Vertical loading and clamping five-edge cutoff blade for rough machining

A blade and included angle technology, which is applied to lathe tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult chip removal in the cutting area, blade wear, poor rigidity of the cutter head, etc., and achieve straightness and surface finish Improve and solve the problem of chip removal and improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

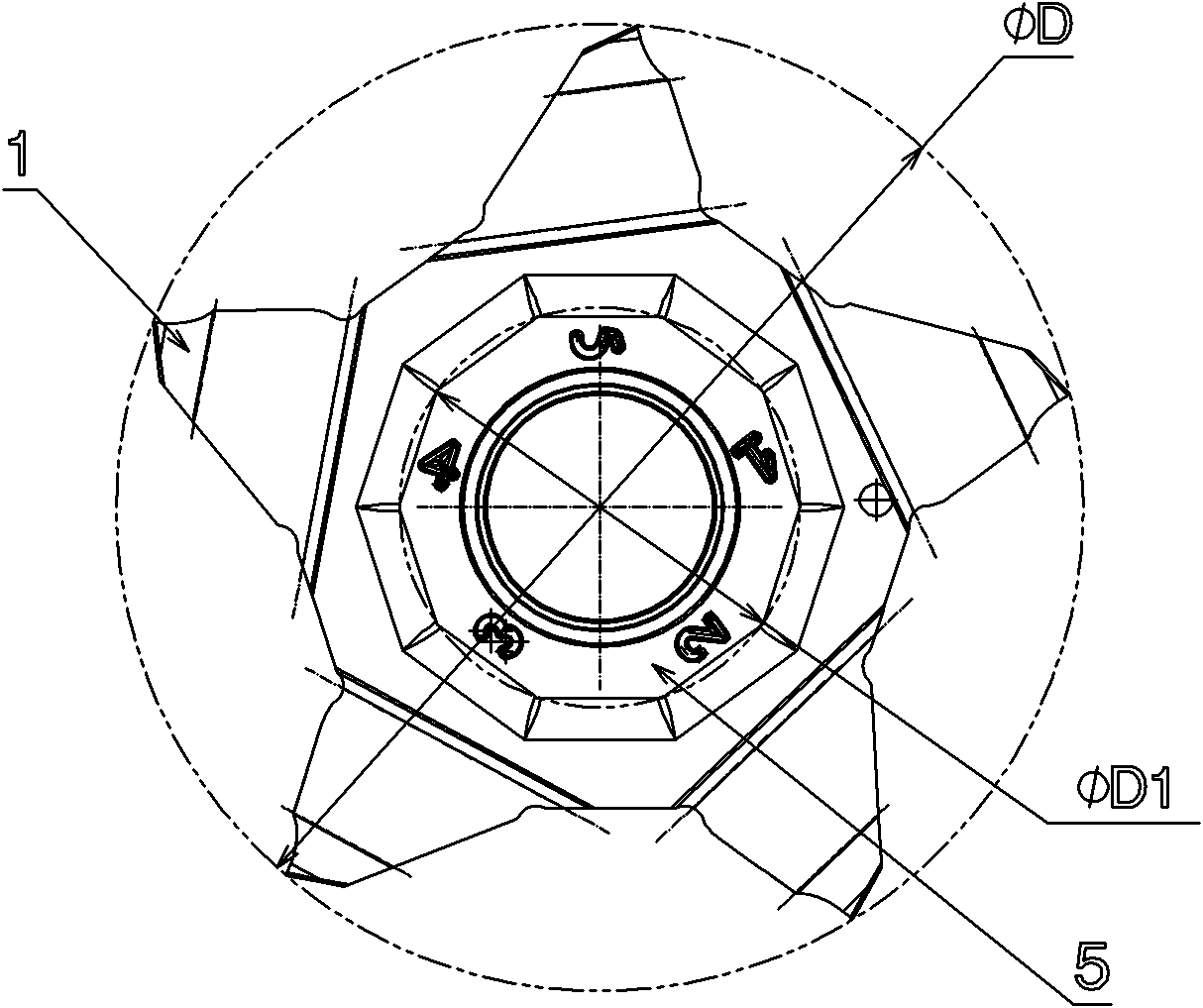

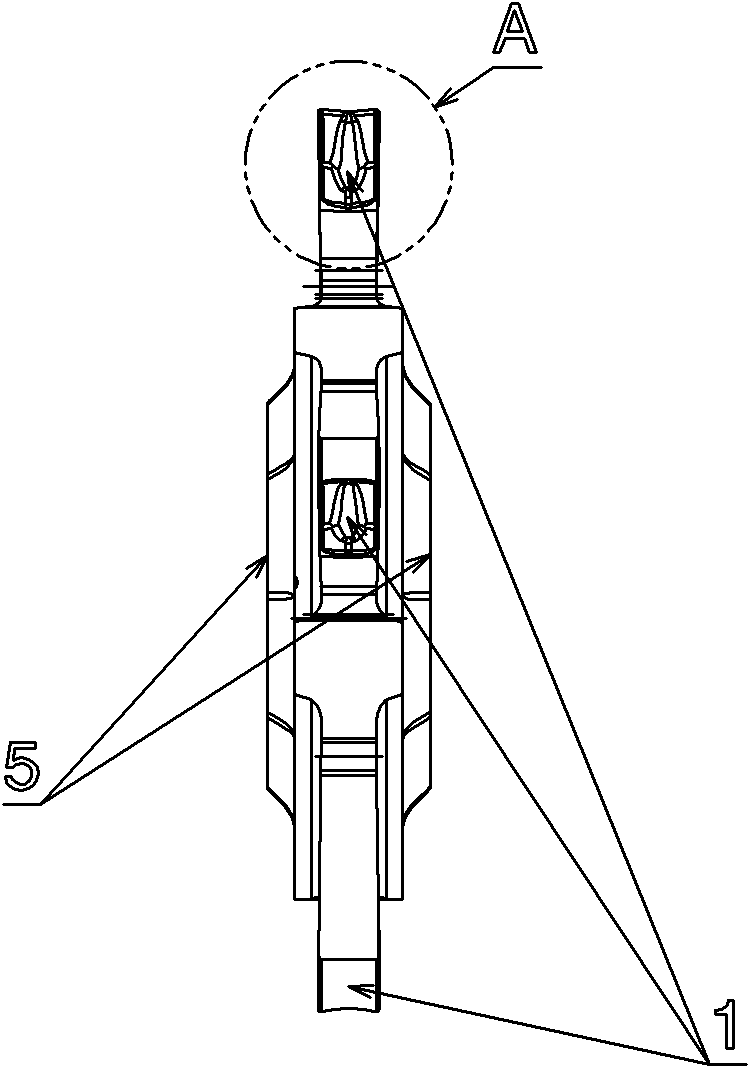

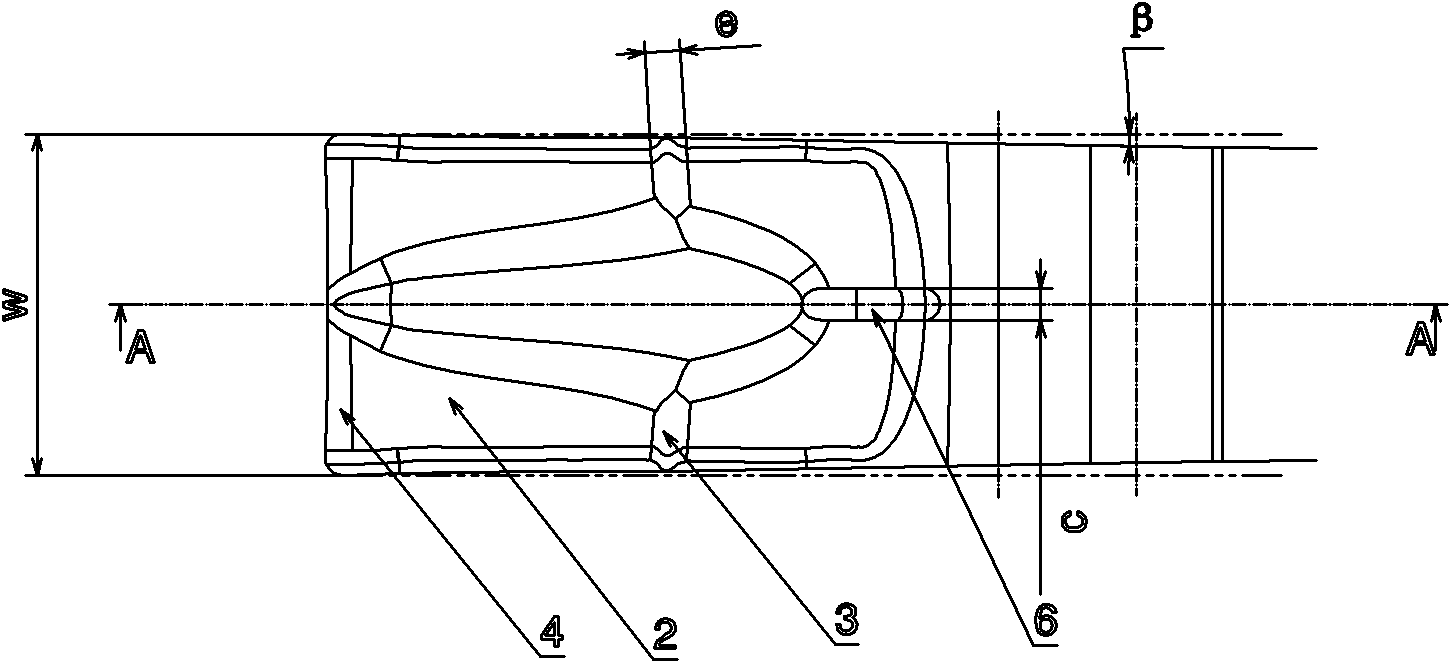

[0022] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-4 Shown is a vertically mounted machine clip five-edged cutting blade for rough machining, the shape of the blade is a convex pentagon, and each corner of the convex pentagon has a cutting edge 1 on the vertical surface, and each cutting edge 1 has a fixed Width w, the cutting edge 1 gradually becomes thinner at a fixed angle β along the direction from the tip to the support surface; the upper and lower clamping surfaces 5 of the blade are octagonal, and the diameter D1 of its circumscribed circle is 8-15mm, and the upper clamping surface 5 Marked with the serial number of cutting edge 1 from 1 to 5; each cutting edge 1 is arranged with chamfer 4, chip flute 2, and chip breaker, and the lower edge of the tool tip forms an angle α with the vertical direction of cutting edge 1, The chamfer 4 is set at the transition of the flute 2 and forms an included a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com