Processing method of special electric power fitting taper sleeve taper hole for carbon fibre compound core wires and special device thereof

A tapered hole processing method and technology of electric fittings, which are applied in the field of electric power transmission, can solve the problems of short tool life, high production cost, and high scrap rate, and achieve advantages in cutting and chip removal, meeting shape tolerances, and small contact surfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

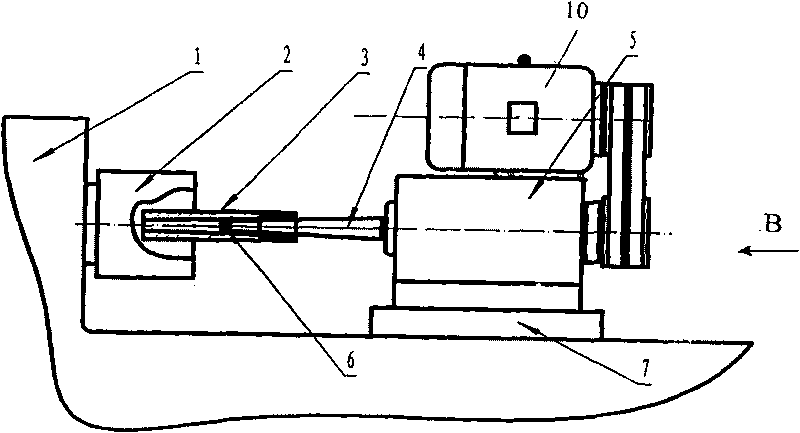

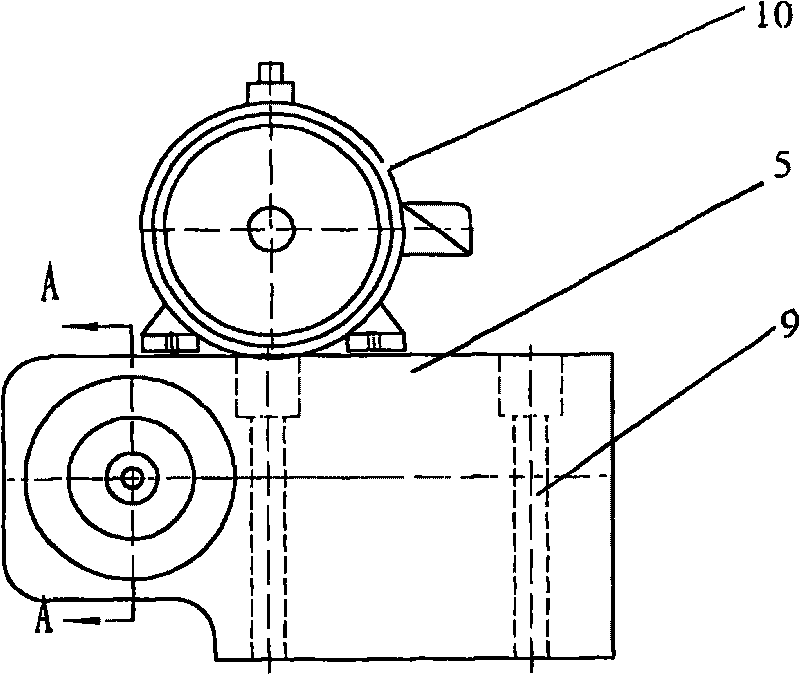

[0022] Such as figure 1 , 2 , Shown in 3, the special equipment of the present invention includes the chuck 2 and the middle pallet 7 of the CNC lathe, and also includes the cutter 4 and the tooling that drives the cutter 4 to rotate. The cutter head of the cutter 4 is equally provided with 4 cutting edges (not shown). The tooling is composed of a rotating shaft 8 and a housing 5, the rotating shaft 8 is movably connected to the housing 5 through bearings, and the housing 5 is fixedly connected to the middle support plate 7 through bolts 9.

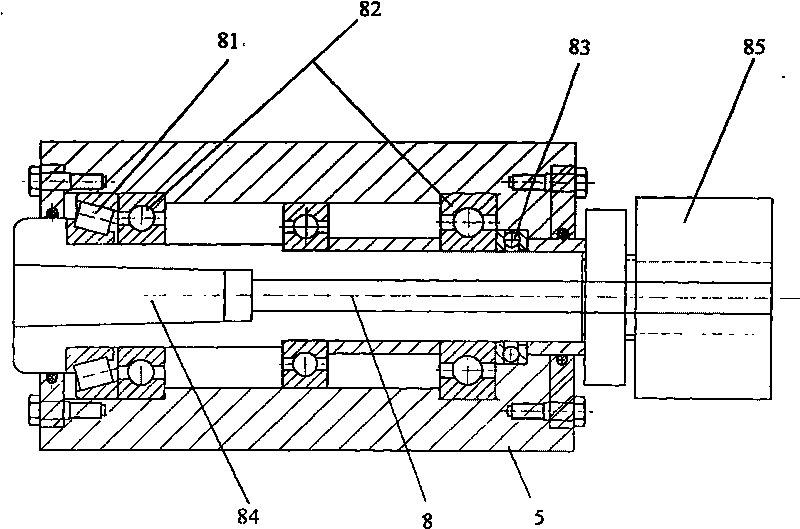

[0023] Such as image 3 As shown, the end of the rotating shaft 8 facing the chuck 2 is provided with a taper hole 84 connected to the cutter 4, the connecting end of the cutter 4 matches it, and the connecting end of the cutter 4 is inserted into the taper hole 84 for fixed connection. The other end of the rotating shaft 8 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com