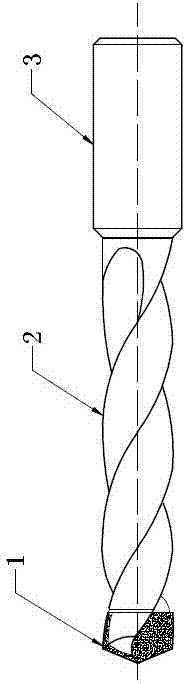

Imbedded carbide drill for steel piece and processing method

A technology of cemented carbide and cemented carbide inserts, which is applied in the direction of twist drills, etc., can solve the problems of rolling chips and breaking chips, and achieve the effects of material cost saving, large economic and social benefits, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The processing method steps of insert type cemented carbide drill bit, comprise,

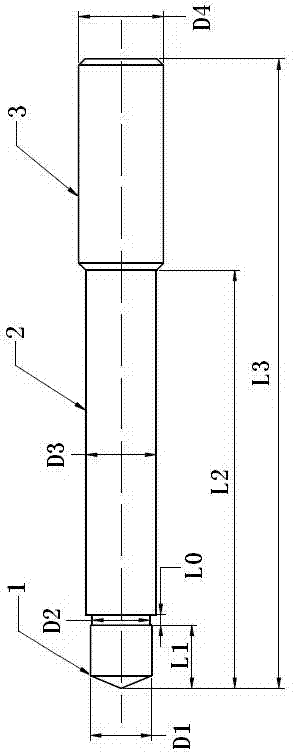

[0034] One, the selection of blade, because drill bit belongs to rough machining tool, so should select strength and impact resistance material when selecting blade material, the present invention determines to select blade material by Co content 10% standard; Determine the proportional relation of blade thickness and drill bit diameter The following table: (unit: mm)

[0035] Specification Φ12 Φ13 Φ14~Φ15 Φ16 Φ17~Φ18 Φ19 Φ20~Φ21 Φ22 Φ23~Φ24 Φ25 Blade Thickness 4mm 4.5mm 5mm 5.5mm 6mm 6.5mm 7mm 7.5mm 8mm 8.5mm

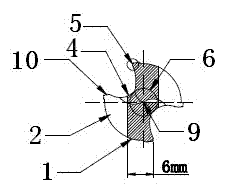

[0036] 2. For the grinding of chip volume and chip breaker of the cutter segment, according to the technical standard for processing steel drill bit chip breaker, use a five-axis tool grinder (model DECKEL S22), set: if the hole depth of the workpiece reaches 3 times The diameter of the drill bit, the edge inclination angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com