Experimental table of wind-driven generator pitching slewing support

A technology for wind turbines and slewing bearings, applied in the direction of mechanical bearing testing, etc., can solve the problems of loading and collecting different specifications of wind turbine pitch slewing bearings, and achieve the effects of wide application, reliable operation, and accurate simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

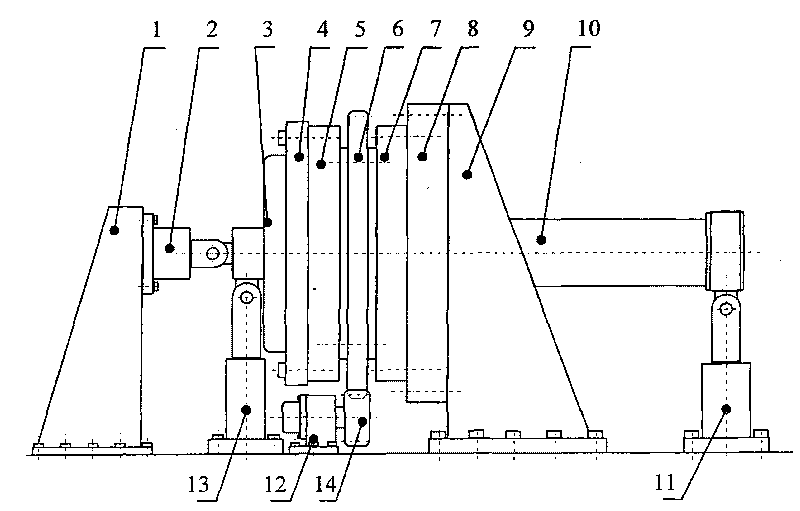

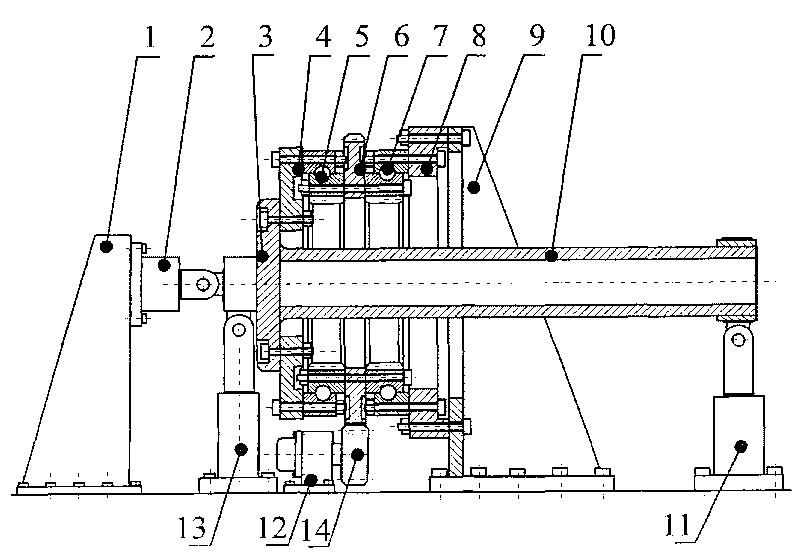

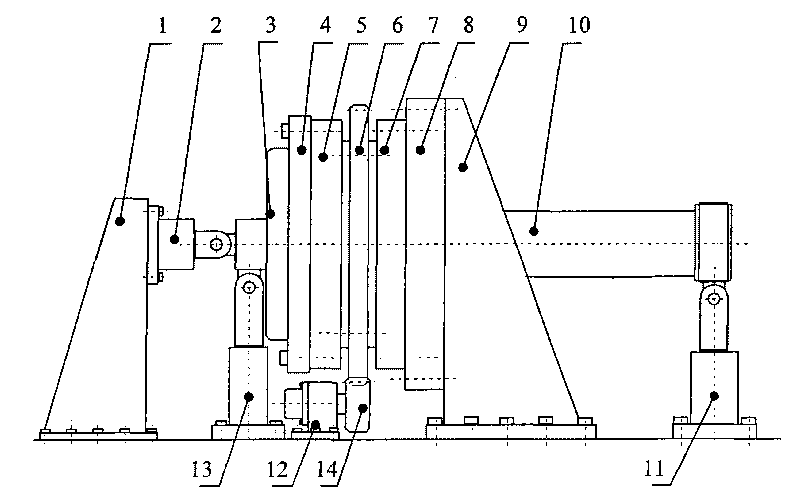

[0024] A wind turbine pitch slewing bearing test bench, comprising a slewing bearing installation base 9, the slewing bearing installation base 9 is placed vertically, and a pair of pitch slewing bearings 5 to be tested and a pitching slewing bearing 7 to be tested are vertically installed on it , the moving coils of the variable pitch slewing ring 5 to be tested and the variable pitch slewing ring 7 to be tested are installed on both sides of the large gear 6 respectively, and the pitch slewing ring 5 to be tested and the pitch slewing ring 7 to be tested pass through the left connecting plate 4 respectively The total loading plate 3 and the slewing bearing installation base 9 are connected with the right connecting plate 8; the left end of the total loading plate 3 is connected to the loading frame 1 through the axial force loading cylinder 2, and the radial force loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com