Method and system of micro three-dimensional structure by micro-nano electric discharge machining

A technology of electrical discharge machining and three-dimensional structure, which is applied in the direction of microstructure technology, microstructure devices, nanostructure manufacturing, etc., can solve the problems of difficult chip removal and the reduction of microstructure size, etc., and achieve the goal of solving chip removal problems and enriching technical methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

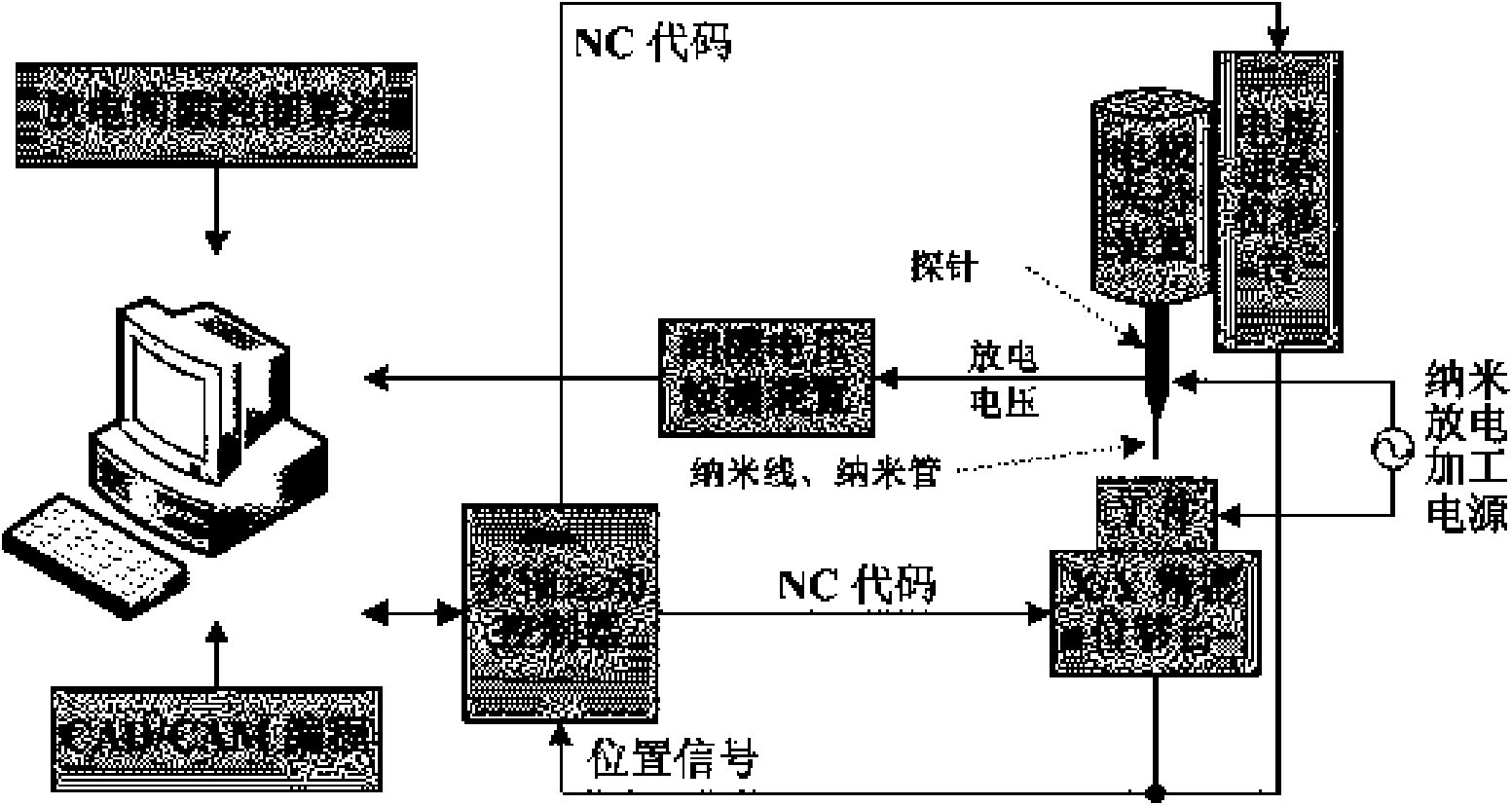

[0020] The present invention uses nanowires and nanotubes as electrodes for nano-discharge processing to process micron and nanoscale complex three-dimensional structures, and the nanowires and nanotubes used as electrodes need to meet the following conditions:

[0021] Nanowires and nanotubes need to have good electrical and thermal conductivity and mechanical properties. For example, the melting point of carbon nanotubes is the highest among known materials at present, and it is not easy to be corroded by heat in electric discharge machining; secondly, the molecular structure of carbon nanotubes is stable and has high thermal stability; thirdly, the structure of carbon nanotubes It has the same sheet structure as graphite, so it has good electrical properties. At the same time, carbon nanotubes have high heat exchange along the tube axis, which is good for heat dissipation during processing; finally, carbon nanotubes have good mechanical properties, and their tensile strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com