Laser discharge chamber device of gas CO2 laser

A laser and discharge cavity technology, applied in gas laser parts, laser parts and other directions, can solve the problems of increasing discharge transition probability, the inability of the laser to operate stably and reliably for a long time, and the inability to maintain the stability of glow discharge, etc. To achieve the effect of stable discharge duration, long discharge duration, and consistent discharge duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

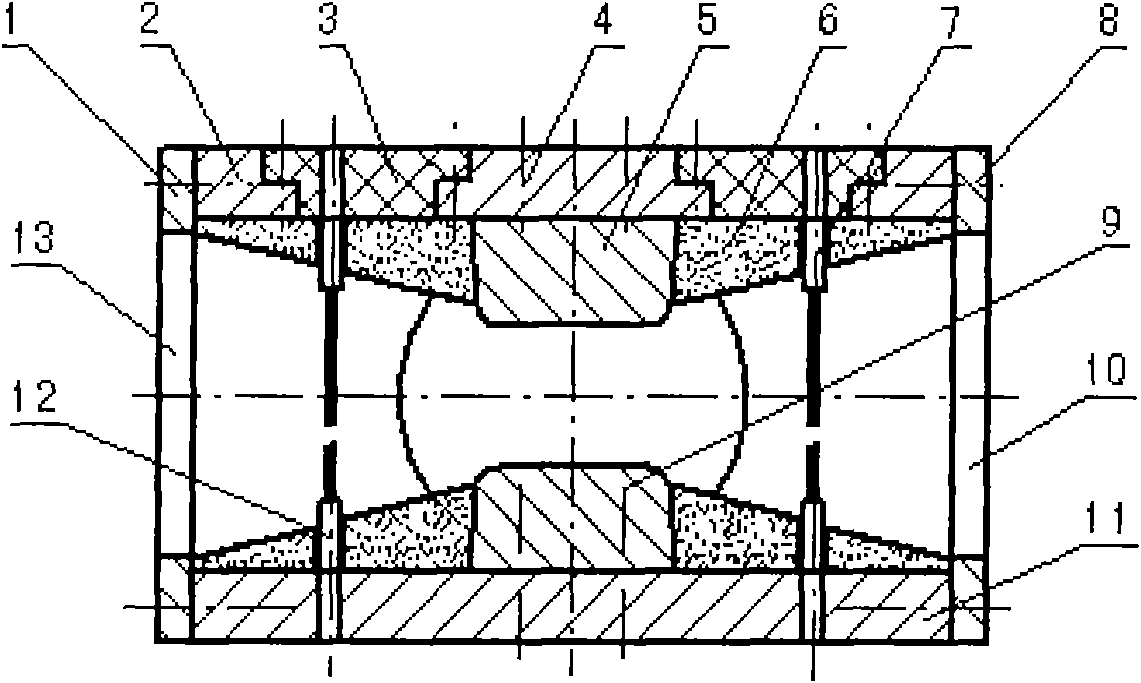

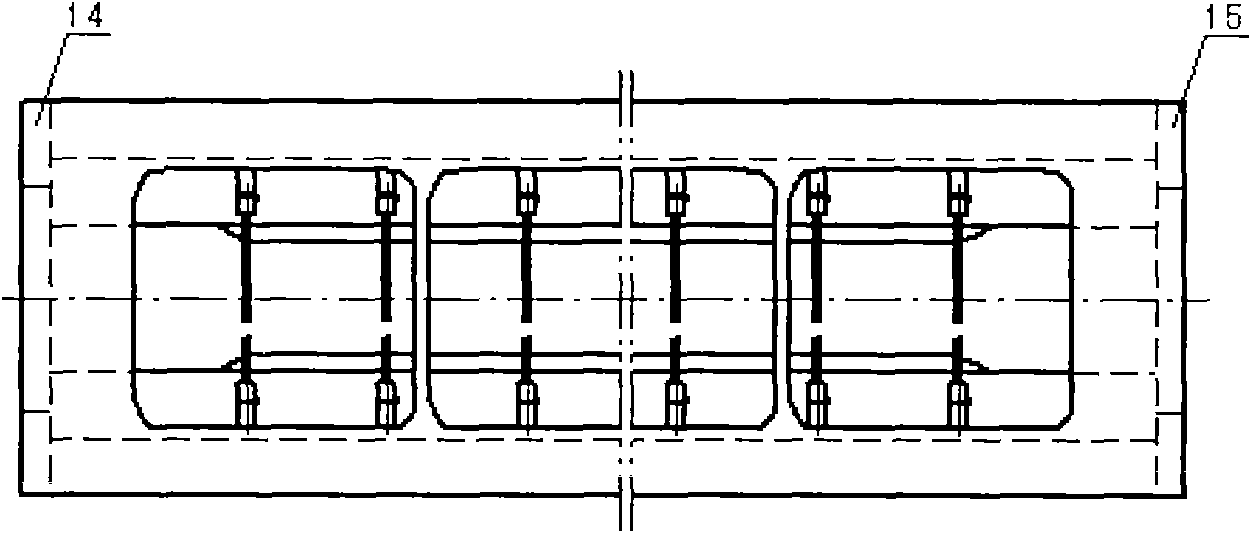

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment: see for details figure 1 and figure 2 :

[0017] The gas CO of the present invention 2 The laser discharge cavity of the laser includes the vertical plate 01 on the right side of the cavity, the support frame plate 02 on the cavity, the insulating frame plate 03 on the cavity, the electrode plate 04 on the cavity, the discharge electrode 05 on the upper cavity, the ceramic insulating sheet 06, the upper pre-ionization trigger pin 07, the cavity Left vertical plate 08, lower discharge electrode 09, gas circulation channel air inlet 10, chamber lower electrode plate 11, lower pre-ionization trigger pin 12, gas circulation channel gas outlet 13, chamber front end plate 14, chamber rear end The plate 15 constitutes the laser discharge chamber arrangement.

[0018] The cavity right vertical plate 01; the cavity left vertical plate 08; the cavity front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com