Gas production rate measurement and gas collection device for thermal runaway process of lithium ion battery

A lithium-ion battery and collection device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as large errors, low accuracy of gas production measurement results, and many gas impurities, and achieve reliable data support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

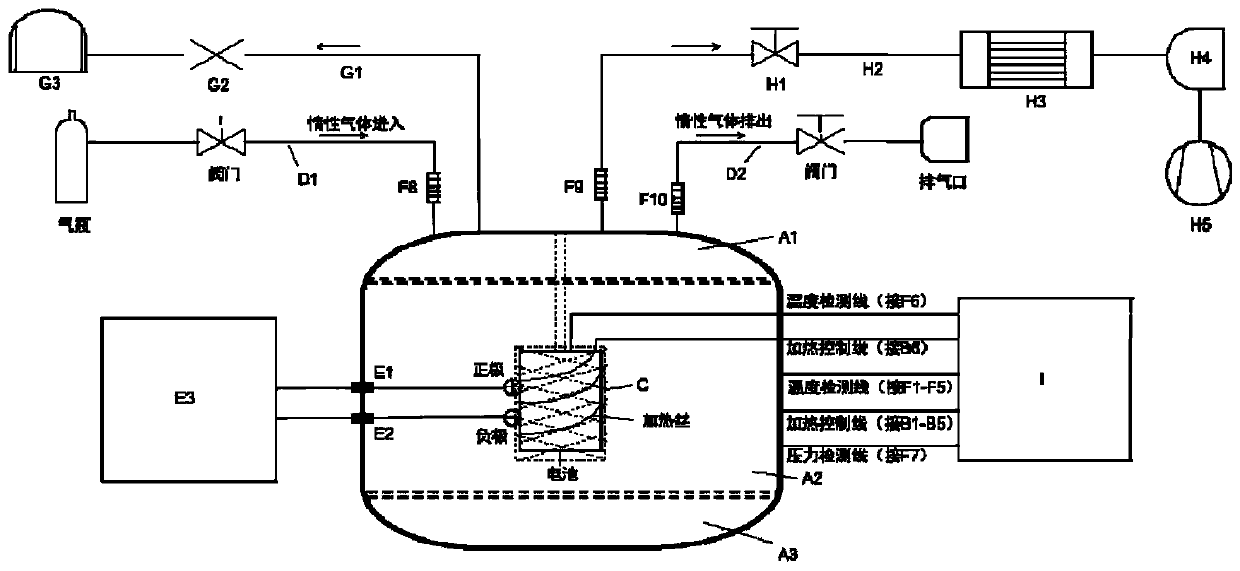

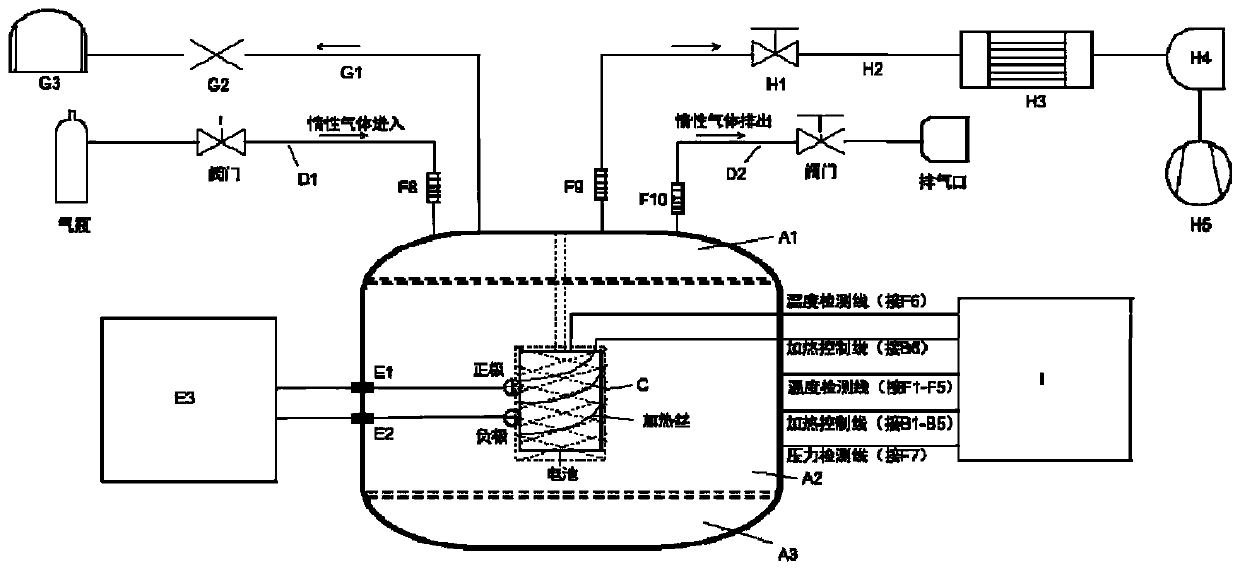

[0052] like figure 1 As shown, this embodiment provides a gas production measurement and gas collection device during thermal runaway of lithium-ion batteries, including:

[0053] A pressure explosion-proof container A with a closed space, including a top cover A1, a container wall A2 and a base A3, the internal volume V of the pressure explosion-proof container 容器 = 1.0L, the pressure range is 0 atmosphere to 6 atmospheres;

[0054] A plurality of heating devices B for heating the pressure explosion-proof container A and the lithium-ion battery to be tested, the heating device includes 3 heating modules B1-B3 evenly distributed on the circumference of the middle part of the container wall, and 1 heating module placed on the top cover A heating module B4, a heating module B5 placed on the base and a heating module B6 placed on the battery, the heating module on the battery is connected with a heating wire wound on the battery. The temperature range of the heating module is 0...

Embodiment 2

[0076] Measure the mass and size of the lithium-ion battery, record its mass as m, and calculate its volume as V;

[0077] The lithium-ion battery is placed in the battery suspension device C of the pressure explosion-proof container A, and the internal volume V of the pressure explosion-proof container is 容器 =1.0L, the battery heating module B6 is connected to the heating wire and wound on the battery, the battery temperature detection module F6 is placed on the battery, the positive and negative electrodes of the battery are connected to the voltage acquisition line through the terminal posts E1 and E2, and the pressure explosion-proof container A is sealed;

[0078] Open the inert gas inlet and outlet valves, pass inert gas for a period of time, drain the air in the container, fill the container with inert gas, and keep the container pressure at about 1 atmosphere, and close the inert gas inlet and outlet valves; at this time Denote the pressure as p 0 , the temperature is...

Embodiment 3

[0086] Measure the mass and size of the lithium-ion battery, record its mass as m, and calculate its volume as V;

[0087] The lithium-ion battery is placed in the battery suspension device C of the pressure explosion-proof container A, and the internal volume V of the pressure explosion-proof container A is 容器 =1.0L, the battery temperature detection module F6 is placed on the battery, the positive and negative poles of the battery are electrically connected to the battery charging and discharging equipment E3 through the terminal posts E1, E2, connected to the voltage acquisition line, and the pressure explosion-proof container A is sealed;

[0088] Open the inert gas inlet and outlet valves, pass inert gas for a period of time, drain the air in the container, fill the container with inert gas, and keep the container pressure at about 1 atmosphere, and close the inert gas inlet and outlet valves; at this time Denote the pressure as p 0 , the temperature is T 0 ;

[0089] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com