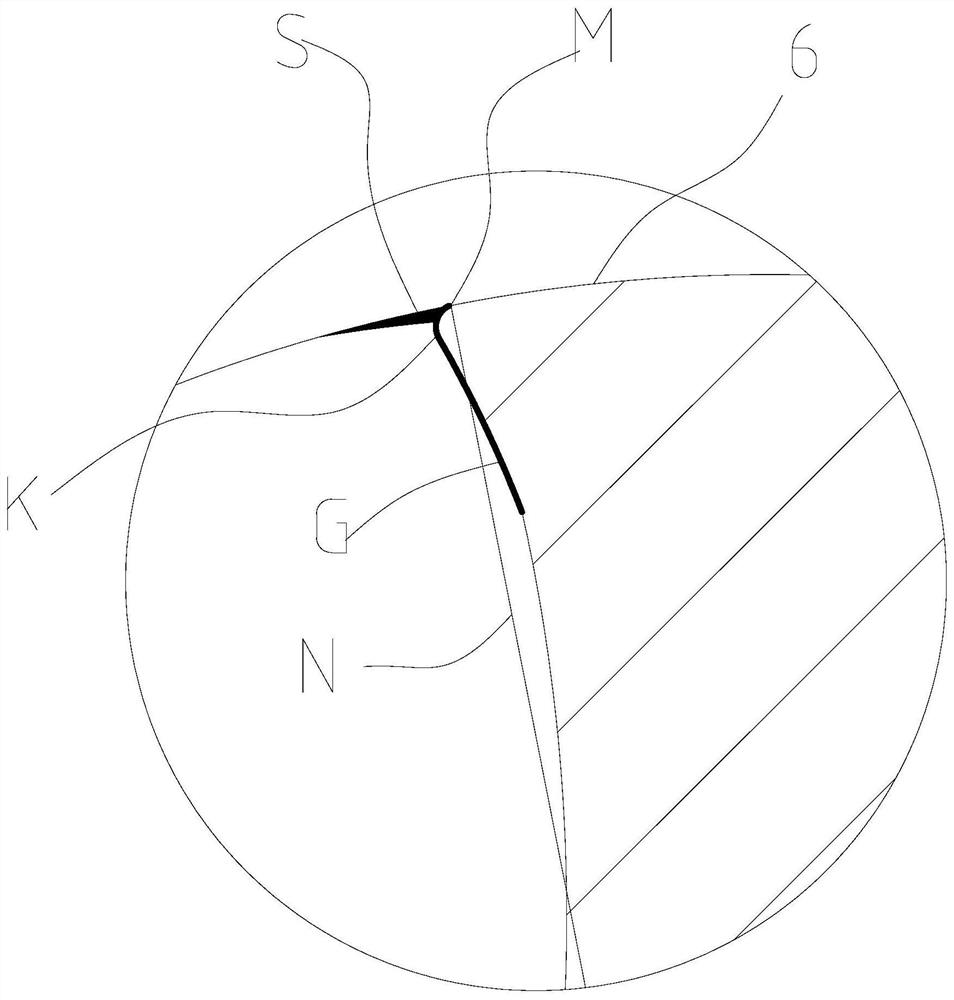

Twist drill with front angle correction and machining method of twist drill

The invention discloses a twist drill with front angle correction and a machining method of the twist drill. The twist drill comprises a cutting part and a handle part; the front end of the cutting part is provided with a drill tip; the cutting part is provided with two spiral chip grooves extending from the drill tip to the handle part; the portion, between the two spiral chip grooves, of the cutting part forms a blade petal; the front end of the blade petal is provided with a main blade belt; the spiral chip grooves are connected with the main blade belt through a front angle correction face; in the section perpendicular to the cutting part, the connecting line of the front end point M of the main blade belt and the center O of the blade petal is a line N; the front angle correction face is concave inwards relative to the line N; and the front angle of the front angle correction face is gamma, and gamma is a positive acute angle. The machining method comprises the steps of rough grinding, brush fine grinding, front angle correction surface grinding and the like. According to the twist drill with front angle correction and the machining method of the twist drill, the sharpness of the twist drill is improved easily, the cutting torque of the twist drill is reduced, the risk of built-up edges generated in the drilling process is reduced, the drilling precision is greatly improved, the service life is greatly prolonged, the brush polishing process is adopted, the manufacturing cost of the twist drill can be greatly saved, and the production efficiency of the twist drill can be greatly improved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

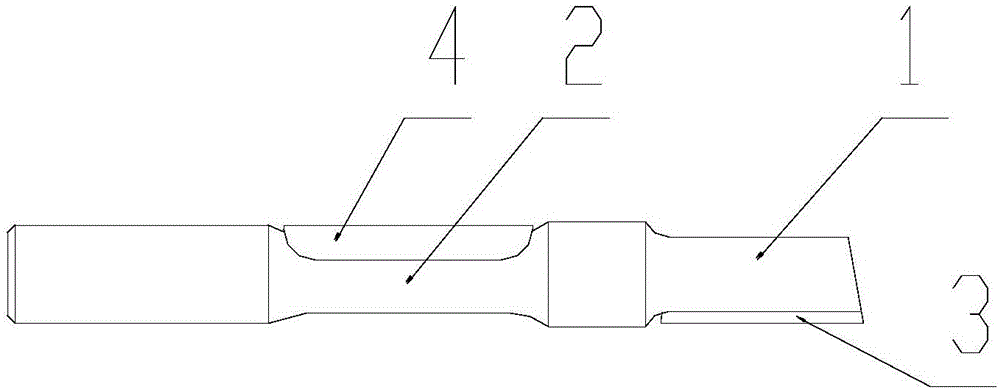

Positioning double-section cutter

ActiveCN105082203AIncrease chip pocketSolve the problem of chip removalMetal working apparatusEngineeringMechanical engineering

The invention relates to a positioning double-section cutter which is high in production efficiency, not prone to wear and long in service life. The positioning double-section cutter comprises a cutter body. The cutter body comprises a first base body outer cylinder, a positioning cylinder, a second base body outer cylinder and a cutter handle in sequence. The first base body outer cylinder is provided with a first cutting blade. The second base body outer cylinder is provided with a second cutting blade. The direction of the cutting edge of the first cutting blade is opposite to that of the cutting edge of the second cutting blade. The length of the first base body outer cylinder is the same as that of the second base body outer cylinder. The size and shape of the first cutting blade are the same as those of the second cutting blade. The excircle diameter of the positioning cylinder is 0.5-0.8 mm larger than the cutting circle diameter of the second cutting blade. The relief angles of the first cutting blade and the second cutting blade are arc relief angles. According to rake faces of the first cutting blade and the second cutting blade, the blade thickness of the cutter point portions is larger than that of the blade roots. The cutter body is further provided with a chip groove.

Owner:ZHEJIANG LANGCHAO PRECISION MACHINERY

Vertical loading and clamping five-edge cutoff blade for rough machining

The invention discloses a vertical loading and clamping five-edge cutoff blade for rough machining. The shape of the blade is a convex pentagon, and the vertical plane of each angle of the convex pentagon is provided with a cutting edge; a chamfered edge, a chip discharge groove and a chip breaker are arranged on each cutting edge; the lower edge of a knife point and the vertical direction of the cutting edge form an included angle alpha, the chamfered edge is arranged at the transition position of the chip discharge groove, and the chip discharge groove and the horizontal direction of the cutting edge form an included angle gamma; the chip discharge groove has an inward concave fan-shaped surface, and the radius r of the upper arc of the surface center line of the fan-shaped surface is 2 to 5 millimeters; and the chip breakers comprise two transverse chip breakers and a longitudinal chip breaker, the two transverse chip breakers are symmetrically distributed on two sides of the center line of the cutting edge, and the fixed width e is 0.1 to 0.5 millimeter. Due to the chip discharge groove of the inward concave fan-shaped surface and the cutting edges of big positive rake angles, the discharge of the residual chips is more directive, the chip discharge problem is radically solved, the service life of the blade is remarkably prolonged, and the surface quality of a processed workpiece is remarkably improved.

Owner:中硬金属切削(大连)有限公司

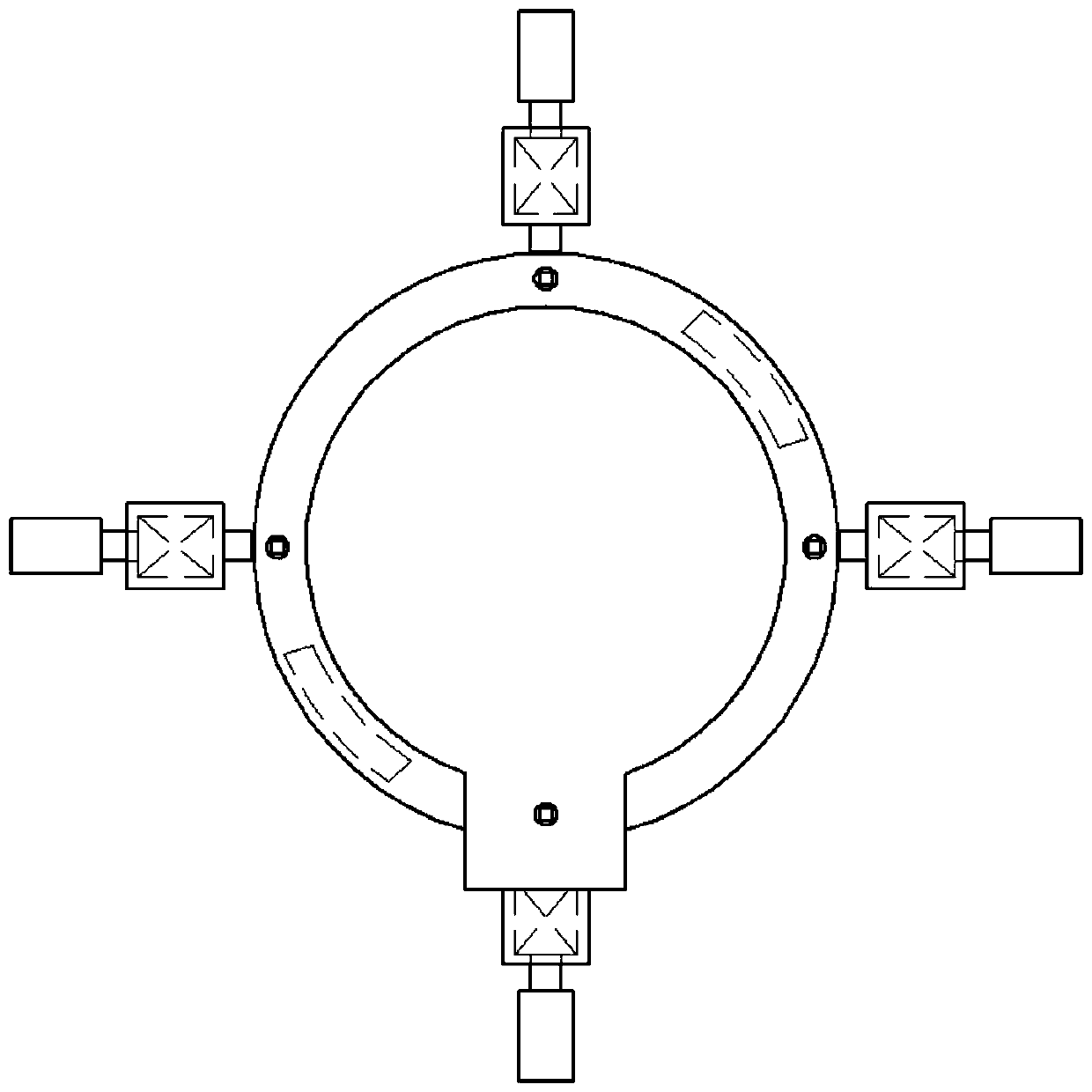

Blind hole boring cutter assembly

The invention provides a blind hole boring cutter assembly. The blind hole boring cutter assembly comprises a cutter head main body, a rotating body, a cutter rod and a rotating shaft. A cutter head is arranged on the periphery of the cutter head main body and used for cutting a hole inner wall. The rotating body is used for rotating the cutter head during cutting, a plurality of height-adjustablesupporting blocks are arranged on the periphery of the rotating body, and during cutting of the cutter head, the supporting blocks make contact with the hole inner wall. The cutter rod is provided with a hand-held part. The rotating shaft penetrates through the rotating body, and the two ends of the rotating shaft are connected with the cutter head main body and the cutter rod correspondingly. When the cutter head cuts the hole inner wall, a hole of a machining piece rotates, the cutter head main body and the cutter rod move in the horizontal direction and simultaneously rotate with the holein the same direction under driving of static friction force, and the rotating speed of the rotating body is the same as that of the hole; and when the cutter head cuts the hole inner wall, the rotating speed of the hole of the machining piece is 50-300 r / min. The blind hole boring cutter assembly has the effects that friction of the supporting blocks is reduced, vibration is eliminated, and chipremoving is facilitated.

Owner:西安鑫旺矿业设备有限公司

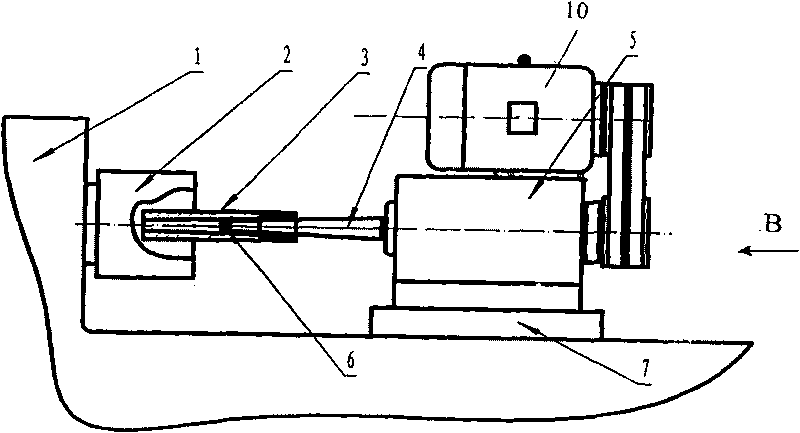

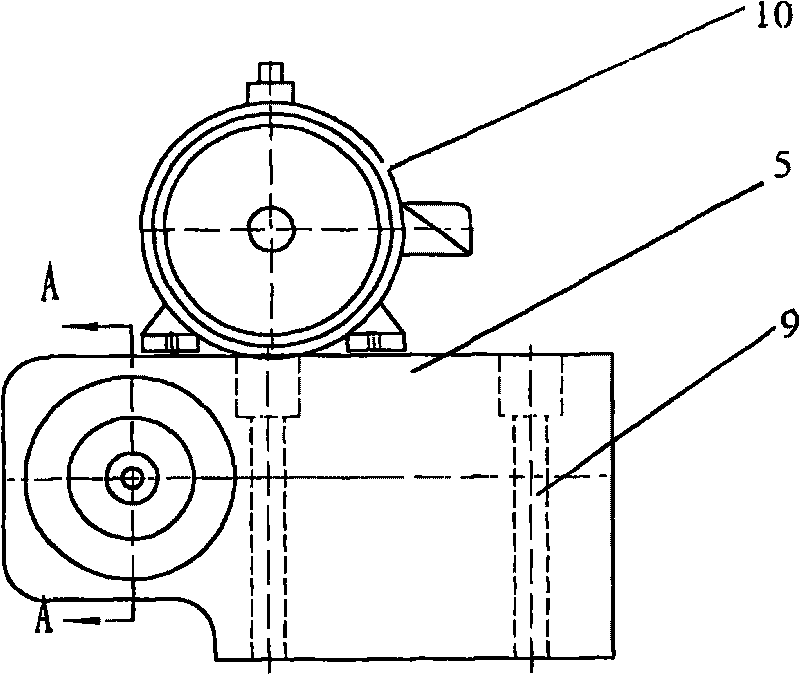

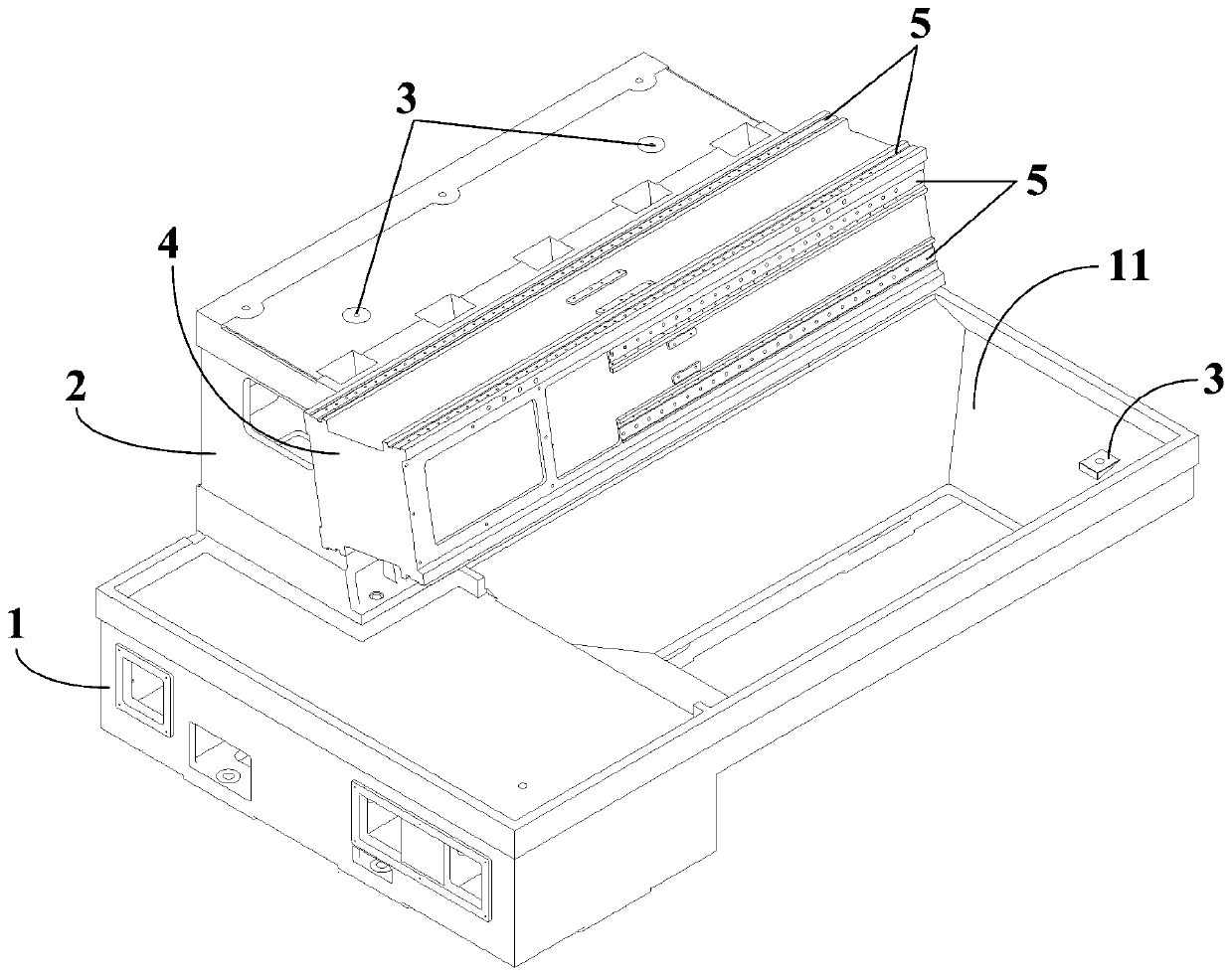

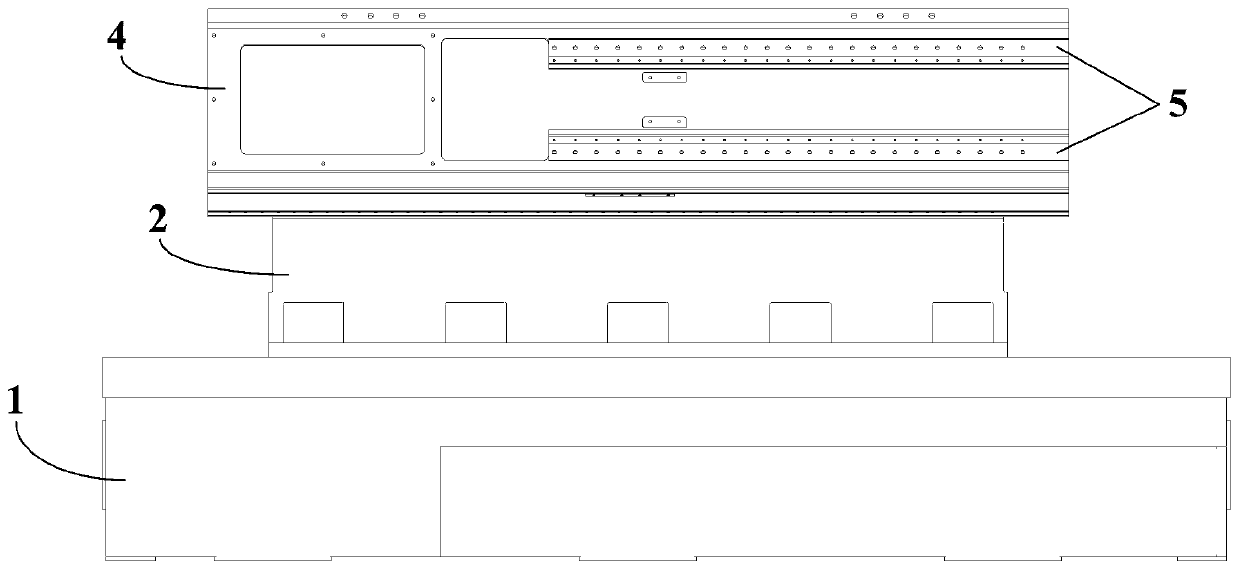

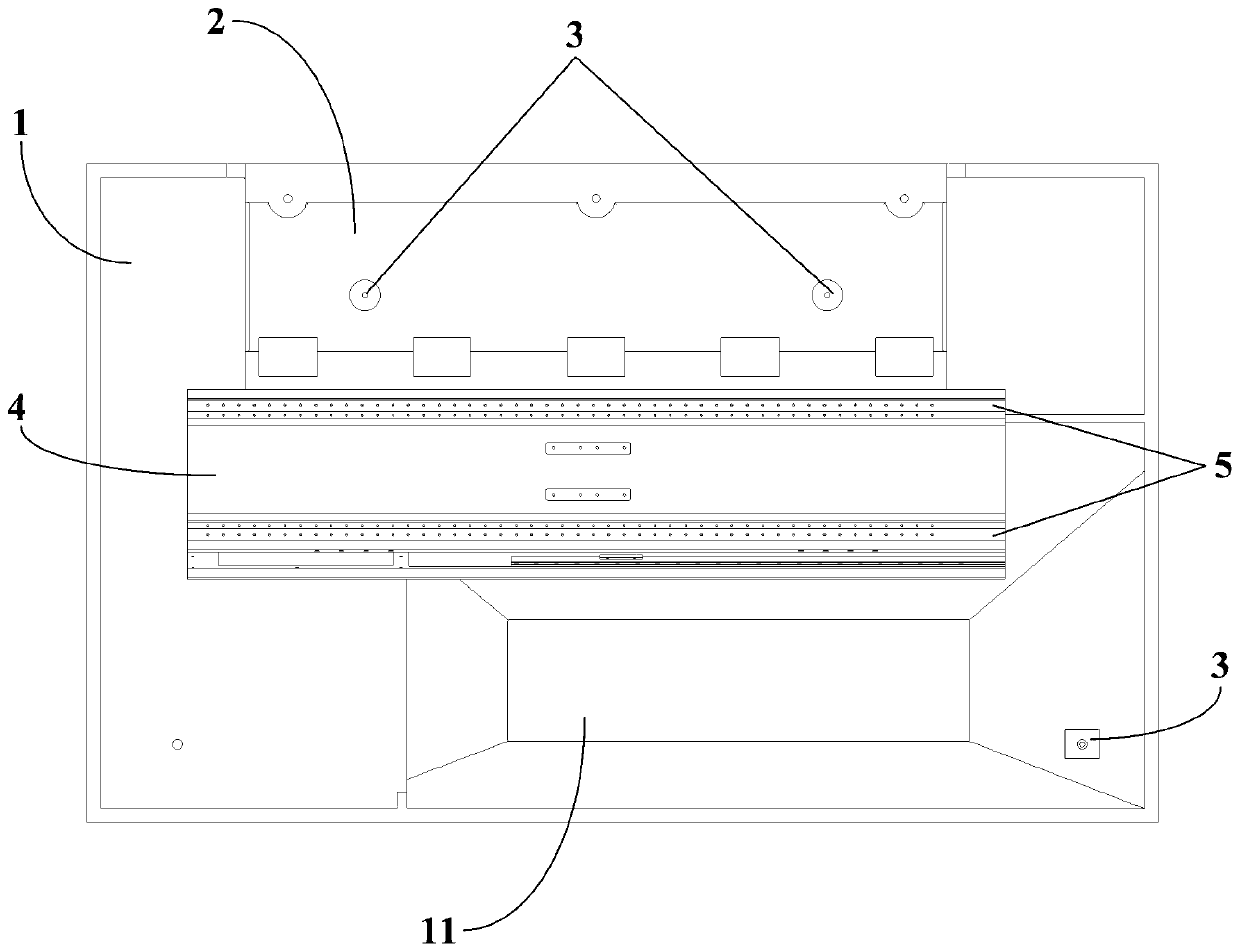

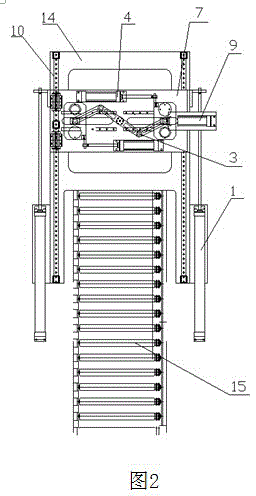

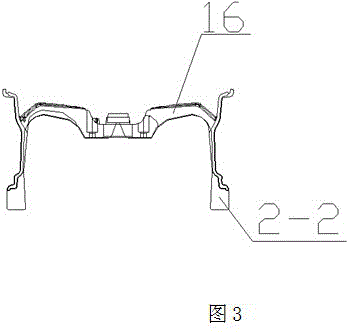

External circle riser removing device for hub

InactiveCN104084831ASolve the problem of chip removalRealize automatic processingMetal working apparatusStructural engineeringMachine tool

An external circle riser removing device for a hub comprises a work platen (14) which is arranged in the middle of a machine tool base (11). The work platen (14) is provided with a longitudinal moving guide rail (10). A clamping jaw supporting seat (7) is installed on the longitudinal moving guide rail (10). A longitudinal moving air cylinder (1) is installed on the work platen (14) and connected with the clamping jaw supporting seat (7). A knocking air cylinder (9) is installed on the side face of the clamping jaw supporting seat (7). The external circle riser removing device is characterized in that a clamping air cylinder drives clamping jaws to move transversely so that the hub (16) connected with a riser sleeve can be clamped, the left clamping jaw (2) and the right clamping jaw (2) clamp the hub through a synchronous link rod (3), a riser of the hub (16) is rapidly knocked through the knocking air cylinder (9), and therefore the riser sleeve falls into a riser sleeve collecting frame (12). According to the external circle riser removing device for the hub, the riser does not need to be completely cut so as to fall into a machine tool when the riser sleeve of the hub is cut, the problem existing in machine tool scrap discharge is solved, and therefore automatic machining of a riser cutting line can be achieved.

Owner:JIANGSU SECURE AUTO PARTS

Drill bit for breaking rock by rotary cutting

ActiveCN102364030BImprove rock breaking efficiencyHigh rock breaking performance at the centerDrill bitsSpray nozzleEngineering

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

Twist drill with rake angle correction and its processing method

The invention discloses a twist drill with rake angle correction and a processing method. The twist drill comprises a cutting part and a shank part, the front end of the cutting part is provided with a drill tip, and the cutting part is provided with two spirals extending from the drill tip to the shank part Chip flute, the part of the cutting part between the two spiral flutes forms a blade, the front end of the blade is provided with a main land, and the spiral flute is connected with the main land through a rake angle correction surface, and is perpendicular to the main land. In the section of the cutting part, the line connecting the front end point M of the main land and the center O of the blade is the line N, the rake angle correction surface is concave relative to the line N, the rake angle of the rake angle correction surface is γ, and γ is a positive acute angle . The processing method includes the steps of rough grinding, fine grinding with brushes, and grinding the rake angle correction surface. The invention is beneficial to improve the sharpness of the twist drill, reduce the cutting torque of the twist drill, reduce the risk of built-up edge in the drilling process, greatly improve the drilling accuracy and service life, and the brush polishing process can greatly improve the Save the manufacturing cost and production efficiency of twist drills.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

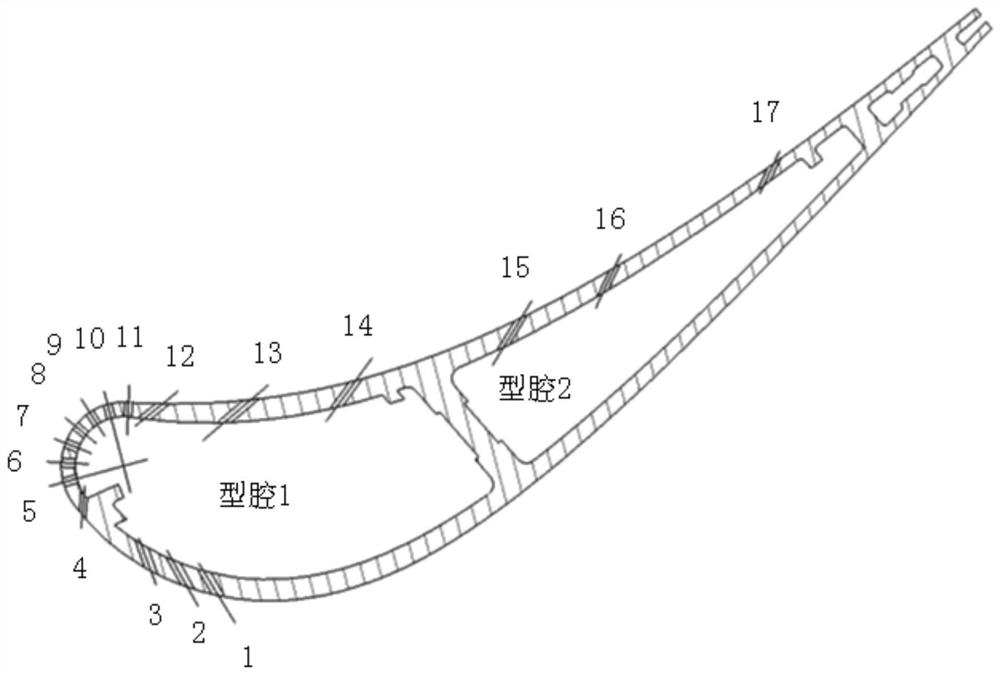

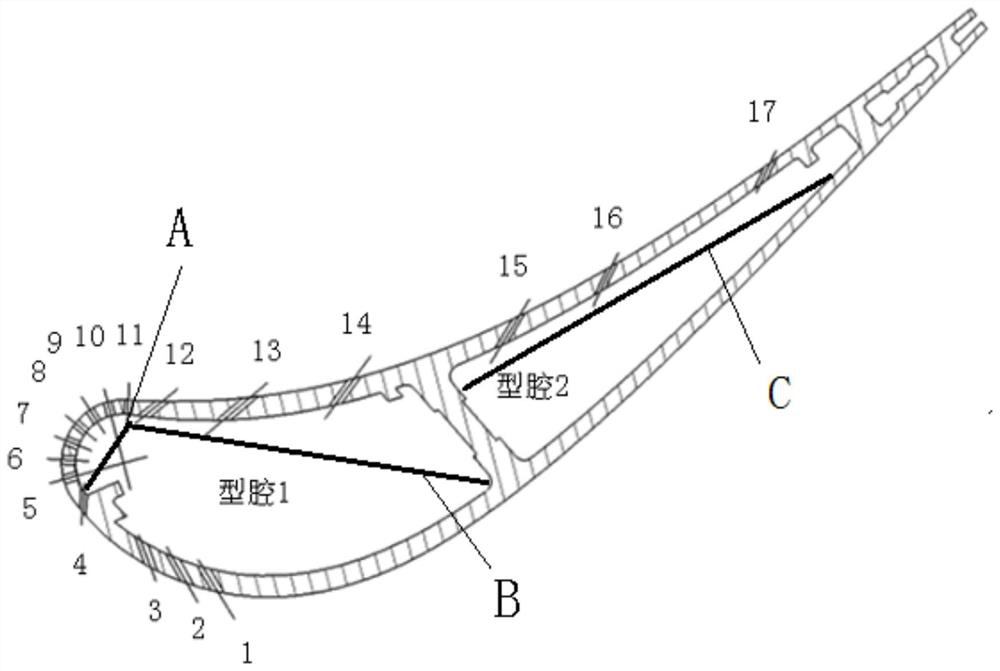

A Composite Machining Method for Gas Film Hole of Guide Vane

Owner:AECC AVIATION POWER CO LTD

Ultrasonic-plasma electrolytic composite processing method and processing device for workpiece

ActiveCN112809111BImprove ECM EfficiencyPromote circulationEfficient propulsion technologiesElectrolytic agentDc voltage

The application discloses an ultrasonic-plasma electrolytic composite processing method and a processing device for workpieces. The processing method comprises the following steps: providing electrolyte solution between the non-metallic layer and the tool electrode; connecting the metal layer to the positive pole of the electrolytic machining power supply, connecting the tool electrode to the negative pole of the electrolytic machining power supply, and applying a DC voltage between the metal layer and the tool electrode; The tool electrode is moved relative to the non-metal layer from the side of the non-metal layer away from the metal layer, and the ultrasonic wave is guided to the non-metal layer. In the above method, the surface of the non-metallic layer is firstly processed by ultrasonic waves guided to the non-metallic layer. During the ultrasonic processing, the induced plasma can promote the circulation of the ultrasonic processing solution, so that the ultrasonic processing products can be quickly discharged from the processing area. After the non-metallic layer is processed, the metal layer is exposed, so that the metal layer is processed in parallel by ultrasonic electrolysis.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

An external expansion type quick-change gear hobbing tool for shafts

ActiveCN105149703BEasy to replaceAvoid uneven tensionGear-cutting machinesGear teethHobbingFeature design

The invention discloses an external expansion type quick-change gear hobbing tool for shafts, which comprises a base installed on the working plane of a machine tool, on which a transition pull plate and an adhesive expansion sleeve are successively installed; the transition pull plate is connected with the pull rod of the machine tool, and the Driven by the pull rod, it moves downward or upward; the adhesive expansion sleeve cooperates with the transition pull plate to tighten or loosen the workpiece. According to the characteristics of many types of power take-off shafts and frequent production changes, the present invention designs an outwardly expanding quick-change gear hobbing tool. The tooling is designed in series for the bonding expansion sleeve and the top, and at the same time, the bonding expansion sleeve and the top are easy to replace. At the same time, the tooling provides expansion functions for the fixture design of new shaft parts in the future.

Owner:SHAANXI FAST GEAR CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com