Positioning double-section cutter

A technology for positioning cylinders and cutter bodies. It is applied in metal processing and other directions. It can solve the problems of rapid tool wear, excessive burrs, and short service life, and achieve the effects of solving chip removal and heat dissipation problems, increasing chip pockets, and ensuring strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further explain below in conjunction with accompanying drawing:

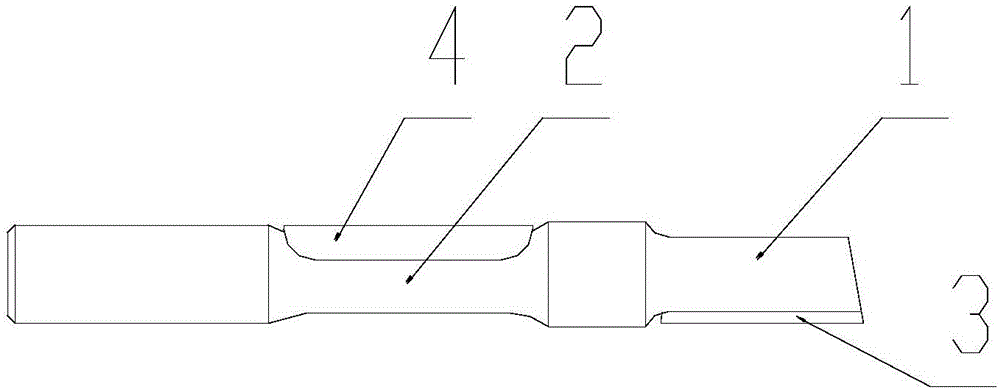

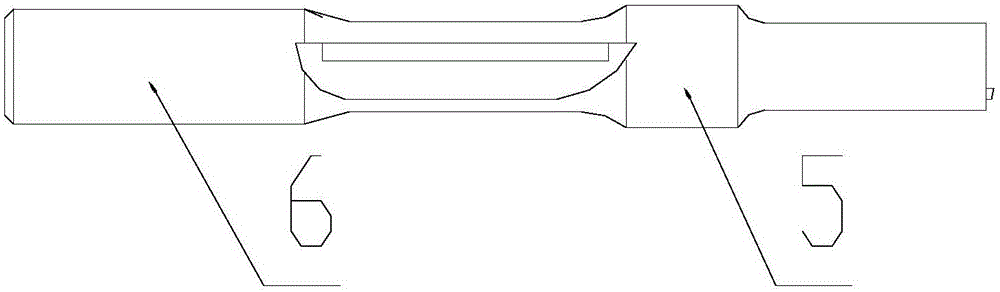

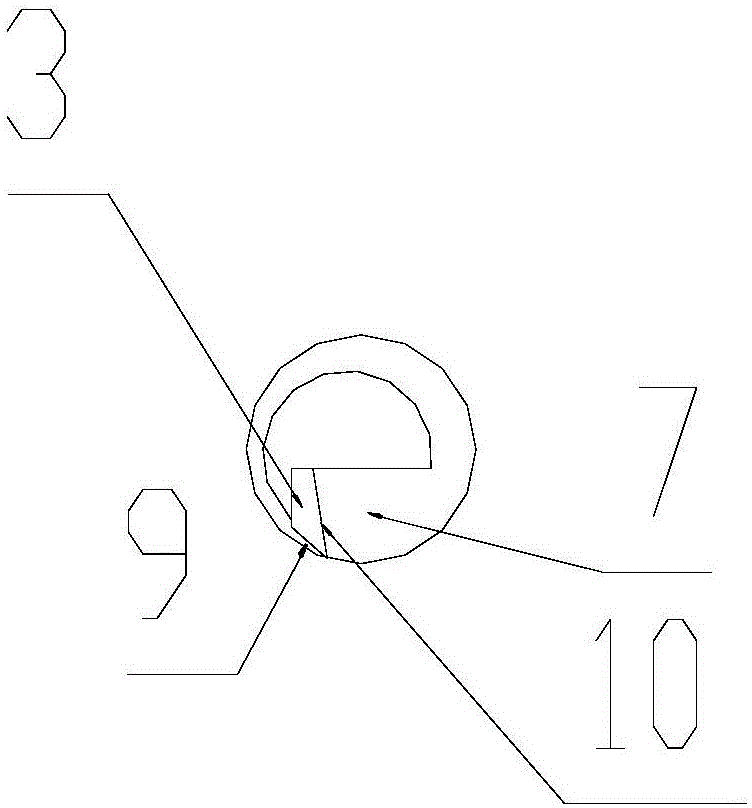

[0015] as attached Figure 1-4 As shown: the present invention includes a cutter body, wherein: the cutter body includes a first base outer cylinder, a positioning cylinder, a second base outer cylinder, and a handle, and the first base outer cylinder is provided with a first cutting blade, so The outer cylinder of the second base is provided with a second cutting blade, the edge direction of the first cutting blade is opposite to that of the second cutting blade, the length of the first outer cylinder of the base is the same as that of the second outer cylinder of the base, and the first cutting blade The same size and shape as the second cutting blade, the diameter of the outer circle of the positioning cylinder is 0.5-0.8mm larger than the cutting circle diameter of the first cutting blade and the second cutting blade, and the clearance angles of the first cutting blade and the second cutting blade are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com