PCD cutter for machining composite material

A technology of composite materials and cutting tools, which is applied in the direction of cutting tools for lathes, manufacturing tools, metal processing equipment, etc., can solve the problems of poor processing efficiency, many burrs on the processing surface, and poor processing quality, so as to improve sharpness and reduce Effect of cutting force and strength guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

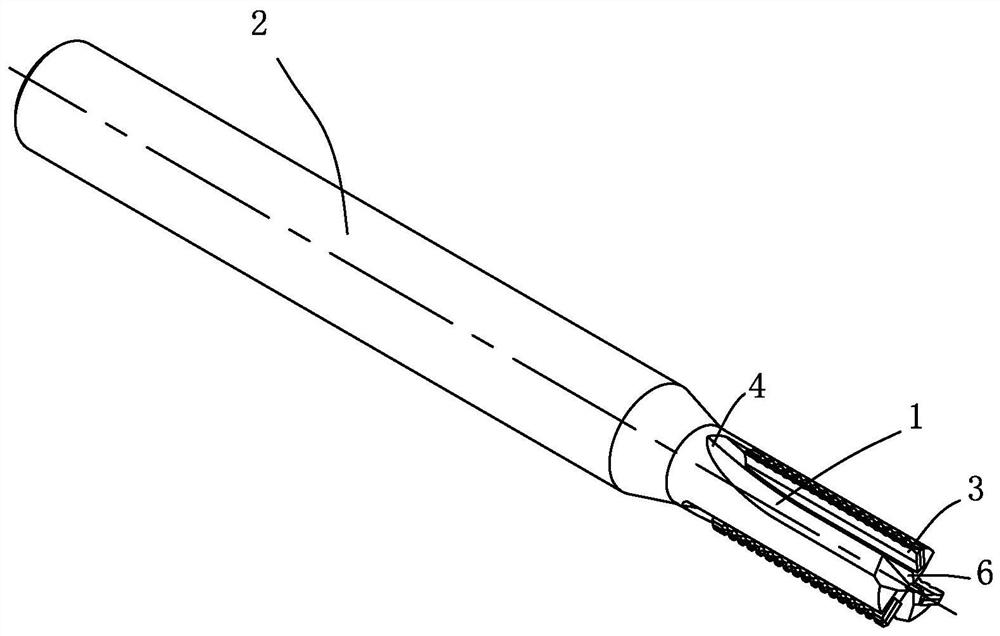

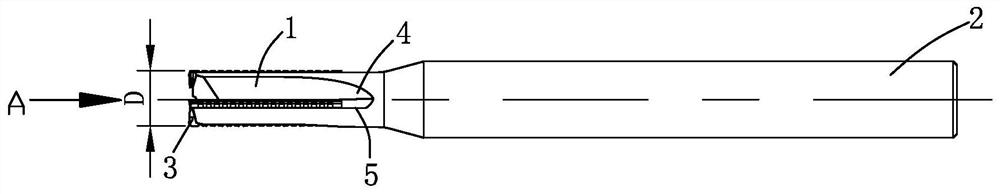

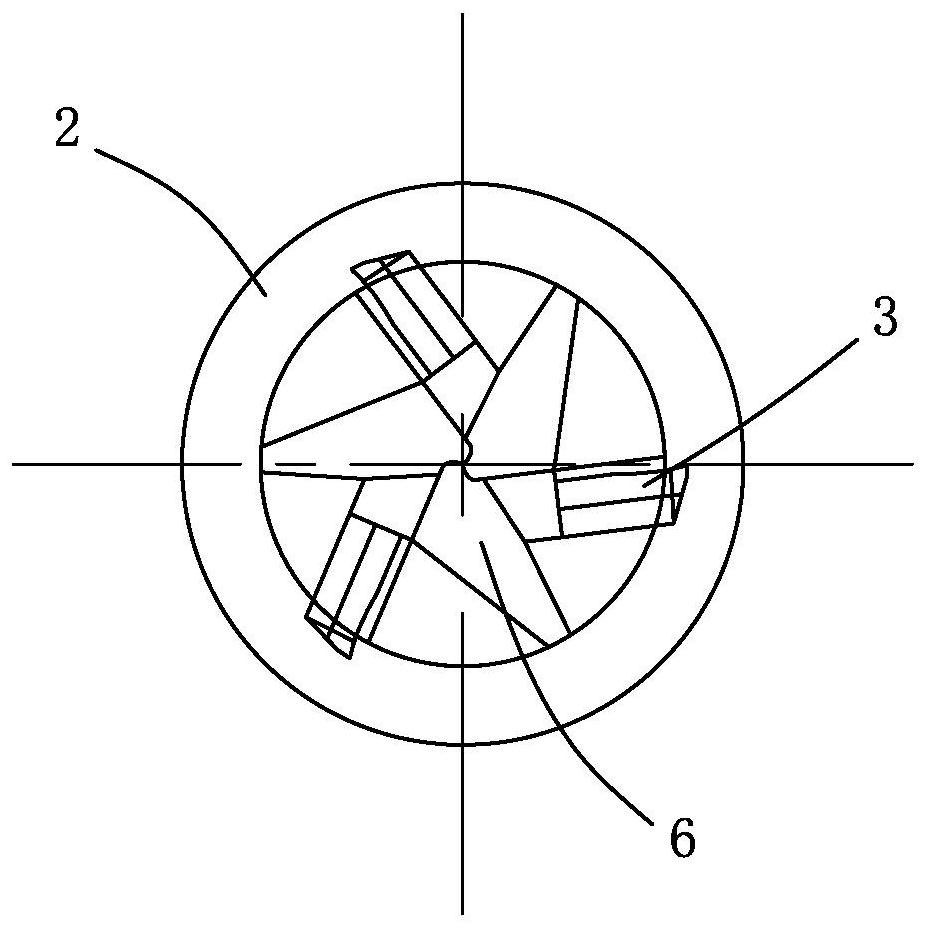

[0030] see Figure 1 to Figure 10 As shown, a PCD cutter of the present invention for processing composite materials includes a cutter body and a welding piece 3; ; In the cutting part 1, at least one chip removal groove 4 is provided with at least one chip removal groove 4 extending linearly from the free end (set as the bottom end) of the cutting part 1 to the handle 2 direction, and the chip removal groove 4 of the present embodiment is three One, the surface facing the cutting rotation direction of the three chip flutes 4 is set as the first welding surface 5, and the first welding surface 5 of each chip flute 4 is welded to fix a welding piece 3, the welding piece 3 of the present embodiment There are three in total, and the second welding surface 18 of each welding piece 3 is welded and fixed with the first welding surface 5 of the corresponding chip flute 4 of the cutter body; the surface of the welding piece 3 facing the cutting rotation direction is set For the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com