Tool and method for machining shaft head hole of machine frame

A processing method and the technology of the shaft head hole, which is applied in the field of metal cutting tools and processing, and the tool field of processing the shaft head hole of the frame, to reduce the risk of high-altitude operations, the processing technology is simple, and the effect of ensuring the processing accuracy is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

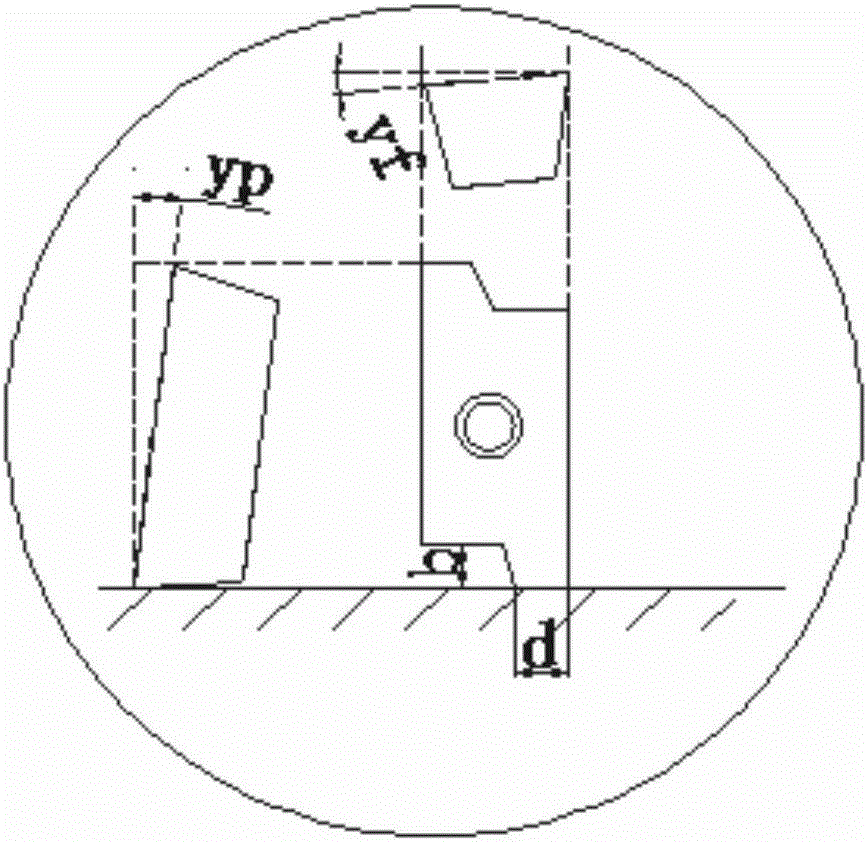

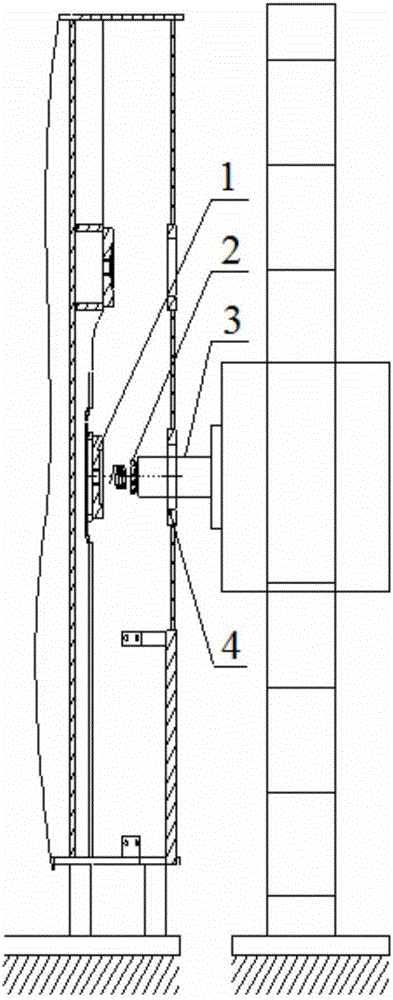

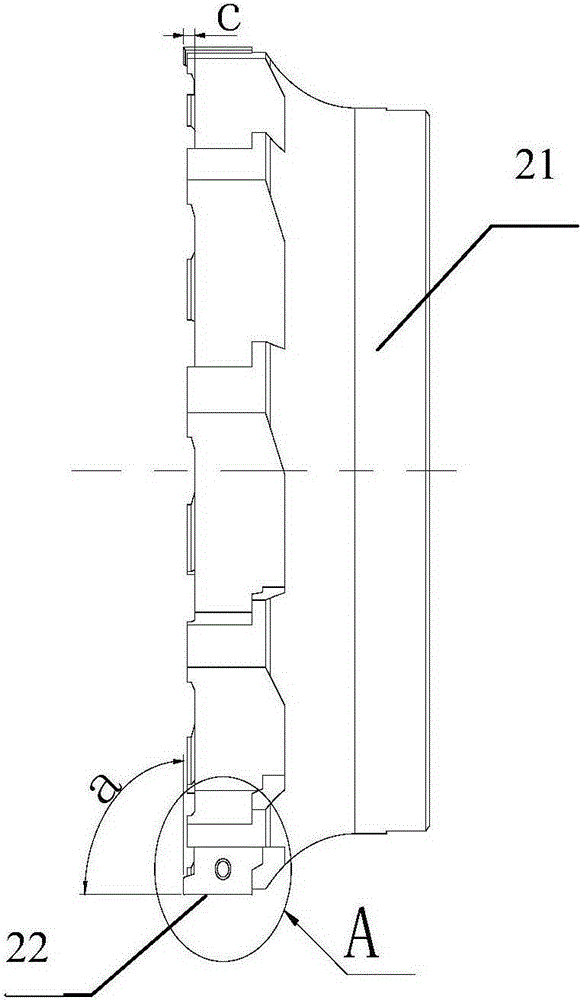

[0027] Please refer to figure 1 , figure 2 and image 3 , the tool 2 for processing the shaft head hole of the frame according to the present invention is installed on the boring bar 3 of the main shaft of the CNC horizontal floor boring and milling machine (see figure 1 ), the cutter 2 includes a cutter body 21 and a number of blades 22 fixed on the periphery of the cutter body 21 and evenly distributed (see figure 2 ), the tool 2 can realize roughing and finishing in the ways of square shoulder milling, ramping milling, helical interpolation milling, linear interpolation milling, circular interpolation milling and conical helical interpolation milling without changing the blade 22 . The shoulder milling refers to the milling method in which the rotary tool feeds the cutting motion synchronously by the radial and axial cutting edges. The shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com