Patents

Literature

37results about How to "Decrease manufacturing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

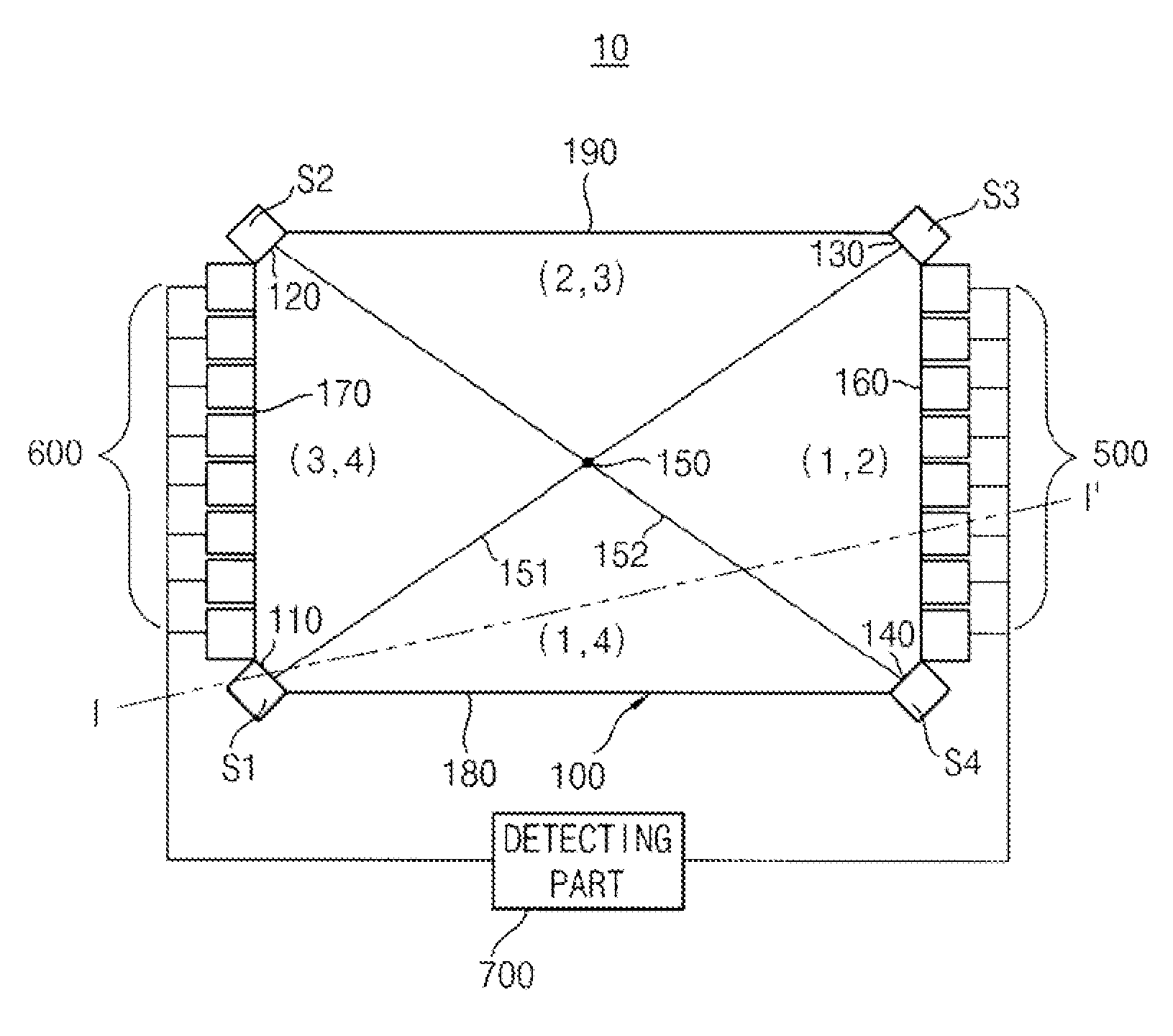

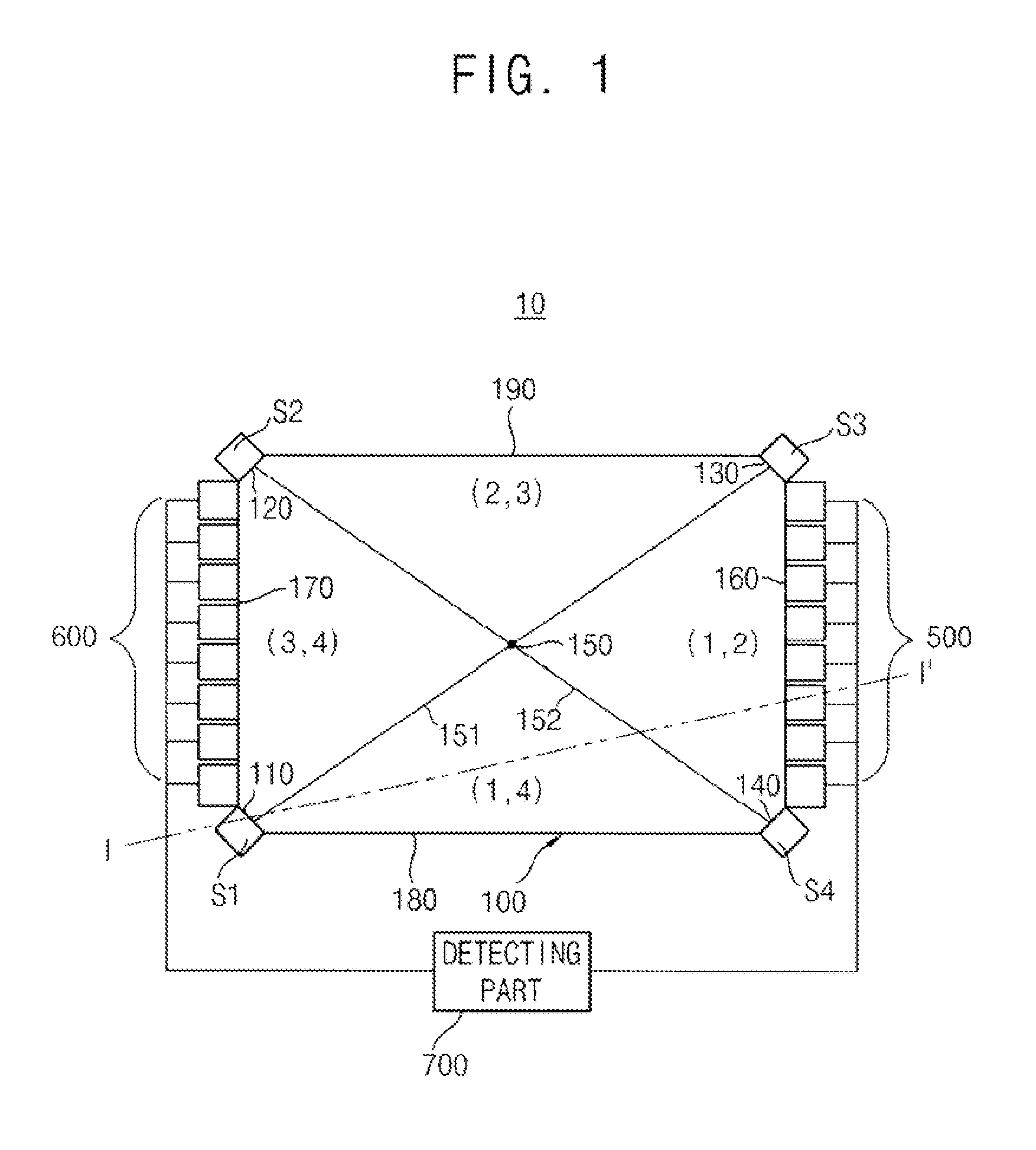

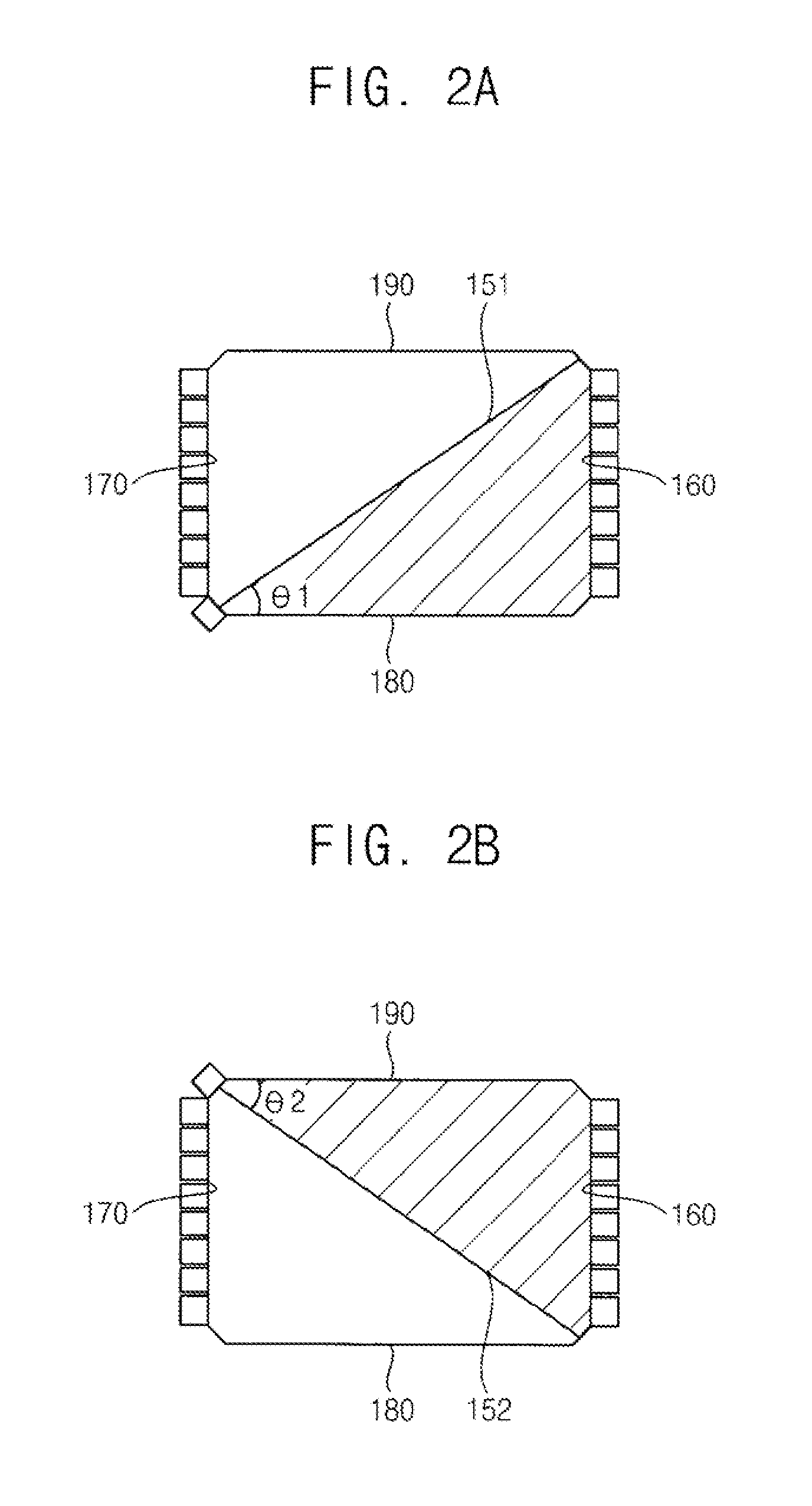

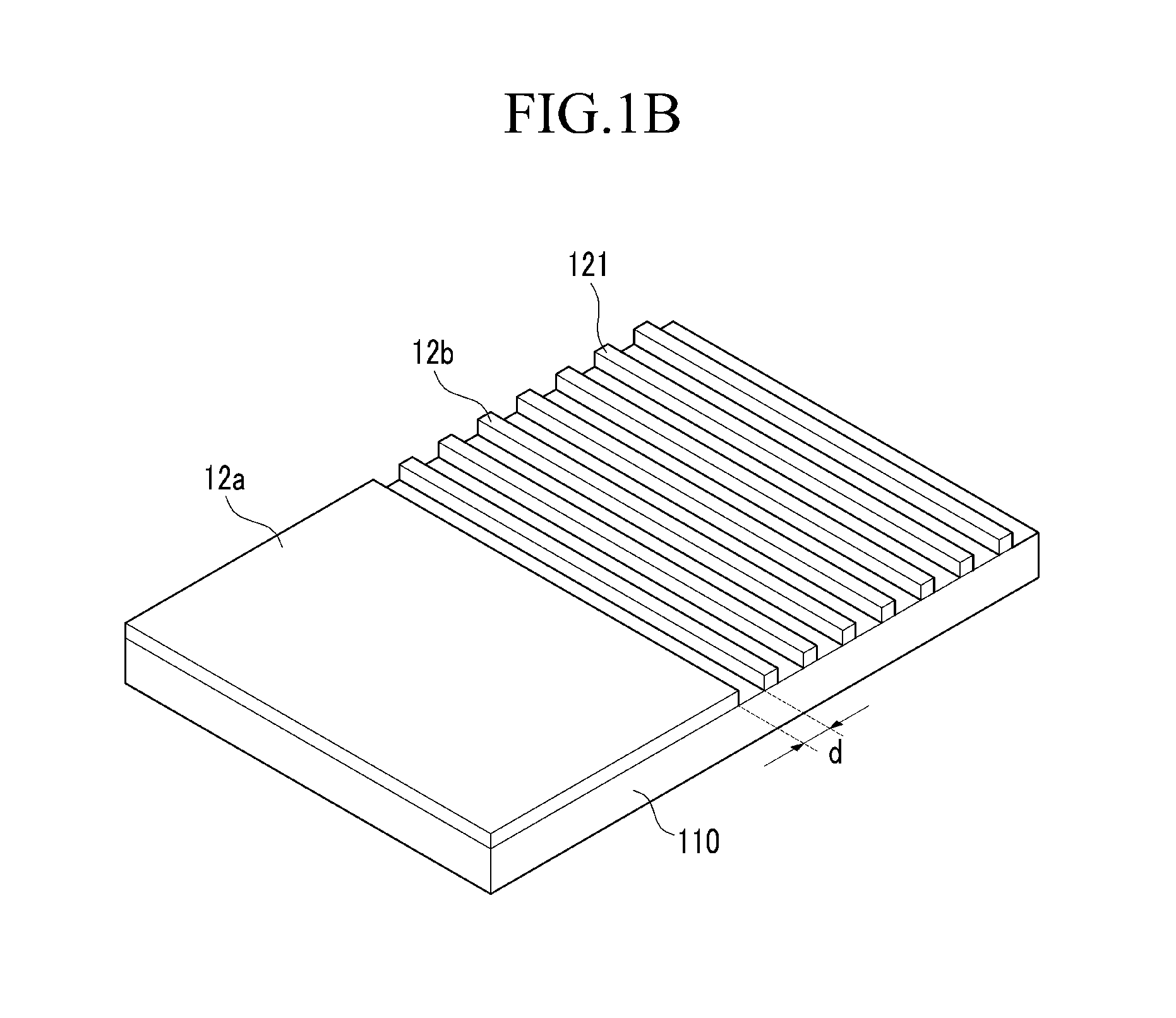

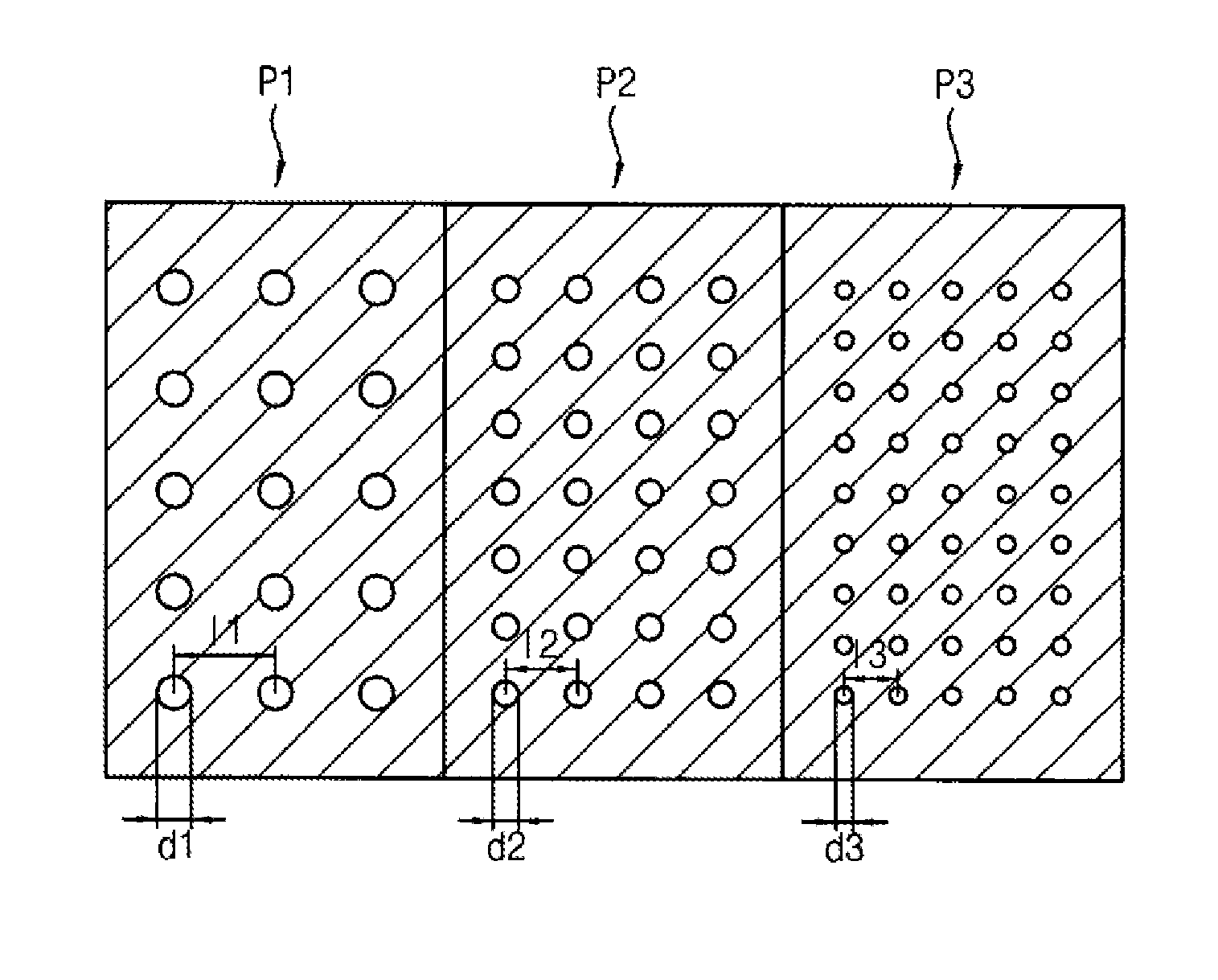

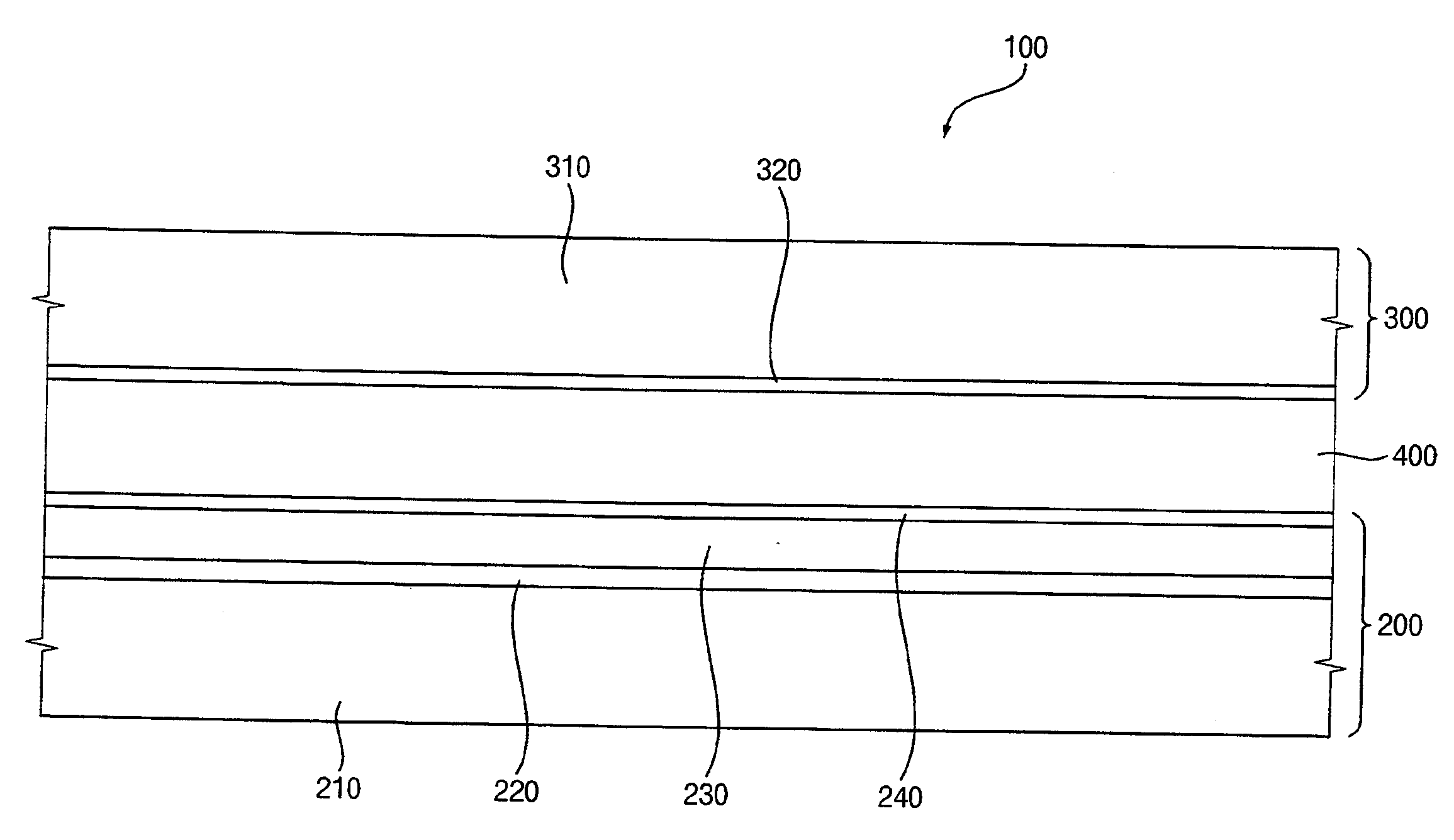

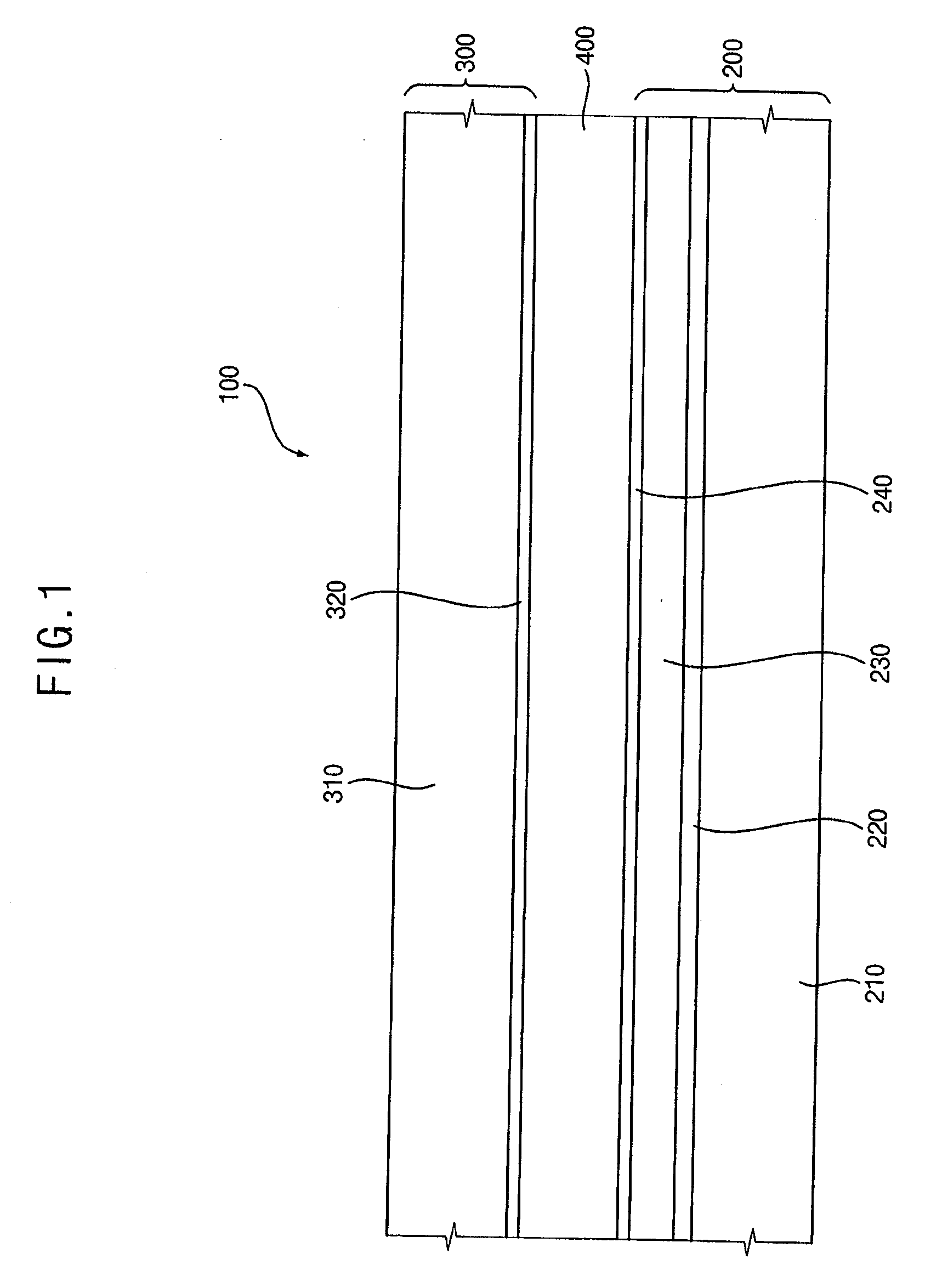

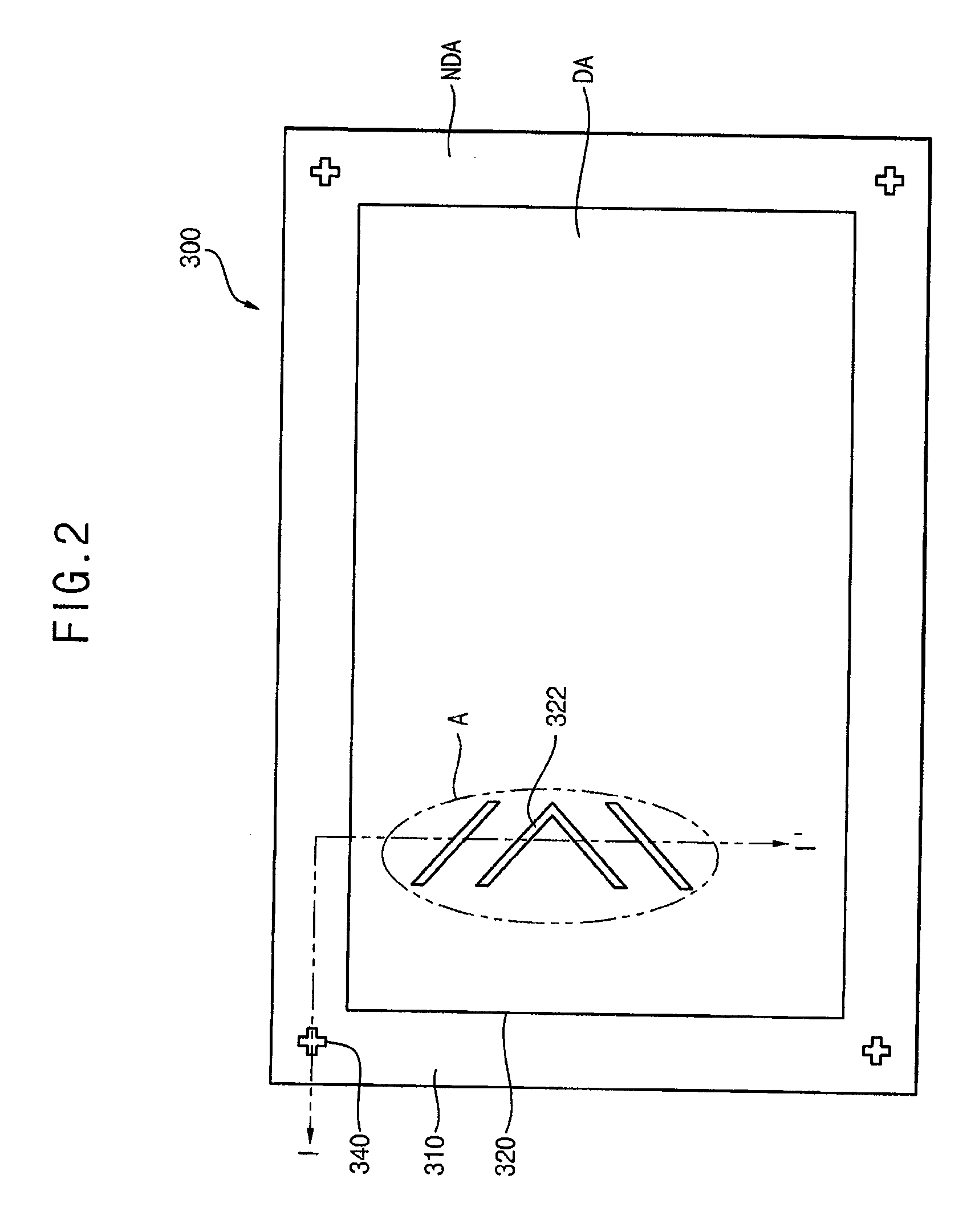

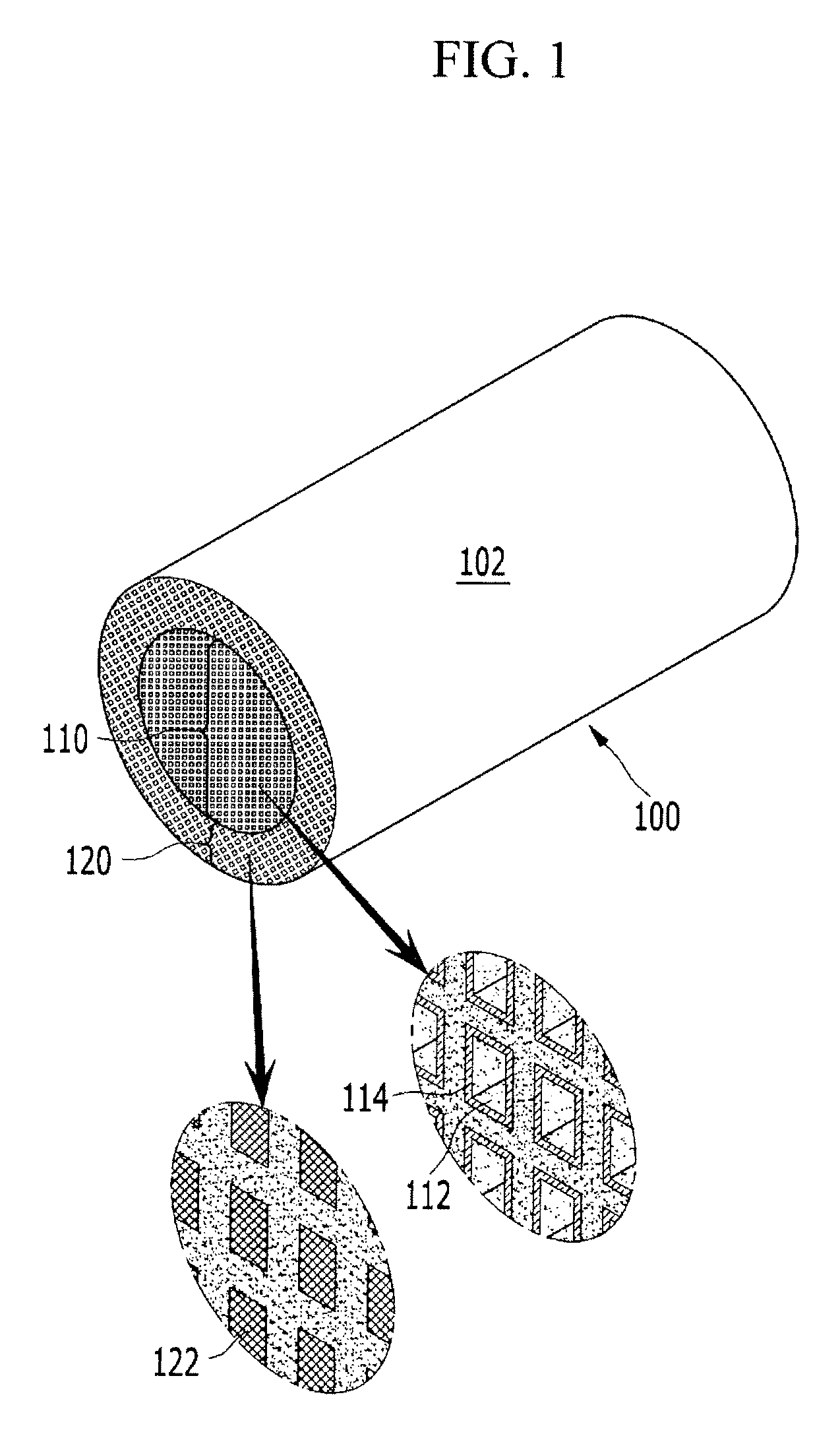

Method of Detecting Touch Position, Touch Position Detecting Apparatus for Performing the Method and Display Apparatus Having the Touch Position Detecting Apparatus

InactiveUS20110221997A1Decrease in numberDecrease manufacturing costOptical waveguide light guideNon-linear opticsPhysicsLight wave

A light waveguide has a rectangular plate shape and is configured to totally reflect internal light arriving at an angle greater than a critical angle. Light emitting parts are disposed at corners of the light waveguide. Each of the light emitting parts emits light once in a period. A first light receiving part is disposed along a first side surface of the light waveguide, and receives light emitted from the light emitting parts adjacent to a second side surface facing the first side surface of the light waveguide. The second light receiving part is disposed along the second side surface of the light waveguide, and receives light emitted from the light emitting parts adjacent to the first side surface. A detecting part detects a touch position based on an amount of the light received by the first and second light receiving parts.

Owner:SAMSUNG DISPLAY CO LTD

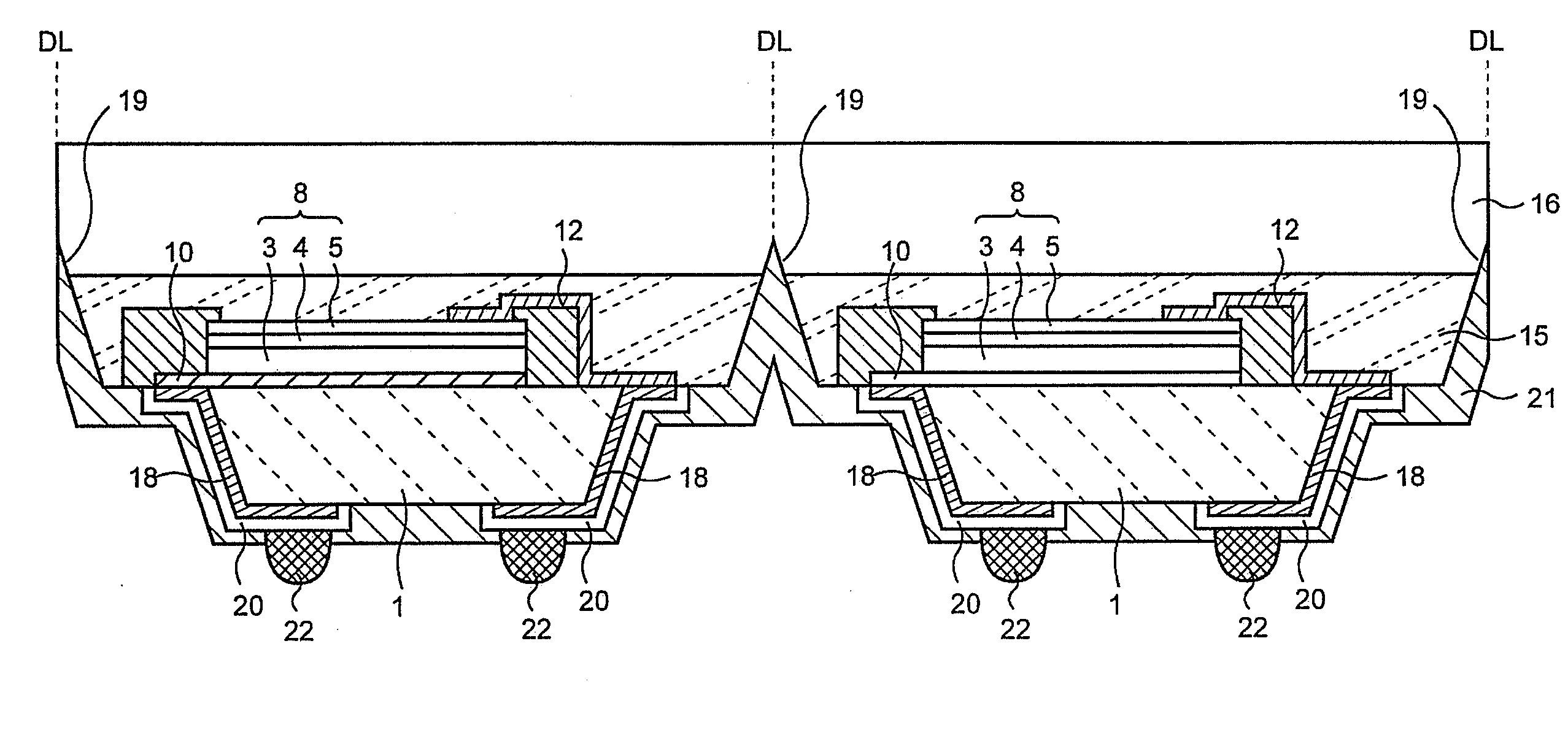

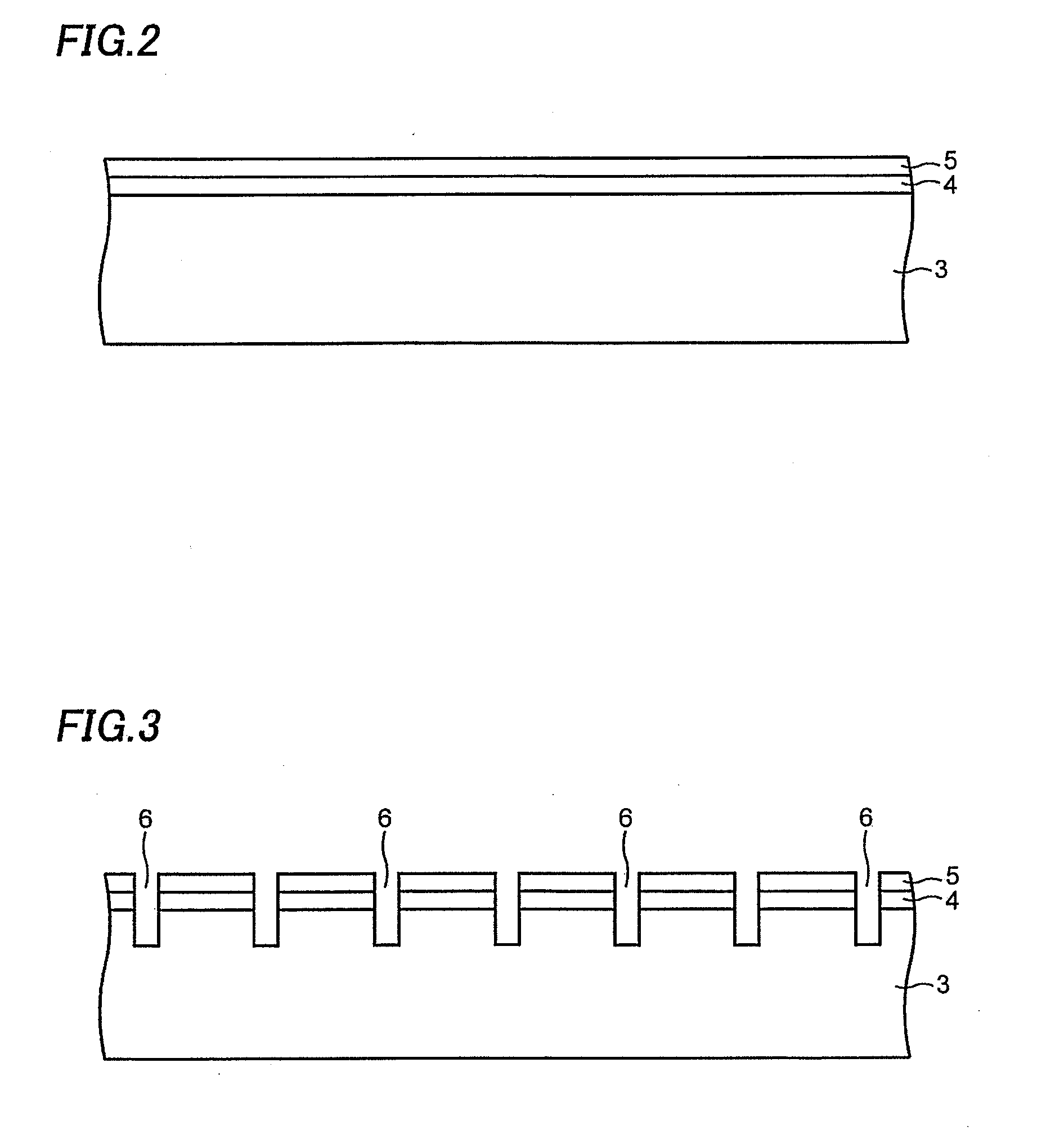

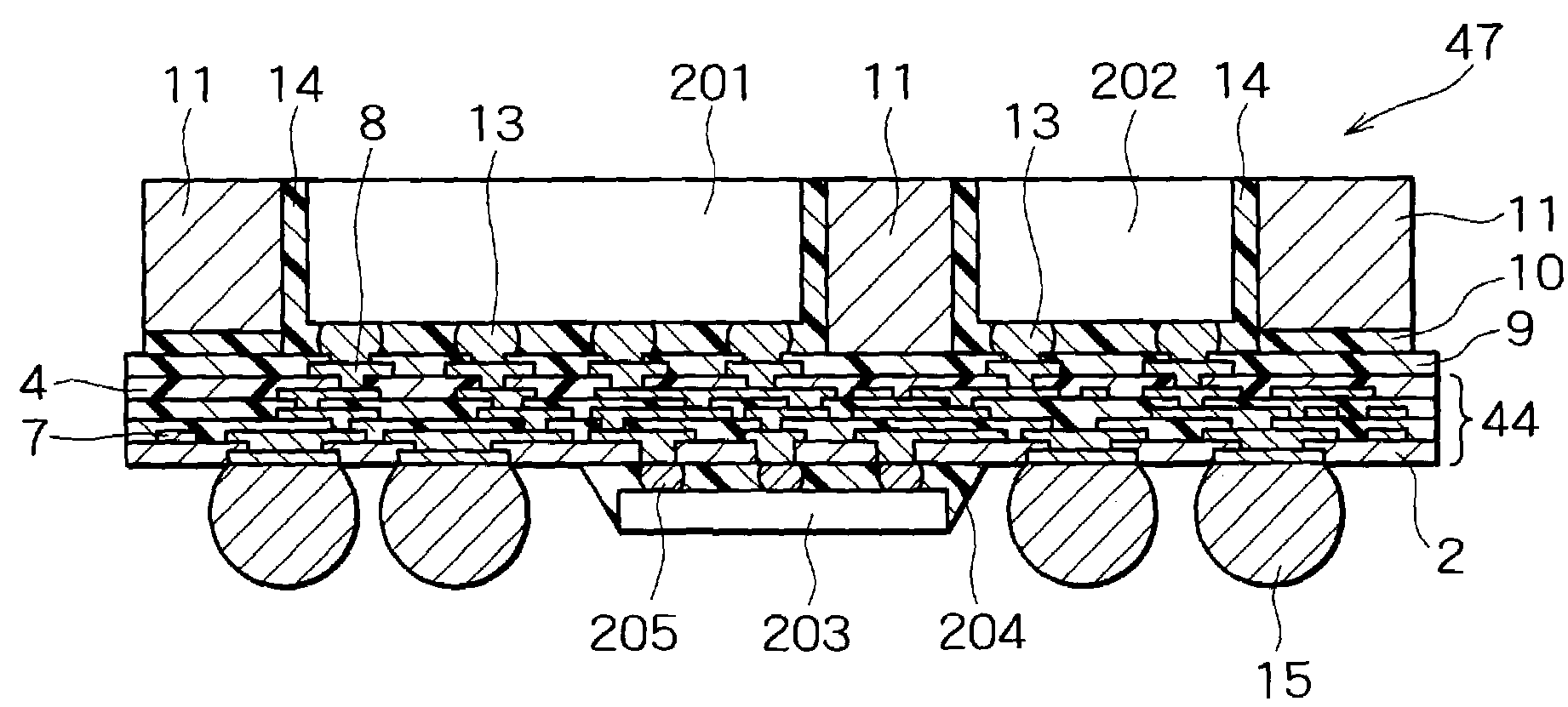

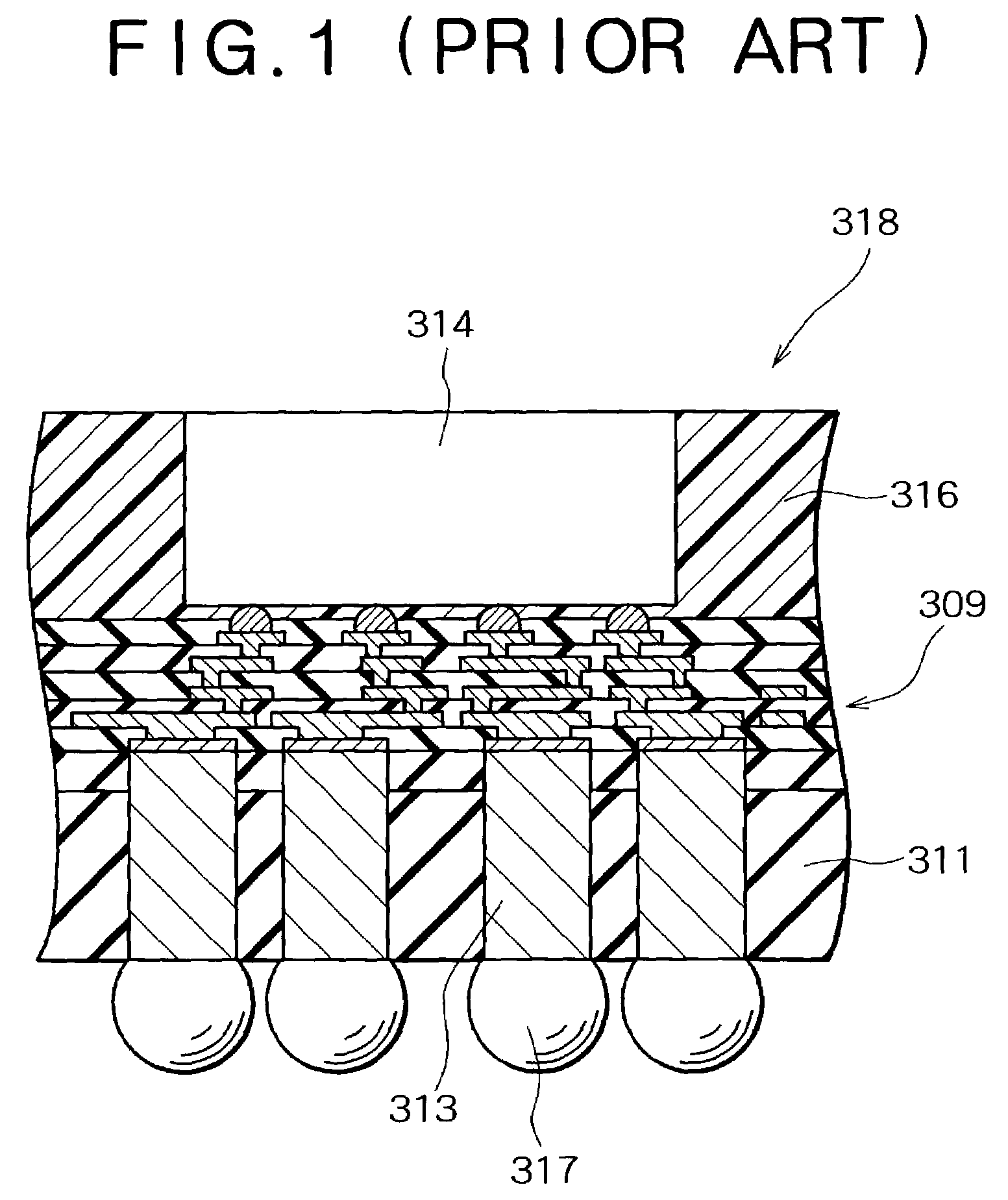

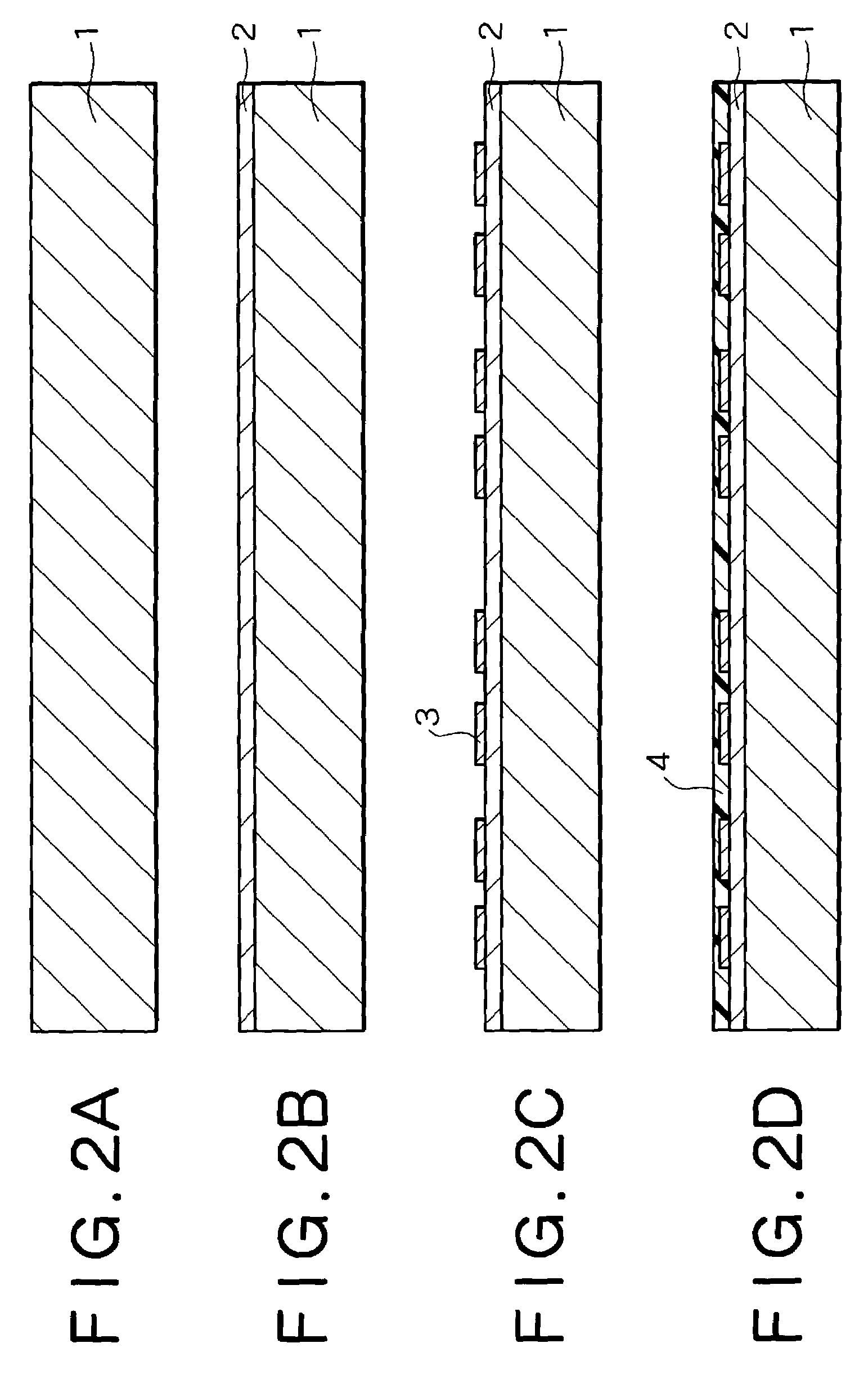

Semiconductor device and method of manufacturing the same

ActiveUS20100038668A1Decrease manufacturing costEnhancement in workability and productivitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringInsulation layer

The invention is directed to providing a smaller semiconductor device with a lower manufacturing cost and higher reliability and a method of manufacturing the same. A light emitting element (a LED die 8) is formed on a first substrate 1. A cathode electrode 10 connected to an N type region of the LED die 8 is formed between the first substrate 1 and the LED die 8. The side surface of the LED die 8 is covered by an insulation layer 11. An anode electrode 12 is formed extending from on the front surface of the first substrate 1 onto a P type region of the LED die 8 along the circumference of the insulation layer 11. Wiring layers 18 electrically connected to the cathode electrode 10 and the anode electrode 12 are formed on the side surface of the first substrate 1 therealong. The wiring layers 18 extend onto the back surface of the first substrate 1. Conductive terminals 22 electrically connected to the wiring layers 18 through electrode connection layers 20 are formed on the back surface of the first substrate 1.

Owner:SEMICON COMPONENTS IND LLC

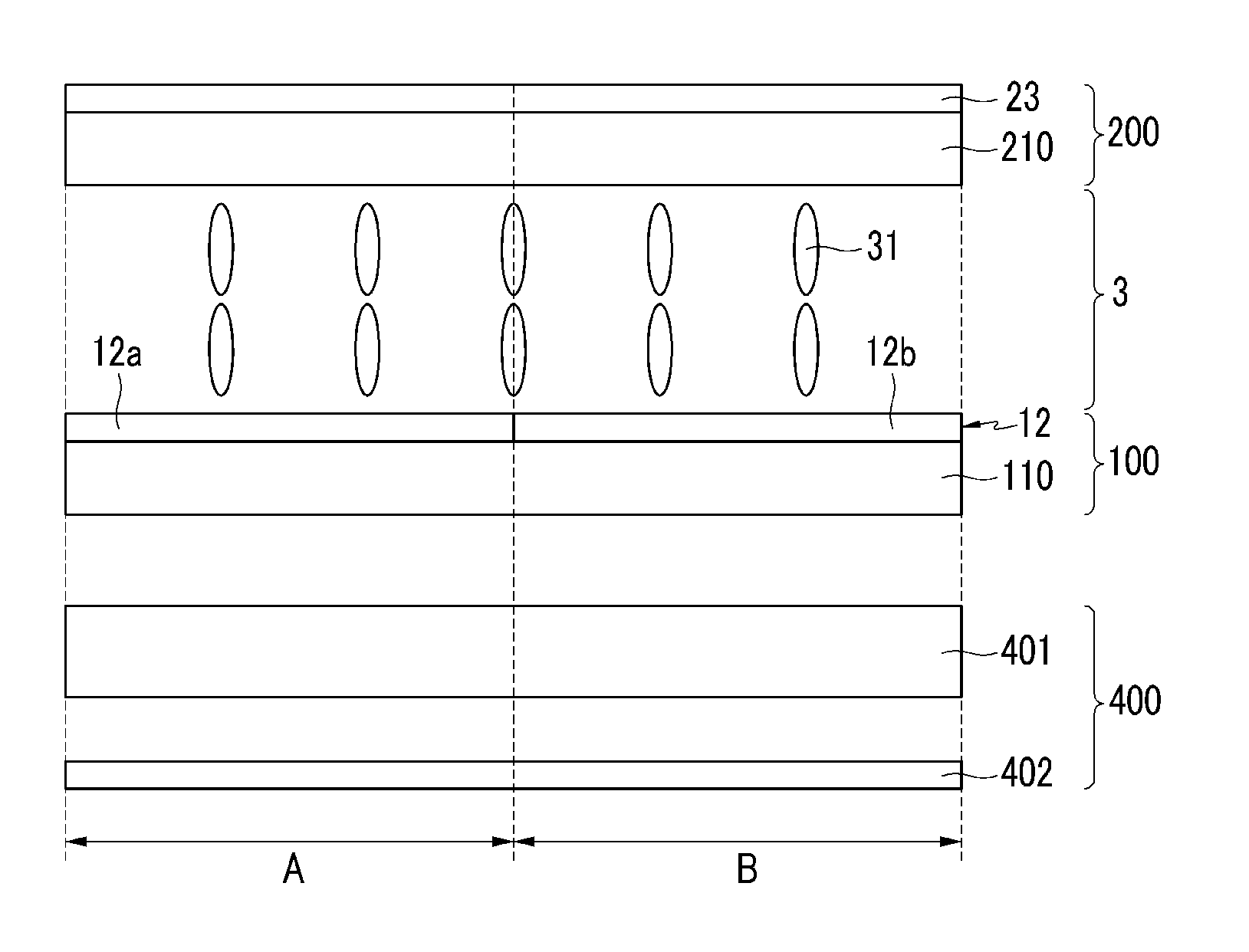

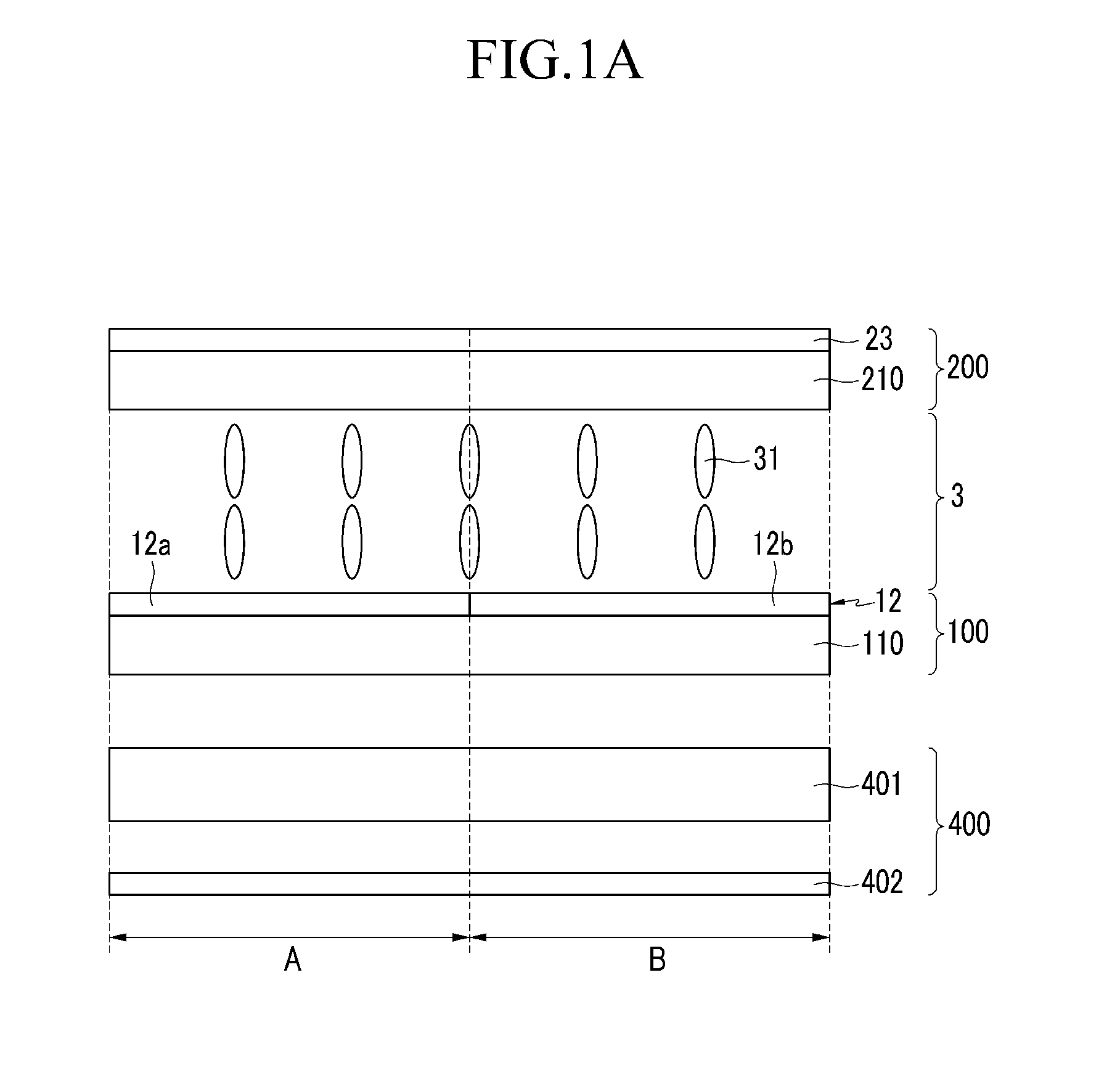

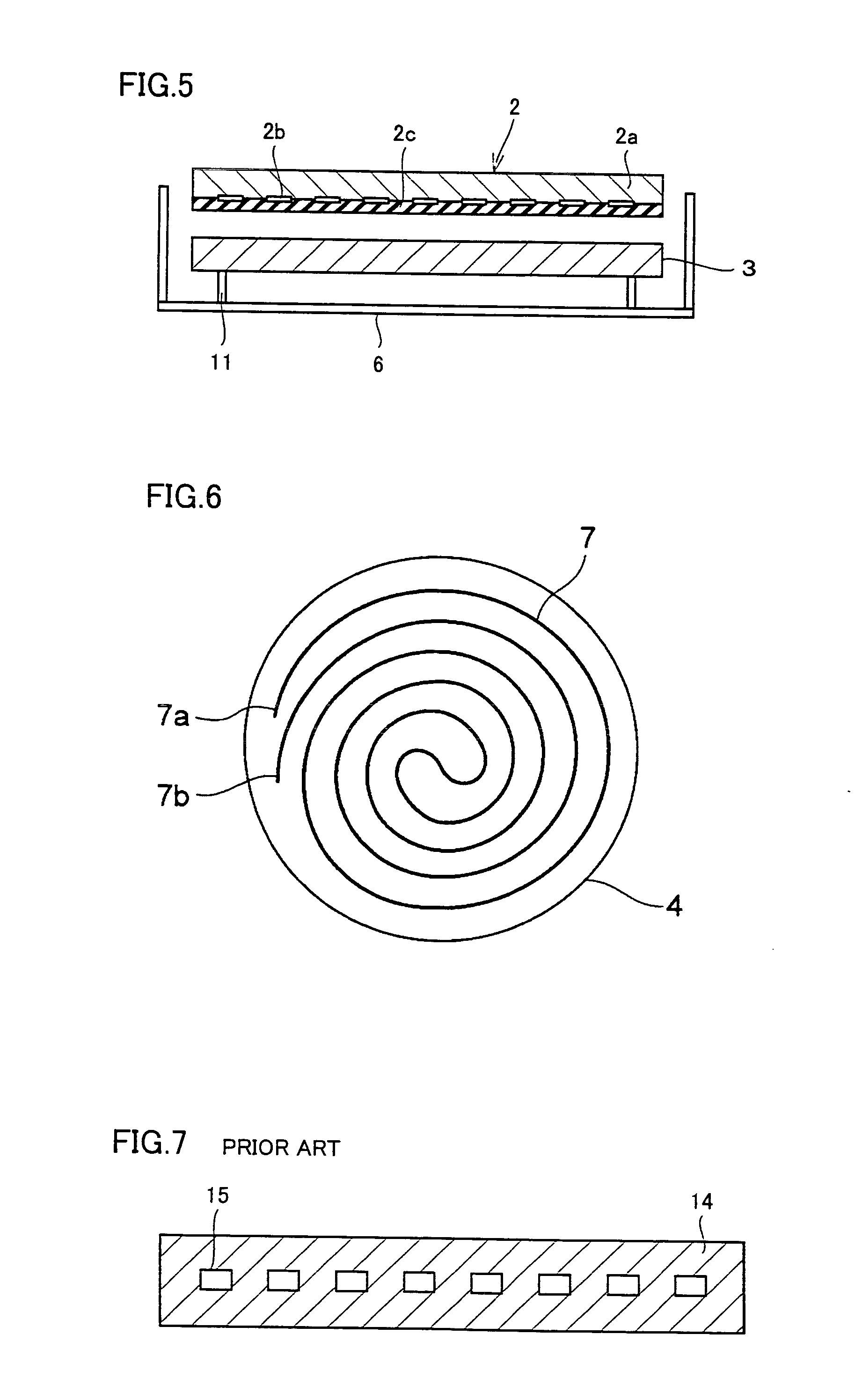

Liquid crystal display

ActiveUS20110222002A1Decrease manufacturing costImprove light efficiencyVessels or leading-in conductors manufactureNon-linear opticsLiquid-crystal displayTransmitted light

A liquid crystal display includes a first substrate, and a first optical conversion layer disposed on the first substrate. The first optical conversion layer includes a reflecting unit reflecting incident light, and a polarizing unit. The polarizing unit transmits light which oscillates in a first direction among the incident light, and reflects light which oscillates in a second direction different from the first direction among the incident light. The reflecting unit and the polarizing unit of the first optical conversion layer may be disposed in at least one pixel area.

Owner:SAMSUNG DISPLAY CO LTD

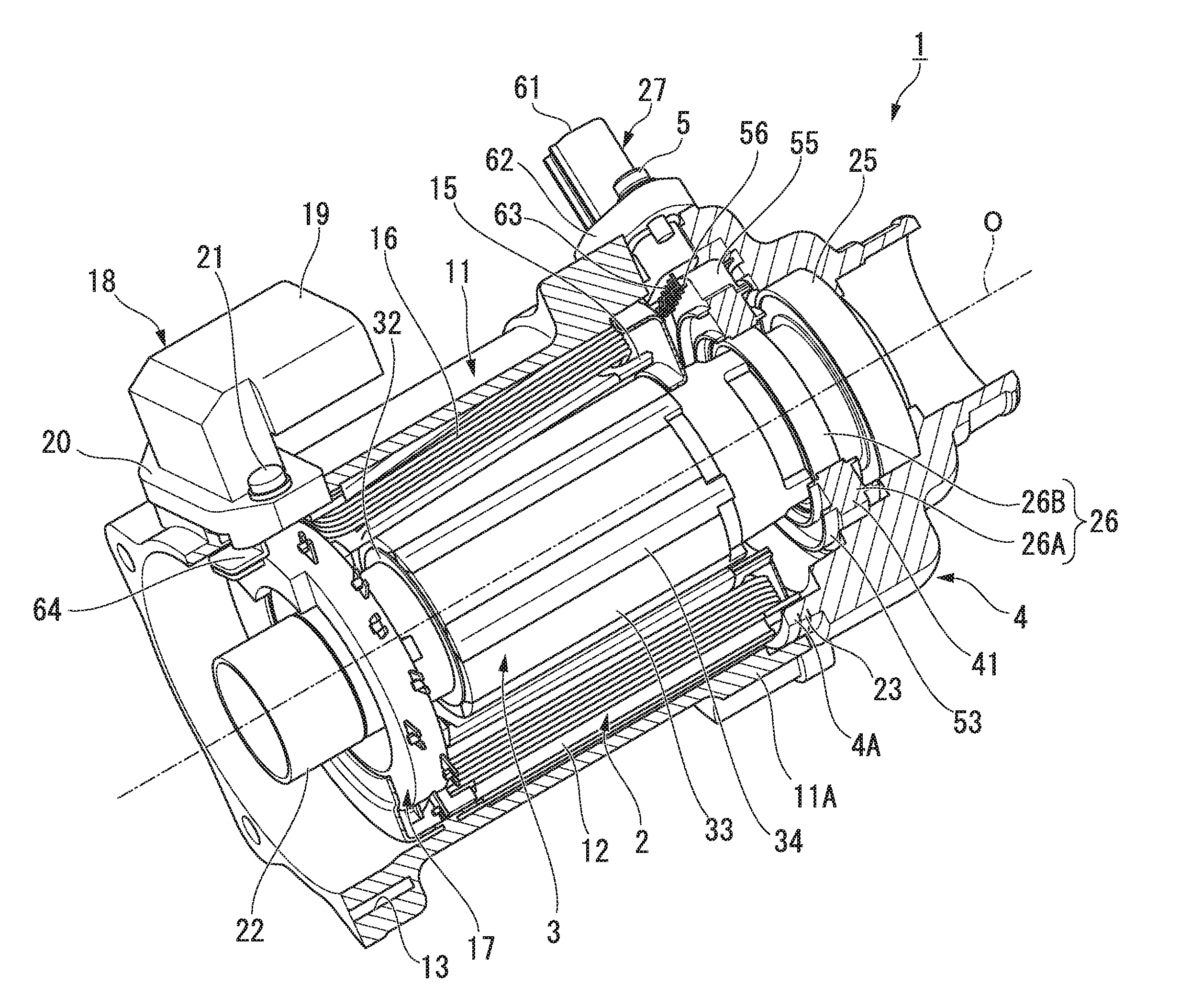

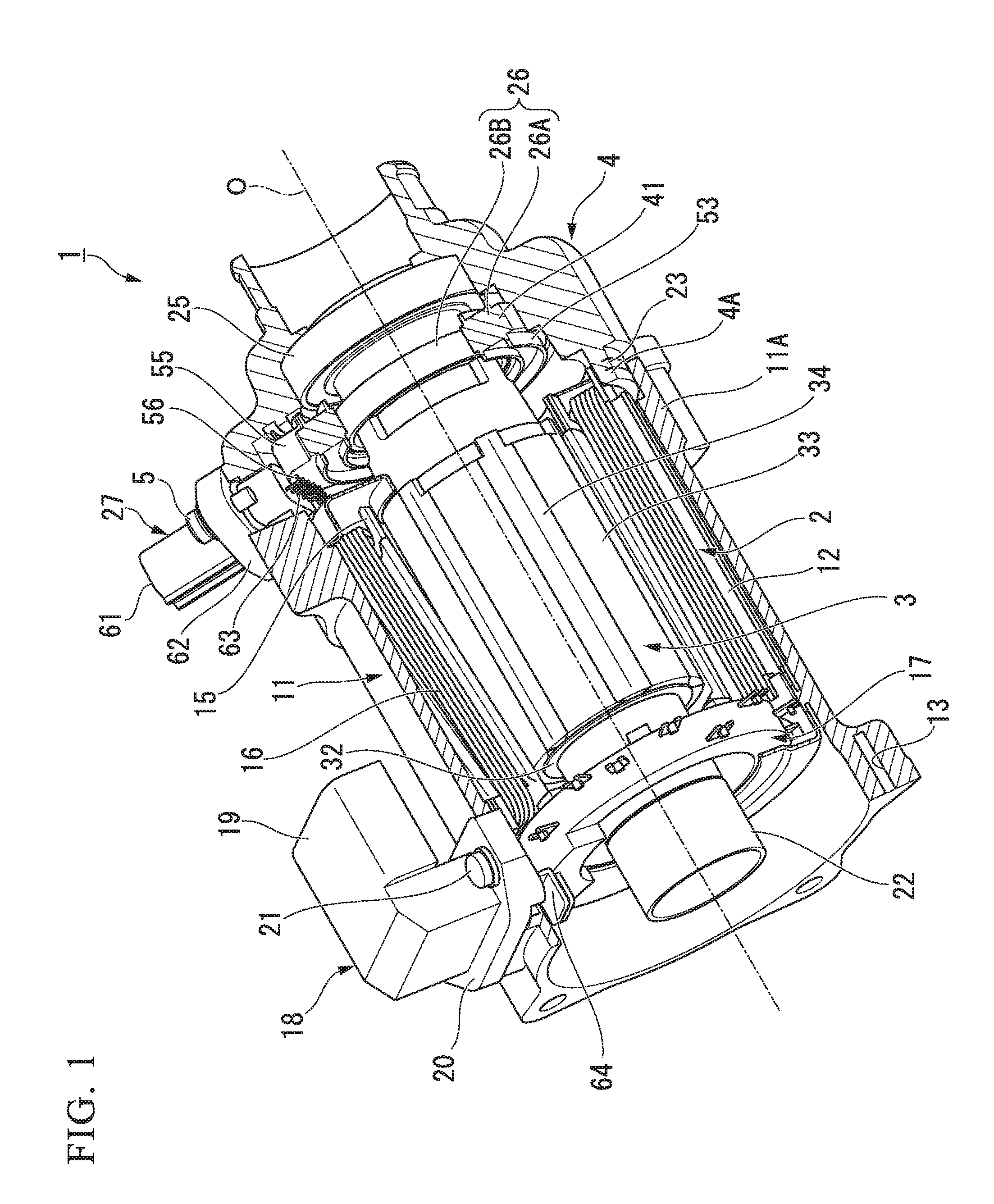

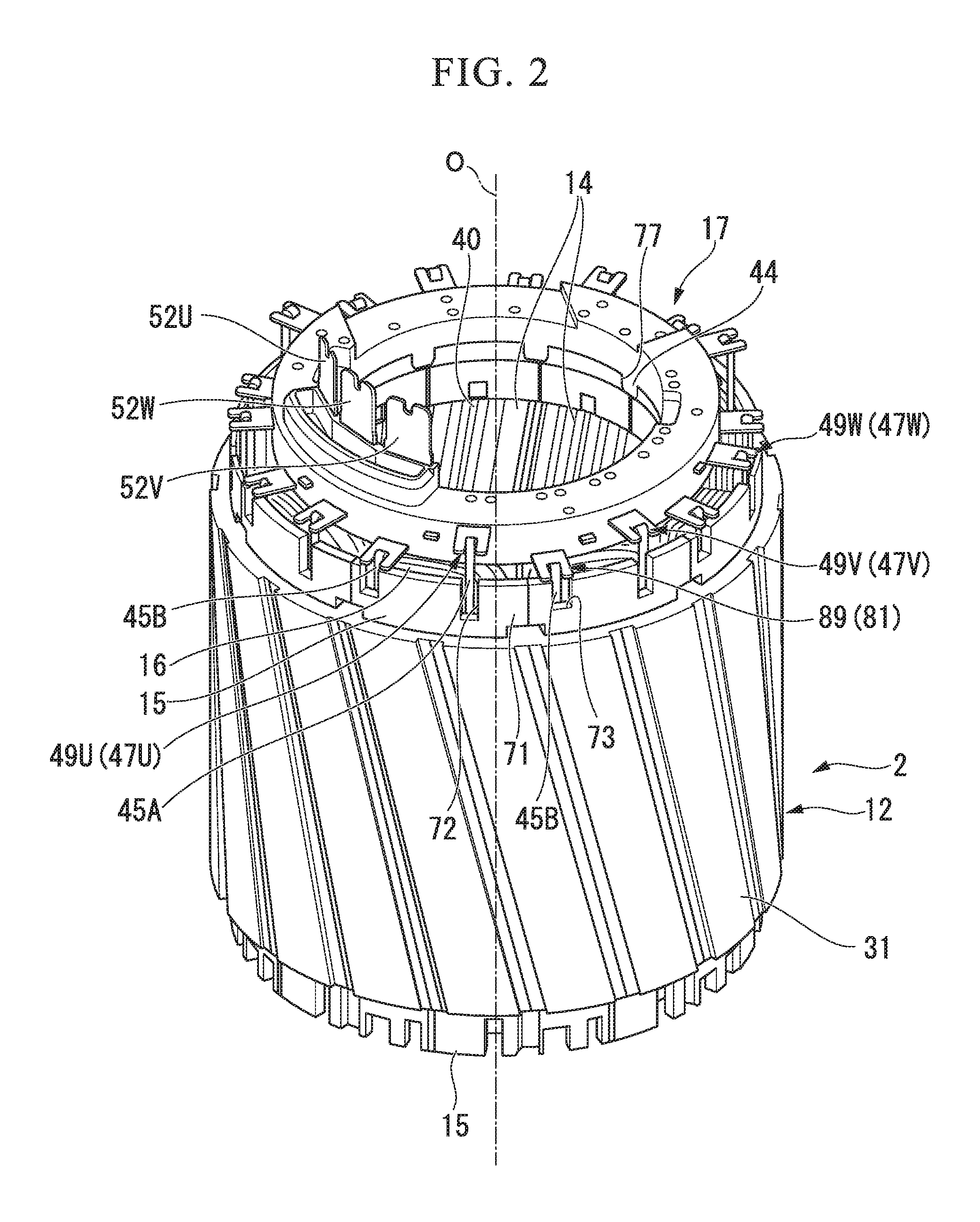

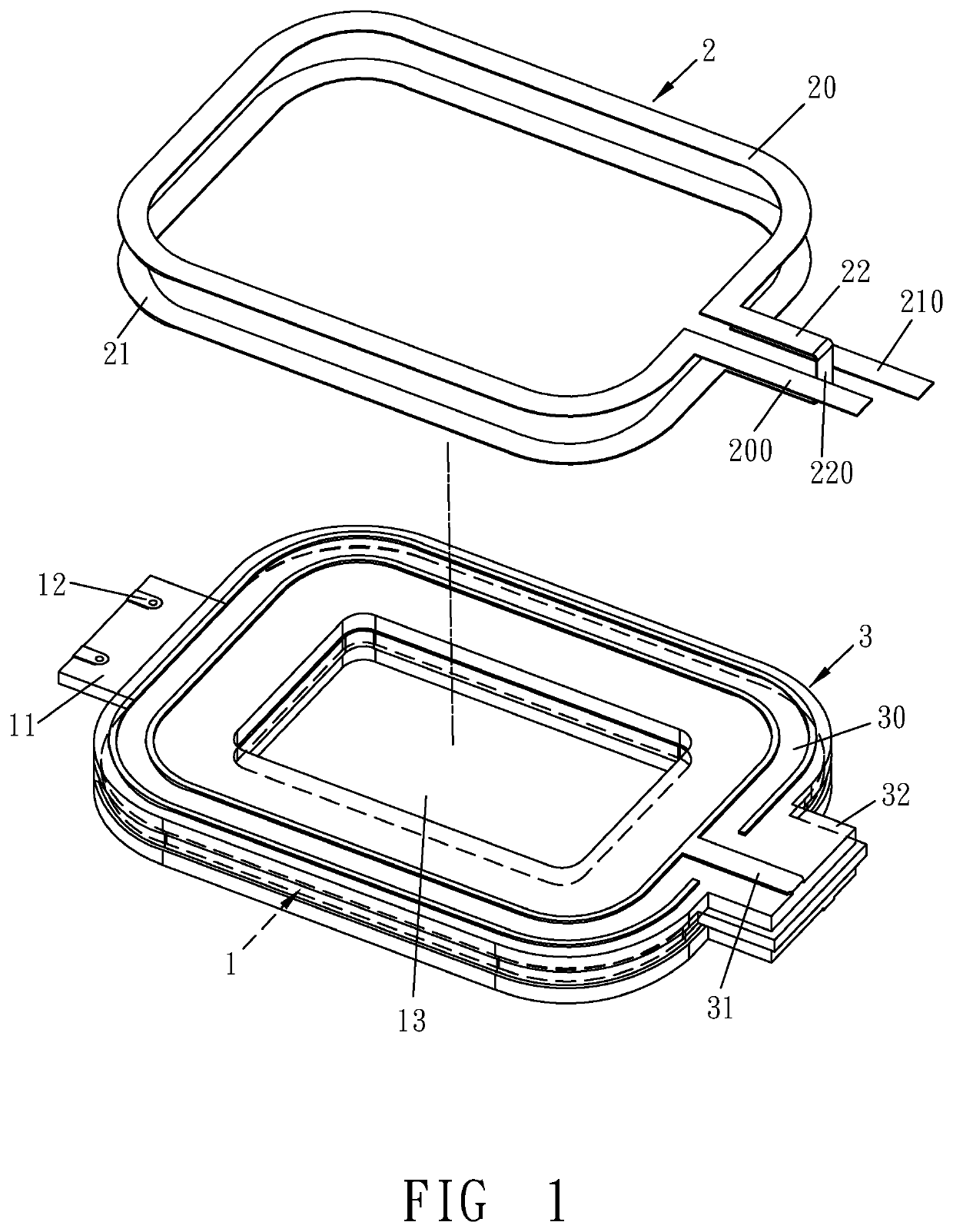

Bus bar unit, method for manufacturing bus bar unit, and brushless motor

InactiveUS20160218578A1Improved yieldDecrease manufacturing costWindings insulation shape/form/constructionManufacturing dynamo-electric machinesElectrical and Electronics engineeringBrushless motors

A bus bar unit is configured to supply power to coils (16) of a plurality of phases, and includes phase bus bars (47U ), (47V), and (47W) which are provided for each phase and are connected to winding start ends of the coils, and a neutral point bus bar (81) which is connected to winding finish ends of the coils, the neutral point bus bar (81) being formed by bending an elongated plate-shaped member such that a width direction of the elongated plate-shaped member and a radial direction of the bus bar unit coincide with each other, and including a plurality of bus bar pieces (82) and a connection portion (83) which connects the bus bar pieces (82) and (82) adjacent to each other, and a width of a deformation portion (85) of the connection portion (83) being narrower than a width of the bus bar piece (82).

Owner:MITSUBA CORP

Semiconductor device and method of manufacturing the same

InactiveUS7138064B2InexpensiveDecrease manufacturing costDecorative surface effectsSemiconductor/solid-state device detailsAluminiumEngineering

The present invention relates to a method of manufacturing a semiconductor device. In the method, an etching-back layer consisting of aluminum or copper is formed on a base substrate and a multilayer wiring board is manufactured on the etching-back layer. After that the etching-back layer is etched to be removed under the condition that the multilayer wiring board and the base substrate are not etched, so that the base substrate is separated from the multilayer wiring board. Accordingly, the base substrate can be reused.

Owner:RENESAS ELECTRONICS CORP

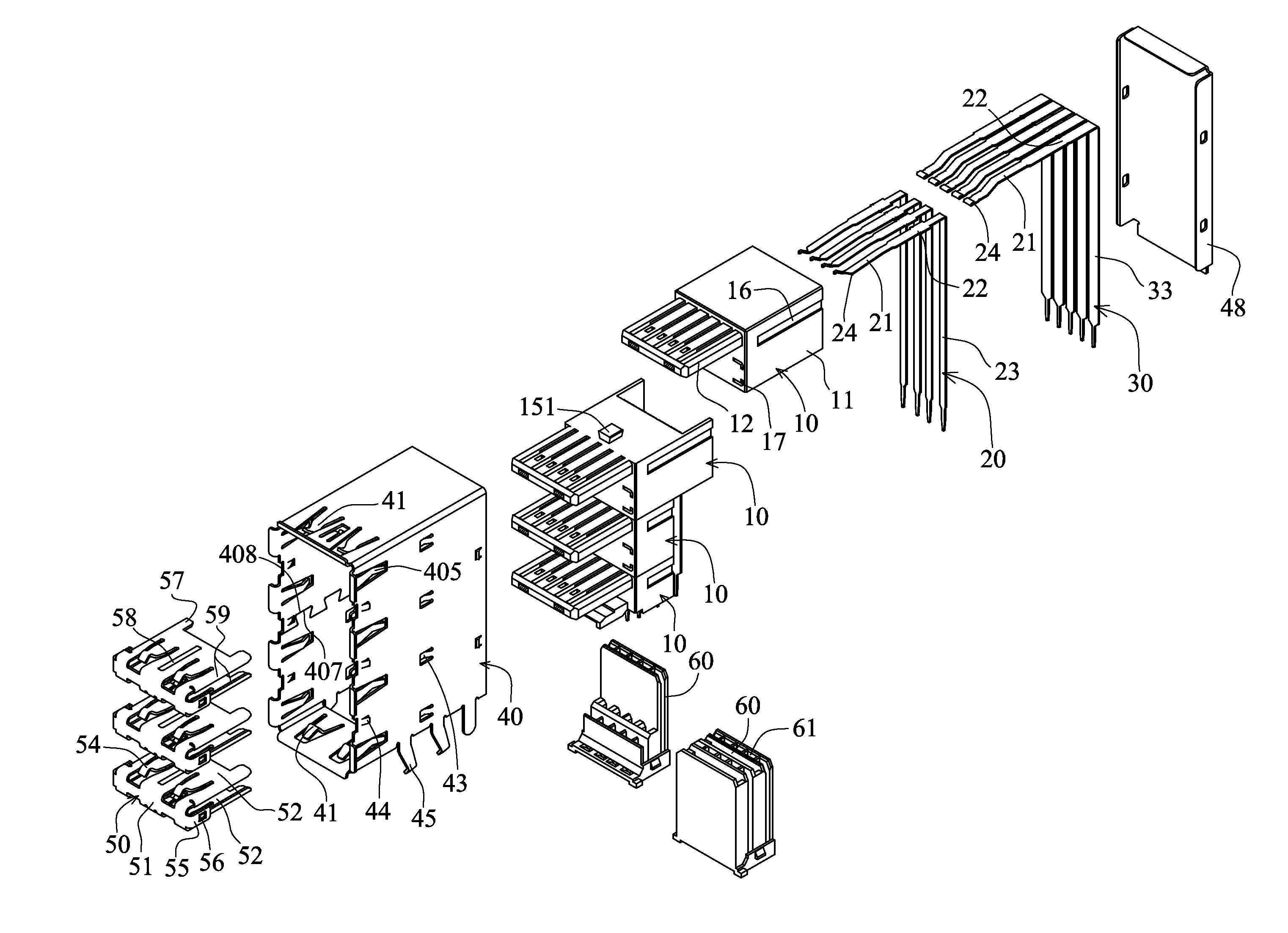

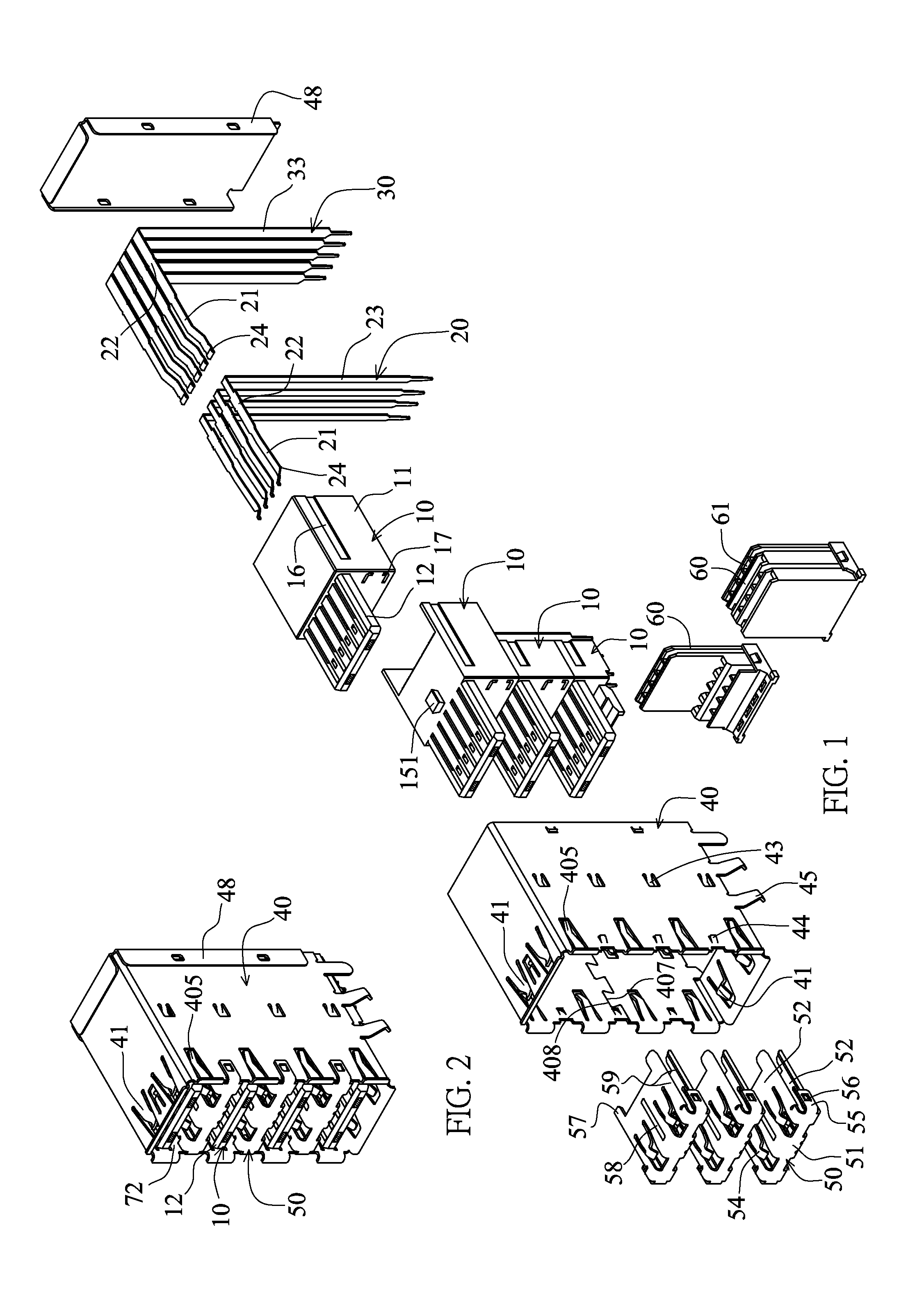

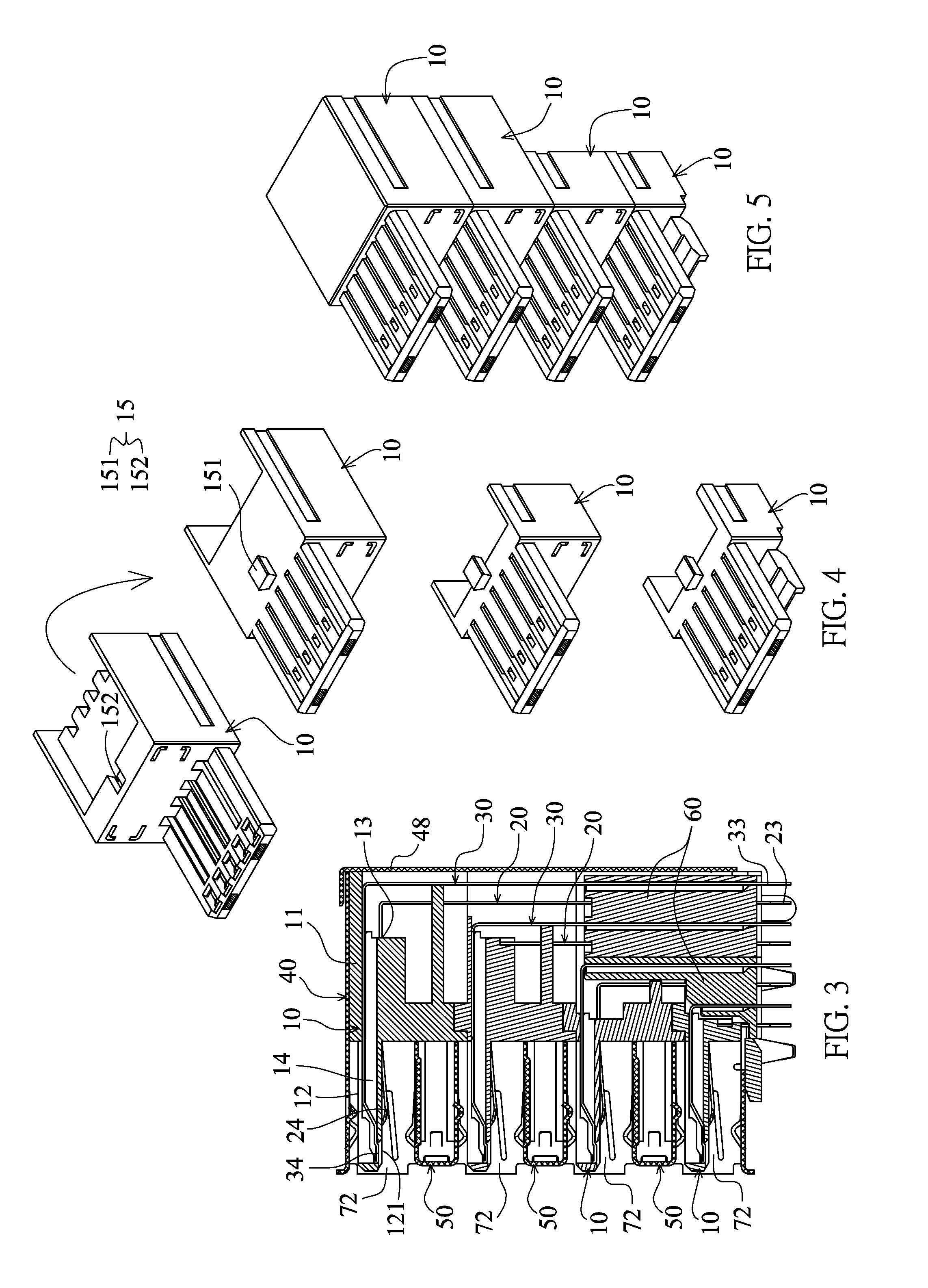

Electrical connection socket

ActiveUS20140017951A1Simplify structureDecrease manufacturing costElectric discharge tubesTwo-part coupling devicesElectrical connectionMetal

An electrical connection socket includes: at least two insulating seats each having a base and terminals to form at least one contact interface, wherein one end of the base of at least one insulating seat is projected to form at least one tongue, the base is thicker than the tongue, the tongue has the contact interface, and the bases of the at least two insulating seats are stacked; a metal casing covering the at least two insulating seats and having one end formed with an opening, the metal casing at least directly resting against one of the insulating seats; and at least two connection slots disposed in the metal casing, wherein the tongue is disposed in a connection slot, and the contact interface to be electrically connected to a plug is disposed in each connection slot.

Owner:KIWI INTELLECTUAL ASSETS CORP

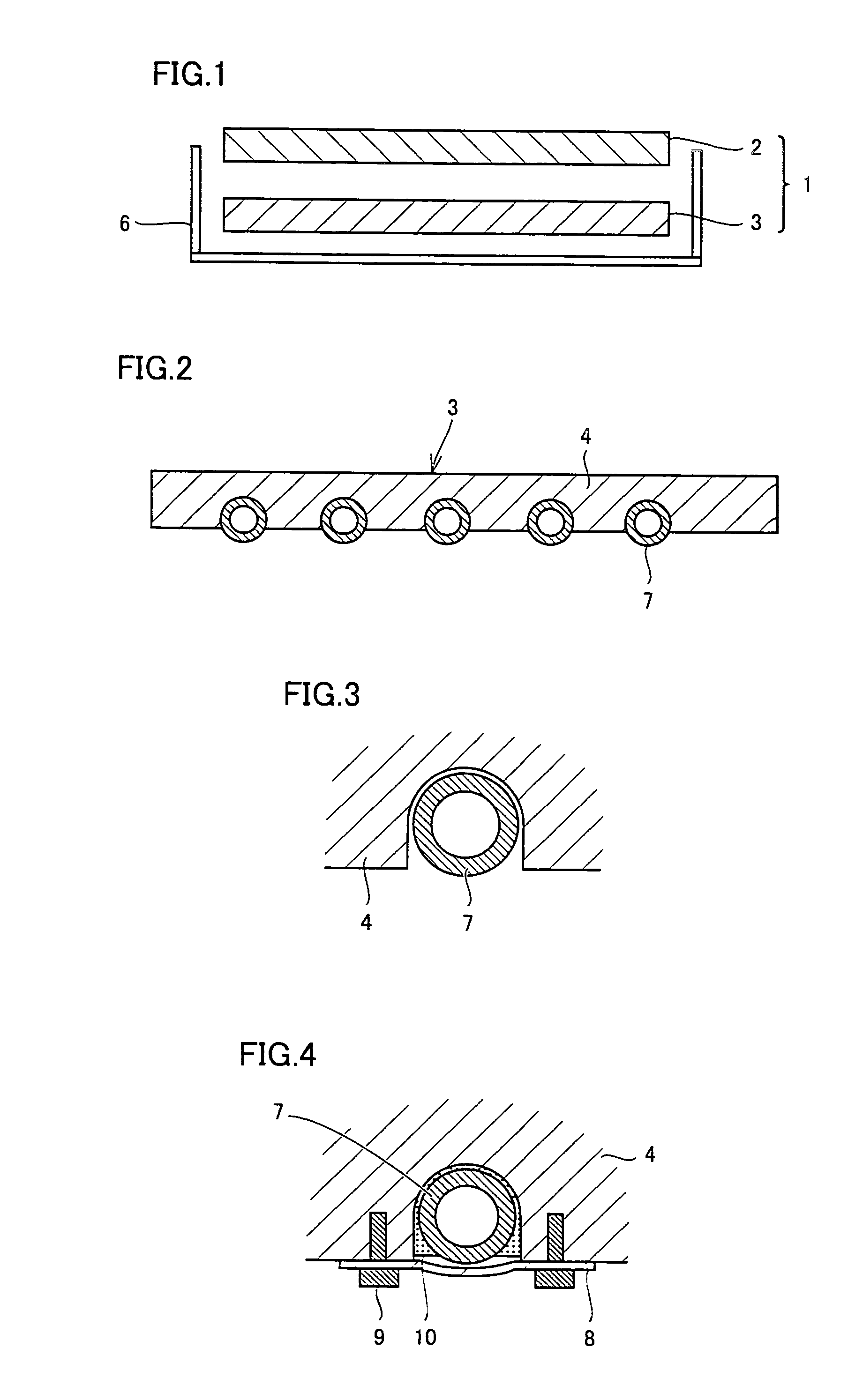

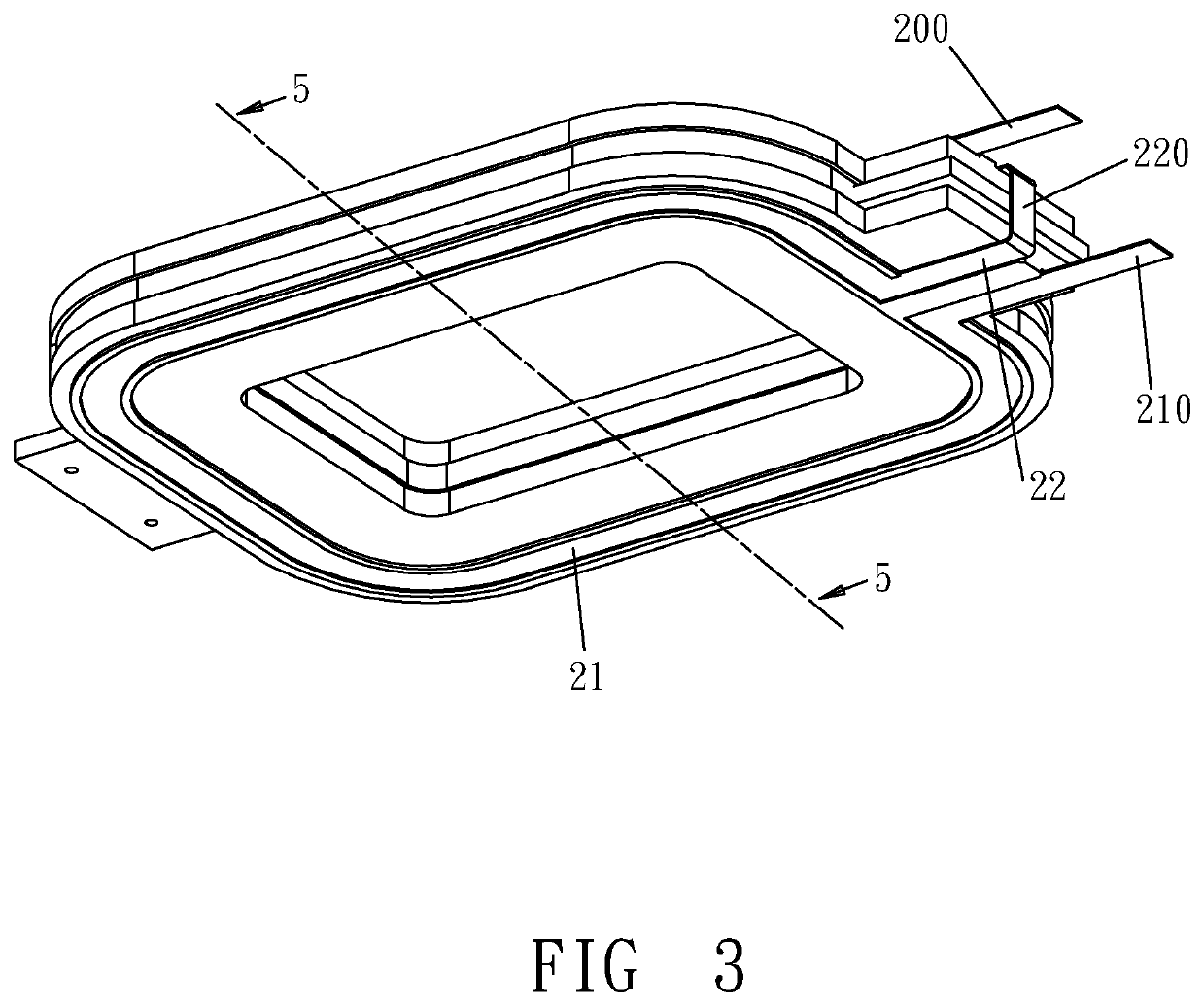

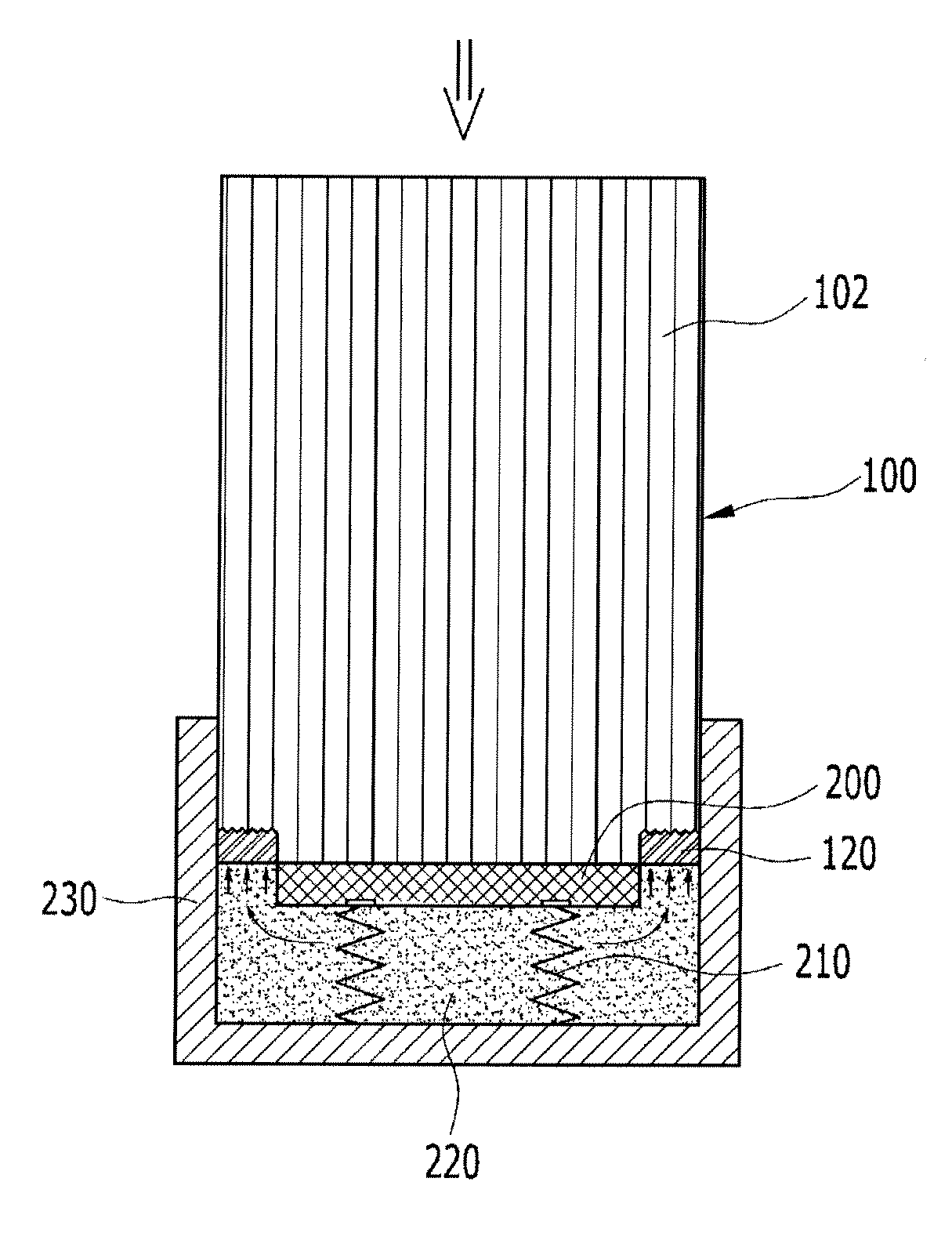

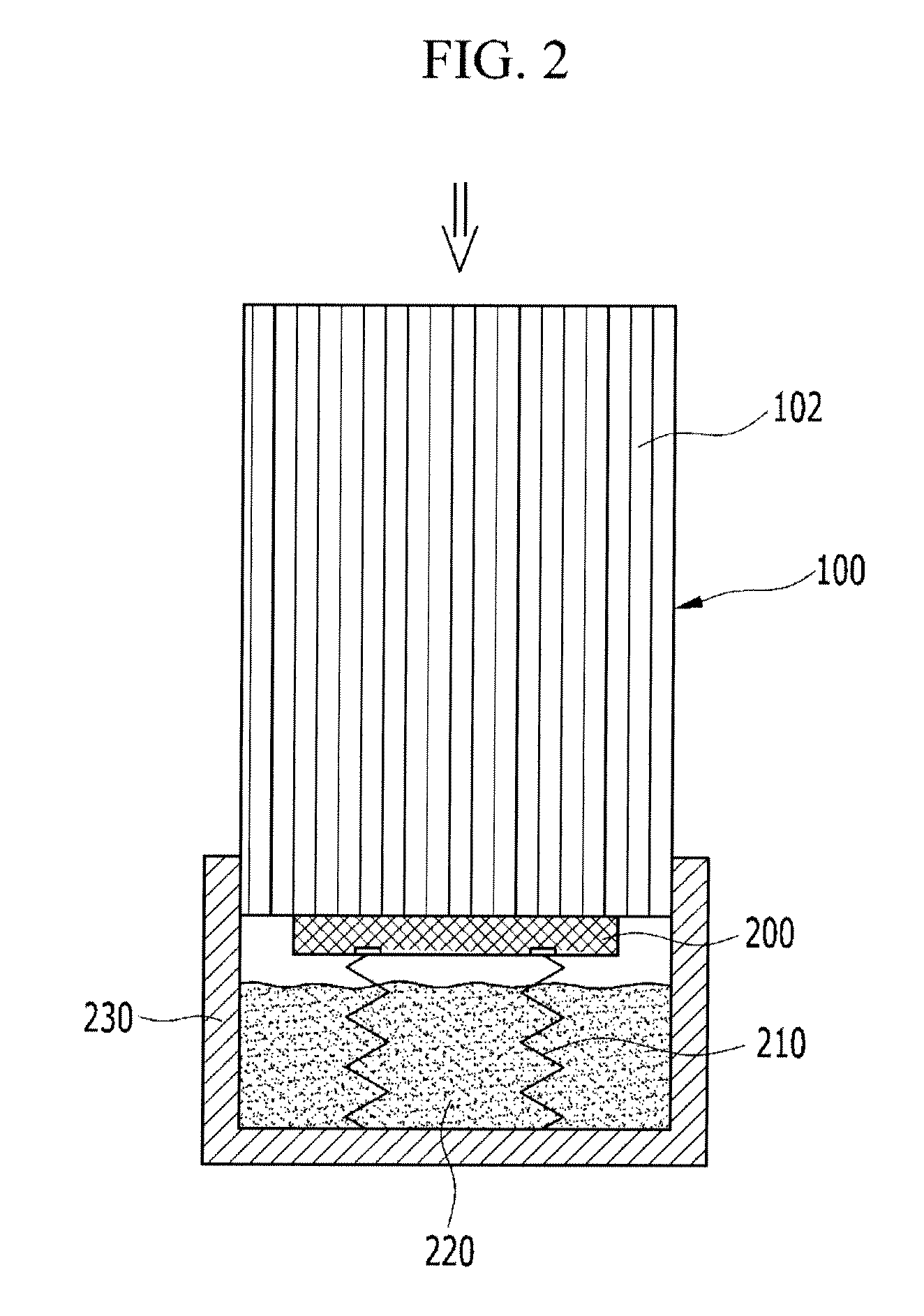

Heater unit and semiconductor manufacturing apparatus including the same

InactiveUS20070056953A1Decrease manufacturing costUniform distribution of temperatureDrying solid materials with heatVacuum evaporation coatingCeramic heaterMetallurgy

A ceramic heater attaining more uniform temperature distribution from the start to the end of cooling is provided. Further, in a cooling module used for cooling the heater, liquid leakage during use is prevented, degradation in cooling capability is prevented and the performance is maintained for a long period of use, and the manufacturing cost of the module is decreased. The ceramic heater includes a ceramic heater body and a cooling module cooling the heater body, and the cooling module has a structure formed by arranging a pipe in a trench formed in a plate-shaped structure.

Owner:SUMITOMO ELECTRIC IND LTD

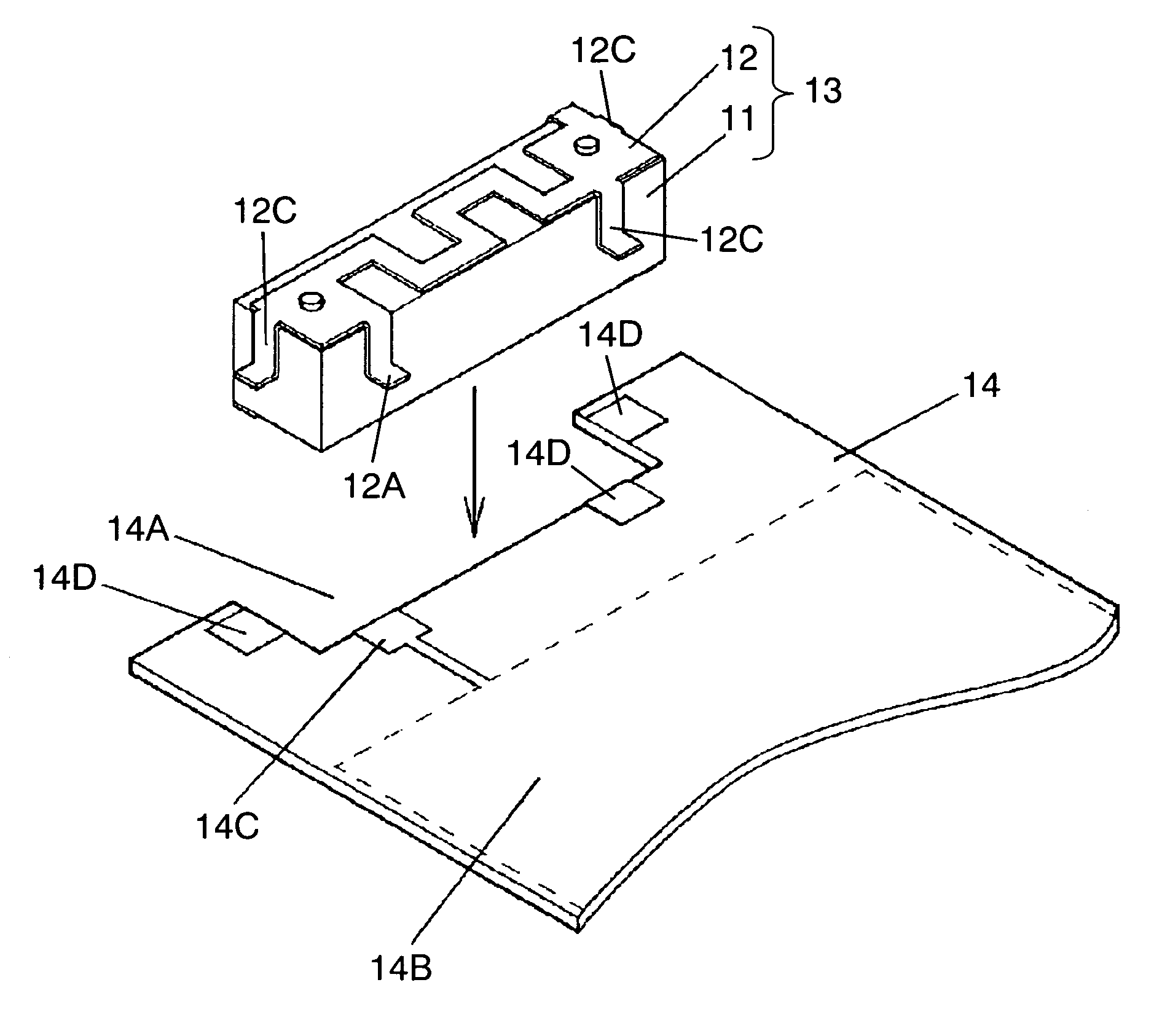

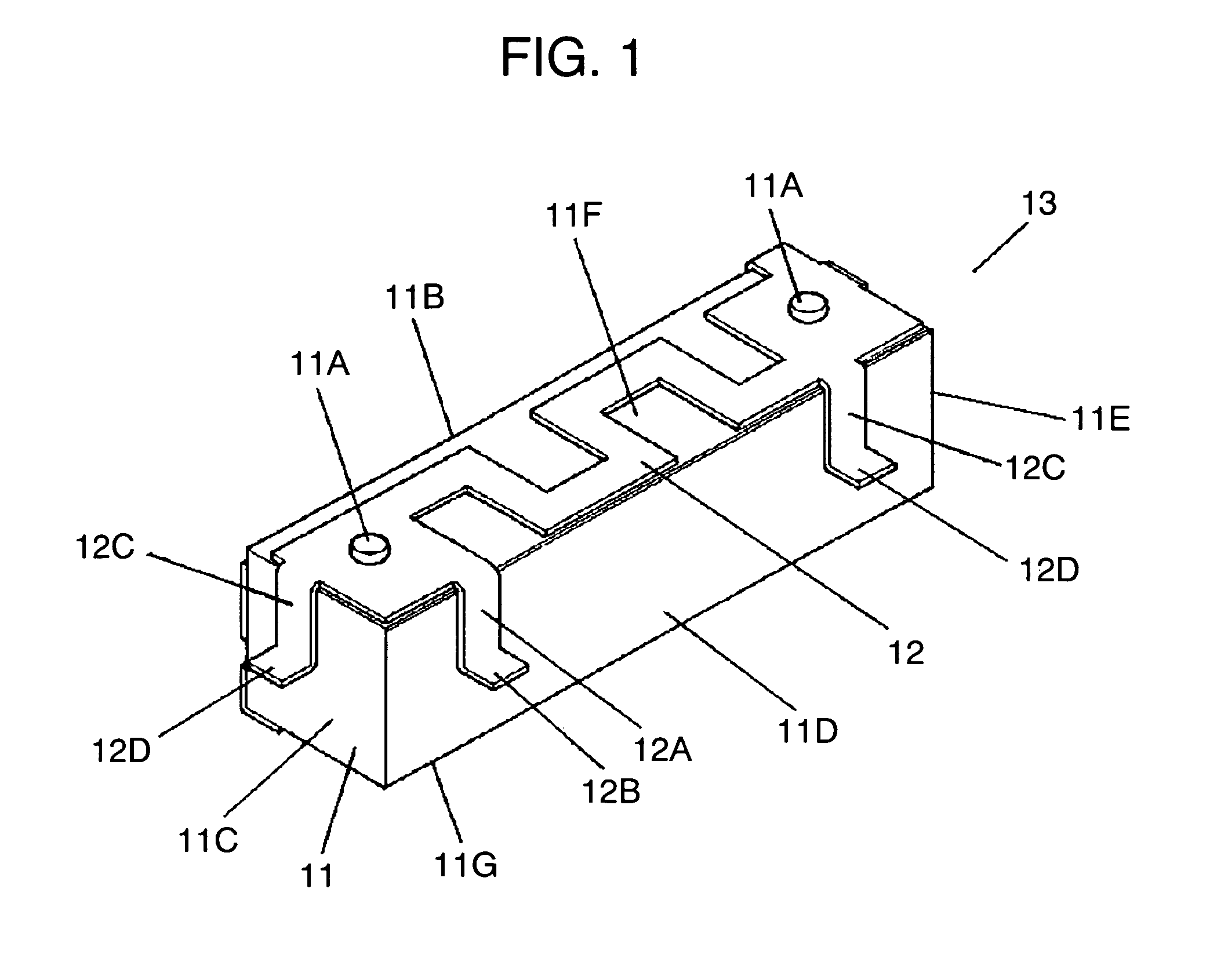

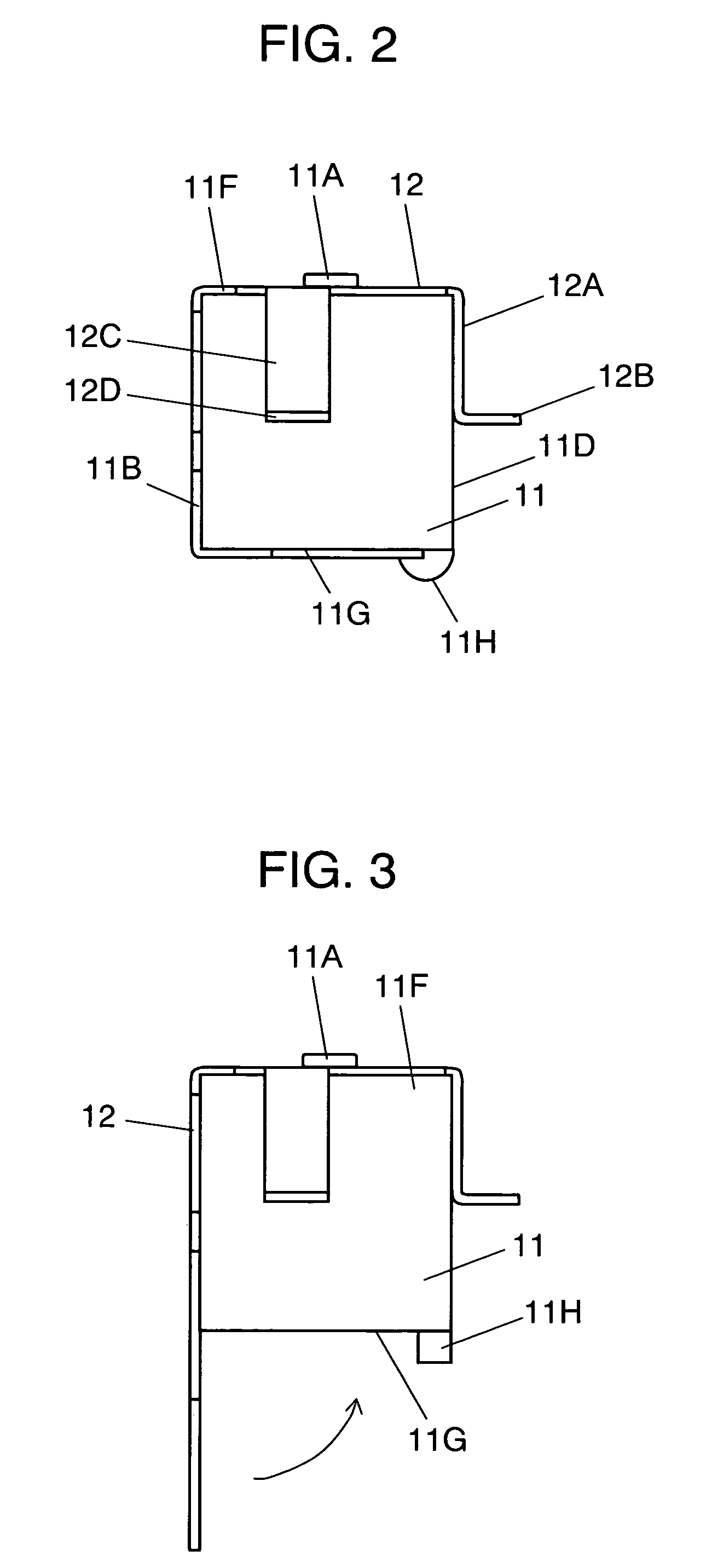

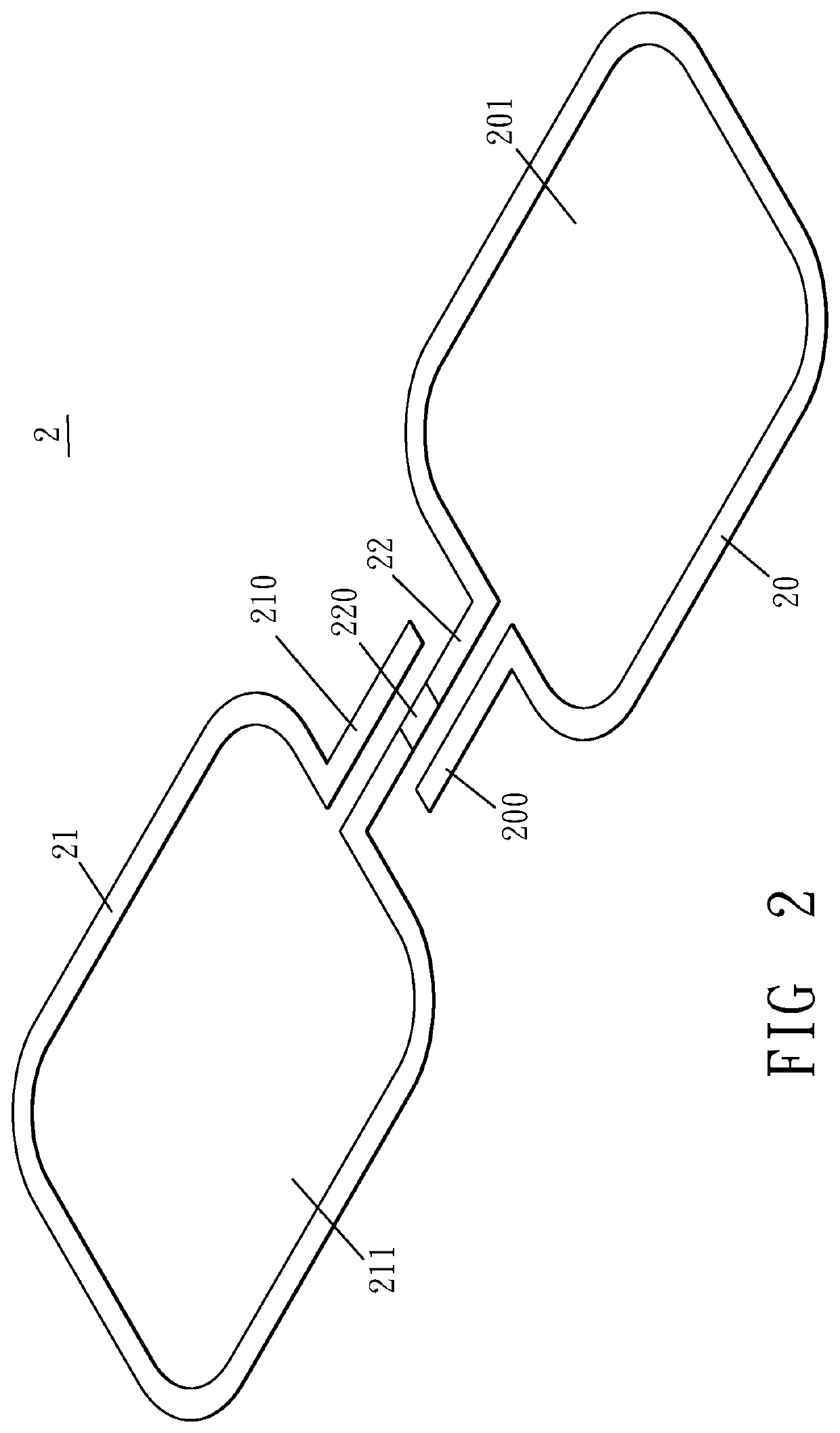

Antenna

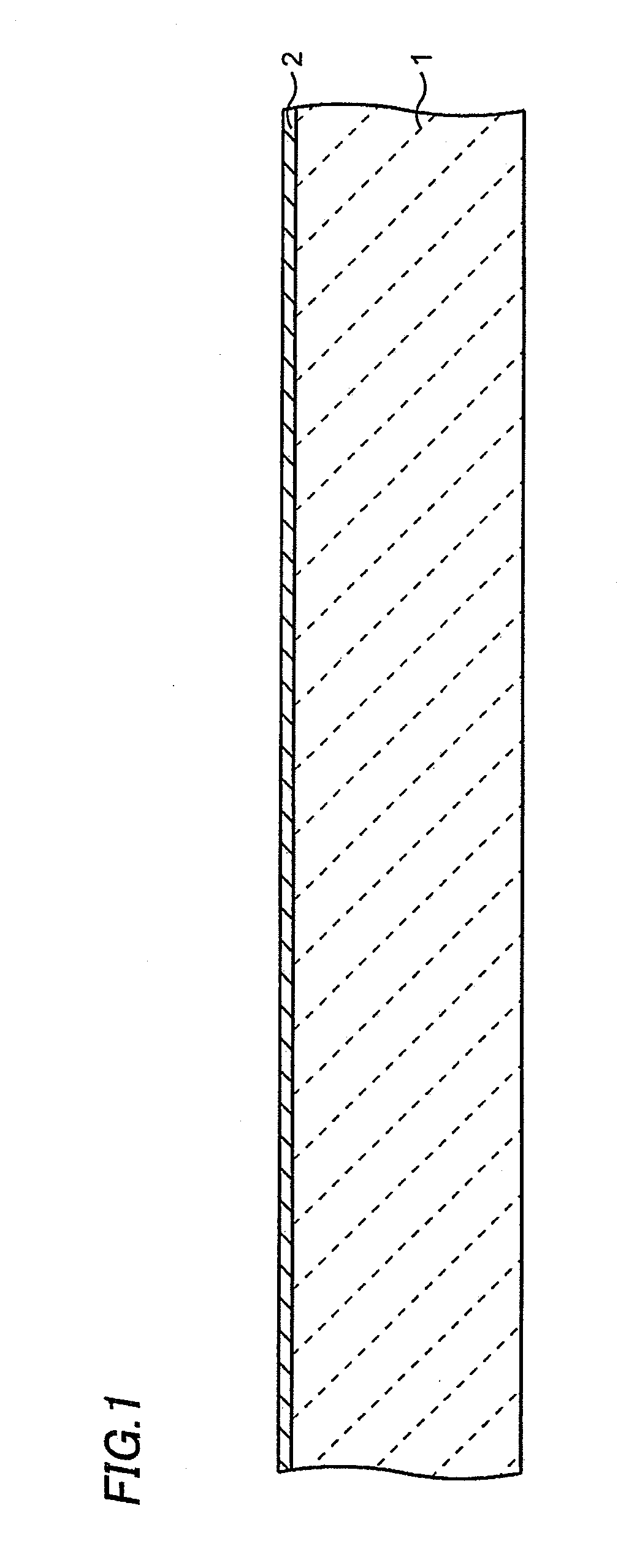

InactiveUS6985112B2Decrease manufacturing costReliability be ensureSimultaneous aerial operationsAntenna supports/mountingsElectrical connectionAntenna element

An antenna providing easy and effective mounting procedures onto a wireless device for mobile communications and highly reliable electrical connections. The antenna contains insulating resin-made core 11 that is generally formed into a rectangular parallelepiped, and metallic thin-plate antenna element 12 from which feeding terminal 12A and joint sections 12C are extended. Antenna element 12 is disposed on top surface 11F, side surface 11B, and bottom surface 11G of core 11. Antenna element 12 is then fixed to core 11 by caulking at caulking projections 11A formed on the top surface of core 11. Feeding terminal 12A is bent to have L-shaped tip 12B on side surface 11D; similarly, joint sections 12C are bent to have L-shaped tips 12D on side surfaces 11C and 11E. These tips are bent at the same level according to the thickness of a wiring board to be soldered.

Owner:PANASONIC CORP

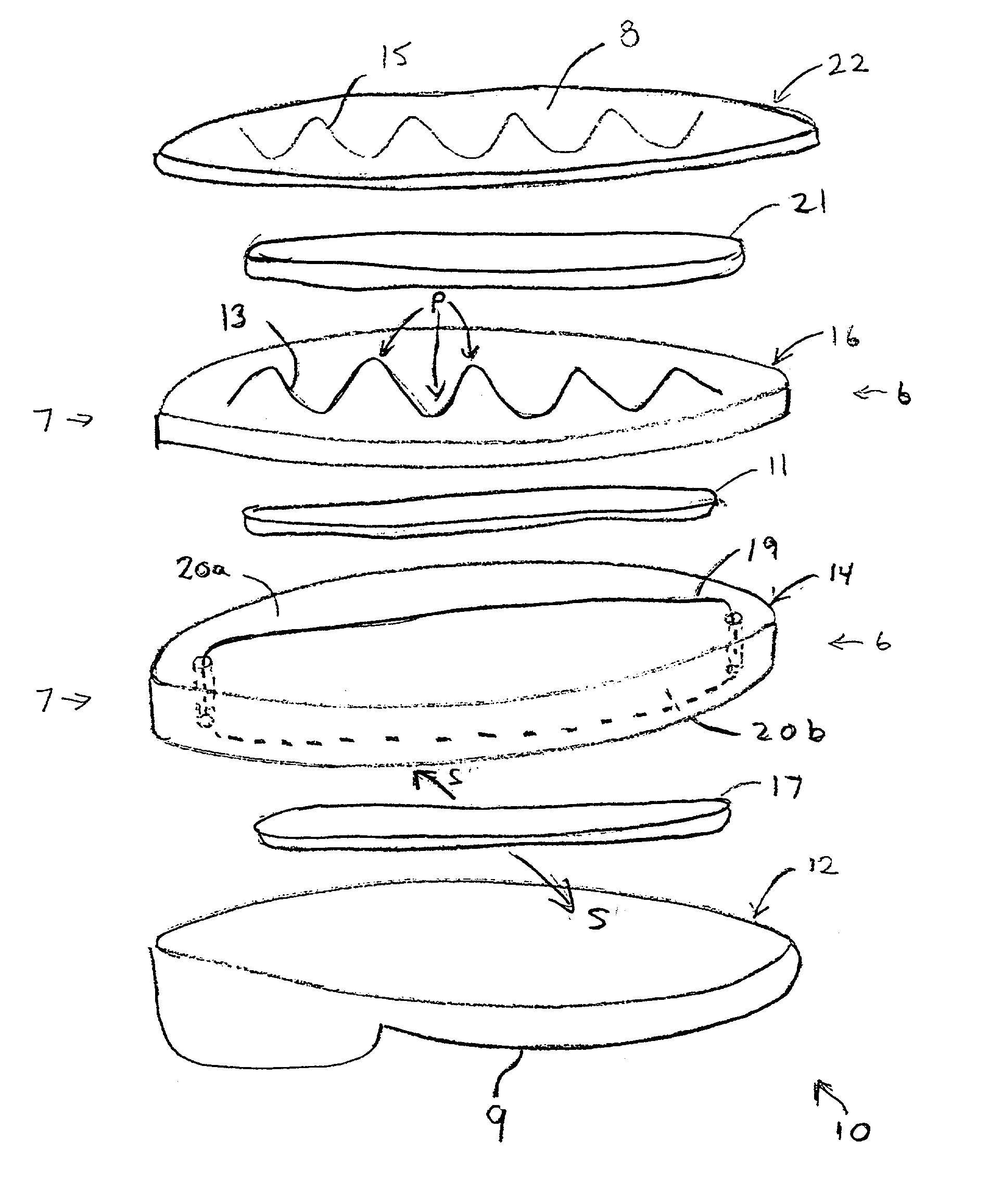

Electrostatically dissipative athletic shoe

InactiveUS7055266B2Increase controlDecrease manufacturing costSolesUpperElectrically conductiveEngineering

An electrostatically dissipative athletic shoe. The shoe includes an outsole, a midsole, and an insole. The insole is preferably formed of a nylon fabric material. The insole is stitched with an electrically conductive thread in a zig-zag pattern, and electrically conductive glue is provided between the insole and the midsole and is disposed so as to make contact with the ESD thread. Preferably, the midsole includes at least two spaced-apart holes therethrough and an electrically continuous loop of ESD thread passes loosely through the holes and across opposite top and bottom surfaces of the midsole. Preferably, ESD glue is provided between the outsole and the midsole and is disposed so as to make contact with the loop. Preferably, the shoe includes a sockliner that is also stitched with an electrically conductive thread in a zig-zag pattern, and electrically conductive glue is provided between the sockliner and the insole and is disposed so as to make contact with the ESD thread of the sockliner and the ESD thread of the insole.

Owner:ELSEY WAYNE

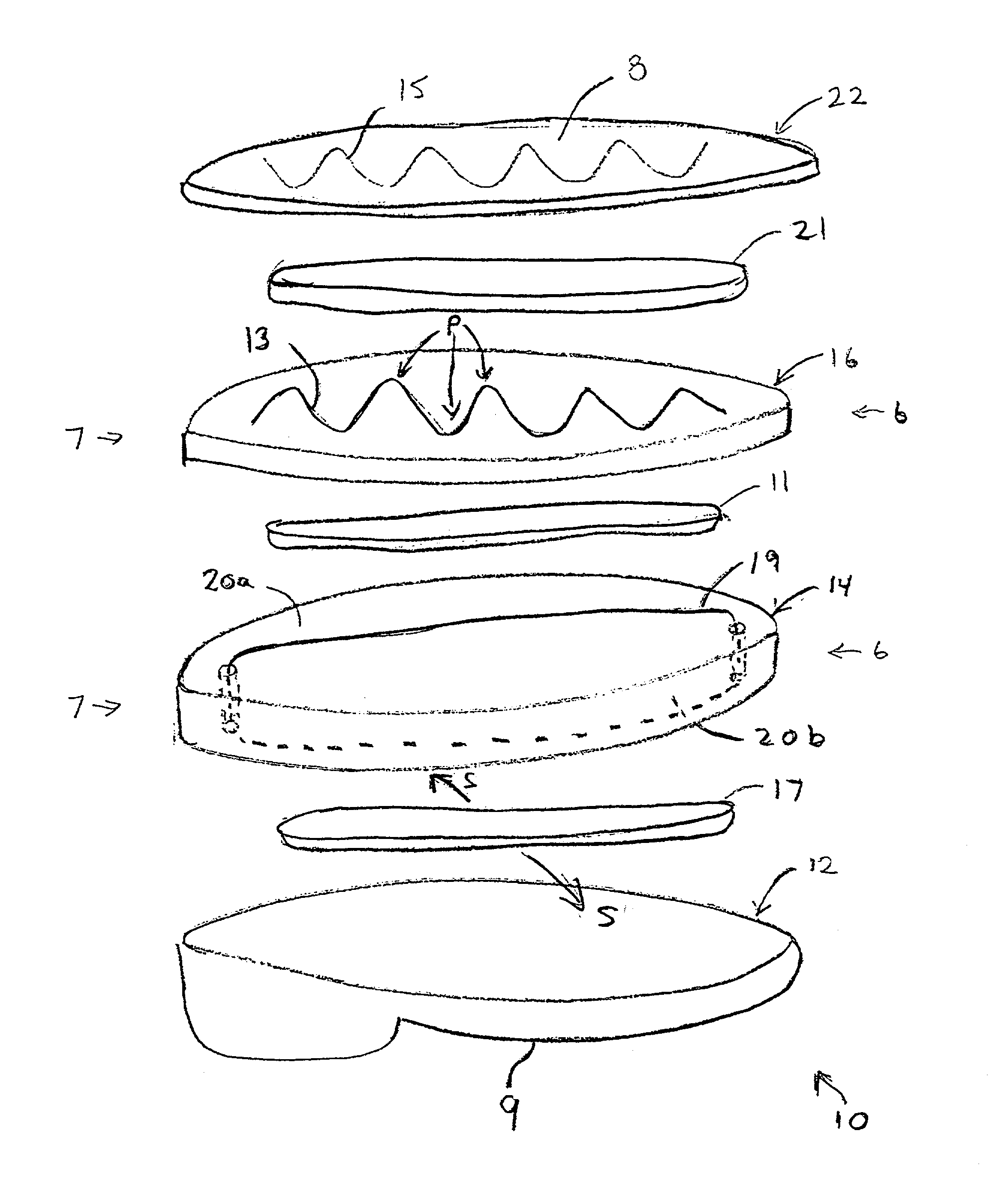

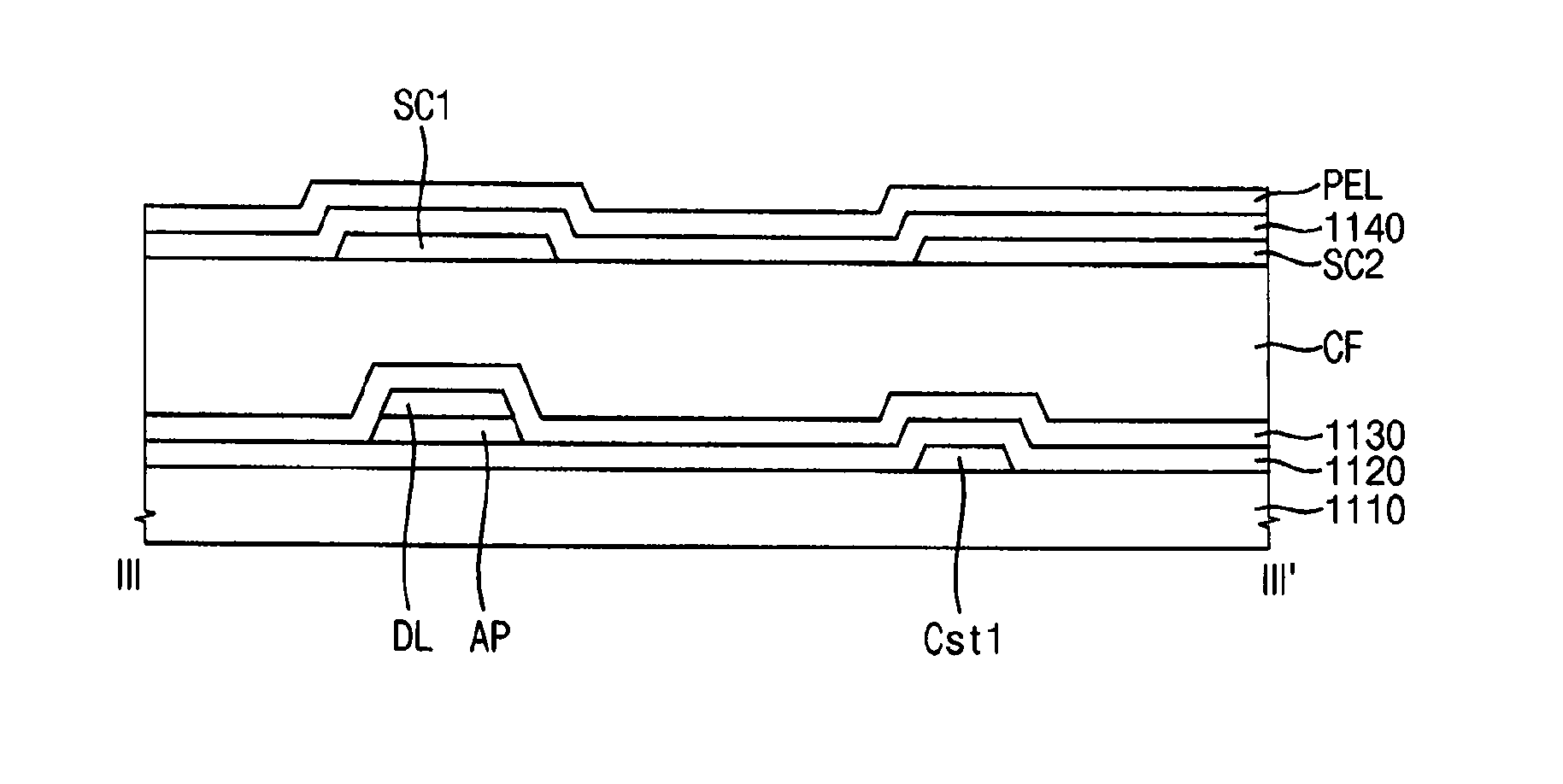

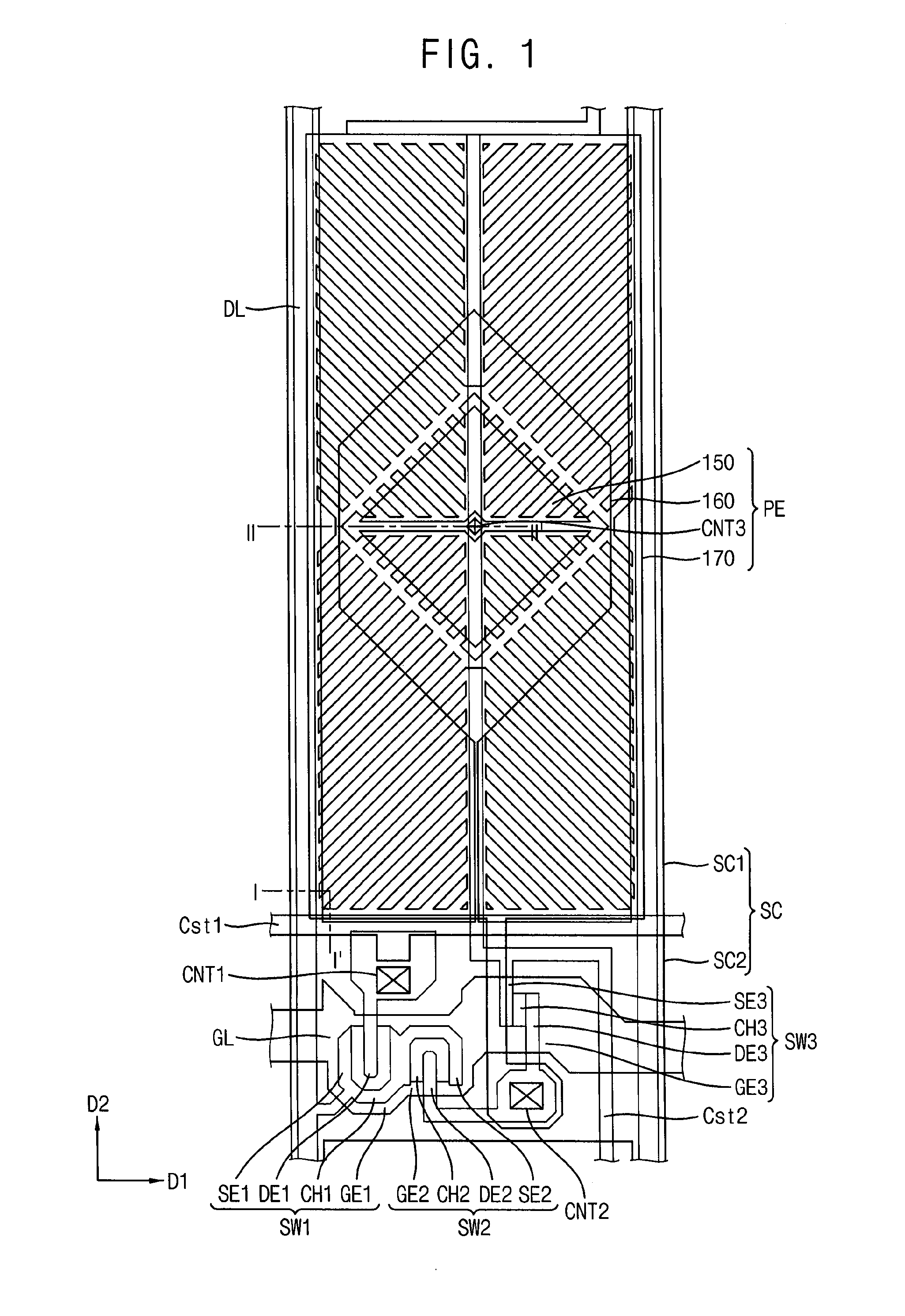

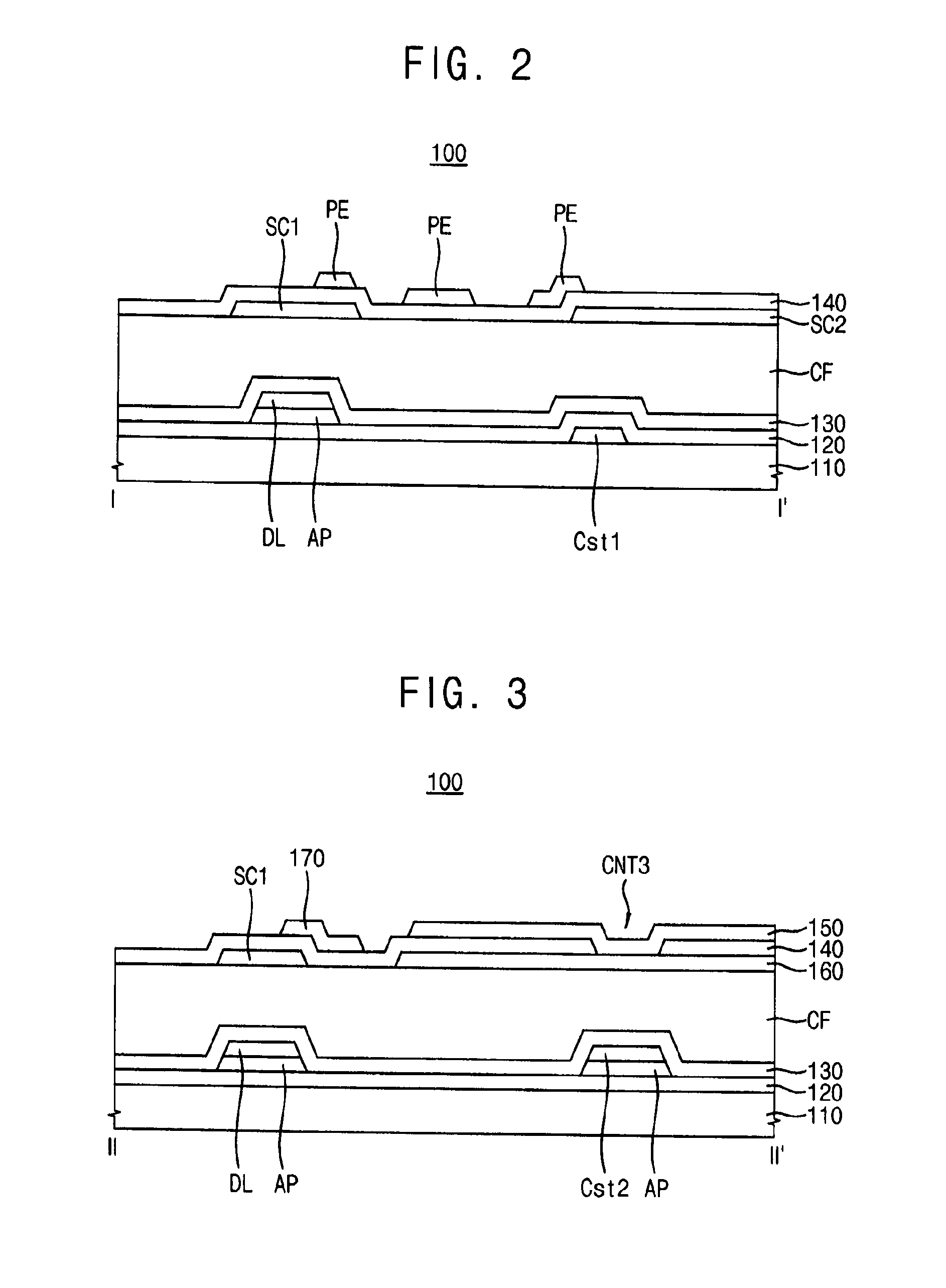

Display substrate and method of manufacturing the same

InactiveUS20150331266A1Decrease manufacturing costIncrease awarenessTransistorSolid-state devicesData linesElectrical and Electronics engineering

Owner:SAMSUNG DISPLAY CO LTD

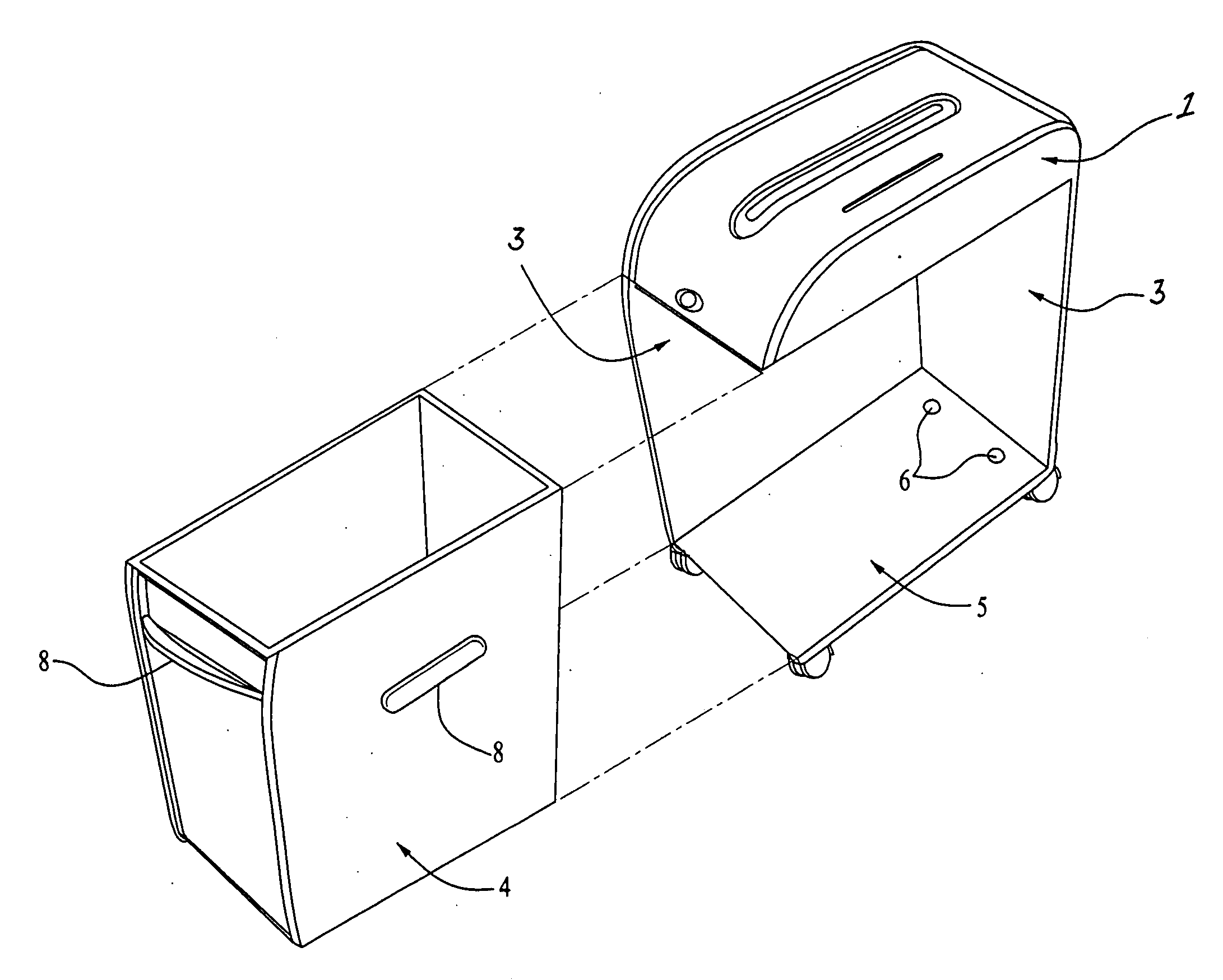

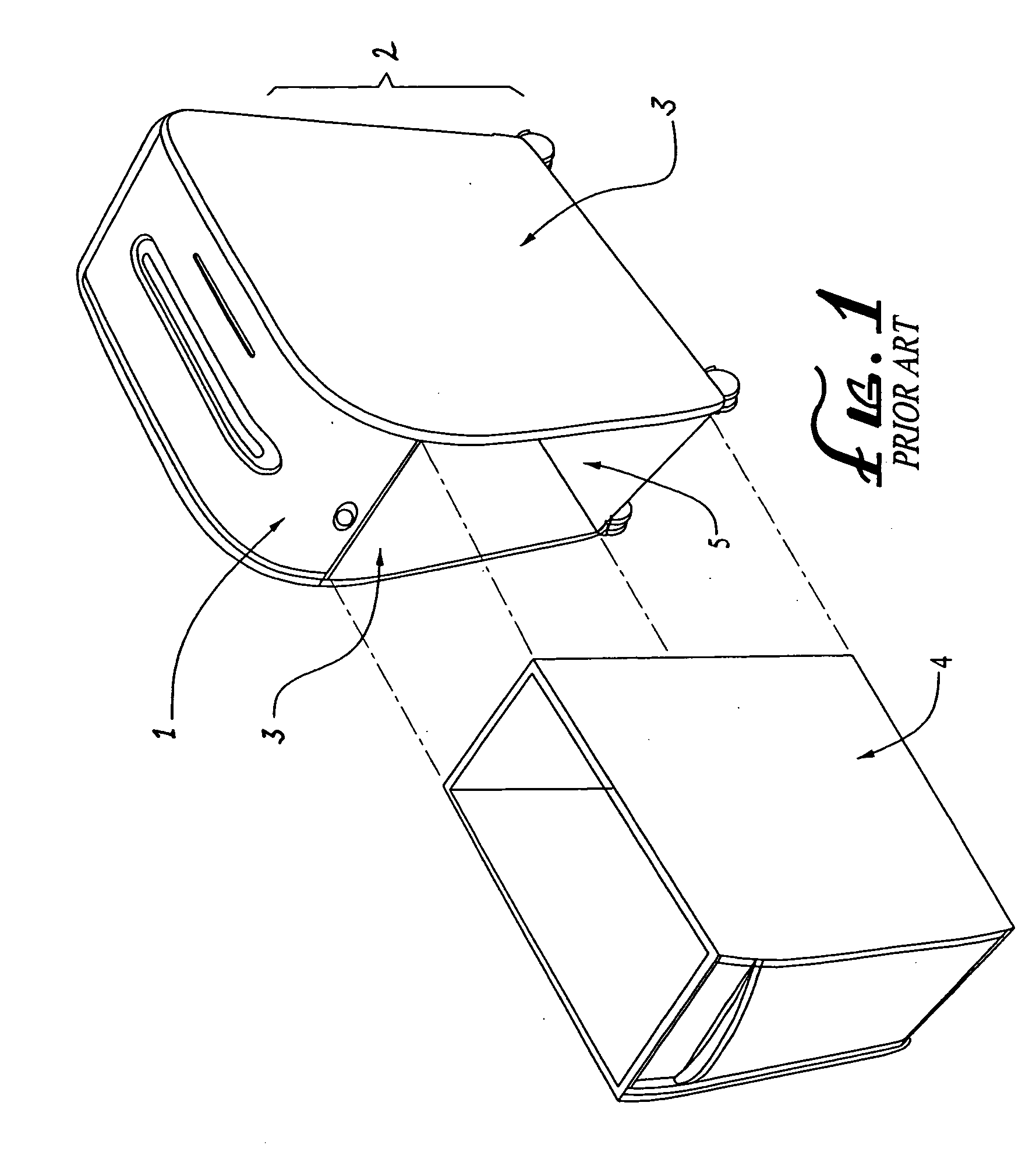

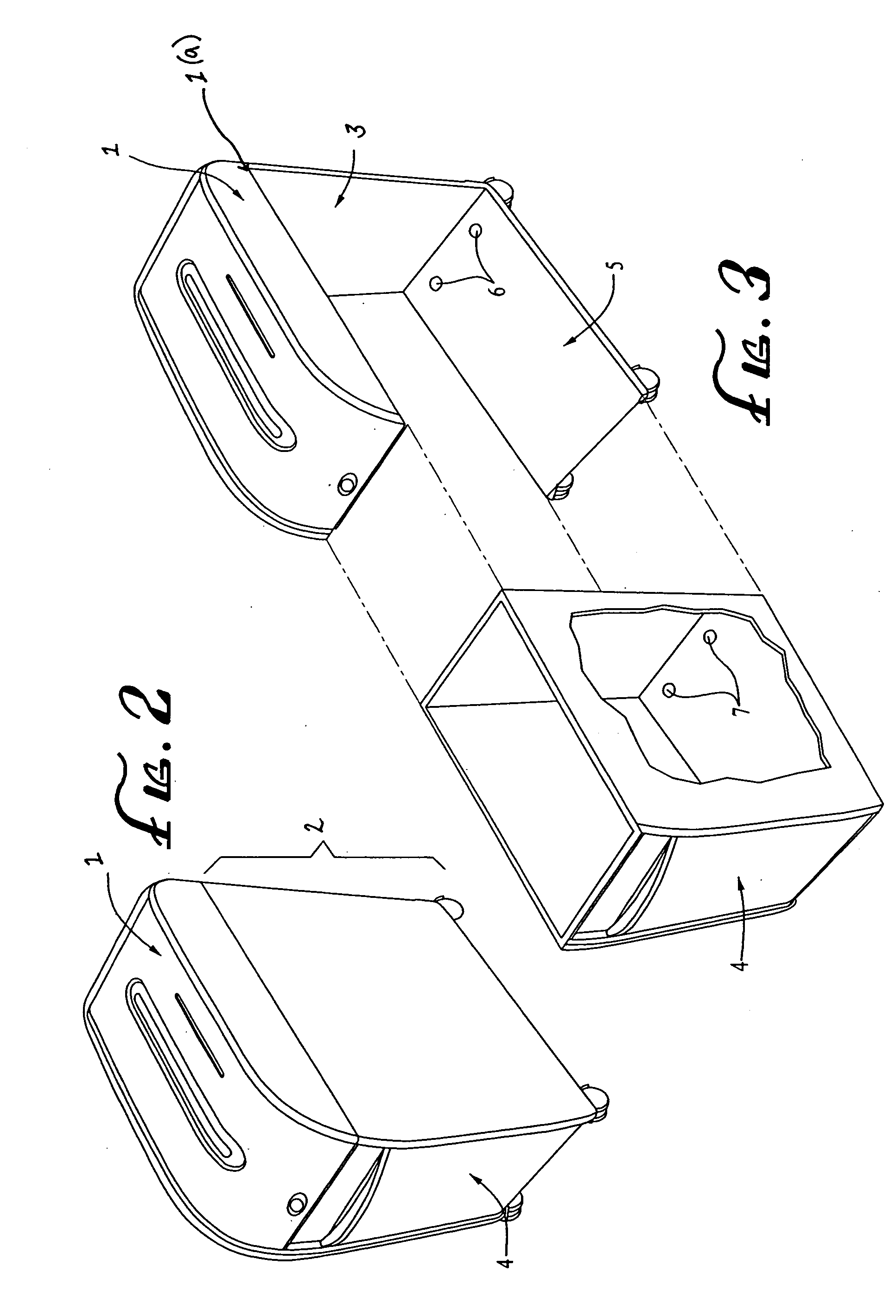

Shredder support and waste receptacle

InactiveUS20080054110A1Decrease manufacturing costIncrease wasteGrinding machine componentsSupporting apparatusMechanical engineeringEnvironmental engineering

The present invention relates generally to the support system and waste receptacles for shredders. By removing certain supports in a shredder, the waste receptacle can be enlarged. In addition, openings in the shredder support walls allow the size of the waste receptacle to be increased, as well as facilitate disposal of other waste through the opening.

Owner:MICHILIN PROSPERITY

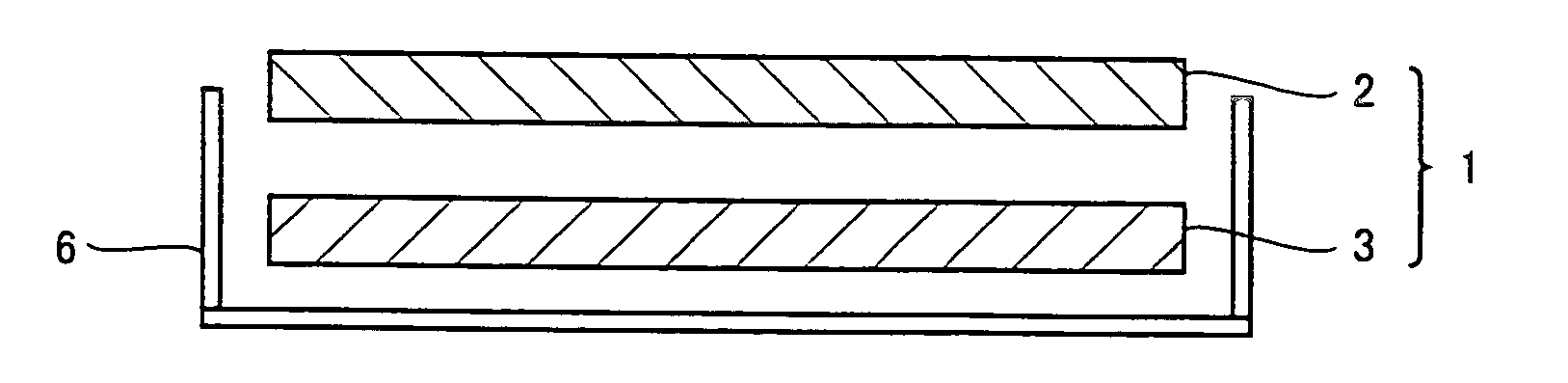

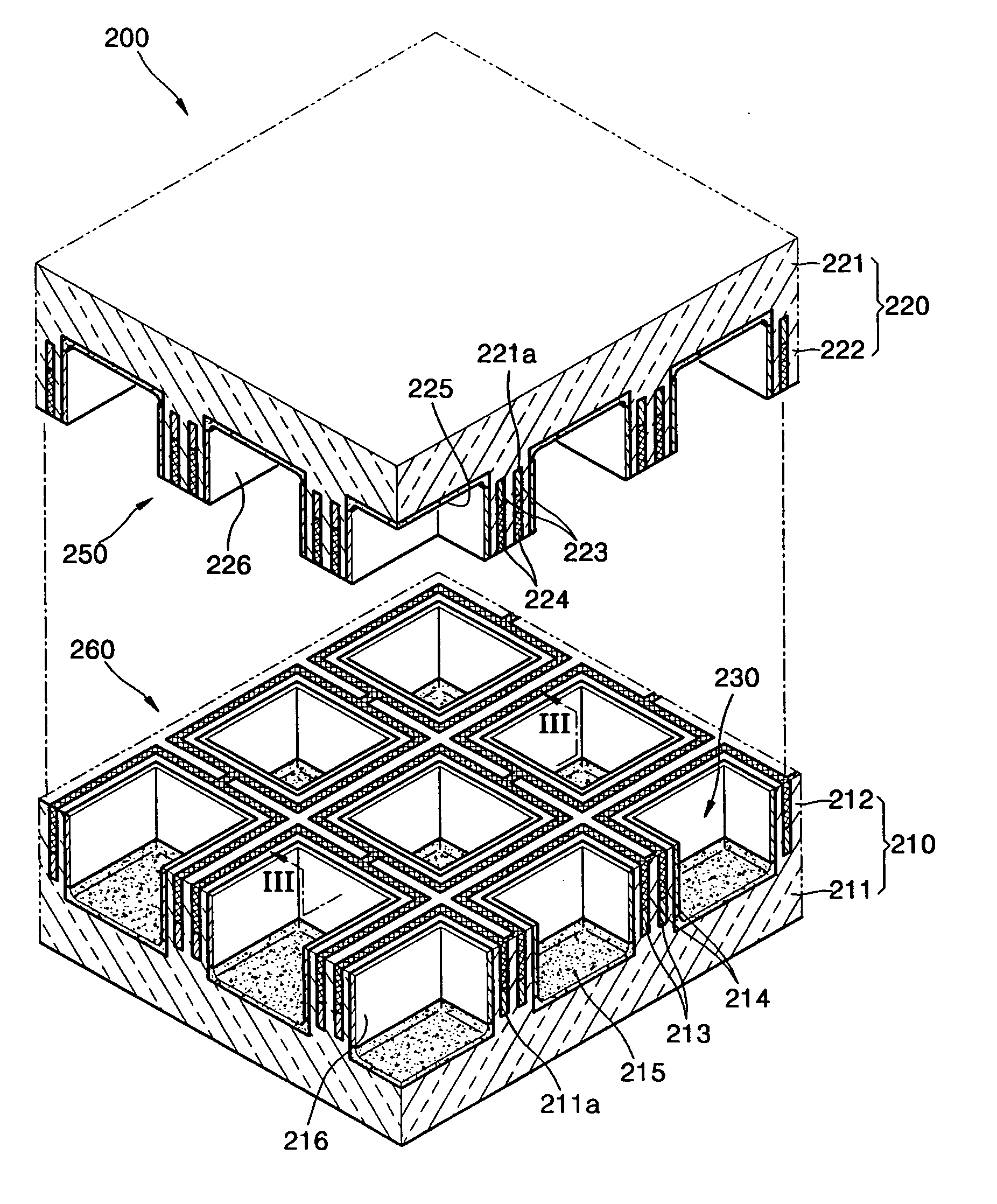

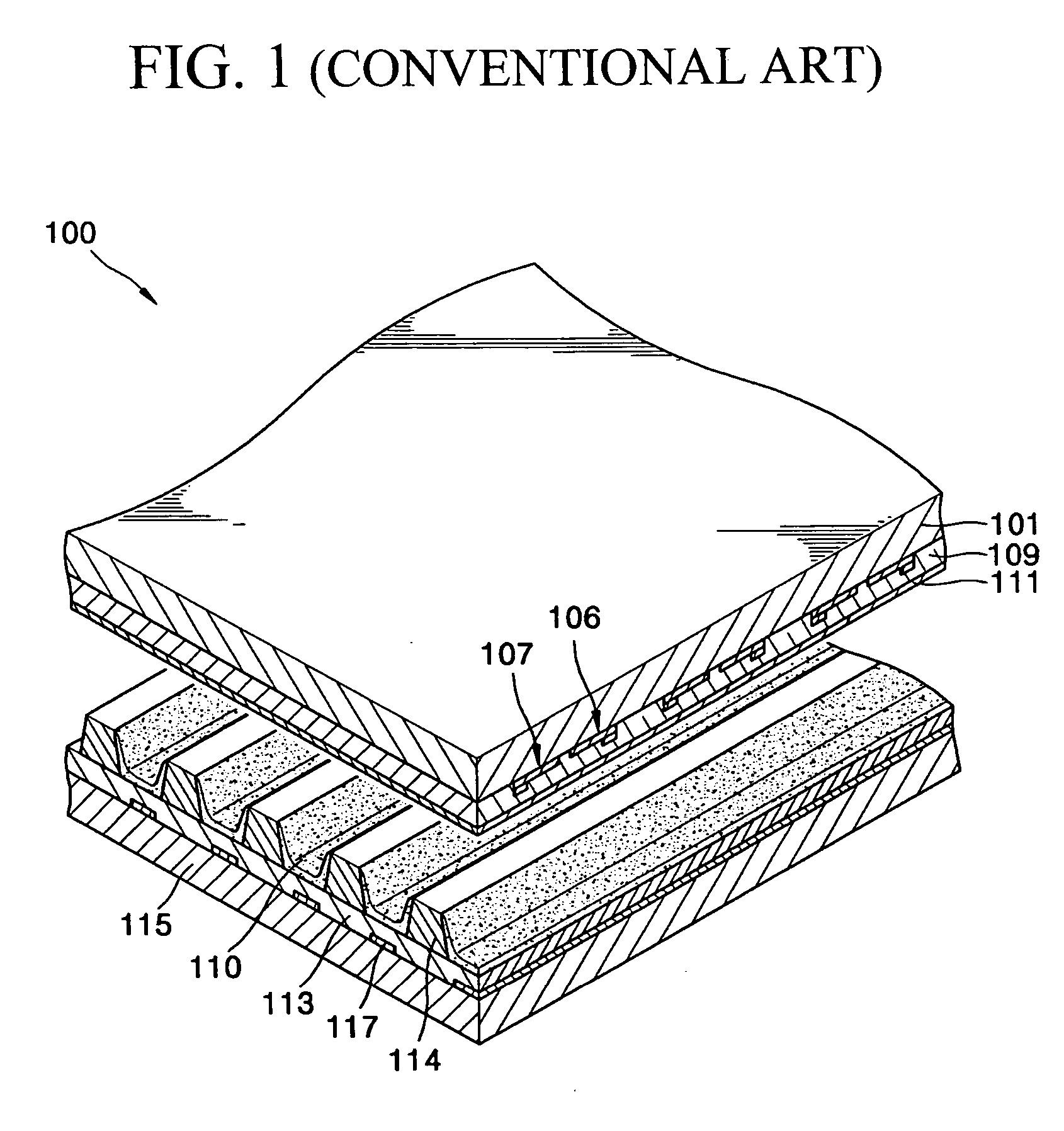

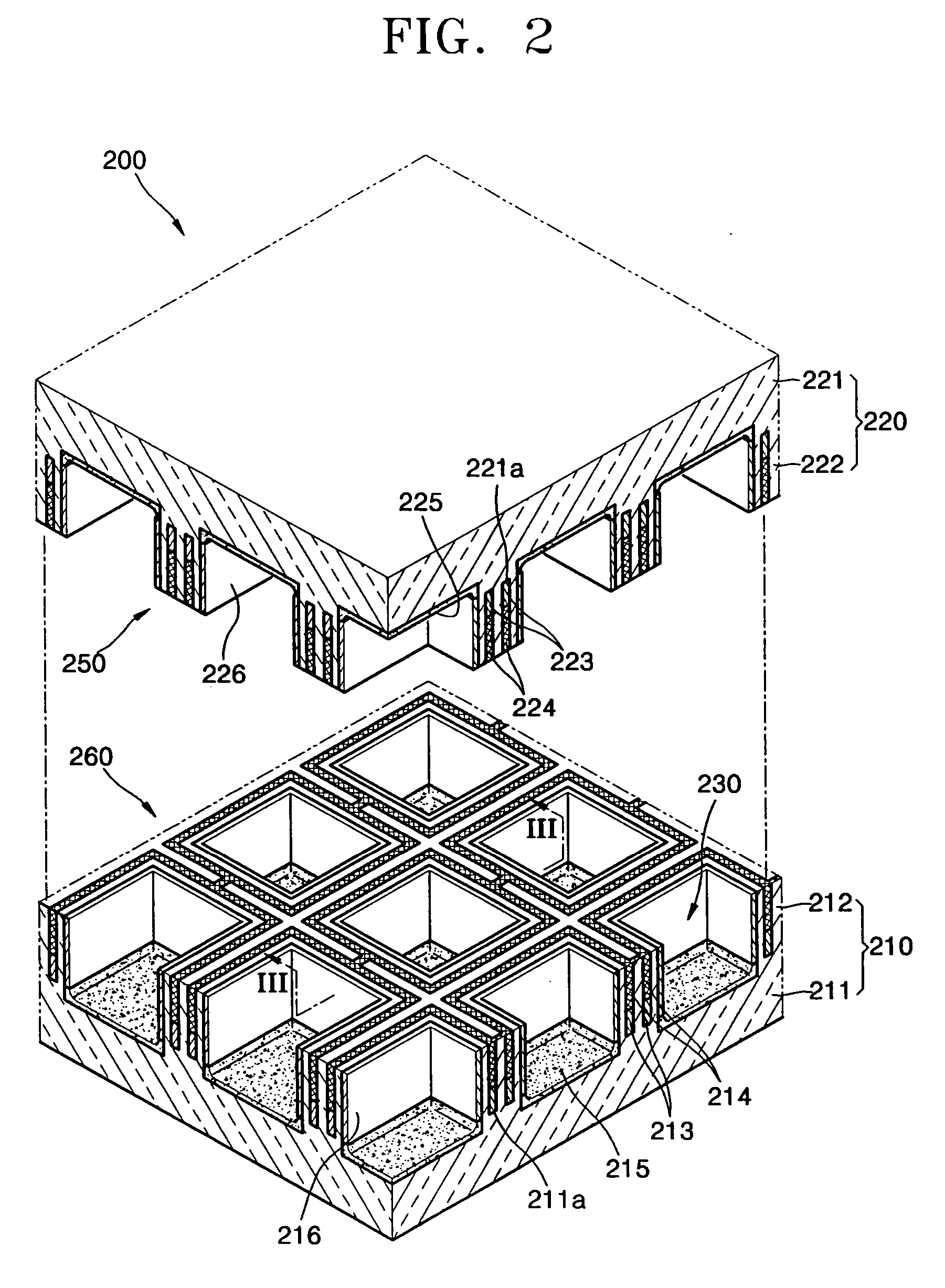

Plasma display panel

InactiveUS20060113910A1Increased strengthDecrease manufacturing costIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationPlasma displaySurface plate

A plasma display panel includes a back substrate having back barrier ribs partitioning a plurality of discharge cells; a front substrate arranged to be opposite to the back substrate and having front barrier ribs partitioning the discharge cells in cooperation with the back barrier ribs; back discharge electrodes arranged within the back barrier ribs to enclose the discharge cells; front discharge electrodes arranged within the front barrier ribs to enclose the discharge cells; phosphor layers arranged within the discharge cells; and discharge gas arranged within the discharge cells.

Owner:SAMSUNG SDI CO LTD

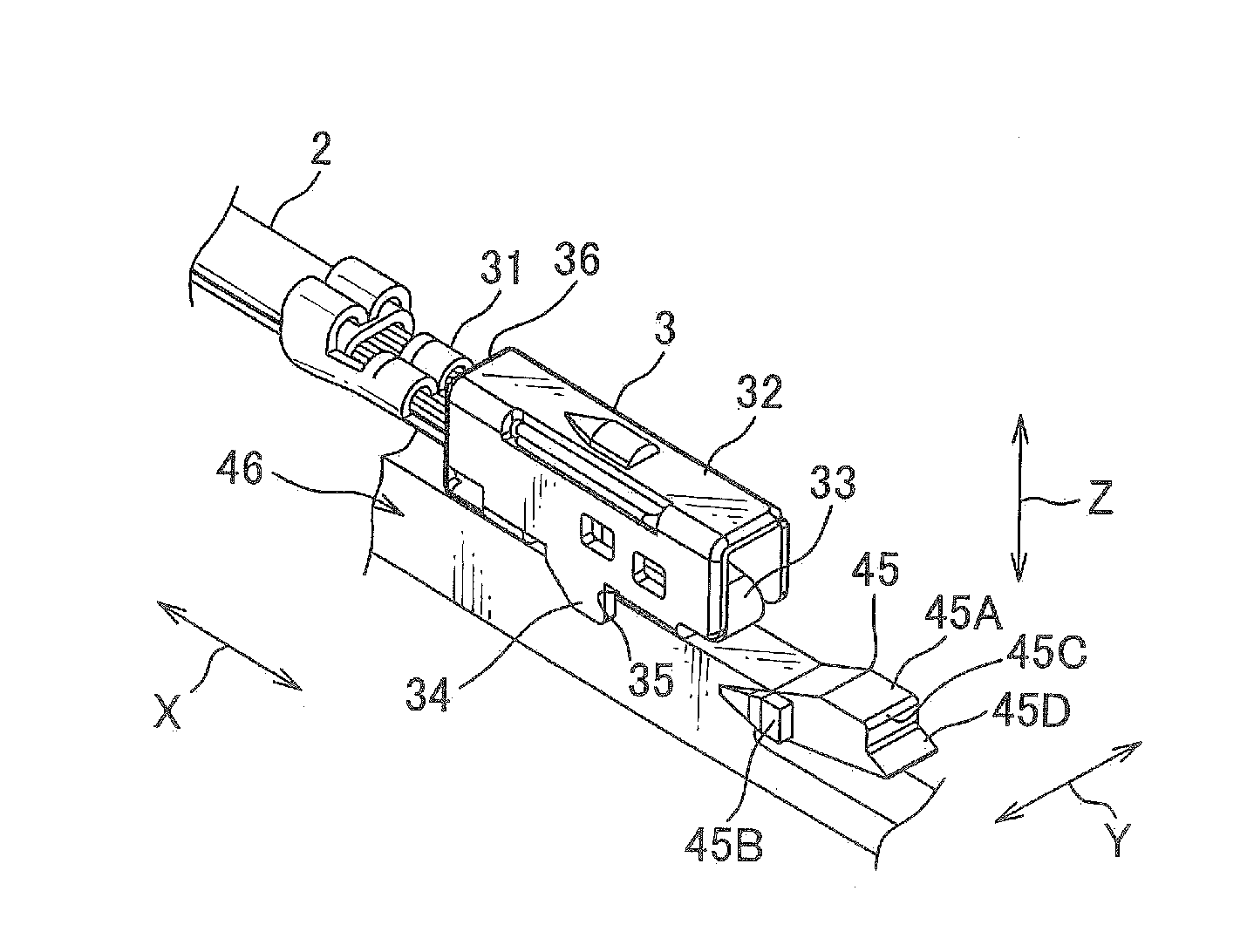

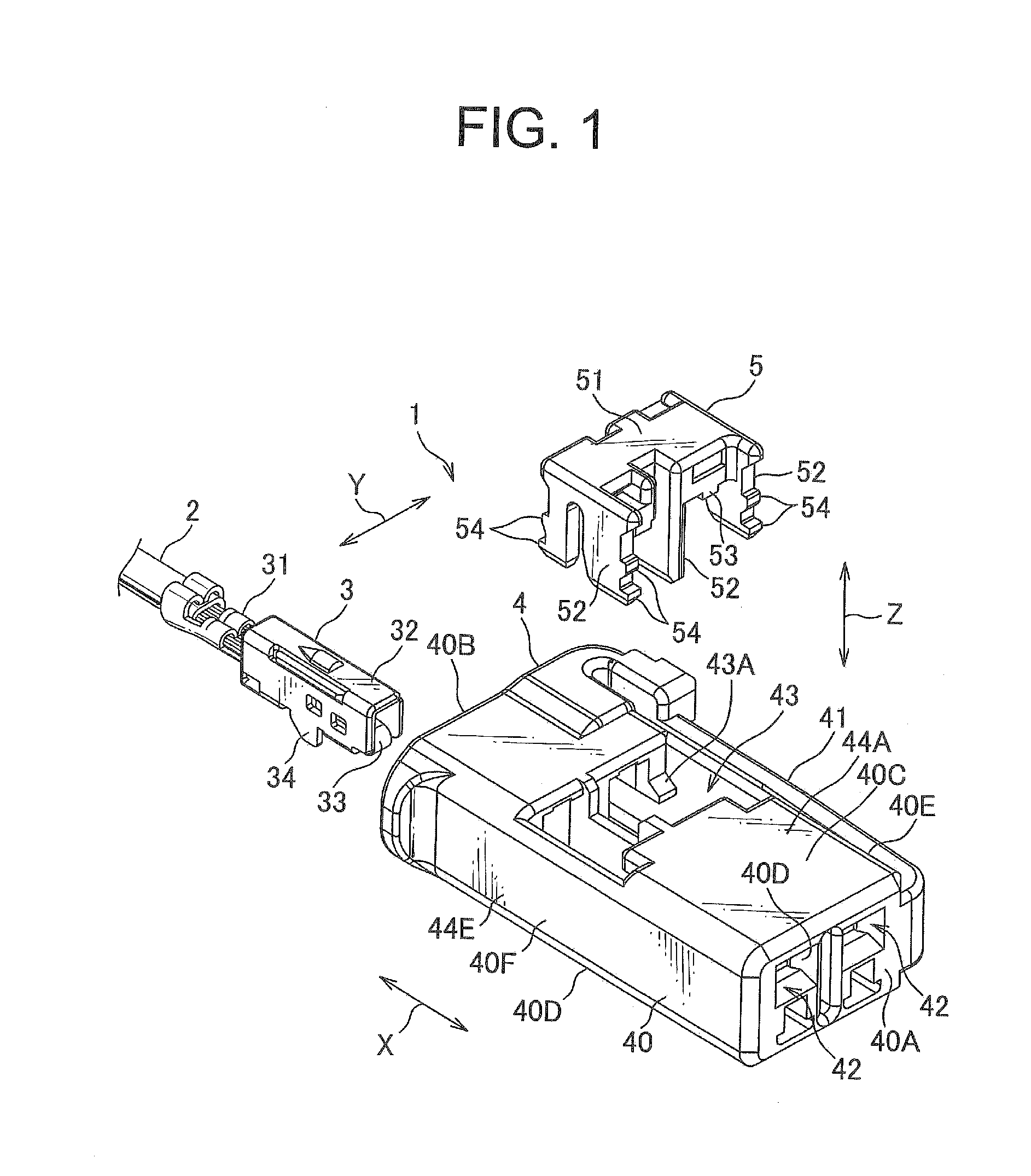

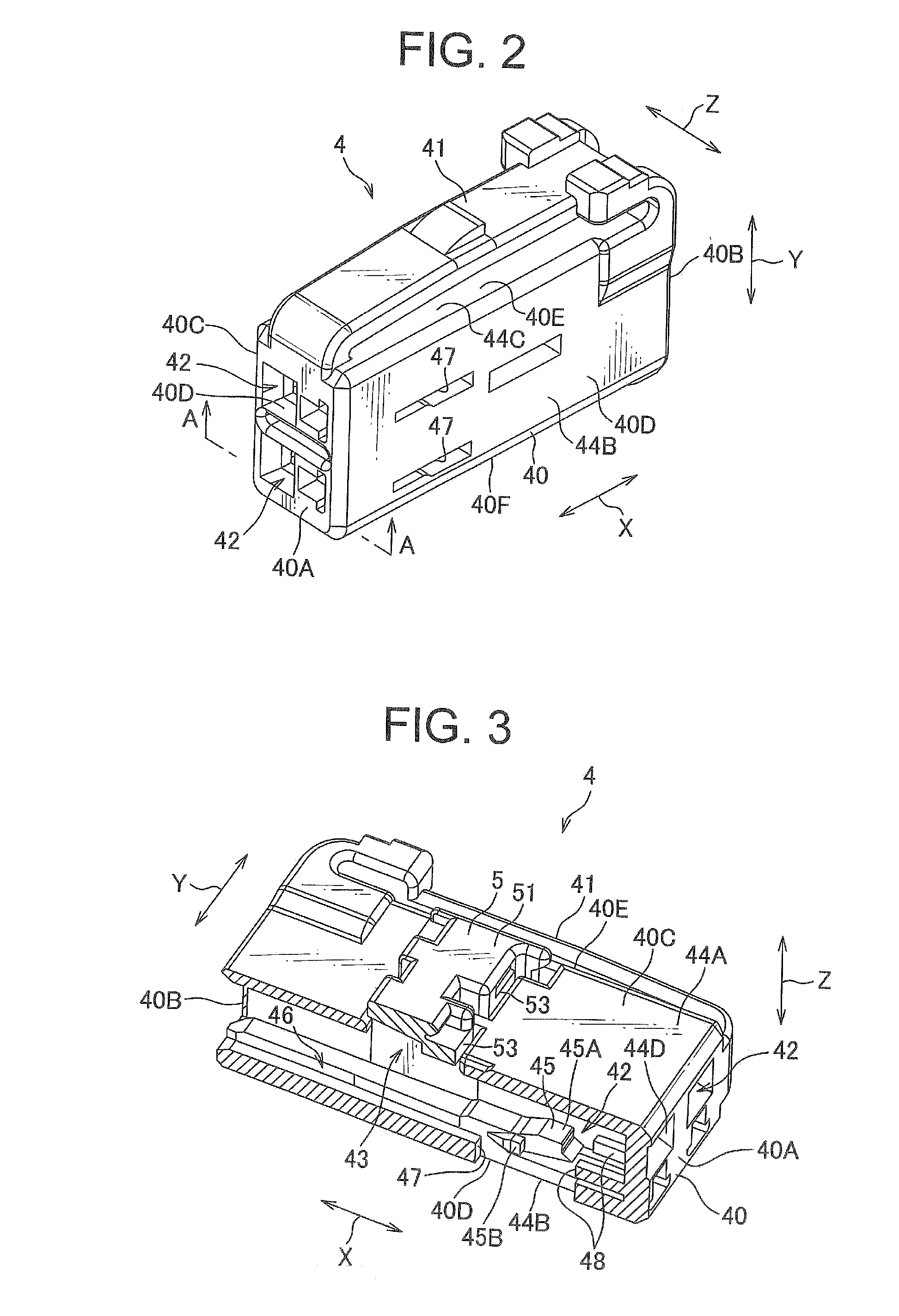

Connector and method of making the same

ActiveUS20140256196A1Decrease manufacturing costIncrease latch forceContact member assembly/disassemblyCoupling device detailsMechanical engineering

There is provided a connector and a method for making the connector preventing escape of a terminal fitting by improving latch force for the terminal fitting over a wide variety of products without inducing upsize or manufacturing cost. The connector comprises a connector housing including a terminal fitting and a terminal housing accommodating the terminal fitting, in which the connector housing includes a wall composing one inner face of the terminal housing, and a latch part latching the terminal fitting, the latch part including a latch arm having a tip extending from a base end disposed the inner face of the wall toward a back side in an insertion direction of the terminal fitting, a latch projection projecting from the latch arm in a direction intersecting the insertion direction.

Owner:YAZAKI CORP

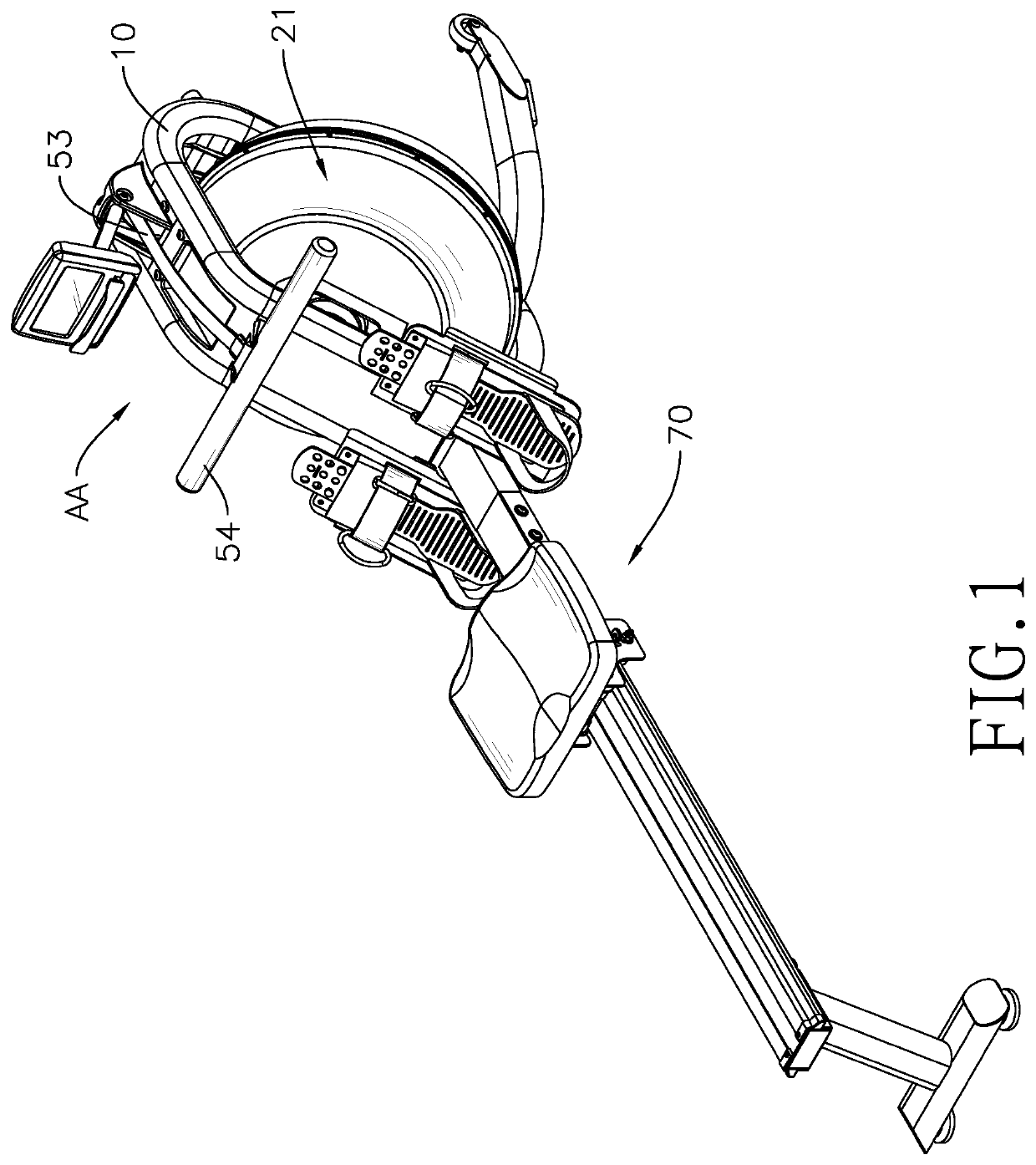

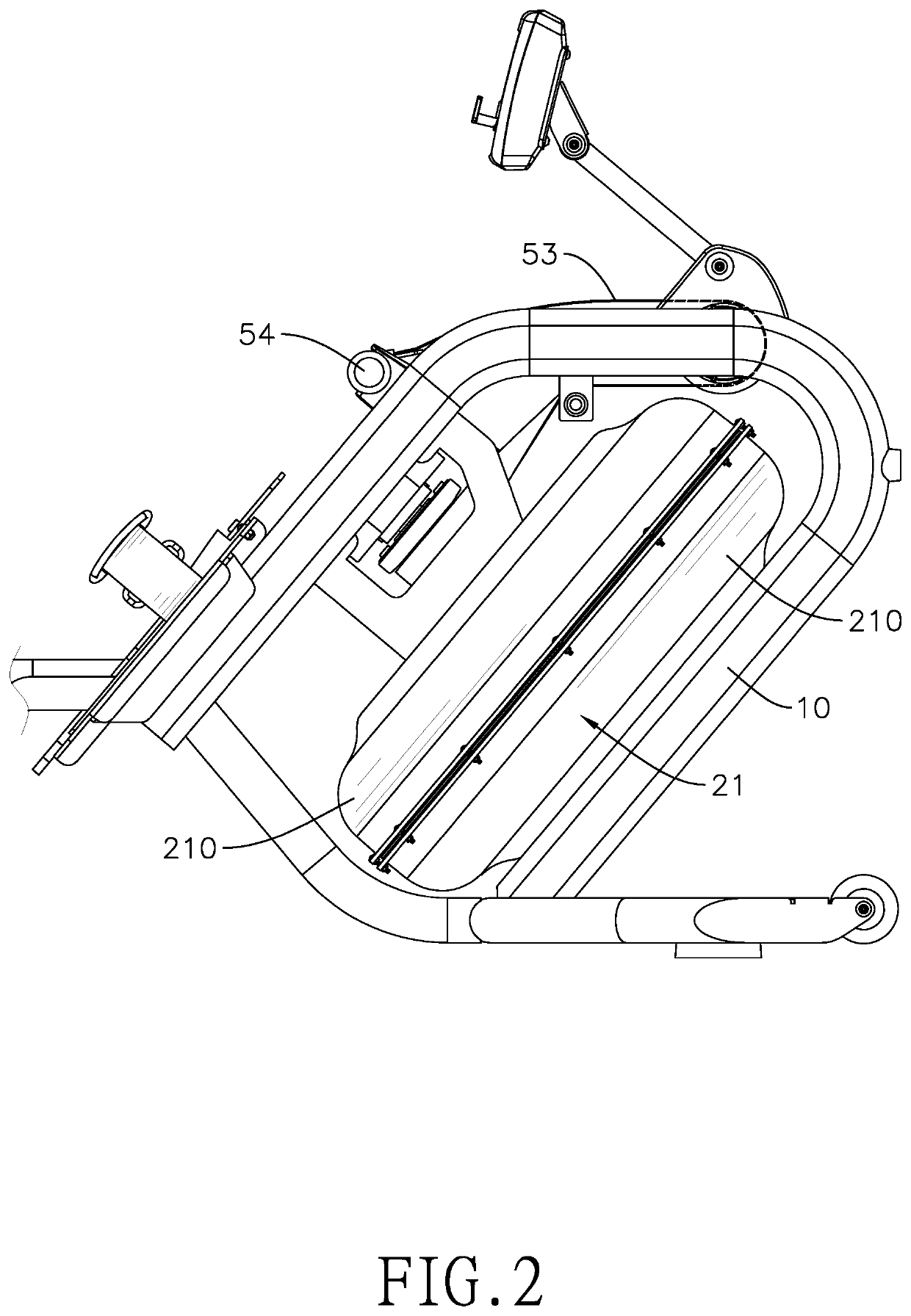

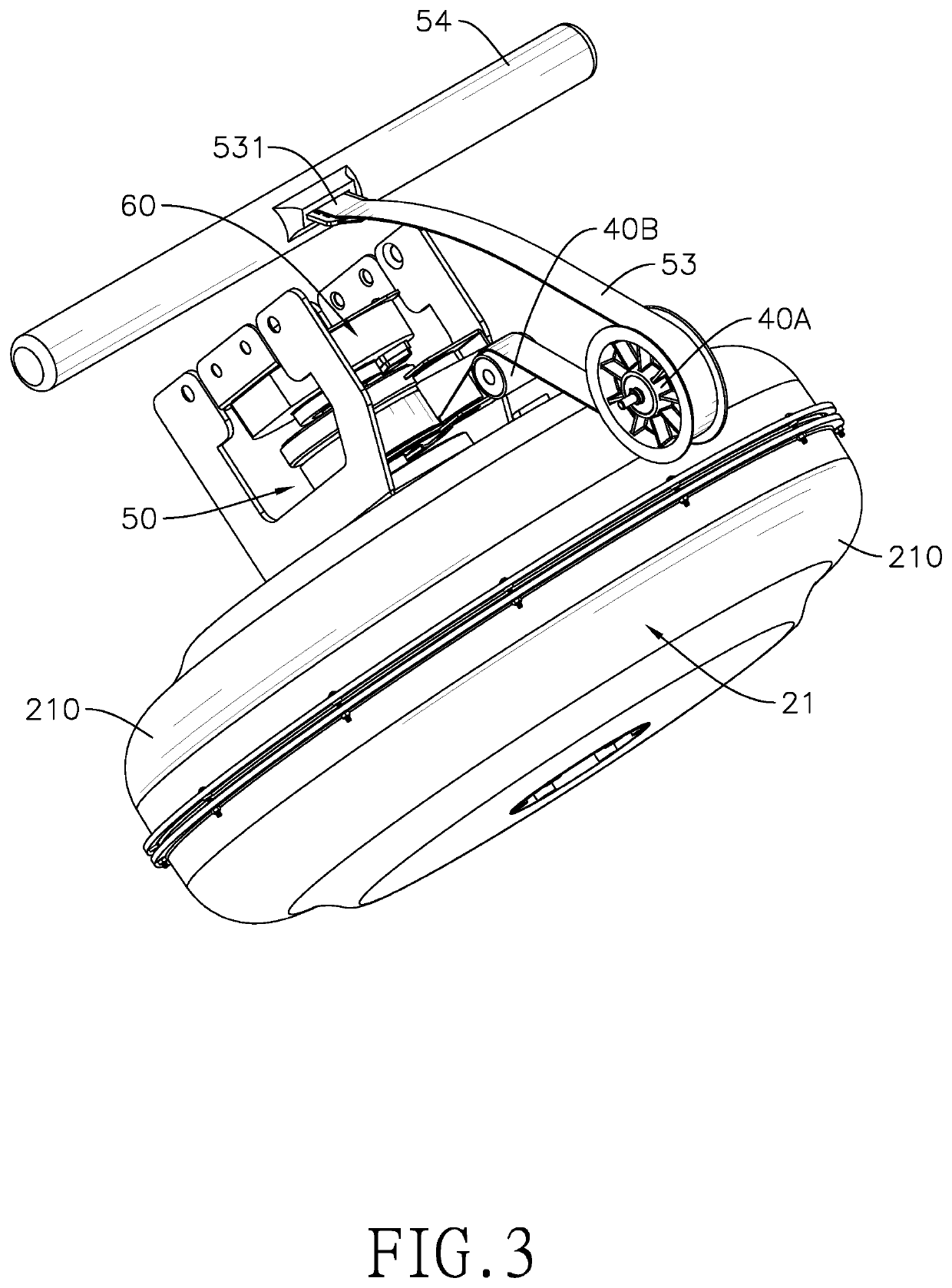

Resistance System for a Rowing Machine

InactiveUS20200197739A1Easily assembleDecrease manufacturing costMuscle exercising devicesMovement coordination devicesPaddle wheelResistance force

A resistance system for a rowing machine has a mounting bracket, and a housing assembly, a driving assembly and a restoring assembly mounted on the mounting bracket. The housing assembly is for storing liquid and a paddle wheel. The driving assembly is connected to the paddle wheel and drives the paddle wheel to rotate in a direction only. The restoring assembly is connected to a strip hub of the driving assembly and is able to drive the strip hub to rotate in a reverse direction. The resistance system for the rowing machine has simplified structure. Therefore, it is easy to assemble to resistance system, and manufacturing cost of the resistance system can be decreased. In addition, a service life of the resistance system as well as the rowing machine can be increased.

Owner:NU SPORT CO LTD

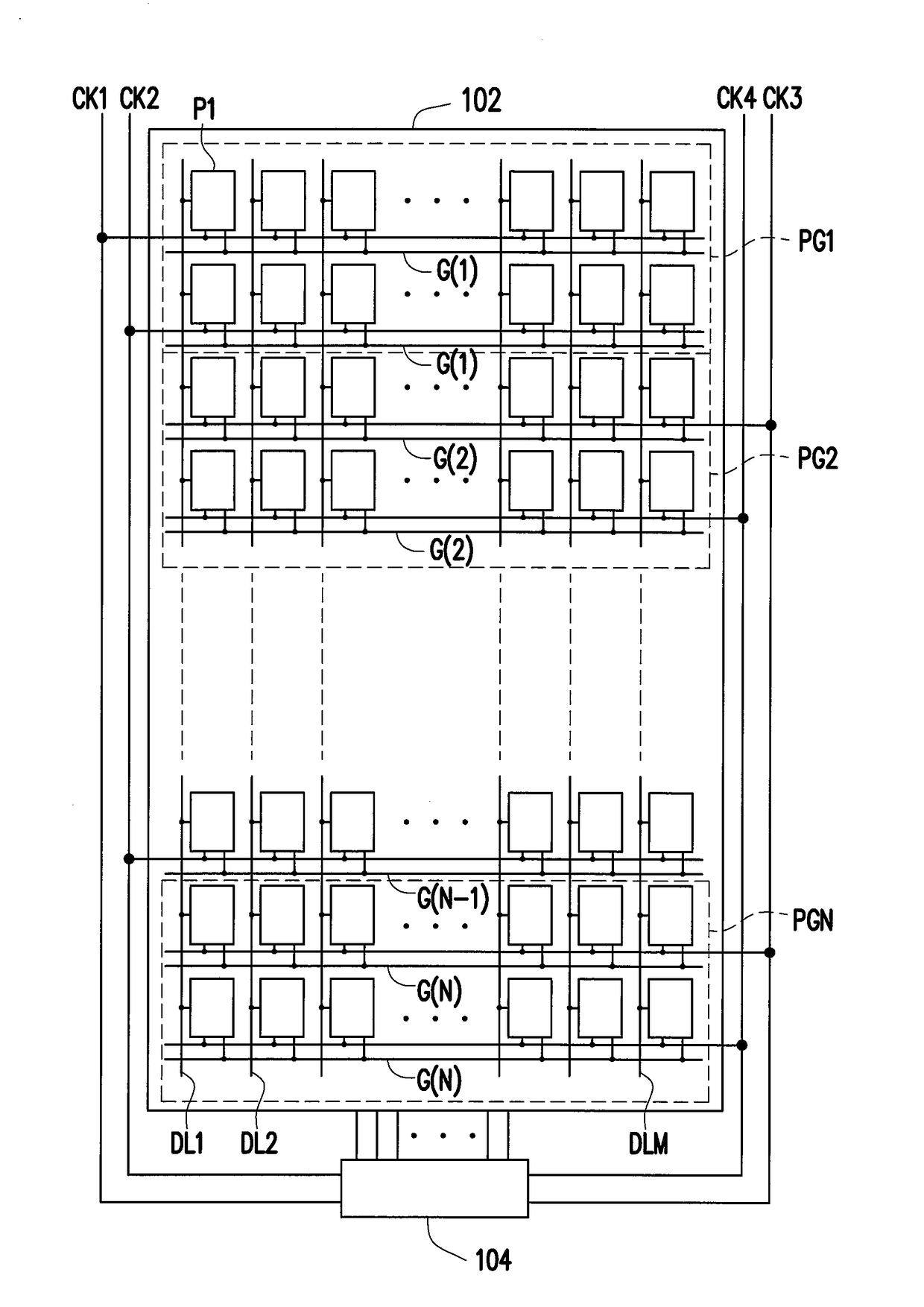

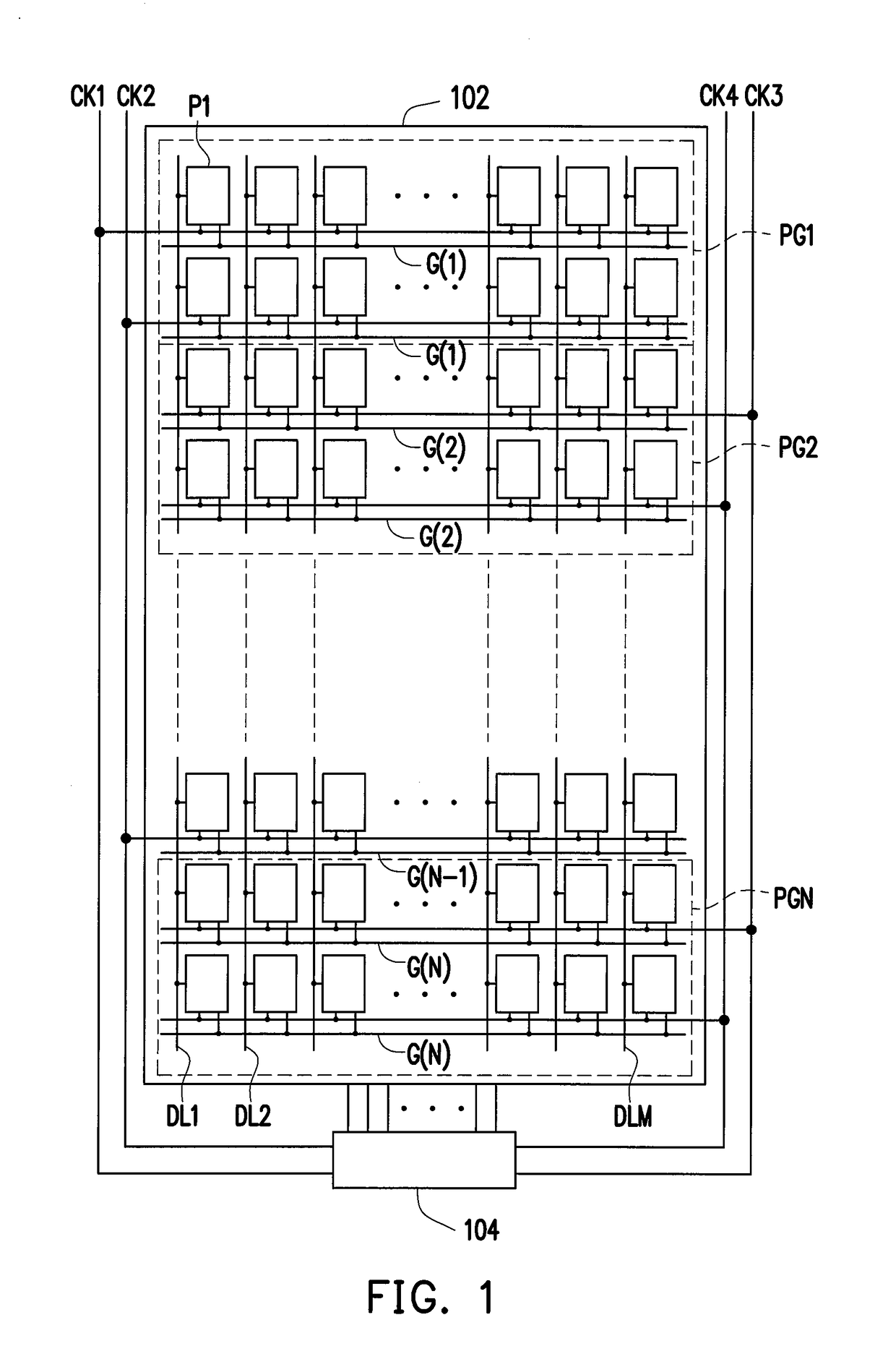

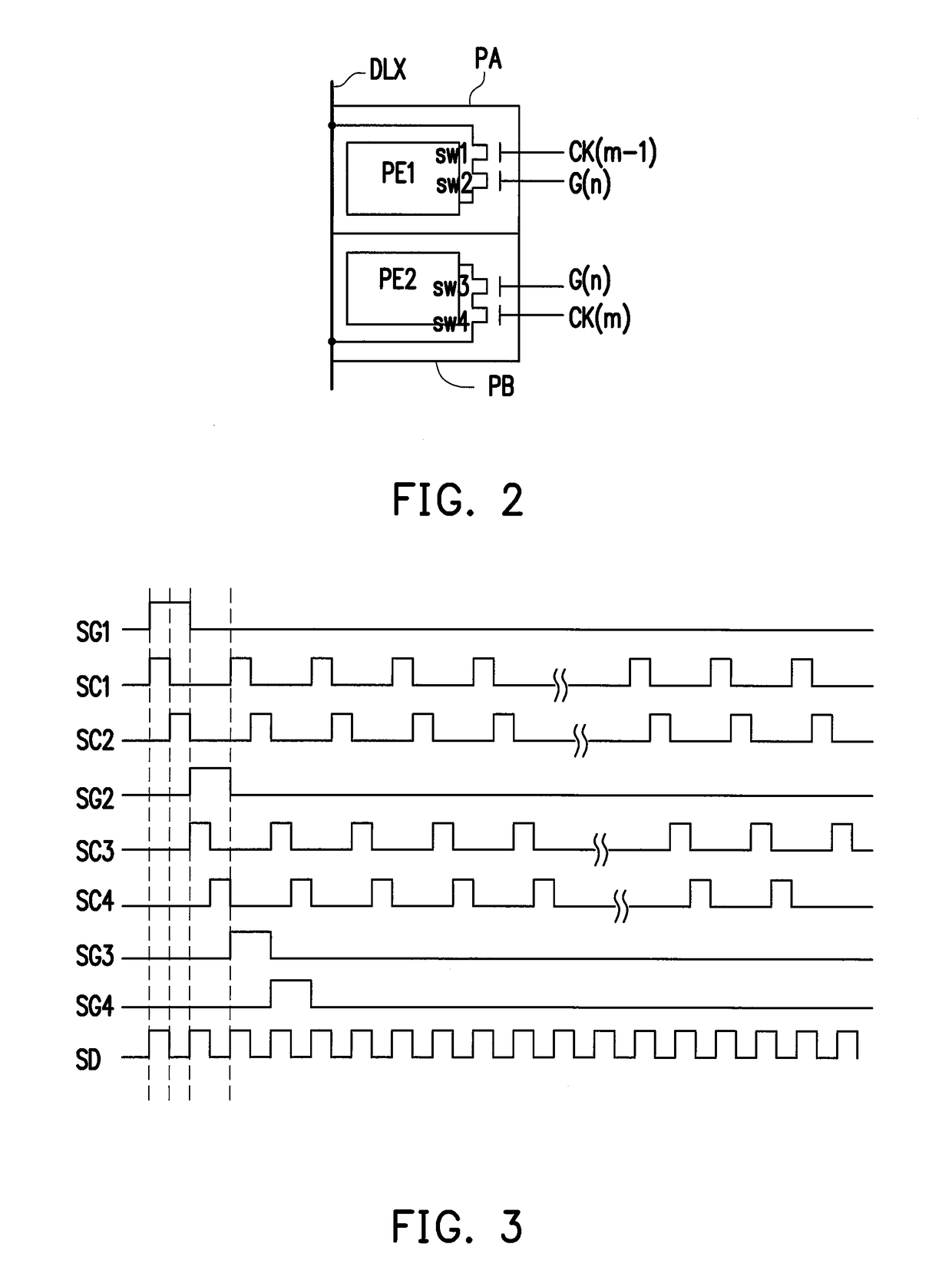

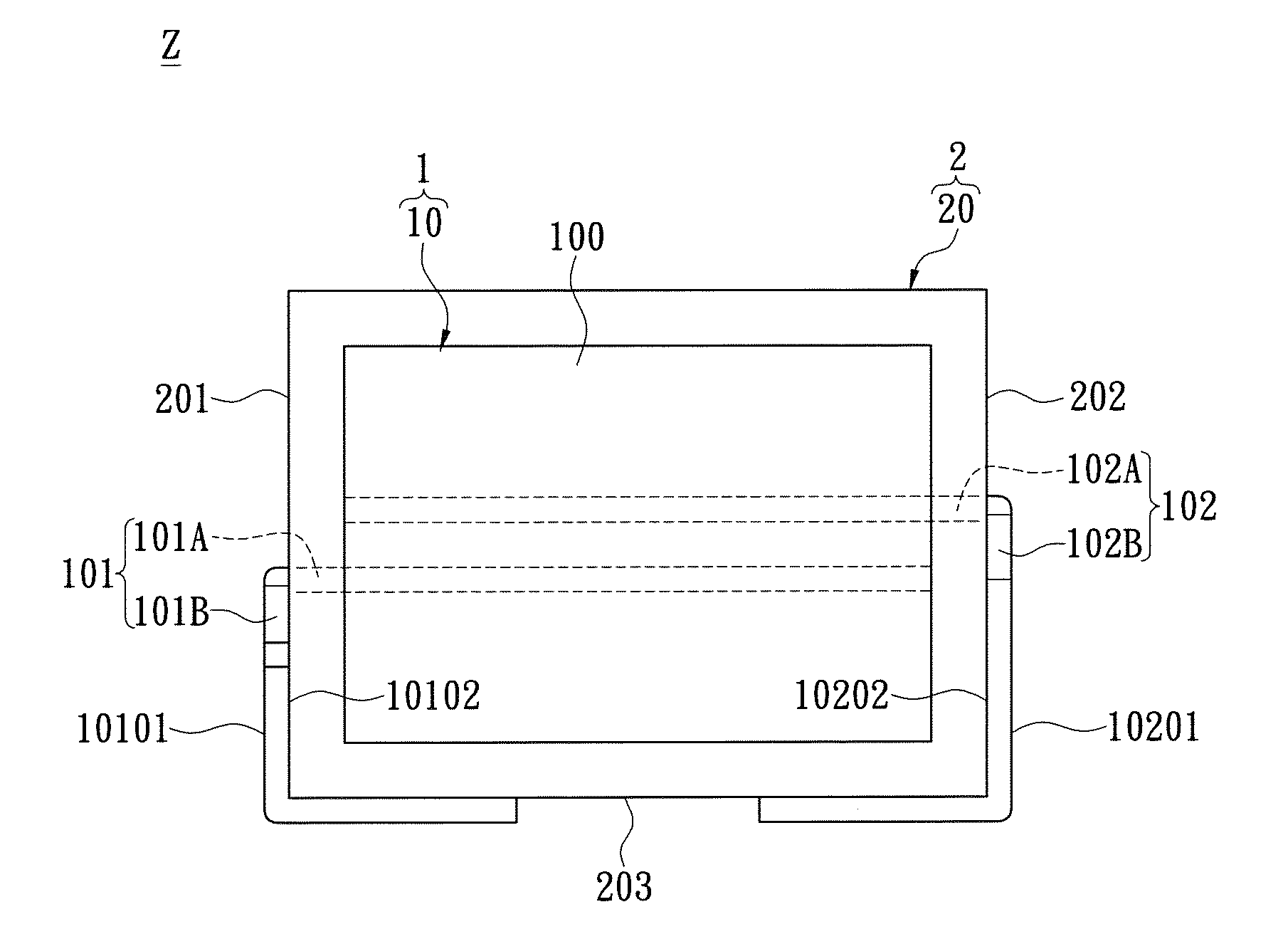

Display device

InactiveUS20180261176A1Decrease manufacturing costReduce border areaStatic indicating devicesNon-linear opticsScan lineClock signal

A display device including scan lines, data lines, k clock signal lines and pixel groups is provided. The pixel groups are respectively driven by the data lines, the corresponding scan lines and the corresponding clock signal lines. Each pixel group includes pixel units respectively configured at intersections of the data lines and the corresponding scan lines, where the scan lines in each pixel group receive a same scan driving signal. Each pixel unit includes two switches and a pixel electrode. Conduction states of the two switches are respectively controlled by the corresponding scan line and the corresponding clock signal line, where clock signals of the clock signal lines corresponding to the pixel units on the adjacent scan lines have a phase difference of 1 / k cycle.

Owner:CHUNGHWA PICTURE TUBES LTD

Lead frame and manufacturing method thereof, and semiconductor apparatus and manufacturing method thereof

InactiveUS20080296746A1Decrease manufacturing costSuppress stress and strainLine/current collector detailsSemiconductor/solid-state device detailsEngineeringSemiconductor components

The present invention includes a plurality of mounting portions on which a semiconductor element is mounted, a plurality of electrodes to which the semiconductor elements that are mounted on each of the mounting portions are electrically connected, a corner portion which connects the plurality of mounting portions and which has a hanging lead piece that supports the mounting portions and an electrode connection piece that connects the plurality of electrodes, and a half-blanking portion that has a concave portion formed in a thickness direction of the lead frame and a protrusion formed at a position corresponding to the concave portion, and which is covered with a sealing resin material that seals the semiconductor element. A stress-dispersing portion for dispersing stress that arises, when the half-blanking portion is formed, is provided in the corner portion.

Owner:RENESAS ELECTRONICS CORP

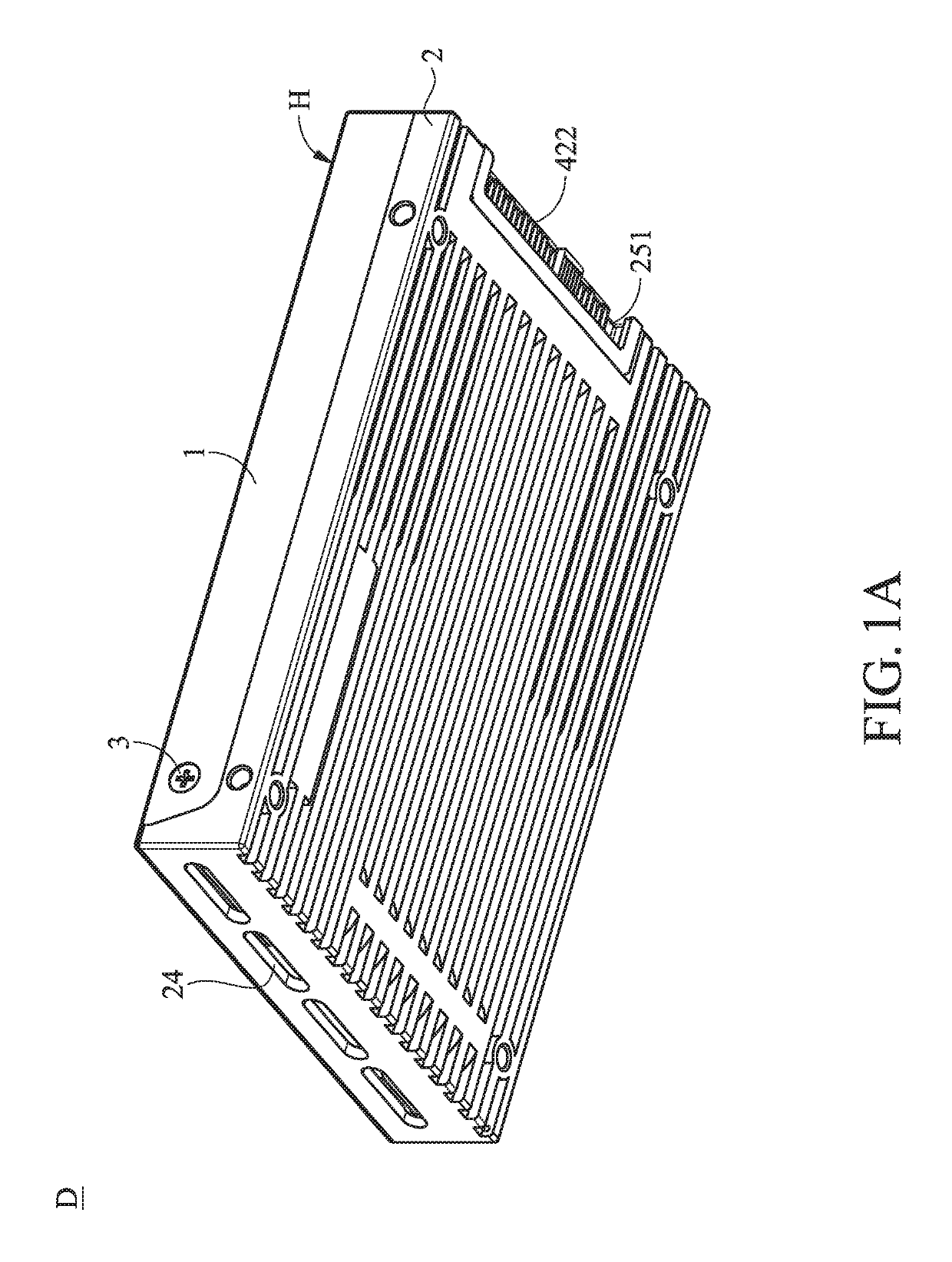

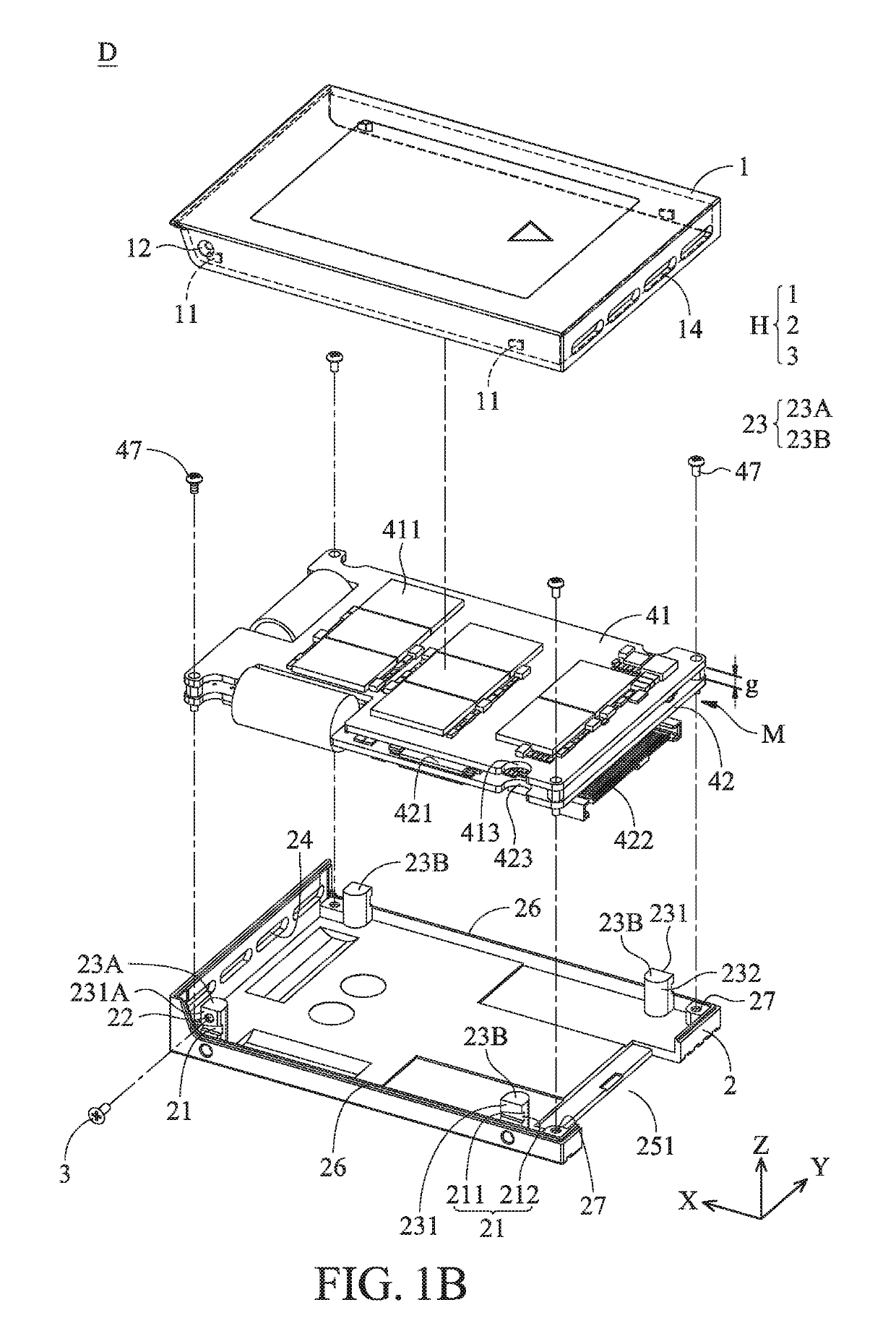

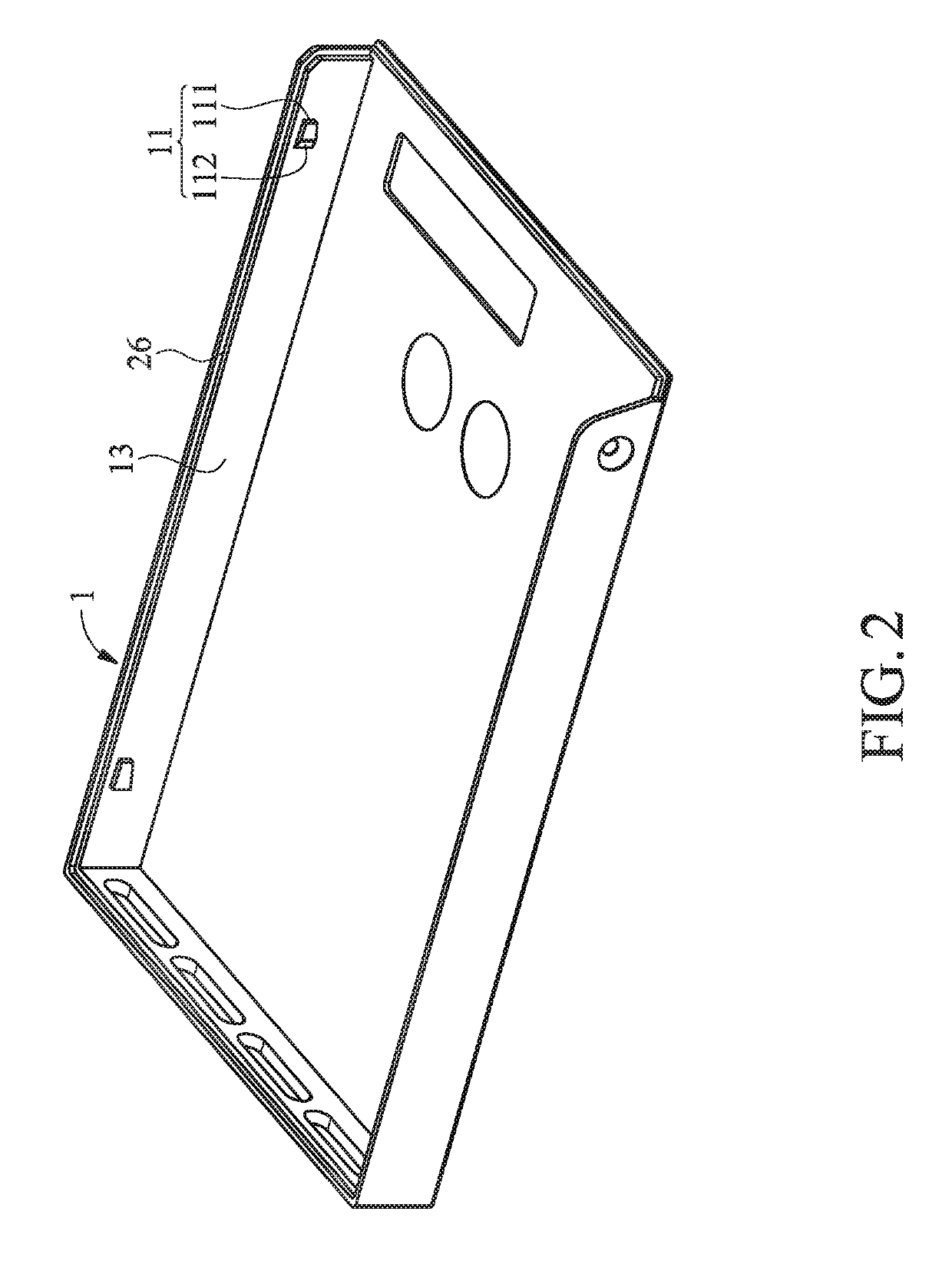

Solid state memory device

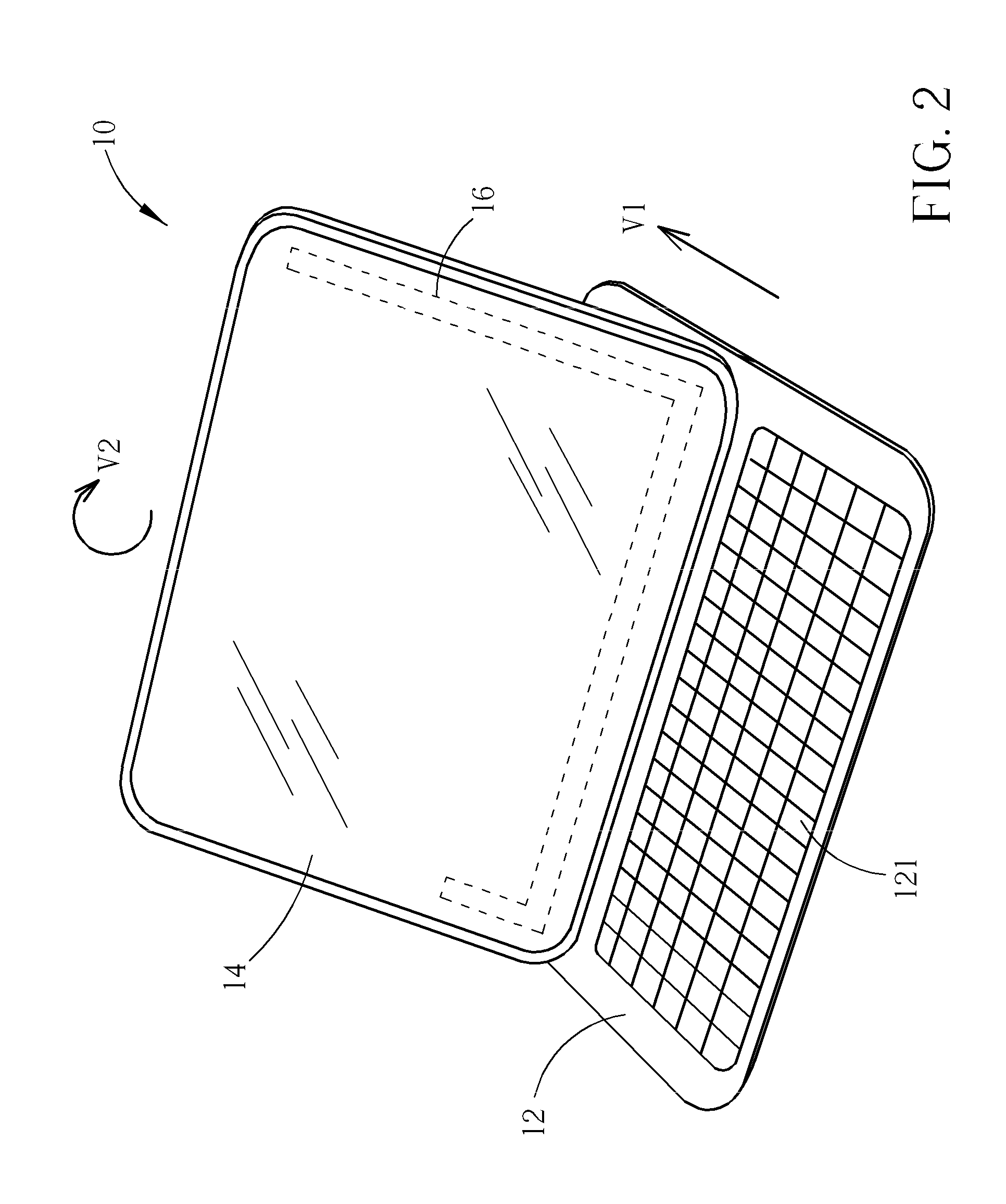

ActiveUS10477706B1Simplify assembly processDecrease manufacturing costClosed casingsCasings/cabinets/drawers detailsSolid-state storageMechanical engineering

A solid state memory device is provided. The solid state memory device includes a housing and a solid state memory module. The housing includes a housing fastening member, a first housing member, and a second housing member, wherein the second housing member is connected to the first housing member. The solid state memory module is disposed in the housing. The first housing member includes a plurality of first wedging portions, and the second housing member includes a plurality of second wedging portions. Each first wedging portion wedges the corresponding second wedging portion in a first direction. The first housing member further includes a first fastening portion, and the second housing member further includes a second fastening portion. The housing fastening member affixes the first fastening portion to the second fastening portion in a second direction, wherein the first direction differs from the second direction.

Owner:SHANNON SYST

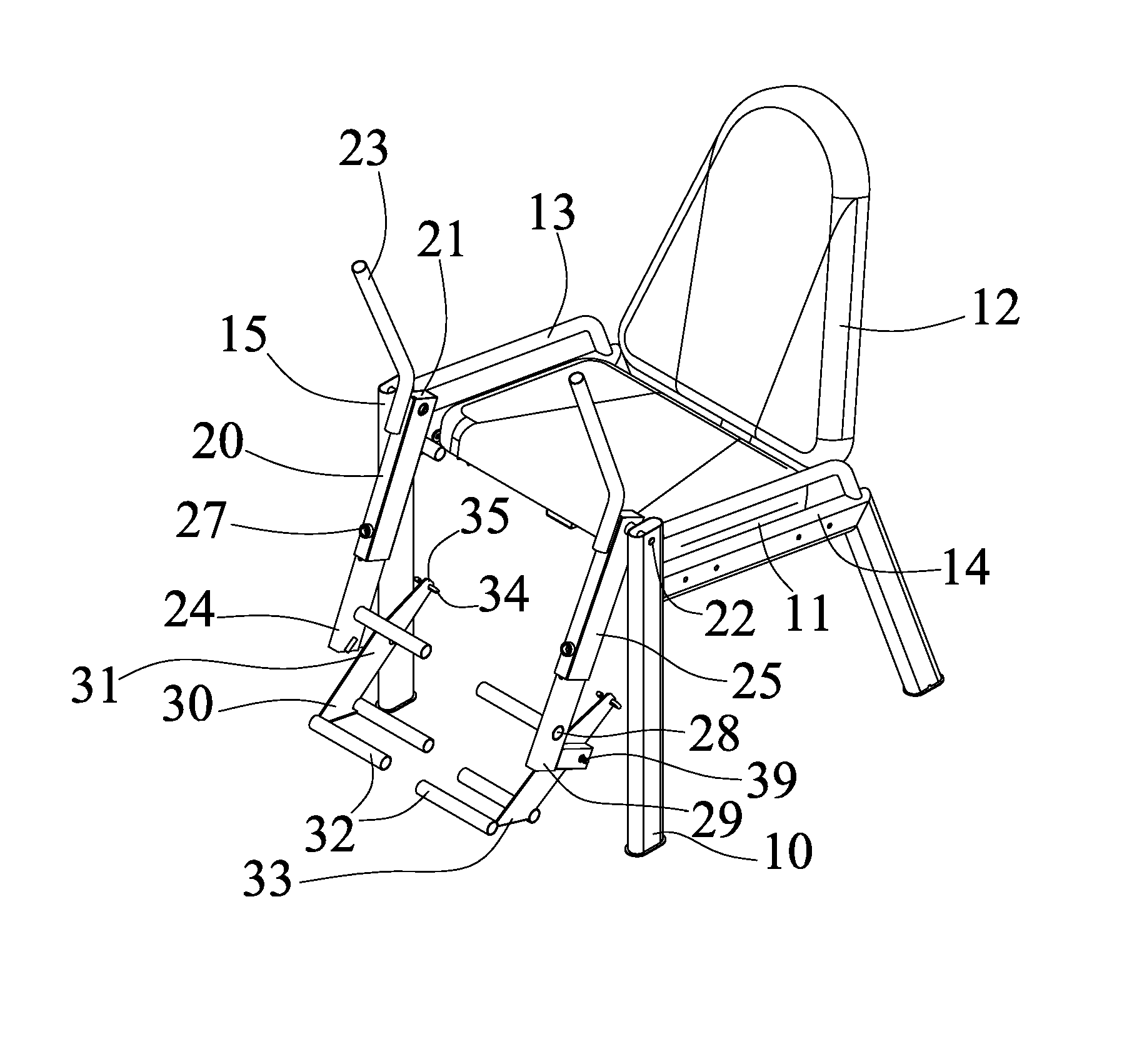

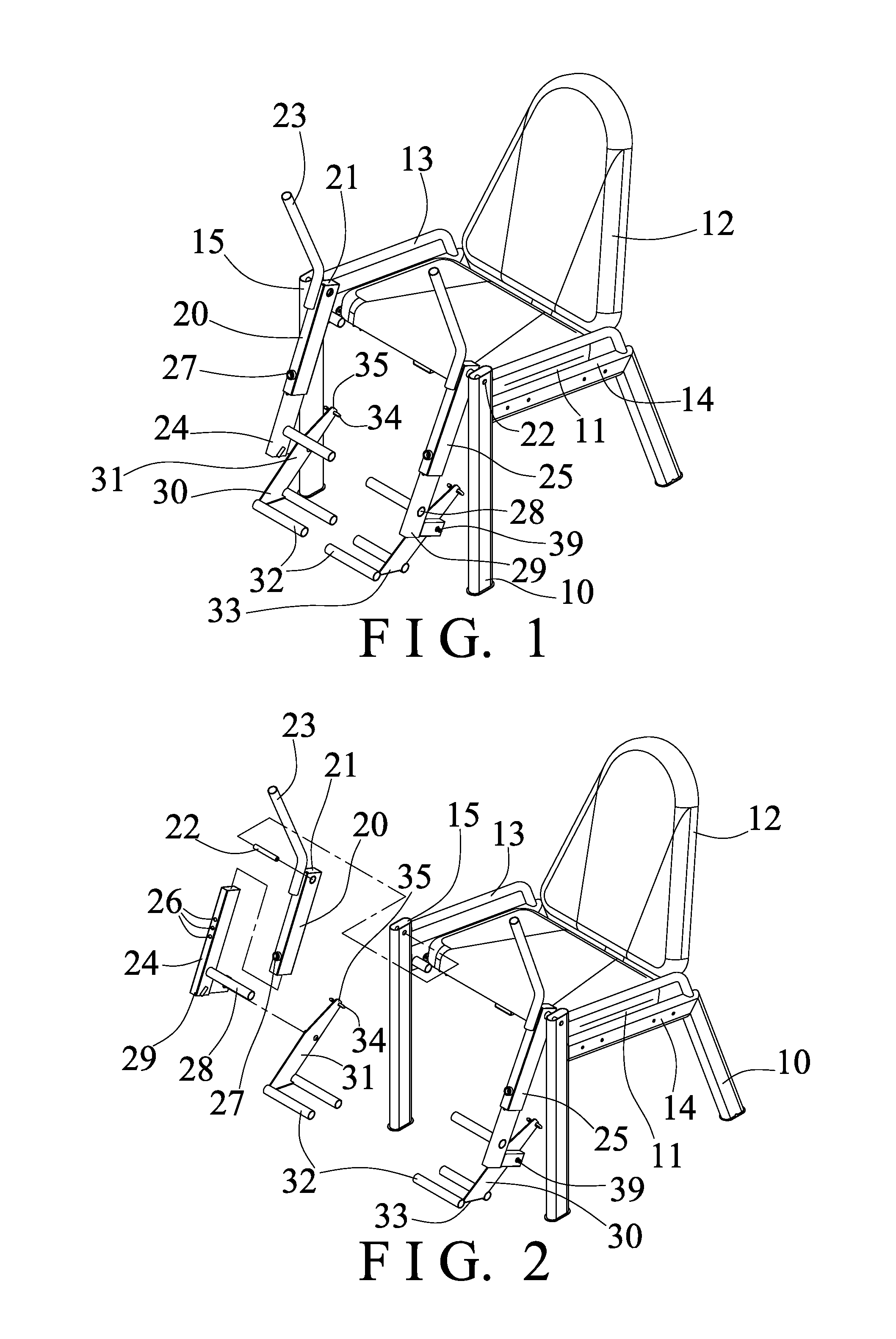

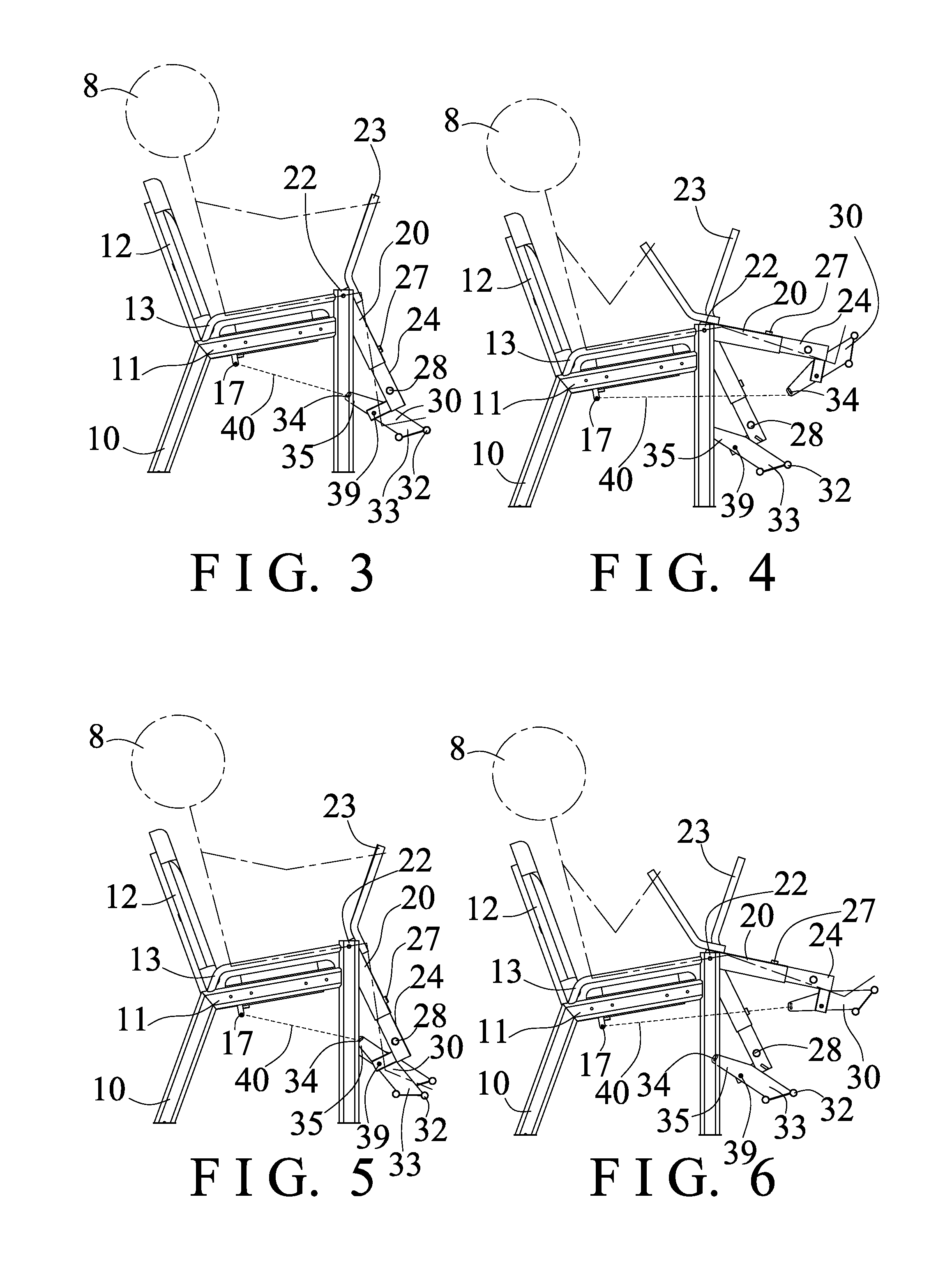

Rehabilitation or exercising chair device

InactiveUS20140274621A1Decrease manufacturing costSimplified structure or configurationStiltsMuscle exercising devicesEngineeringFoot supports

An exercising chair device includes a chair member having a seat element, two handles pivotally attached to the upper and front side portions of the chair member and each having a shaft for engaging with an ankle portion of the user, two levers pivotally attached to the handle and each having a foot support attached to the lower portion, and two cables coupled between the levers and the chair member for applying a spring biasing force to pull the levers and the handles toward the feet of the user. The handles each include an extension adjustably attached to a lower portion of the handle and adjustable relative to the handle to different positions.

Owner:CHEN PAUL

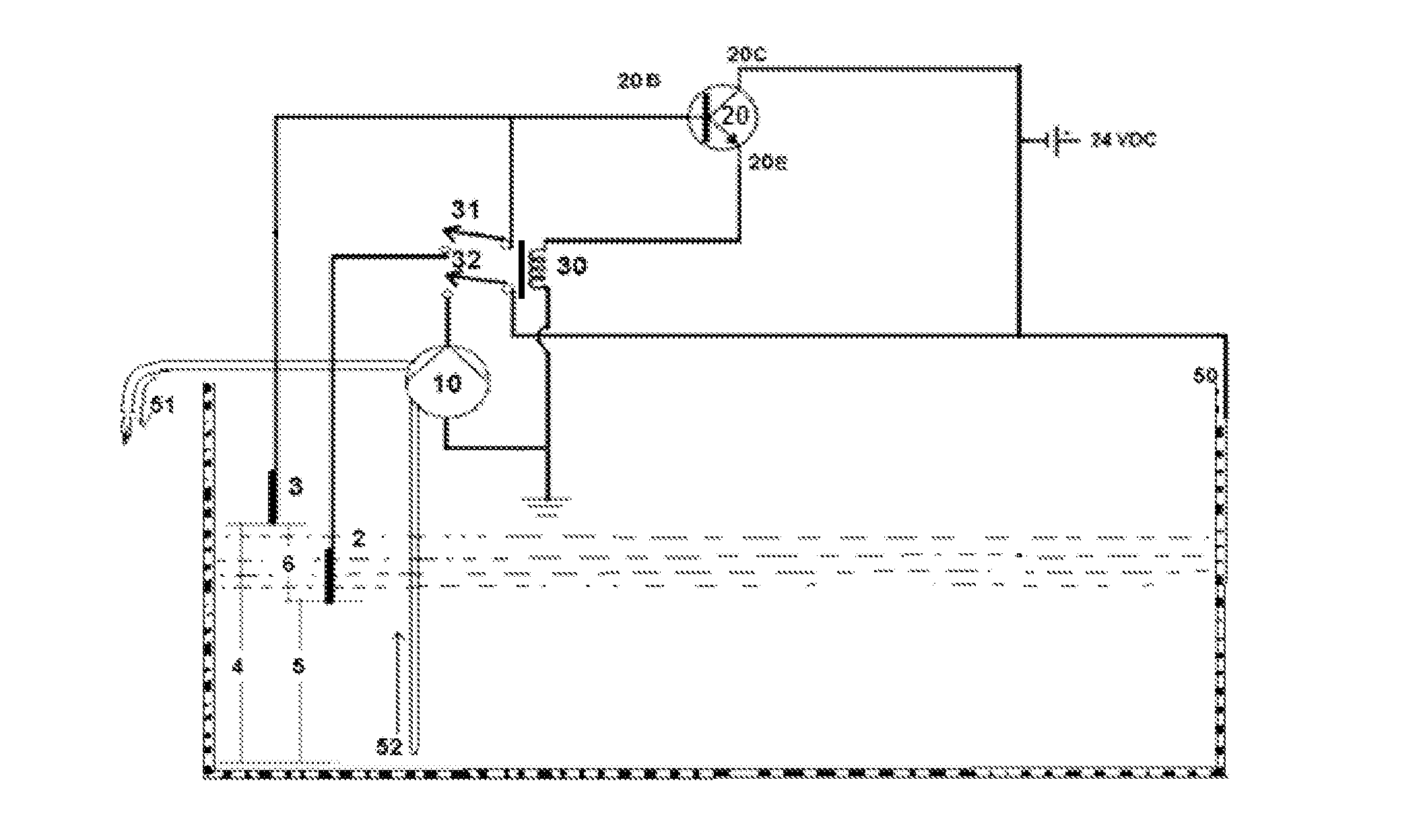

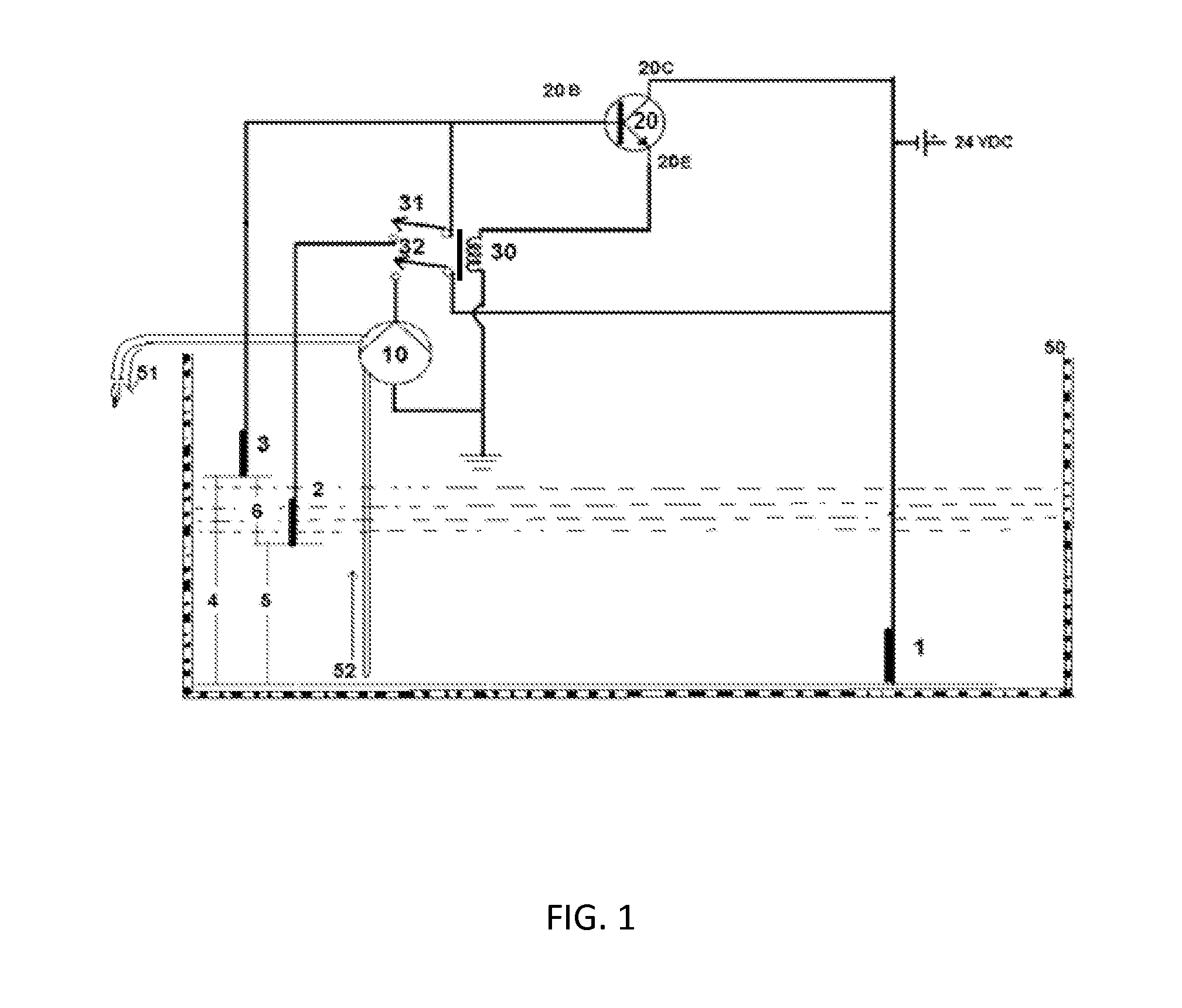

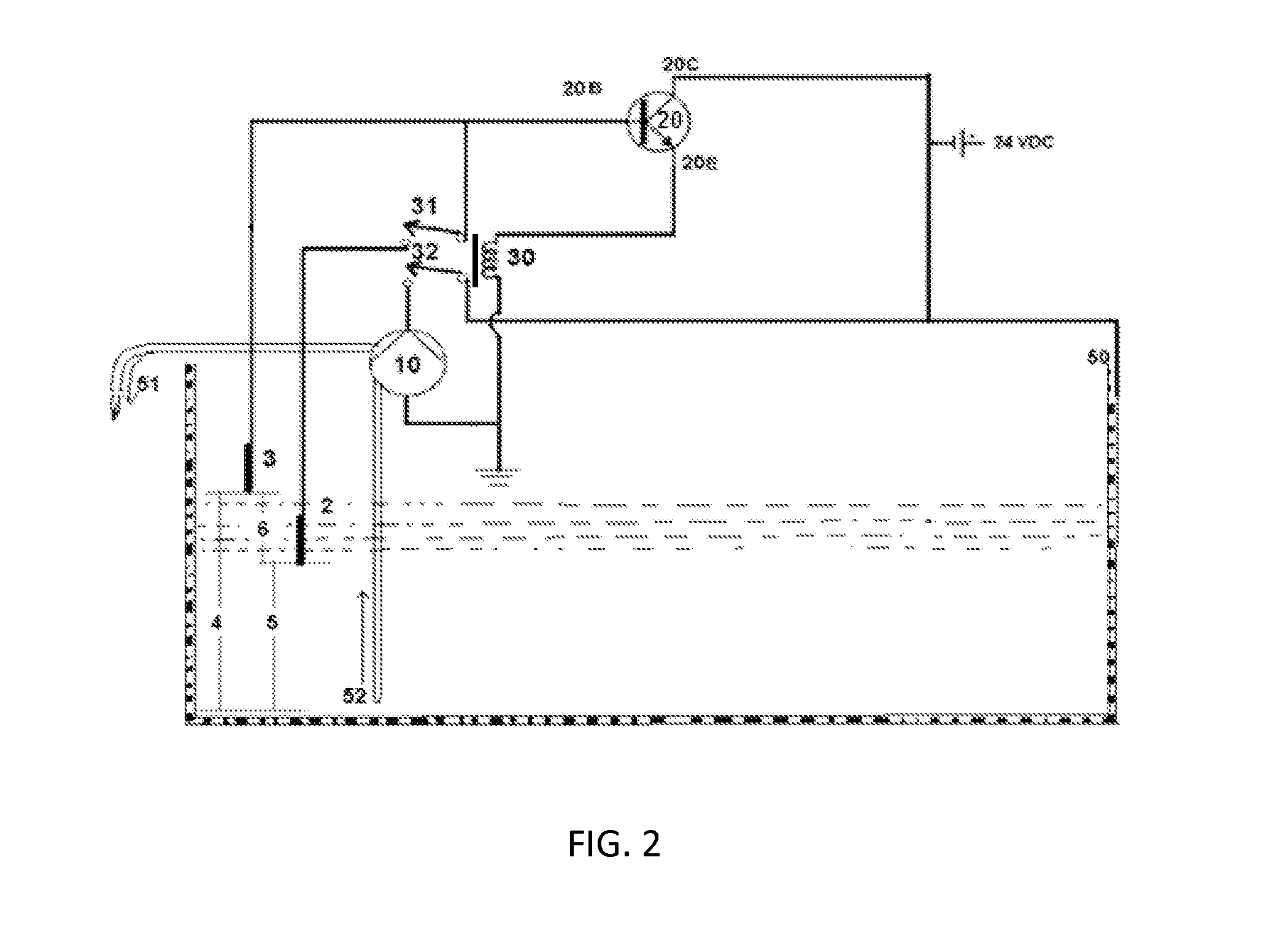

Condensate Liquid Level Control System

InactiveUS20140158225A1Decrease manufacturing costIncrease reliabilityLevel controlFluid-delivery valvesCondensate pumpEngineering

Owner:MCBRIDE ROSS

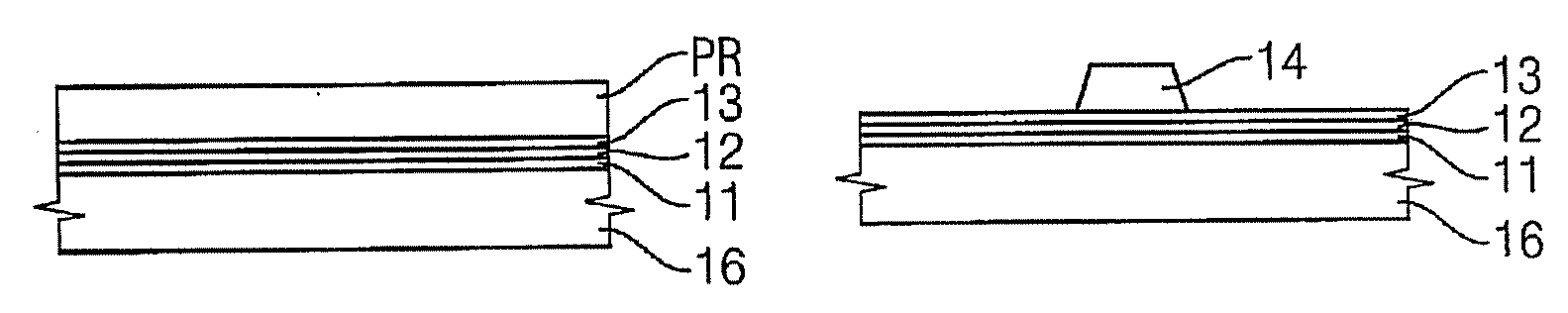

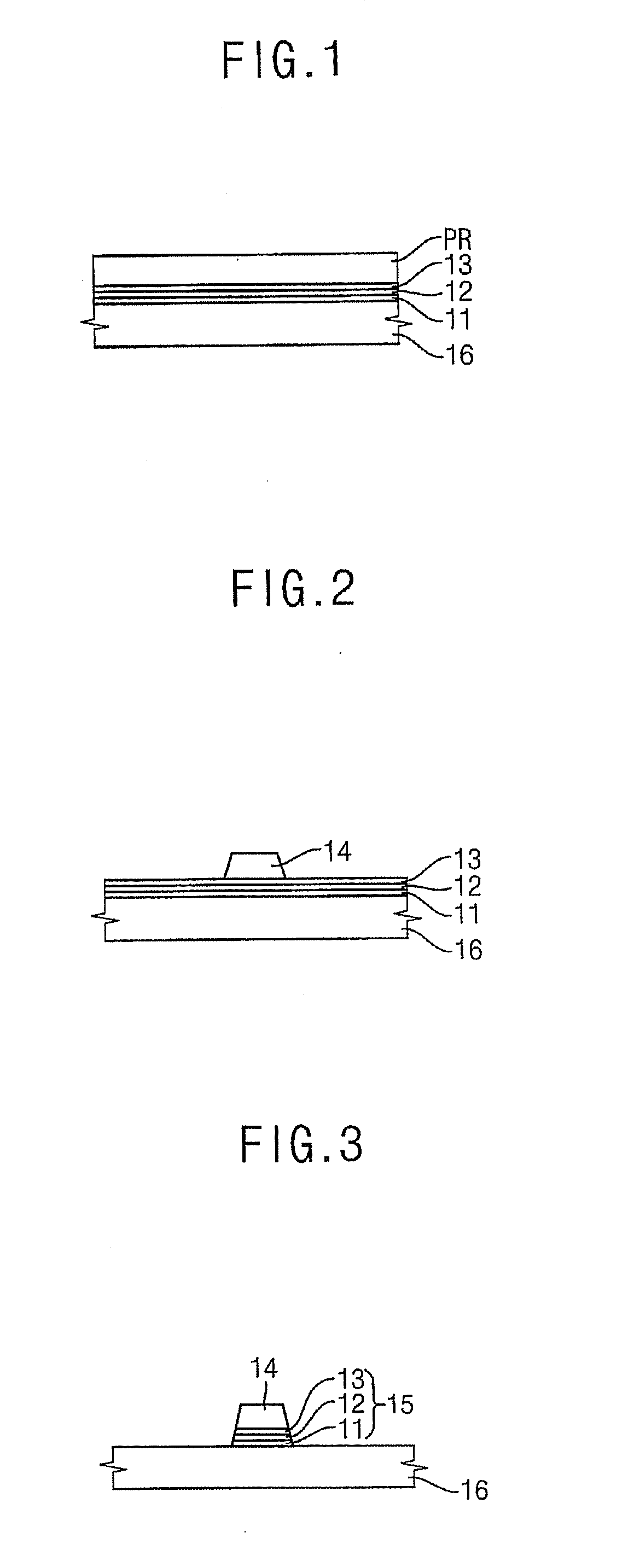

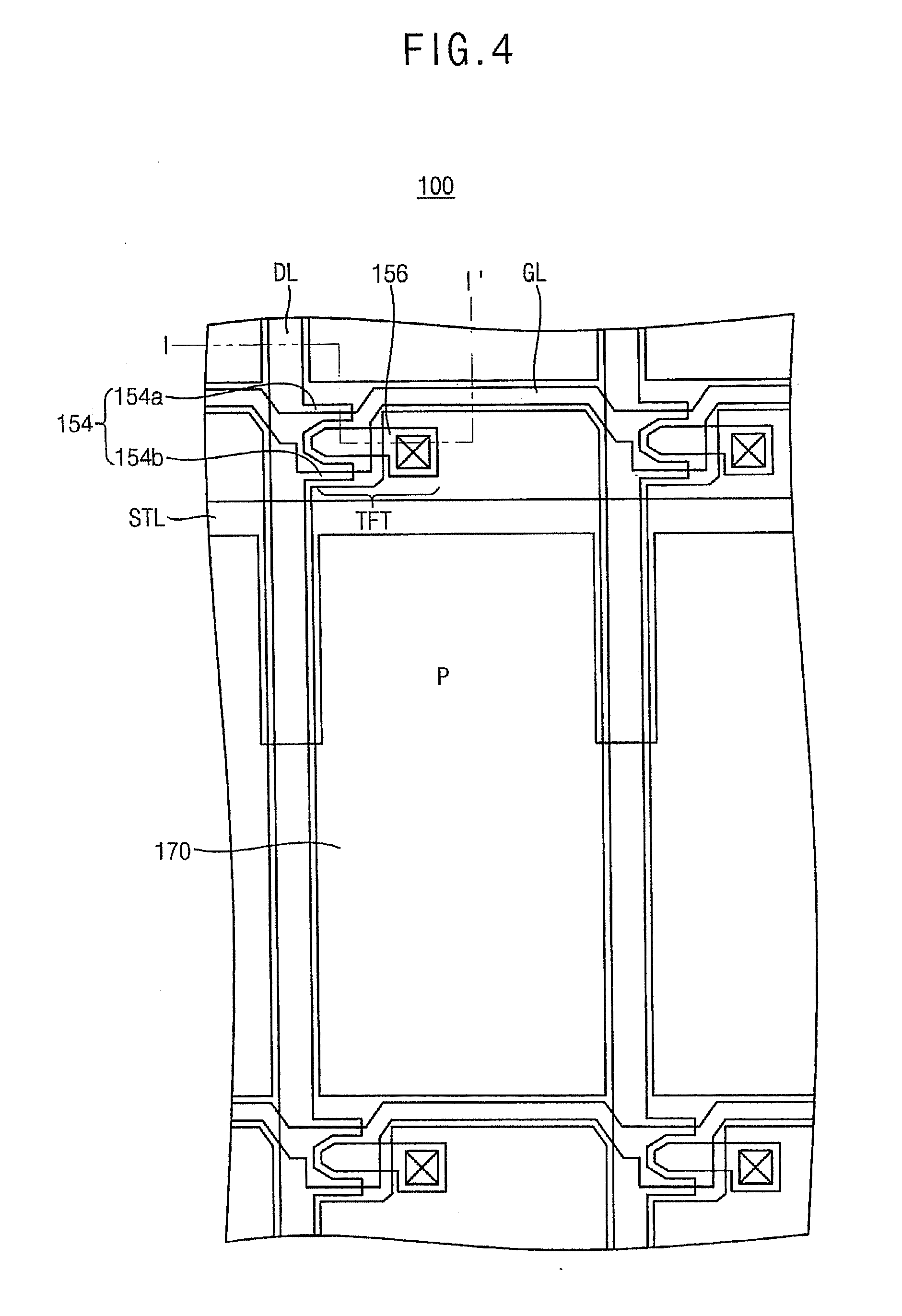

Method of forming a metal line and method of manufacturing display substrate having the same

InactiveUS20070158306A1Prevent corrosionDecrease manufacturing costDecorative surface effectsSemiconductor/solid-state device manufacturingResistCorrosion

A method of forming a metal line is provided. A first metal layer and a second metal layer protecting the first metal layer are formed on a base substrate. The first metal layer includes aluminum or aluminum alloy. A photoresist pattern having a linear shape is formed on the second metal layer. The first and second metal layers are dry-etched using etching gas and the photoresist pattern as an etching mask. An etching material is removed from the base substrate, to prevent corrosion of the dry-etched first metal layer. Therefore, the source metal pattern without corrosion may be formed through a dry-etching process so that a manufacturing cost is decreased.

Owner:SAMSUNG DISPLAY CO LTD

Back sheet for solar cell module and method for manufacturing the same

InactiveUS20150013761A1Simplify manufacturing processDecrease manufacturing costSynthetic resin layered productsFlat articlesEngineeringSolar cell

Provided is a back sheet for a solar cell module, and more particularly, a back sheet having a novel multilayer structure substituted for an existing structure in which PVF (Tedlar) film / PET film / PVF (Tedlar) film are sequentially laminated, excellent hydrolysis resistance, and significantly excellent heat adhesion.

Owner:KOLON IND INC

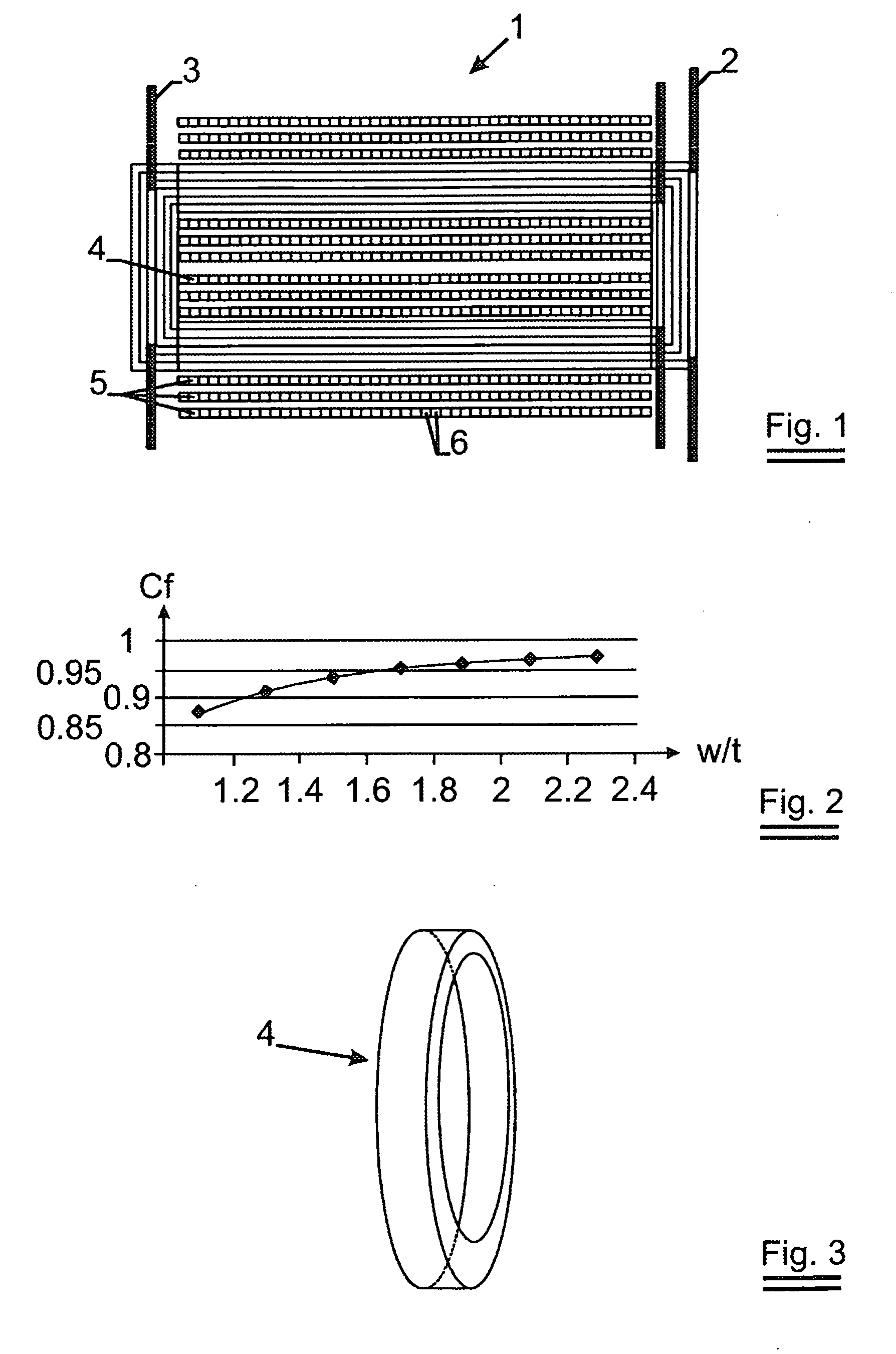

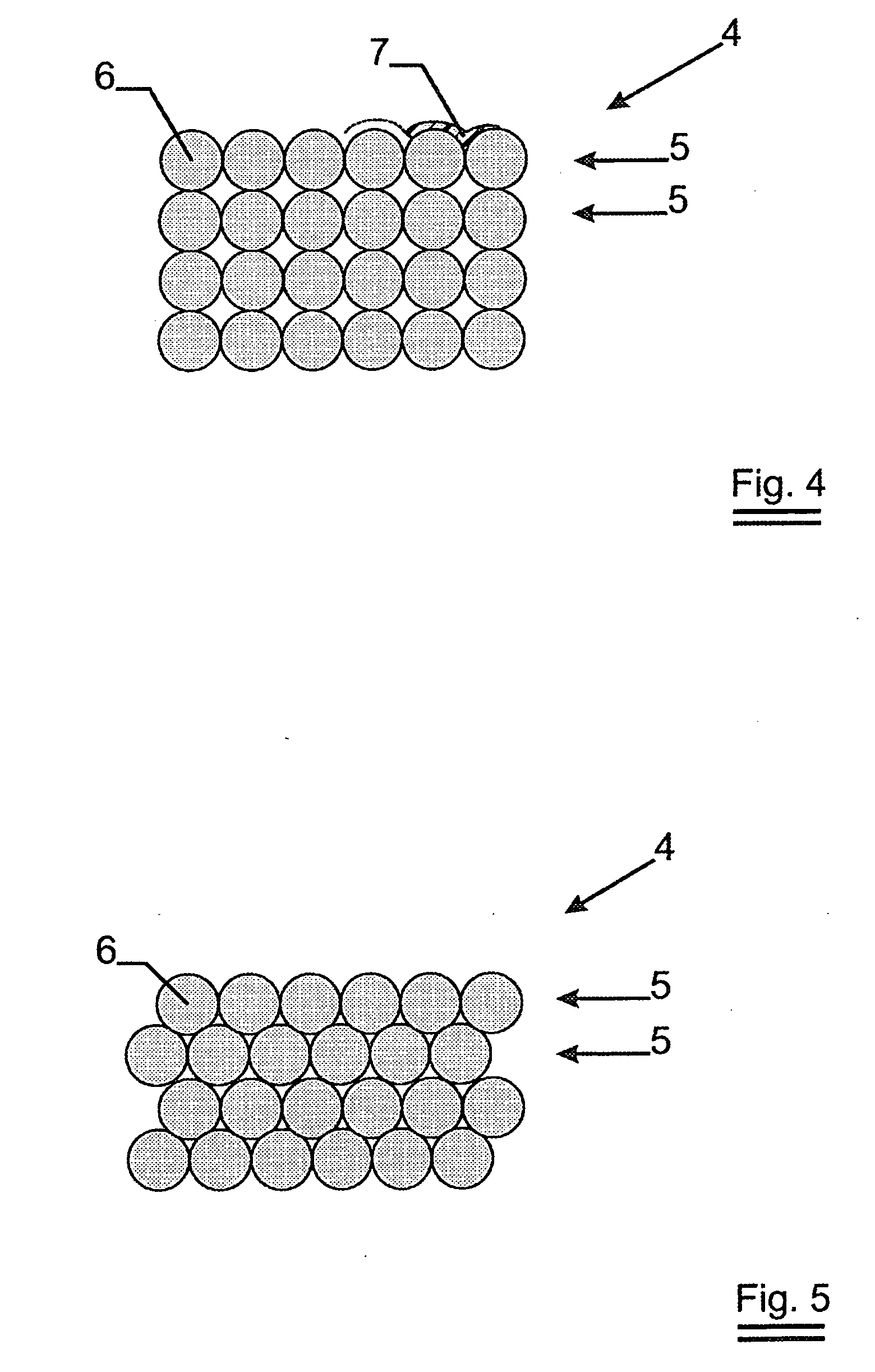

Magnetic flux return path with collated bands of wire

InactiveUS20090094819A1Decrease manufacturing costReduce manufacturing costTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMagnetic coreMagnetic flux

Method of forming a magnetic core or part of a magnetic core including several layers of windings of magnetic wire in a very compact configuration, and the core or part of core is formed by winding several layers of a collated band of wires side by side until desired number of layers of core or part of core is obtained. Method includes forming magnetic core or magnetic flux return path or part of magnetic core including several layers of windings of magnetic wire in compact configuration; core or part of core being formed by winding several layers of a collated band of wires side by side until reaching desired number of layers of the core or part of the core. Magnetic core or magnetic flux return path includes several layers of windings of magnetic wire in compact configuration; part of layers of windings being formed by collated band of wires.

Owner:NV BEKAERT SA

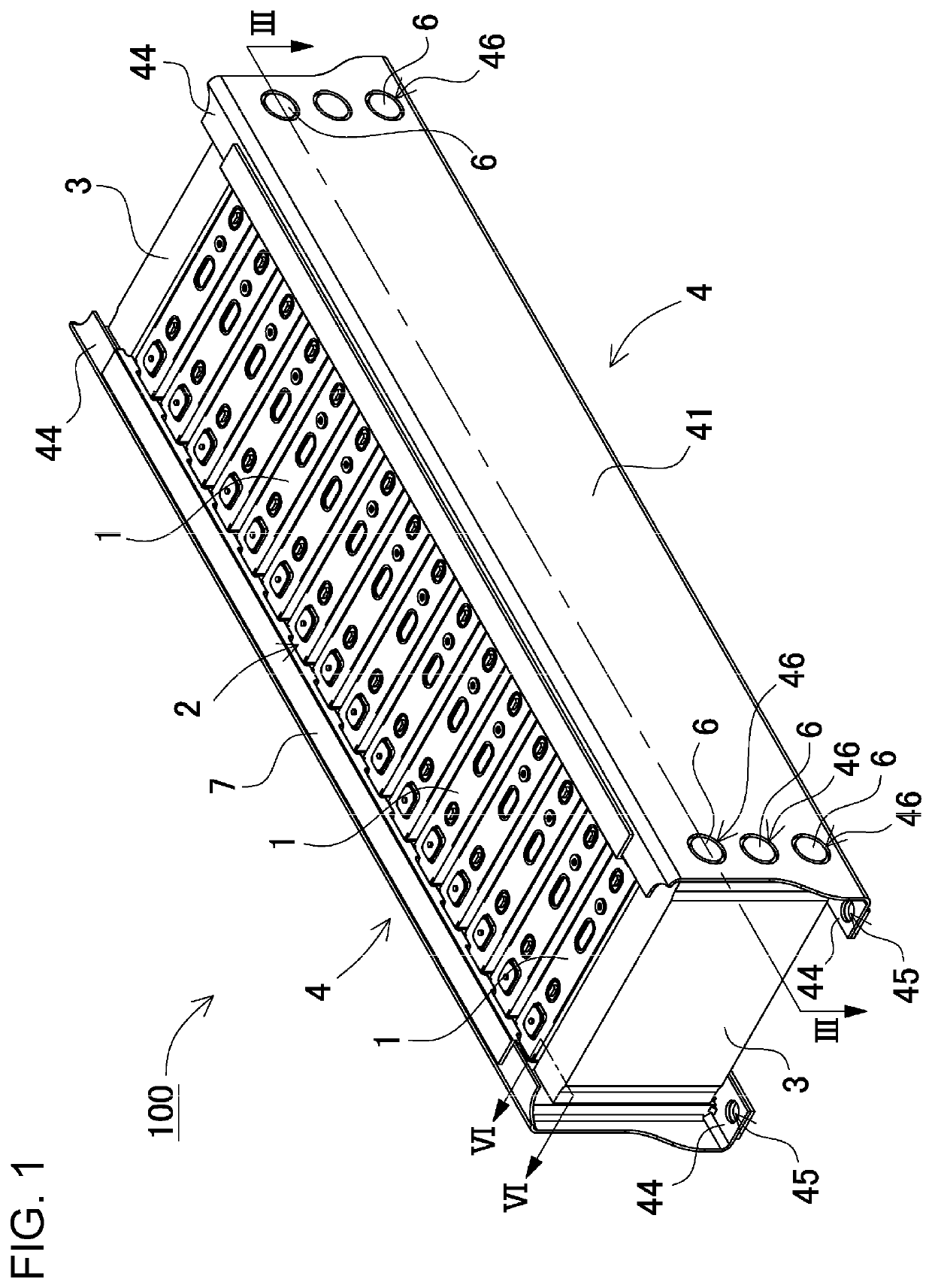

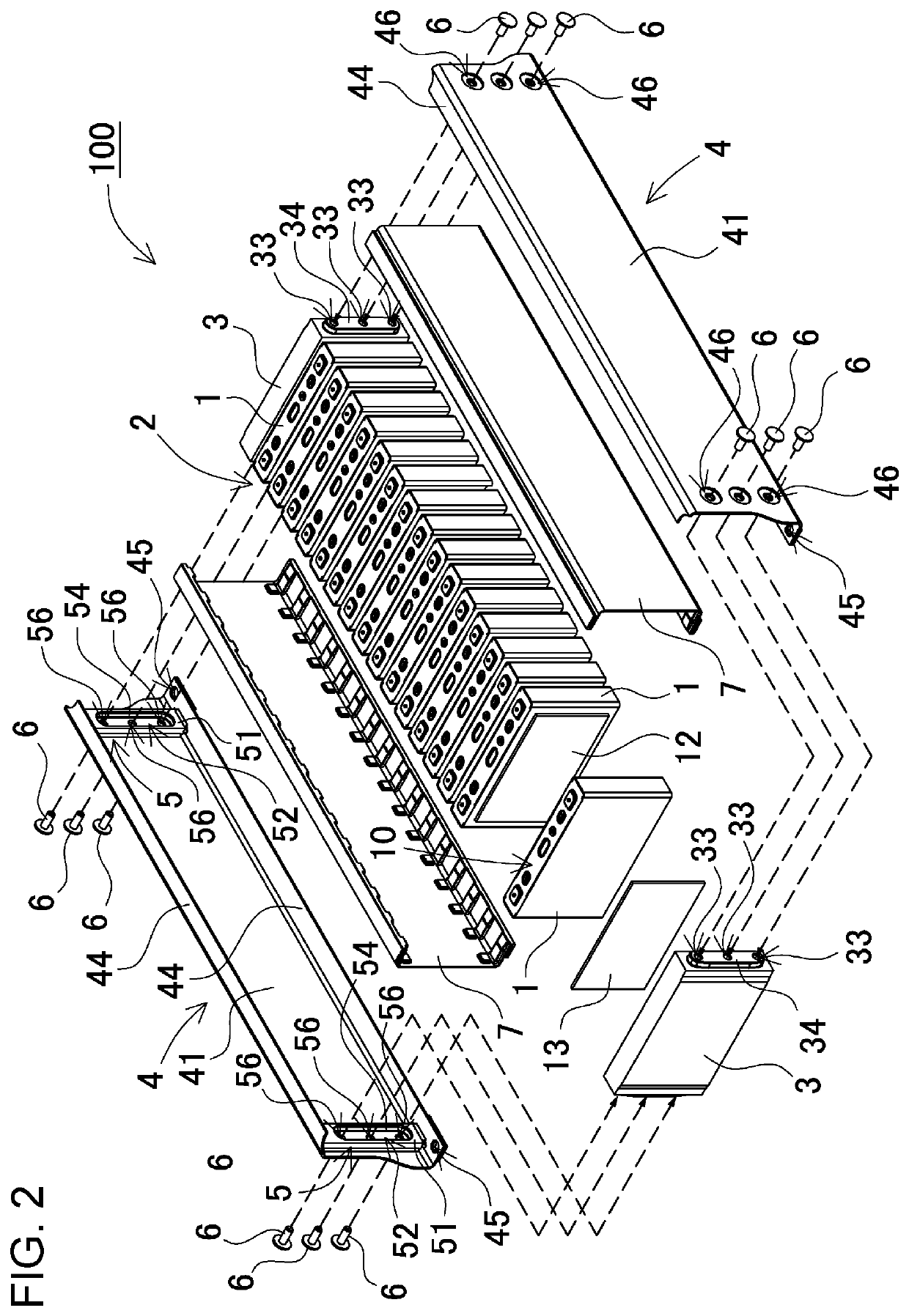

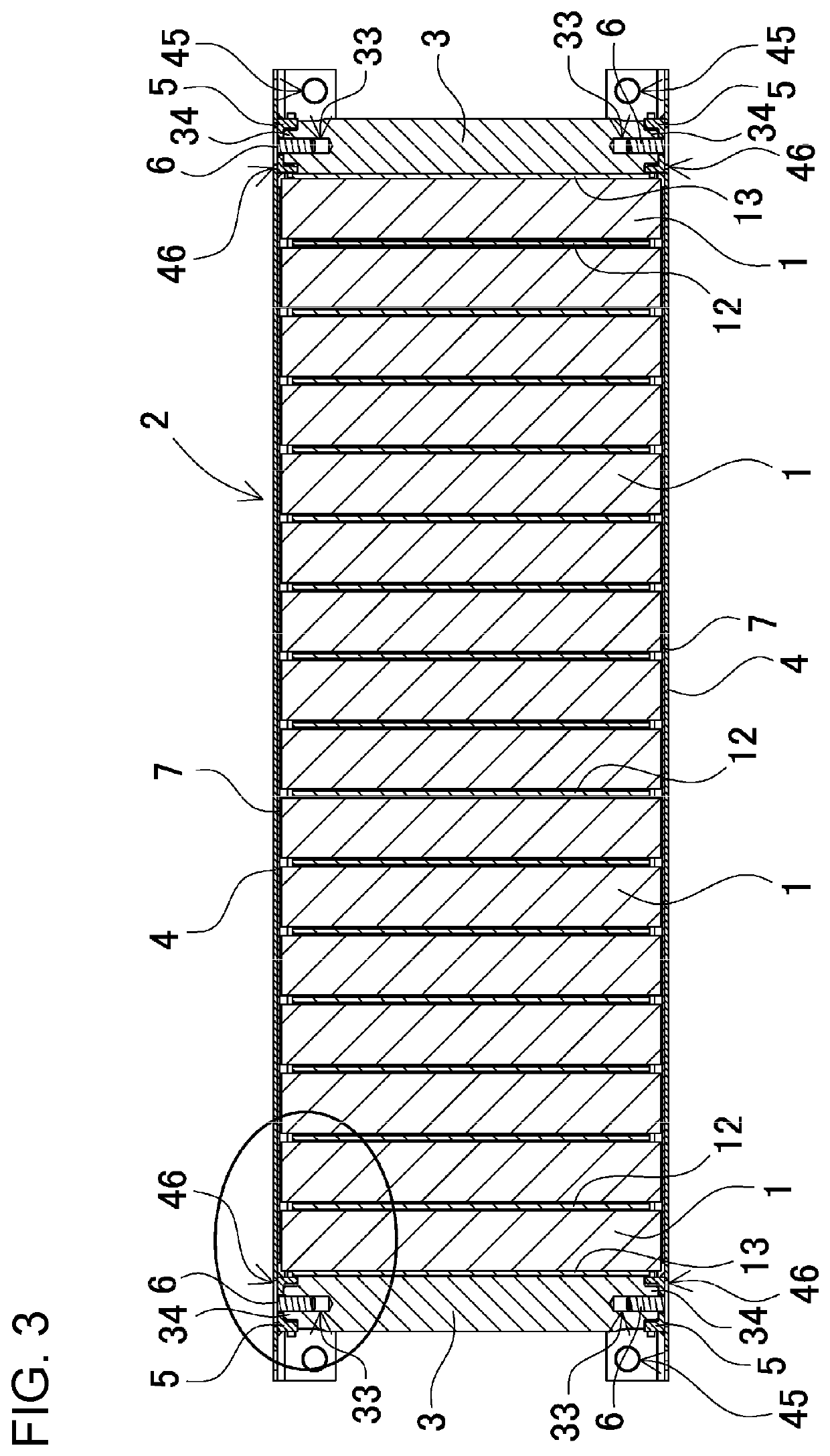

Power supply device, vehicle equipped with same, and electricity storage device

PendingUS20200099027A1Increase rigidityDecrease manufacturing costLarge-sized flat cells/batteriesGas pressure propulsion mountingElectrical batteryStructural engineering

Owner:SANYO ELECTRIC CO LTD

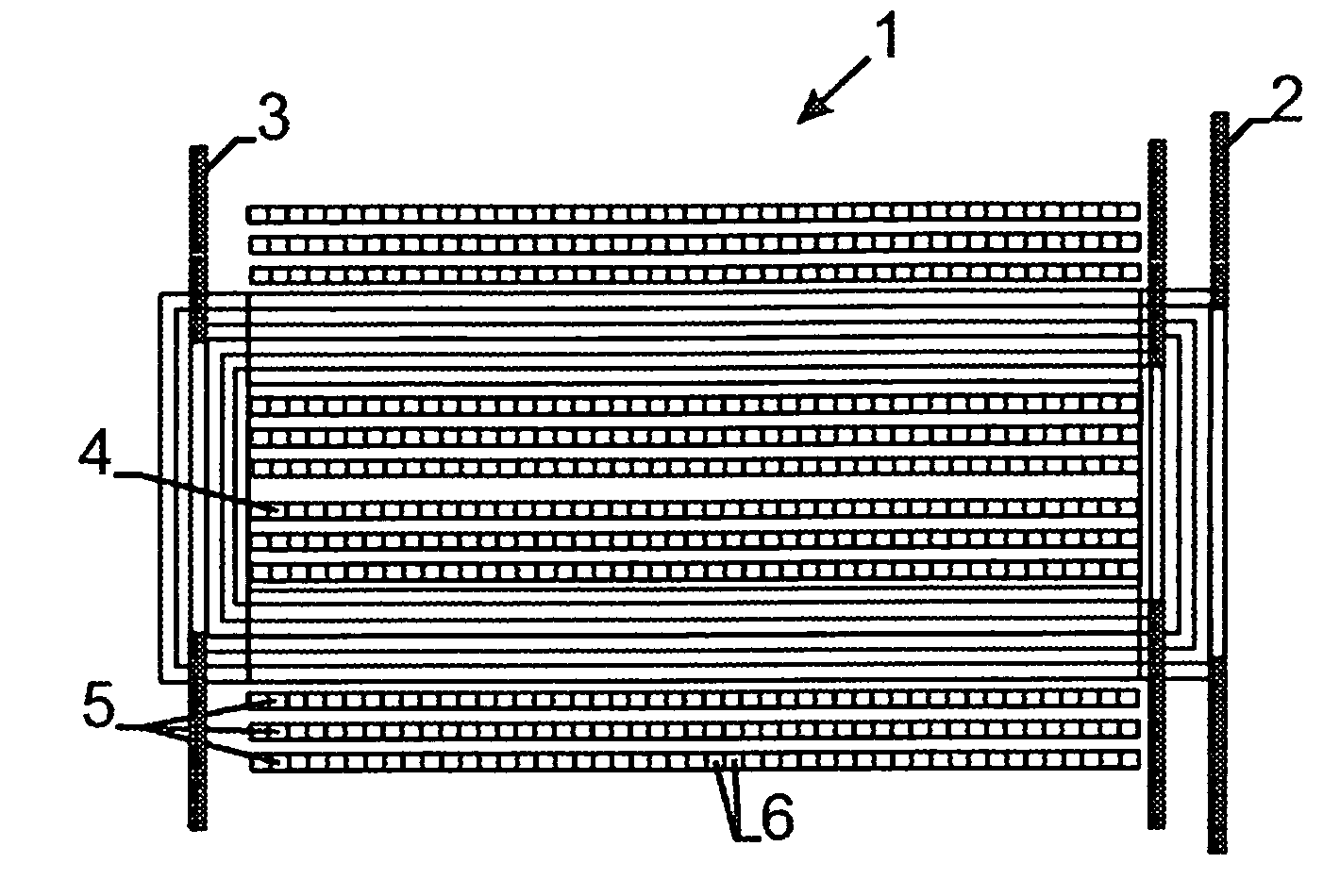

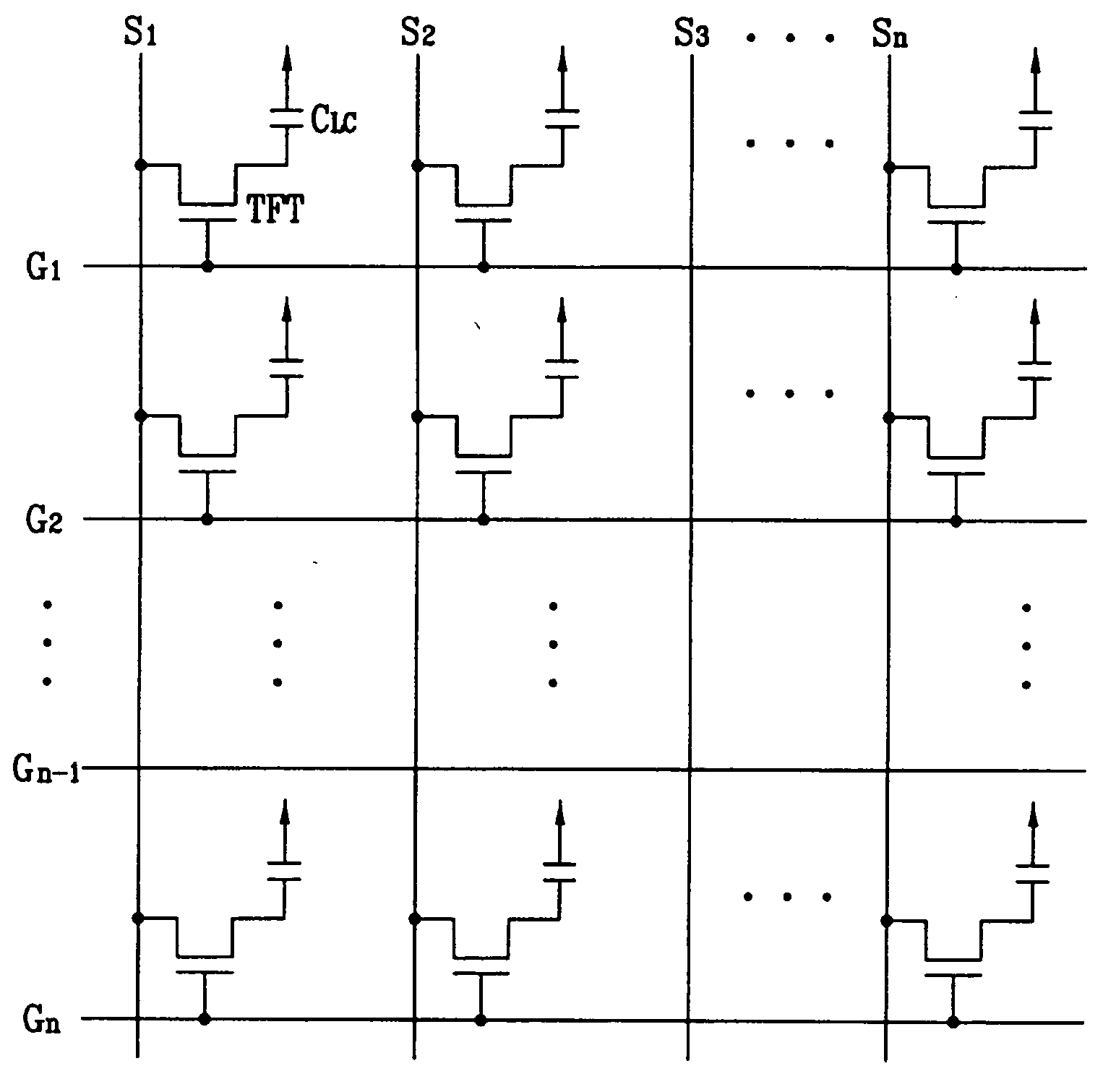

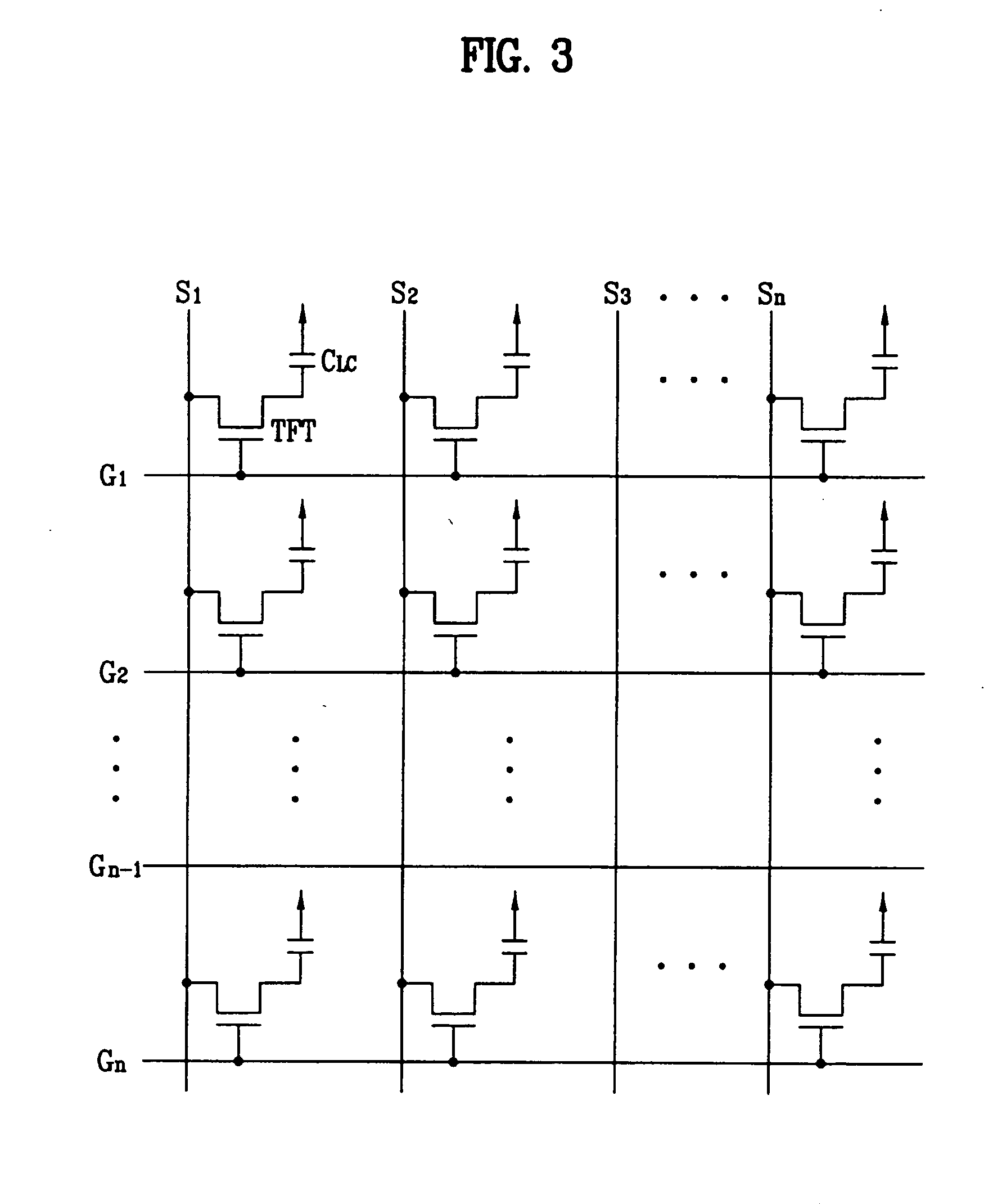

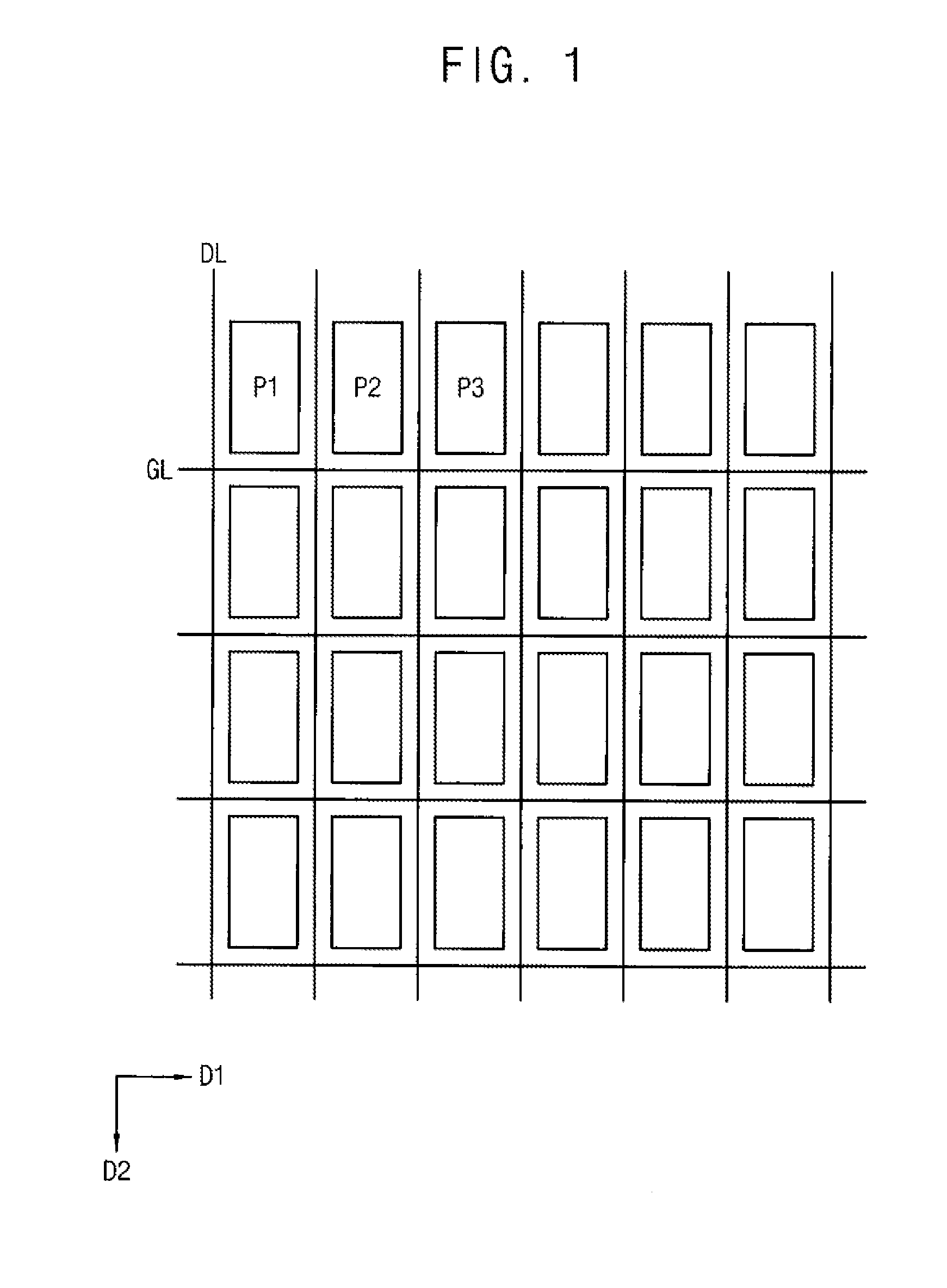

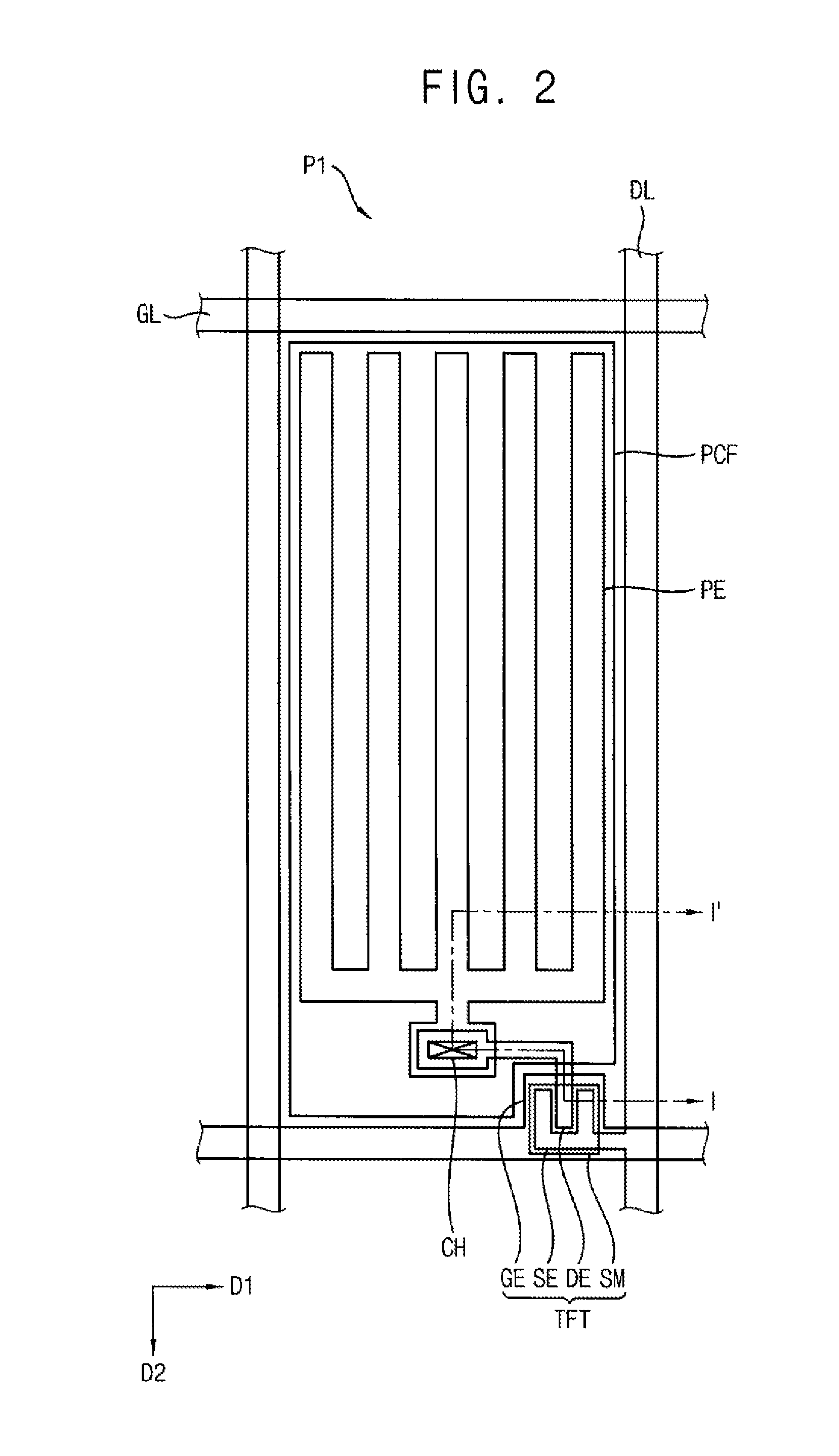

Liquid crystal display device

ActiveUS20050052400A1Decrease manufacturing costReduce in quantityStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device is disclosed, which provides data in a time-divided manner to left and right pixel regions of one data line, thereby reducing the number of source drive ICs, expensive component. The liquid crystal display device includes a plurality of pairs having first and second gate lines being adjacent to each other; a plurality of data lines for being in perpendicular to the pair of the first and second gate lines, thereby defining a plurality of left and right side pixel regions; and left and right side pixel electrodes, respectively formed in the left and right side pixel regions, and selectively driven by switching parts of the first and second gate lines.

Owner:LG DISPLAY CO LTD

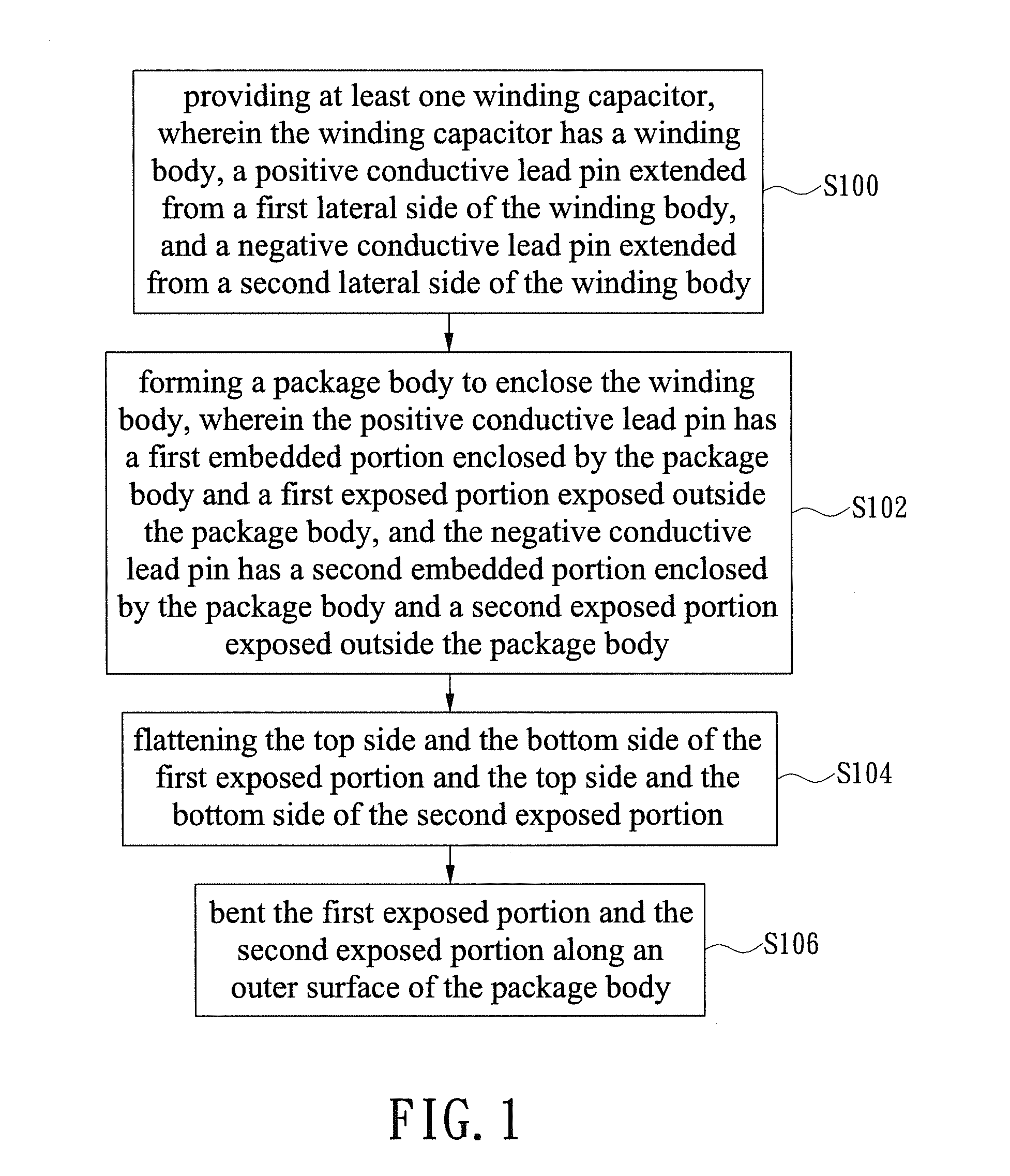

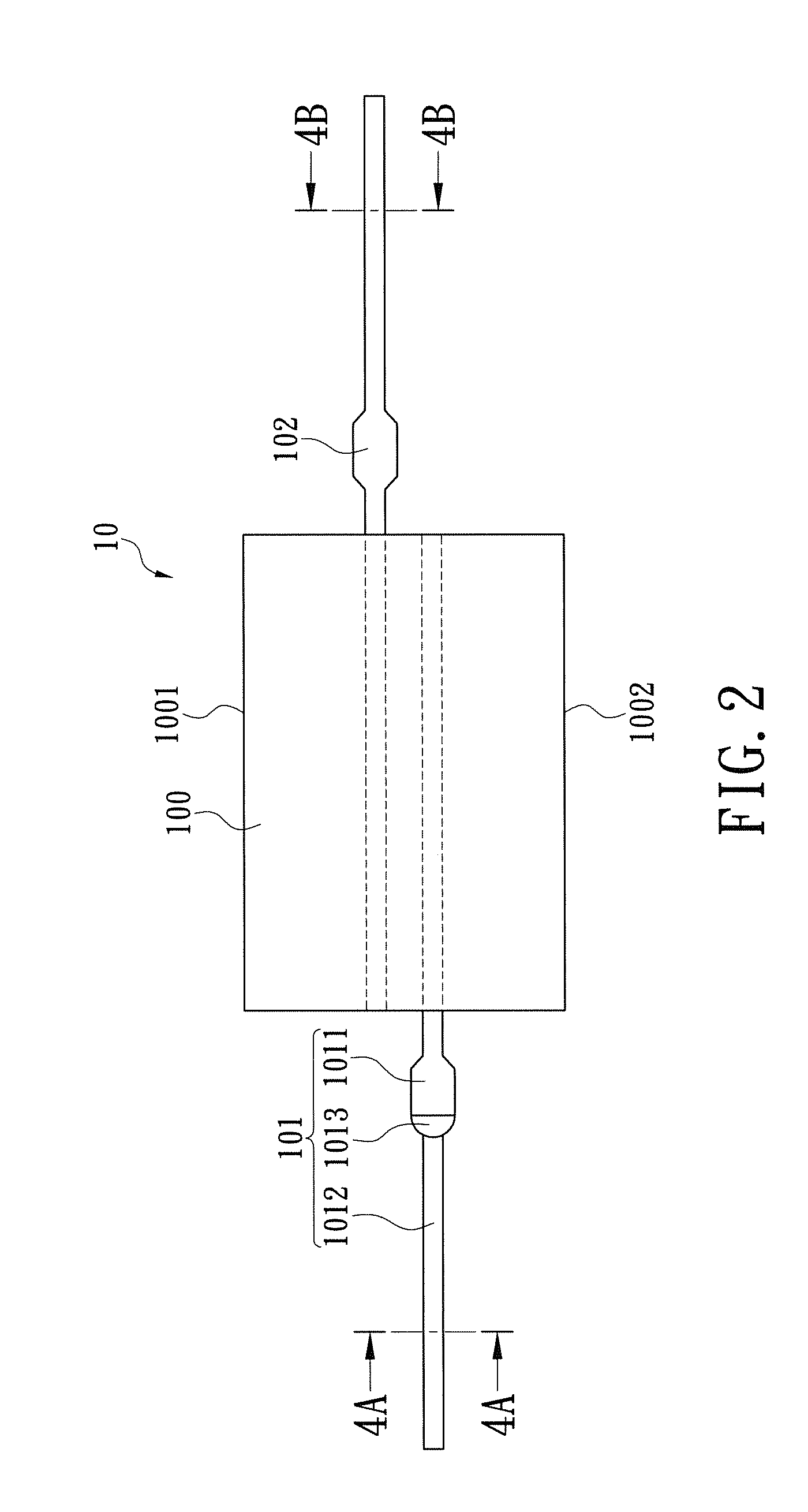

Winding-type solid electrolytic capacitor package structure without using a lead frame and method of manufacturing the same

ActiveUS20140268503A1Decrease manufacturing costIncrease manufacturing speedSolid electrolytic capacitorsCapacitor terminalsConductor CoilLead frame

A winding-type solid electrolytic capacitor package structure without using any lead frame includes a winding capacitor and a package body. The winding capacitor has a winding body enclosed by the package body, a positive conductive lead pin extended from a first lateral side of the winding body, and a negative conductive lead pin extended from a second lateral side of the winding body. The positive conductive lead pin has a first embedded portion enclosed by the package body and a first exposed portion exposed outside the package body and extended along the first lateral surface and the bottom surface of the package body. The negative conductive lead pin has a second embedded portion enclosed by the package body and a second exposed portion exposed outside the package body and extended along the second lateral surface and the bottom surface of the package body.

Owner:APAQ TECH

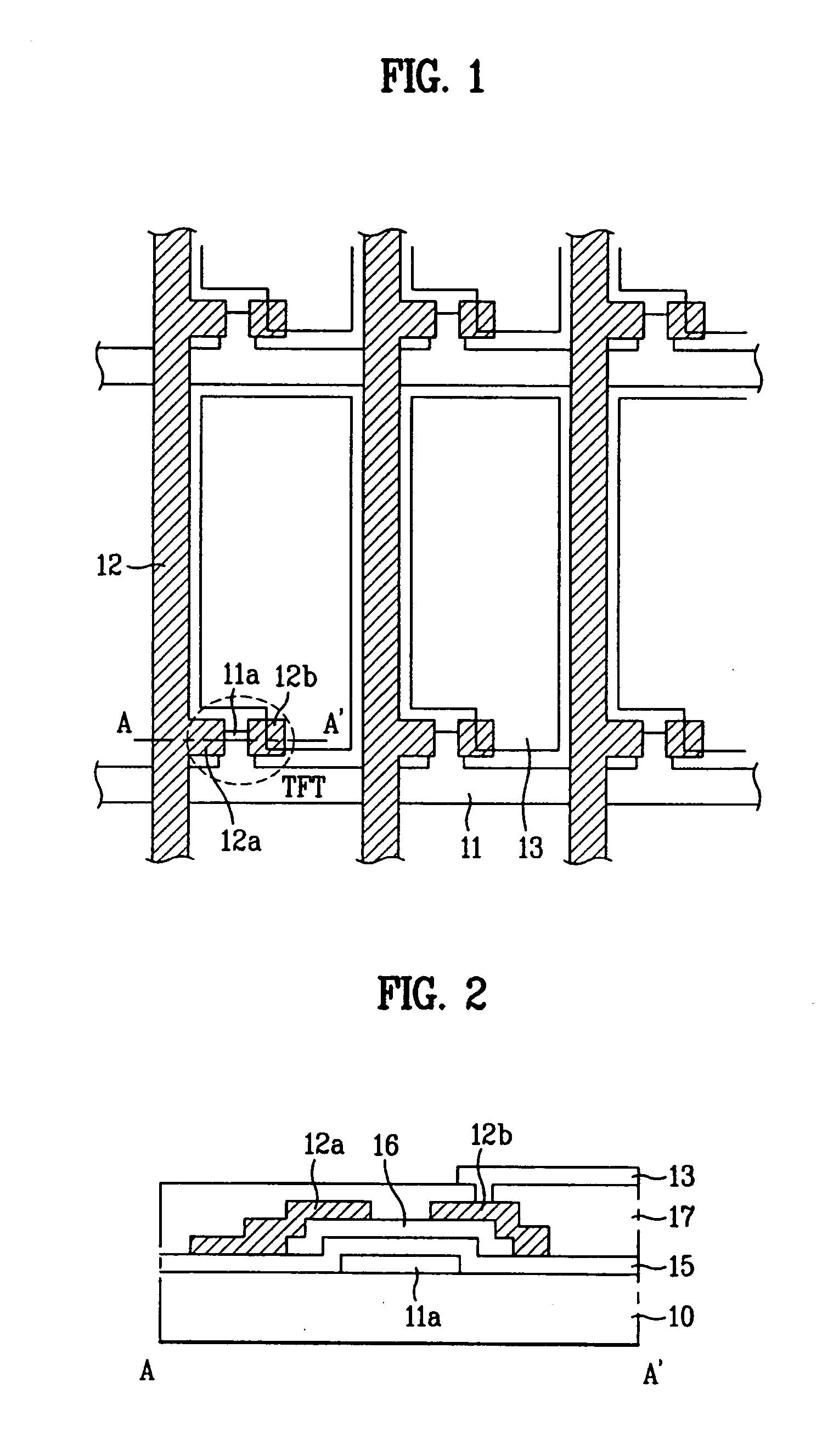

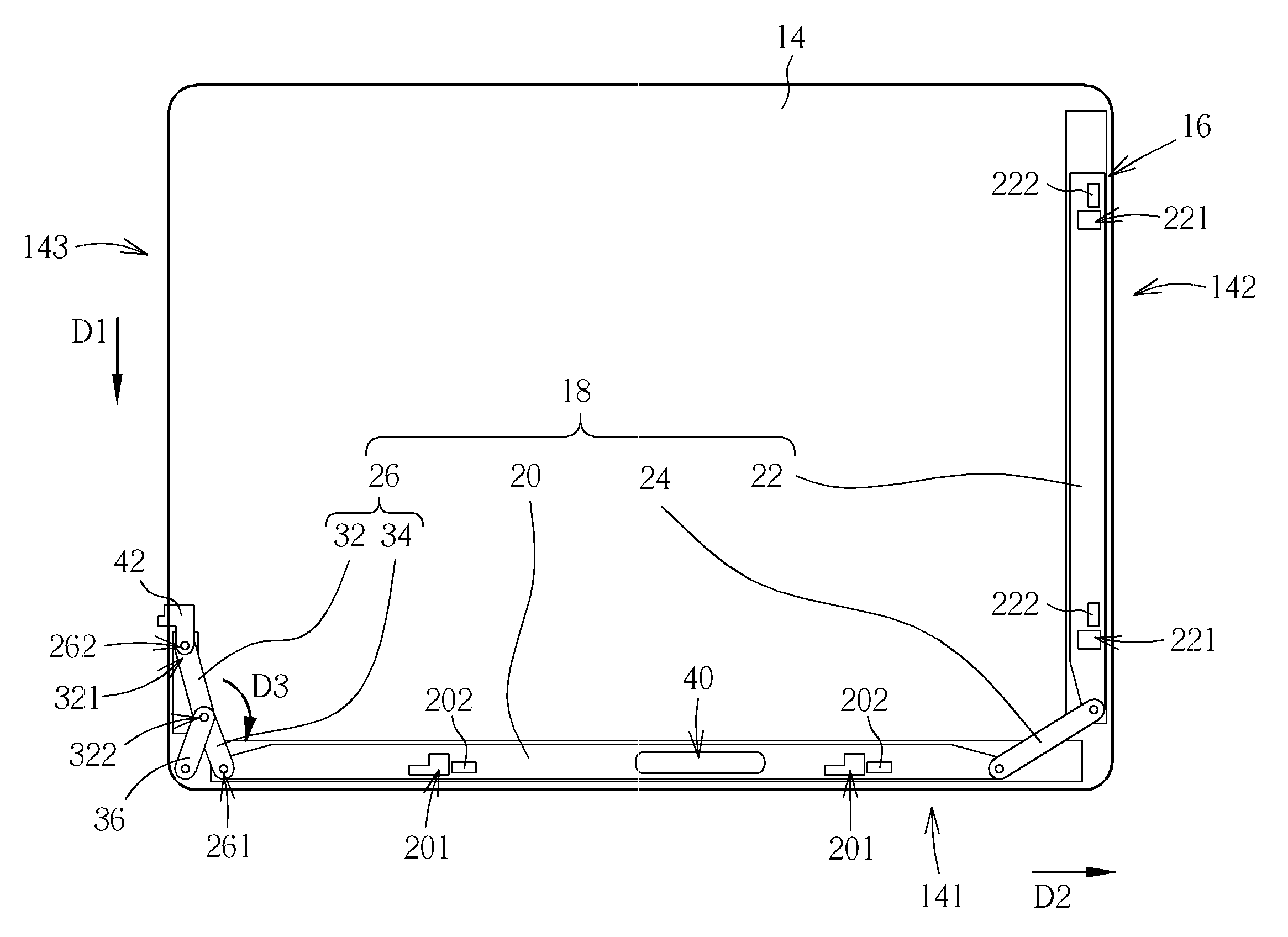

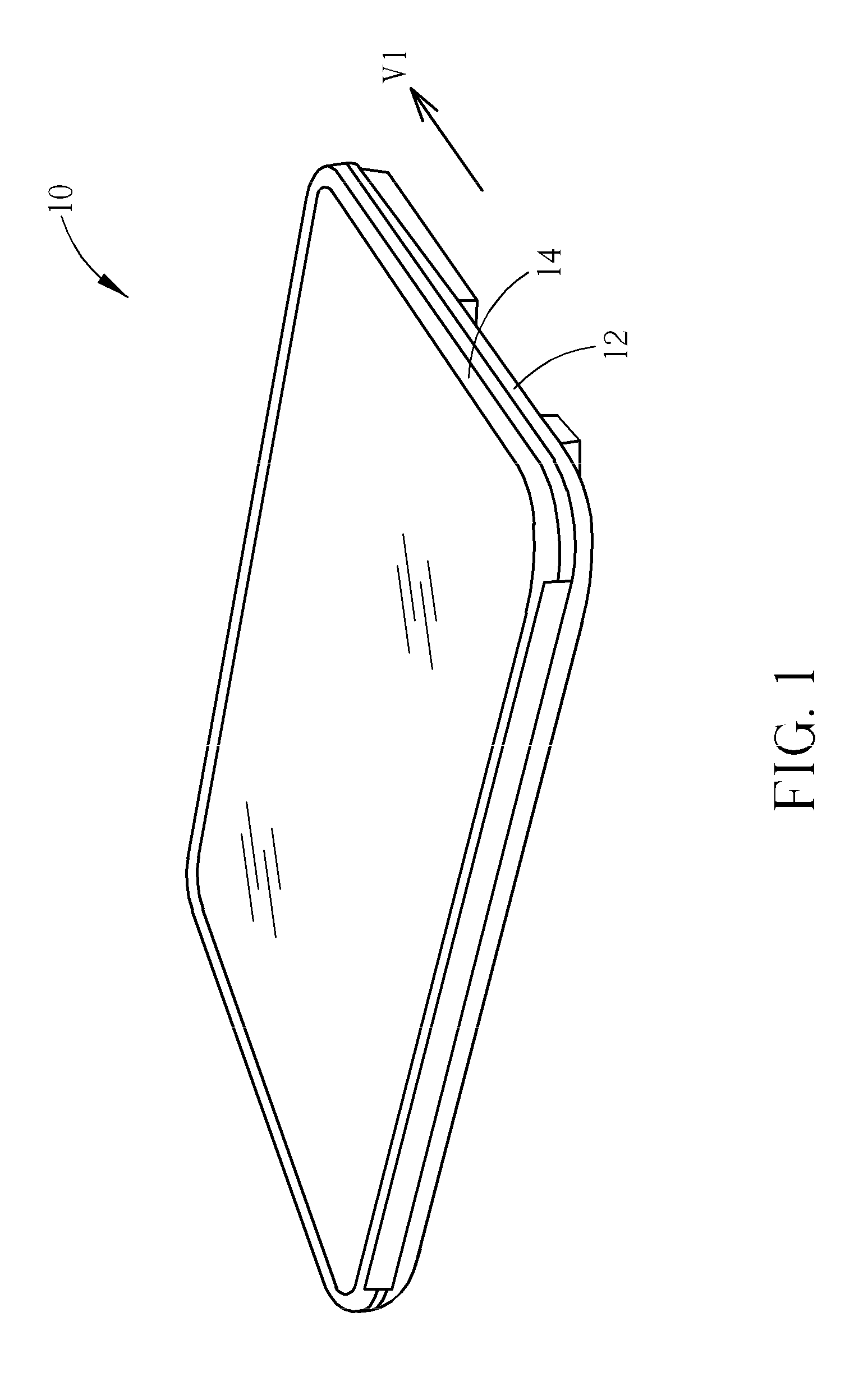

Display panel and method of manufacturing the same

ActiveUS20160116795A1Simplify manufacturing processDecrease manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingLiquid crystalSemiconductor

A display panel includes a first substrate comprising a plurality of pixel areas, a second substrate facing the first substrate, a liquid crystal layer interposed between the first substrate and the second substrate, a thin film transistor comprising a gate electrode disposed on the first substrate, a semiconductor pattern overlapping with the gate electrode, a source electrode and a drain electrode overlapping with the semiconductor pattern and spaced apart from each other, a plasmonic color filter to which a common voltage is configured to be applied, and comprising a same material as the gate electrode, disposed on a same layer as the gate electrode, and comprising a plurality of holes through which light is configured to be transmitted and a pixel electrode to which a gray scale voltage is configured to be applied, and overlapping with the plasmonic color filter, and electrically connected to the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

Slide device having a multi constraint function

ActiveUS20130163899A1Simple structureDecrease manufacturing costRotary combination bearingsLinear bearingsEngineeringLinkage concept

A slide device includes a first body, a second body and a constraint mechanism. The constraint mechanism includes a linkage set disposed on the second body, and a first hook and a second hook respectively disposed on the first body. The linkage set includes a first rod disposed on a first side of the second body, a second rod disposed on a second side of the second body, a first bar disposed between the first rod and the second rod, and a second bar disposed between the first rod and a third side of the second body. The first hook is for hooking a hole on the first rod, and the second hook is for hooking holes on the first rod or the second rod.

Owner:WISTRON CORP

Magnetic Inductive Coil Module

PendingUS20210090791A1Decrease manufacturing costEasy to implementTransformers/inductances coils/windings/connectionsElectrically conductiveEngineering

Owner:PIN SHINE INDAL

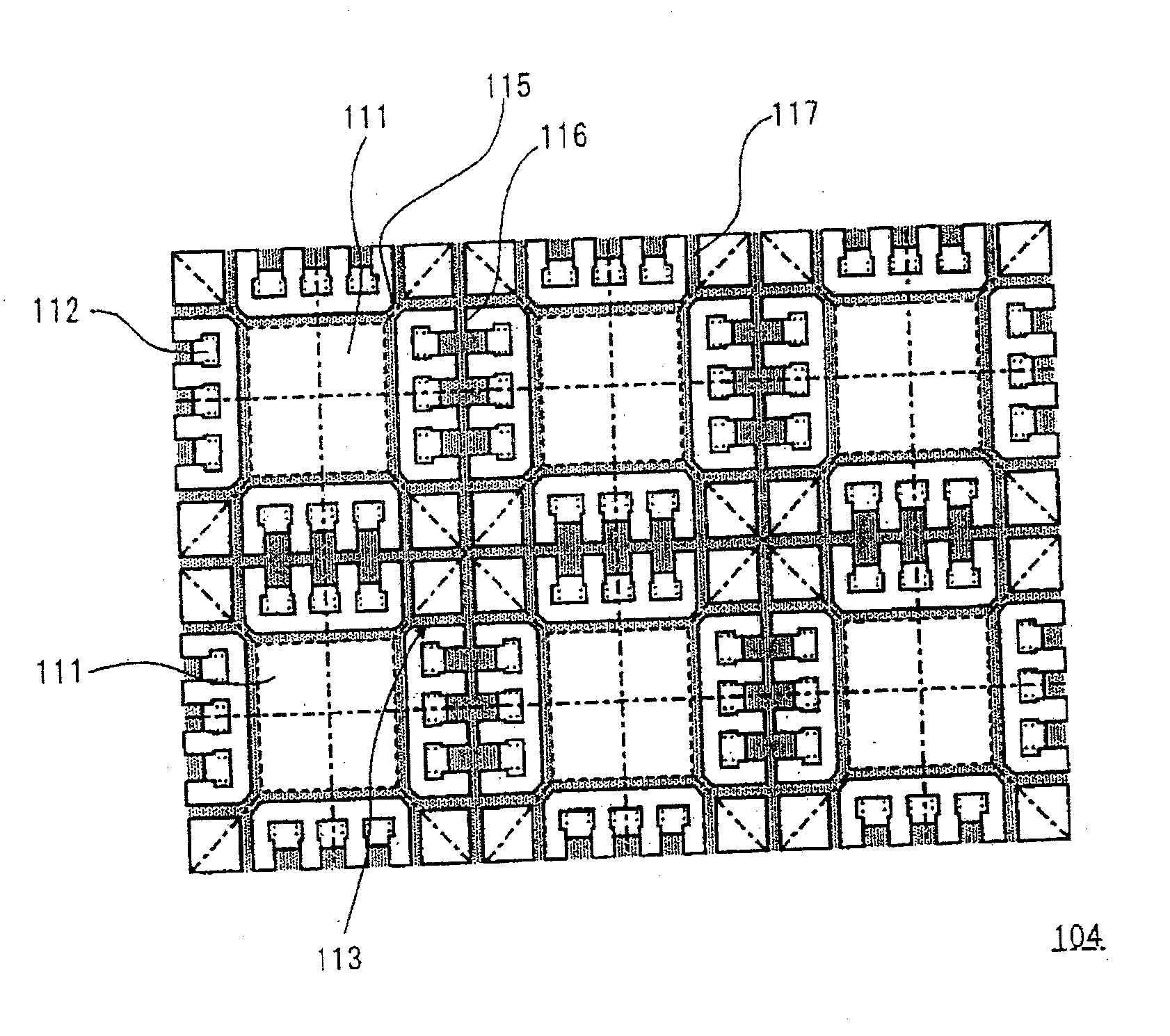

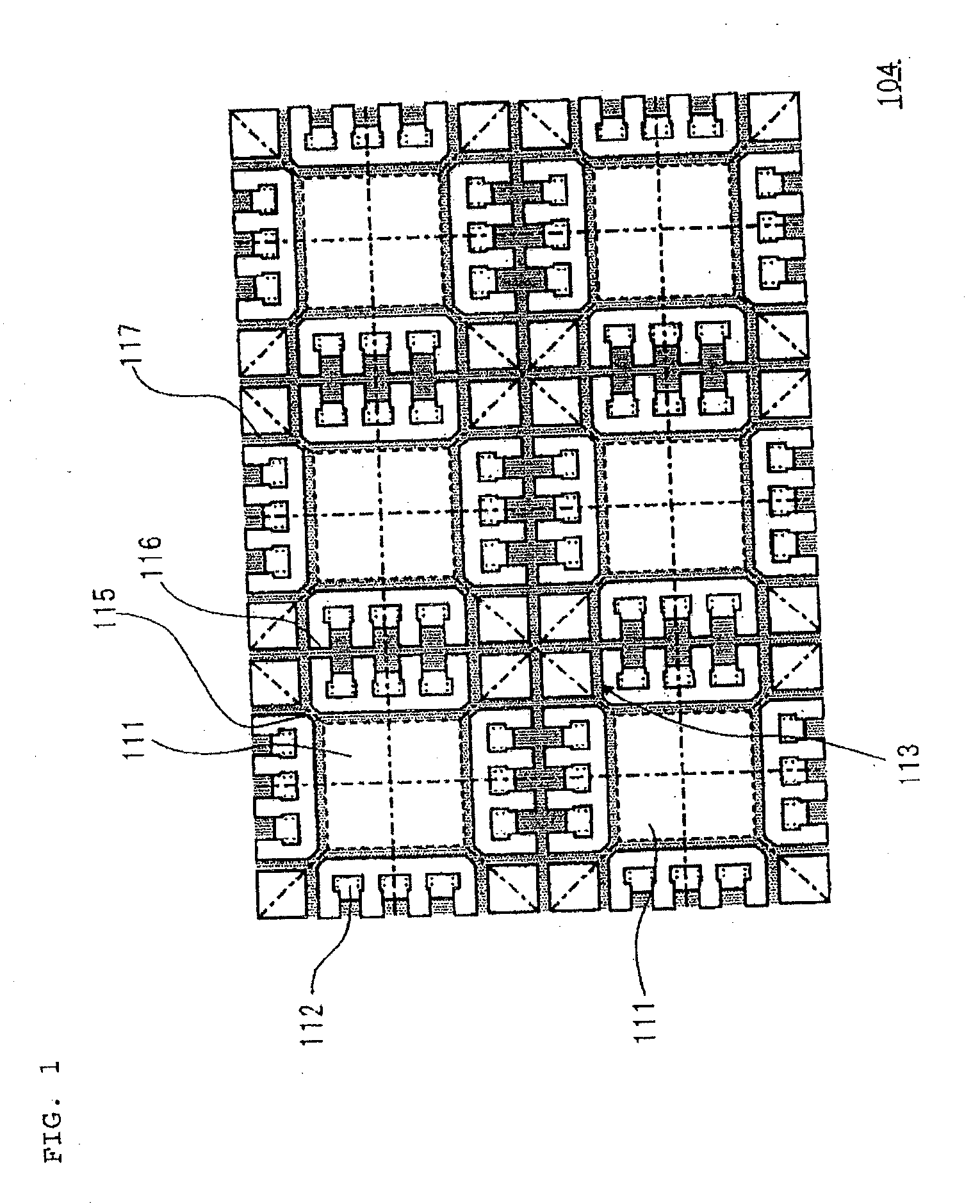

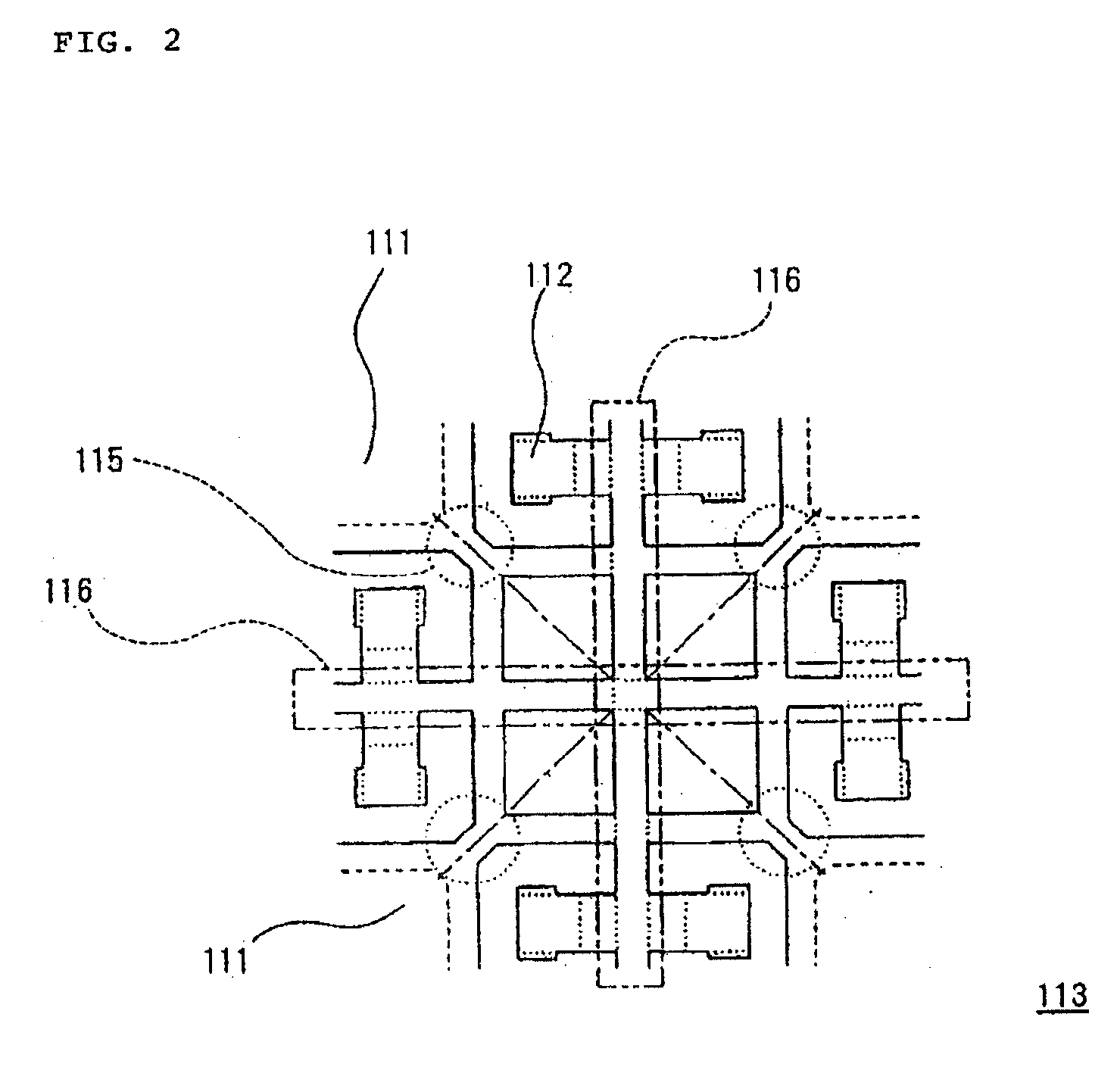

Display substrate, method of manufacturing the same and display device having the same

ActiveUS20090141227A1Simplify manufacturing processDecrease manufacturing costStatic indicating devicesNon-linear opticsPhotoresistEngineering

A display substrate includes a transparent insulating substrate, a transparent common electrode, a dummy pattern and a key pattern. The transparent insulating substrate has a display area and a non-display area. Images are displayed in the display area, and the non-display area surrounds the display area. The transparent common electrode is formed in the display area of the insulating substrate. The dummy pattern is formed in the non-display area of the insulating substrate. The dummy pattern is formed from the same material as the common electrode. The key pattern is formed on the dummy pattern. The key pattern may include a metal or an opaque photoresist. Therefore, a process of manufacturing the display substrate may be simplified.

Owner:SAMSUNG DISPLAY CO LTD

Catalytic converter and fabrication method thereof

ActiveUS20120321859A1Decrease manufacturing costReduce manufacturing costInternal combustion piston enginesDispersed particle filtrationEngineeringMechanical engineering

A catalyst unit may include a carrier, a channel opening portion through which exhaust gas passes, a skin portion that is formed along a circumference and integrally formed with the channel opening portion, and a skin addition portion that is formed with a second thickness on an outside surface of the skin portion. A fabrication device of the catalyst unit may include a container, a masking member, and an elastic member, wherein plugging material flows through opened channels and does not contact the masking member. A manufacturing method of the catalyst unit may include covering the masking member and inserting plugging material into an opened channel. A channel corresponding to a dead zone is plugged and the catalyst coating layer is not formed in the plugged channels, thus reducing the cost of the catalyst.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com