Resistance System for a Rowing Machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

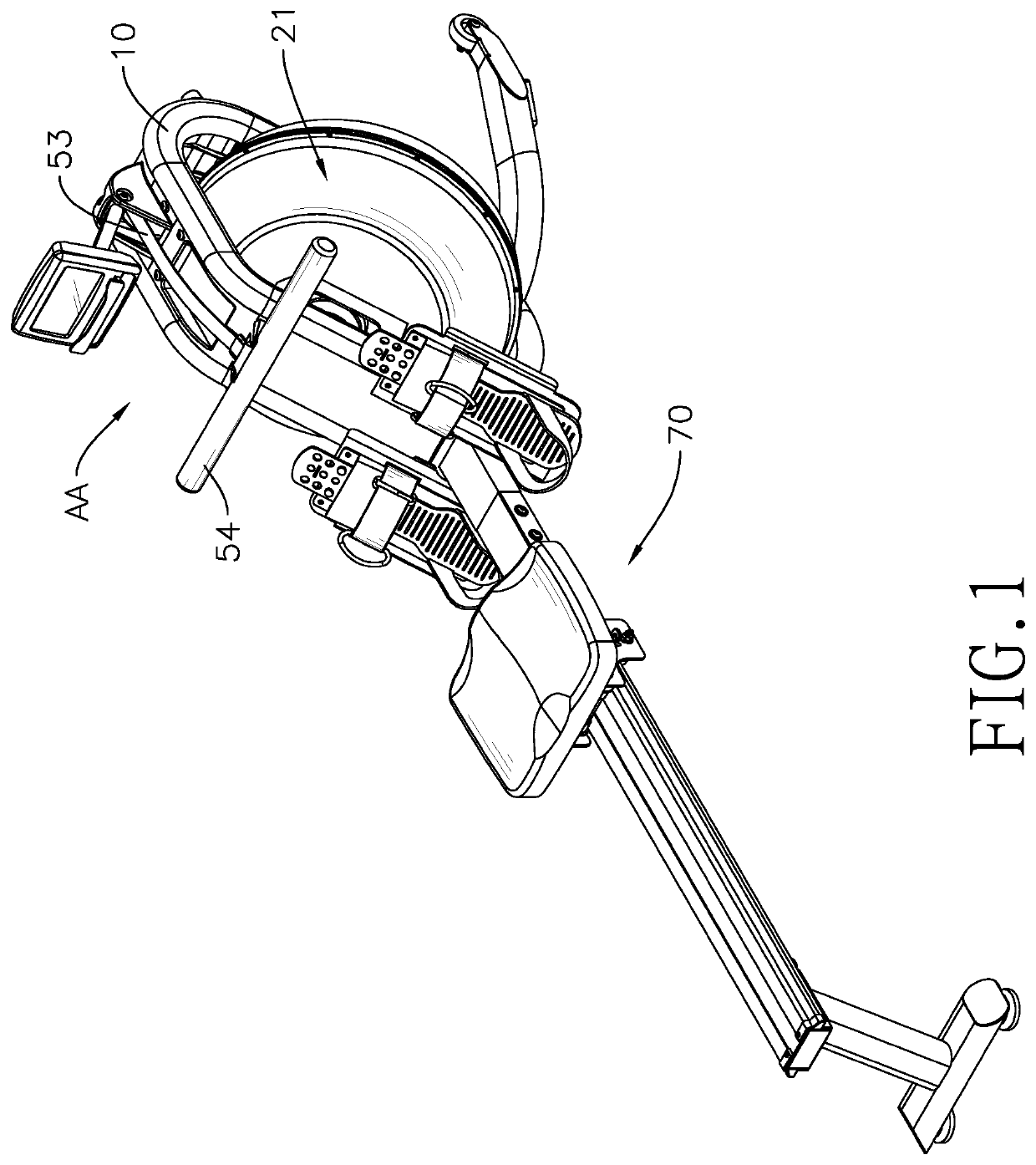

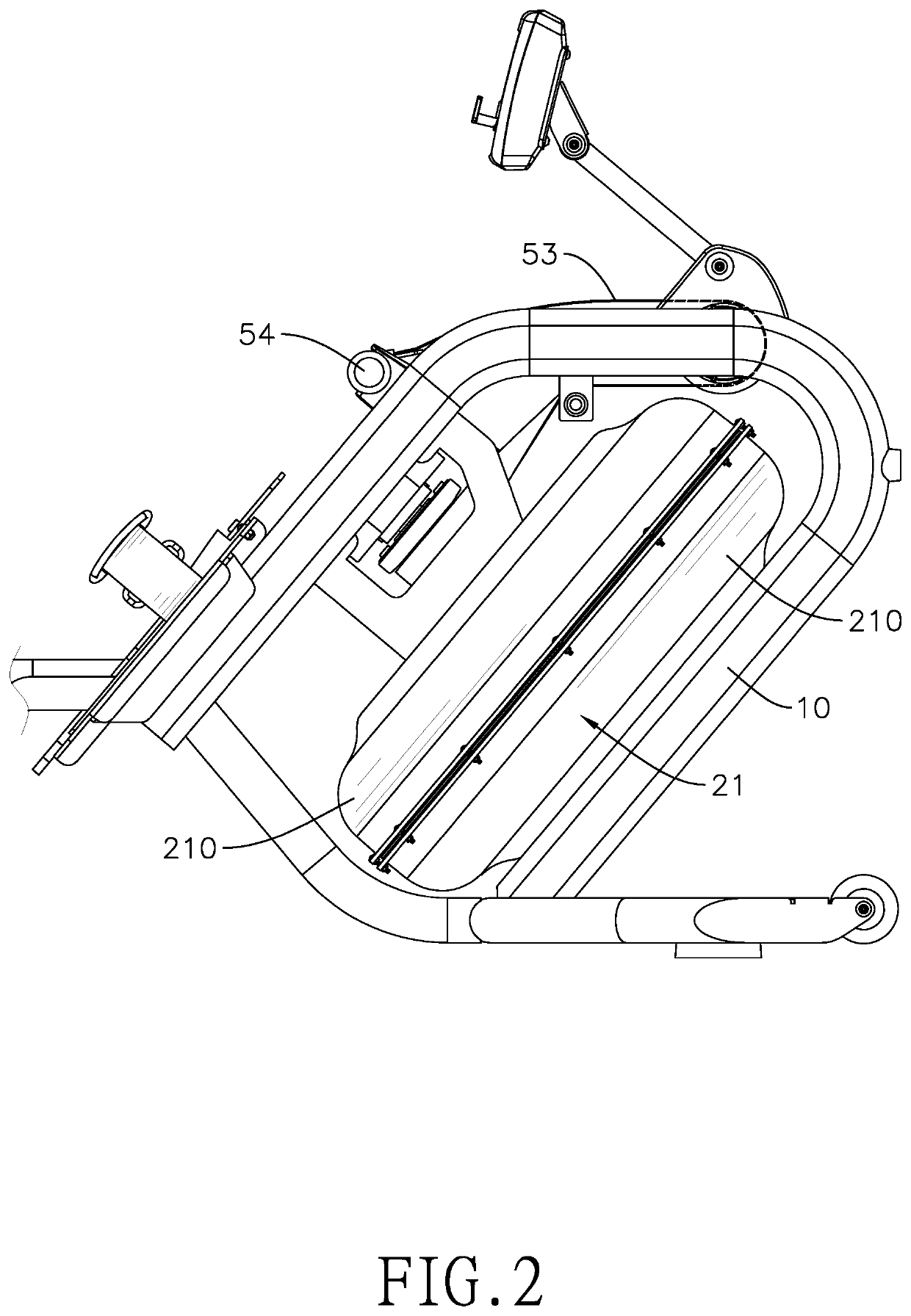

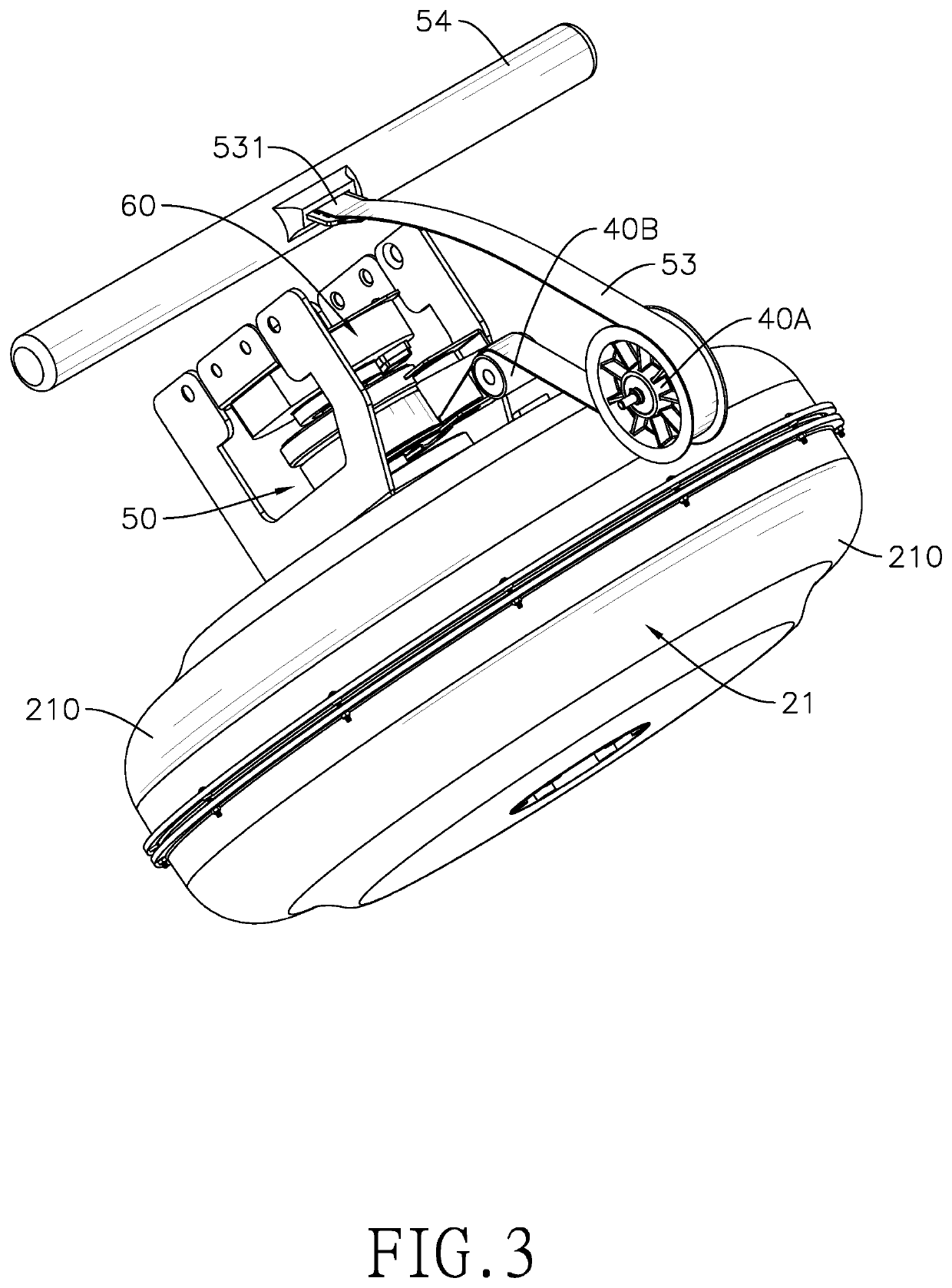

[0021]With reference to FIGS. 1 to 3, a resistance system AA for a rowing machine comprises a mounting bracket 10, a housing assembly 20, a paddle wheel 30, at least one strip guiding member 40A, 40B, a driving assembly 50, and a restoring assembly 60.

[0022]The mounting bracket 10 is connected to a front end of a seat assembly 70 of the rowing machine.

[0023]With further reference to FIGS. 2 and 5, the housing assembly 20 is mounted on the mounted bracket 10 and includes a liquid tank 21 and two baffles 22.

[0024]The liquid tank 21 is for storing liquid such as water, and has two side walls 211 and an annular wall 212. The side walls 211 are oppositely defined on the liquid tank 21. The annular wall 212 is formed between the two side walls 211.

[0025]The baffles 22 are disposed in the liquid tank 21 and are attached to the two side walls 211 of the liquid tank 21 respectively. Each of the baffles 22 is annular and has a through hole 221 defined through the baffle 22. An interior of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com