Processing method for diesel oil engine piston rod deep hole

A processing method and piston rod technology, applied in the direction of pistons, metal processing equipment, mechanical equipment, etc., can solve the problems of low processing efficiency, low cutting parameters, and affecting high-precision processing, and achieve scientific and reasonable cutting sequence and scientific and reasonable arrangement , Guarantee the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, but the protection scope of the present invention cannot be limited thereby.

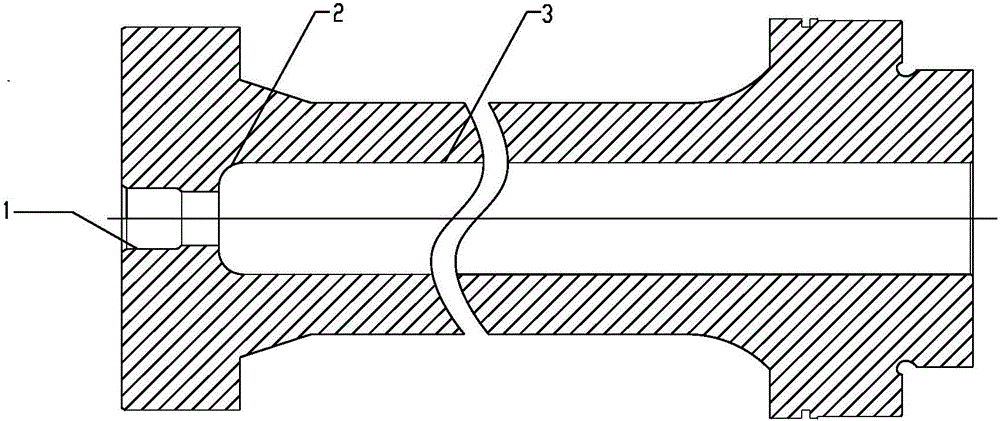

[0031] Taking the processing of a diesel engine piston rod with an outer diameter of Φ310 and a length of 4695mm as an example, the diameter of the processed deep hole 2 is Φ150, the length of the deep hole 2 is 4549mm, and the radius of the arc 3 at the bottom of the deep hole 2 is R32 , requiring straightness <0.2mm, the specific processing process is as follows:

[0032] In order to obtain the best straightness, the workpiece is rotated, the tool is rotated in the opposite direction, and the feeding motion is used during processing.

[0033] Step 1, rough drill the inner hole

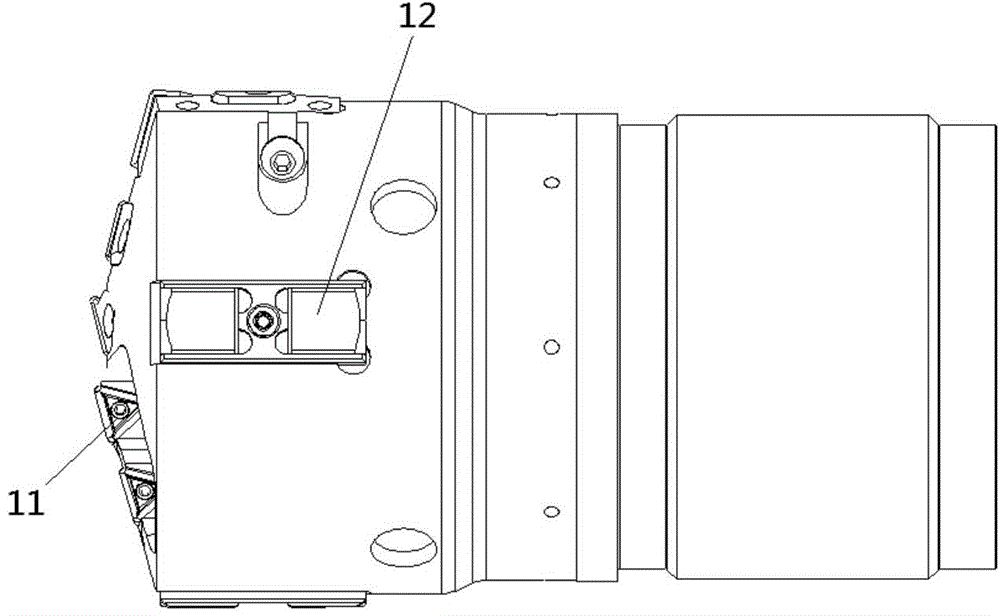

[0034] The tool uses an ejector drill, see image 3 , the ejector d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com