Patents

Literature

211 results about "Discharge problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

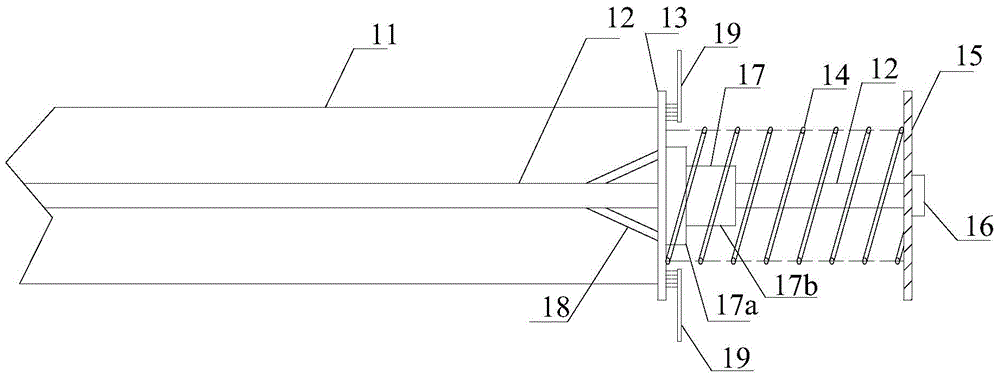

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

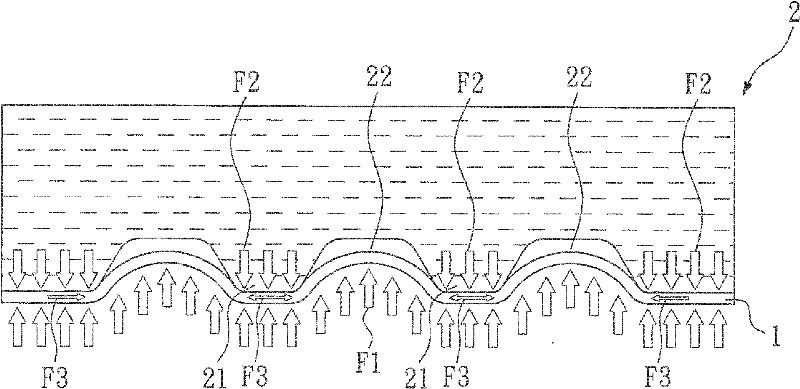

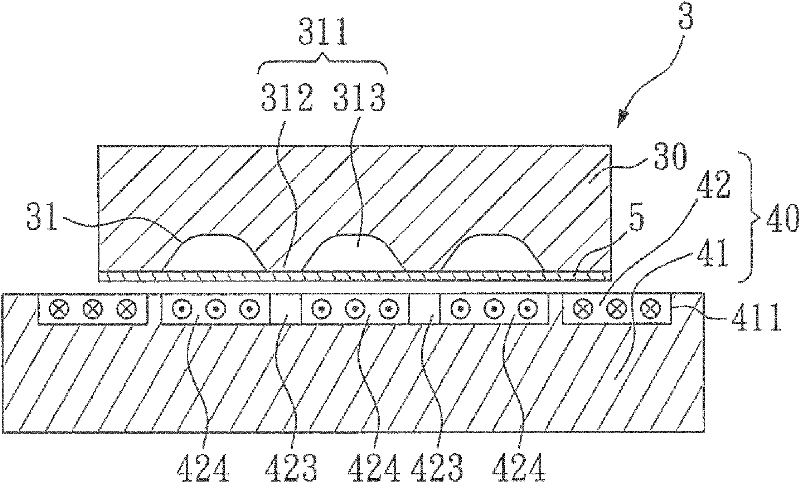

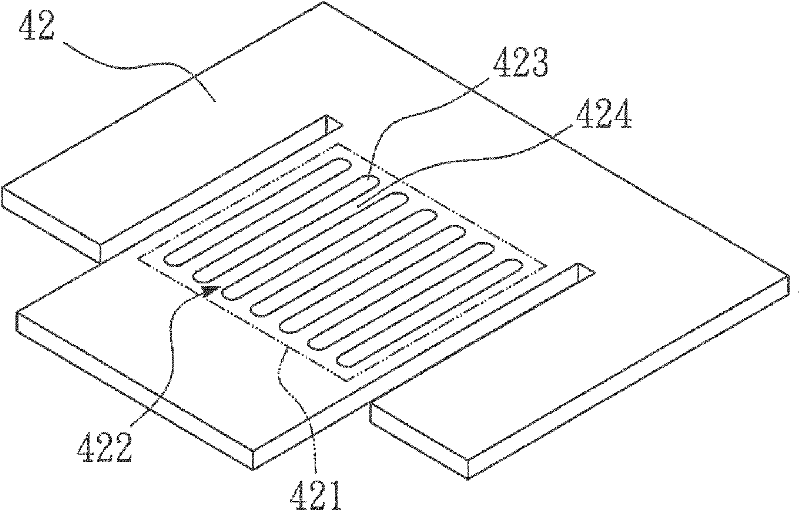

Metal plate forming device

The invention discloses a metal plate forming device which comprises a mold and an electromagnetic production device, wherein a forming mask of the mold has a pattern structure, and the pattern structure comprises at least one high part and at least one low part; a plate-shaped electromagnetic coil of the electromagnetic production device has a forming region, and a feature structure corresponding to the pattern structure is arranged in the forming region; and a metal plate can be driven by a mutually-repelled electromagnetic force generated between the plate-shaped electromagnetic coil and the metal plate to abut on the pattern structure, thereby forming the preset pattern. Thus, the metal plate forming device has the following advantages: the lateral binding force of the blank (metal plate) in the forming process can be reduced; the formed pattern has a higher depth-width ratio; the forming performance of the blank is improved; the thinning rate and warpage problem of the blank can be reduced; the structure is simple; a higher primary current value can be produced; and the arcing discharge problem can be completely avoided.

Owner:METAL INDS RES & DEV CENT

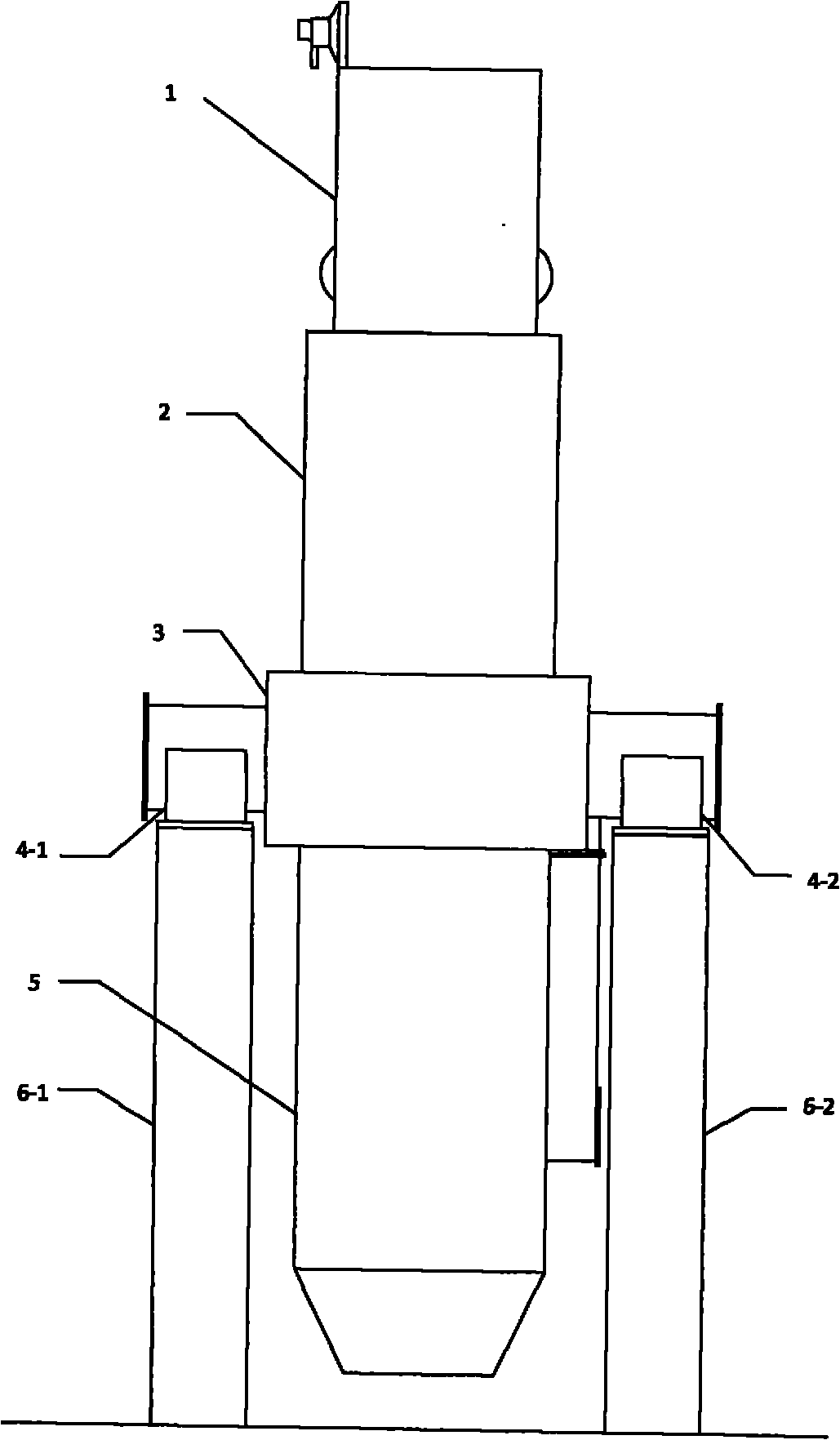

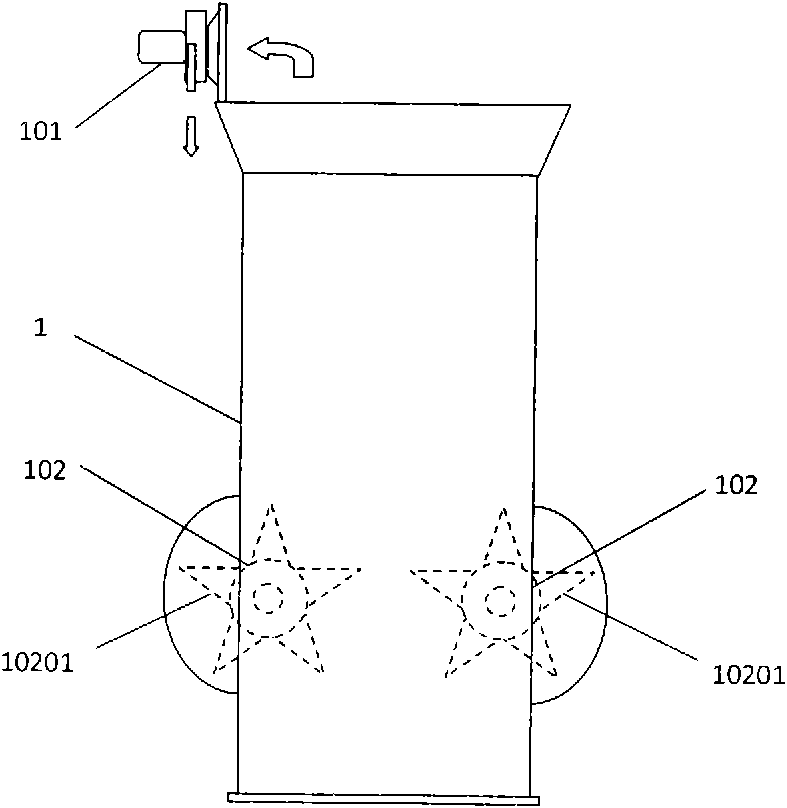

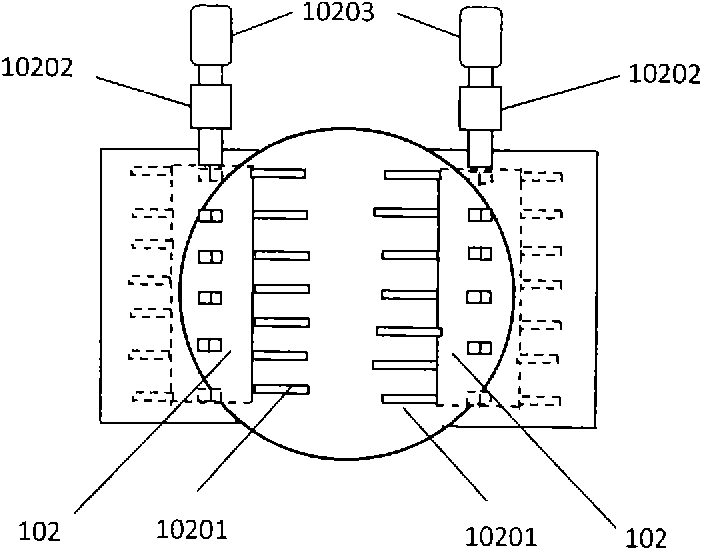

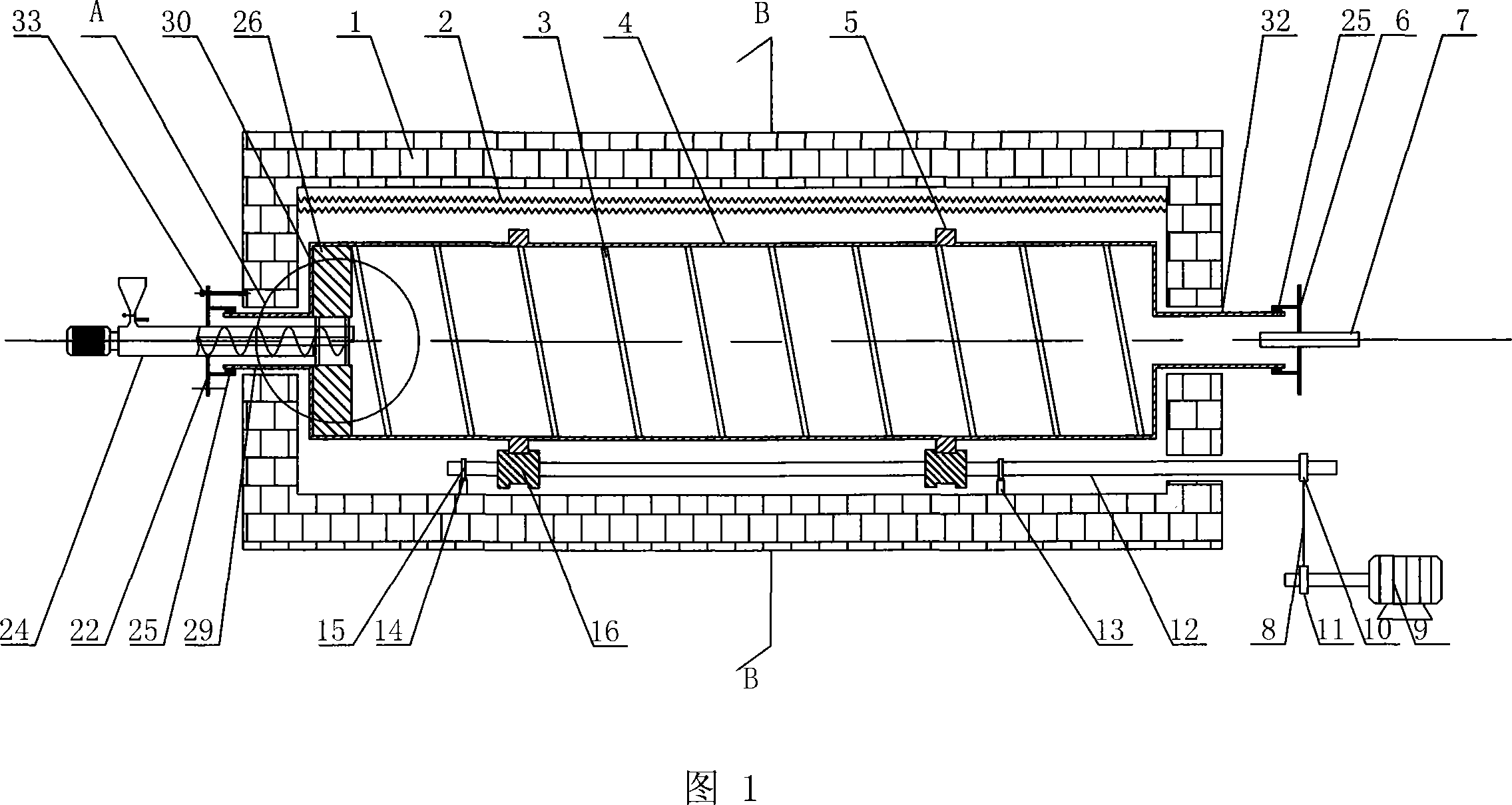

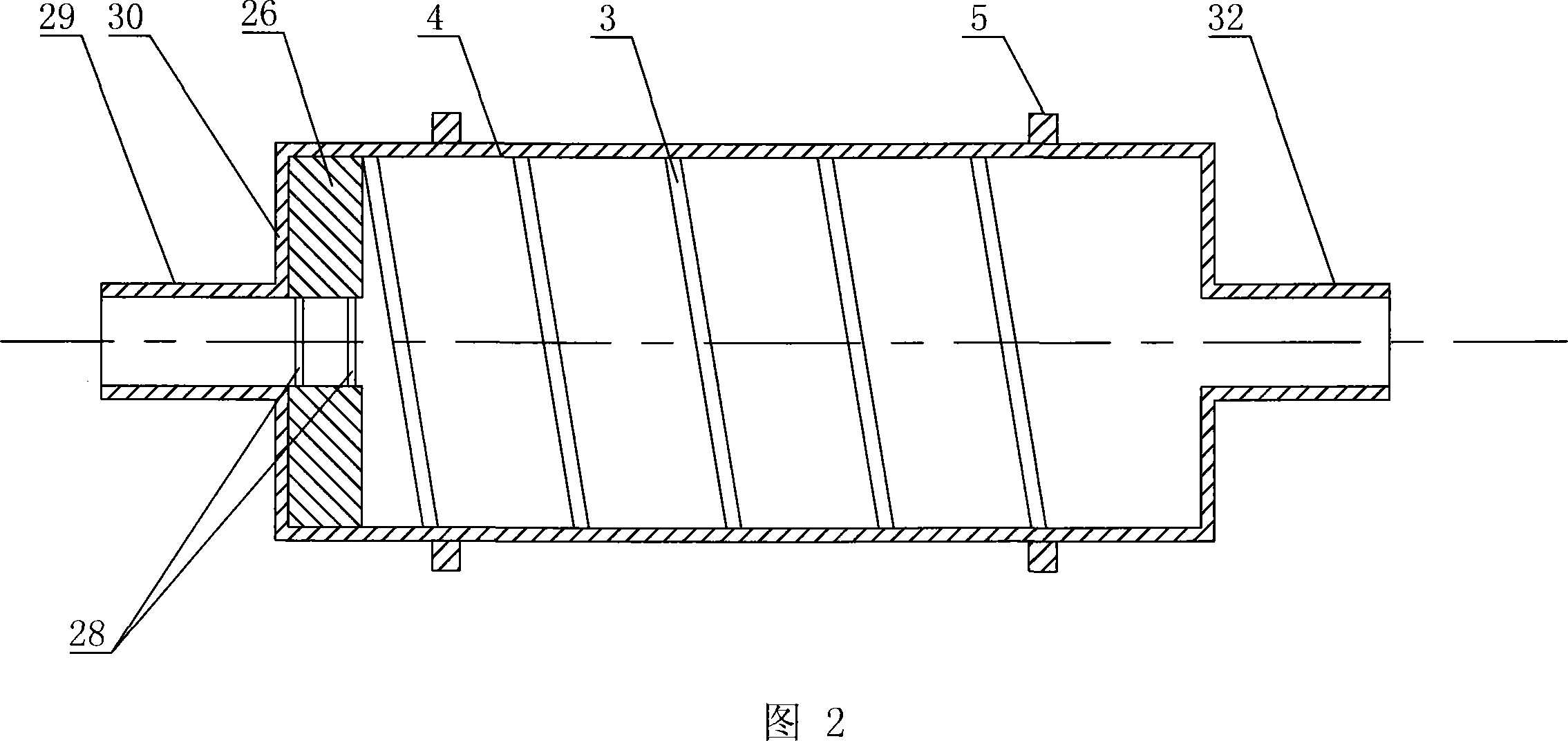

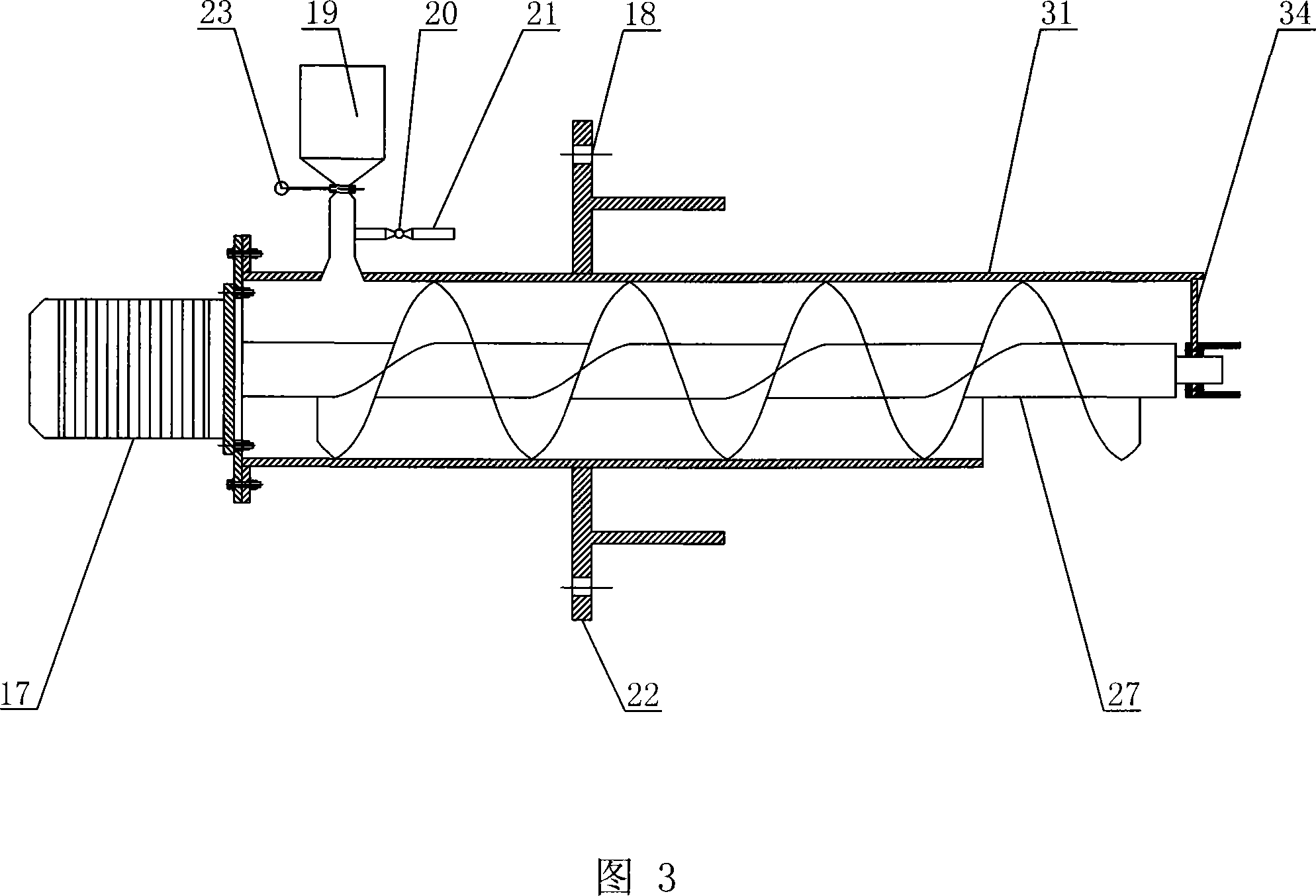

Revolving furnace

InactiveCN101216246AReduce pollutionSimple and fast operationRotary drum furnacesSmall footprintEngineering

The invention discloses a rotary furnace, aiming to solve manual feeding and discharging problem of the batch rotary furnace. The inventive rotary furnace comprises a rotary drum and a feeding and discharging device, wherein the feeding and discharging device is disposed at the feeding and discharging end of the rotary drum and extrudes into the rotary drum; spiral baffles are distributed on the inner wall of the rotary drum in equal interval, two symmetric discharge guide plates are disposed at the feeding and discharging end of the rotary drum in radial direction, and when feeding, a screw rod of the feeding and discharging device and the rotary drum perform forward rotation at the same time, so as to automatically feed to the rotary drum; when discharging, the rotary drum rotates in reverse direction, the materials in the rotary drum are introduced into the discharge device via the spiral baffles and the discharge guide plates, and the screw rod of the feeding and discharging device and the rotary drum perform reverse rotation at the same time, so as to automatically discharge. The inventive rotary furnace has the advantages of convenient feeding and discharging, simple structure, convenient operation, uniform material heating and low floor area; and is suitable for calcinating small or medium-scaled catalyst or carrier and high-temperature drying material.

Owner:XIAN MODERN CHEM RES INST

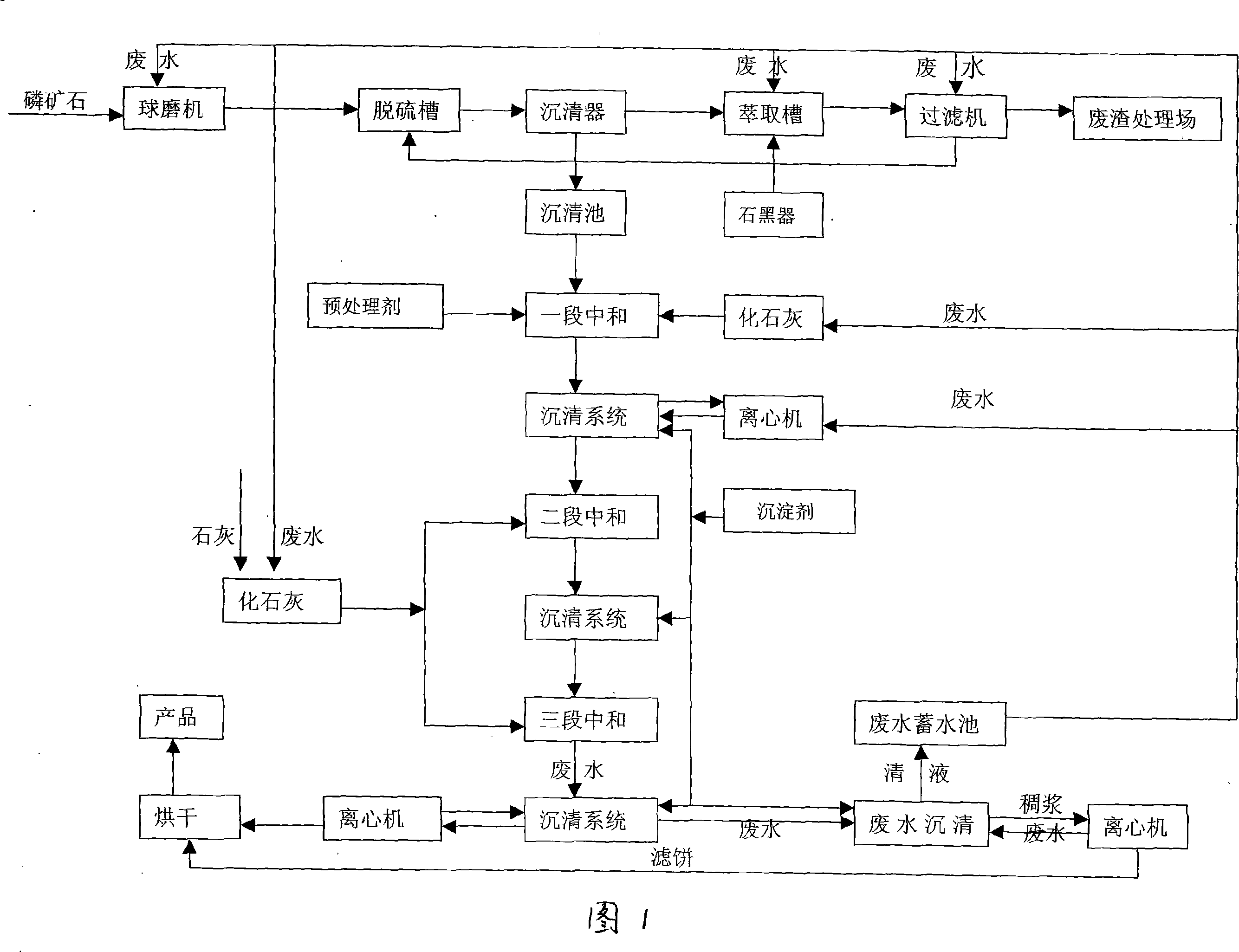

Reused process for waste water in calcium hydrogen orthophosphate production

InactiveCN101058414AImprove the experimental effectSignificant technological progressWater/sewage treatmentPhosphorus compoundsIndustrial waste waterPhosphoric acid

The invention discloses a seal circulating using technique of waste water in the dicalcium orthophosphate making course after three-segment neutralizing, which is characterized by the following: adopting phosphorus ore and sulfuric acid as raw material; adding phosphoric acid into sodium sulfate, diatomaceous soil and amino-hydroxy complexing agent to predispose the impurity; adding limestone to do preliminary defluorinating and impurity removing reaction; controlling pH value between 2. 0 and 2. 5; sedimenting the dense slurry; centrifuging; separating; making the liquid do two-segment and three-segment neutralizing reaction; defluorinating and removing impurity within one step; accumulating the residual water in the reservoir; transmitting the water to each segment to circulate and use through pump. The invention can save water by 10t per ton of calcium hydrophosphate, which makes business obtain the profit and benefit and solves the discharge problem of industrial waste water.

Owner:四川绵竹新清华化工有限责任公司

Method for preparing high-purity fused silica by recovering waste quartz crucible

InactiveCN102557389AReduce overdependenceAchieve recyclingGlass furnace apparatusDischarge problemsContamination

The invention discloses a method for preparing high-purity fused silica by recovering waste quartz crucible, which comprises steps of smash classification, scouring edulcoration, washing stoving and amorphization treatment and the like. The high-purity fused silica meeting use requirements of the quartz crucible can be obtained through that fact that purification edulcoration and the amorphization treatment are carried out on quartz crucible waste, so that excessive depending on quartz raw ore can be obviously remitted, cyclic utilization of quartz sands can be achieved, the method is applicable to protection of territorial resources, greatly reduces cost of manufacture of quartz ceramic crucible, simultaneously solves contamination and discharge problems of solid waste of quartz crucible production and using enterprises.

Owner:徐州协鑫太阳能材料有限公司

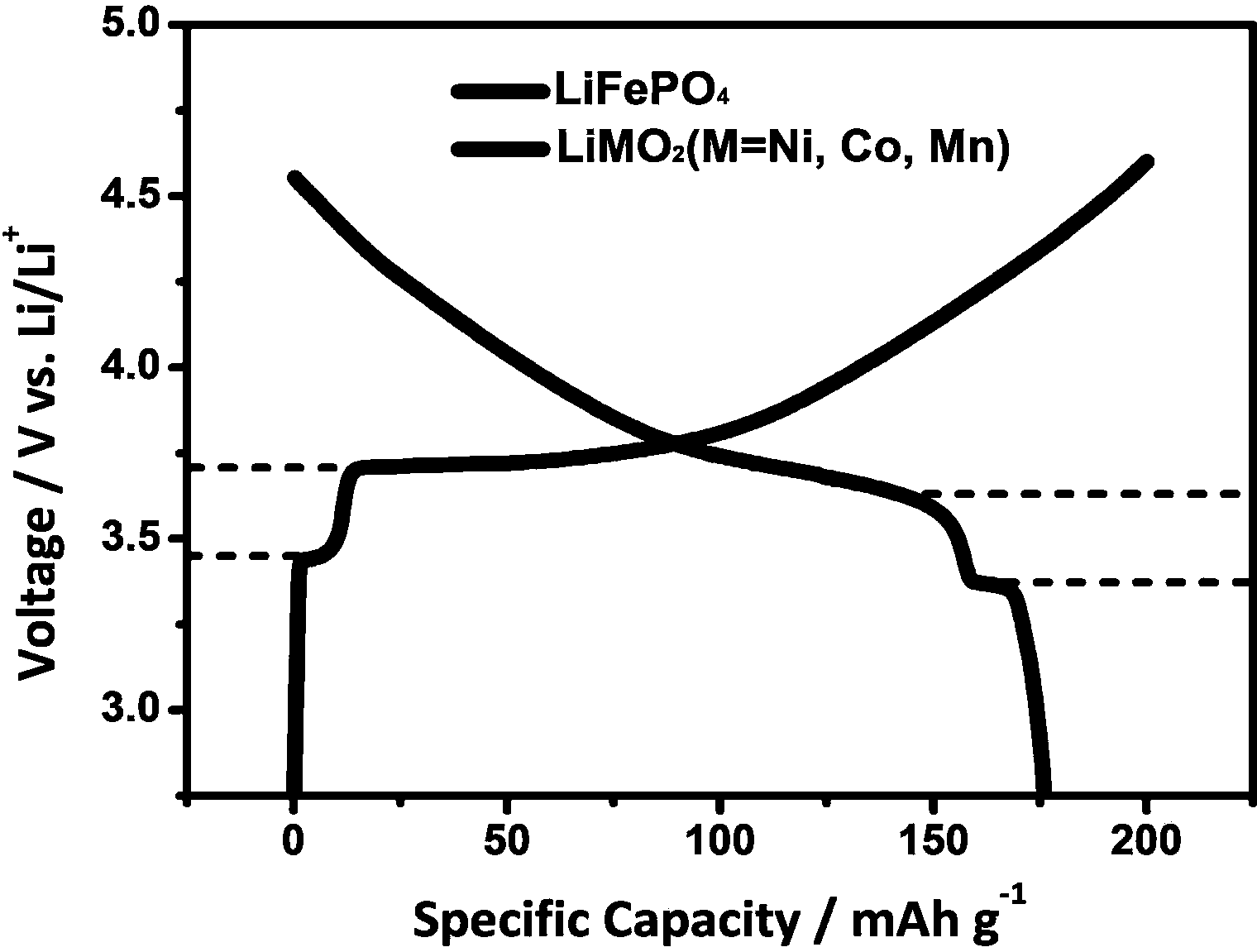

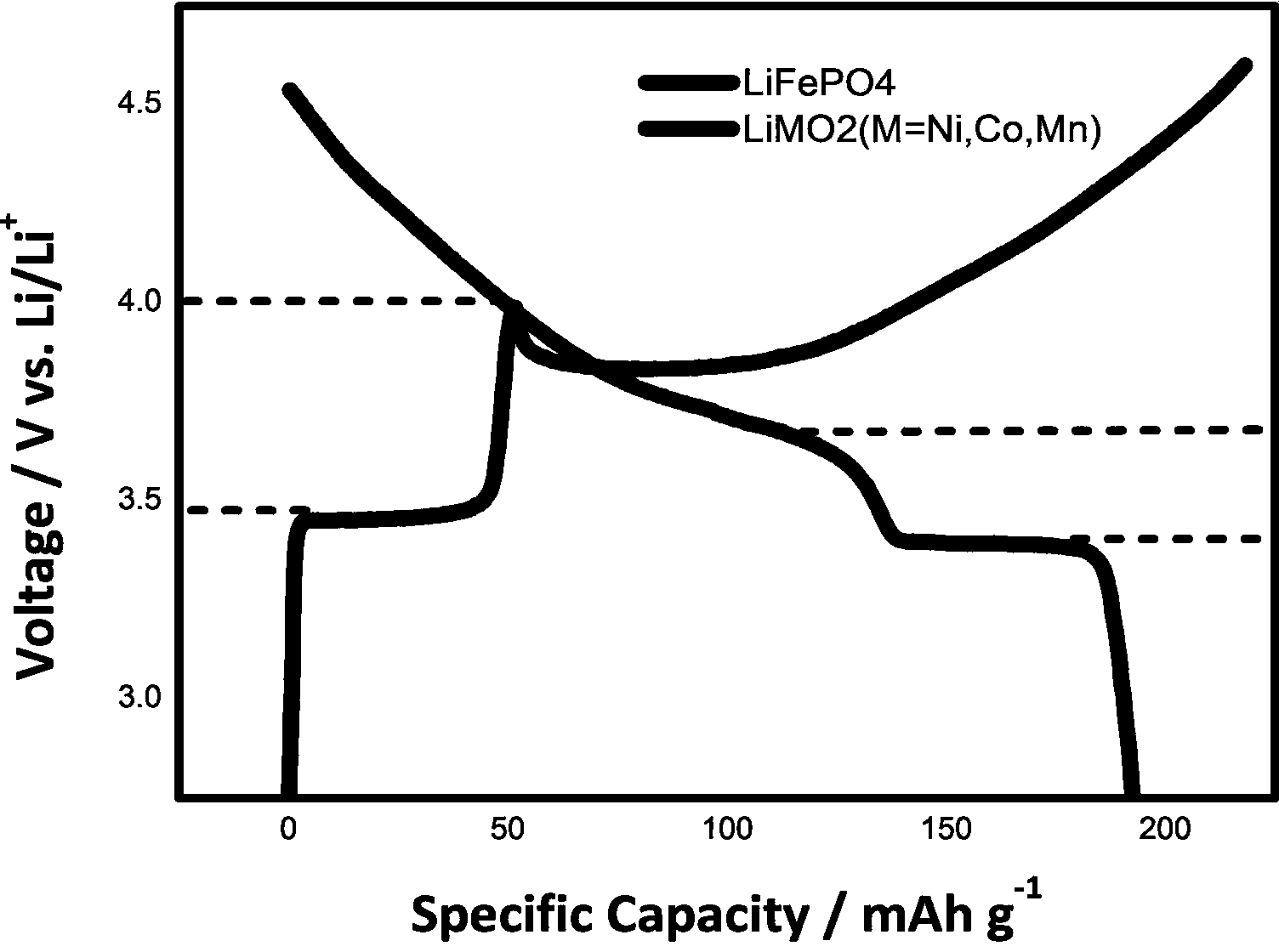

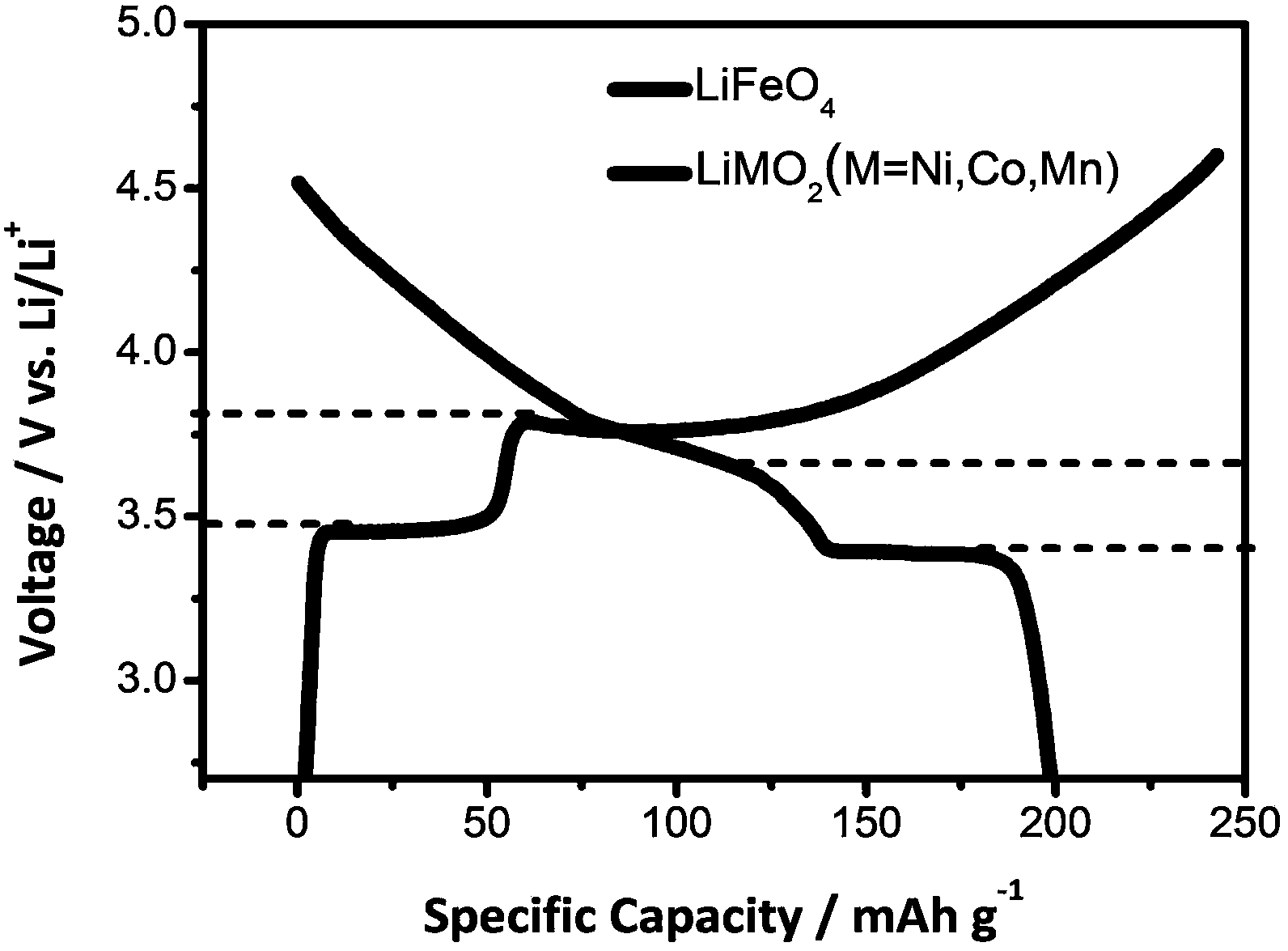

Method for preparing lithium iron phosphate and lithium nickel cobalt manganese oxide composite cathode material

ActiveCN104377353AImprove cycle performanceImprove overcharge and discharge performanceCell electrodesManganese oxideCobalt

The invention relates to a method for preparing a lithium iron phosphate and lithium nickel cobalt manganese oxide composite cathode material. The method comprises the following steps: cathode active materials, including lithium iron phosphate and lithium nickel cobalt manganese oxide, are respectively mixed with a conductive agent to obtain a mixture, ball-milling is performed on the two mixtures, pre-coating is performed, the two pre-coated mixtures are mixed to obtain a mixture, then dry or wet ball-milling is performed, and then the mixture is dried, crushed and graded so as to obtain the surface-coated lithium iron phosphate and lithium nickel cobalt manganese oxide composite cathode material. By adopting the method provided by the invention, the cycle performance of a lithium nickel cobalt manganese oxide lithium-ion battery can be improved, the over-charging and over-discharging problem of the battery is solved, and the service life of the battery can be prolonged. The cathode material is formed by mixing lithium iron phosphate and lithium nickel cobalt manganese oxide, no new material needs to be prepared, only these two cathode materials need to be mixed evenly, and therefore no cost is increased obviously.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Inorganic ferrous sulfide passivation abluent

ActiveCN102373122ASolve environmental problems of emissionsEfficient removalInorganic non-surface-active detergent compositionsTreatment apparatus corrosion/fouling inhibitionSodium bicarbonateHypochlorite

The invention relates to an inorganic ferrous sulfide passivation abluent which is characterized in that: the inorganic ferrous sulfide passivation abluent is composed of components of, by mass: 5 to 15% of sodium pyrosulfate, 15 to 35% of hypochlorite, 0.5 to 10% of trisodium phosphate, 0.1 to 5% of sodium bicarbonate, and 35 to 79% of water. The pH value of the product is controlled at 11 to 12. With the inorganic ferrous sulfide passivator, FeS and oil stains on refining equipments can be effectively and quickly removed; and gases such as H2S, micro-molecular sulfur and alcohol in equipments such as towers and containers can be absorbed. Indexes such as COD of the abluent satisfy an oil refinery sewage discharging standard. With the inorganic ferrous sulfide passivation abluent, environment protection problems such as a FeS passivation problem and an abluent waste liquid discharging problem can be well solved.

Owner:CHINA PETROLEUM & CHEM CORP

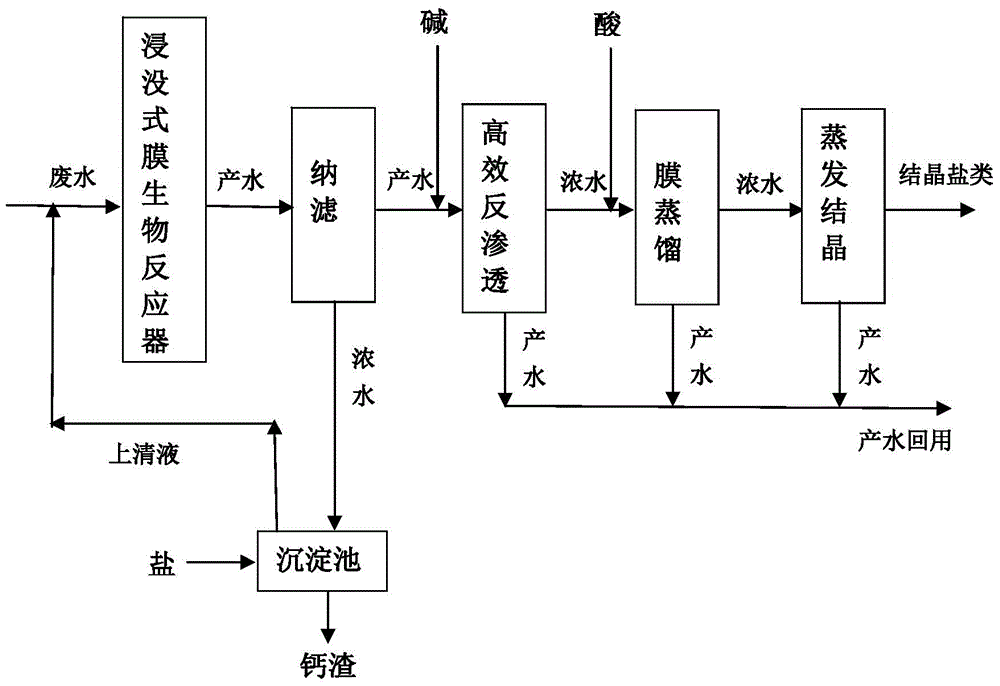

High-salinity high-organic-matter contentwastewater zero discharge method

InactiveCN105461157ASolve the problem of advanced treatment and even zero dischargeEfficient reverse osmosis treatmentWater contaminantsEnergy based wastewater treatmentFiltrationEvaporation

The invention relates to the field of industrial wastewater treatment, and specifically relates to a high-salinity high-organic-matter content wastewater zero discharge method. According to the invention, the high-salinity high-organic-matter content wastewater is treated with submerged membrane bioreactor treatment, nano-filtration, high-efficiency reverse osmosis, membrane distillation, and evaporation crystallization. Most of the suspended solids and organic matters in the wastewater are removed with the submerged membrane bioreactor; hardness matters such as multivalent ions, and part of the remaining organic matters in the wastewater are removed through nano-filtration, such that nano-filtration produced water and nano-filtration concentrated water are obtained; the nano-filtration produced water is subjected to a deep concentration treatment with the high-efficiency reverse osmosis technology, such that high-efficiency reverse osmosis produced water and high-efficiency reverse osmosis concentrated water are obtained; the high-efficiency reverse osmosis concentrated water is subjected to a membrane distillation deep concentration treatment, such that membrane distillation produced water and membrane distillation concentrated water are obtained; and the membrane distillation concentrated water is subjected to the evaporation crystallization treatment, such that salt solids in the concentrated water are crystallized. Through the above process flow, water resource is recovered to a maximal extent while a wastewater discharge problem is solved , and high-salinity high-organic-matter wastewater zero discharge is substantially realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

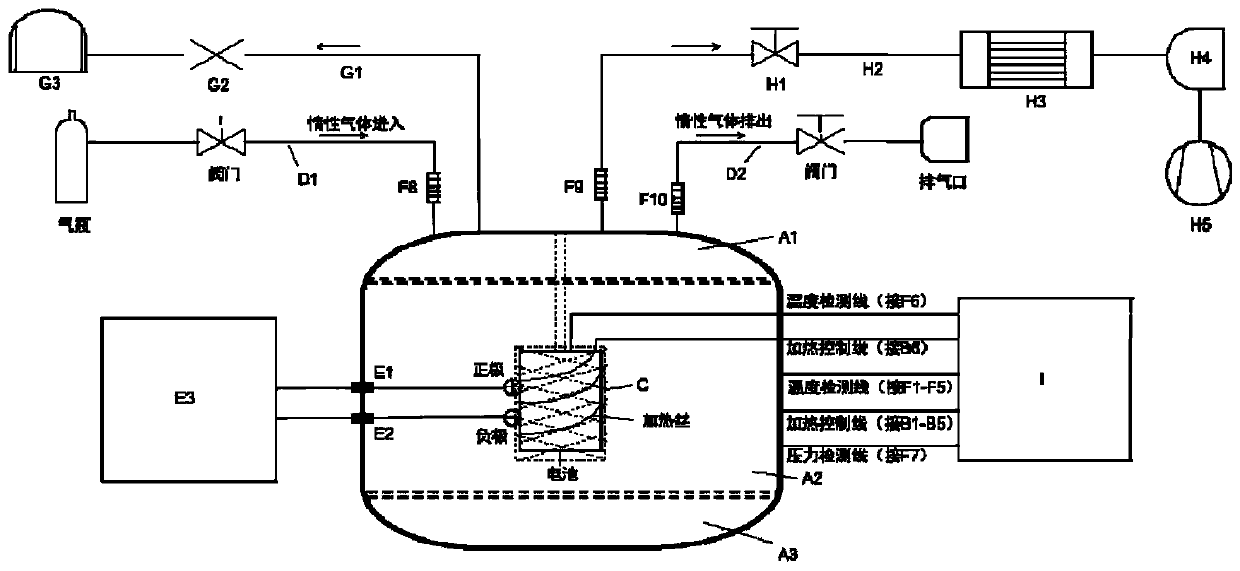

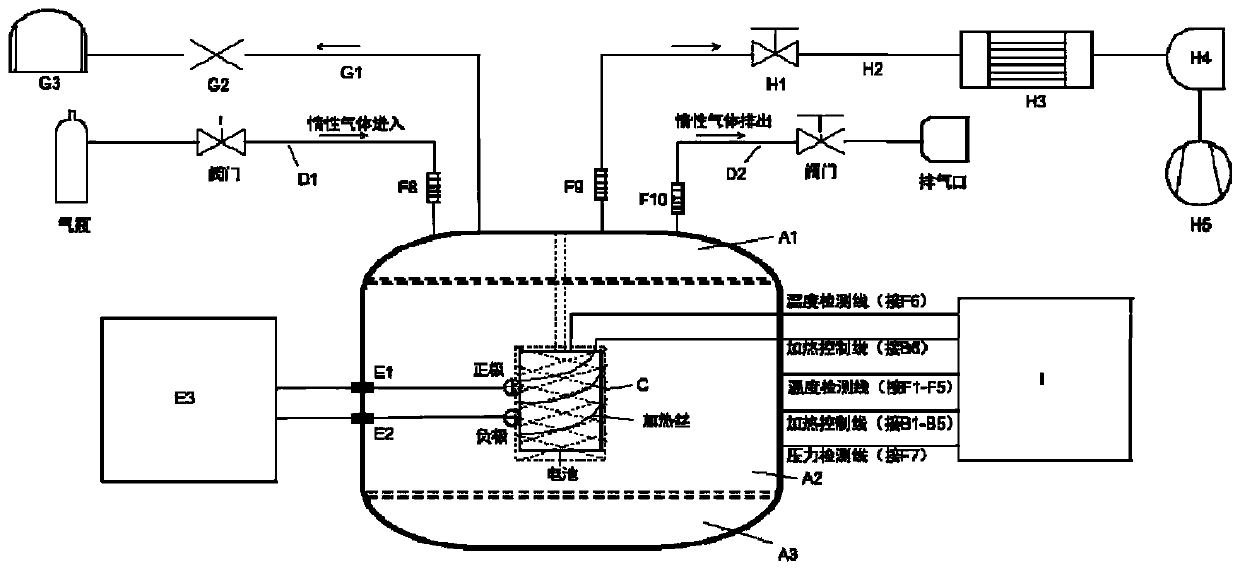

Gas production rate measurement and gas collection device for thermal runaway process of lithium ion battery

InactiveCN109959579AMonitor temperature in real timeReal-time monitoringElectrical testingMaterial analysisElectrical batterySafety control

The invention, which belongs to the technical field of safety control, particularly relates to a gas production rate measurement and gas collection device for the thermal runaway process of a lithiumion battery. The device comprises a pressure explosion-proof container, a heating device, a battery suspension device, an inert gas circulation device, a battery charge and discharge module, a detection device, an explosion-proof pressure relief module, a control system, and a gas collection module. Compared with the prior art, the gas production rate measurement and gas collection device has thefollowing beneficial effects: gas production rate measurement and gas collection are carried out on gas generated by the thermal runaway triggered by the high-temperature, over-charging, and over-discharge problems of the lithium-ion battery; the temperature and voltage changing situations of the thermal runaway process of the lithium ion battery are monitored in real time; and the reliable data support is provided for the analysis of thermal runaway of the lithium ion battery.

Owner:CHINA NORTH VEHICLE RES INST

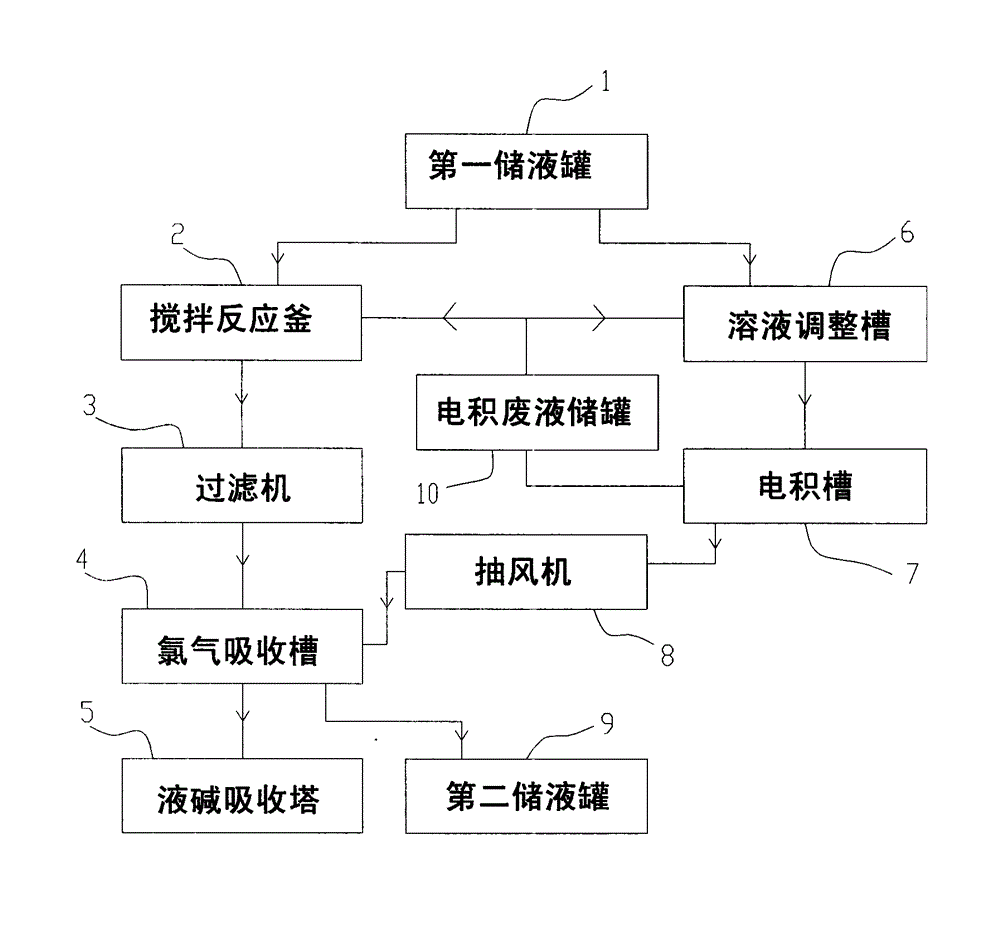

Method and system for preparing ferric chloride, electrodeposited copper and copper powder from copper-containing hydrochloric acid waste liquid

ActiveCN103936081ASolve pollutionHigh pricePhotography auxillary processesIron halidesLiquid storage tankIron(II) chloride

The invention provides a method and a system for preparing ferric chloride, electrodeposited copper and copper powder from copper-containing hydrochloric acid waste liquid. The system comprises a first liquid storage tank, a stirring reactor, a filter, a chlorine absorption tank, a caustic soda solution absorption tower, a solution adjusting tank, an electrodeposition cell and an exhaust fan, wherein the first liquid storage tank is used for storing the copper-containing hydrochloric acid waste liquid; the stirring reactor is used for carrying out replacement reaction between ferrum and copper chloride; the filter is used for filtering a solution obtained through the replacement reaction; the chlorine absorption tank is used for enabling the solution filtered by the filter to absorb chlorine, so that ferrous chloride is oxidized into ferric trichloride; the caustic soda liquid absorption tower is used for treating tail gas emitted from the chlorine adsorption tank; the solution adjusting tank is used for adjusting the concentration of a solution in the electrodeposition cell; the electrodeposition cell is used for an electrodeposition reaction; and the exhaust fan is used for conveying chlorine gas produced by the electrodeposition cell to the chlorine absorption tank. According to the method and the system provided by the invention, replacement of copper ions from ferrous powder is combined with the electrodeposited copper, so that the wastewater discharge problem of the copper-containing hydrochloric acid waste liquid and the pollution problem of the chlorine gas to the environment can be solved, and the phenomenon that the power consumption sharply rises is avoided.

Owner:SHENZHEN YUEPENG ENVIRONMENTAL PROTECTION TECH

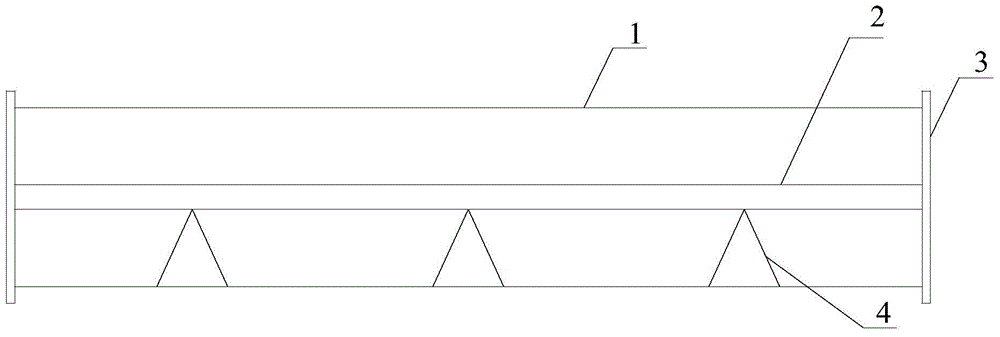

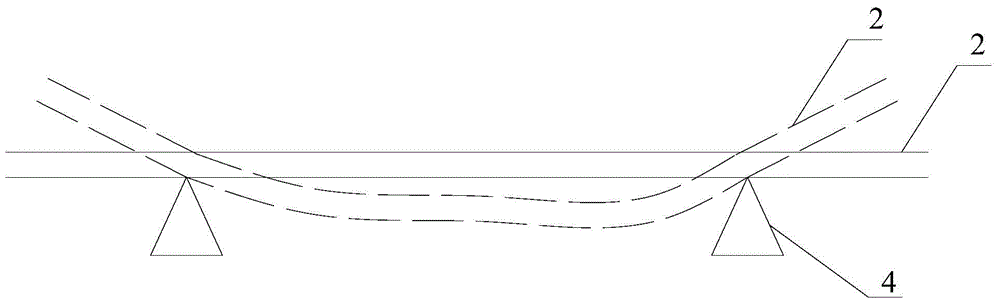

High-voltage wall bushing

ActiveCN105119217AImprove reliabilityGuaranteed reliabilityInsulating bodiesElectrical conductorEngineering

The present invention provides a high-voltage wall bushing including a bushing, a connecting flange arranged on the bushing, and a conductor arranged in the bushing and passed through the connecting flange, wherein, the high-voltage wall bushing also includes a stretching device connected to the conductor. The high-voltage wall bushing overcomes a droop problem of the conductor caused by an own weight at non-vertical mounting through a tensile force provided by the stretching device so that the conductor keeps in a straight line state as soon as possible at non-vertical mounting, and thereby avoiding a gas gap or a discharging problem of an insulating surface of a solid body caused by a shortened distance between the conductor and the bushing, and preventing the bushing from being damaged and improving a reliability of the high-voltage wall bushing for usage. The arrangement of the stretch device enables the high-voltage wall bushing to cancel an insulating supporter for the conductor, and thereby ensuring the reliability of the high-voltage wall bushing efficiently.

Owner:SHANGHAI RUNJING ENERGY TECH

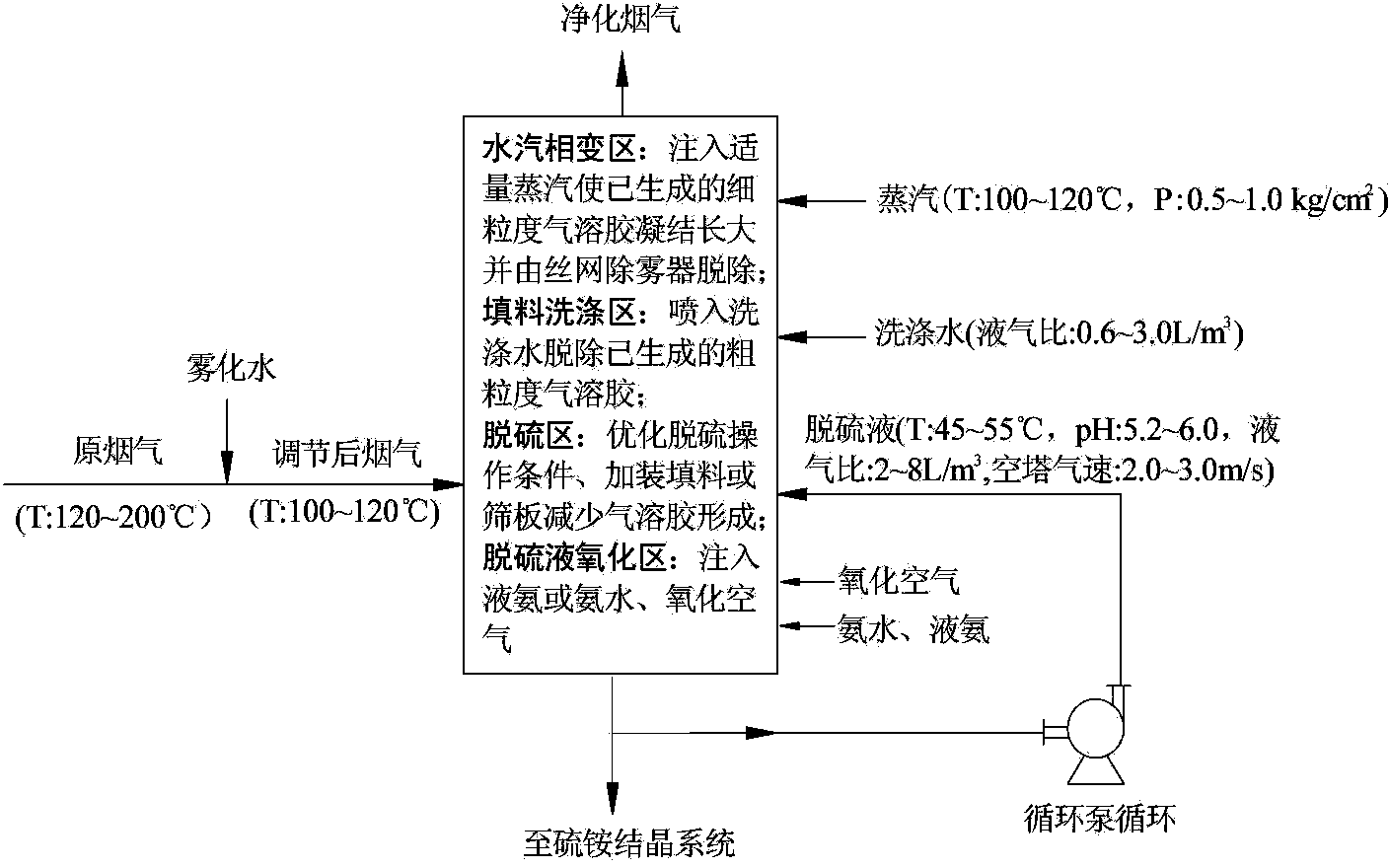

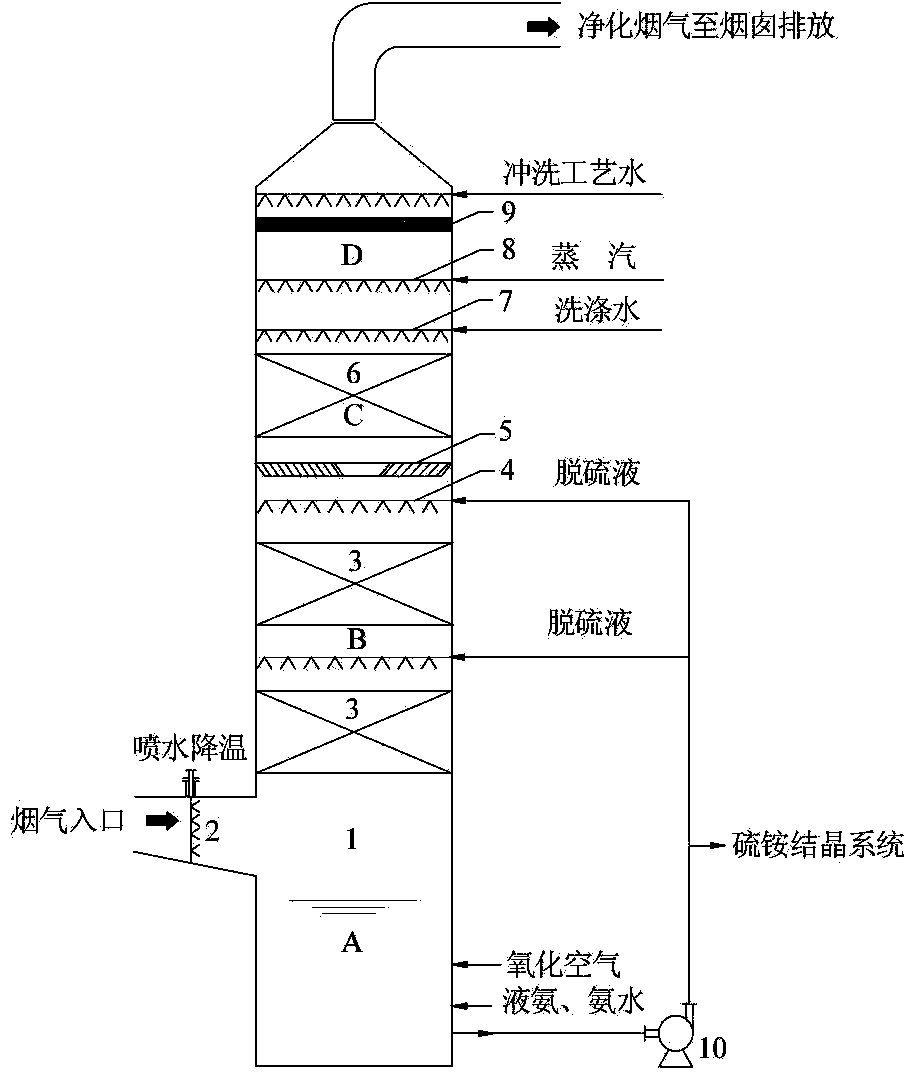

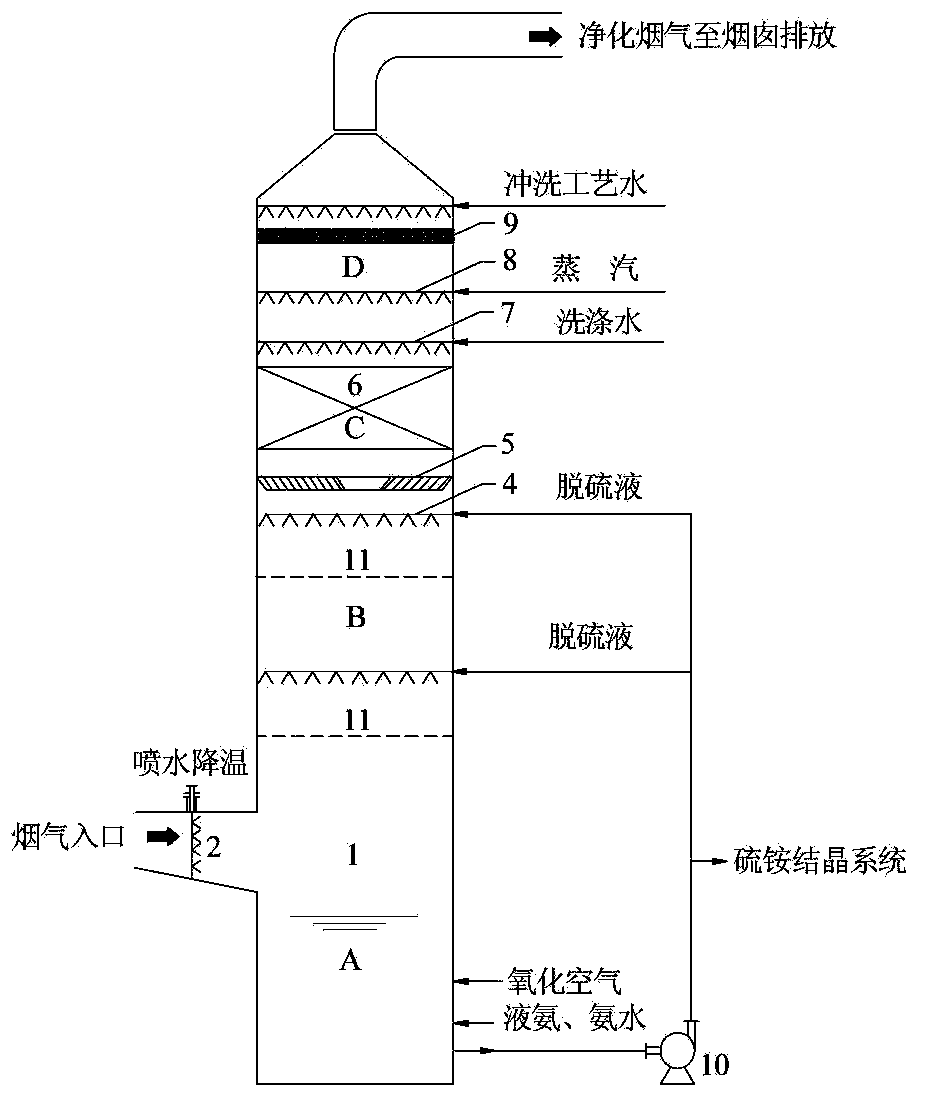

Method for controlling ammonia-process desulfurization aerosol discharge and dedicated absorption tower thereof

ActiveCN104338426ASolve the emission problemSimple processCombination devicesUsing liquid separation agentWater vaporFlue gas

A method for controlling ammonia-process desulfurization aerosol discharge is a method for controlling the aerosol discharge in an ammonia-process flue gas desulfurization technology, and comprises the steps: flue gas subjected to spray temperature reduction and cooled to 100-120 DEG C by atomized water is introduced to a desulfurization zone of a desulfurization absorption tower, flue gas from bottom to top in the desulfurization zone is subjected to countercurrent contact with a desulfurization liquid sprayed from top to bottom so as to absorb SO2 in the flue gas, and a packing or a sieve plate is arranged in the desulfurization zone; the flue gas enters a packing washing zone after desulfurization, and washing water is injected to remove coarse-grained aerosol generated in ammonia-process desulfurization; then the treated aerosol enters a water vapor phase transformation zone, vapor is injected from the middle part of the water vapor phase transformation zone, a supersaturated water vapor environment needed by water vapor phase transformation is established, and fine-grained aerosol micro-particles which are not removed are congealed, grow up and are removed from a silk screen mist eliminator at a flue gas outlet of the water vapor phase transformation zone; and the purified flue gas is discharged through a chimney from a flue gas outlet at the top of the desulfurization absorption tower. The method can effectively solve the discharge problem of the aerosol in the ammonia-process flue gas desulfurization. The invention discloses the dedicated desulfurization absorption tower of the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmental protection treatment method for citric acid chemical plating waste water

InactiveCN101239761ASolve the problem of COD emission standardsEfficient recyclingWaste water treatment from metallurgical processMultistage water/sewage treatmentChemical platingEmission standard

The present invention provides an environment-protecting processing method for the lemon acid chemical plaiting wastewater, the lemon acid chemical plating wastewater is added with hydrochloric acid and calcium chloride, the vacuum suction-filtering or pressing-filtering is executed after reaction, the pressing-filtering is executed after adding sodium sulfide for sufficient reaction and the filter residue is the sulfide deposition of the nickel and cobalt, the filter residue is recovered as the mineral product; measuring the COD of the filter liquor separated last, the conventional biochemical treatment is executed until the discharge standard is obtained when the COD value does not get to the discharging standard. The method of the invention has the beneficial effects of greatly shortening of the processing period, effectively recycling the costly nickel and cobalt product, better settling the COD discharging problem of the wastewater up to standard, higher economic benefit and social benefit.

Owner:丁四宜 +1

Comprehensive utilization method for phosphate flame retardant wastewater

ActiveCN104692571AGive full play to the energy-saving featuresAvoid structurePhosphatesMultistage water/sewage treatmentLiquid wasteHigh concentration

The invention relates to a method for treating phosphate flame retardant wastewater and particularly relates to a comprehensive phosphate flame retardant wastewater utilization method integrating energy-saving rectification-evaporation, oriented conversion and other technologies. The method specifically comprises the following steps: (1) effectively separating wastewater components by adopting a rectification-evaporation technology; (2) converting high-concentration phosphate waste liquor into polyphosphates by adopting an oriented conversion technology, and purifying to obtain the industrial grade polyphosphate product, so that the harmless problem of the phosphate waste liquor is solved; (3) using the water obtained by rectification to produce phosphate flame retardant products, and recycling the water; (4) converting inorganic salt solid wastes into recyclable industrial products by virtue of a fractionation and purification method, so that the discharge problem of the inorganic salt solid wastes is solved; and (5) taking the product as fuel in an oriented conversion process in the basis of the characteristic that the rectified low-boiling-point compound is high in heating value. Therefore, the discharge problem is solved, the energy can be saved, and the wastewater treatment cost is reduced.

Owner:ZHENJIANG JIANGNAN CHEM

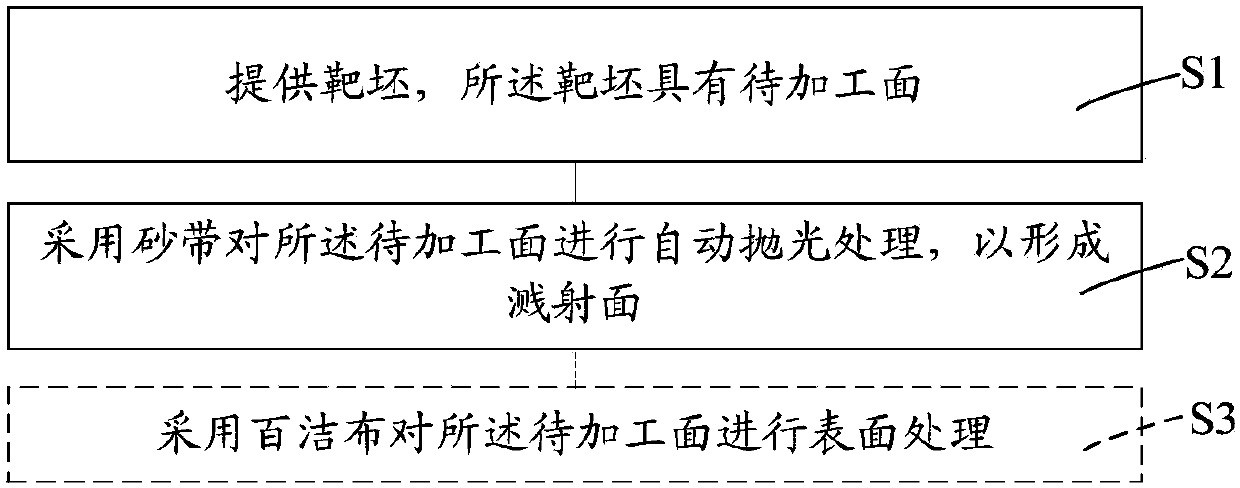

Target material assembly machining method

InactiveCN107866721AIncrease contact areaReduce surface textureBelt grinding machinesSurface patternDischarge problems

The invention provides a target material assembly machining method. The target material assembly processing method comprises the steps that a target blank with a to-be-machined face is provided; and the to-be-machined face is subjected to automatic polishing treatment through an abrasive belt so as to form a sputtering face. The to-be-machined face is subjected to automatic polishing treatment through the abrasive belt so as to form the sputtering face; on the one hand, compared with abrasive paper, the size of the abrasive belt is larger, therefore, the contact area of the abrasive belt and the to-be-machined face is larger, in order to finish polishing treatment of the whole to-be-machined face, the moving times of the abrasive belt in the direction parallel to the to-be-machined face isdecreased correspondingly, accordingly, surface patterns and edges of the sputtering face are reduced, and the roughness of the sputtering face is reduced; and on the other hand, compared with a manual polishing treatment scheme, according to the automatic polishing method, intensity uniformity during polishing treatment can be improved, accordingly, the roughness uniformity and surface pattern uniformity of the sputtering face are improved, and the cumulative discharge problem of a target material assembly in the initial sputtering stage can be improved.

Owner:合肥江丰电子材料有限公司

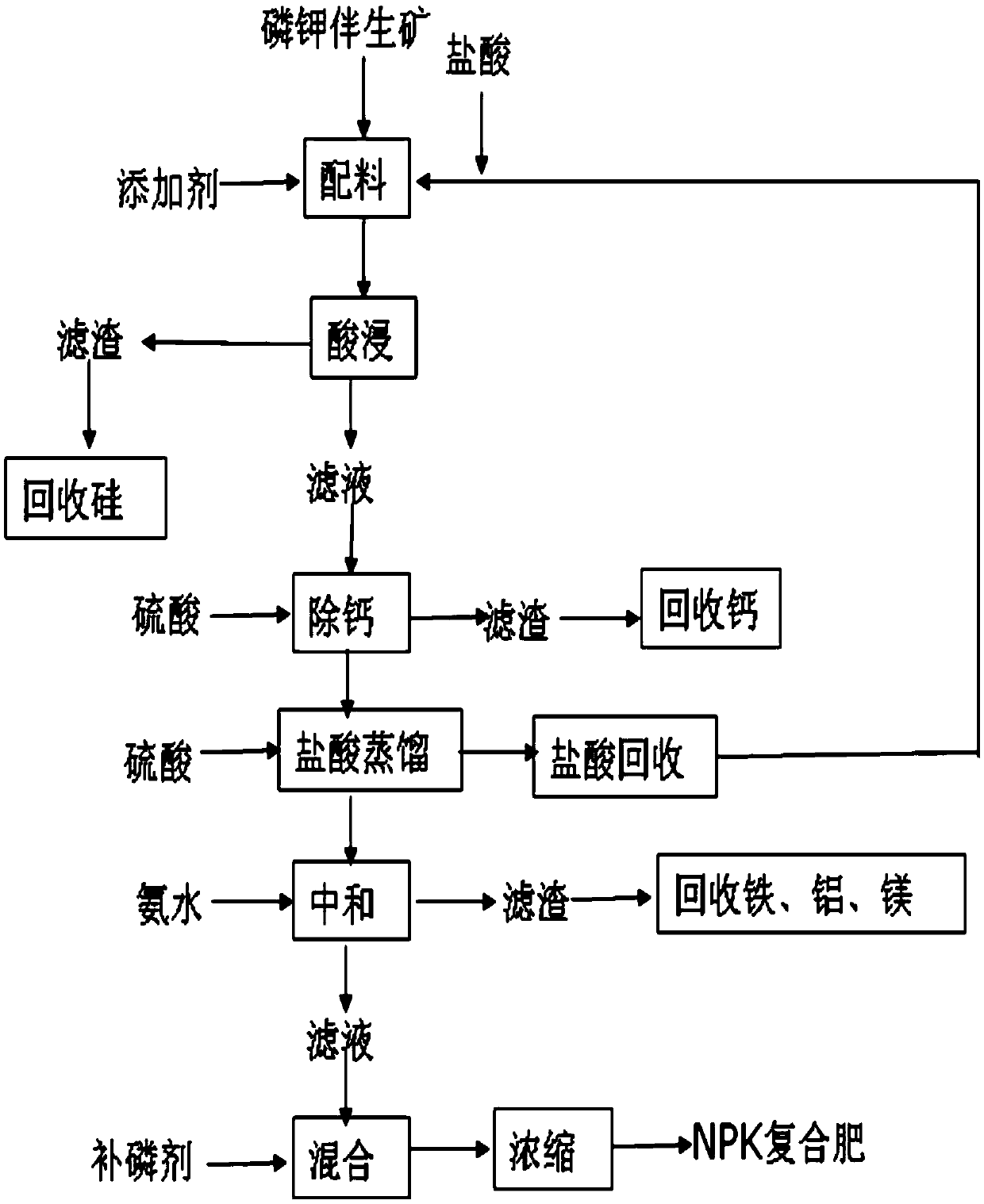

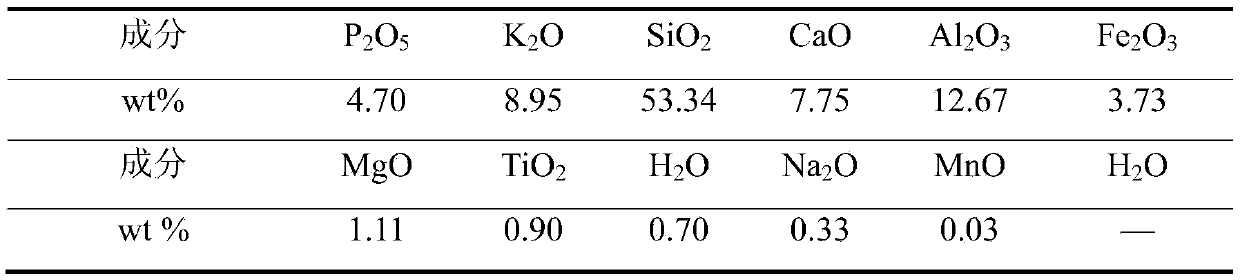

Multi-element comprehensive utilization process for phosphorus-potassium associated ore

ActiveCN105367176ARealize the comprehensive utilization of multiple elementsRealize comprehensive utilizationFertilizer mixturesHigh concentrationDecomposition

The present invention discloses a multi-element comprehensive utilization process for phosphorus-potassium associated ore. The process comprises: firstly, a fluorine-containing compound is used as an additional aid, and a leaching reaction of the phosphorus-potassium associated ore at a low temperature under an acidic condition is implemented, so as to obtain a silica residue and a leachate. The steps of calcium removal, hydrochloric acid distillation and neutralization are then performed successively to the resulting leachate, so as to obtain a calcium sulfate residue, a heavy iron residue, a heavy aluminum residue, a heavy magnesium residue, and a filtrate. The resulting filtrate is then supplemented with phosphorus, evaporated, and concentrated, so as to obtain a high concentration of NPK compound fertilizer. According to the process provided by the present invention, the fluorine-containing compound is used as the additional aid and hydrochloric acid is used as a leaching agent to process the phosphorus-potassium associated ore. Potassium feldspar is decomposed by means of a reaction of villiaumite and an acid to generate hydrofluoric acid in situ, effectively implementing a process of complete decomposition, complete separation and complete utilization. The process has advantages of low energy consumption, a high element leaching rate, and simple subsequent treatment processes, etc. No discharge problem of three waste exists in the treatment process. In addition, the involved process is simple and the reaction conditions are mild, so that the process is easy to implement and is suitable for popularization and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Recovery method of rare earth oxalate precipitation wastewater

ActiveCN103408091ASolve the emission problemWater/sewage treatment by extractionRecovery methodOxalate precipitation

The invention relates to a recovery method of rare earth oxalate precipitation wastewater. The method is characterized in that the rare earth oxalate precipitation wastewater and hydrochloric acid are prepared into a solution, wherein the concentration of oxalate is 0.01-10g / L, and the concentration of H<+> is 3.5-6mol / L. According to the method provided in the invention, the rare earth oxalate precipitation wastewater and hydrochloric acid are prepared into a solution for back extraction of rare earth from a rare earth loaded extraction solution. Therefore, the wastewater discharge problem is solved, and the acid needed by back extraction of rare earth and the oxalic acid required by final rare earth precipitation can also be saved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Contiguous seam efficient filling material

InactiveCN106517940AWide variety of sourcesLow costSolid waste managementPortland cementCompressive strength

The invention relates to a contiguous seam efficient filling material. The problem of application of waste rock blocks and coal ash in seam filling is solved. The contiguous seam efficient filling material is composed of, by mass, 84-134 parts of water, 164-174 parts of ordinary portland cement, 0-44 parts of coal ash, 425-452 parts of waste rock blocks and pebbles, 227-291 parts of bank sand, 2.8-5.5 parts of early strength agent and 3.2-3.5 parts of water reducing agents; and the mass parts of the waste rock blocks and the pebbles are 85-452 parts and 0-340 parts correspondingly by total amount of the waste rock blocks and the pebbles. The proper proportion of the waste rock blocks and the pebbles in seam filling is determined through lots of experiments and data analysis. The contiguous seam efficient filling material is wide in material source and low in cost, the pollution discharge problem of mine enterprises can be solved, and material uniaxial compressive strength, slump and the like of the material meet the requirements.

Owner:DATONG COAL MINE GRP

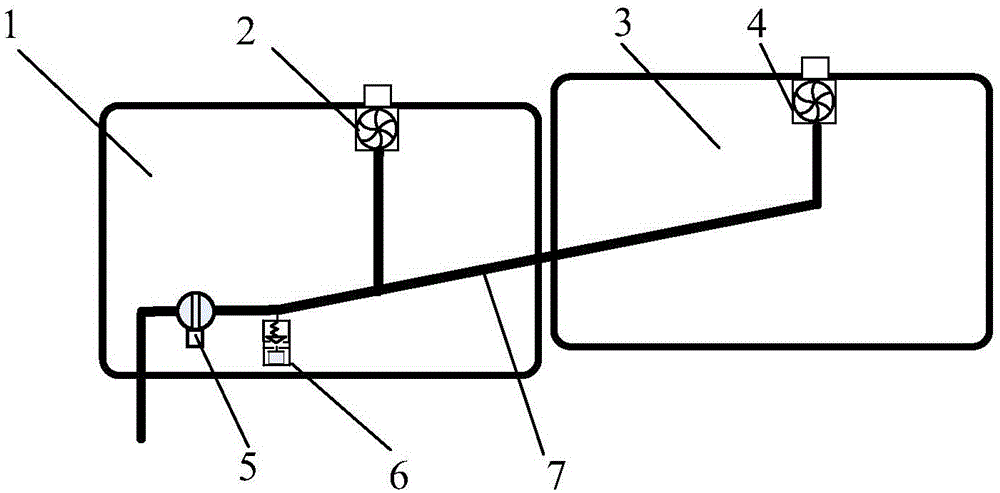

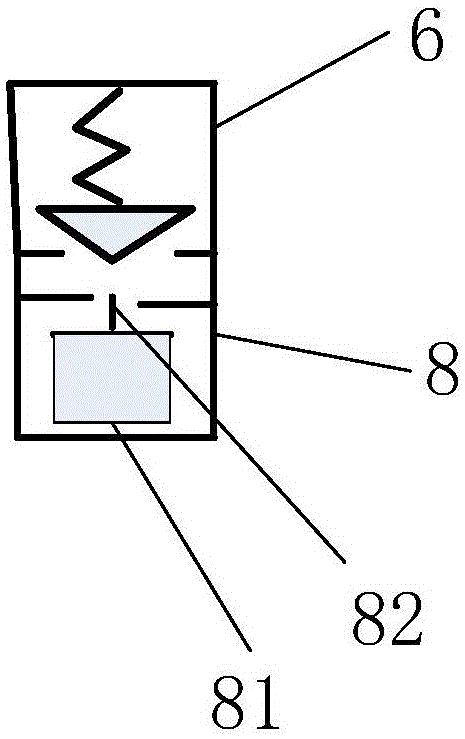

Tail gas absorbing device in acetone cyanohydrin production

InactiveCN102728185ASolve the emission problemEnsure safetyDispersed particle separationSocial benefitsWastewater

The invention relates to an organic chemical substance production device, and concretely relates to a tail gas absorbing device in acetone cyanohydrin production. The device is characterized in that an acetone pump is arranged, fresh acetone is cooled by an acetone cooler and is sent to a tail gas absorbing tower, and a waste tail gas is discharged to air. The tail gas absorbing device has the following beneficial effects: the tail gas absorbing tower is arranged to treat the tail gas of the acetone cyanohydrin device on the basis of an acetone tank, the acetone pump and the acetone cooler which have been arranged in the acetone cyanohydrin device, so the tail gas discharge problem of the acetone cyanohydrin device is solved, tail gas discharge standards reach national standards, wastewater amount reduction, energy saving, emission reduction and good economic benefits are realized, cyanogen harms are released, the safeties of onsite operators are guaranteed, the environment is protected, and country and human benefiting is realized. The device allows the cost for burning cyanogen-containing wastewater to be saved by above 2 billion yuan each year, so the device has substantial economic and social benefits.

Owner:JILIN DESIGNING INST OF CNPC NORTHEAST REFINING & CHEM ENG

Residual-oil discharging system and oil discharging method of emergency oil discharging header pipe

ActiveCN105109700ASimple structureExtended preparation timePower plant fuel tanksFuel tankResidual oil

The invention relates to a design of an emergency oil discharging system of a plane, particularly to a residual-oil discharging system and an oil discharging method of an emergency oil discharging header pipe. The residual-oil discharging system and the oil discharging method are disclosed so as to solve the residual-oil discharging problem of an emergency oil discharging header pipe, and to avoid the mixing of oil in oil tanks caused by a leakage discharge valve. The discharging system comprises the emergency oil discharging pipe header pipe, a leakage discharge valve and a floater, wherein the emergency oil discharging header pipe is arranged between a first oil tank and a second oil tank, are communicated with a first emergency oil discharging pump and a second emergency oil discharging pump respectively, and are connected with a cut-off valve; the leakage discharge valve is arranged at the lowest position of the emergency oil discharging header pipe in the second oil tank, and is positioned at the upstream of the cut-off valve; the floater is arranged at an outlet at the bottom of the leakage discharge valve, and is used for sealing and blocking the leakage discharge valve. According to the invention, the leakage discharge device is simple in structure; by the use of the leakage discharge device, the residual oil of the oil discharging header pipe of the plane can be conveniently discharged, so that the adverse influences, such as pump power increase, efficiency decrease, weight increase and the like, caused by reduction of forward leakage of an emergency oil discharging pump, are avoided, and the adverse influence of mixing of oil from different oil tanks and plane preparation time prolongation due to employment of a common leakage discharge valve is avoided.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Method for preparation of chrome tanning agent and combined production of vitamin K3 through using chromium-rich sludge

InactiveCN103352092ASolving RecyclingImprove the environmentSludge treatment by de-watering/drying/thickeningTanning treatmentSludgeVitamin K3

The invention relates to a method for the preparation of a chrome tanning agent and the combined production of vitamin K3 through using chromium-rich sludge. The method comprises a step of purifying chromium-rich sludge generated in a leather making enterprise, and a step of combining with a waste liquid generated in the production of vitamin K3 to prepare the chrome tanning agent. The method solves a discharge problem of the waste liquid generated in the production of vitamin K3, and also well solves discharge and processing problems of chromium-containing solid dangerous wastes of the leather making enterprise.

Owner:SHANDONG HUASHENG CHEM TECH

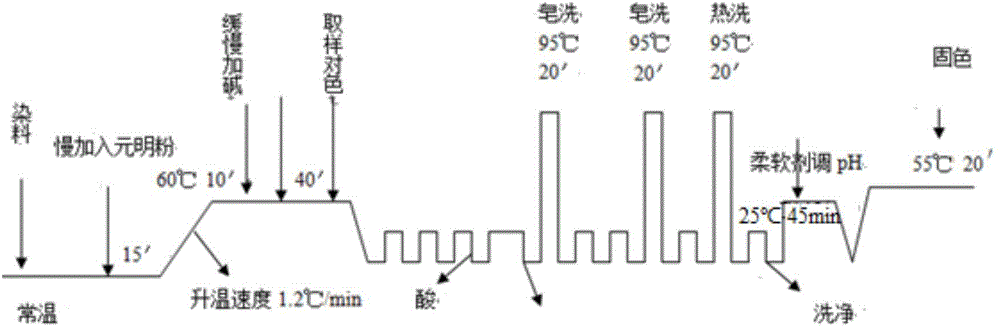

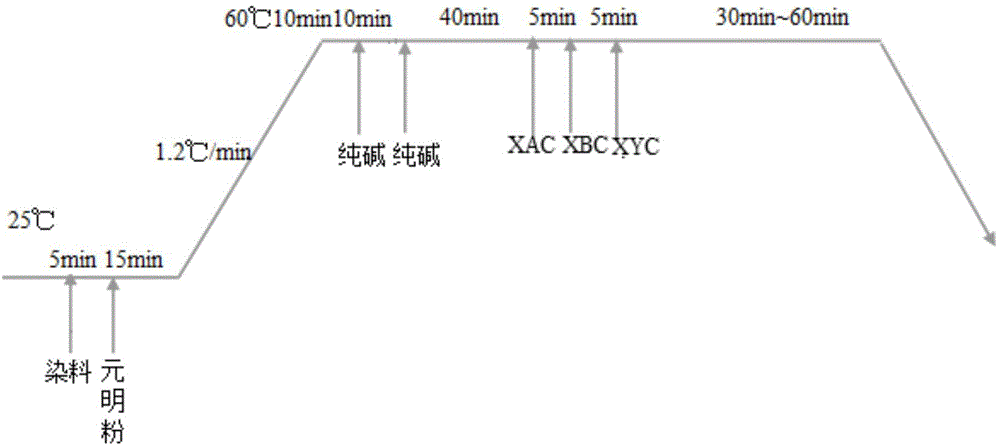

Cellulosic fiber in-situ mineralization deep water-saving and emission reduction dyeing aftertreatment method and additive

The invention discloses a cellulosic fiber in-situ mineralization deep water-saving and emission reduction dyeing aftertreatment method which comprises the following steps: firstly, putting a fabric to be dyed into dyeing equipment, adding dyeing water into the dyeing equipment, and keeping circulation of a dye bath; performing dyeing processing on the fabric to be dyed by using a common deying method for the cellulosic fiber, and after dyeing is completed, retaining the residual dyeing liquid; further simultaneously performing in-situ mineralization treatment on the residual dyeing liquid obtained after cellulosic fiber dyeing processing and the dyed fabric by using cellulosic fiber aftertreatment additives XAC, XBC and XYC; storing the residual dyeing liquid obtained after the mineralization treatment as later dyeing water; dehydrating and drying the dyed fabric, thereby completing dyeing and aftertreatment on the fabric. The invention further discloses the cellulosic fiber dyeing aftertreatment additives XAC, XBC and XYC. By adopting the dyeing aftertreatment method disclosed by the invention, the water consumption problem and the wastewater discharge problem in the cellulosic fiber dyeing processing can be fundamentally solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

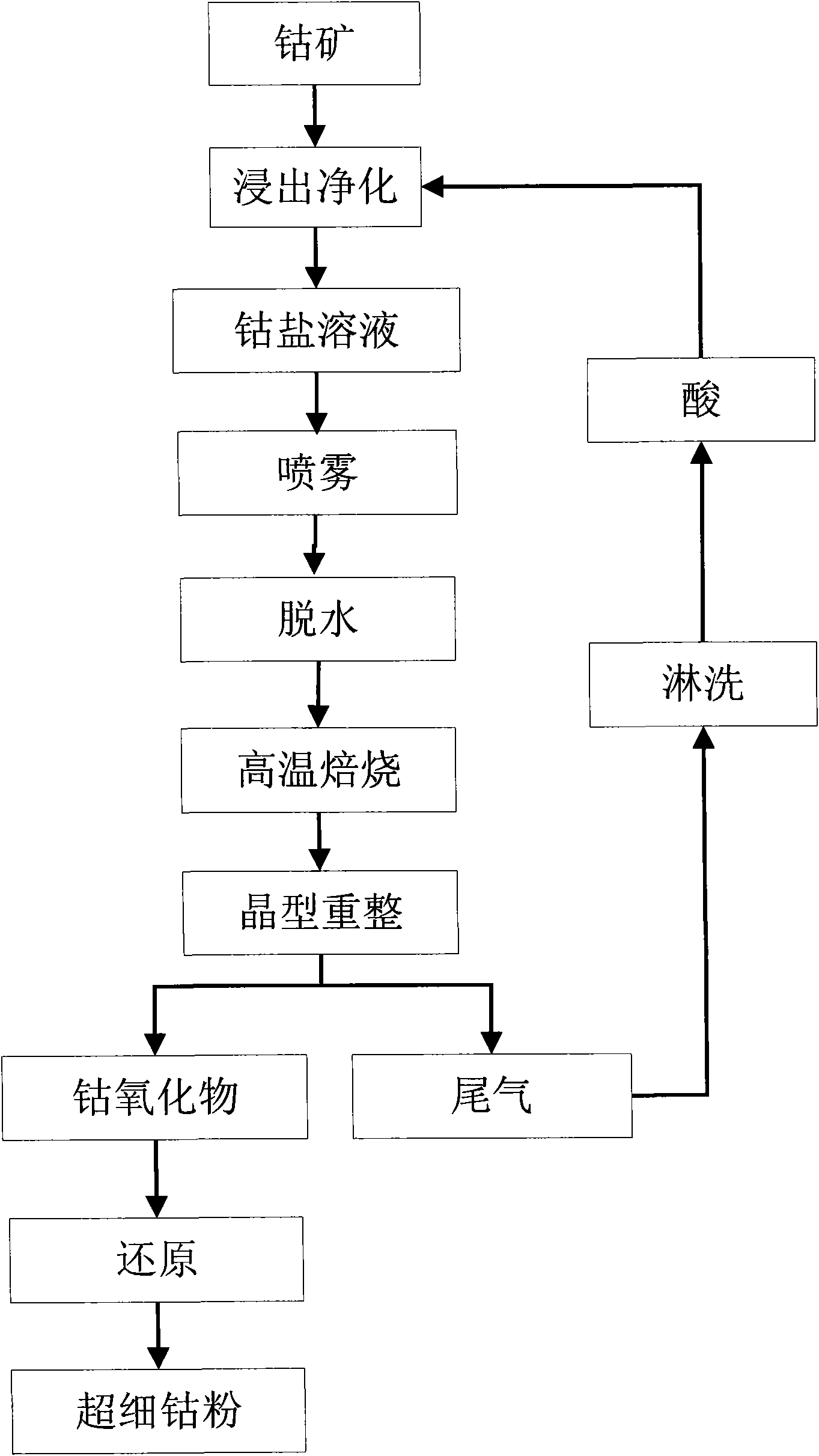

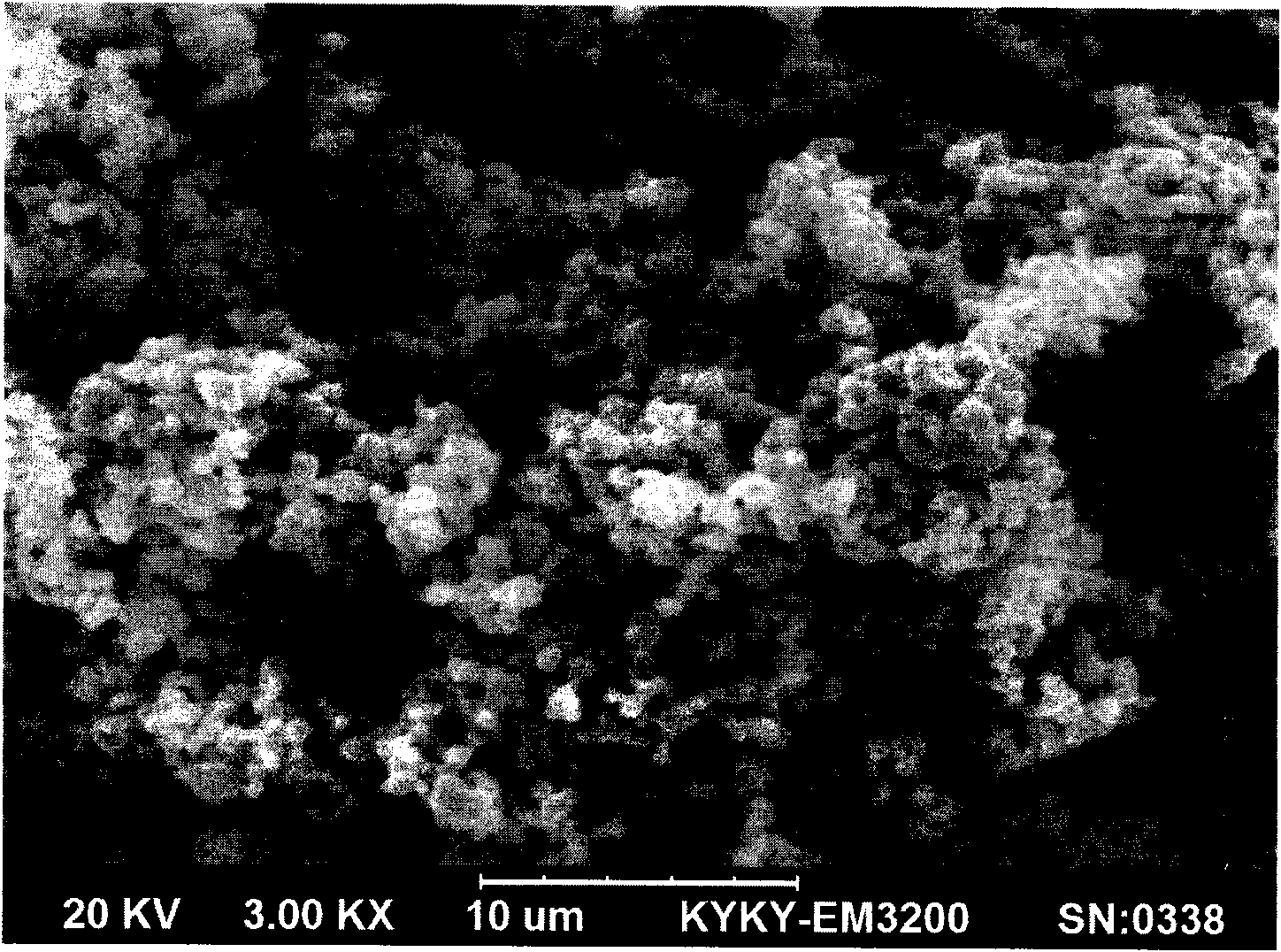

Preparation method of ultrafine cobalt powder

The invention discloses a preparation method of ultrafine cobalt powder. Some prior methods have the disadvantages of higher cost, or existence of discharge problems of ammonia-nitrogen waste water, or coarser cobalt powder particles or difficult acquisition of high-purity products, and the like; and the prior methods are not suitable for large-scale industrialized production. In the invention, the cobalt ore is used as raw material, a spraying and roasting-reducing method is used for preparing ultrafine spherical cobalt powder, and meanwhile, the tail gas generated in the spraying and roasting processes is absorbed, treated and returns to a production system for recycling, thereby shortening the technological processes, reducing the discharge of the waste water and achieving the purposesof environmental protection and large-scale industrialized production of ultrafine spherical cobalt powder.

Owner:ZHEJIANG HUAYOU COBALT

Method for extracting o-phenylendiamine from waste water of o-phenylendiamine production

InactiveCN1865223AHigh removal rateHigh purityAmino compound purification/separationDistillationFiltration

This invention relates to a method for extracting o-phenylenediamine from waste water of o-phenylenediamine production. Wherein: filtrate the waste water containing o-phenylenediamine, and load it on the absorption column filled with macroreticular resin which absorbs o-phenylenediamine and other organic compounds in the waste water, and then elute with ethanol solution to desorb the o-phenylenediamine and form the desorption solution, distill the desorption solution to remove the ethanol, cool the residual liquid after distillation at controlled temperature to precipitate the o-phenylenediamine crystals, and then obtain the o-phenylenediamine by filtration. This invention is characterized of high clearance of o-phenylenediamine in the waste water, high-purity of recovered o-phenylenediamine, simple and rational process. It accomplishes the object of turning waste to be useful, solves the waste discharging problem, and has a good economical benefit.

Owner:陈义龙

Electrochemical copper removing solution

The present invention relates to a solution for electrochemistry copper stripping, belongs to the chemical field, and is characterized in that said electrochemistry copper stripping solution contains a complexant of ethylene diamine of 100-300 g / L, a corrosion inhibitor of triethanolamine of 40-120 g / L and of erinitrit of 50-150 g / L, and an electrolyte of potassium nitrate of 50-150 g / L.The invention possesses the advantages that the discharging problem of Cr6+ containing waster water does not exist in the copper layer stripping by using said copper stripping solution, non-corroding on matrix metal occurs, the electrical current efficiency is high, the copper stripping time is shout, the productivity effect is high, and the adjustment and regeneration of the copper stripping solution is convenient.

Owner:内蒙古第一机械集团股份有限公司

Circulating fluidized bed boiler oxygen-enriched combustion dry desulphurization system and method

ActiveCN104807002AIncrease profitEase of Controlling EmissionsFluidized bed combustionSolid fuel pretreatmentCycloneHearth

The invention discloses a circulating fluidized bed boiler oxygen-enriched combustion dry desulphurization system and method. The dry desulphurization system comprises a hearth, a coal feeding hole, a primary air chamber, an air distribution device, a high-temperature cyclone separator, a tail flue, a coal economizer and a return device, wherein a desulfurizer feeding hole is formed in the coal feeding hole or / and in a return leg of the return device; a medium-temperature cyclone separator is arranged on the tail flue on the rear of the coal economizer; a return bin of the medium-temperature cyclone separator is connected with the hearth through a pipeline; a central drum of the medium-temperature cyclone separator is connected with the primary air chamber through an air hose and a primary air hose and is connected with the hearth through the air hose and a secondary air hose; an induced draft fan is arranged on the air hose; an oxygen injection device is arranged on at least one of the air hose, the primary air hose and the second air hose. The circulating fluidized bed boiler oxygen-enriched combustion dry desulphurization system can effectively solve the SOx up-to-standard discharge problem of a boiler, increase the utilization ratio of limestone, reduce consumption of limestone, improve desulphurization efficiency, realize efficient and economical desulphurization in the boiler as well as CO2 enrichment, facilitate compression, purification, utilization, sealing and storage of CO2, and meet environmental protection demand.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Vanadium-nitrogen alloy production method

ActiveCN102936678APrevent collision with each otherHigh apparent densityIron powderPositive pressure

The invention relates to a vanadium-nitrogen alloy production method which belongs to the technical field of metallurgy. The method comprises the steps of: stirring and uniformly mixing vanadium-containing raw material powder, iron powder, carbon powder and bonder for briquetting and forming, sending the mixture and rice husk into a calcining kiln according to a volume ratio of 1: 1 for dry distillation in the absence of oxygen at a temperature of 600-650 DEG C for 6-7h, heating to 1300-1500 DEG C, sending high-purity nitrogen into the calcining kiln from different gas inlets under micro-positive pressure for 2-4h, carrying out carbonization and nitrogenization on the formed material briquette, and cooling and discharging to obtain a vanadium nitride product. According to the method, the discharge problem of the gas generated in the reaction and the penetration problem of the reaction participation gas are solved through changing a reaction environment of the formed material briquette in the calcining kiln, so that the carbonization and the nitrogenization are promoted and the aims of improving the nitrogen content of the vanadium-nitrogen alloy, homogenizing and stabilizing the product quality, shortening the reaction time, improving the output and reducing the production cost are finally achieved.

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

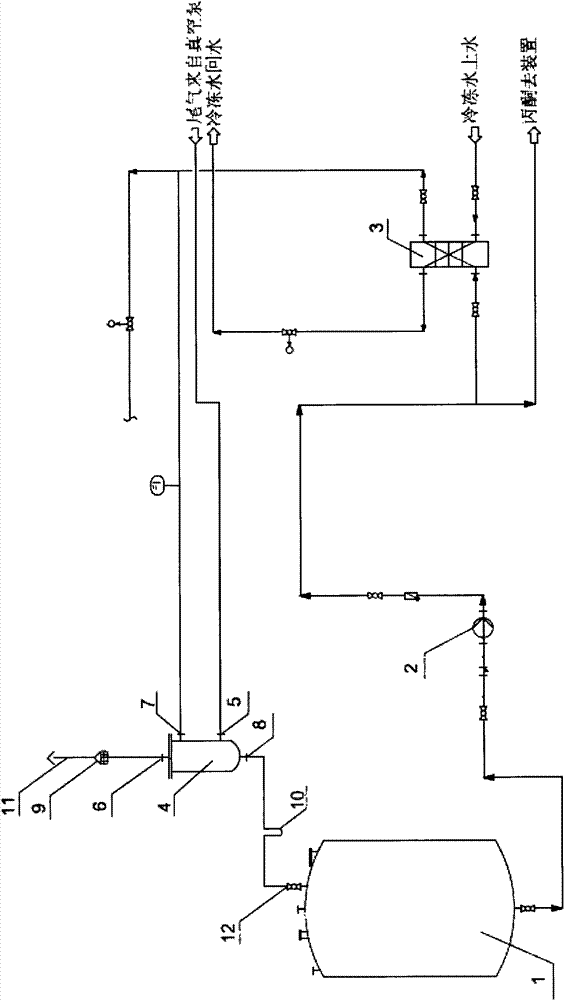

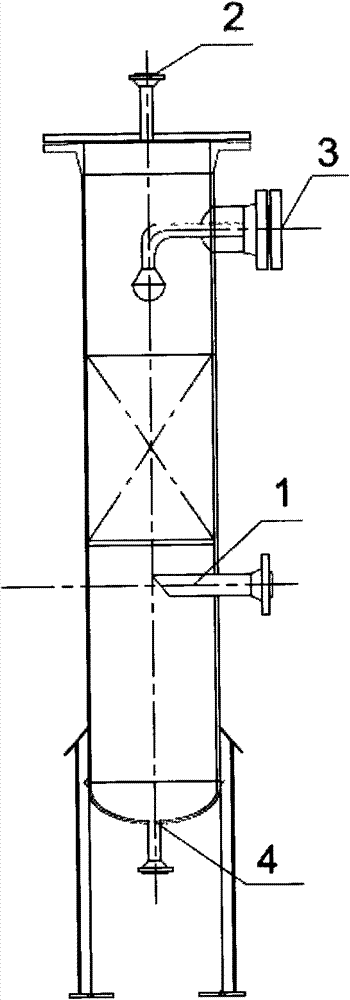

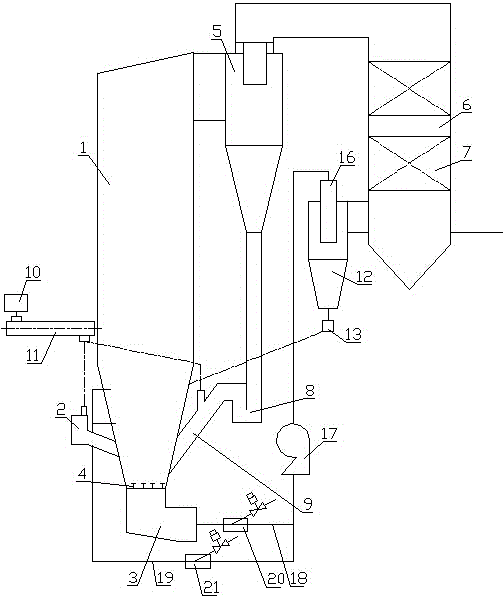

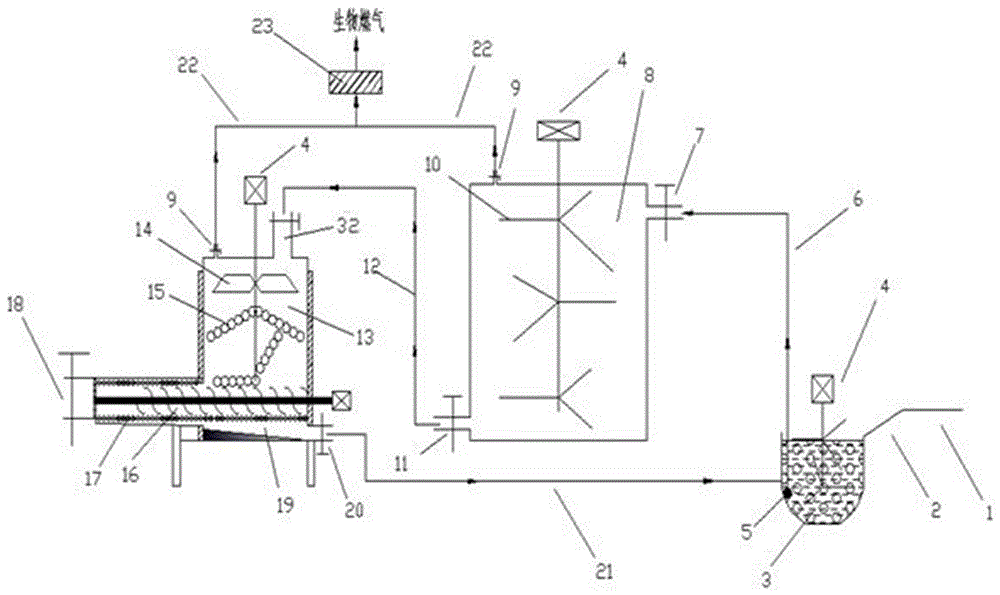

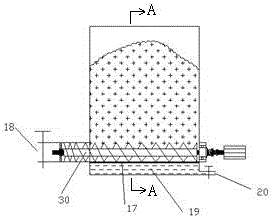

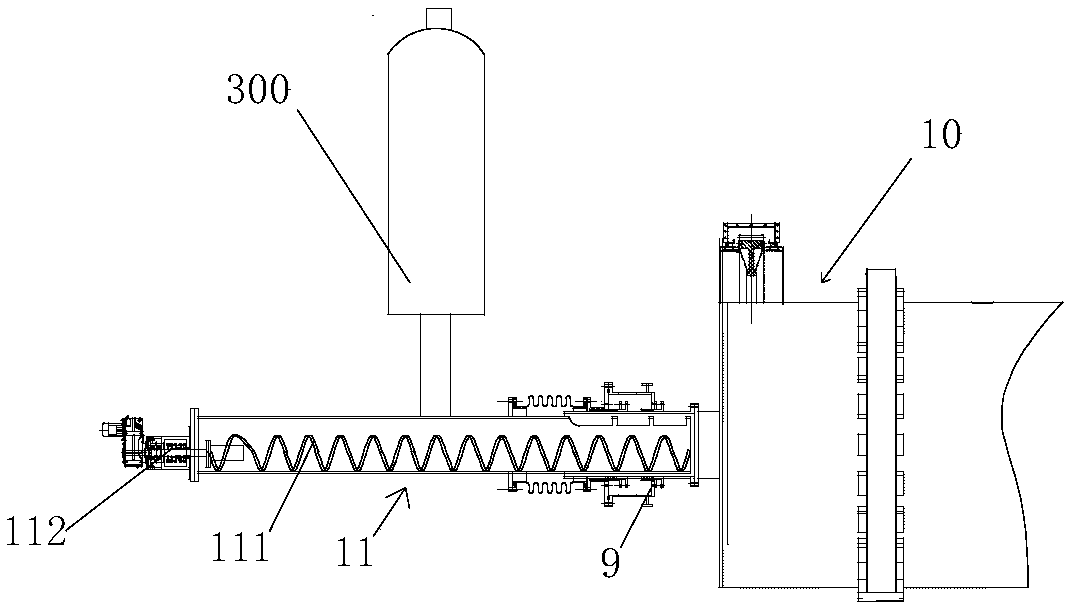

Continuous wet-dry two-stage dynamic anaerobic fermentation device

ActiveCN106222074AEasy to handleIncrease volumetric gas production rateBioreactor/fermenter combinationsBiological substance pretreatmentsDischarge problemsFermentation

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

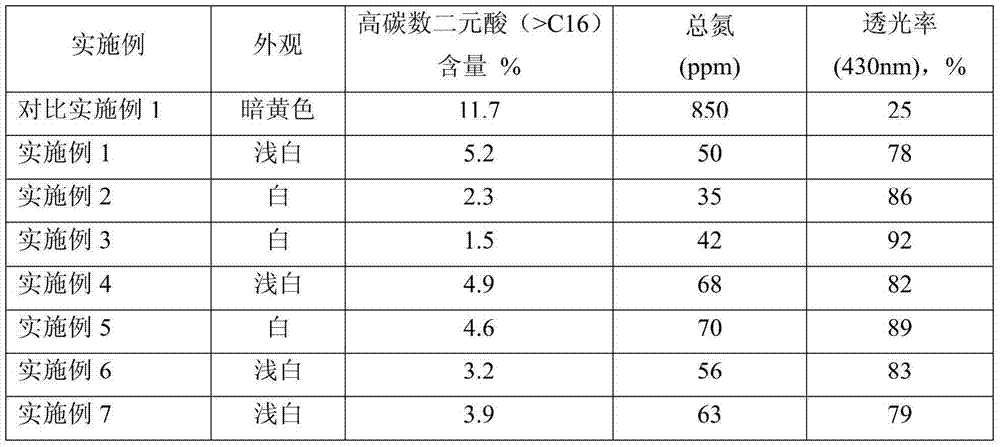

Long-chain mixed dicarboxylic acid purification method

ActiveCN104844441AQuality improvementSolve the emission problemPreparation from carboxylic acid saltsOrganic compound preparationCarbon numberPurification methods

The present invention relates to a long-chain mixed dicarboxylic acid extraction method, which comprises: (1) adding a mixed dicarboxylic acid solid to water, heating, adding an alkali to adjust the pH value, dissolving, cooling, precipitating, and separating to obtain a solid I; (2) pouring the solid I to water, heating to increase the temperature, and after dissolving the solid I, adding an oxidizing agent to oxidize so as to improve the solution color and reduce the high carbon number dicarboxylic acid content in the solution; and (3) adding an acid to the obtained solution to adjust the pH value so as to precipitate the mixed dicarboxylic acid, separating the solid, and drying to obtain the long-chain mixed dicarboxylic acid finished product. According to the present invention, the second precipitation and the oxidizing process are combined in the water phase to obtain the high quality dicarboxylic acid finished product, wherein the dicarboxylic acid finished product has characteristics of white color, good quality, and low high-carbon-number dicarboxylic acid (dicarboxylic acid having more than or equal to 16 carbon number) content, and is especially suitable for the anti-rust field; and with the extraction process, the by-product discharge problem during the long-chain dicarboxylic acid production can be simply and effectively solved, such that the environment is protected and the enterprise incomes are increased.

Owner:CATHAY (JINXIANG) BIOMATERIAL CO LTD +1

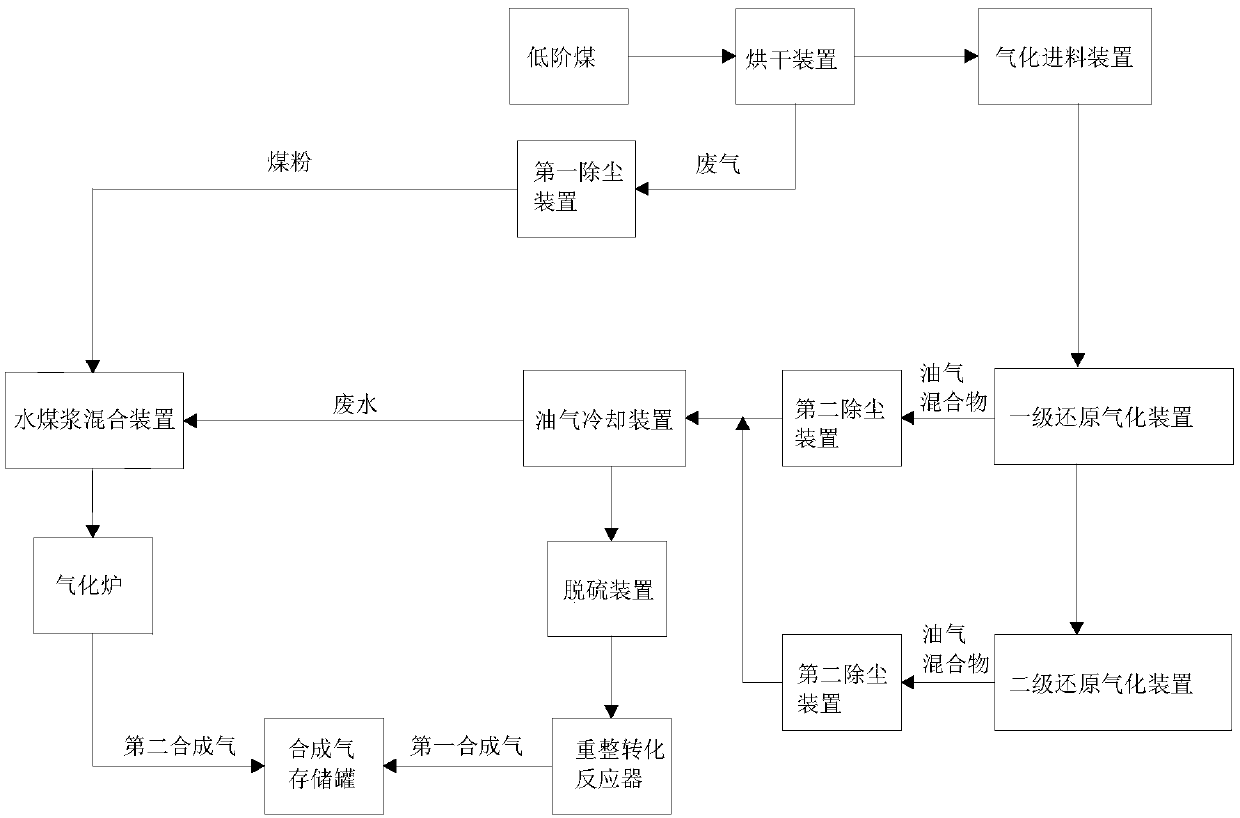

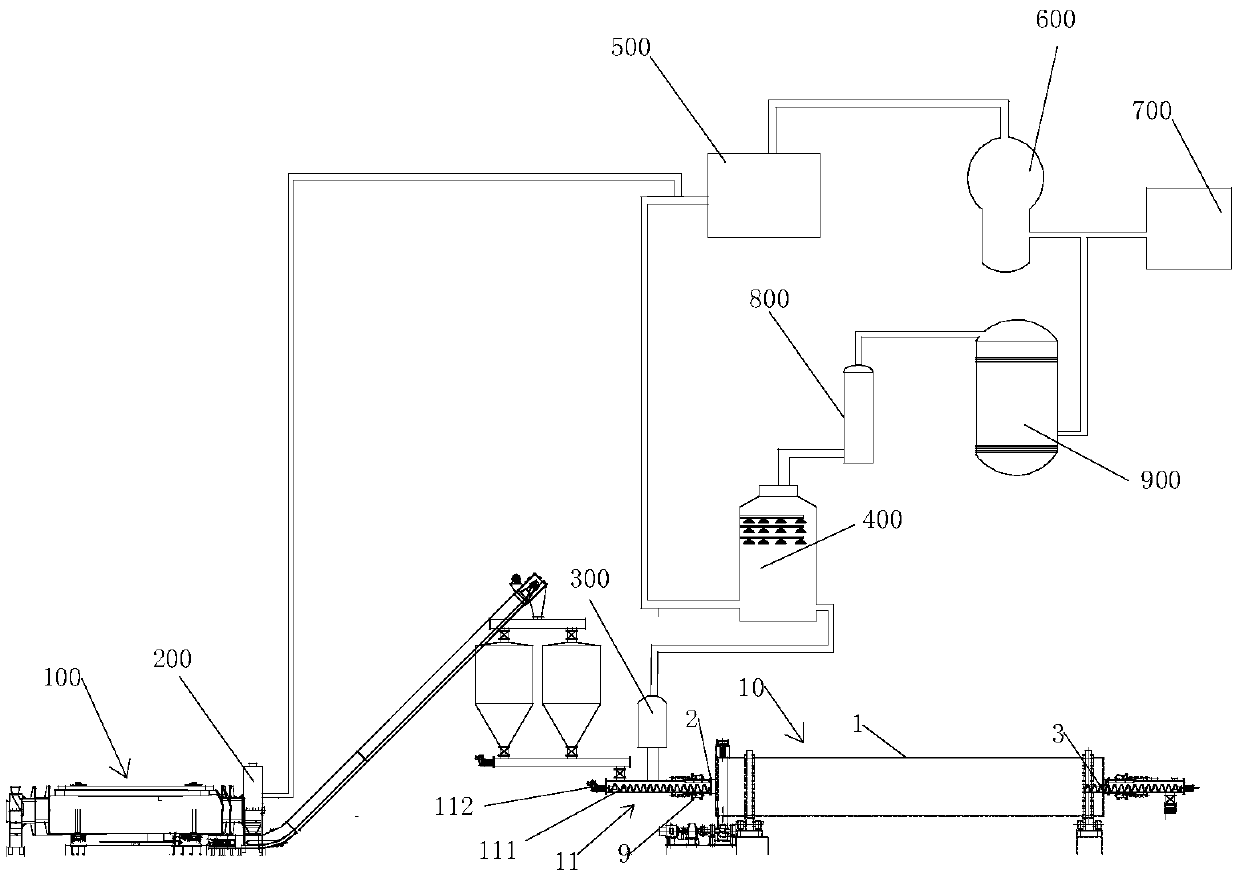

Method for preparing synthetic gas by using volatile compound and waste water in low rank coal and system thereof

PendingCN109652139AImprove overall utilizationHigh organic contentGaseous fuelsGasification processes detailsCoal waterSyngas

The invention provides a method for preparing synthetic gas by using a volatile compound and waste water in low rank coal. The low rank coal is processed by a drying process to obtain dried low-rank coal and exhaust gas, and the exhaust gas is treated by a first dust removal process to obtain coal dust; the dried low-rank coal is treated by a gasification reduction process to obtain a gas-oil mixture; the gas-oil mixture is treated by a purification process to obtain a gas mixture and wastewater; the gas mixture is treated by a reforming conversion process to obtain a first synthetic gas containing CO and H2; the wastewater, the coal dust and a coal water slurry additive are mixed to obtain coal water slurry, and the coal water slurry and O2 are treated by a coal water slurry gasificationprocess to obtain a second synthetic gas comprising CO and H2; and the synthetic gas is obtained by mixing the first synthetic gas and the second synthetic gas. In the invention, the volatile compoundin the low rank coal is used for preparation of the synthetic gas, and moisture and coal dust in the low rank coal are effectively recovered to be used for making the coal water slurry, and the low rank coal is used for making the synthetic gas. With the reutilization of waste water, the wastewater discharge problem is solved.

Owner:浙江天禄环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com