External circle riser removing device for hub

A hub and riser technology, which is applied in the field of robot handling and cutting, can solve the problems of danger and waste of labor, and achieve the effect of automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

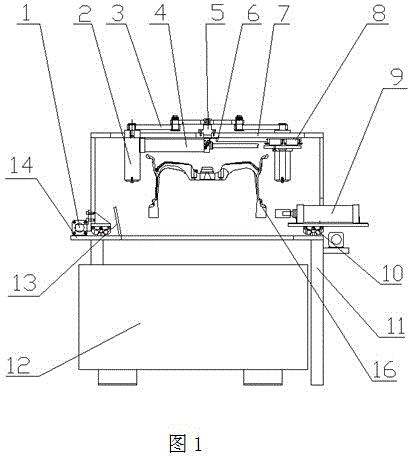

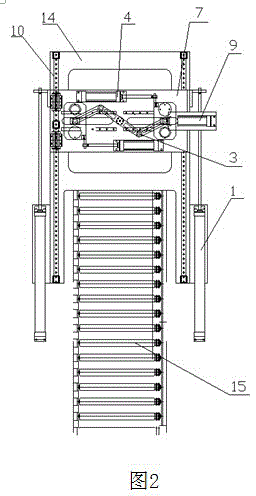

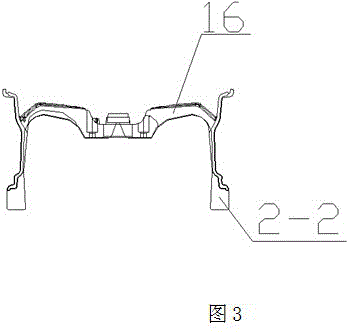

[0013] Depend on figure 1 It is known that a wheel hub outer circle riser removal device is composed of a longitudinal moving cylinder 1, a jaw 2, a synchronous link 3, a clamping cylinder 4, a link bracket 5, a jaw guide rail 6, a jaw support seat 7, a clamp Claw guide block 8, percussion cylinder 9, longitudinal guide rail 10, machine base 11, riser ring collection frame 12, riser ring baffle plate 13, worktable 14, and discharge raceway 15. The jaws 2 are mounted on the jaw guide block 8 and guided by the jaw guide rail 6. The left and right jaws 2 are each equipped with a clamping cylinder 4, and the synchronous link 3 is installed on the link bracket 5 to synchronize The connecting rod 3 is connected with the left and right jaws 2, and the clamping parts such as the jaws 2 and the clamping cylinder 4 are all installed on the jaw support base 7, and the jaw support base 7 is installed on the longitudinal guide rail 10, and the longitudinal movement cylinder 1 Press on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com