A kind of peripheral forming tool holder type milling assembly

A forming knife and frame technology, which is applied in the direction of milling cutting blades, milling cutters, milling machine equipment, etc., can solve the problems of disassembly and replacement, heavy workload of replacement, complicated detection and debugging work, complex design of forming equipment, etc., and achieve easy handling , Easy blade maintenance, and strong scalability in milling trajectory processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

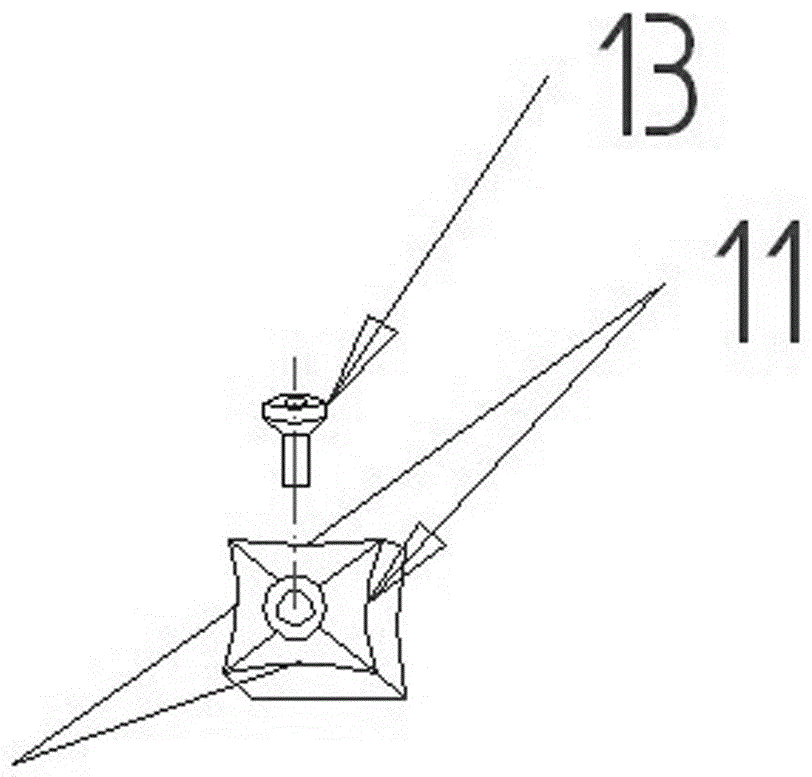

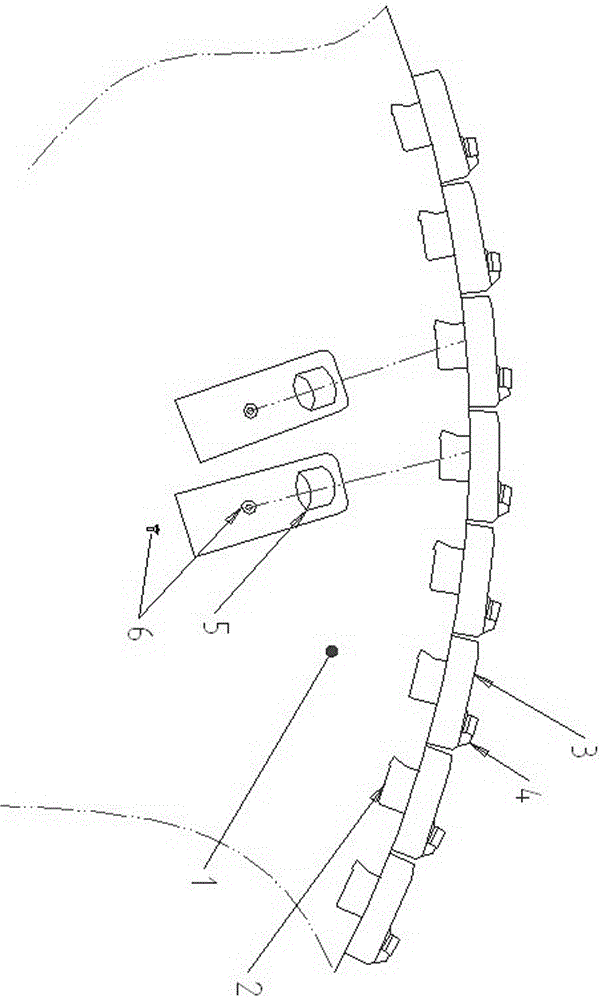

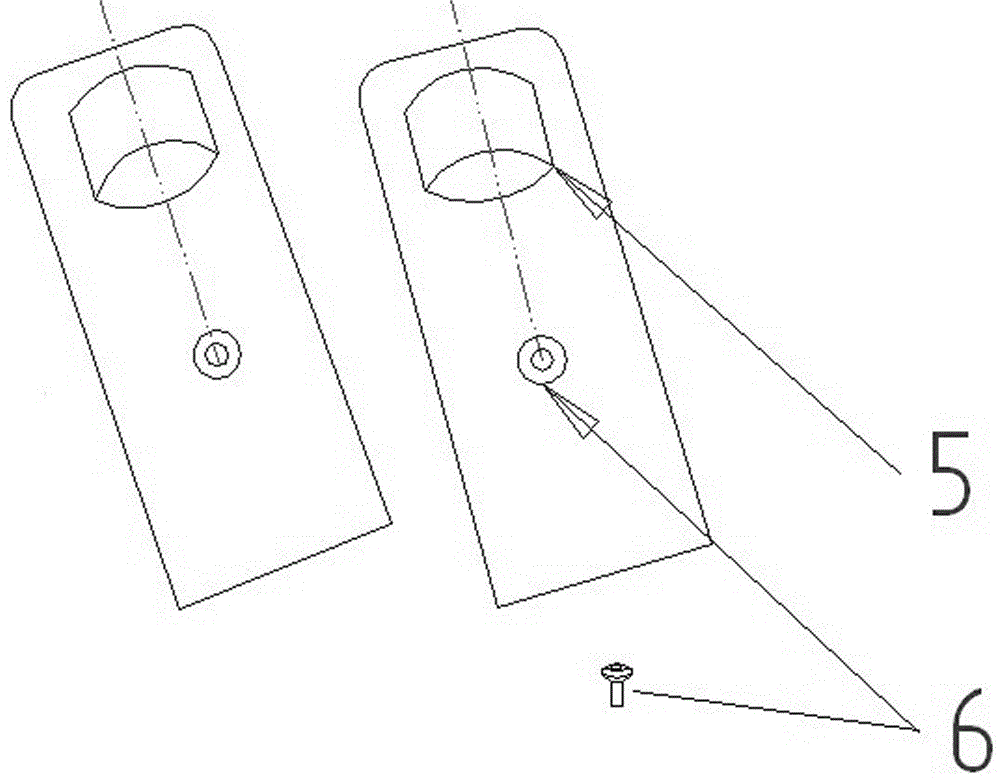

[0067] Example 1: figure 1 It is a schematic structural diagram of a preferred embodiment in which the turret-type milling assembly of the circumferentially-shaped turret-type milling assembly of the present invention cooperates with the circumferentially-shaped turret base body, figure 2 for figure 1 A schematic structural diagram of a preferred embodiment of the turret-type milling assembly of the embodiment shown, image 3 for figure 2 A schematic structural diagram of a preferred embodiment of the blade A of the embodiment shown, Figure 4 for figure 2 A schematic structural diagram of a preferred embodiment of the blade B of the shown embodiment, Figure 5 for figure 1 Schematic diagram of the assembly between the tool holder-type milling assembly and the base body of the circumferentially formed cutter head through bolts and stoppers in the embodiment shown.

[0068] In this embodiment, a circumferentially-shaped turret-type milling assembly includes a circumfer...

Embodiment 2

[0095] Embodiment 2: A circular forming tool holder type milling assembly, the same as Embodiment 1, the difference is: the insert B has four arc cutting edges.

Embodiment 3

[0096] Embodiment 3: A circular forming turret type milling assembly, the same as the first embodiment, the difference is: three rows of cutting inserts are arranged on the turret type milling assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com