Ultrasonic vibration modulation bidirectional narrow-pulse-width micro-energy pulse power supply

A technology of pulse power supply and ultrasonic vibration, which is used in circuits, manufacturing tools, electric machining equipment, etc., to achieve the needs of micro-precision machining, improve gap discharge conditions, and improve machining speed and machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

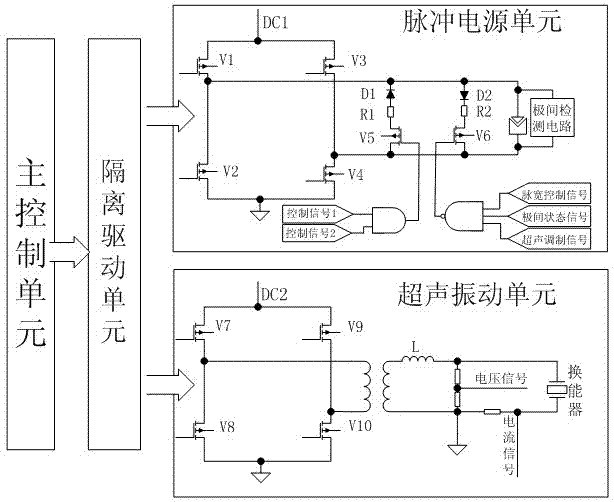

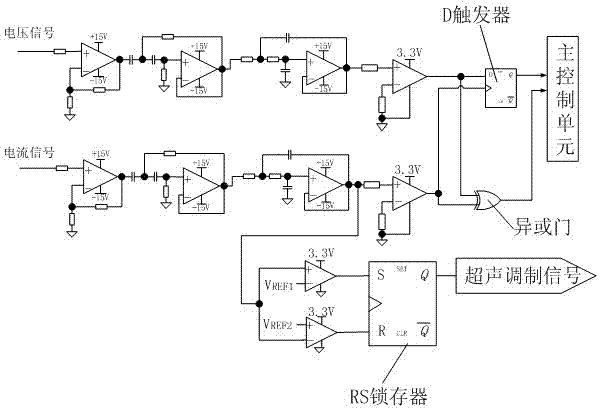

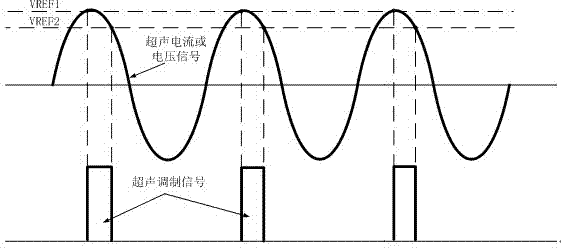

[0033] The structure diagram of the main body of the ultrasonic vibration modulation bidirectional narrow pulse width micro-energy pulse power supply of the present invention is as attachedfigure 1 shown. The main part of the pulse power supply of the present invention includes a pulse power supply and an ultrasonic vibration system. The ultrasonic vibration system drives the tool electrode or the workpiece to perform ultrasonic vibration. The frequency of tool electrode or workpiece ultrasonic vibration is the same as the frequency of pulse power chopping, which is controlled by the same set of signals output by the main control unit, which provides a premise for the organic combination of ultrasonic vibration and pulse discharge for EDM.

[0034] The working principle of the pulse power supply of the present invention:

[0035] (1) In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com