Rice milling machine

A rice milling machine and rice milling roller technology, applied in the field of rice milling machines, can solve problems such as the inability to meet the requirements of different types of rice milling and processing, and achieve the effects of preventing over-milling, reducing internal pressure and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

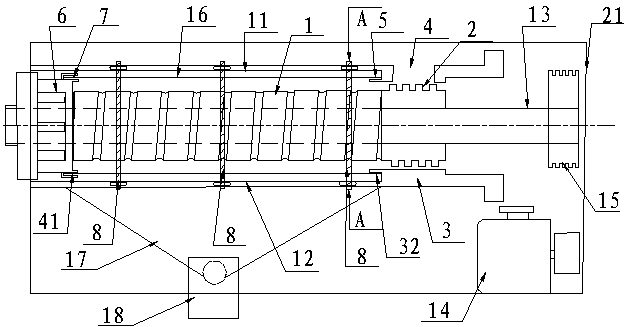

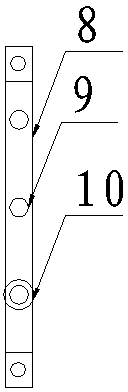

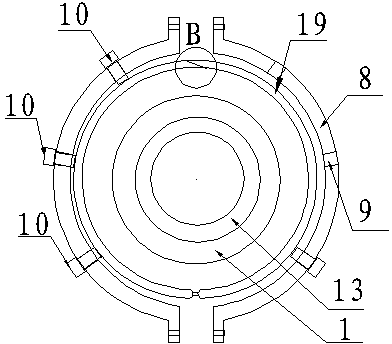

[0027] Such as figure 1 Shown, a kind of rice milling machine comprises casing 27, blower fan 18 is connected with chaff bucket 17, has motor 14 to place in casing 27, and main shaft 13 is horizontally arranged along casing 27, and motor 14 is connected with main shaft 13 by belt pulley 15, and main shaft 13 is a hollow tubular structure, the main shaft 13 is externally connected with a propeller 2 and a rice milling roller 1, a rice milling chamber is formed between the rice milling roller 1 and the sieve plate 16, and the feed port 4 on the feed bearing seat 3 is connected Into the top of the propeller 2 head end, the discharge port 7 on the discharge bearing seat 6 is located at the end of the rice milling chamber, the split sieve plate 16 is fixedly connected with the upper and lower beams 11, 12 through several sieve brackets 8, at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com