A Composite Machining Method for Gas Film Hole of Guide Vane

A guide vane and composite machining technology, which is applied in the field of composite machining of air film holes of guide vanes, can solve the problems of affecting the safety and reliability of the vane, low absorption rate, difficult processing, etc., so as to improve the aperture qualification rate, processing efficiency, and oxidation resistance. and high temperature resistance, avoiding the effect of poor hole forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

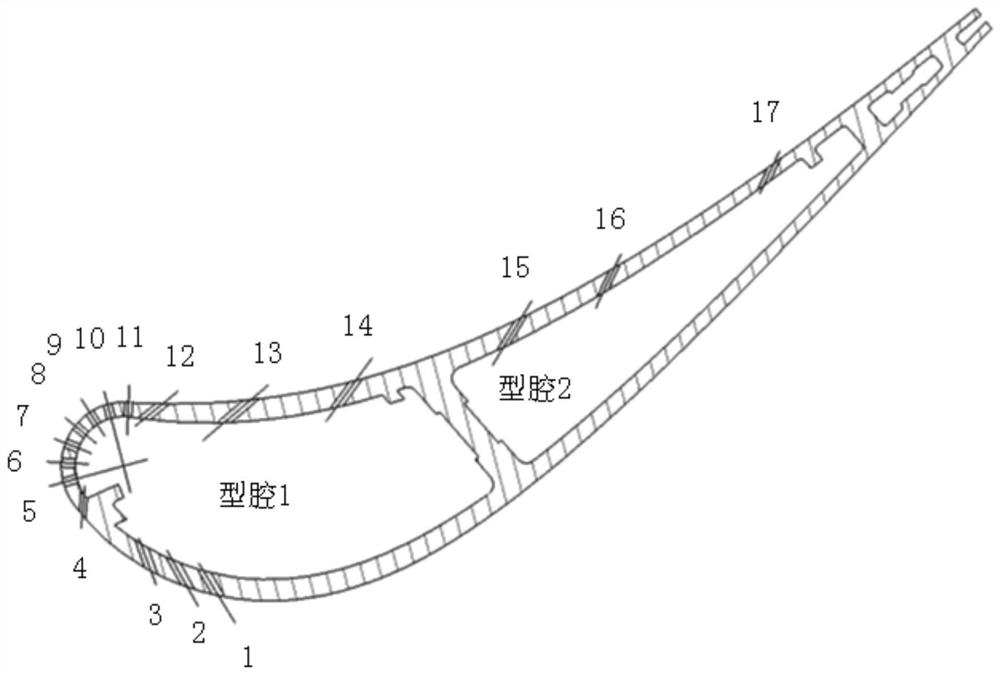

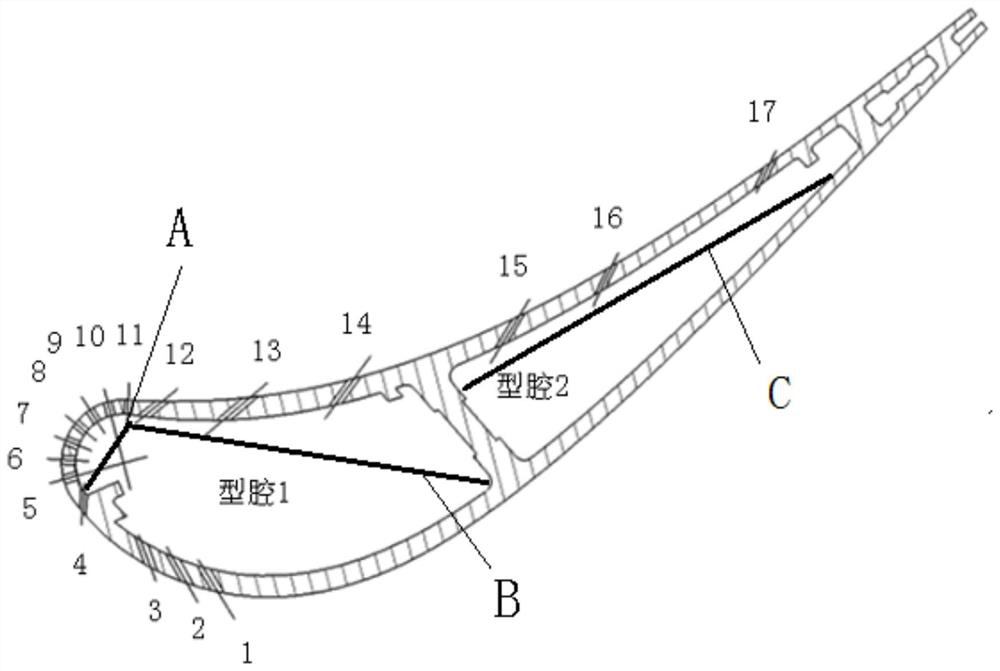

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] The present invention is aimed at Ni 3 Al-based IC10 directionally solidified high-temperature alloy material, blade body and upper and lower edge plates are integrally cast without allowance, new material and new structure aero-engine high-pressure turbine guide vane, and a method for machining gas film holes by laser-electric spark composite processing is provided. Specifically, it can be achieved through the following measures:

[0031] Apply anti-splash agent: It has been verified by the process that the hexagonal boron nitride water-based coating is suitable as an anti-splash agent for laser processing air film holes, and the material has no effect on the part matrix material during processing. Hexagonal boron nitride and graphite are isoelectronics. It has a layered structure similar to graphite, and has good lubricity, electrical insulation, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com