A high-efficiency die-cutting machine

A die-cutting machine and high-efficiency technology, applied in metal processing and other directions, can solve the problems of affecting the accuracy of the finished product, unable to extend the length horizontally, and the diameter of the cutting die occupying a certain space, so as to avoid the effect of the horizontal diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] as attached figure 1 to attach Figure 5 Shown:

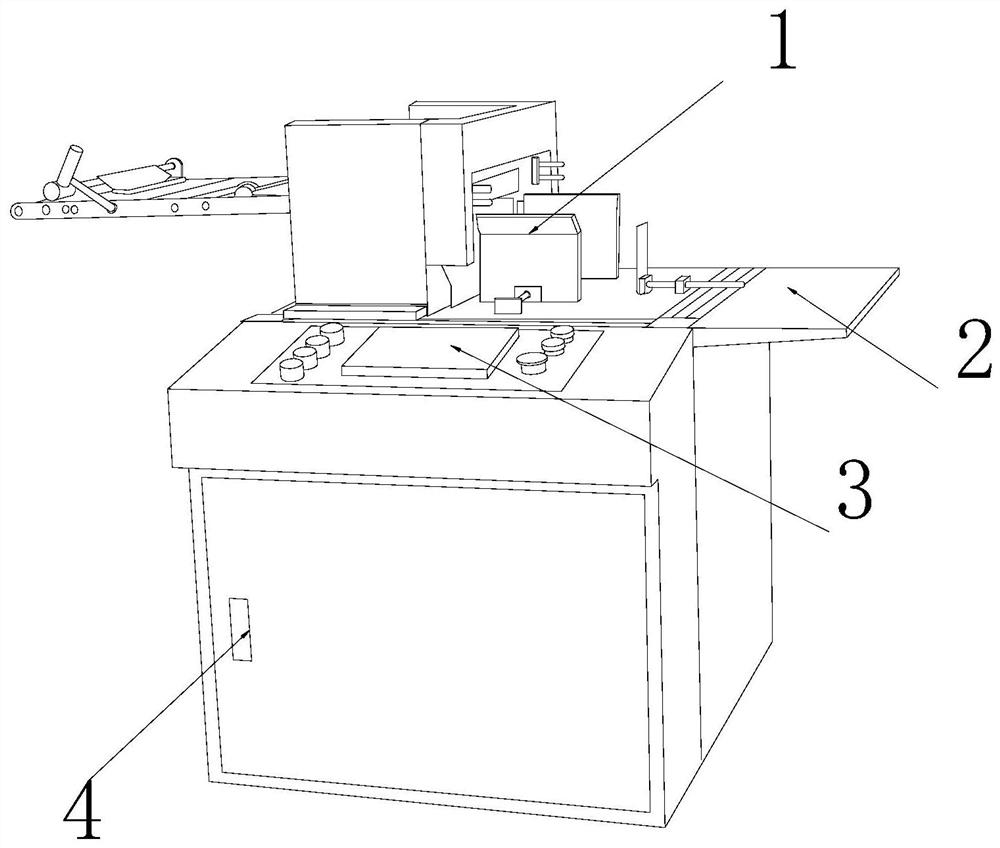

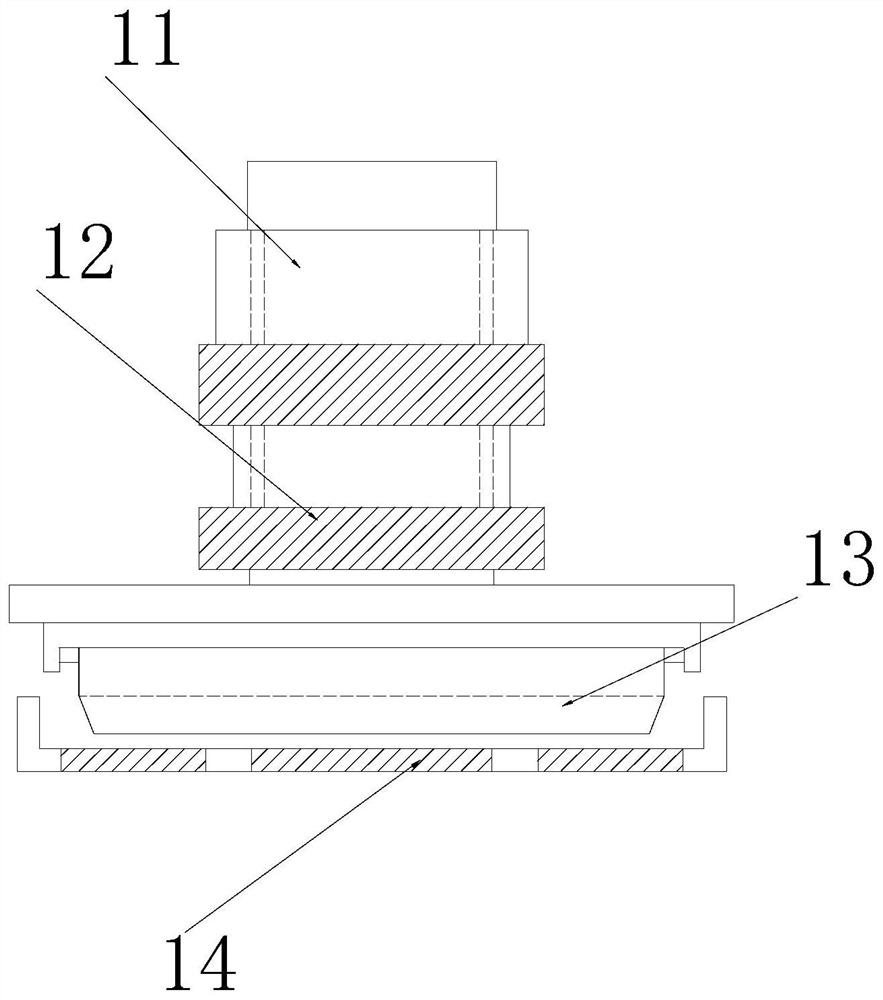

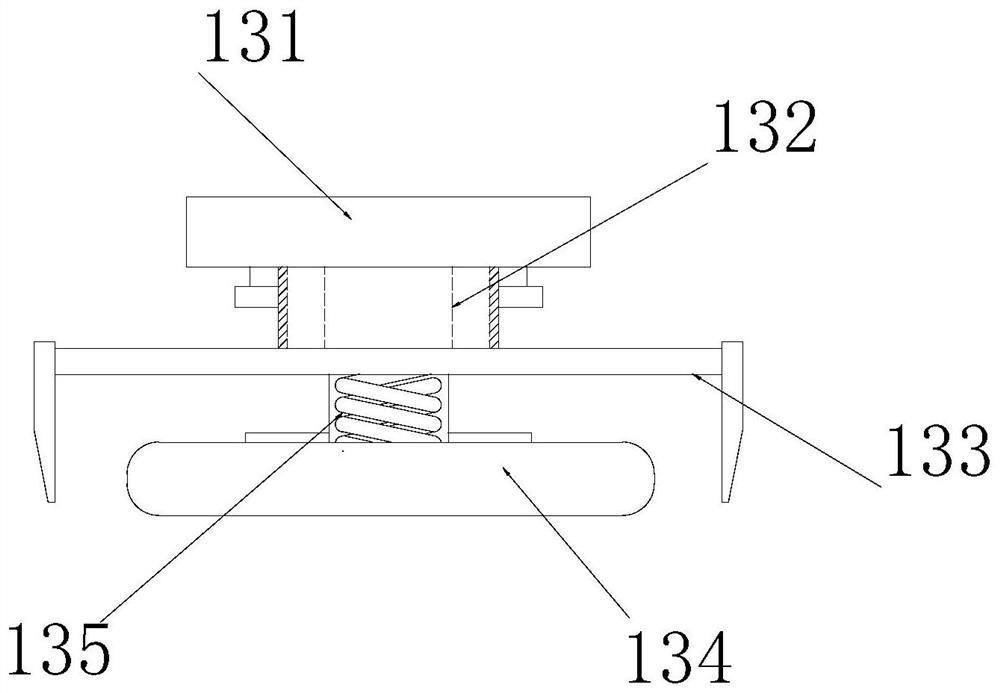

[0026] The invention provides a high-efficiency die-cutting machine, the structure of which includes a shearing device 1, a working platform 2, an operating platform 3, and an equipment box 4. The shearing device 1 is embedded and installed directly above the working platform 2. The working The platform 2 is connected to the outer surface of the upper end of the equipment box 4 by electric welding, and the operating platform 3 is inlaid and installed directly above the equipment box 4; the shearing equipment 1 includes a hydraulic rod 11, a fixed block 12, a mold mechanism 13, a fixing device 14. The lower end surface of the hydraulic rod 11 is embedded and connected with the fixed block 12, and the fixed block 12 is embedded with a mold mechanism 13. The mold mechanism 13 is located directly above the fixing device 14 and the surfaces are in contact. The fixing device 14 embeddings are installed on the upper surface o...

Embodiment 2

[0033] as attached Figure 6 to attach Figure 7As shown: the fixing device 14 includes a fixing seat 141, a rubber layer 142, a half-arc fixing block 143, and a fixing mechanism 144. The fixing seat 141 is symmetrically installed on the left and right sides of the fixing device 14, and the rubber layer 142 is inlaid Fitted and installed on the inner end surface of the half-arc fixed block 143, the half-arc fixed block 143 is connected and installed on the upper surface of the fixed seat 141 through a fixing mechanism 144, and the fixed mechanism 144 is symmetrically installed on the left and right sides of the lower end of the half-arc fixed block 143 On both sides, there are four sets of semi-arc fixing blocks 143, which can form a ring shape, and can effectively share the thrust and vibration caused by shearing during clamping.

[0034] Wherein, the fixing mechanism 144 includes a third embedding groove 4a1, an elastic cord 4f1, a second spring 4c1, and a second fixing blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com