Novel process for processing vertex chamber hole on diesel engine cylinder cover

A vortex chamber and hole processing technology, which is applied in the direction of cylinder head, cylinder, mechanical equipment, etc., can solve the problems of shortened tool wear cycle, poor surface roughness, and high labor intensity of the operator, so as to achieve longer wear cycle and light processing , Improve the effect of equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

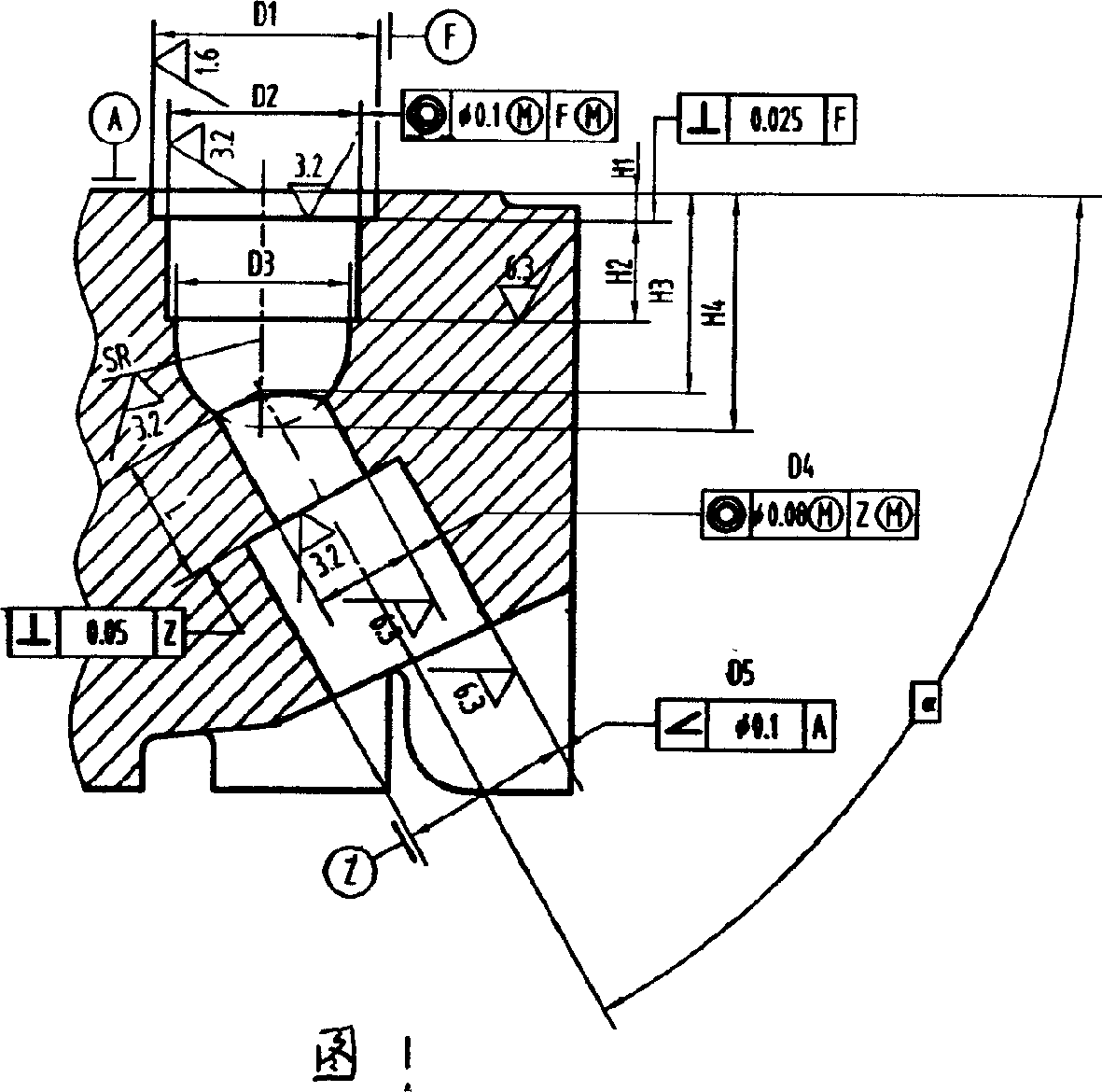

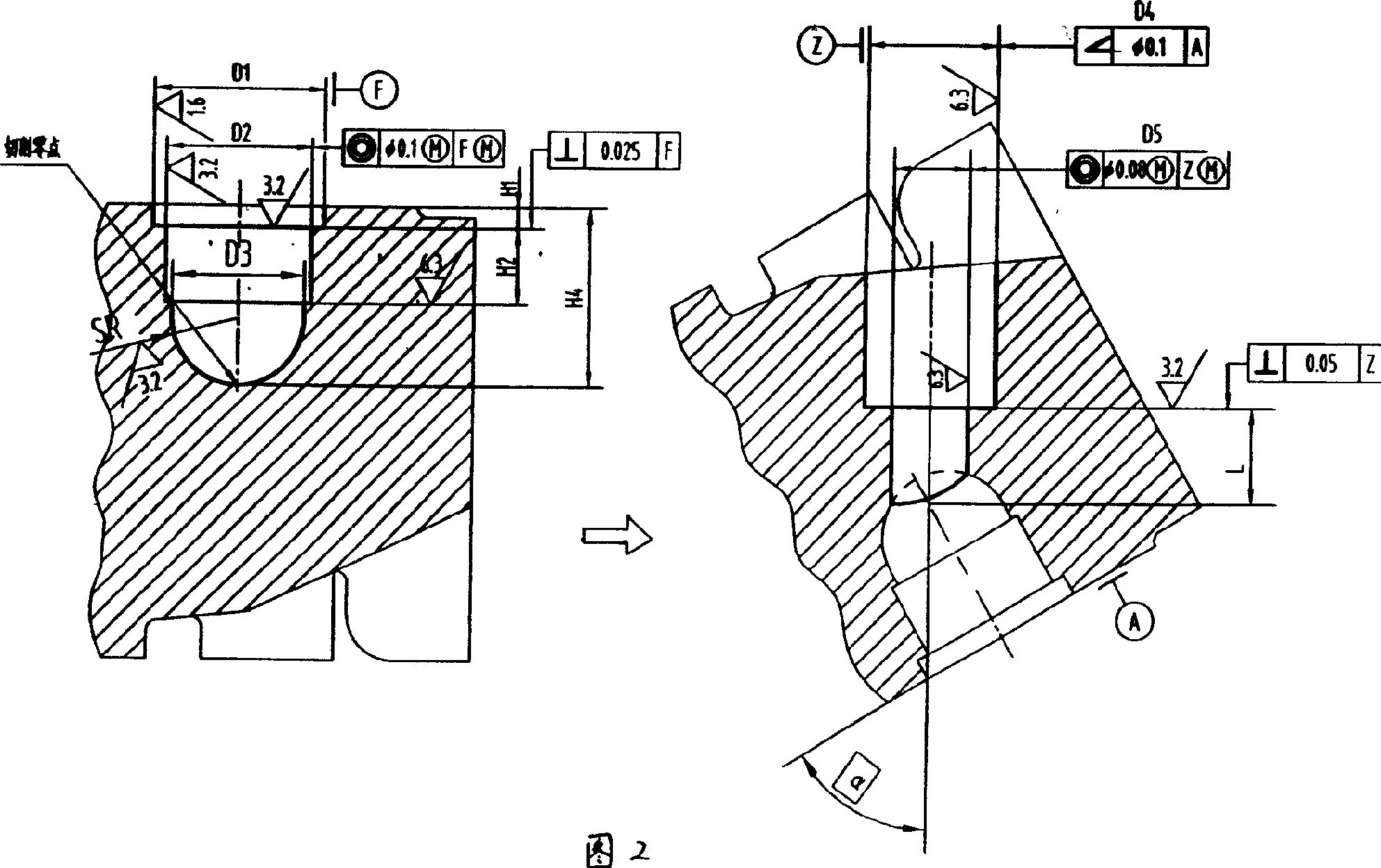

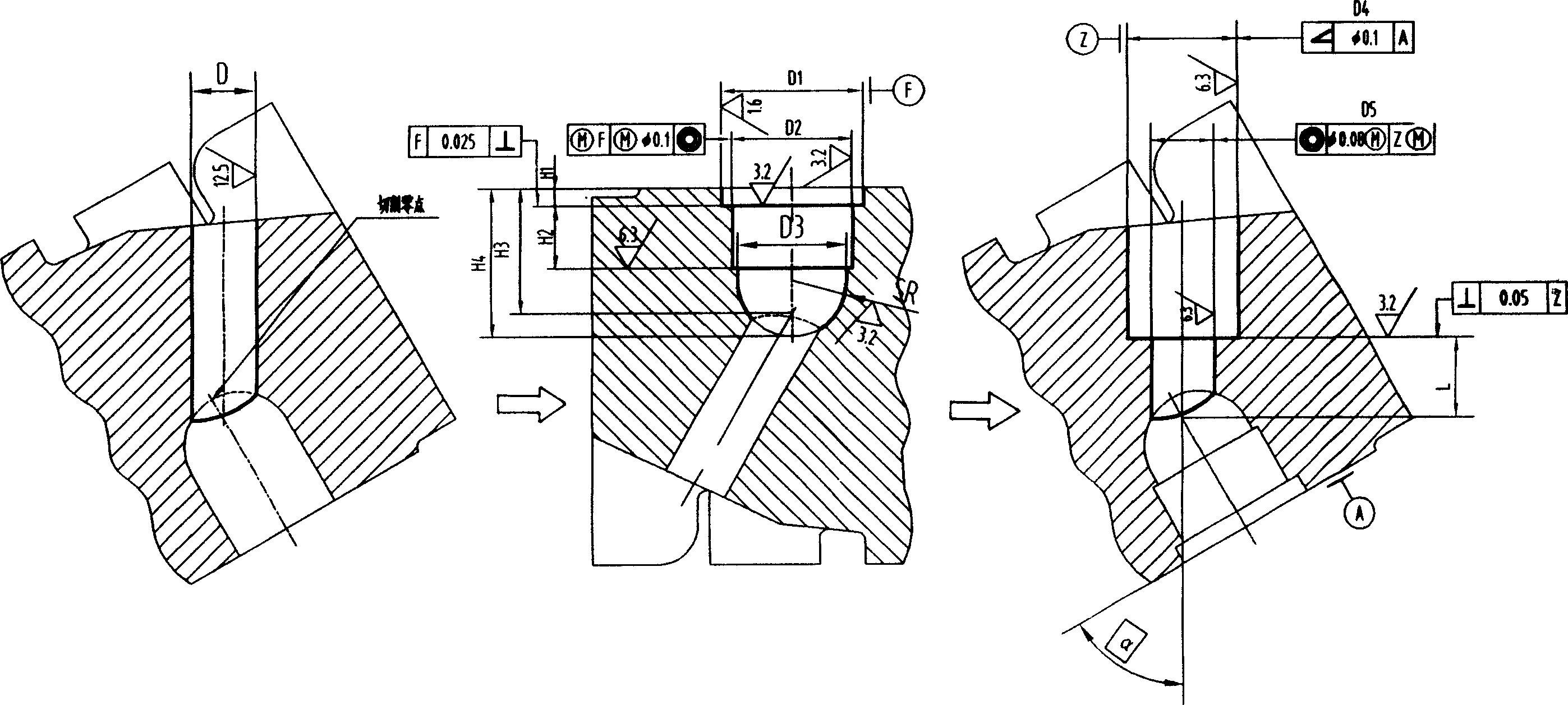

[0013] Referring to Figure 1 and image 3 , the specific processing steps are:

[0014] (1) For cylinder head castings, pre-drill the injector hole D with a twist drill on a small bench drill. The size of the pre-drilled hole should be able to remove the cutting zero point;

[0015] (2) Roughly expand the spherical hole D of the vortex chamber with a forming knife 3 (vortex holes have been reserved on the casting);

[0016] (3) Composite reaming insert hole D with compound reaming knife 1 , Vortex chamber hole D 2 , Vortex chamber spherical hole D 3 ;

[0017] (4) Composite reaming insert hole D with compound reamer 1 , Vortex chamber hole D 2 , Vortex chamber spherical hole D 3 ;

[0018] (5) Composite reaming injector hole D with compound reaming knife 4 、D 5 ;

[0019] (6) Compound reaming injector hole D with compound reamer 4 、D 5 .

[0020] Above steps (2) to (6) are carried out on the vertical drilling machine. Finally, finishing the injector hole can ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com