Deep hole drilling device

A technology of drilling depth and bit, which is applied in the direction of boring/drilling, drilling/drilling equipment, drilling repair, etc. It can solve the problems of insufficient cooling and chip removal when drilling deep holes, and achieve sufficient cooling and removal. The effect of crumbs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0012] This embodiment is illustrated by taking the deep hole drilling device combined with a boring machine as an example. It should be understood that the deep hole drilling device of the present invention can be used in combination with a power head, a feeding device, etc., and is not limited thereto.

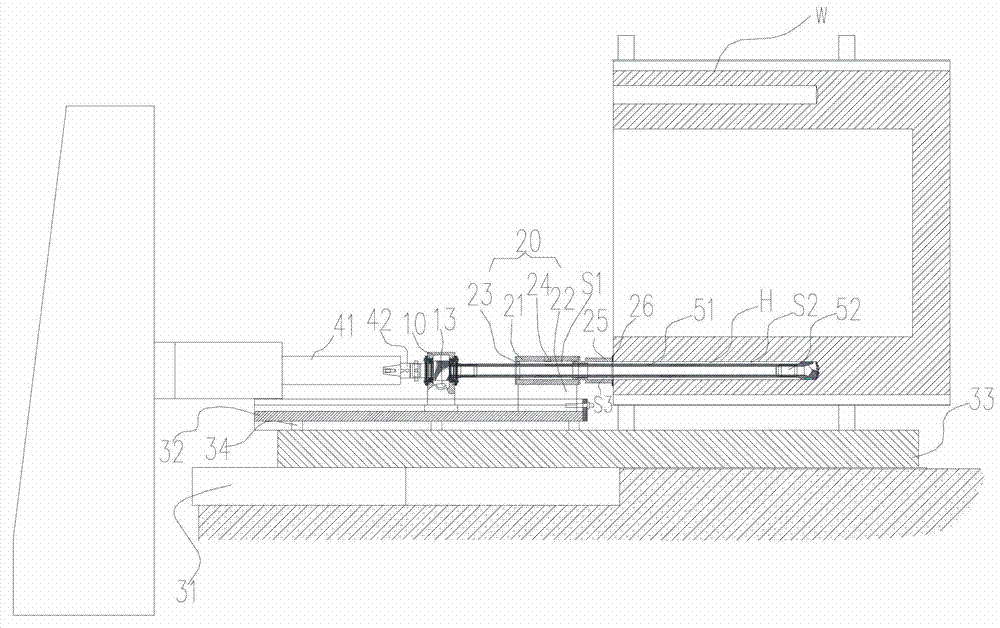

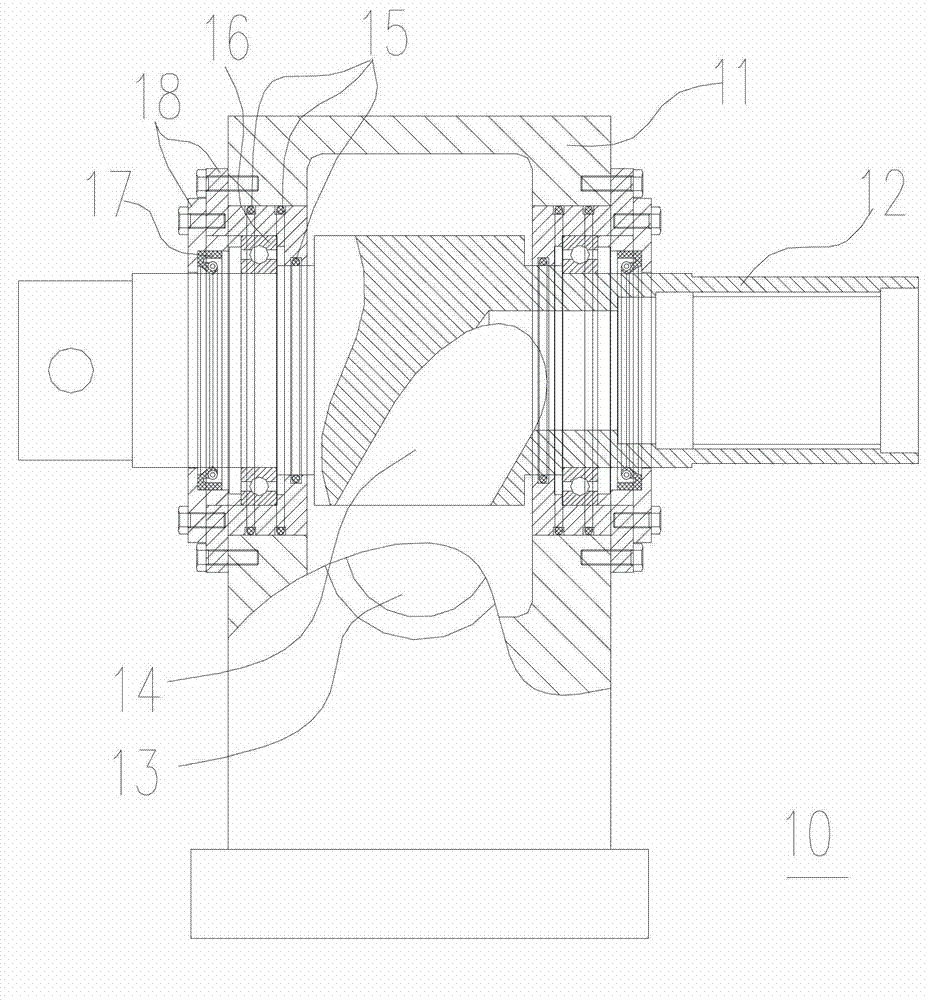

[0013] like figure 1 As shown, the deep hole drilling device includes a chip conveyor 10, an oil feeder 20 and a drilling part. The chip conveyor 10 and the oil feeder 20 are slidably arranged on the guide ram 32 on the worktable 31 . An additional workbench 33, an adjustment pad 34, etc. can also be added between the workbench 31 and the guide ram 32 to mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com