Full-automatic tab forming machine

A molding machine, fully automatic technology, used in battery electrodes, electrical components, circuits, etc., can solve the problems of large occupied space, low production efficiency, inconsistency of functions, etc., to solve the problem of chip removal, improve production efficiency, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

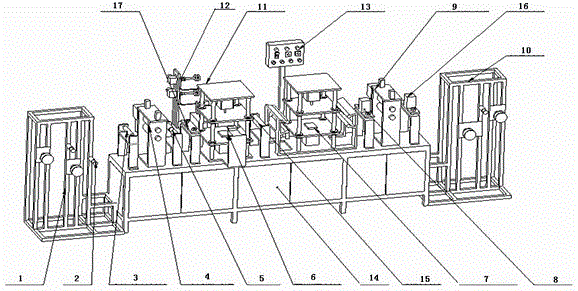

[0018] The present invention provides a fully automatic tab forming machine. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail with reference to the accompanying drawings and examples. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

[0019] refer to figure 1 The fully automatic tab forming machine shown mainly includes a discharging mechanism 1, a main machine, a glue feeding mechanism 12 and a winding mechanism 10. The main machine is sequentially provided with a conductor cleaning mechanism 3, a first servo motor 4, a heating mechanism, a cover Film mechanism 15 , cutting mechanism 8 , second servo motor 9 and cutting mechanism 16 .

[0020] The tab forming machine includes an integral frame, on which a platform is arranged, and the lower part of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com