Patents

Literature

60results about How to "Increase rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

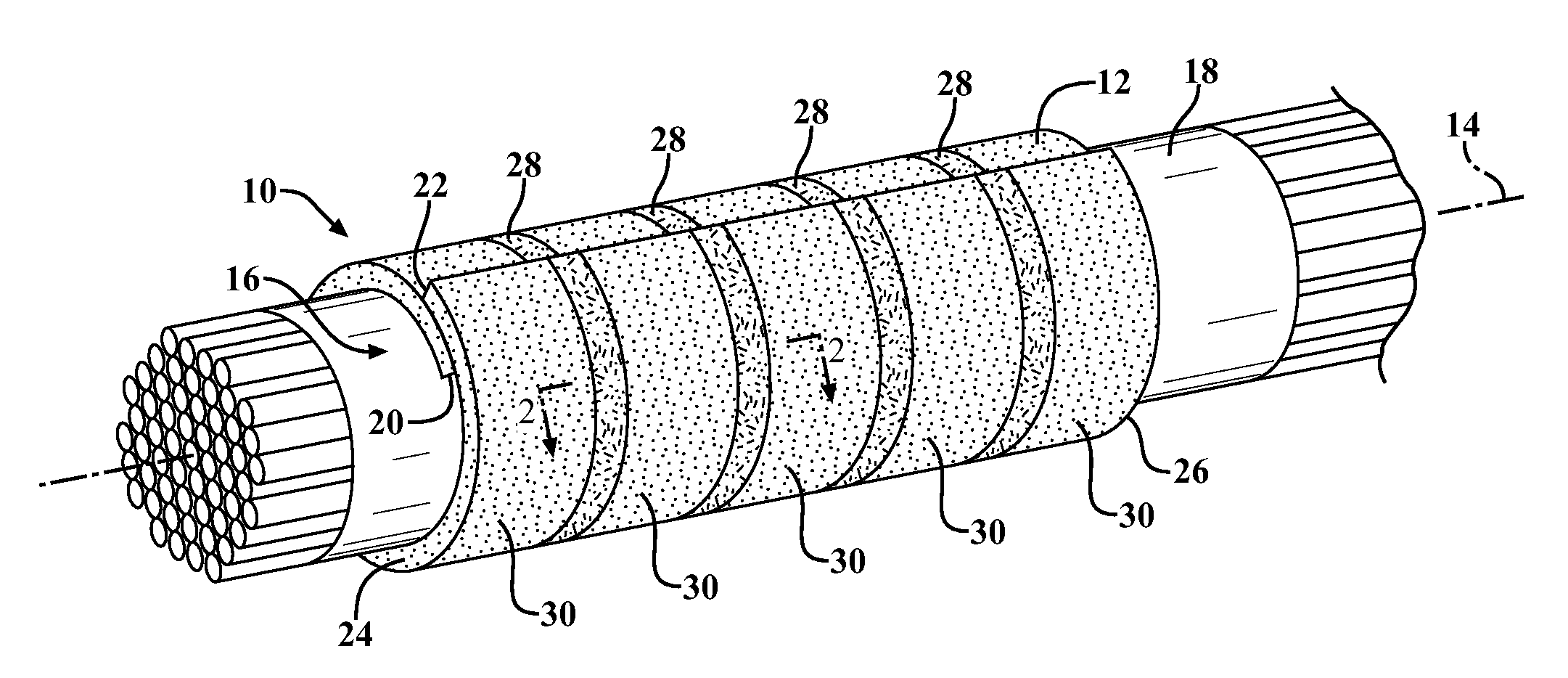

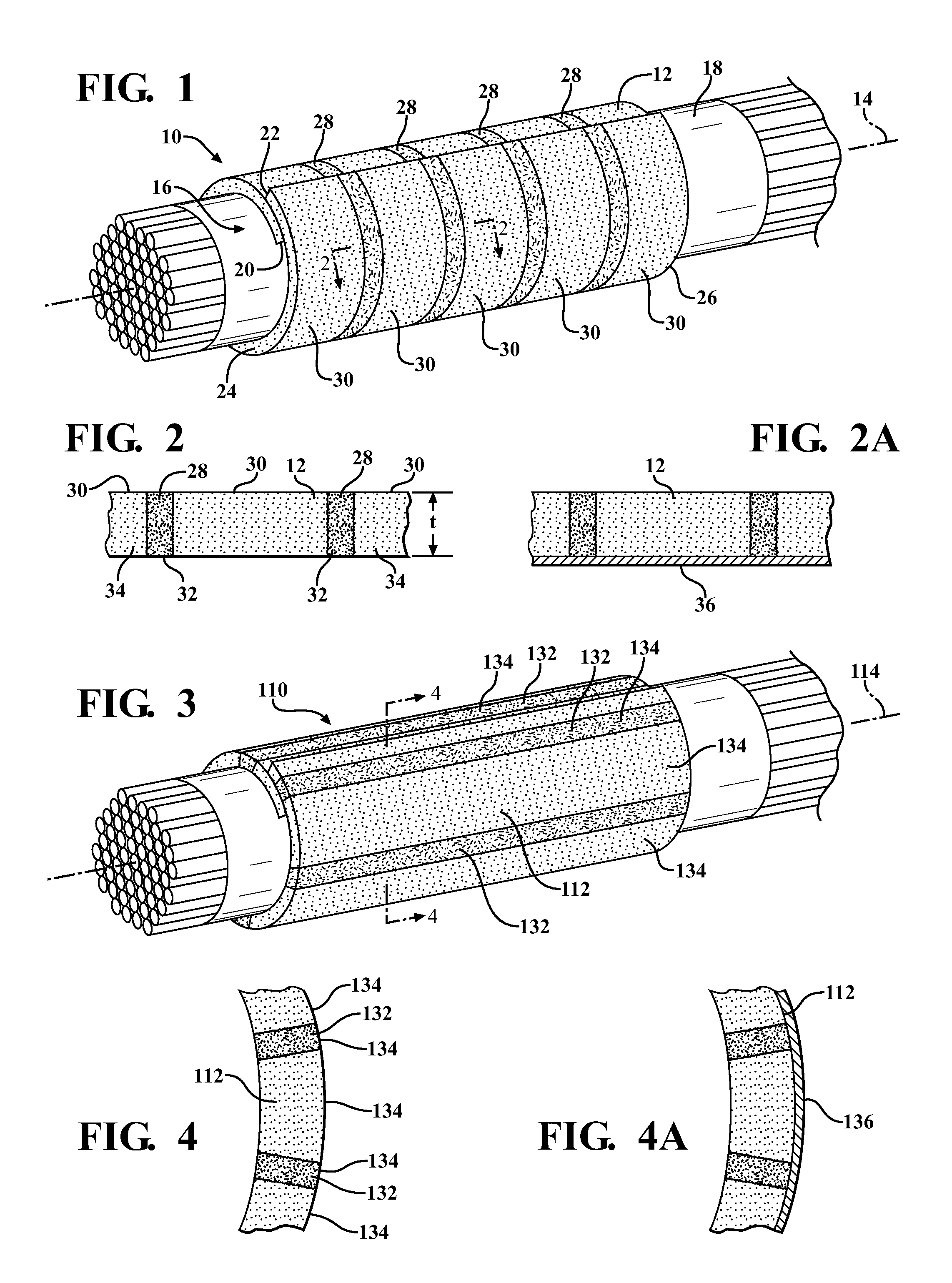

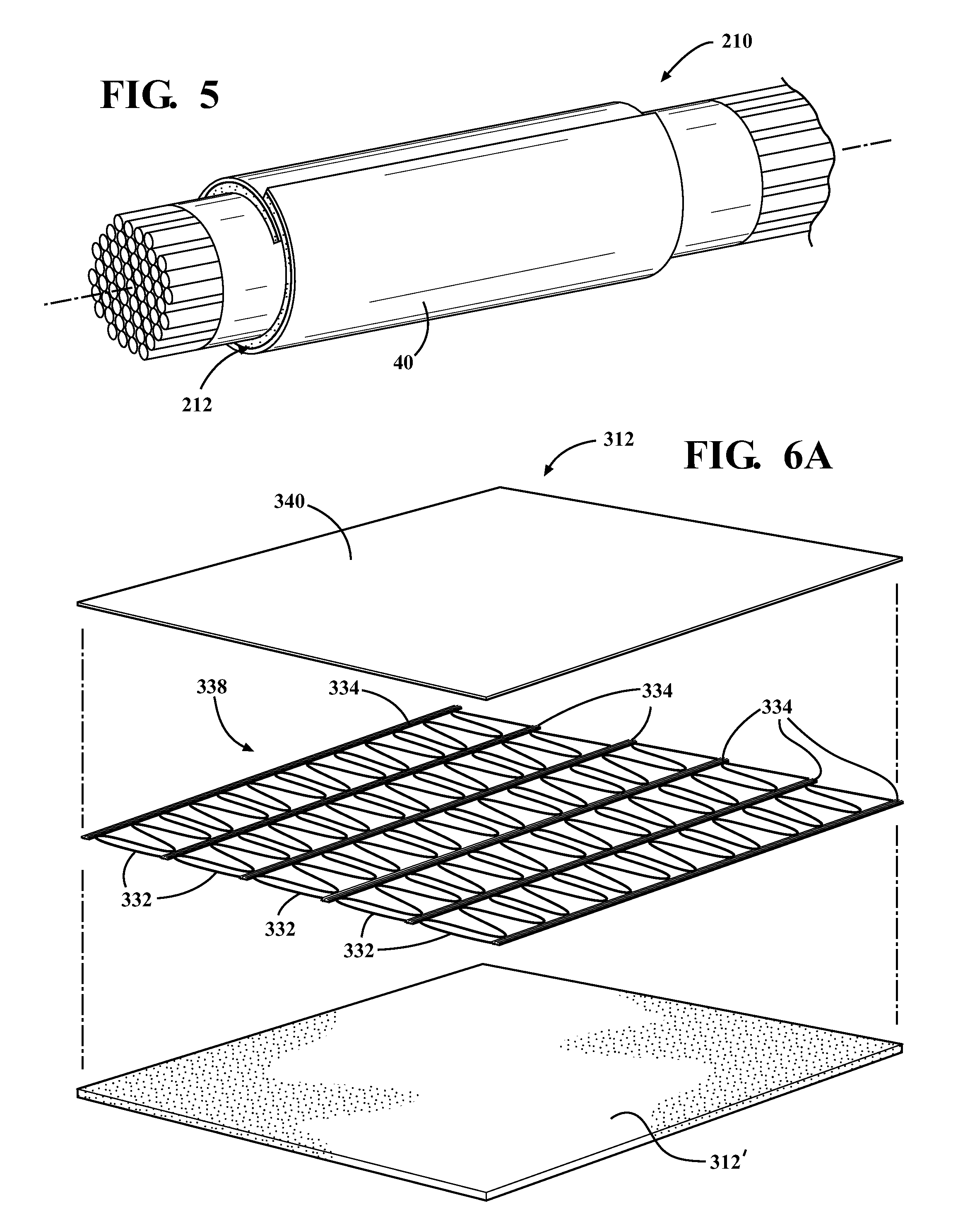

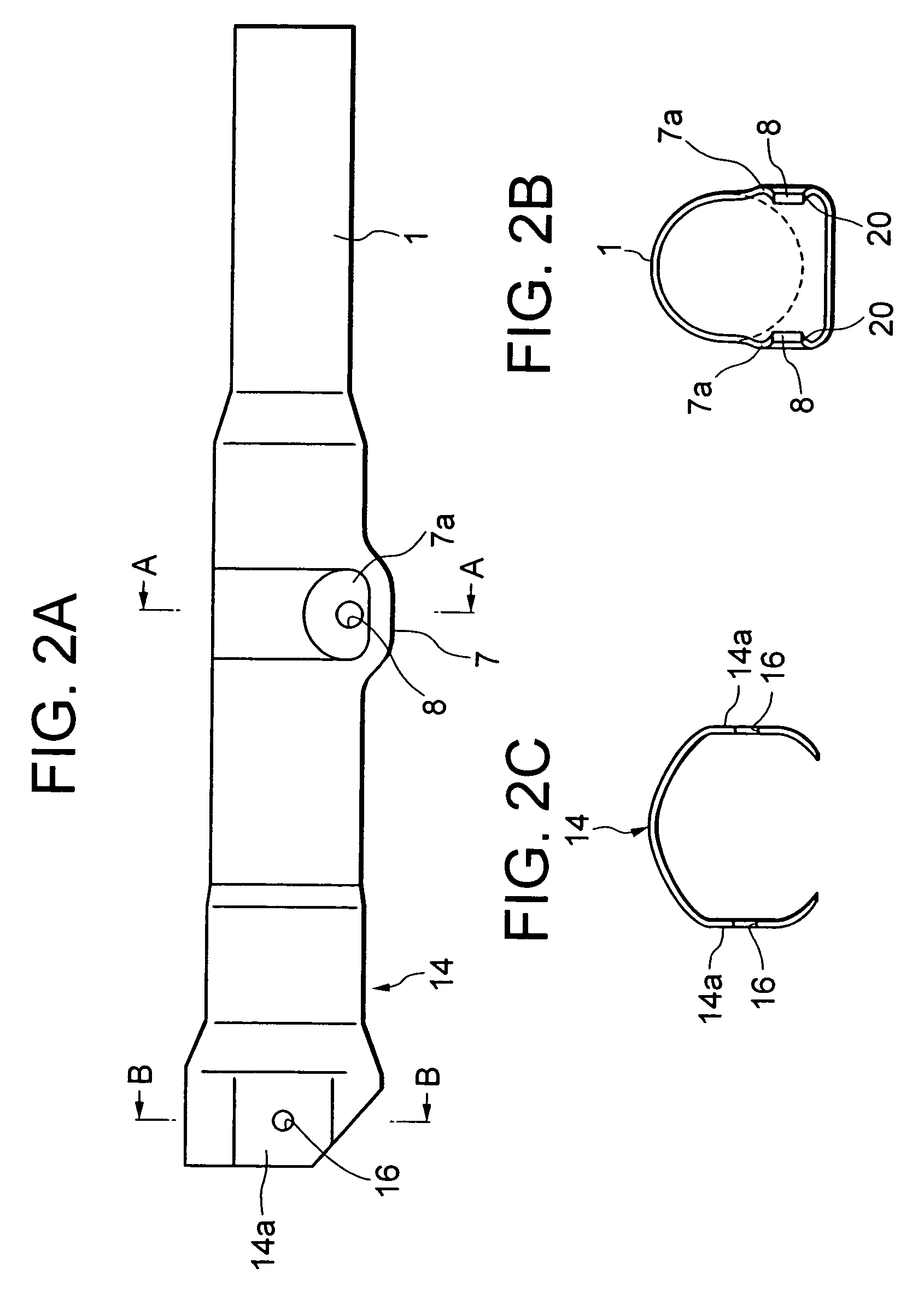

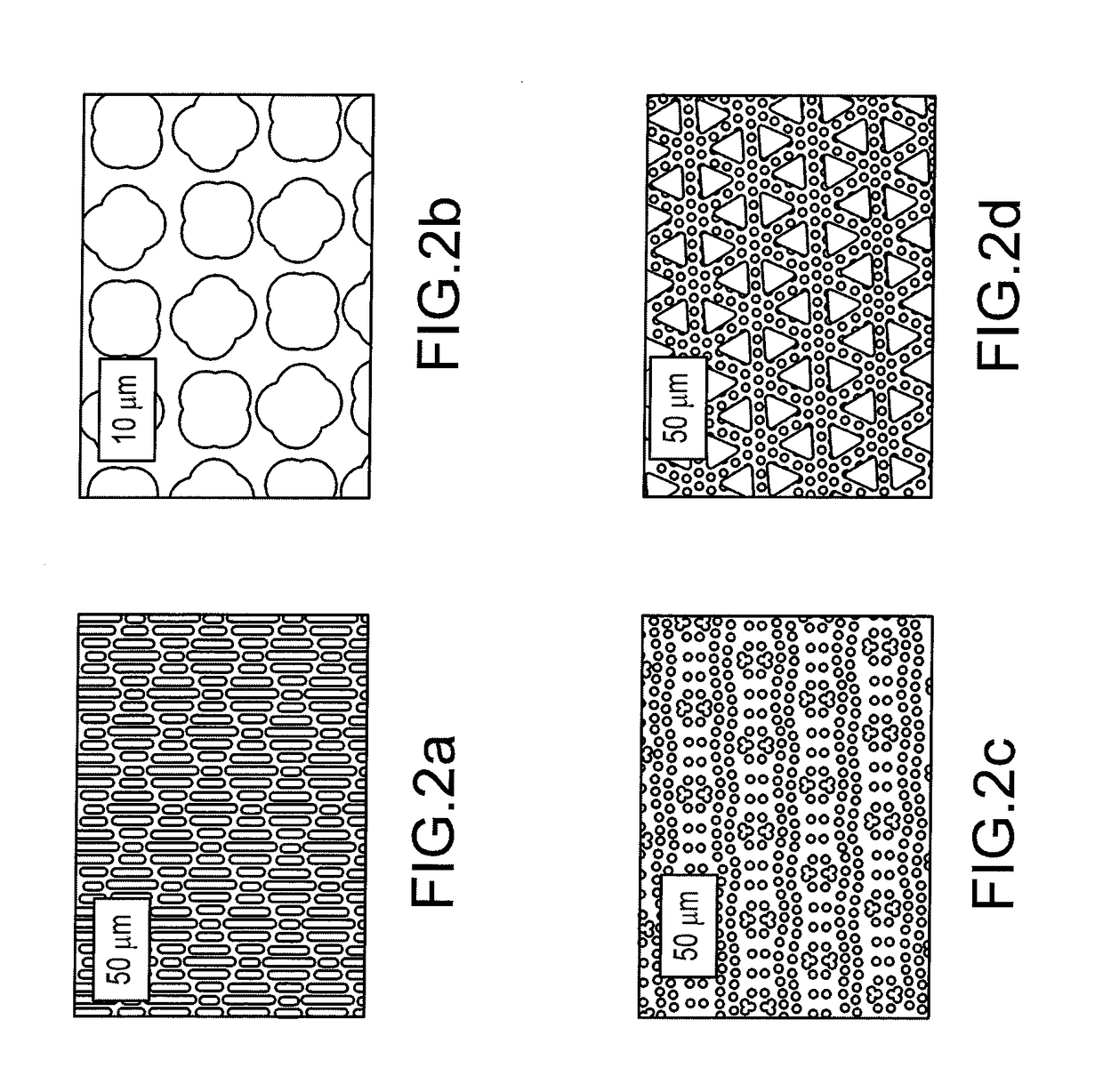

Non-woven, self-wrapping thermal sleeve and method of construction thereof

InactiveUS20110275268A1Enhance flexibilityIncrease rigidityElectrical apparatusOrnamental textile articlesEngineeringMechanical engineering

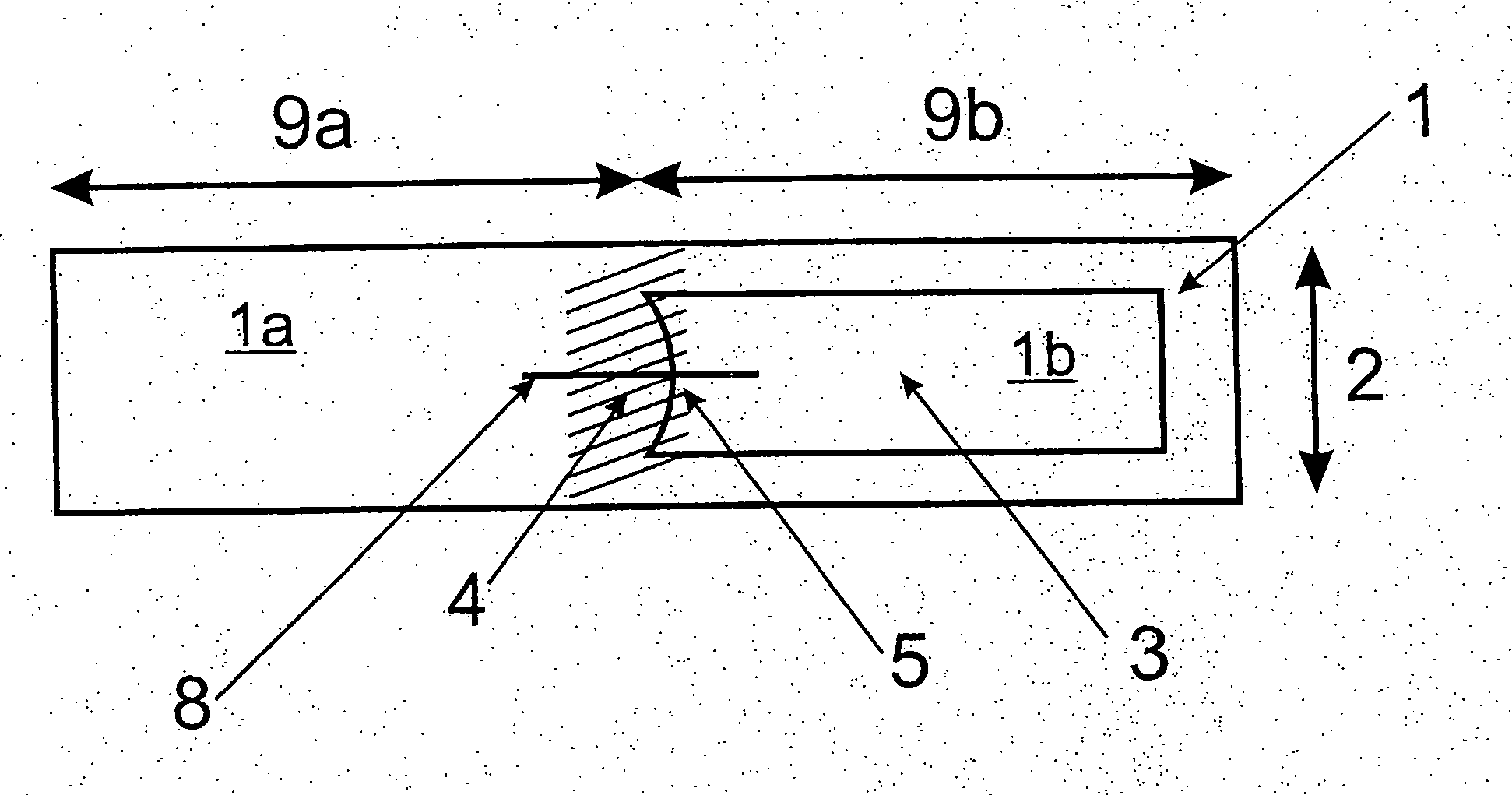

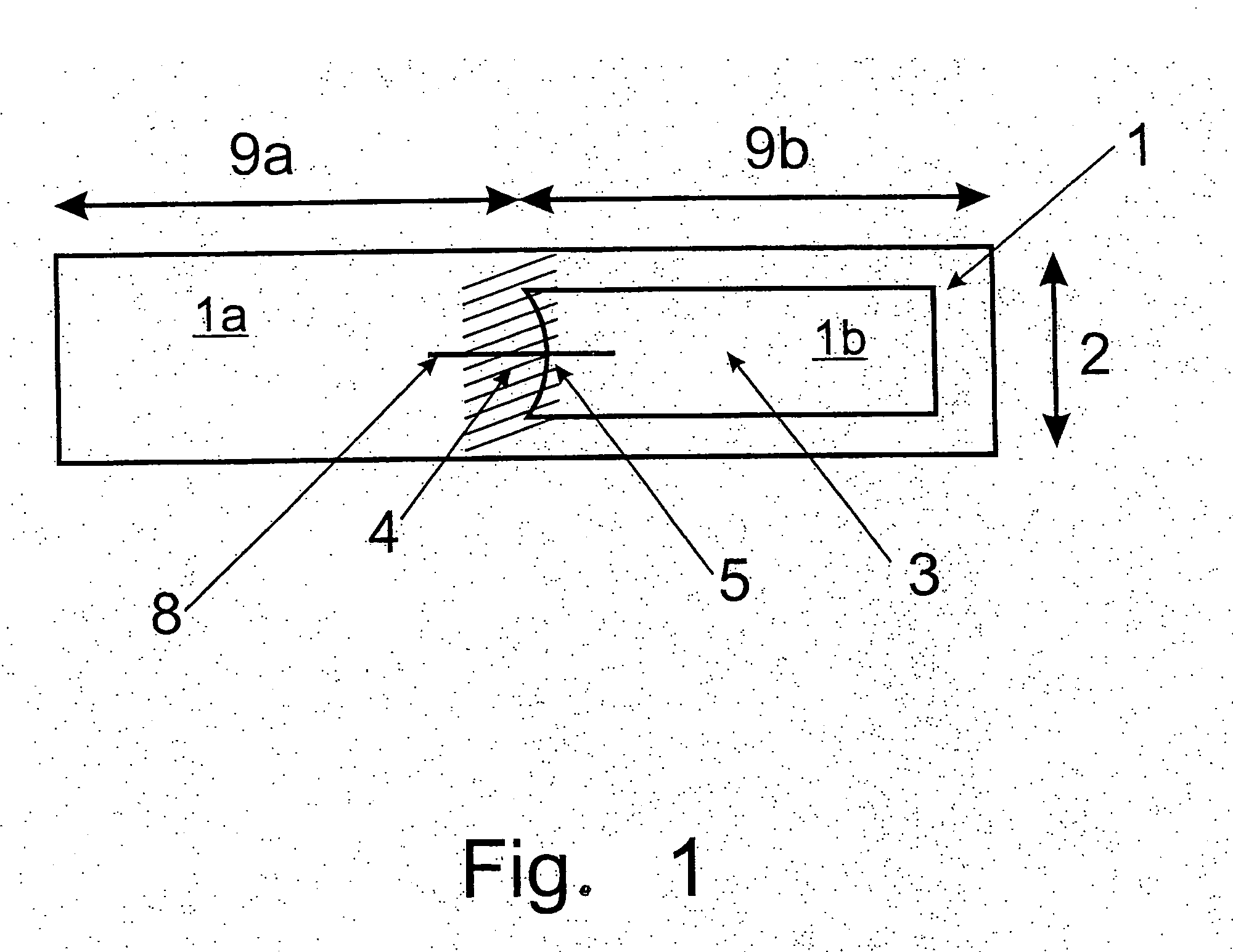

A self-wrapping, non-woven sleeve for routing and protecting elongate members and method of construction thereof is provided. The sleeve includes an elongate non-woven wall having opposite sides extending along a longitudinal axis of the sleeve. The sides are self-wrapping about the longitudinal axis to provide a tubular cavity. The sides are extendable away from one another under an externally applied force to expose the cavity for insertion of the elongate members, wherein the sides return to their self-wrapped configuration upon removal of the externally applied force. The wall includes discrete first regions of a material and discrete second regions of a material. The first and second regions of material are different and provide the wall with non-uniform physical properties.

Owner:FEDERAL MOGUL POWERTAIN LLC

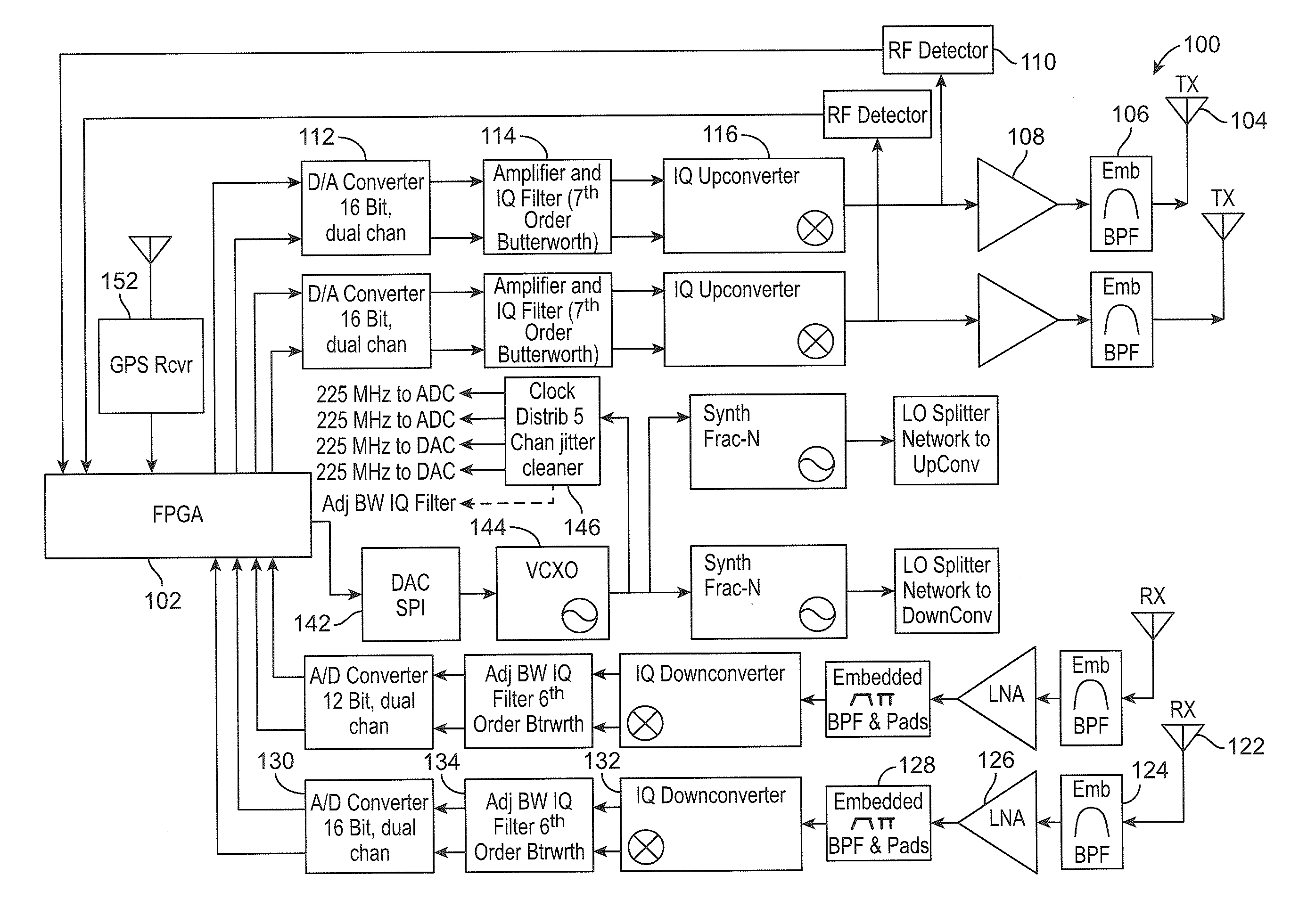

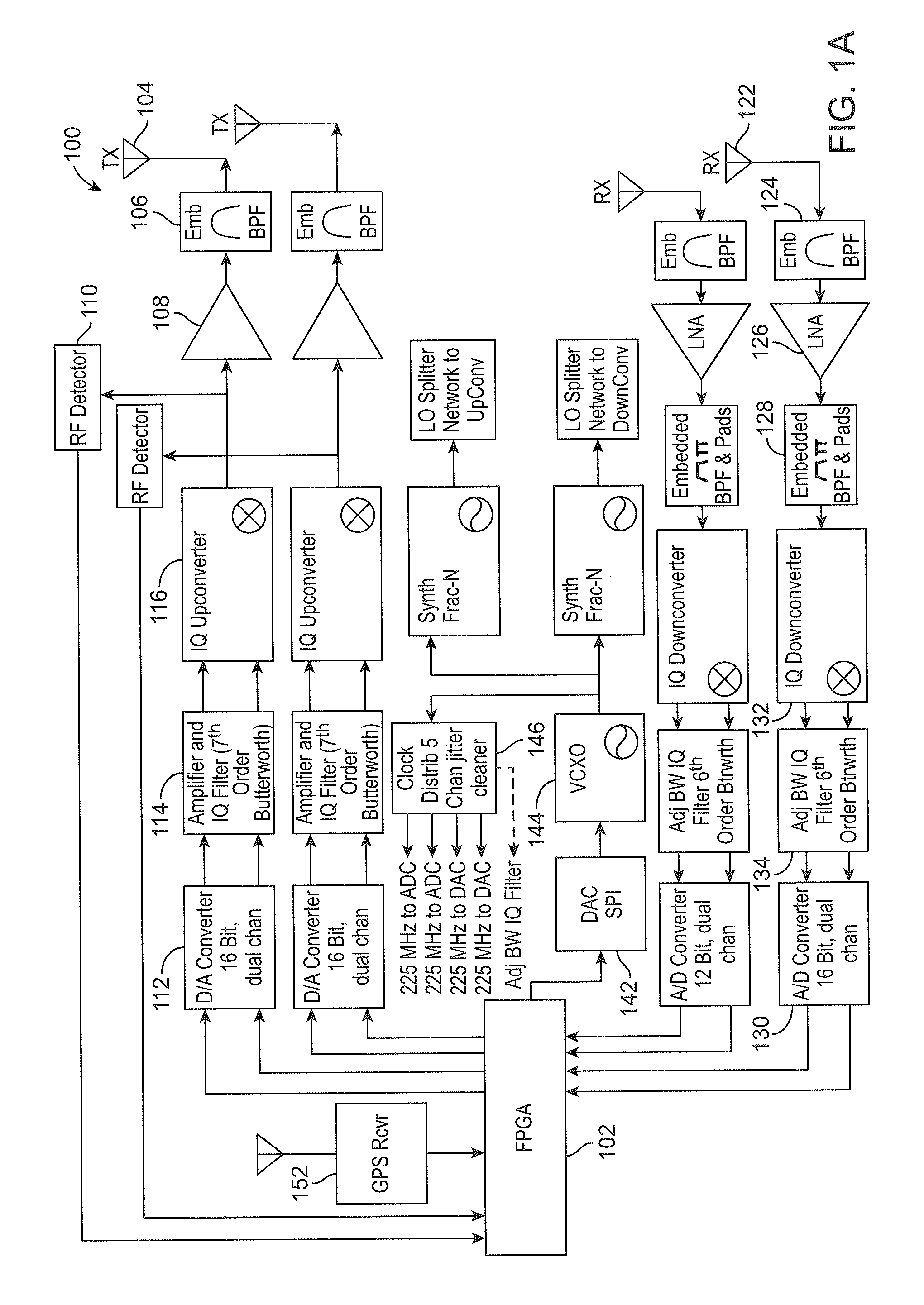

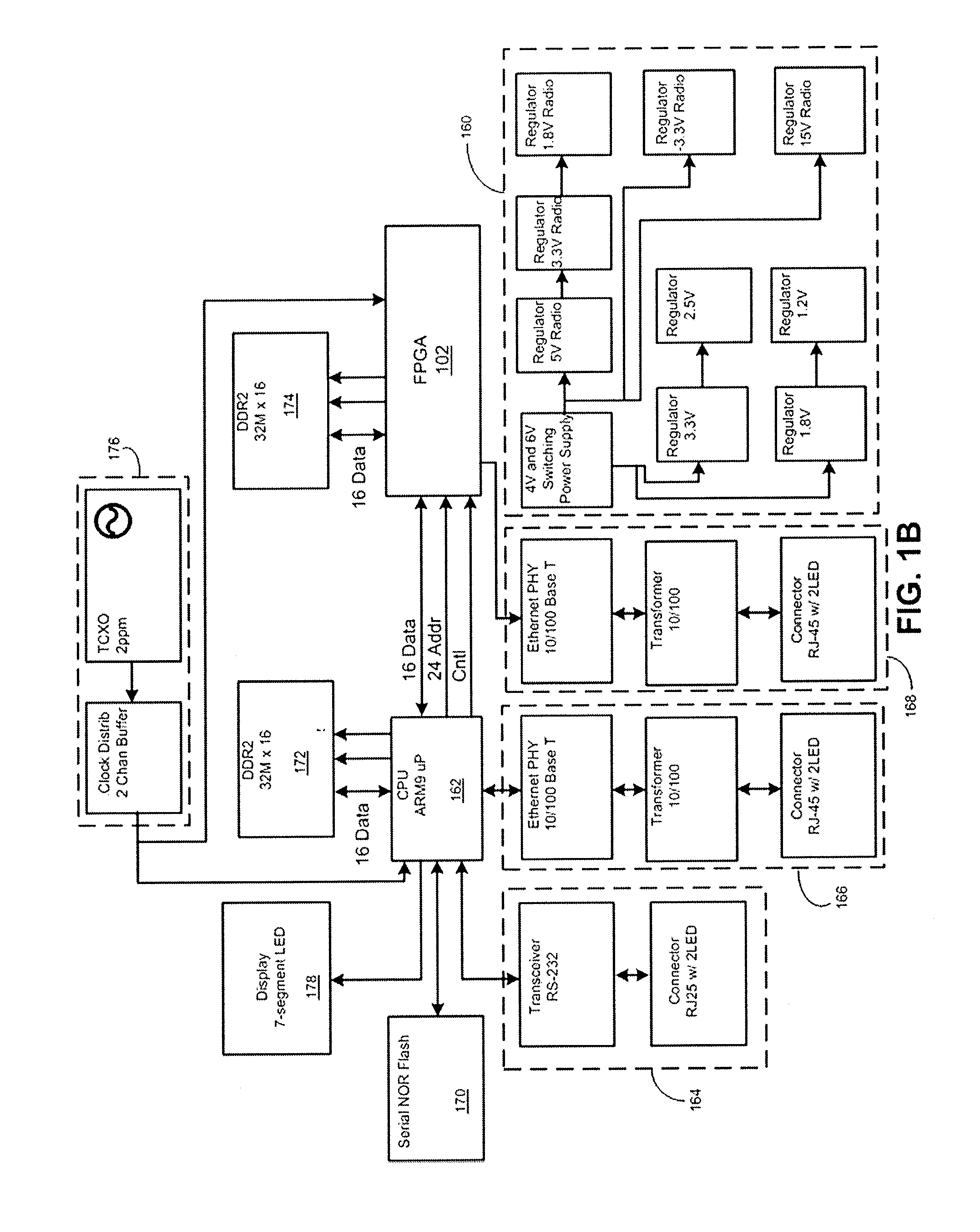

Agile duplexing wireless radio devices

ActiveUS20140219142A1Increase rigidityHigh alignmentTime-division multiplexCommunication jammingRadar signalsFrequency division duplex

Radio devices having separate transmission and reception reflectors for transmitting and receiving wireless signals that detect interference in a transmission channel and may be automatically or manually switch duplexing schemes when reflections, radar or other interference is detected. These devices typically include both a transmission antenna reflector and a receiving transmitter reflector, which may be connected or formed of a single housing, that are operatively coupled to radio circuitry for transmission and reception of wireless signals. Interference, and particularly reflected signals between the transmitter and receiver, are avoided by including a detector coupled to either (or both) reflectors that monitors the transmitting frequency channel; reflections and / or radar signals may be detected and may trigger switching (manual or automatic switching) to a different duplexing modes such as frequency-division duplexing (FDD), time-division duplexing (TDD), etc.

Owner:UBIQUITI INC

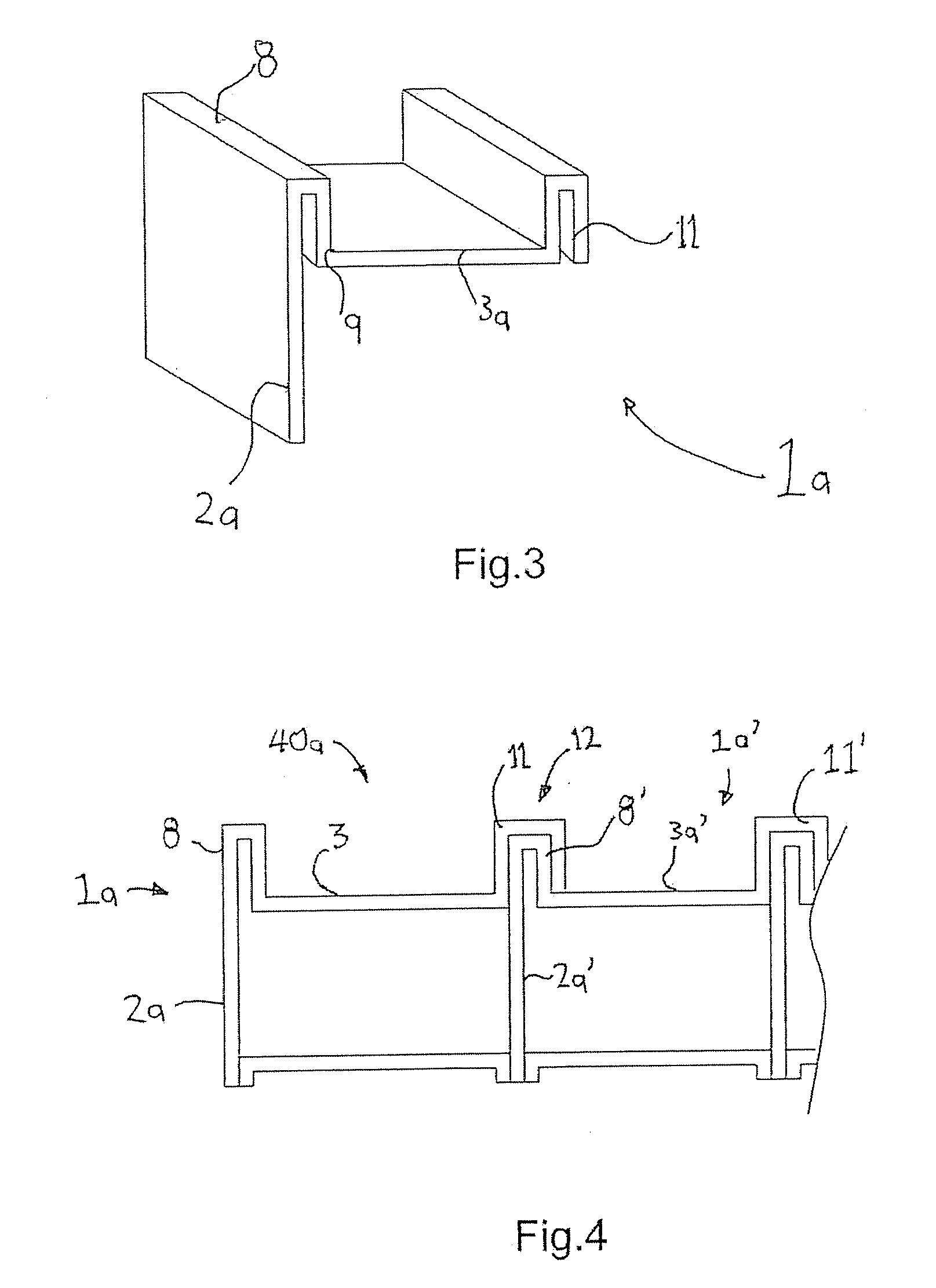

Architectural pavements in elevated exterior deck applications

A deck assembly uses plurality of joists preferably formed from metal located side by side and each having a web portion and a deck portion integrally formed with the web portion. The deck portion extends laterally from the web portion and the joists are spaced from one another such that the deck portions from a continuous deck surface with the joists being connected to one another.

Owner:CASATA TECH

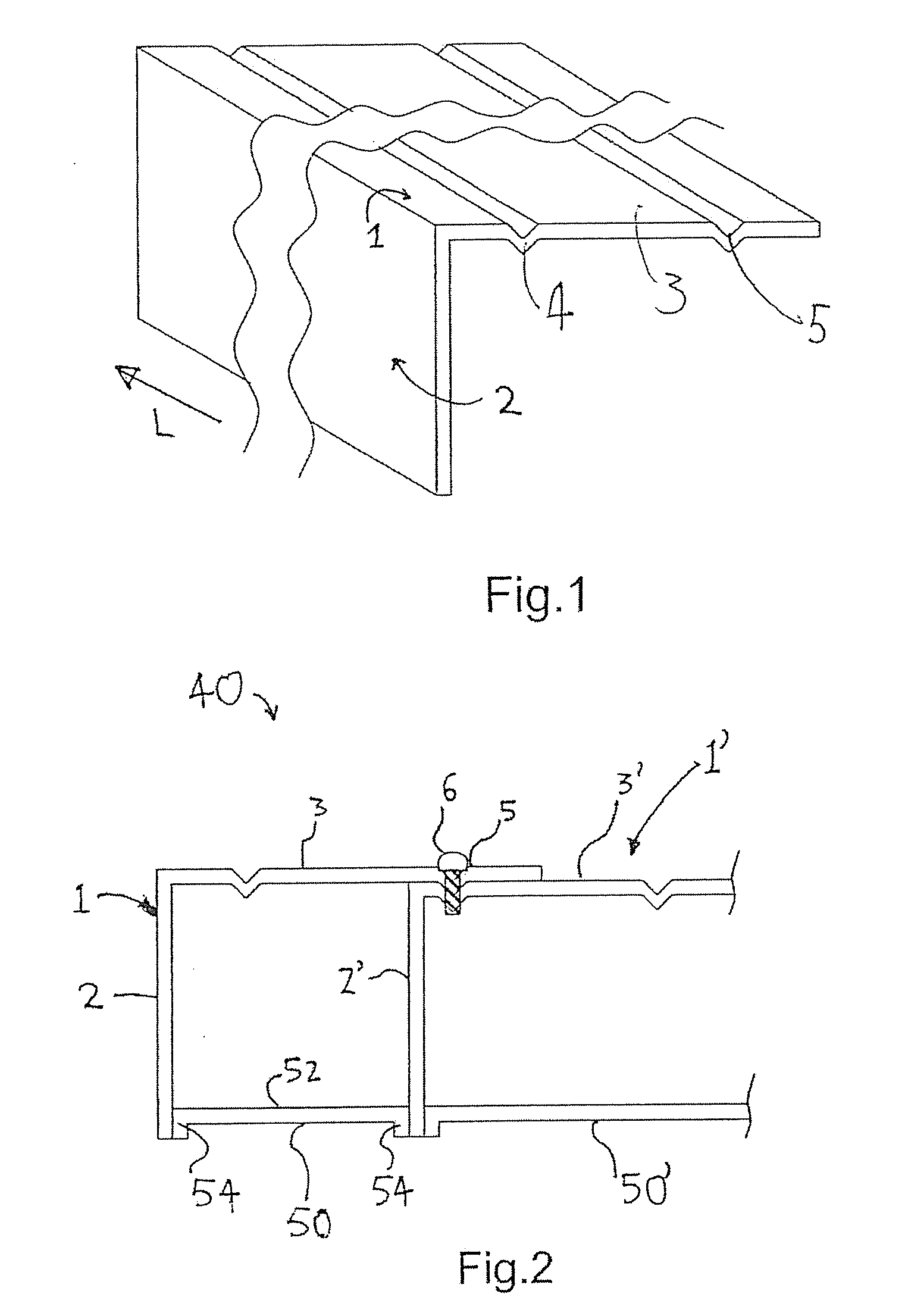

Construction enclosure system

InactiveUS6904720B1Increase rigidityIncreasing the thicknessCeilingsCovering/liningsEngineeringSurface plate

There is provided a framework for a construction enclosure system comprising a plurality of brackets, a plurality of rigid elongated frame members, and a plurality of reinforcement members. The brackets are adapted to be attached to a structure under construction. The frame members are adapted to be retained by the brackets in a desired spatial relationship with an outer face of the structure. The frame members are adapted to retain one or more sheet-like enclosure panels. The reinforcement members are adapted to be secured against respective frame members to increase the rigidity of such frame members. One embodiment of the invention provides a frame member comprising a pair of elongated bodies adapted to be retained in a mated configuration to cooperatively define first and second channels therebetween, wherein each channel is adapted to retain one edge portion of a sheet-like enclosure panel.

Owner:ADOLFSON & PETERSON

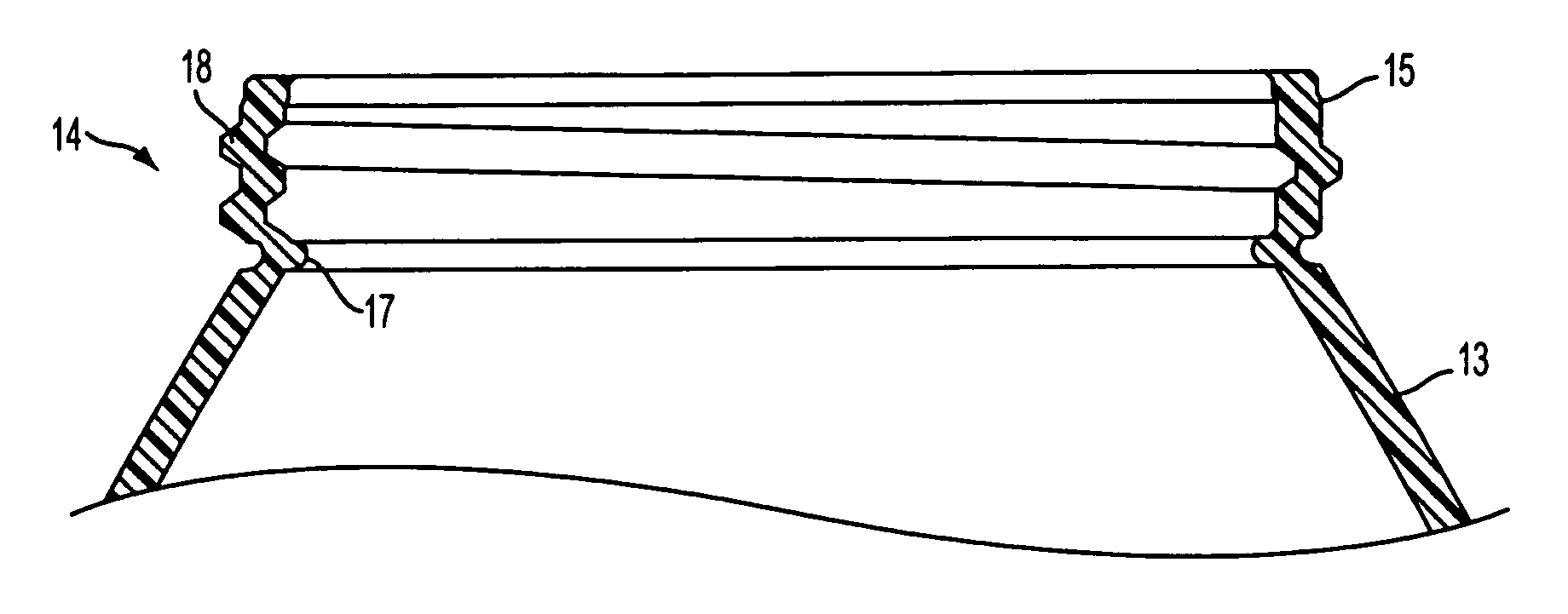

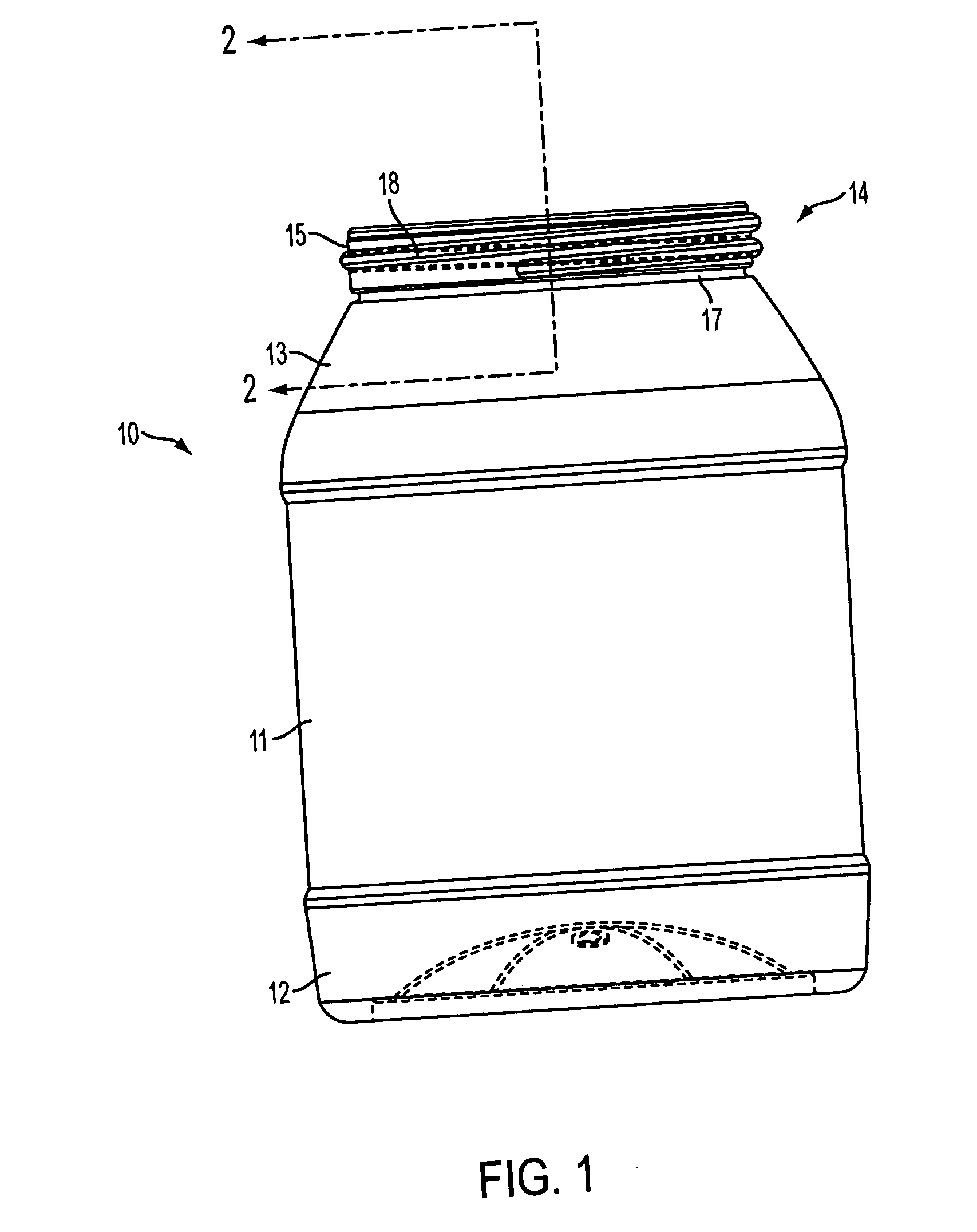

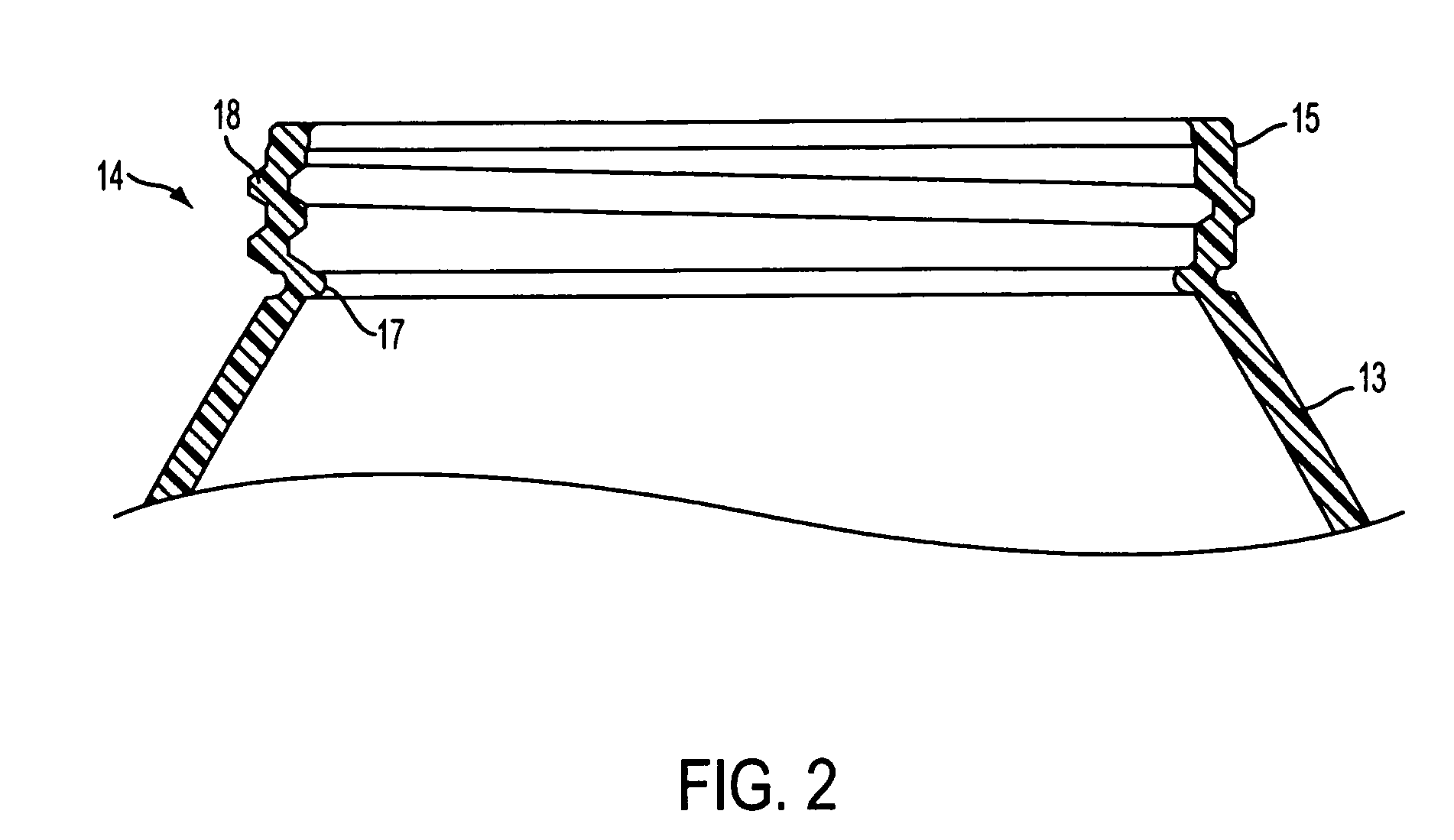

Plastic container finish with structural rib

Owner:GRAHAM PACKAGING CO LP

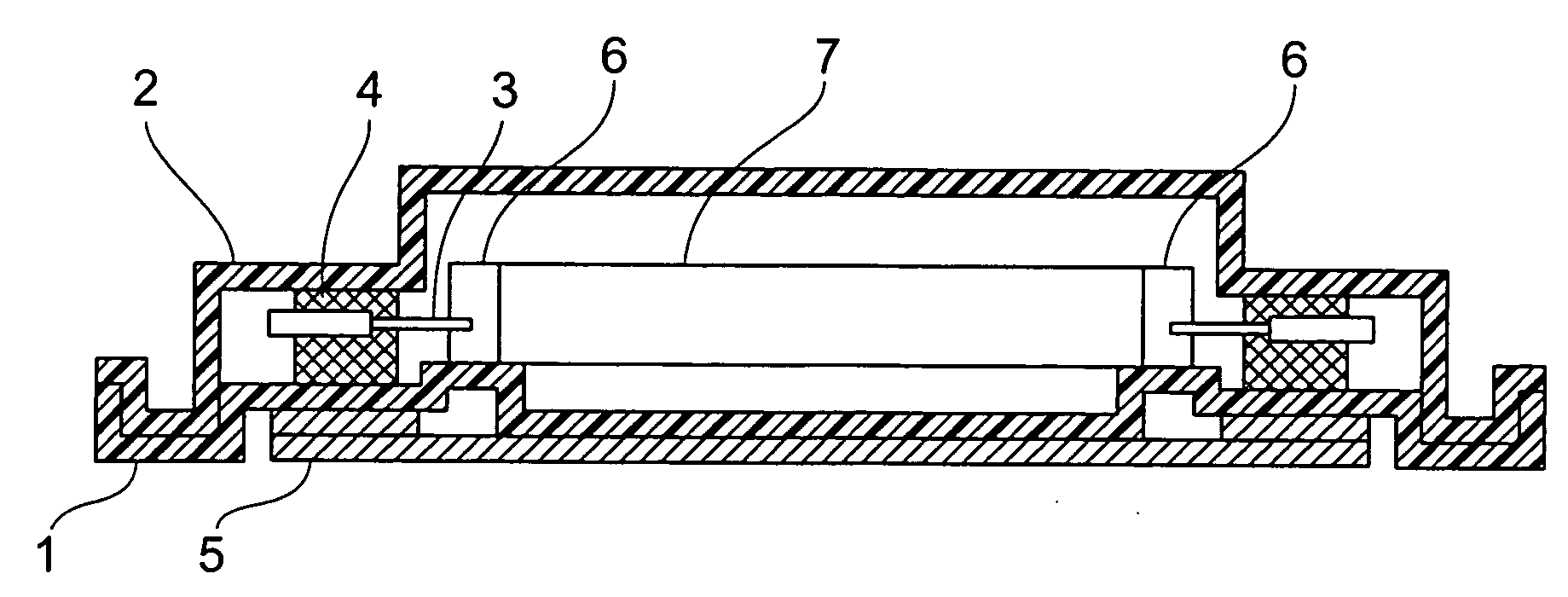

Ionization device

InactiveUS20080130190A1Increase rigidityAvoid dischargeCorona dischargeElectrostatic chargesIonizationNeedle electrode

An ionization device with increased rigidity of a coupling portion is provided. The ionization device includes a casing member for applying high voltage to each needle electrode; a coupling member for mechanically coupling a plurality of casing members in a longitudinal direction and electrically connecting high voltage plates of the respective casing members; and a elongated main body casing for housing a casing body constituted by coupling the plurality of casing members with the coupling member and the electrical circuit unit, the main body casing having the needle electrodes with a space from each other in the longitudinal direction and protruding outside. The main body casing integrally forms a space for arranging the casing body therein so as to be separated from a space for arranging the electrical circuit unit. With this configuration, the casing body to be applied with the high voltage is separated from the electrical circuit unit including a portion having low voltage, thereby avoiding unnecessary discharge.

Owner:KEYENCE

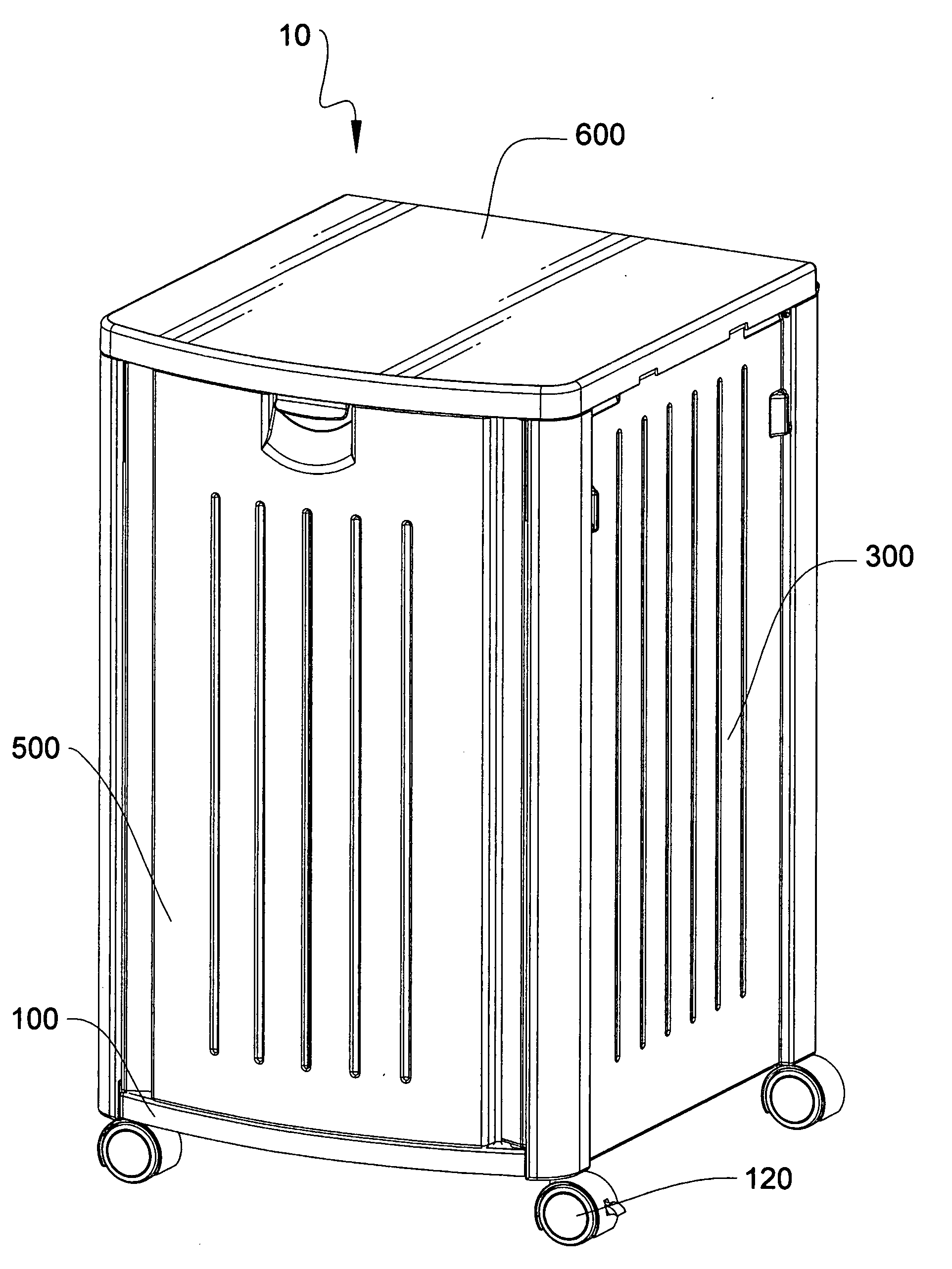

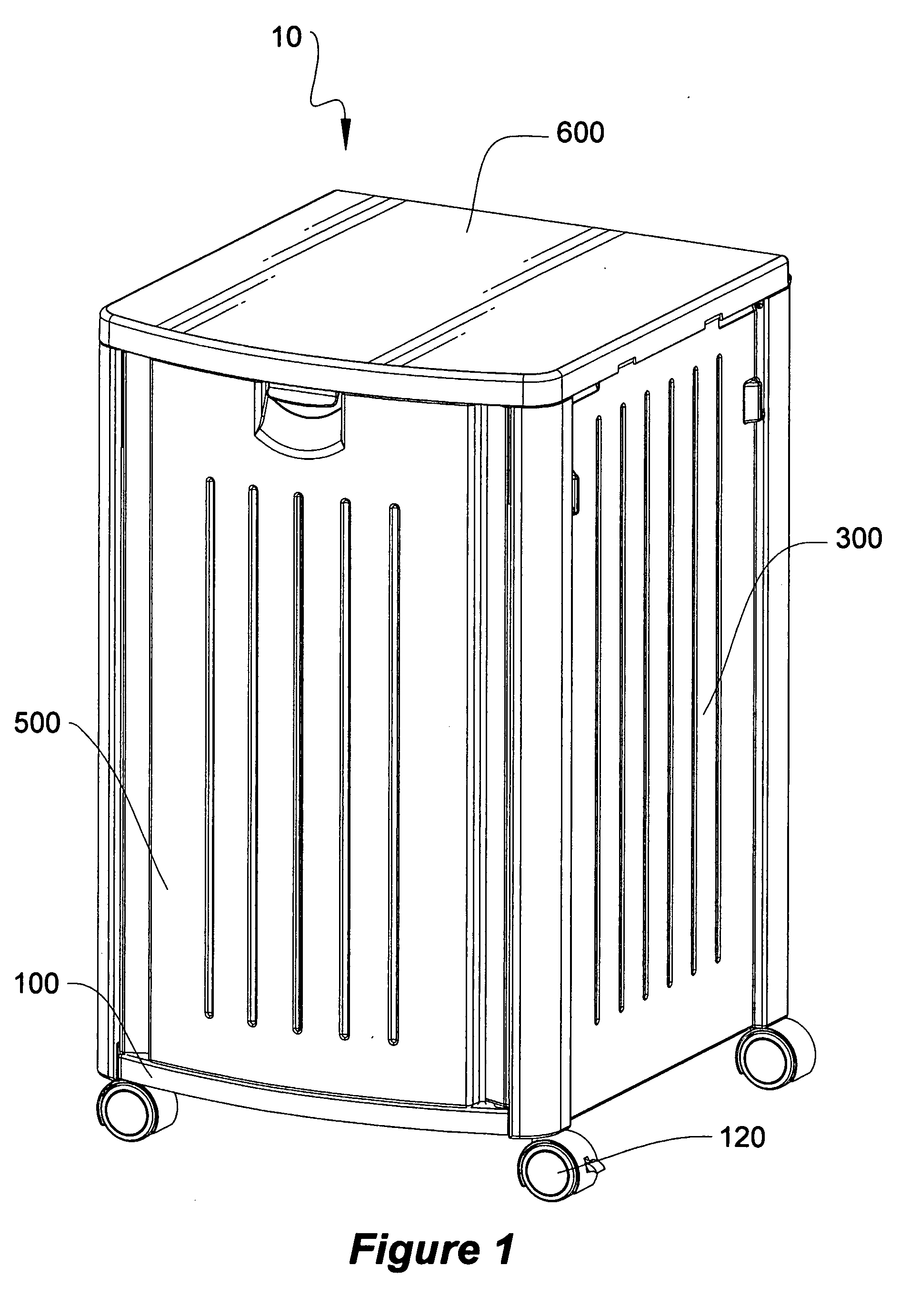

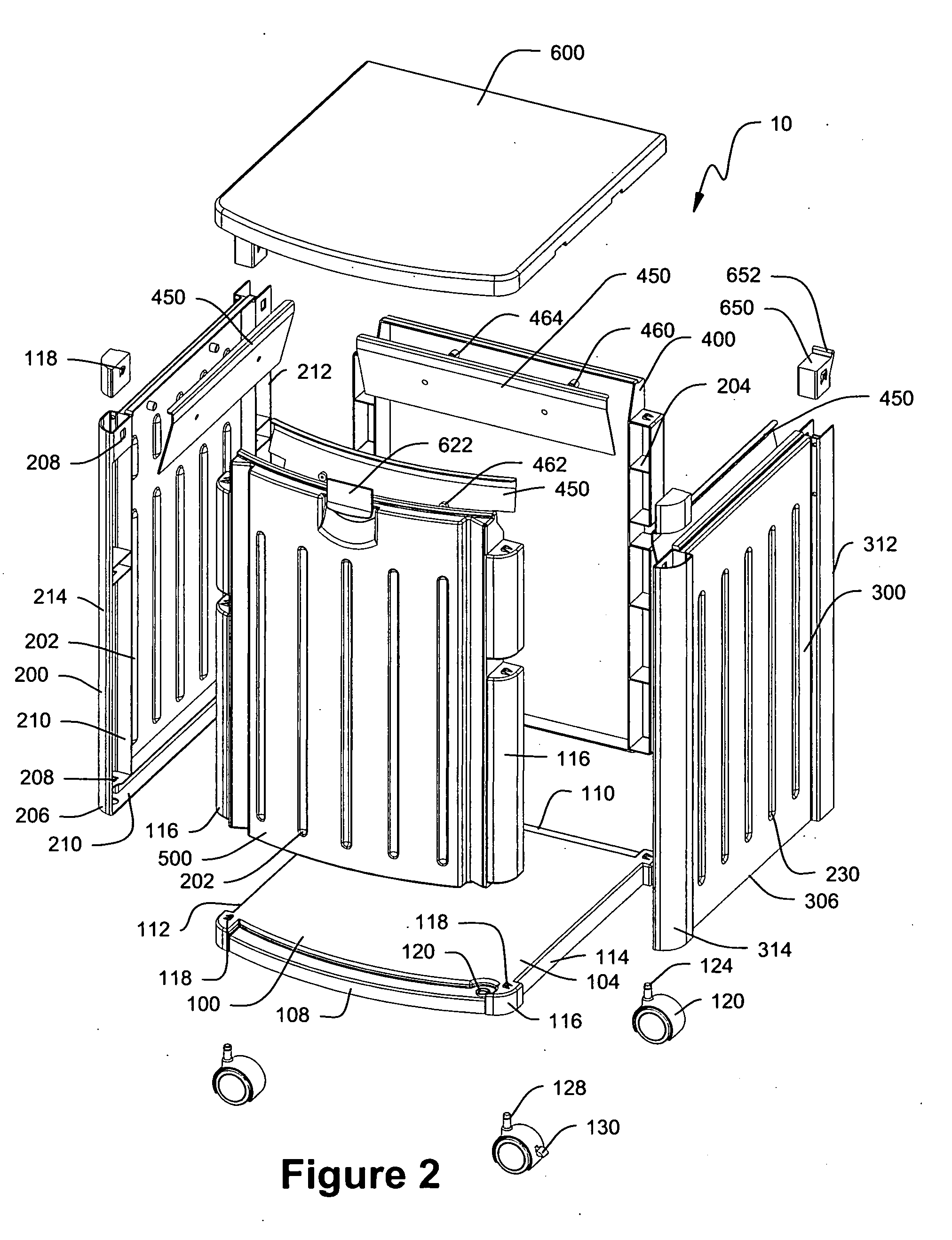

Trash container assembly

InactiveUS20070125778A1Simplify constructionIncrease rigidityRefuse receptaclesRigid containersFastenerBackplane

The present invention provides a plurality of injection molded plastic panels having integrated connectors which are capable of being packaged and shipped in a knocked-down state and constructed to form an aesthetically pleasing trash container. The integrated connection of the side wall, cover and bottom panel components simplifies trash container construction. The panels are formed of injection molded plastic to interlock with one another without the need for separate metal fasteners or connectors. The system incorporates a minimum number of components by integrally forming the connectors into the injection molded panels which are snapped together to complete the assembly.

Owner:SUNCAST

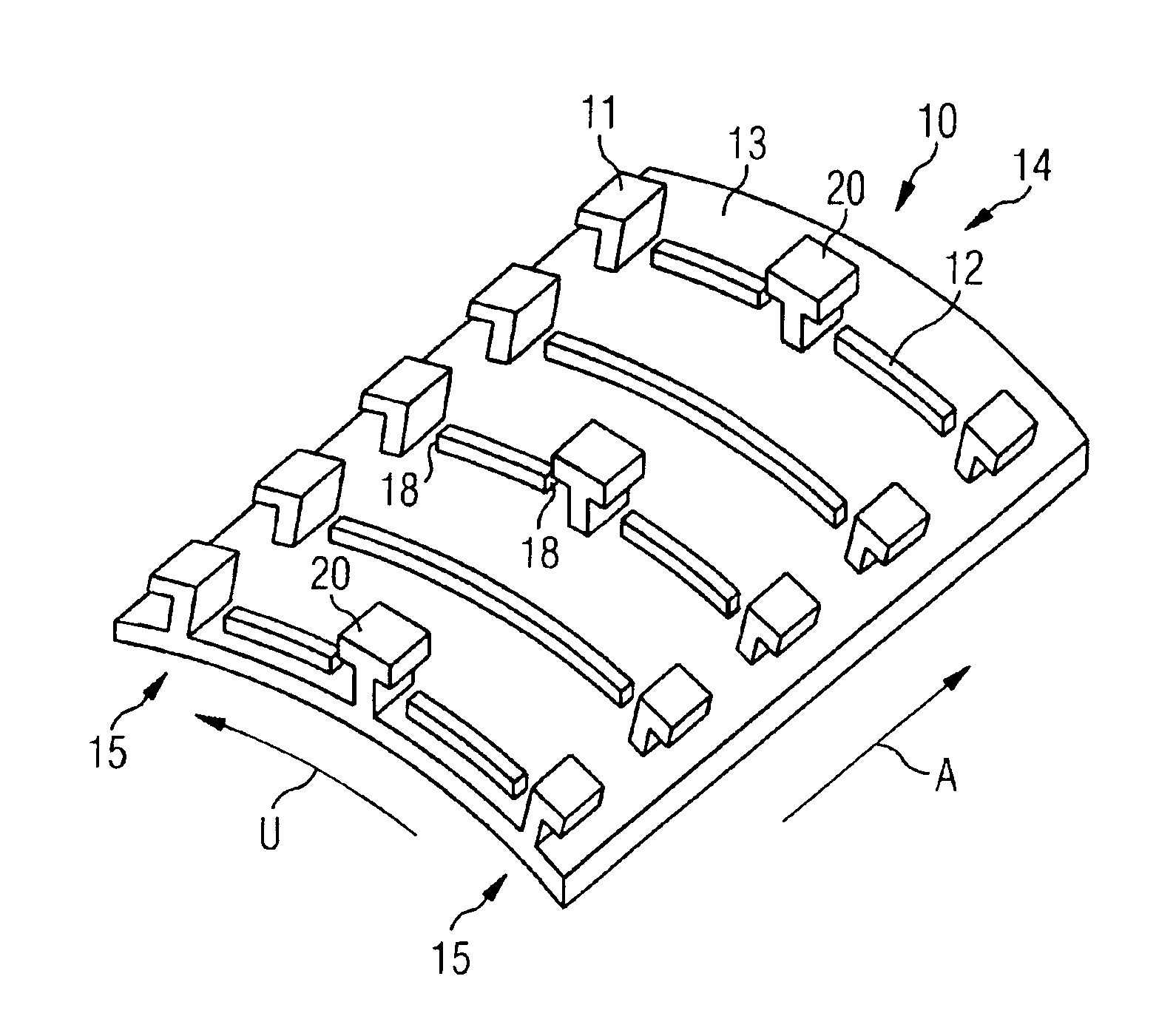

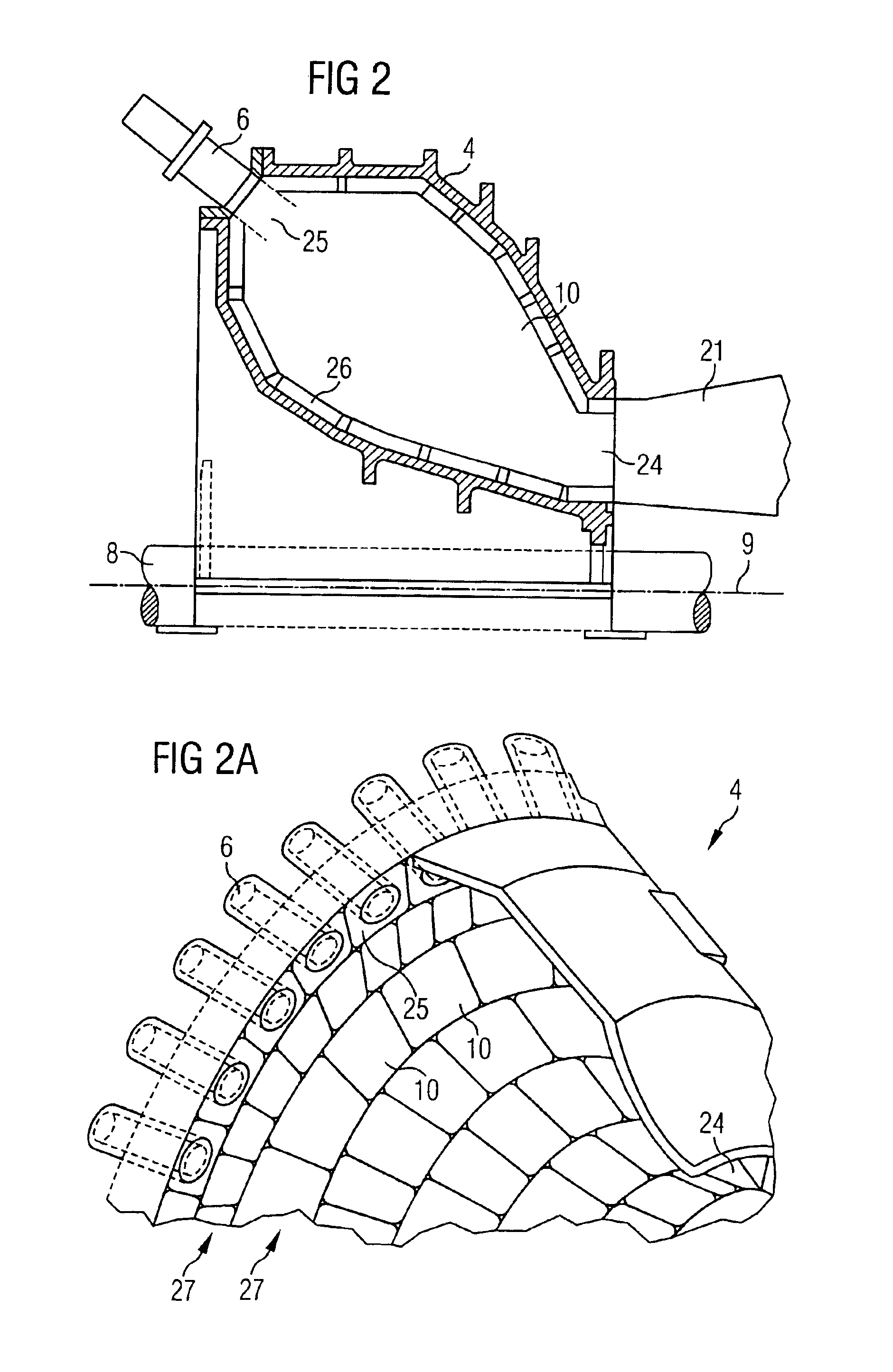

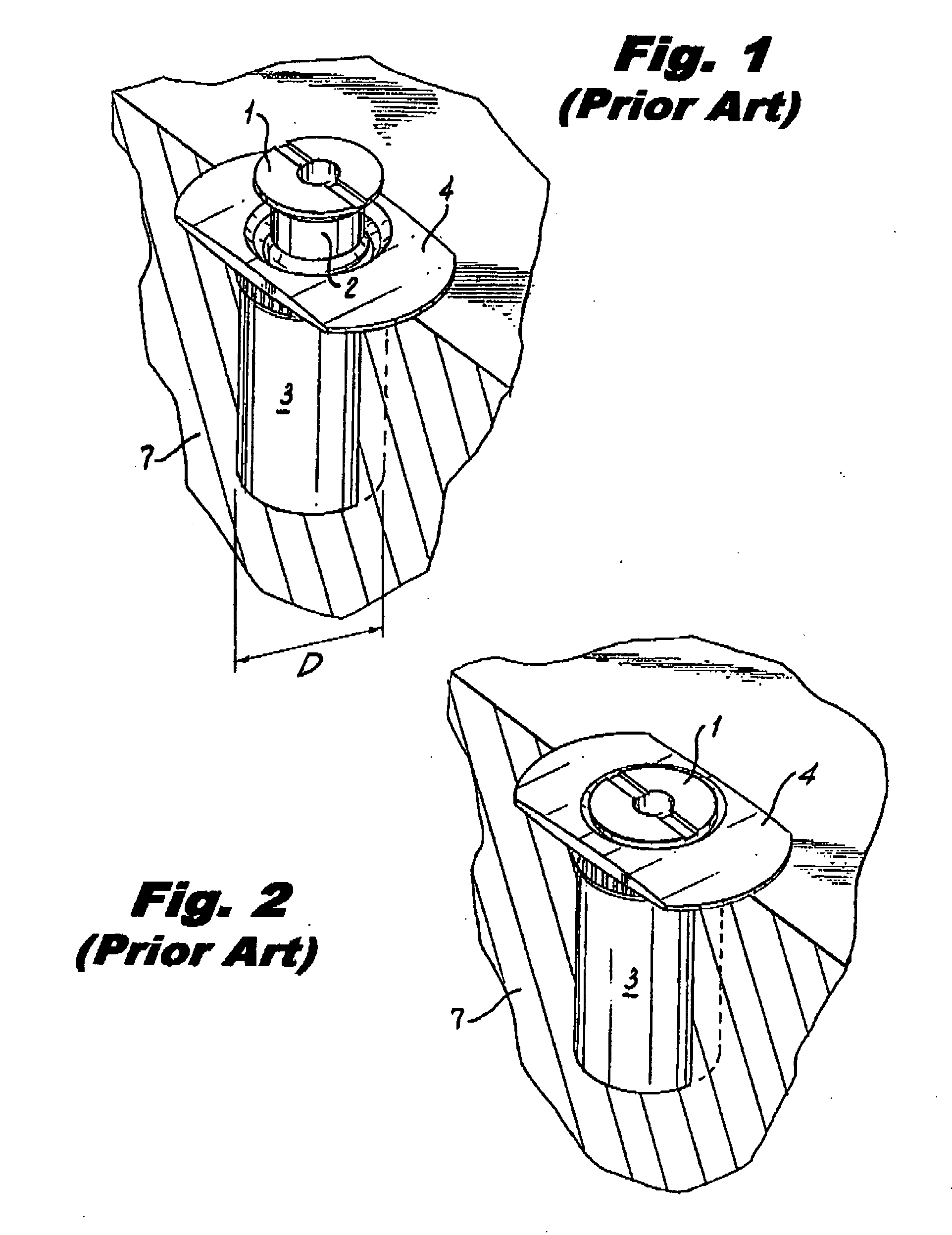

Annular combustion chambers for a gas turbine and gas turbine

ActiveUS6938424B2Increase rigidityEnsure rigidityContinuous combustion chamberGas turbine plantsEdge regionAerospace engineering

The invention relates to an annular combustion chamber for a gas turbine wherein the annular combustion chamber extends in an axial direction, encloses a combustor and has on its inside facing the combustor a bearing structure on which a lining element secured to this lines the annular combustion chamber. The object is to disclose an annular combustion chamber with a lining element that meets the mechanical requirements while at the same time taking account of the system's maintenance-friendliness. The object is achieved in that the annular combustion chamber has a lining element wherein on the rear side facing away from the combustor of two edge areas on the lining element a plurality of interlocking means are located which have a hook width and wherein the lining element is secured to the corresponding bearing structure such that in order to release the lining element from the bearing structure the lining element is moved by the extent of the hook width of the interlocking means in the axial direction.

Owner:SIEMENS AG

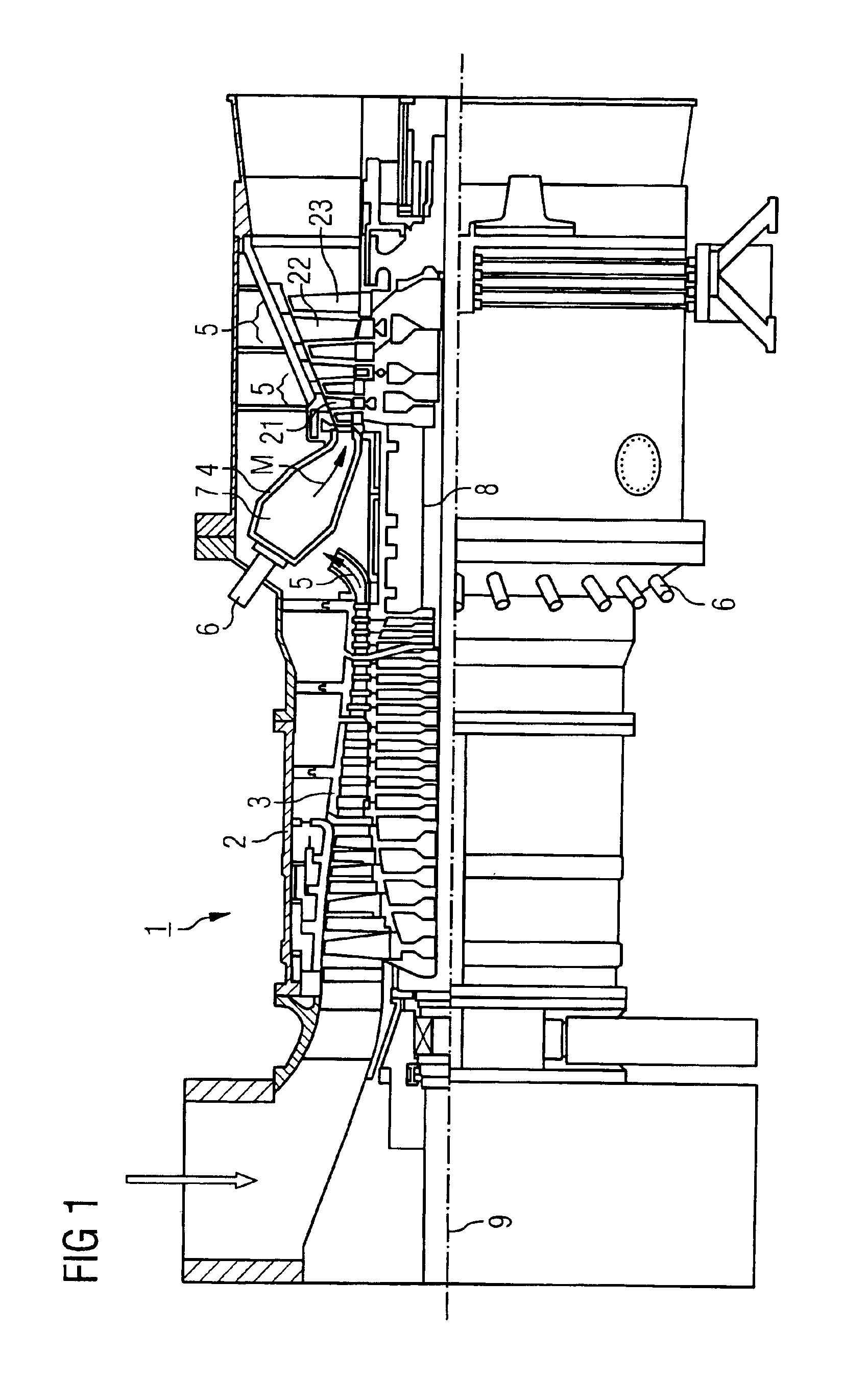

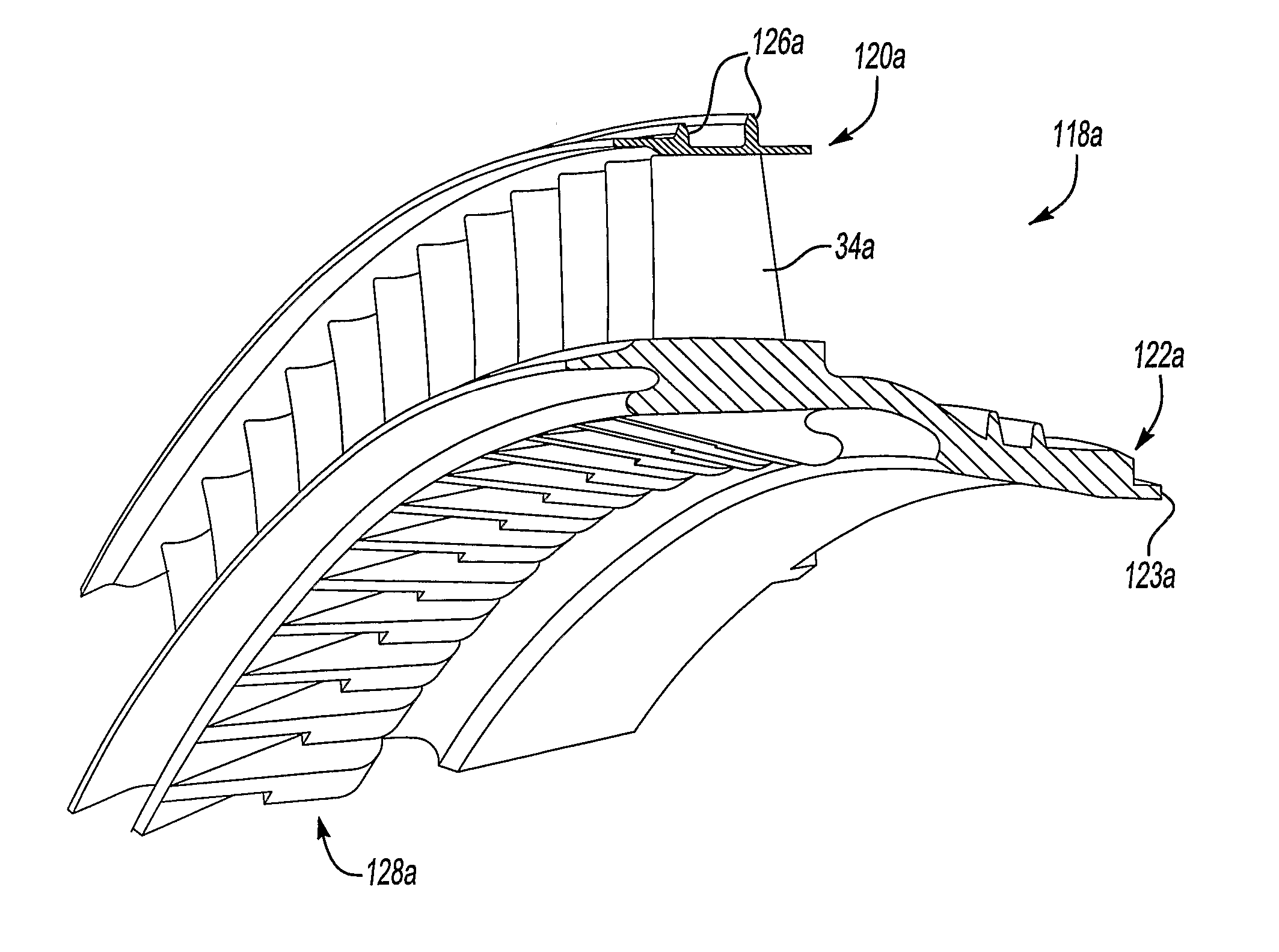

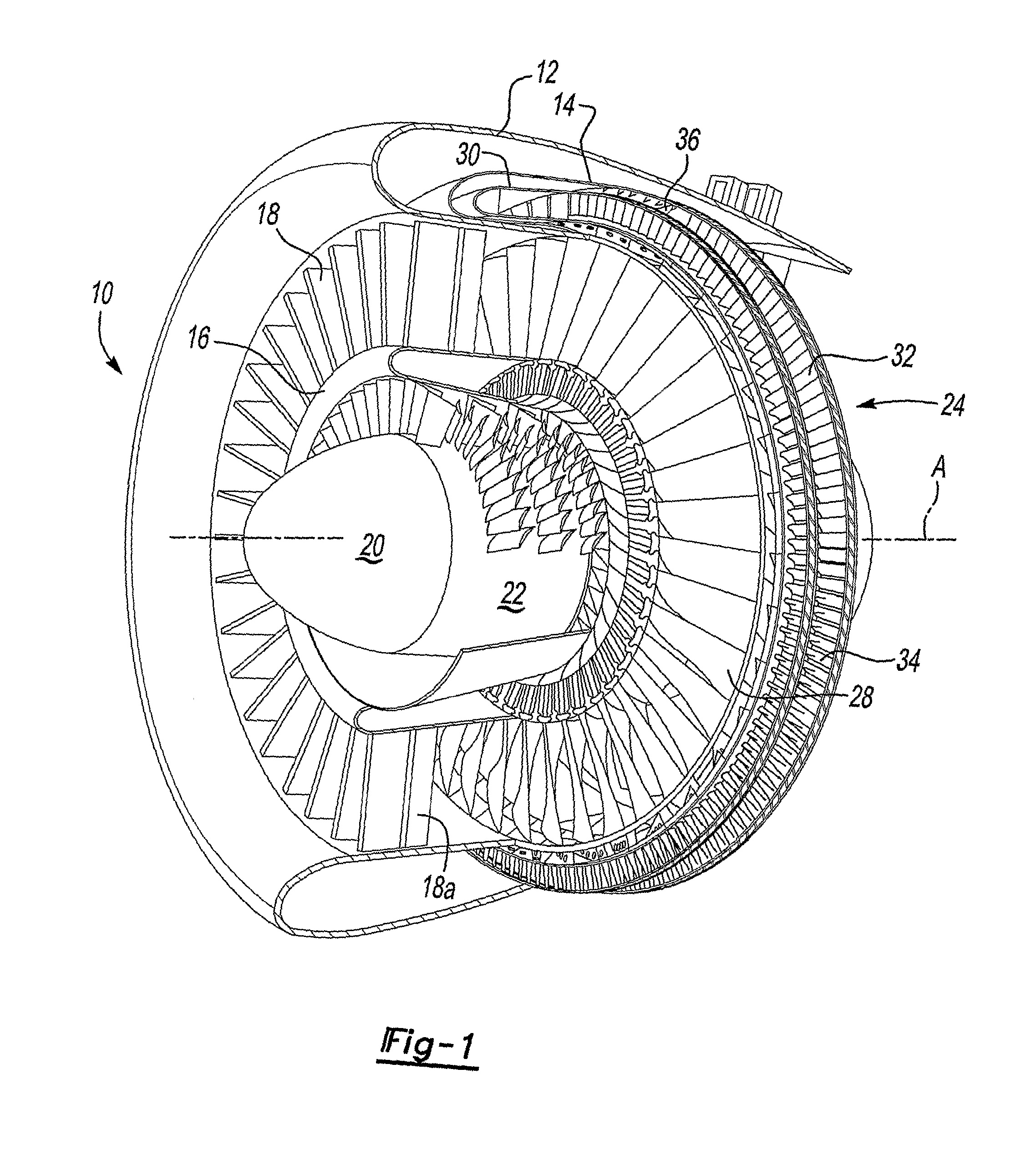

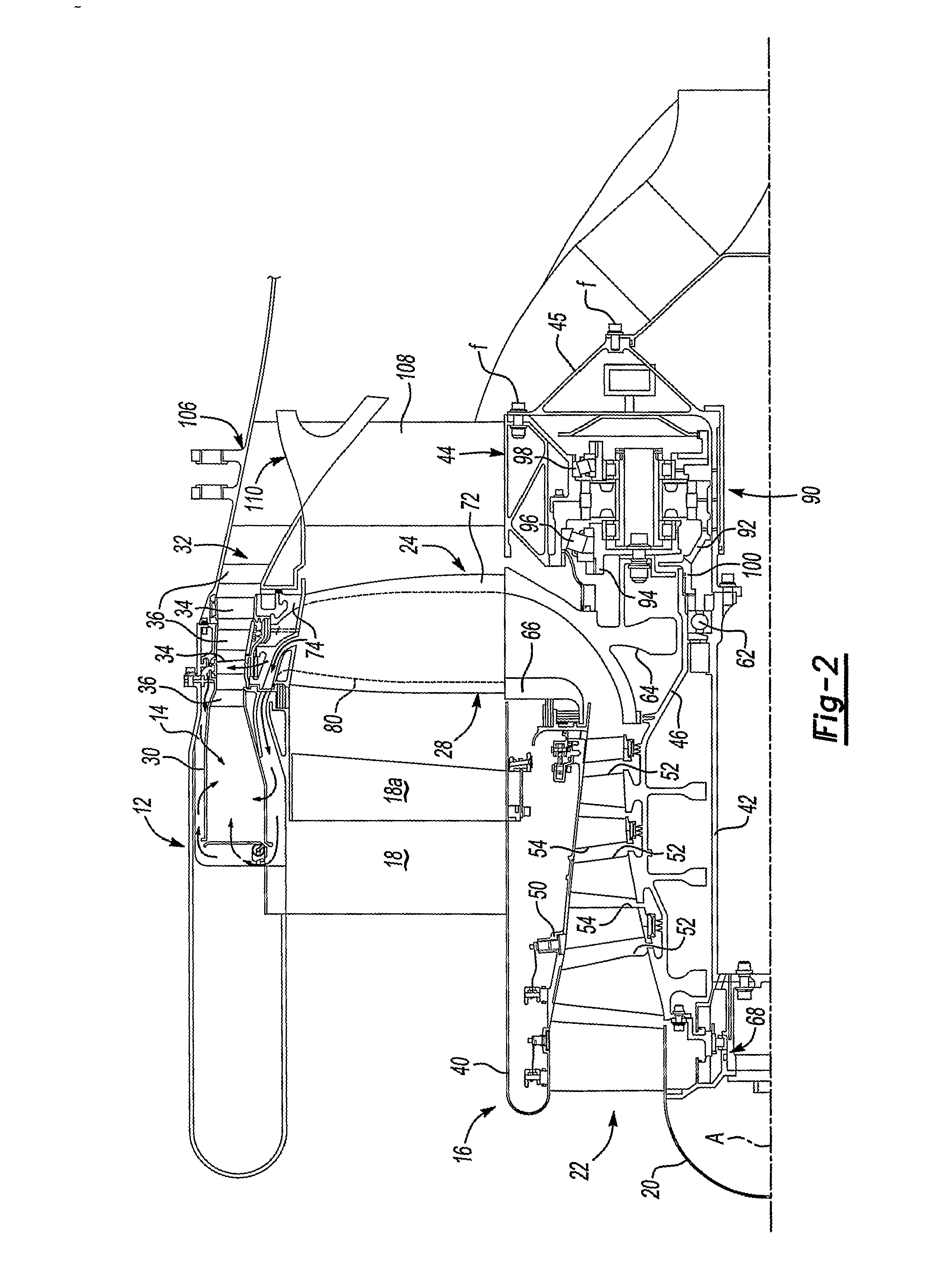

Tip Turbine Engine Comprising Turbine Blade Clusters and Method of Assembly

ActiveUS20070292270A1Increase efficiencyIncrease rigidityPropellersRotary propellersTurbine bladeTurbine rotor

A tip turbine engine comprises a fan-turbine rotor assembly that includes one or more turbine ring rotors. Each turbine ring is assembled from a multitude of turbine blade clusters. Assembly of a multitude of turbine blade clusters to a diffuser includes axial installation and radial rotation. The clusters are axially installed, then rotated toward a radial stop in a direction which will maintain each cluster against the radial stop during operation of the fan-turbine rotor assembly. A multitude of turbine rotor ring stages may also be locked together to future increase the rigidity of the turbine

Owner:RAYTHEON TECH CORP

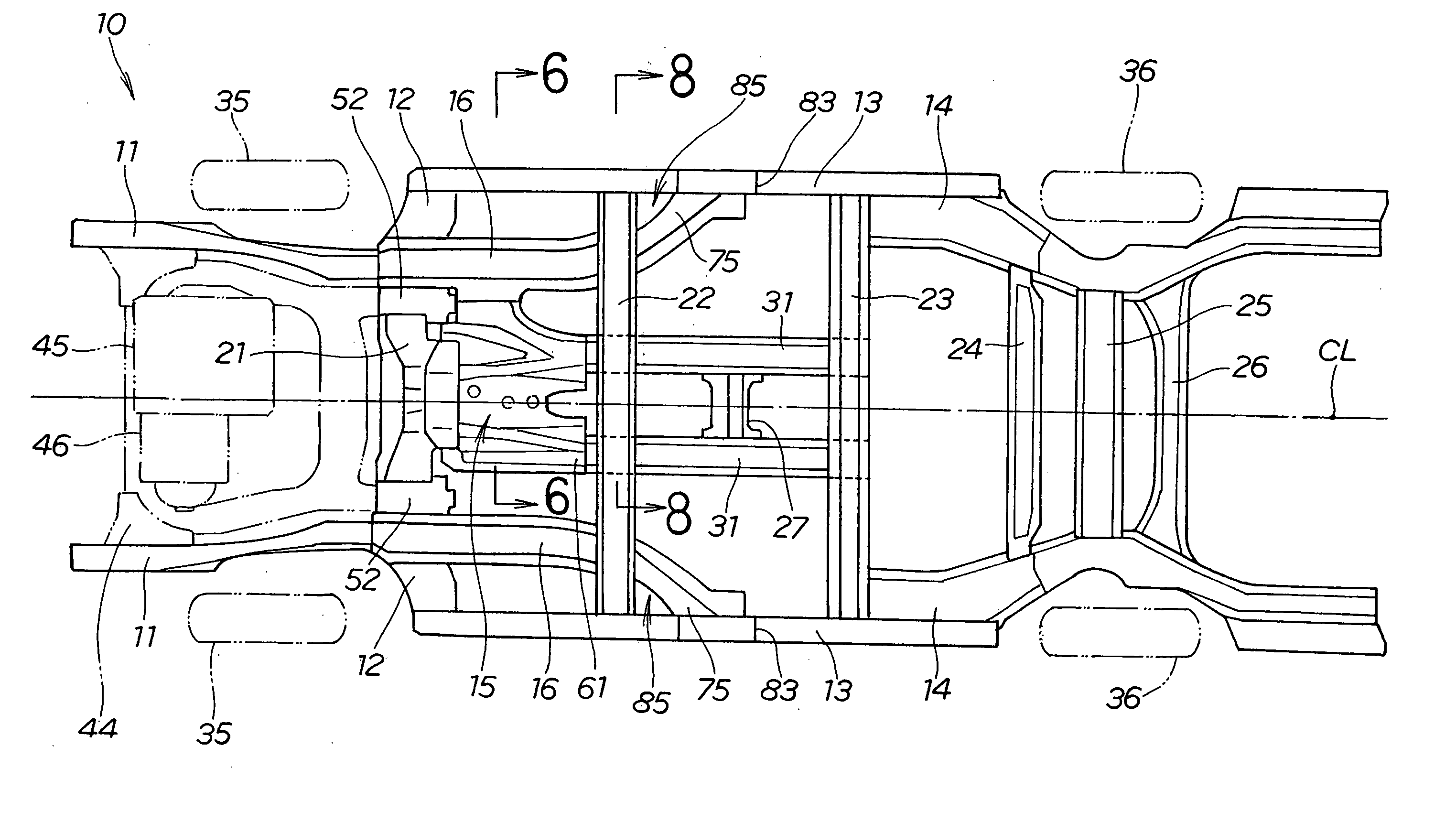

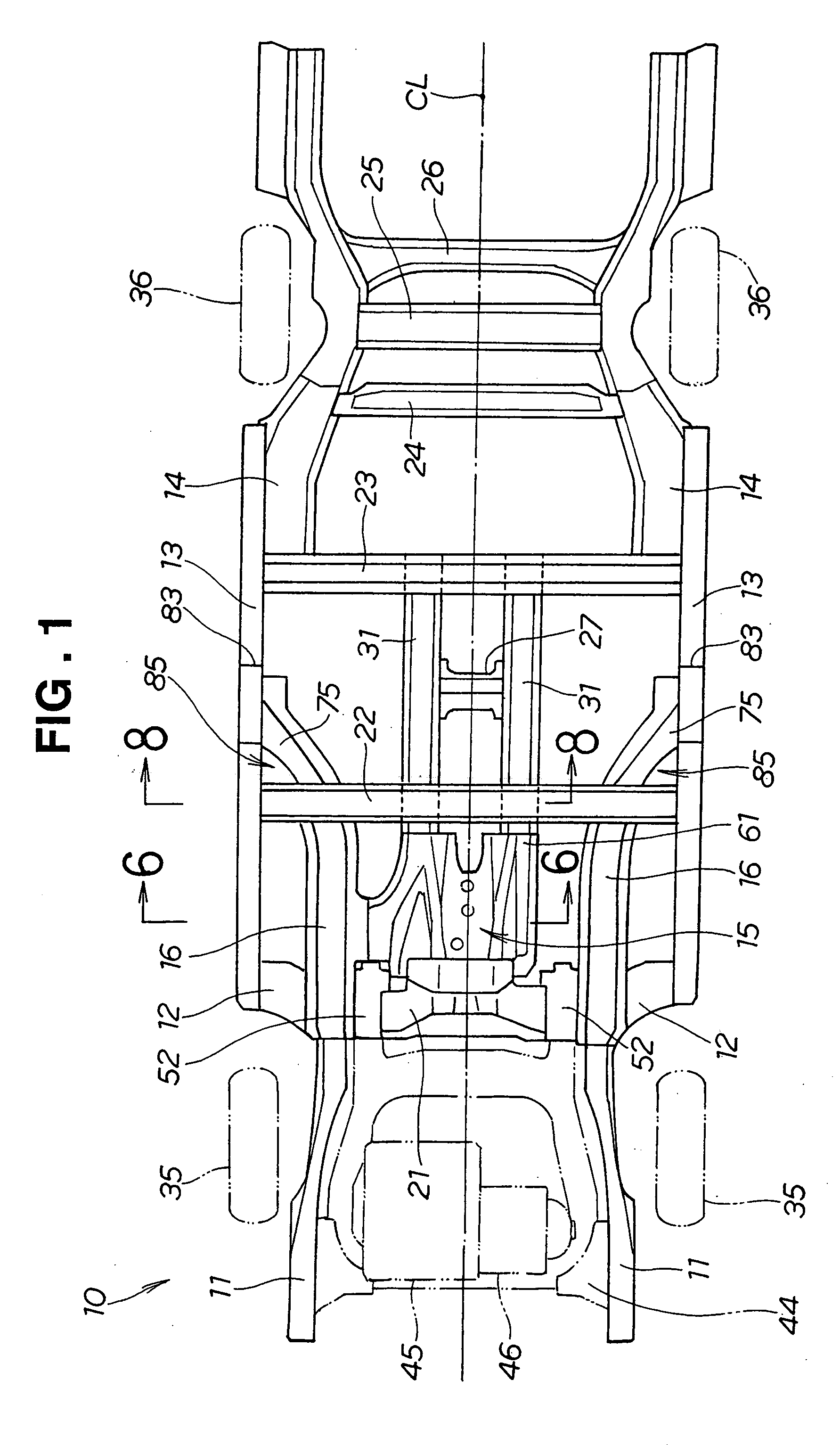

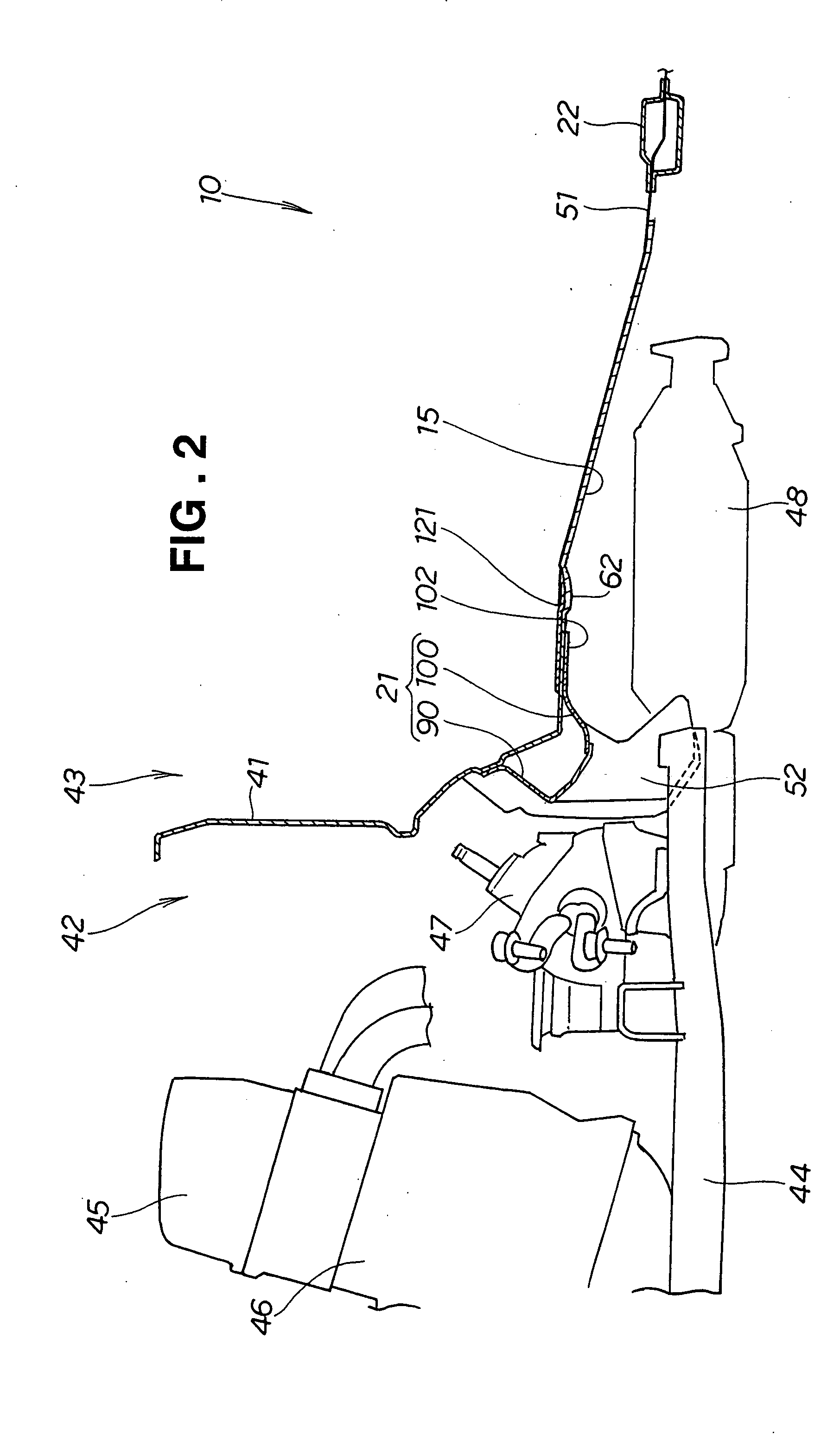

Vehicle front body structure

InactiveUS20050082876A1Improve performanceIncrease rigidityVehicle seatsUnderstructuresAutomotive engineeringEngineering

A front part structure of a vehicle body for efficiently absorbing collision energy acting from the front of the vehicle body is provided. The front part structure of the vehicle body includes right and left front side members extending longitudinally of the vehicle body within an engine compartment separated by a dashboard. A crossmember is attached to the dashboard and extended between the right and left front side members. A floor tunnel extending longitudinally of the vehicle body is joined to a rear end portion of an extension of the crossmember. Collision energy acting from the front of the vehicle body is transmitted from the front side members to the crossmember, and then is transmitted through the extension of the crossmember to the floor tunnel and dispersed throughout the vehicle body.

Owner:HONDA MOTOR CO LTD

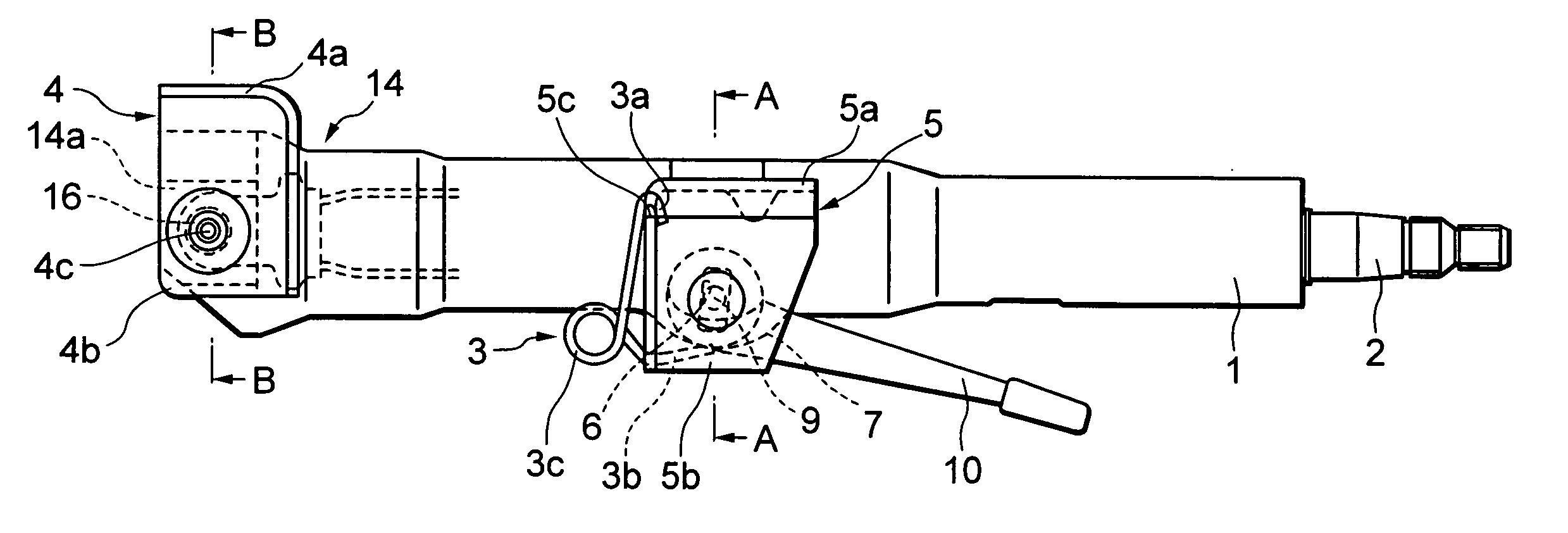

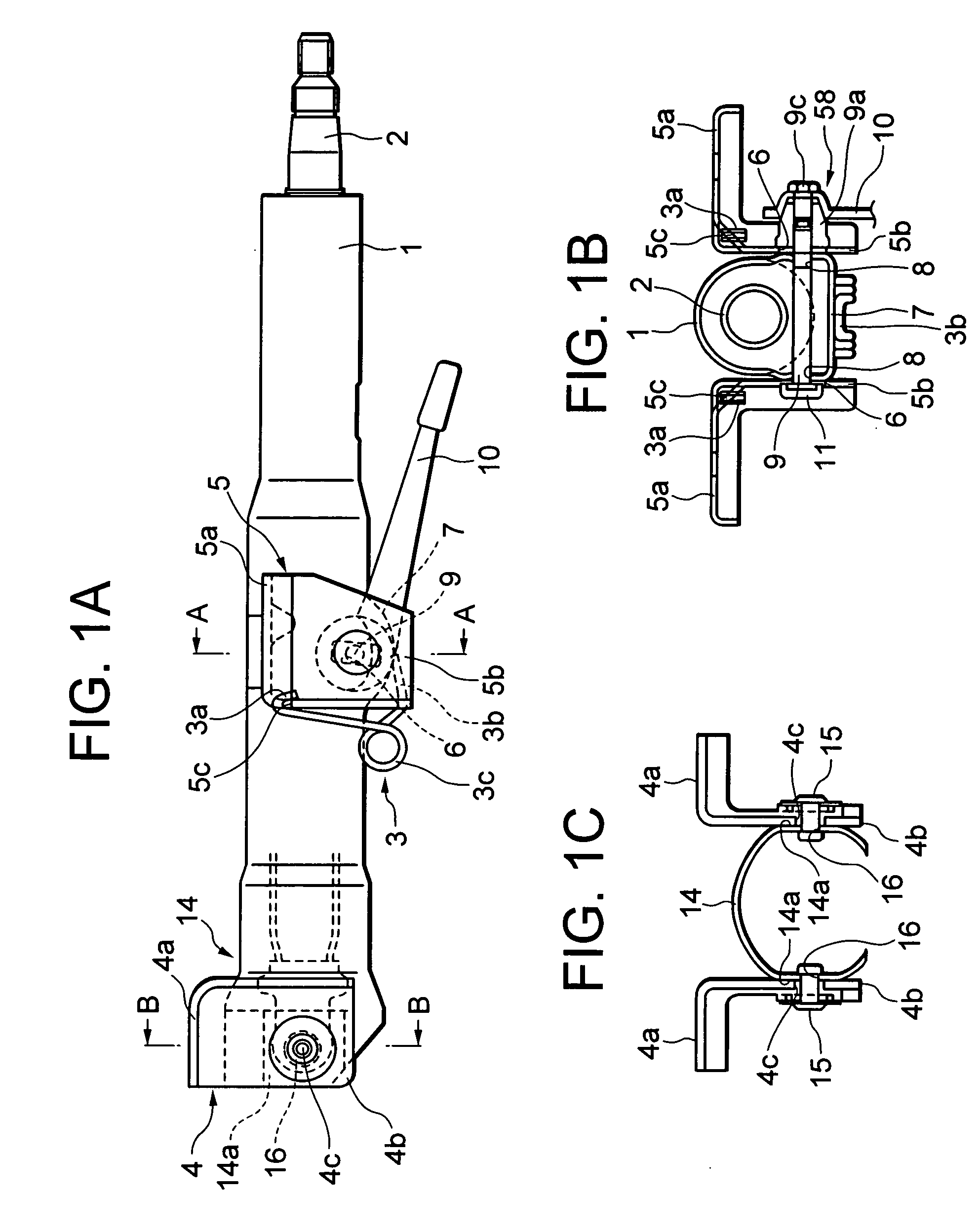

Steering device for motor vehicle

A steering apparatus for a vehicle has a steering column rotatably supporting a steering shaft, a first support member held between opposed flat plate portions of an upper bracket and supporting the steering column, a second support member held between opposed flat plate portions of a lower bracket and supporting the steering column, a first support mechanism for supporting the steering column on the upper bracket, and a second support mechanism for supporting the steering column on the lower bracket, wherein the steering column, the first support member and the second support member are integrally formed, the first support member is integrally formed with a first swelling portion having a pair of side portions that respectively press-abut on a pair of opposed flat plate portions of the upper bracket, and the second support member is integrally formed with a second swelling portion having a pair of side portions that respectively press-abut on a pair of opposed flat plate portions of the lower bracket.

Owner:NSK LTD

Container box for framed pellicle

InactiveUS20060213797A1Reduce likelihoodIncrease rigidityPhotomechanical apparatusSemiconductor/solid-state device manufacturingSurface resistivityPhotolithography

There is provided a pellicle container for use in photolithography, with which no dust particles are deposited onto the pellicle contained therein, and contamination of the pellicle can be prevented and good condition is ensured. The present invention provides a pellicle container consisting of a container base on which a pellicle is mounted, and a covering body that covers the pellicle and latches with the container base by engagement together with the container base along the peripheral edges, wherein the pellicle is supported by inserting a frame supporting pin in the opening of a sleeve provided on the outside surface of the pellicle frame. Preferably, the container base is made from a plastic resin and a metal component is joined to the container base; the metal component fixedly connected to the container base is mechanically connected to a positioning component that positions the frame supporting pin that supports the pellicle; and an elastic member is disposed on the point of contact between the frame supporting pin that supports the pellicle and the pellicle frame. It is even more preferable that the container boase and the Icovering body are made of a plastic resin, and these have antistatic performance such that their surface resistivity is no higher than 1×1012 ohms.

Owner:SHIN ETSU CHEM IND CO LTD

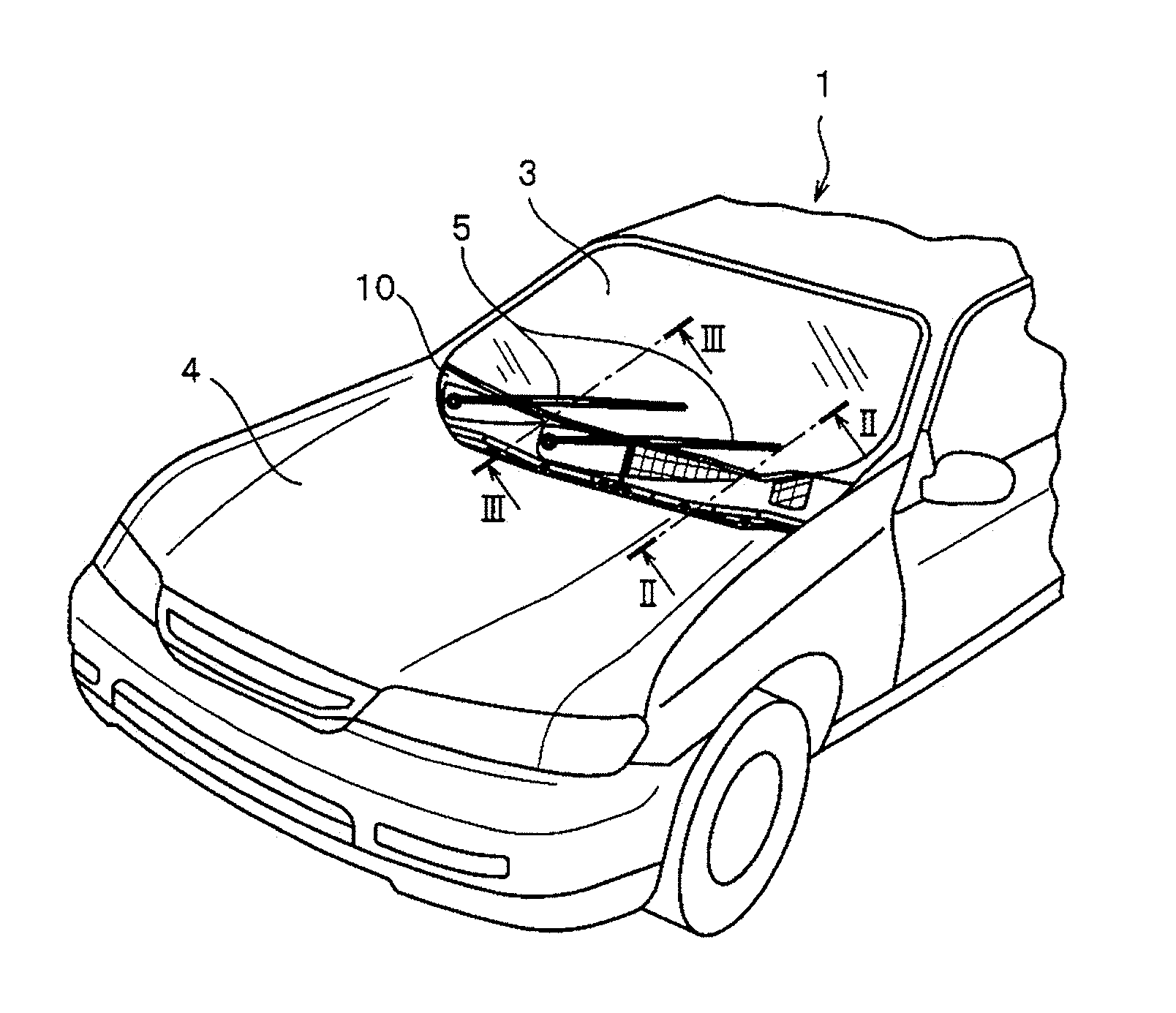

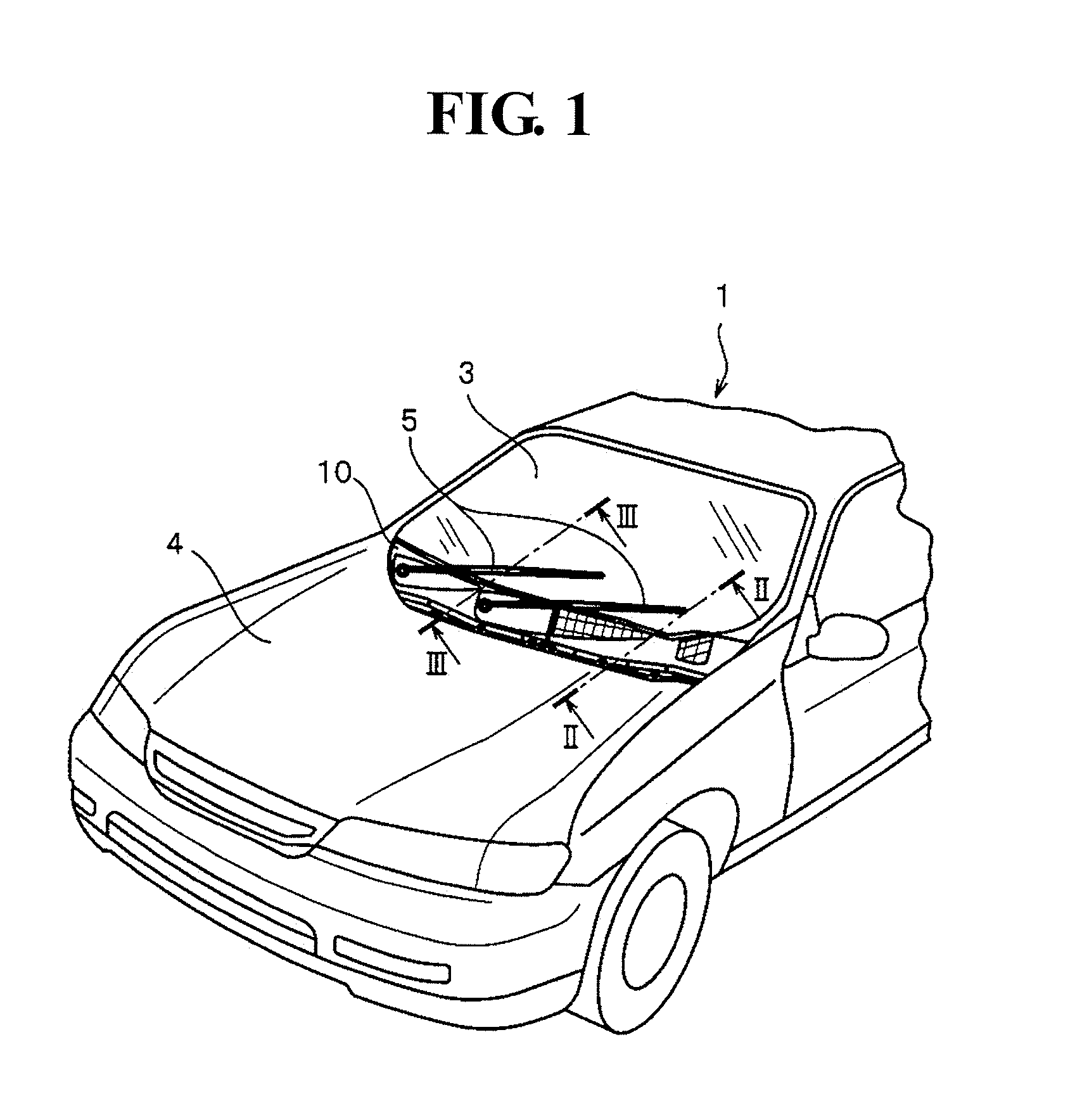

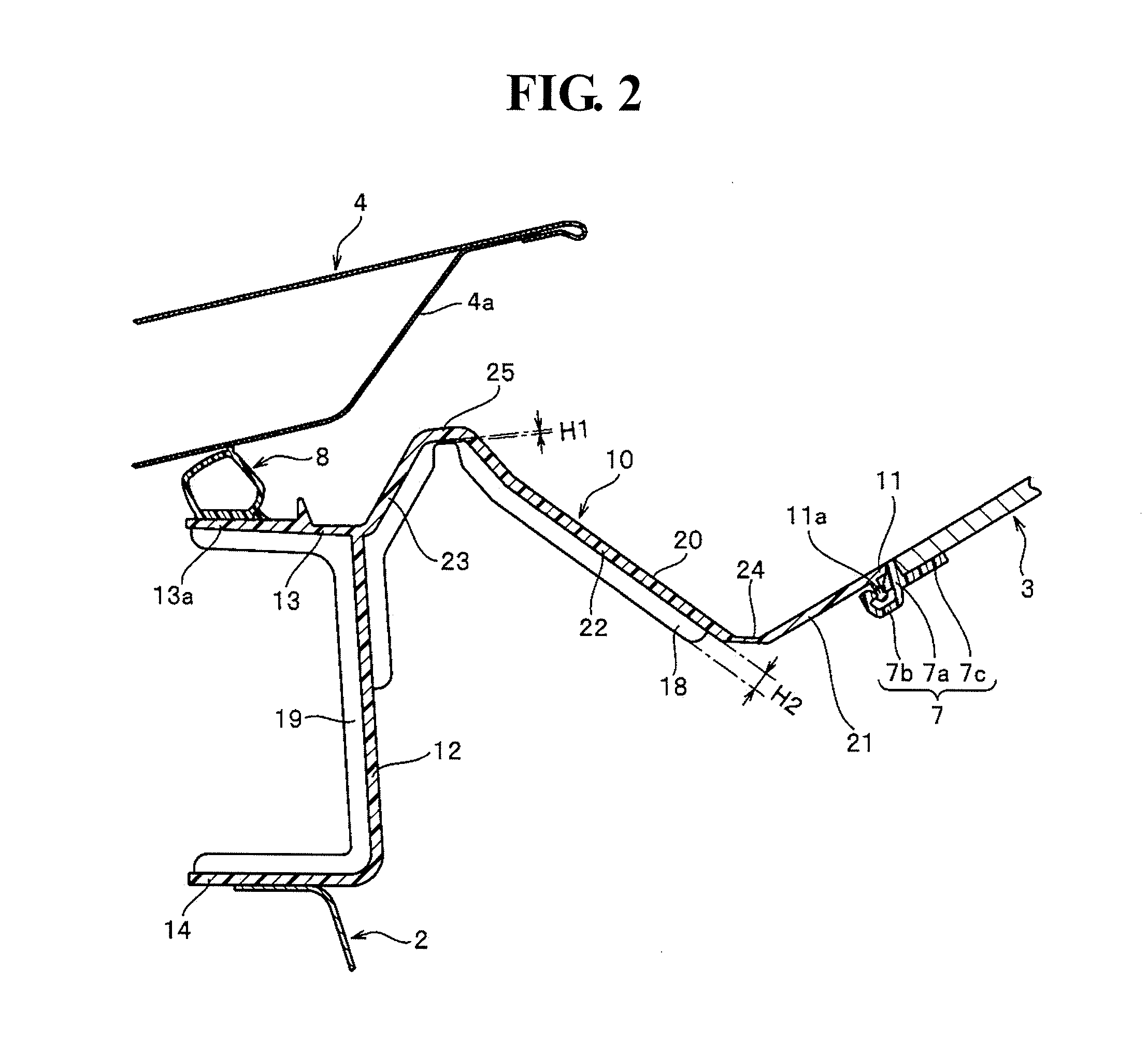

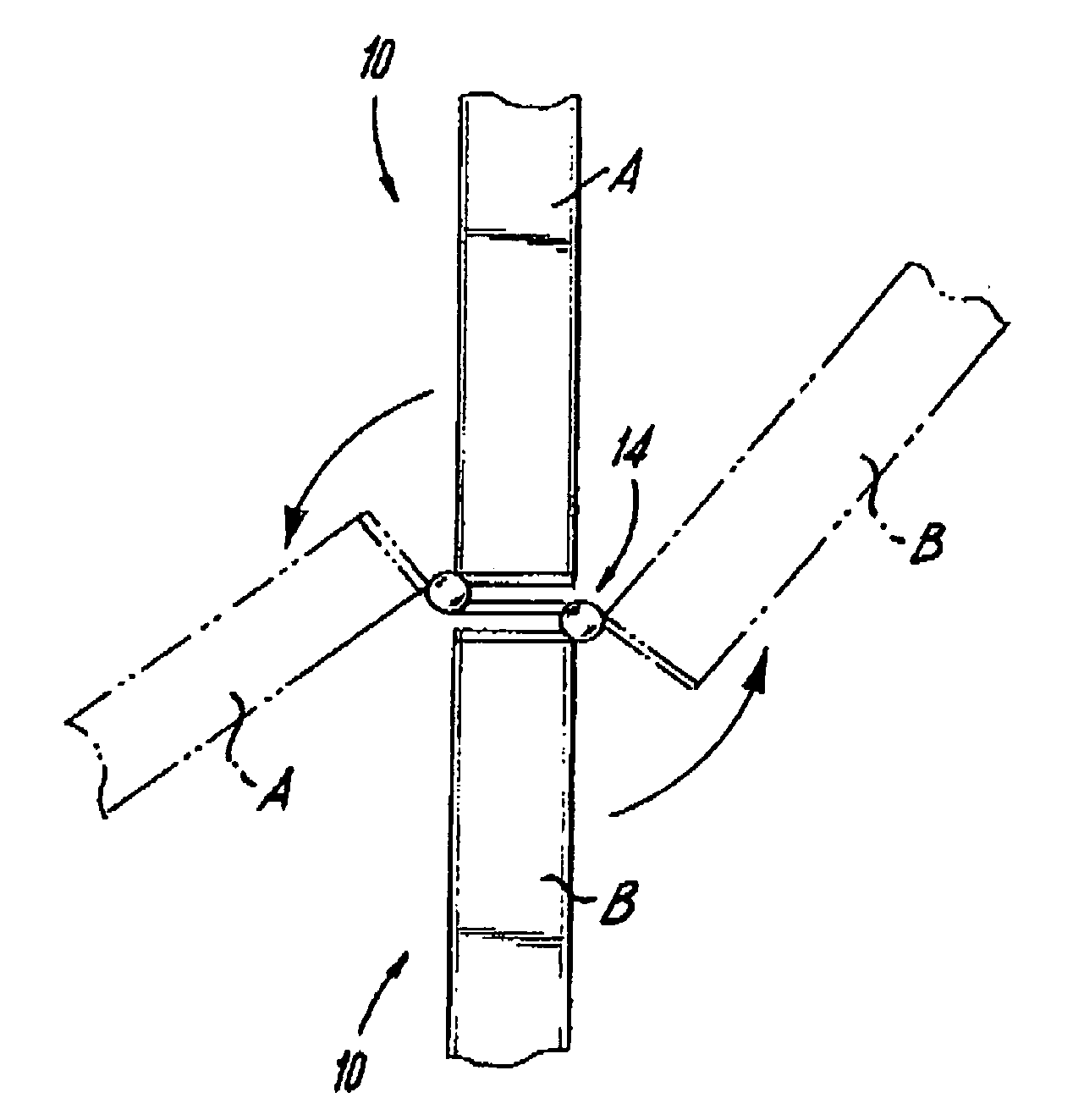

Cowl top cover

ActiveUS20140319878A1Easily absorb dimension errorIncrease rigidityVehicle heating/cooling devicesSuperstructure subunitsEngineeringCowling

A cowl top cover of the present invention provides that hardly applies influence when a dimension error occurs to a component, on sealability between the cowl top cover and a bonnet hood, a performance of a washer nozzle. The cowl top cover of the present invention includes at least one bent part that is formed to be bent in a mountain-like and a valley-like shape in a vehicle height direction as viewed in a cross section orthogonal to a vehicle widthwise direction, and the bent part includes a flexural deformation structure with which it is possible to allow a locally flexural deformation in a vehicle lengthwise direction in the bent part and to enable expansion and contraction of a distance in the vehicle lengthwise direction between a locking pawl part disposed at first end of the cowl top cover and a seal member fixation part disposed at second end of the cowl top cover.

Owner:NIHON PLAST CO LTD

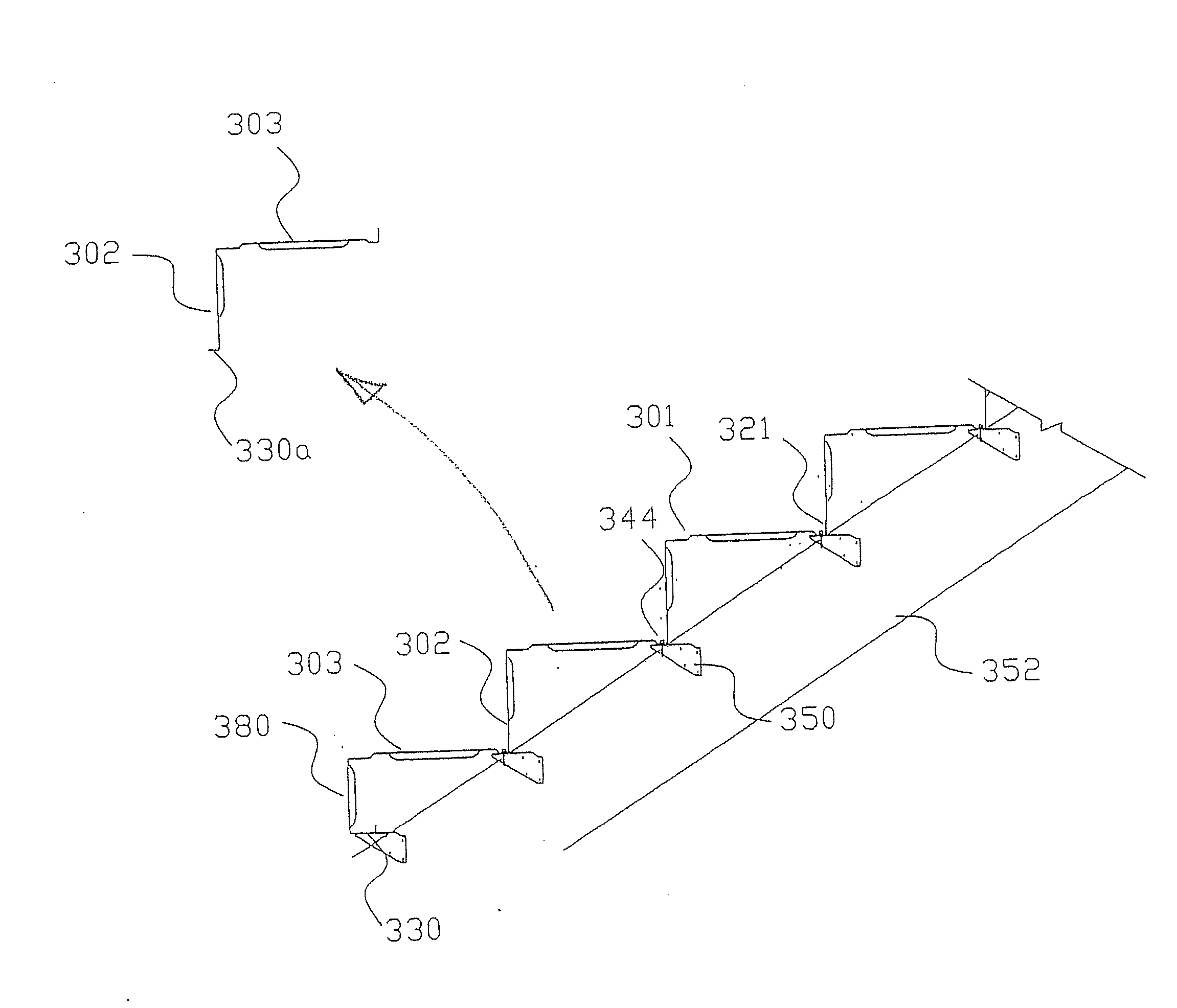

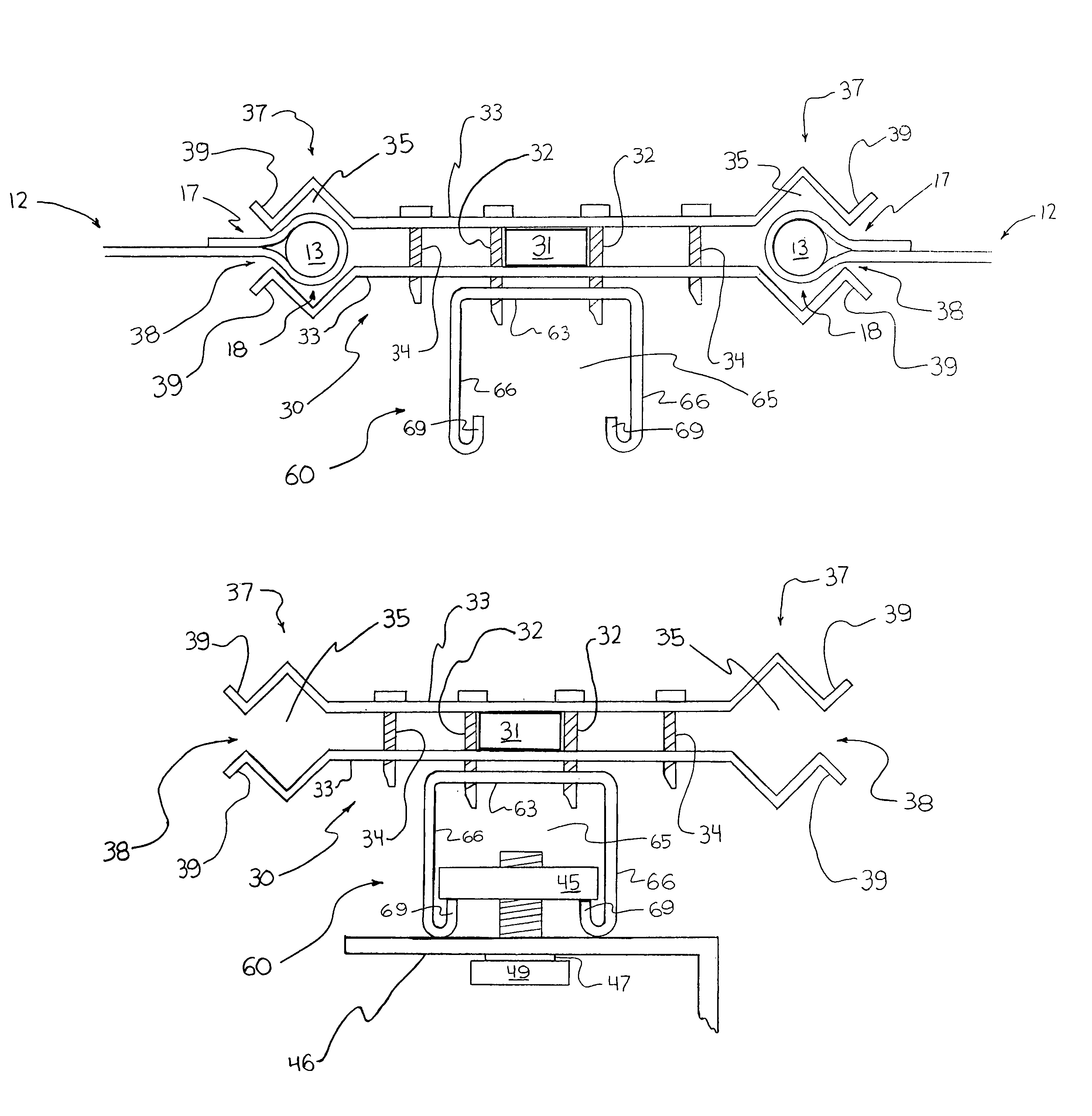

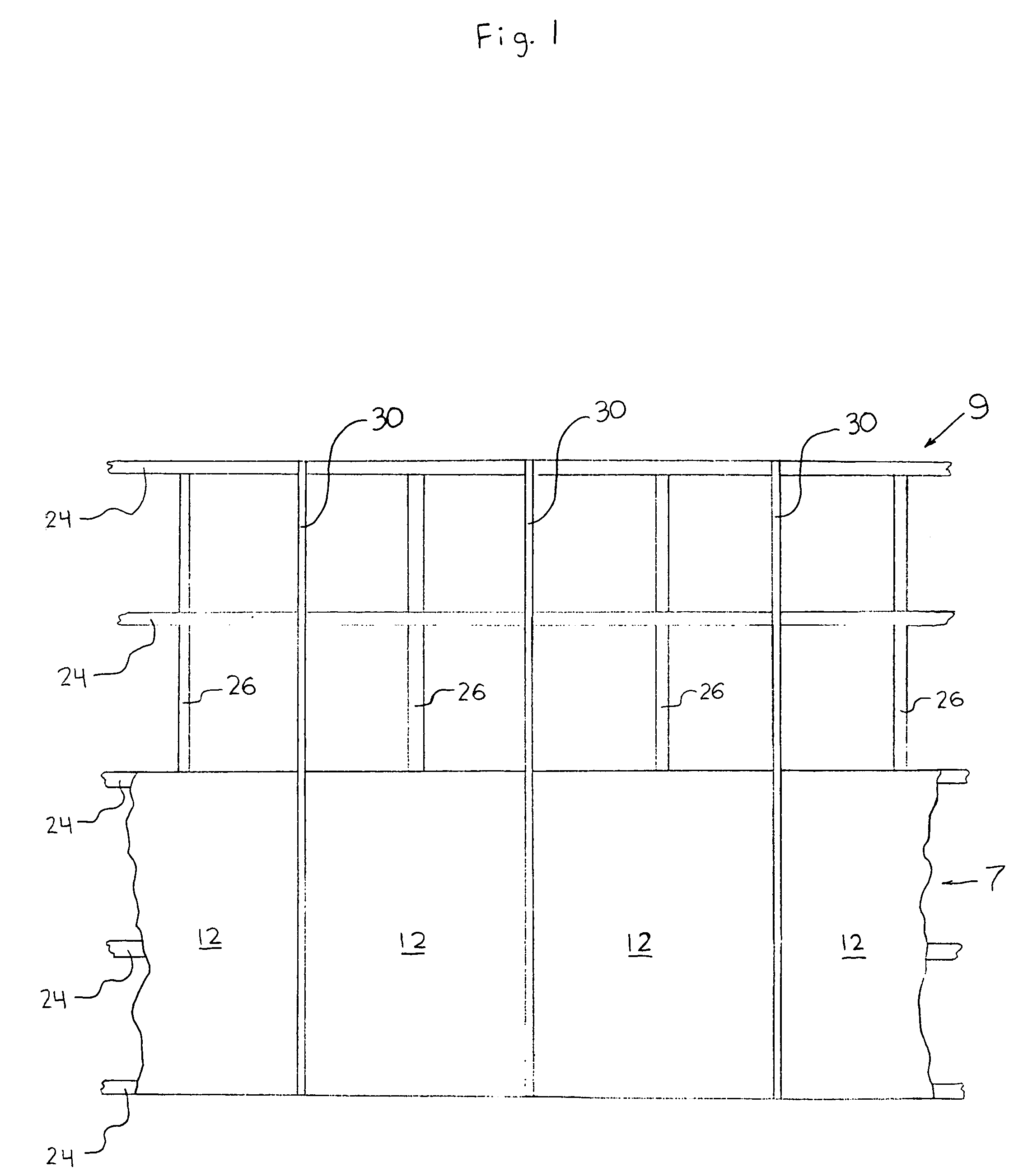

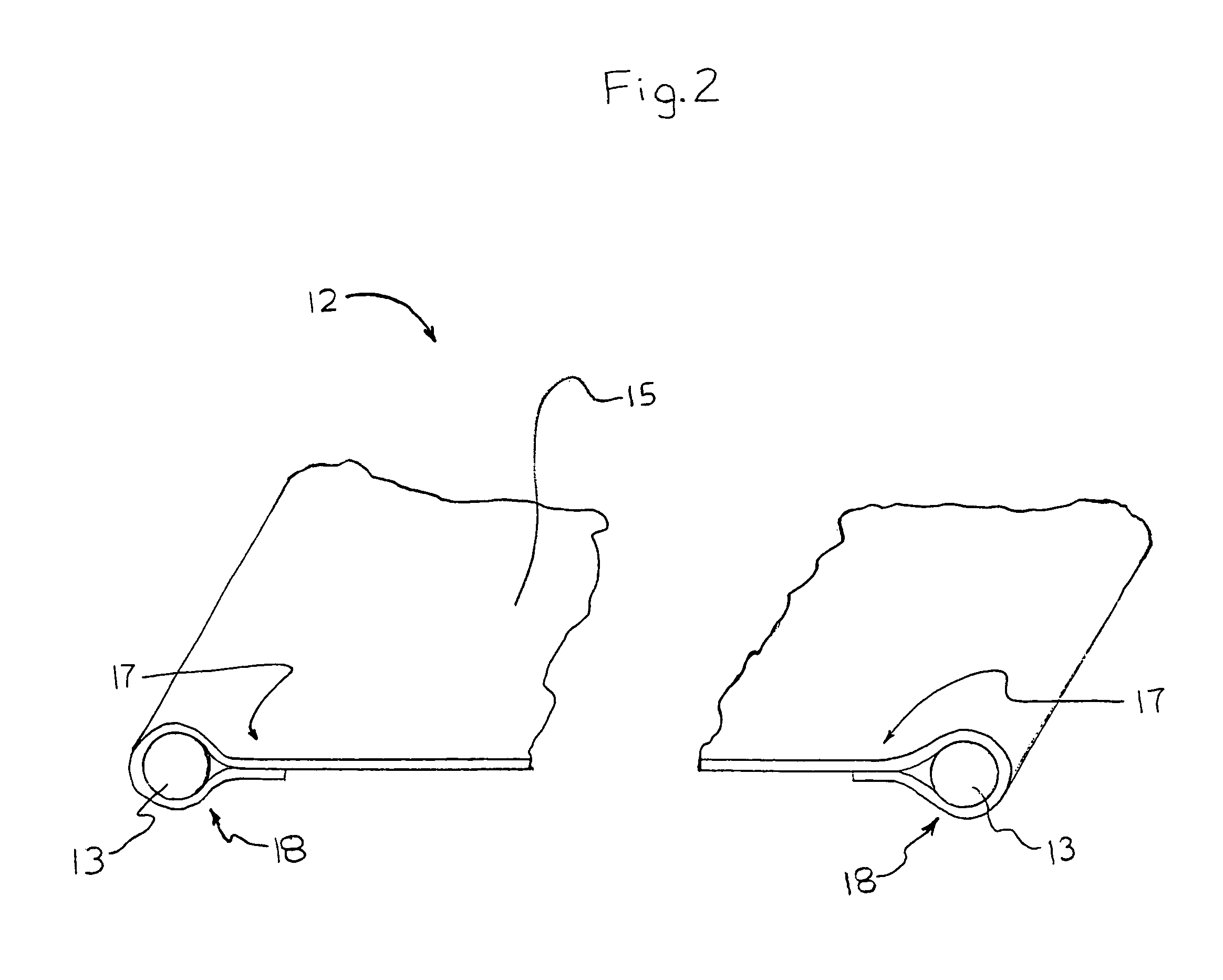

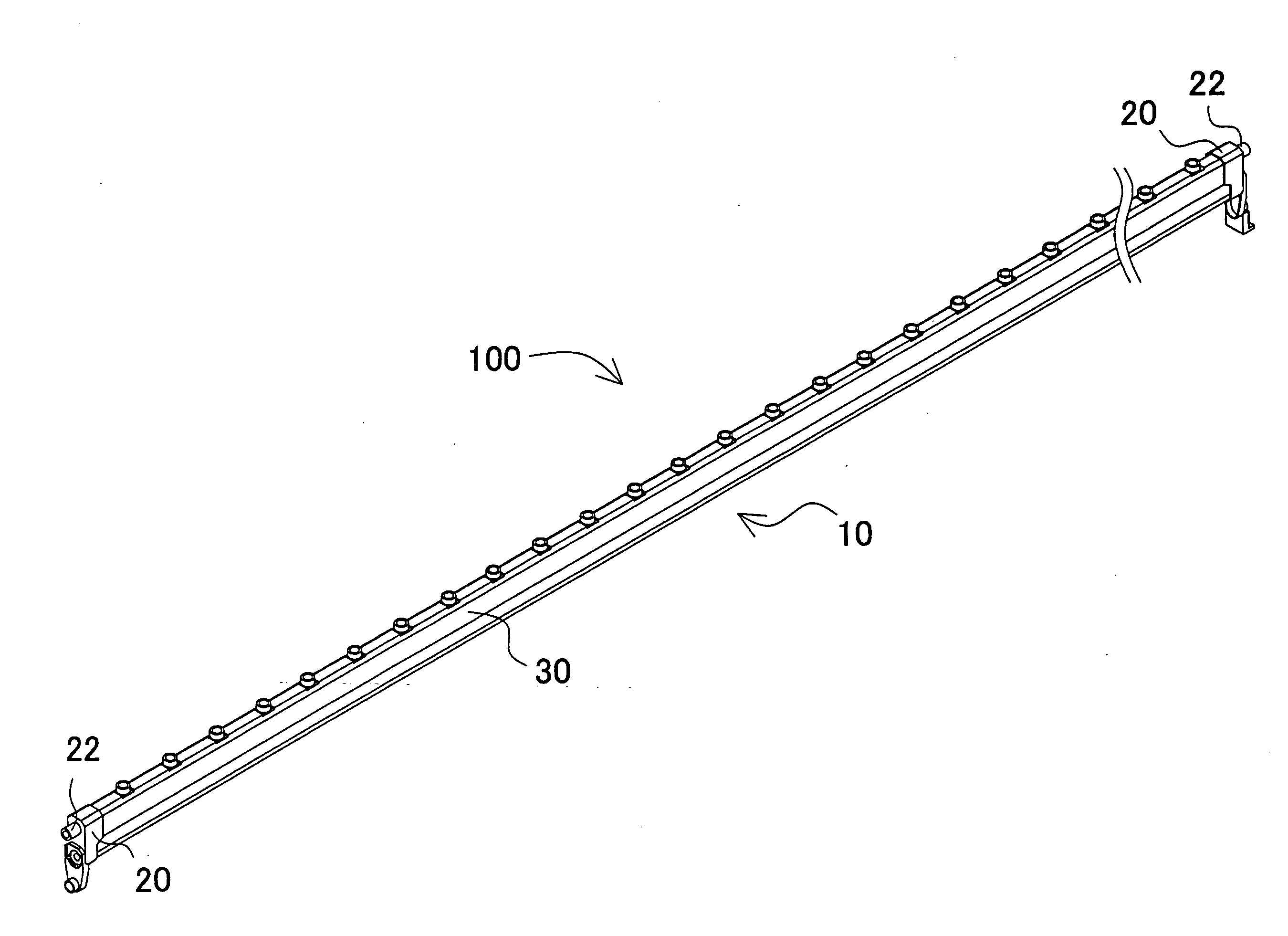

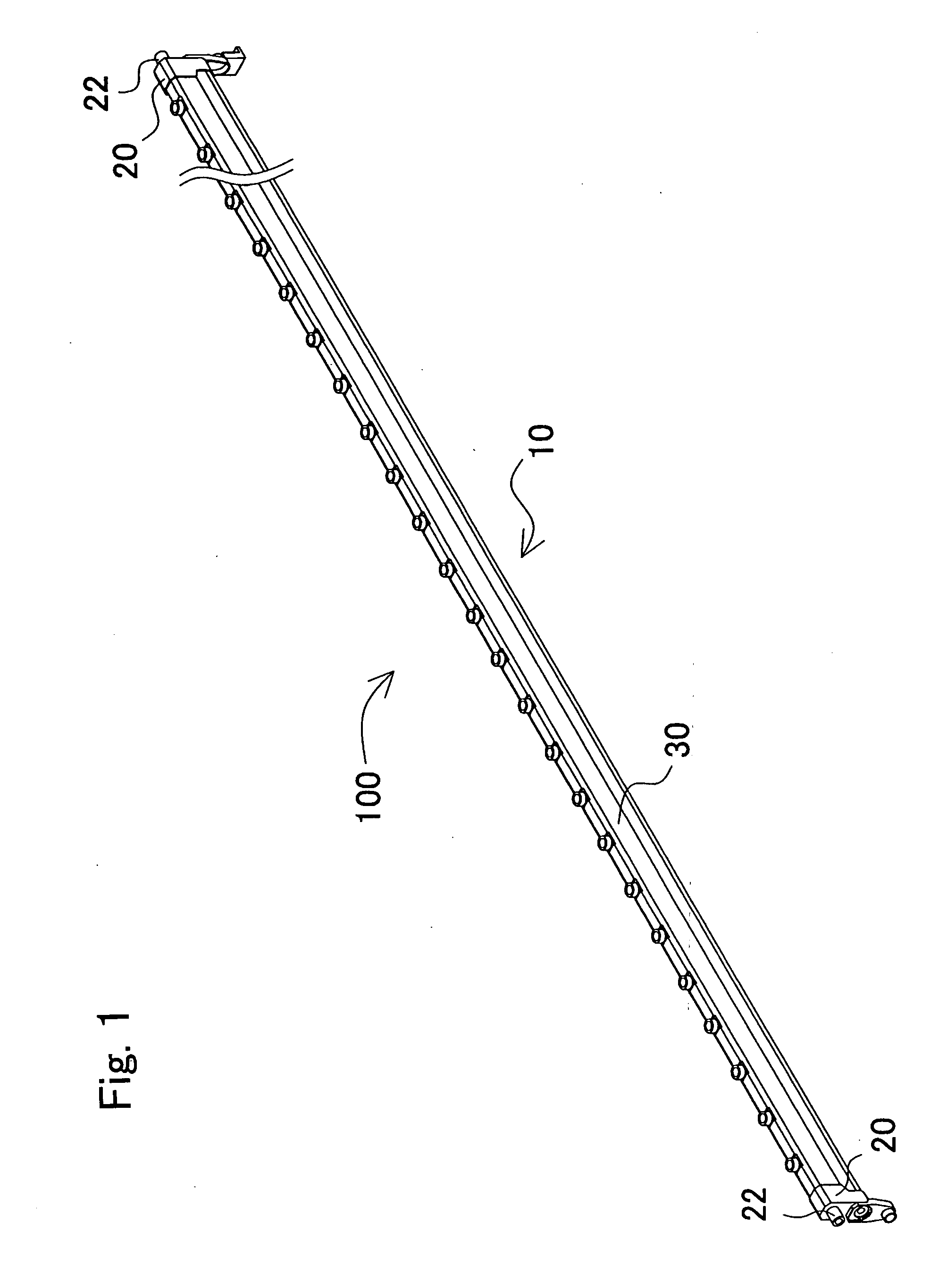

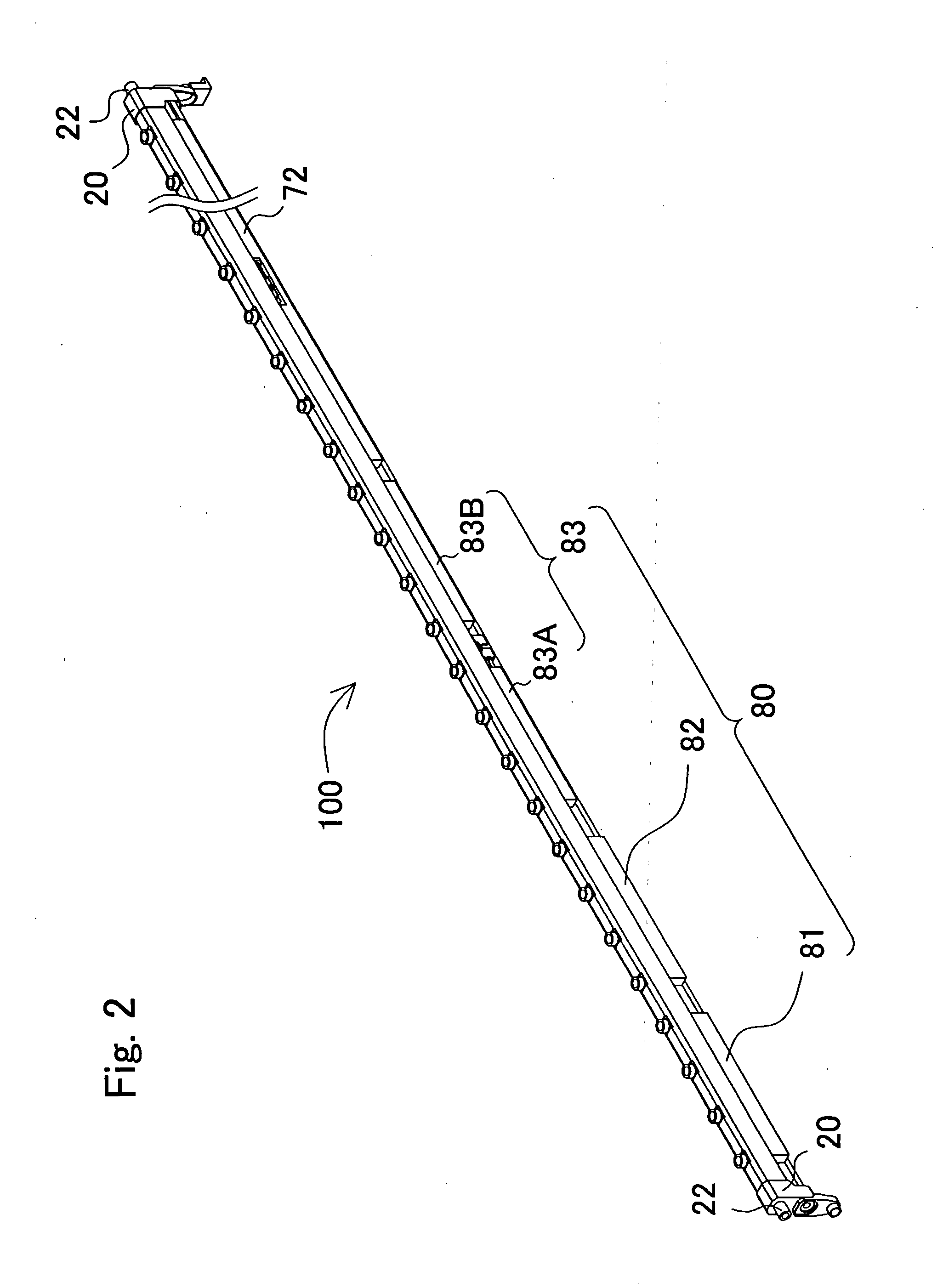

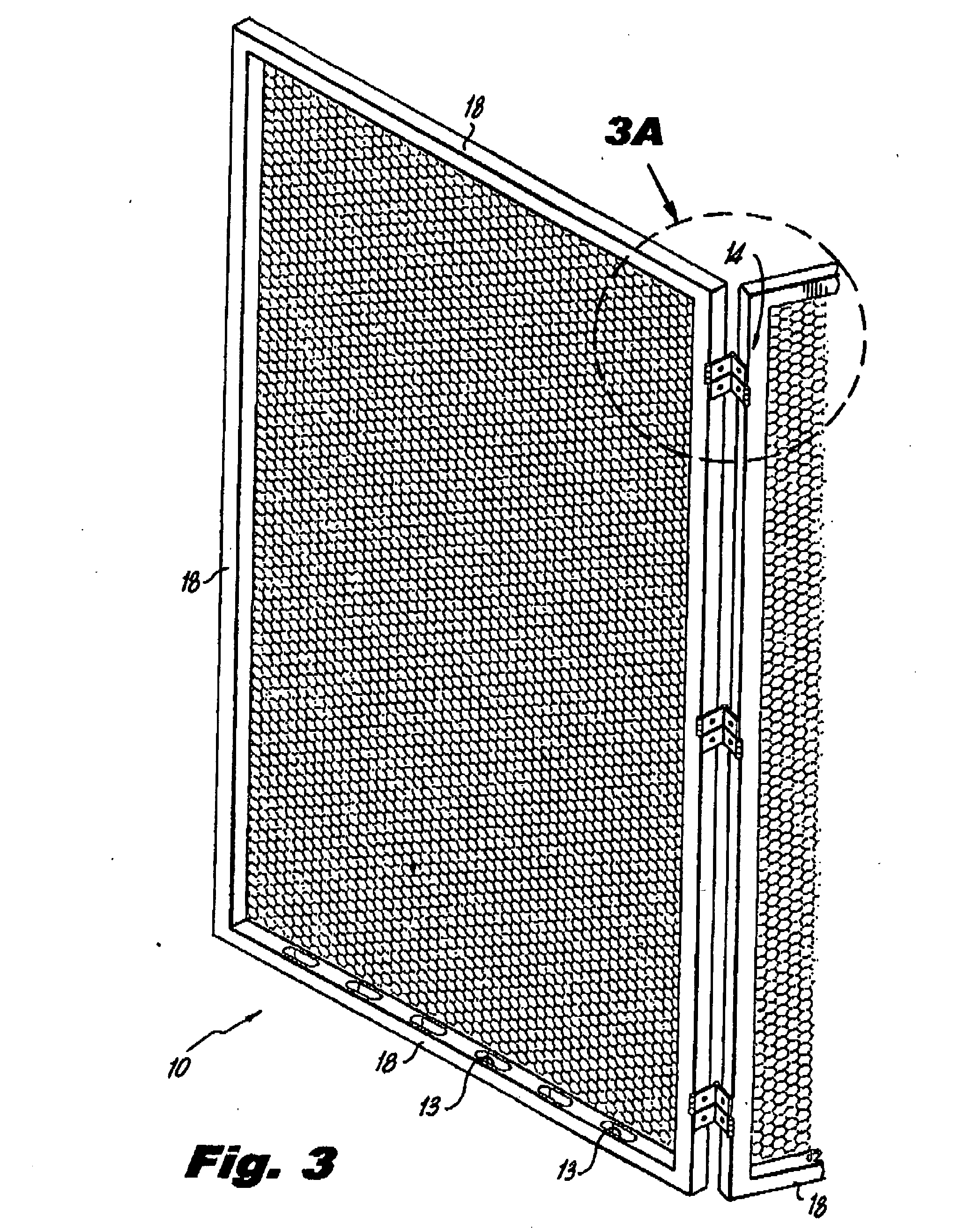

Method of using clips for retrofit installation of a portable swimming pool barrier fence

ActiveUS20080141450A1Increase rigidityEasily avoid obstaclesFencingGymnasiumEngineeringSurface plate

The installation and removal of a portable but sturdy pool barrier fence uses the hardware installed for attaching a safety pool cover during the pool use season. Multiple rectangular panel frames support a mesh fabric. Spaced anchors mounted in said deck adapted to support a cover or said fence when said cover is removed. The fence has rectangular sections formed by upper, lower and side frame members enclosing the fencing material. Each lower frame member in the fence sections has a centrally located rib extending longitudinally along a top surface thereof. Anchor clips, preferably Z-shaped clips, are located and attached to the deck at the anchors in the deck. Each of the anchor clips has a keyway for engaging a respective rib on the lower frame member of the rectangular fence section to secure the fence to the deck.

Owner:POOL COVER

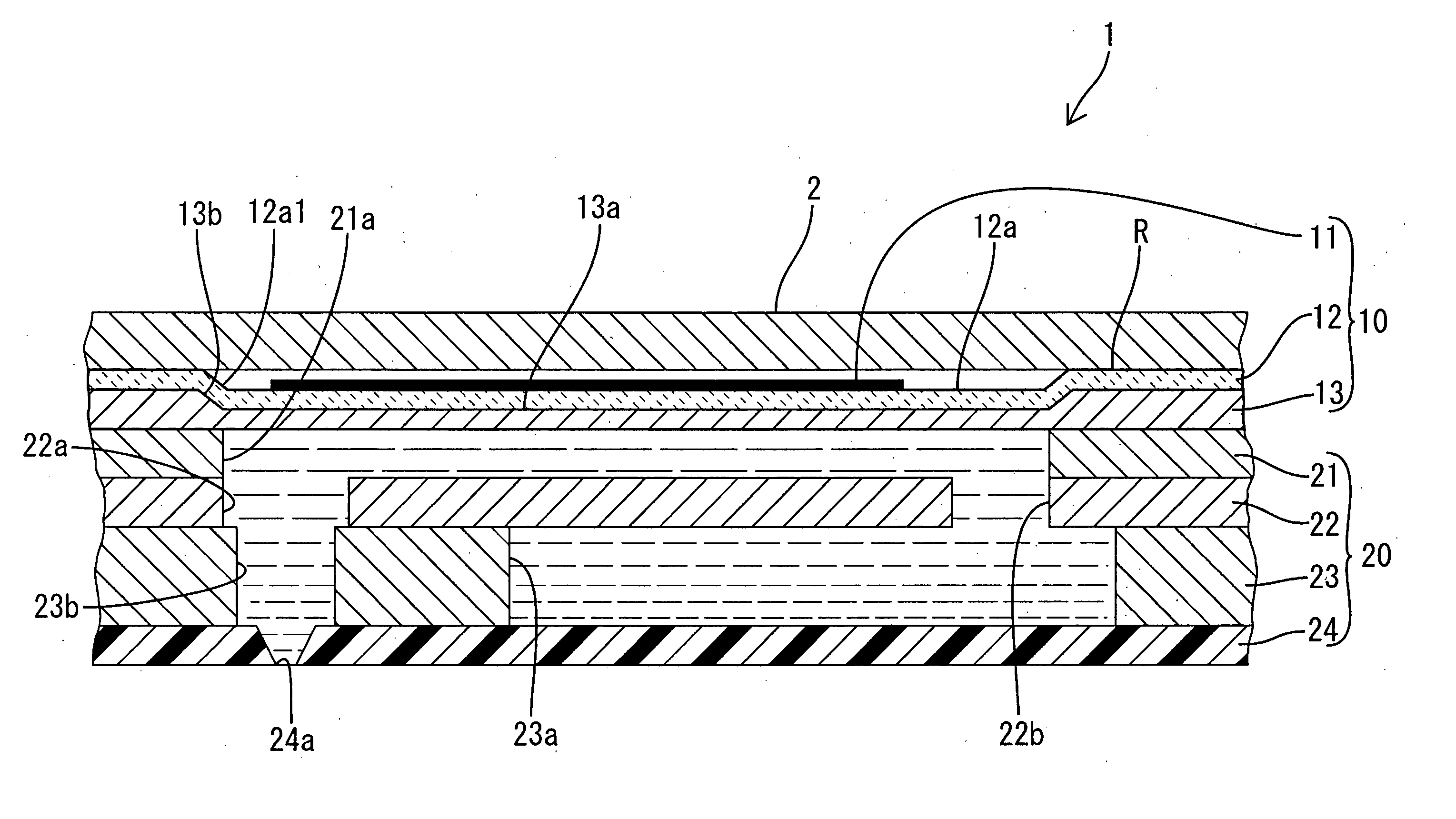

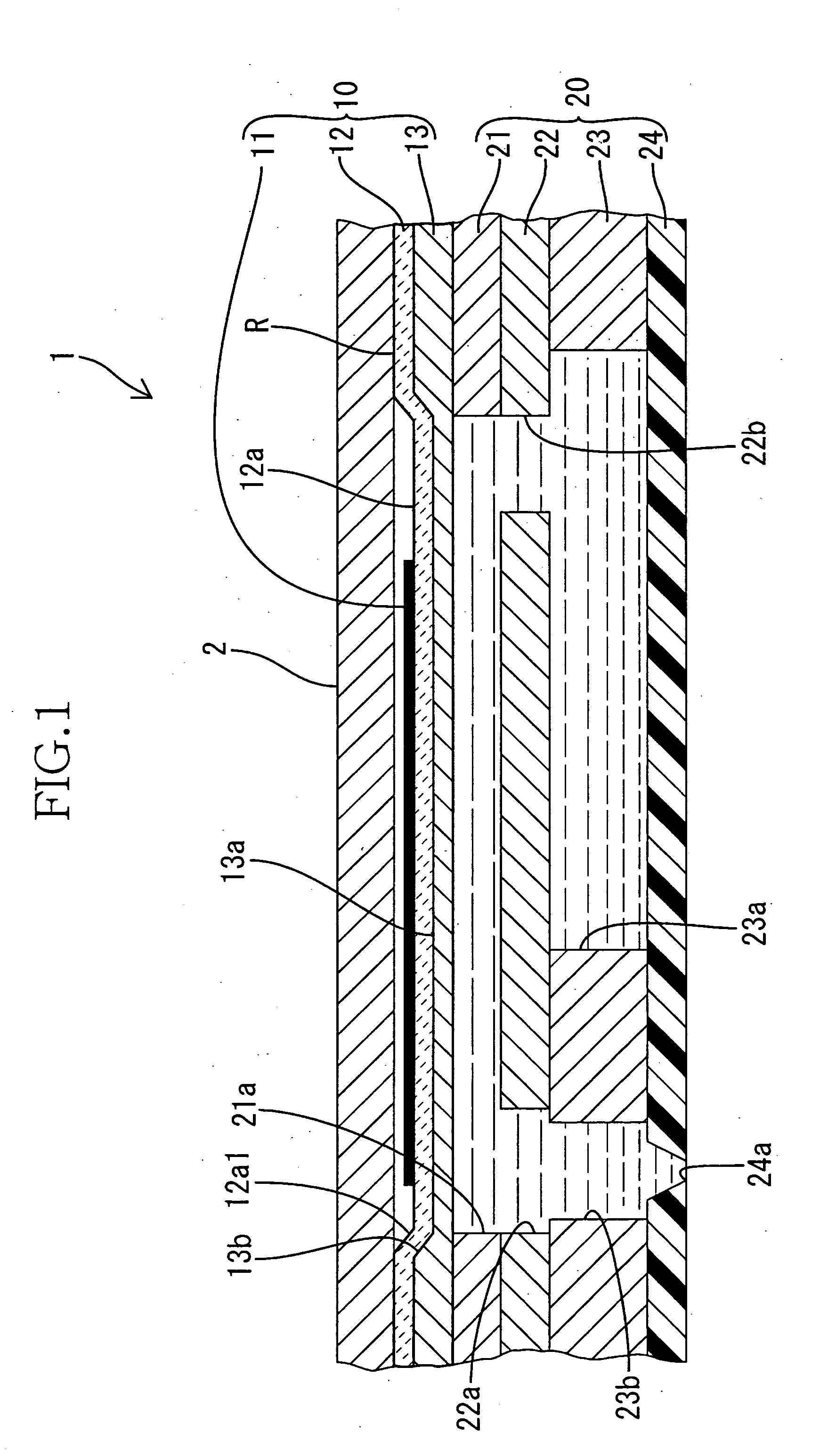

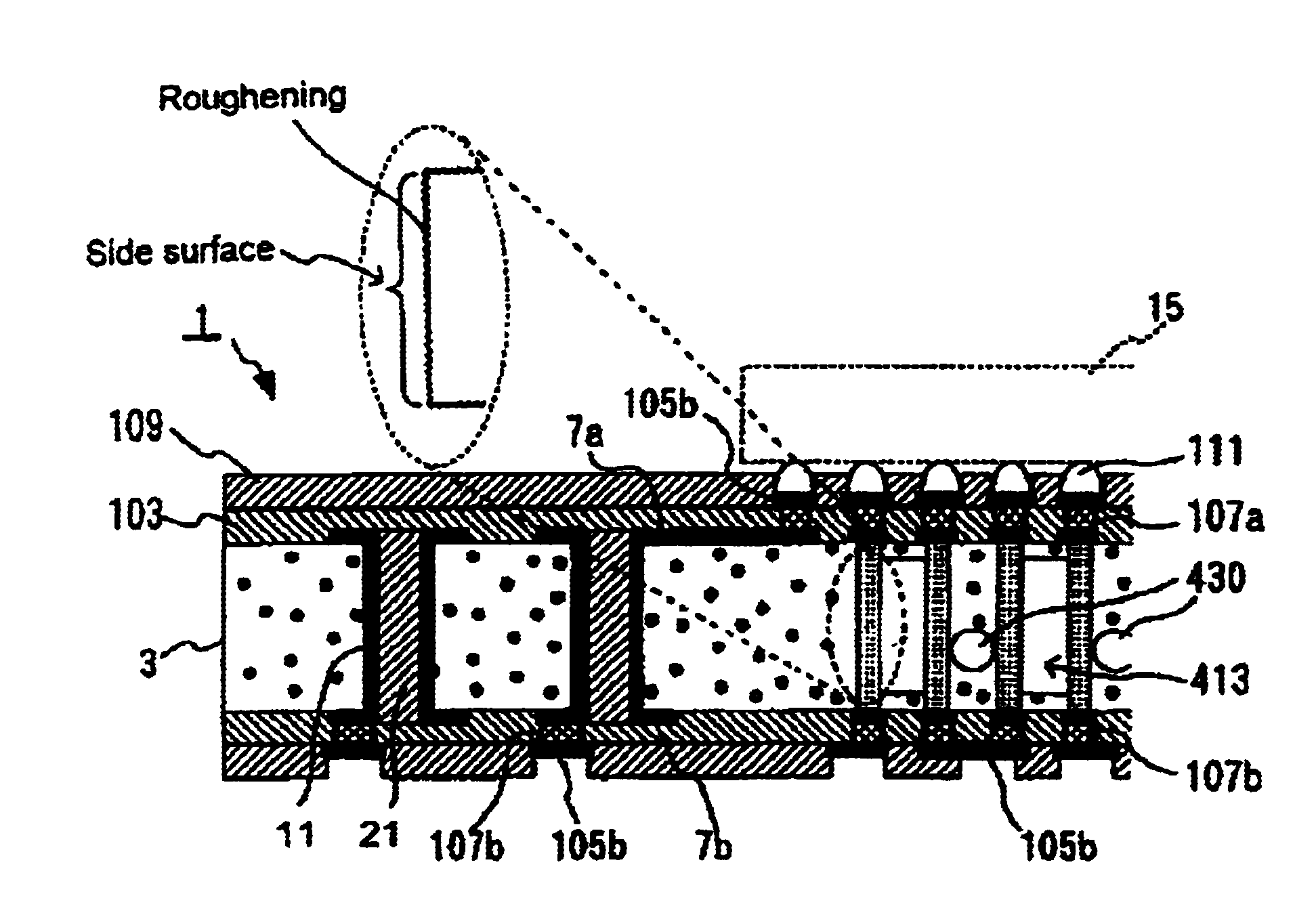

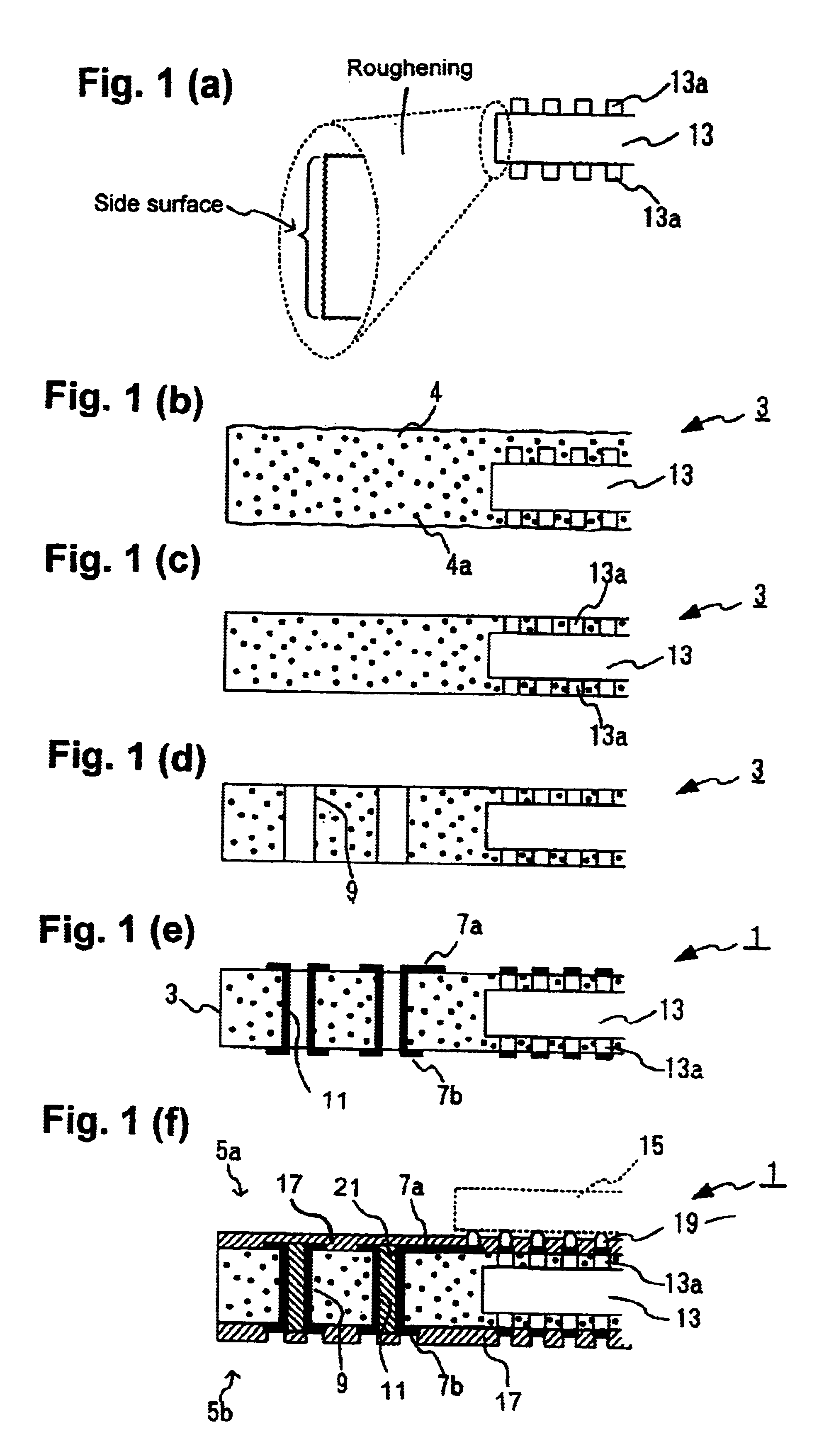

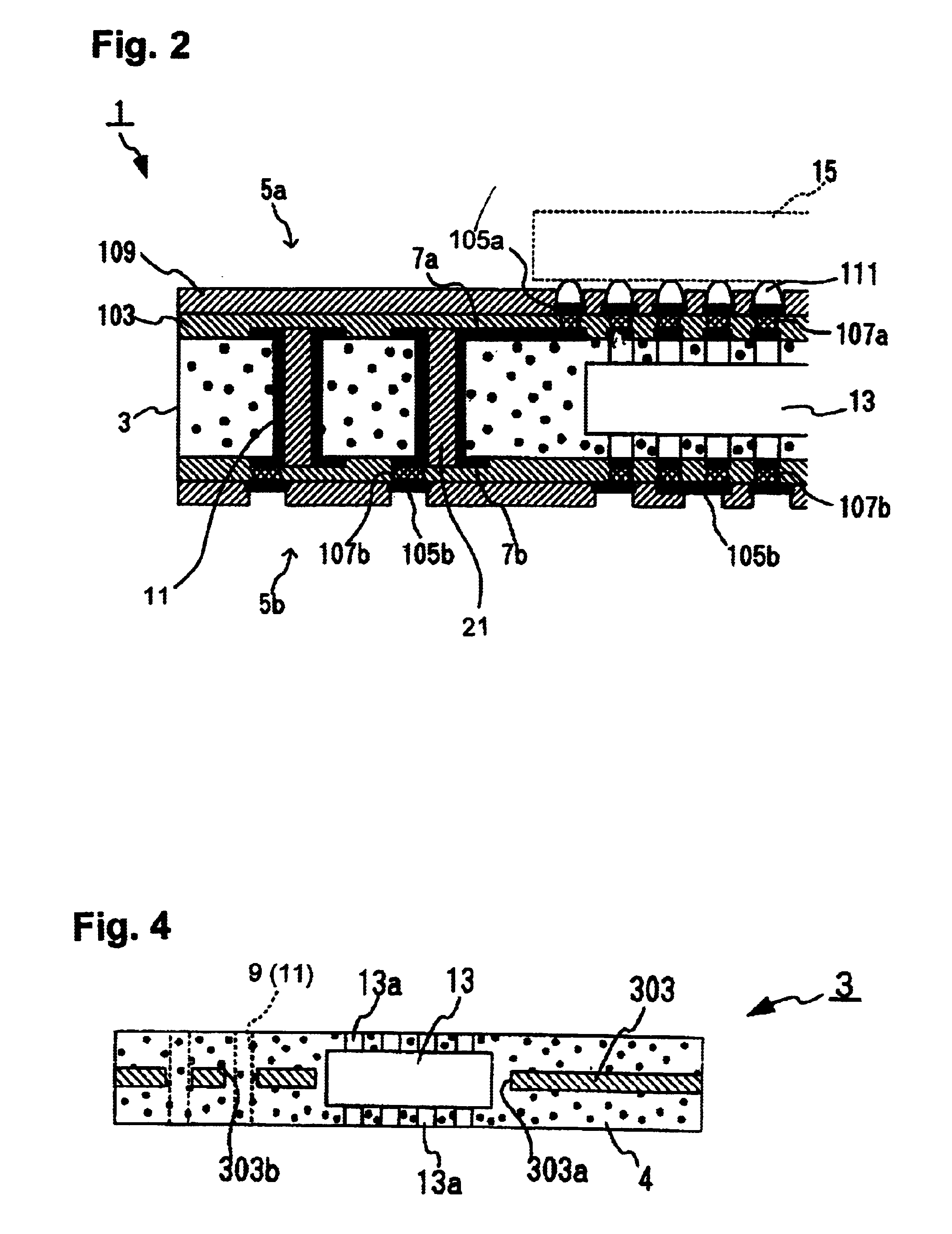

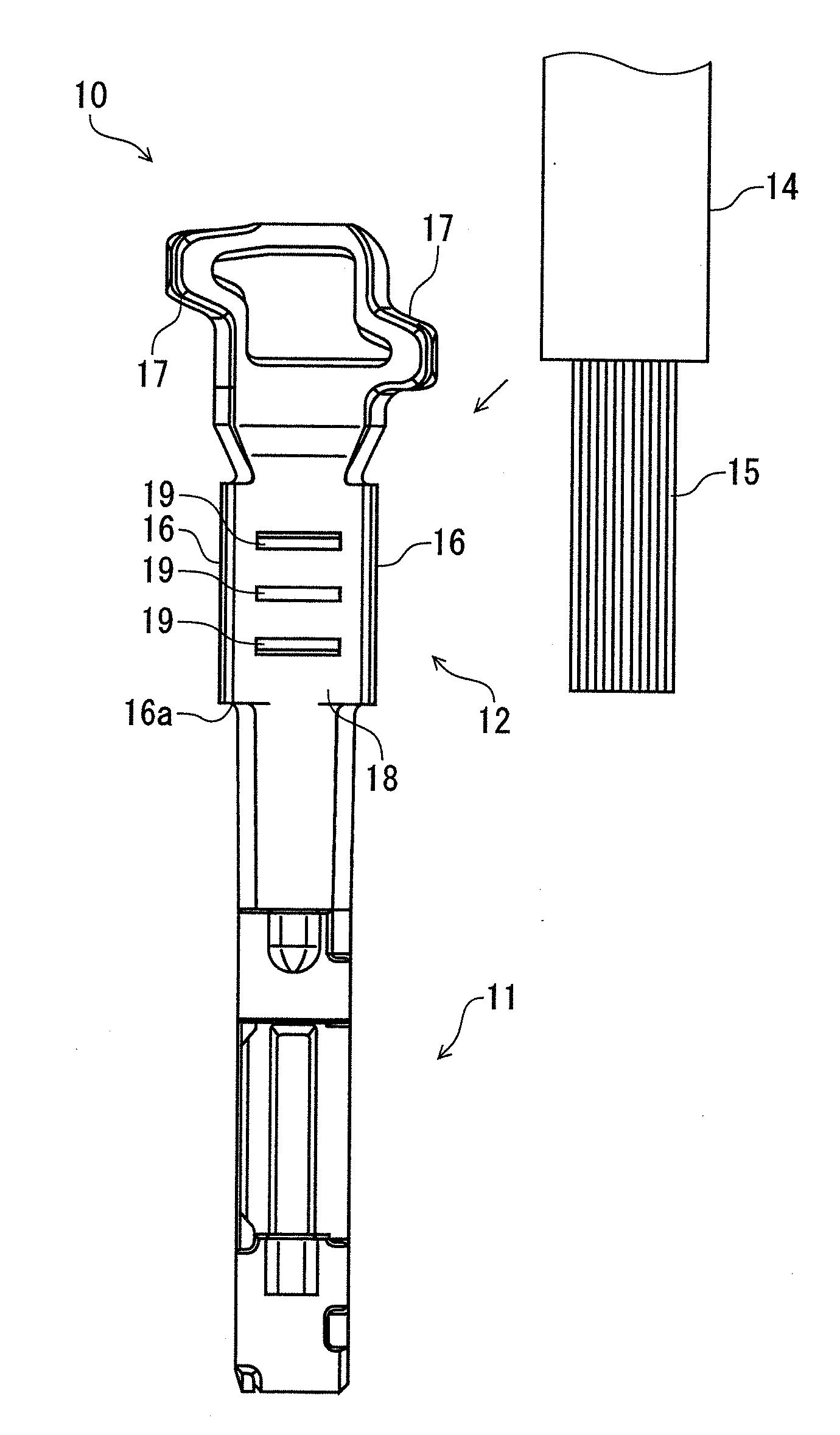

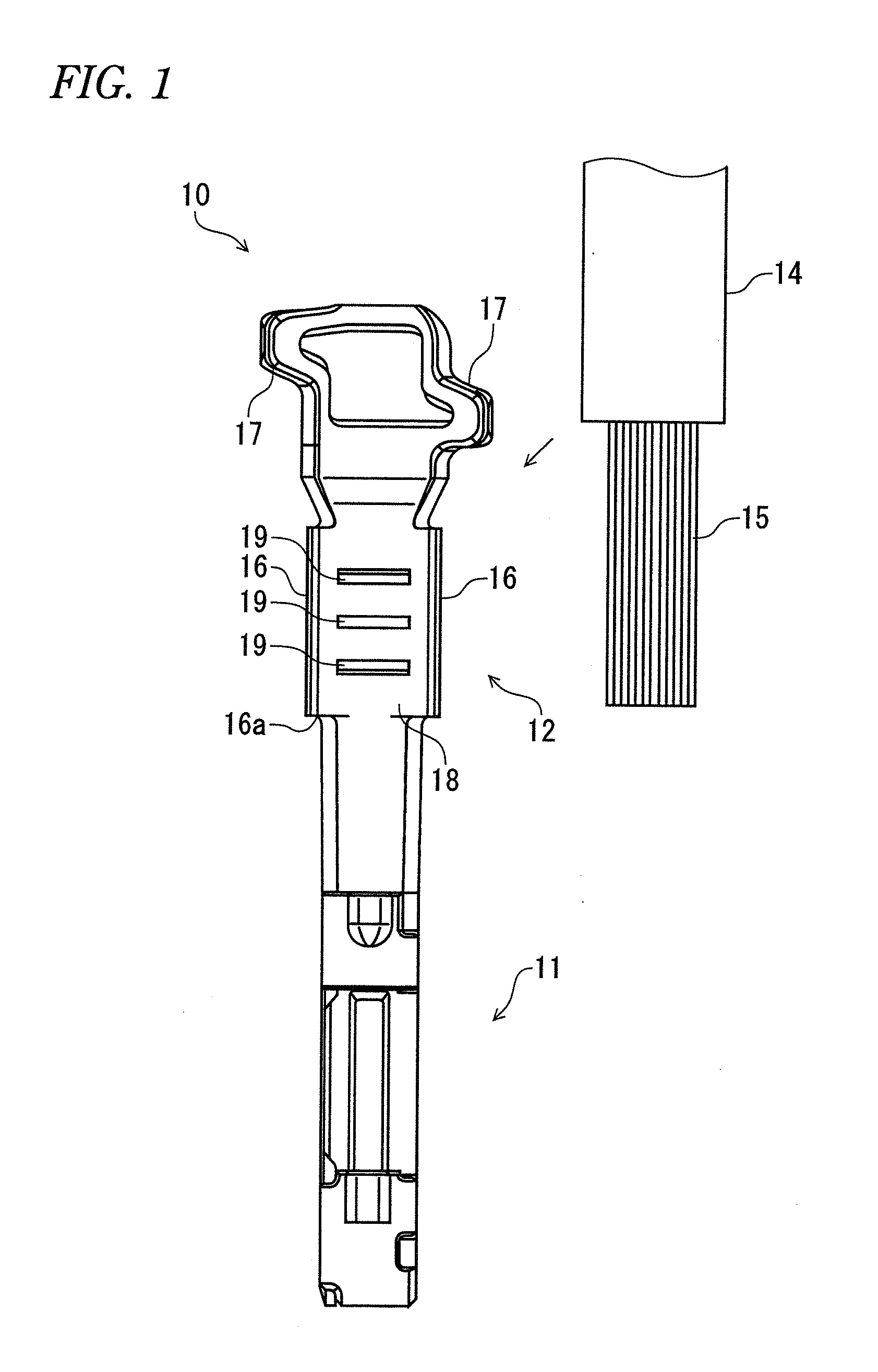

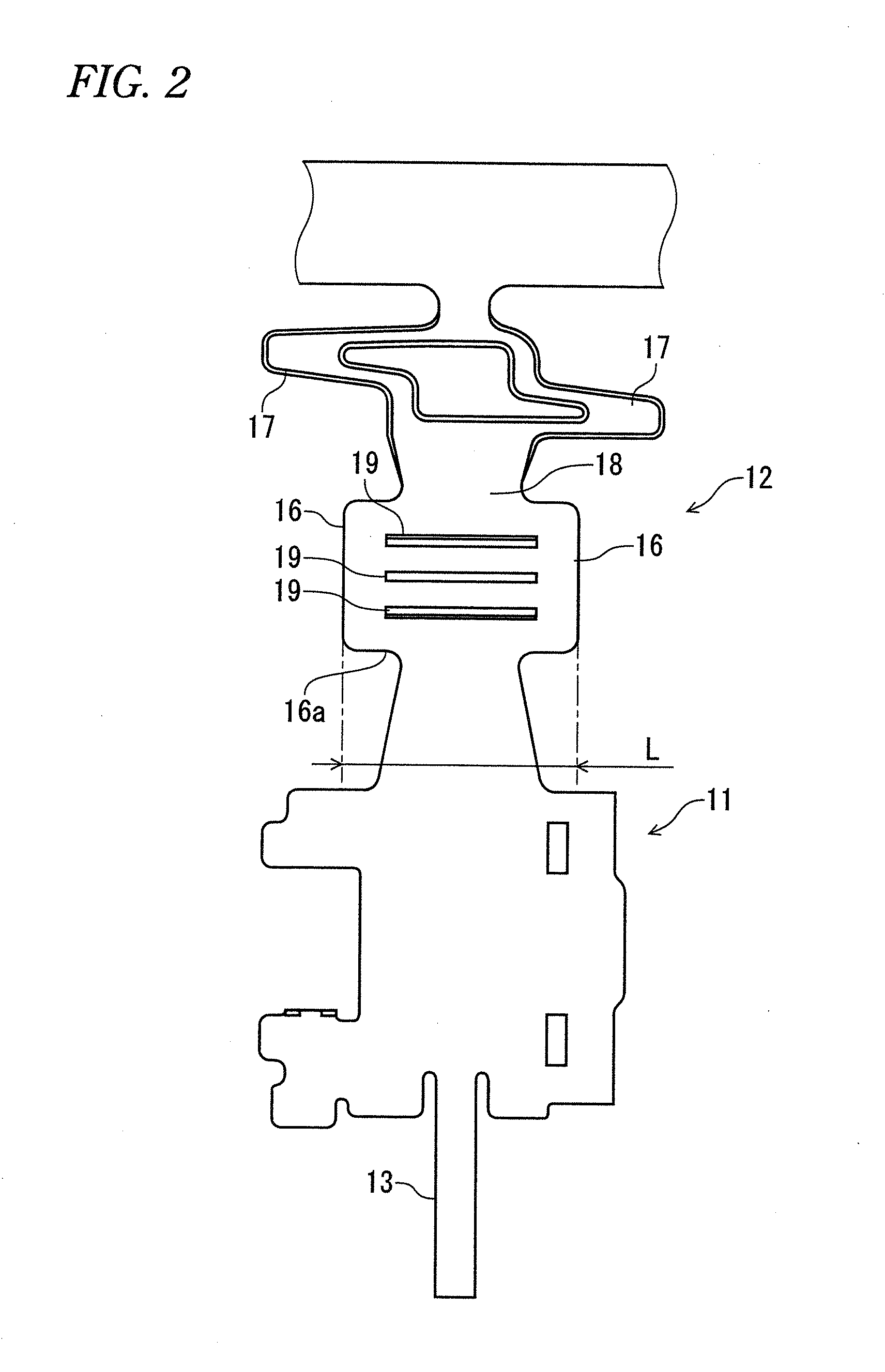

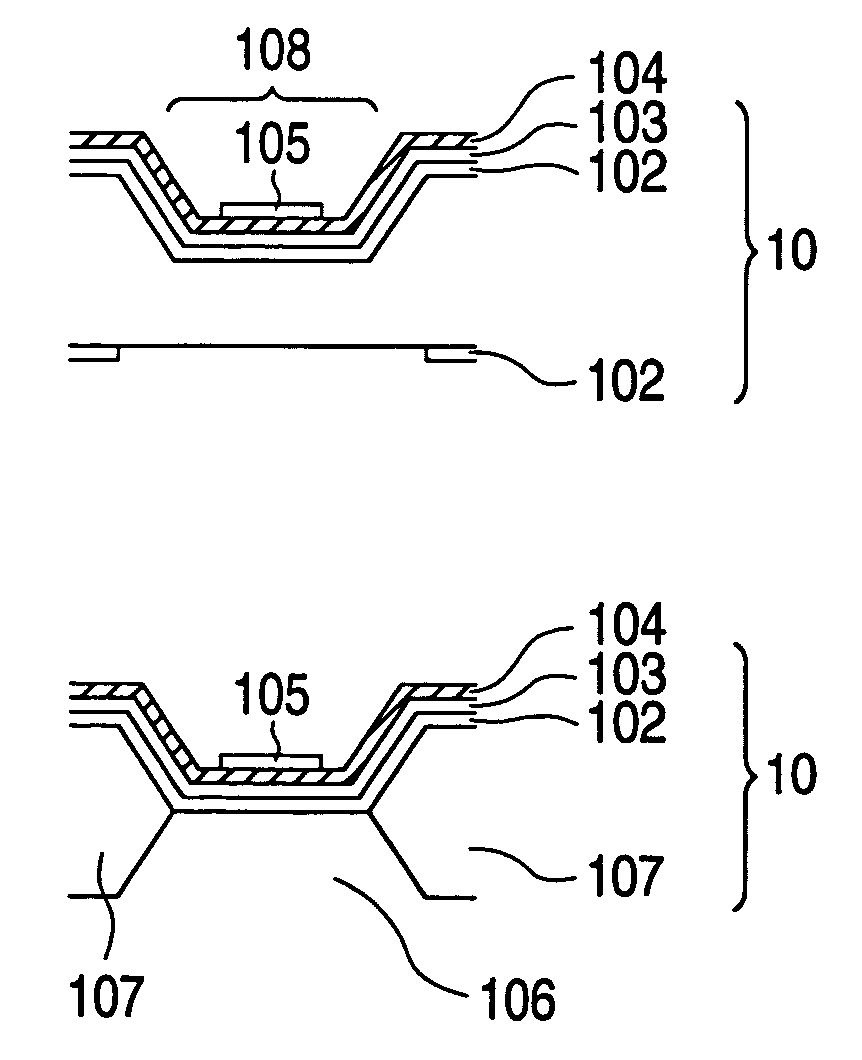

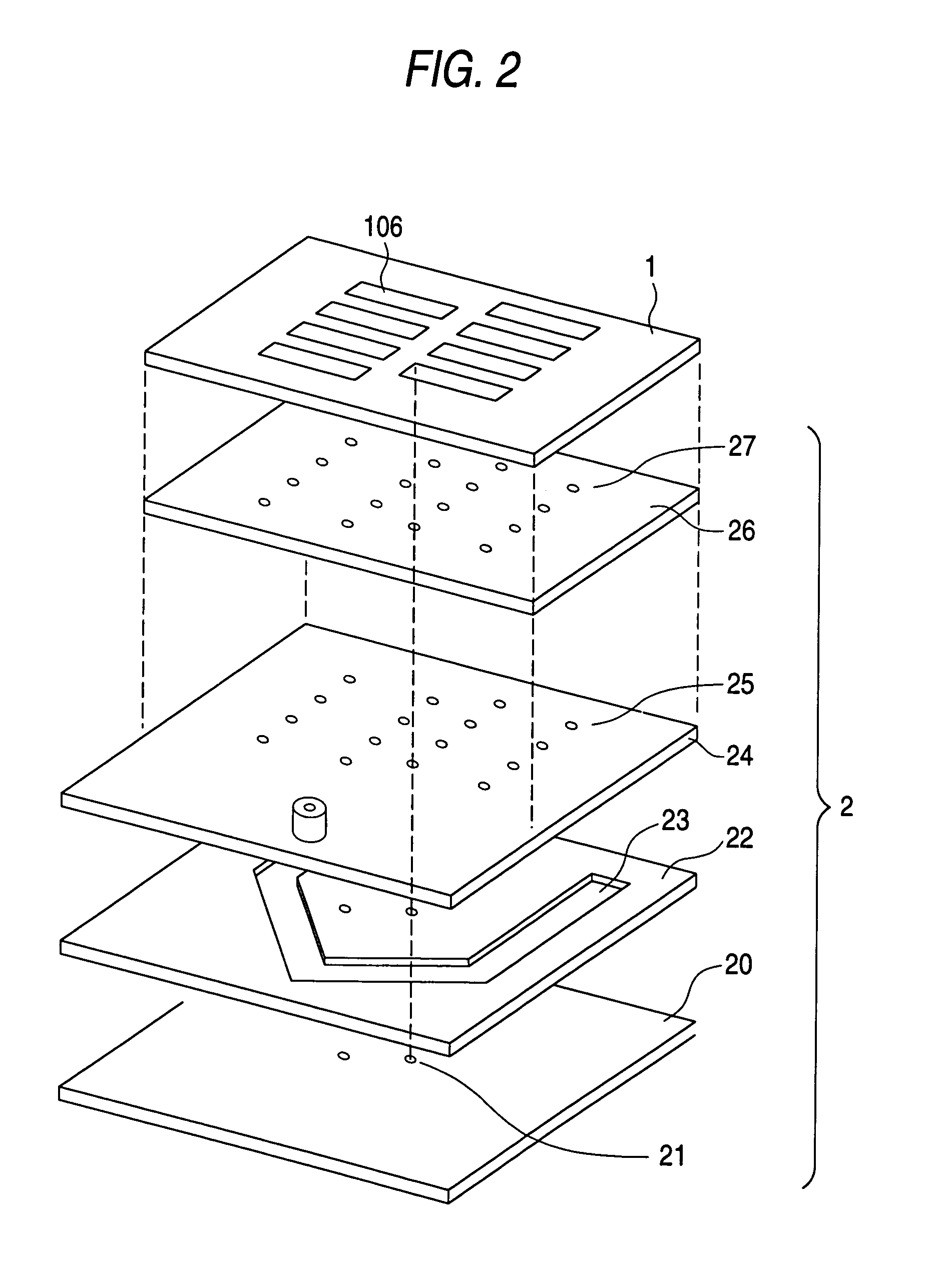

Liquid delivering device

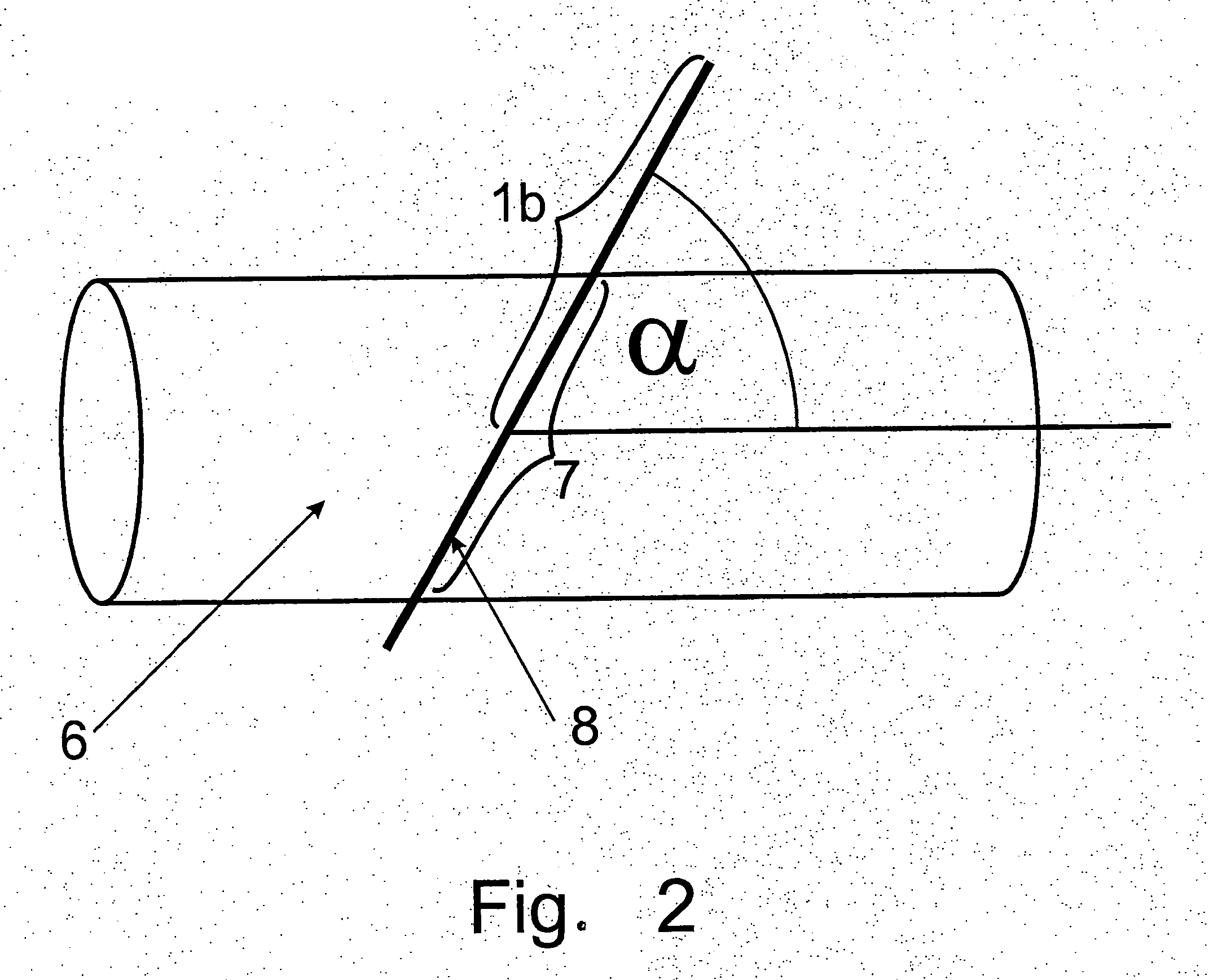

ActiveUS20050069429A1Increase rigidityReduce occurrencePiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsElectric fieldVoltage

A liquid delivering device including: (a) a cavity unit defining cavities for accommodating a liquid which is to be delivered to an exterior of the liquid delivering device; (b) a piezoelectric actuator unit superposed on the cavity unit, and having active portions which correspond to the respective cavities and which are selectively deformable upon application of a drive voltage thereto so as to deliver the liquid from the corresponding cavities to the exterior of the liquid delivering device; and (c) a backup plate superposed on the actuator unit such that the actuator unit is interposed between the cavity unit and the backup plate. The backup plate is jointed, at least at portions thereof corresponding to peripheries of the cavities, to the actuator unit. The actuator unit includes (b-1) a piezoelectric material layer deformable upon generation of an electric field therein as a result of the application of the drive voltage to the actuator unit, and (b-2) a flexible layer laminated on the piezoelectric material layer so as to be deformable together with deformation of the piezoelectric material layer.

Owner:BROTHER KOGYO KK

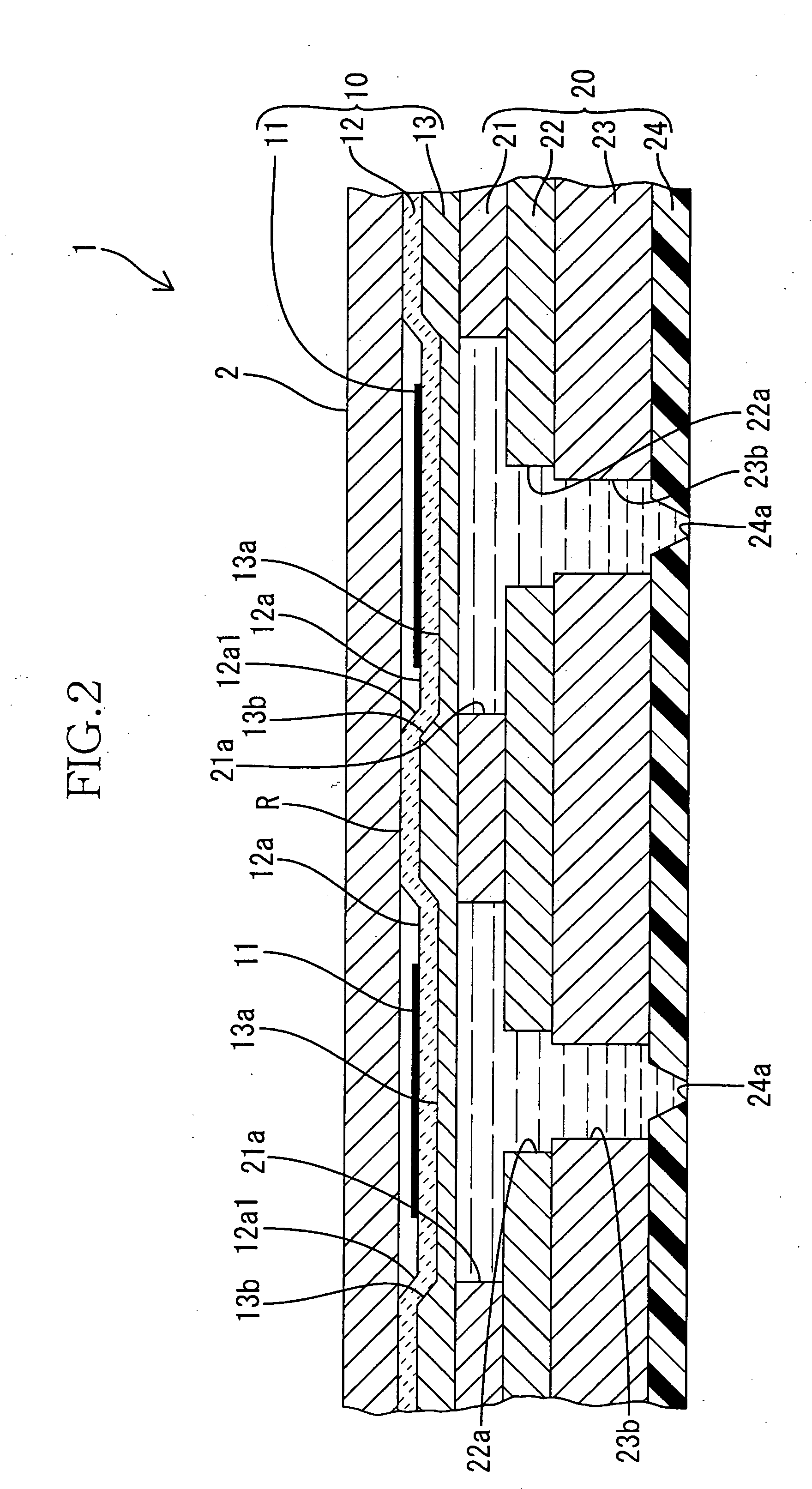

Printed-wiring substrate and method for fabricating the same

InactiveUS6841740B2Increase rigidityReduce numberLine/current collector detailsPrinted electric component incorporationCapacitanceEngineering

A printed-wiring substrate including a capacitor element, as well as a method for fabricating the printed-wiring substrate. An insulating substrate 3 is molded by placing a capacitor element 13 in a mold and charging a resin 4 into the mold. Therefore, the capacitor element 13 having a size (i.e., electrostatic capacitance) sufficient to suppress switching noise of an IC chip 15 and stabilize operation power voltage can be disposed, while providing a dimensional margin. Since the possibility of failing to embed the capacitor element 13 decreases, the printed-wiring substrate can be fabricated at reduced cost.

Owner:NGK SPARK PLUG CO LTD

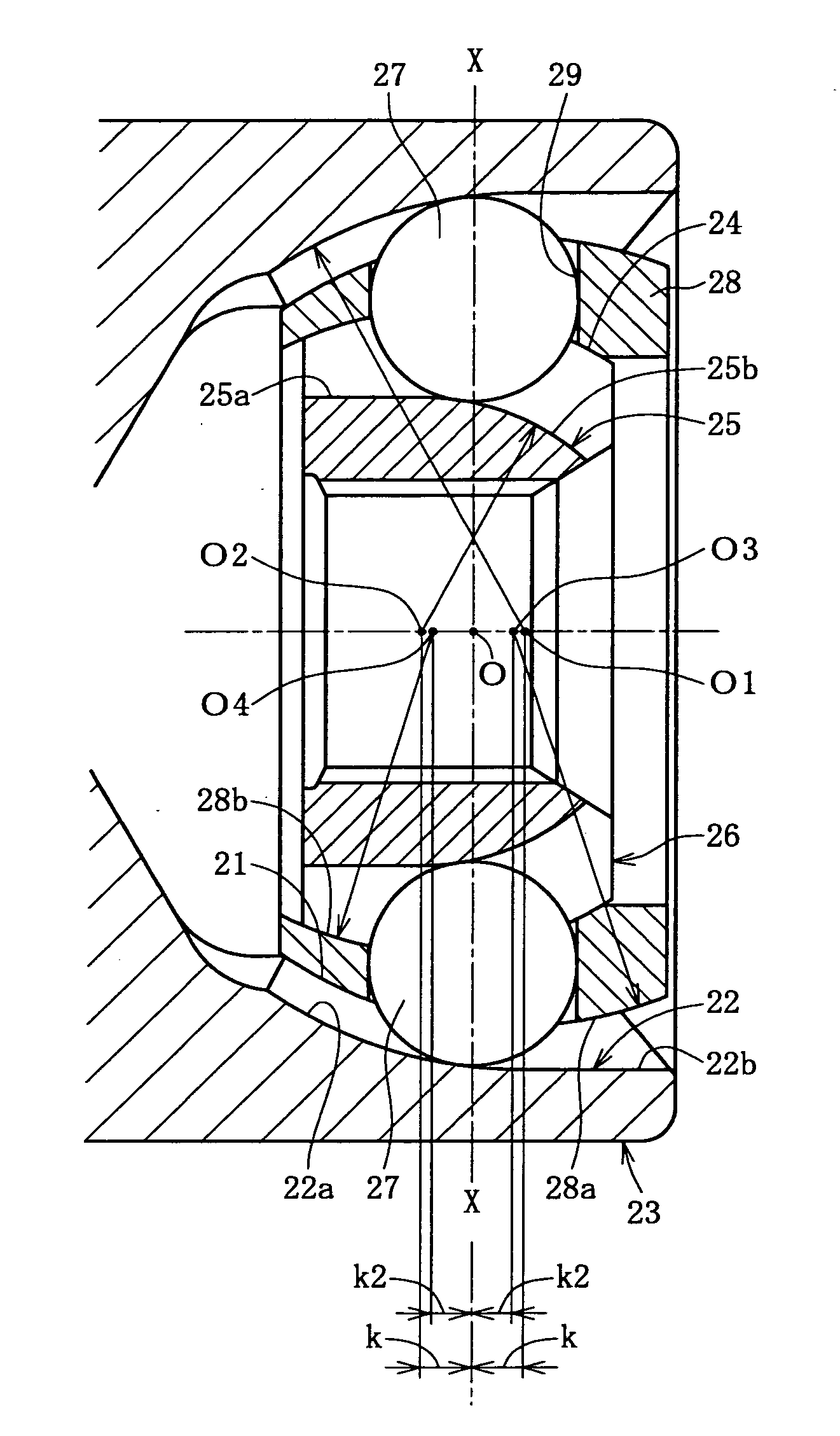

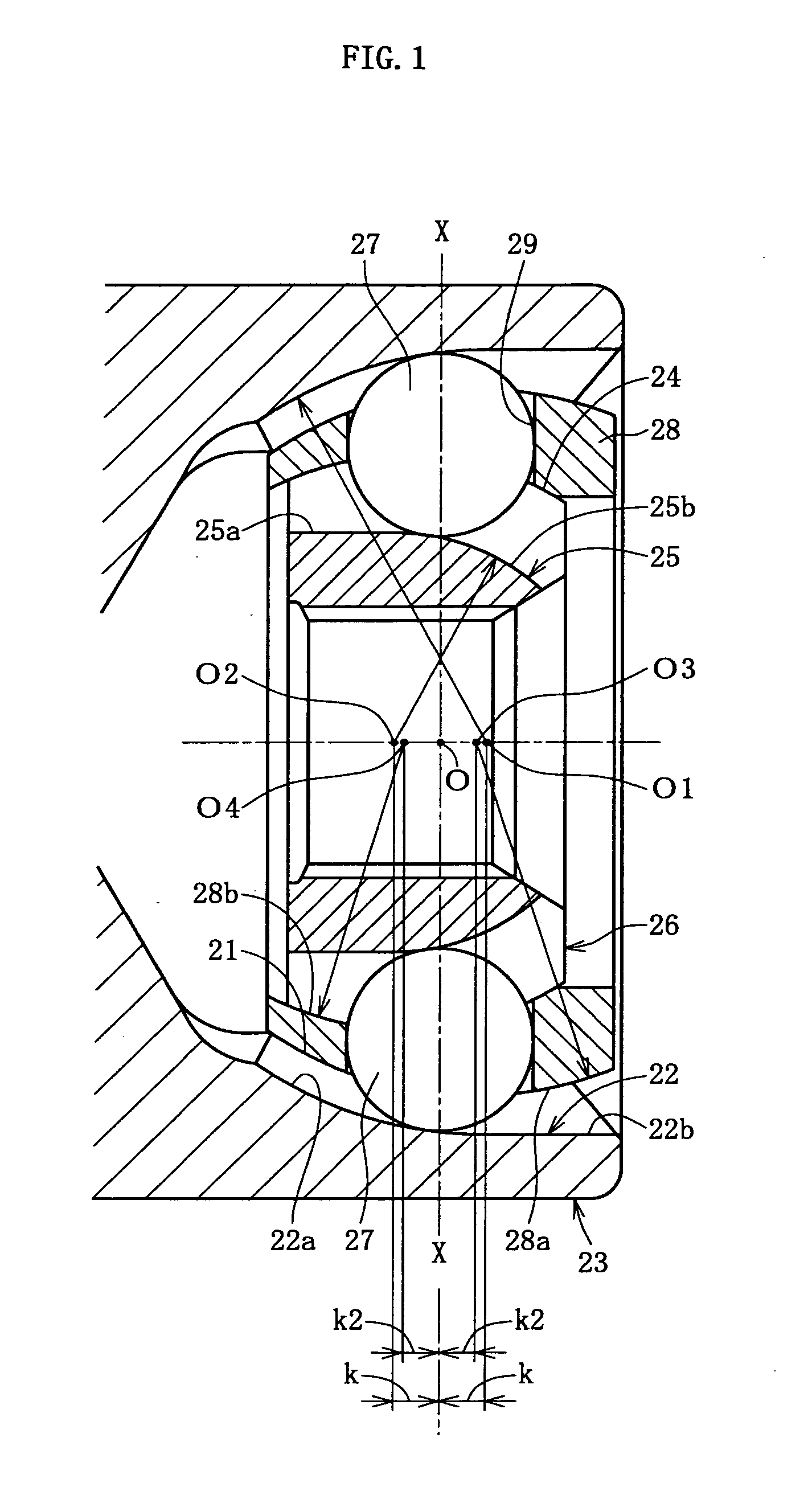

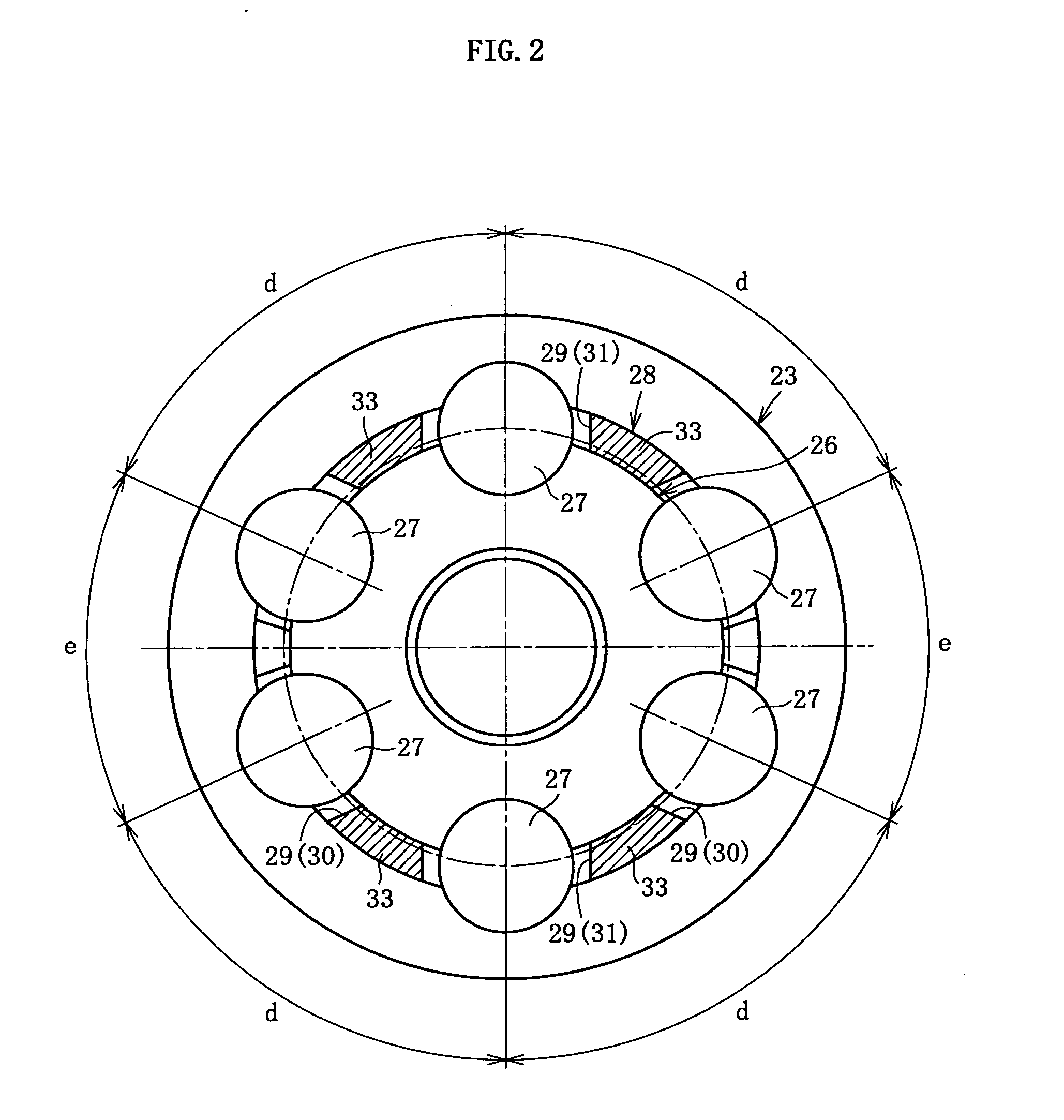

Fixed constant-velocity universal joint

ActiveUS20100029396A1Increase rigidityImprove operabilityClutchesYielding couplingHigh angleEngineering

The present invention provides a fixed constant velocity universal joint that can be made compact, has little decrease in load capacity even when the fixed constant velocity universal joint is made compact and is at an operating angle, and can improve high angle strength and durability through lessening instances in which a ball runs over a track at a high angle. In the fixed constant velocity universal joint of the present invention, a cage 28 includes four pockets 29, the pockets 29 being a pair of long pockets 30 of which a circumferential direction spacing is wide and a pair of short pockets 31 of which the circumferential direction spacing is narrow. The pair of long pockets 30 are shifted by 180 degrees along a circumferential direction and a pair of short pockets 31 are shifted by 180 degrees along the circumferential direction. As a result, the long pockets 30 and the short pockets 31 are alternately disposed along the circumferential direction. A long pocket 30 houses two balls 27. A short pocket 31 houses one ball. Two ball housing sections 38 connected by a slit 37 are formed in the long pocket 30 by projections 36 that project towards a long pocket inner side being provided on opposing long sides 35 of the long pocket 30.

Owner:NTN CORP

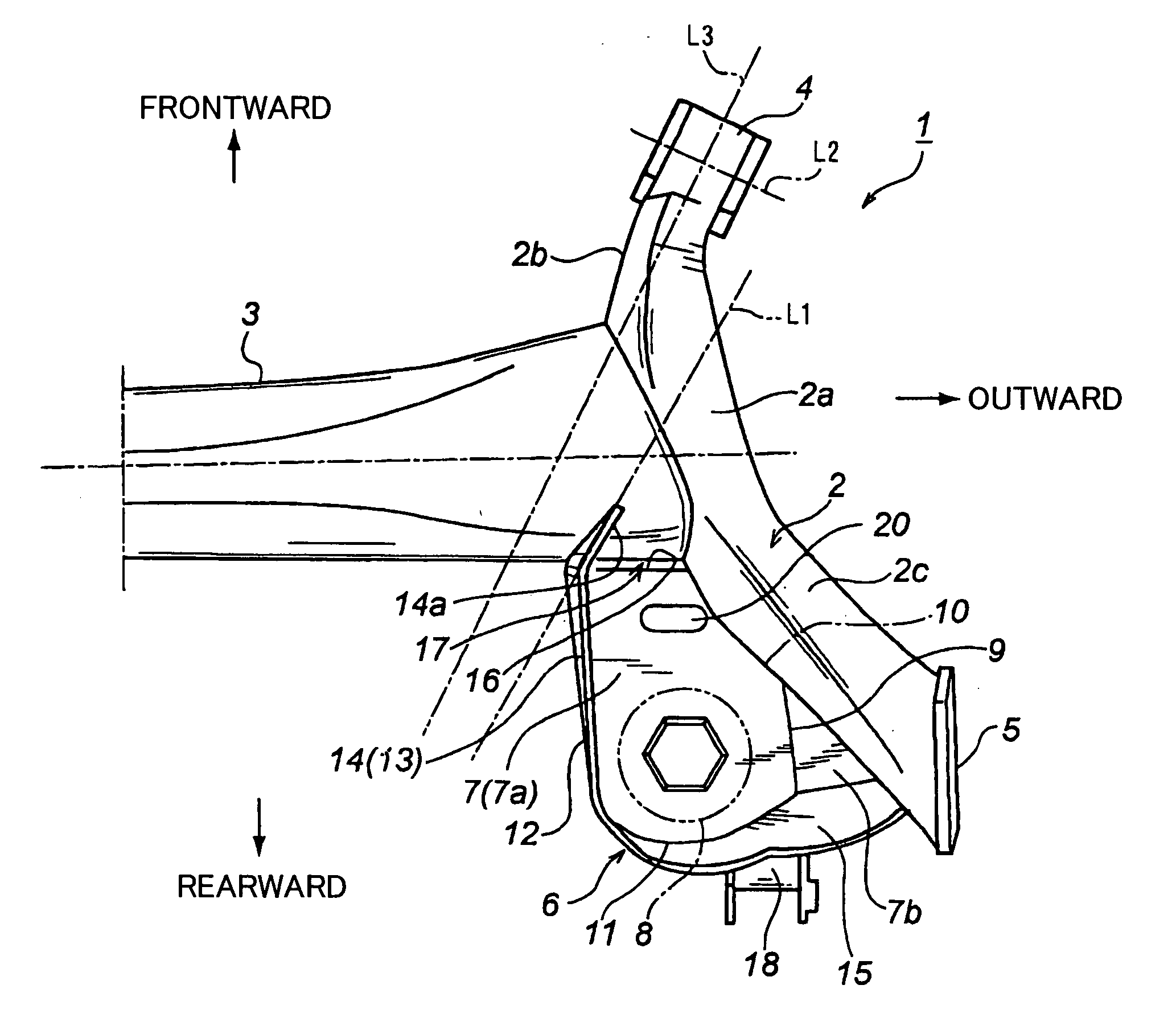

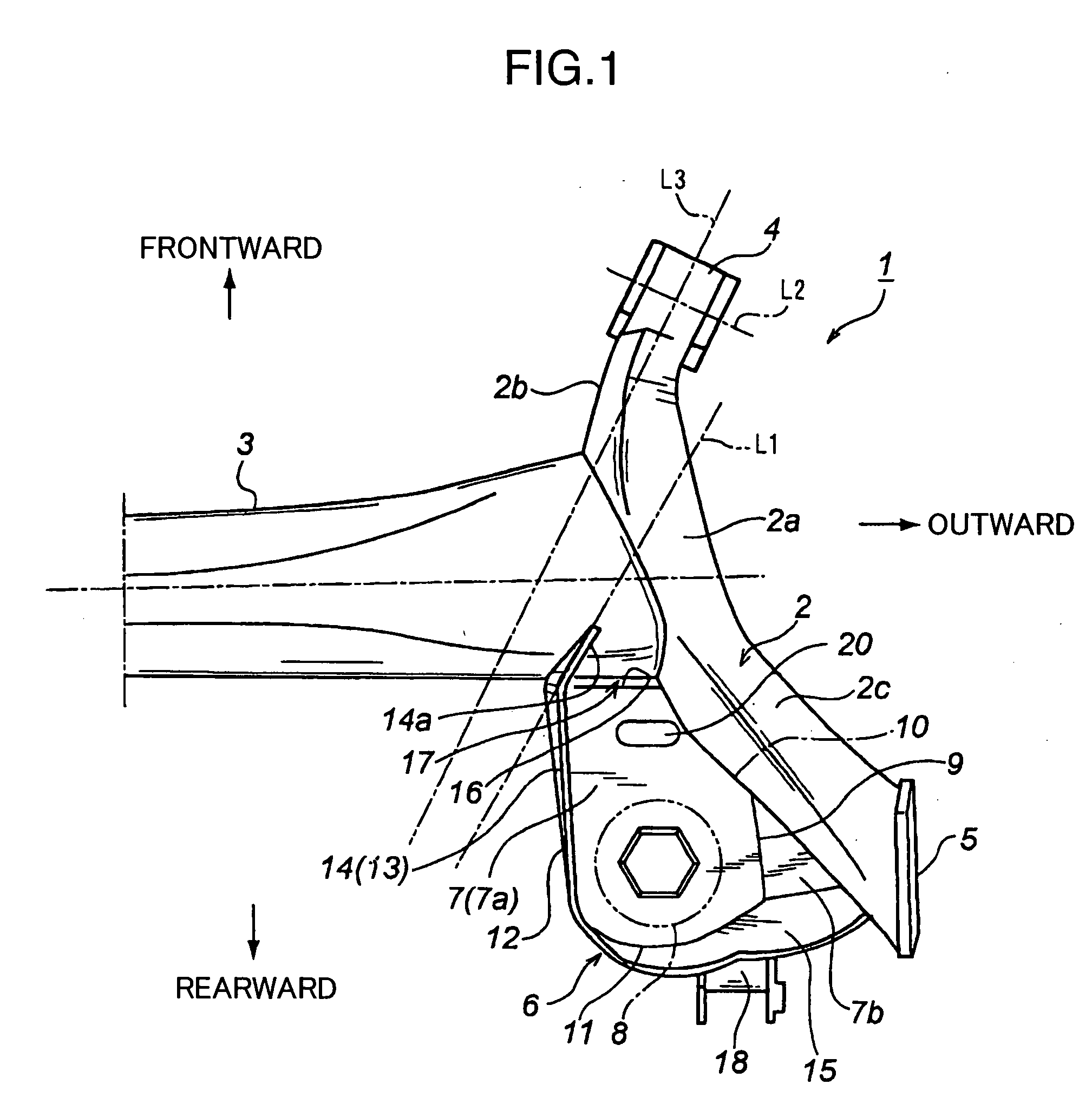

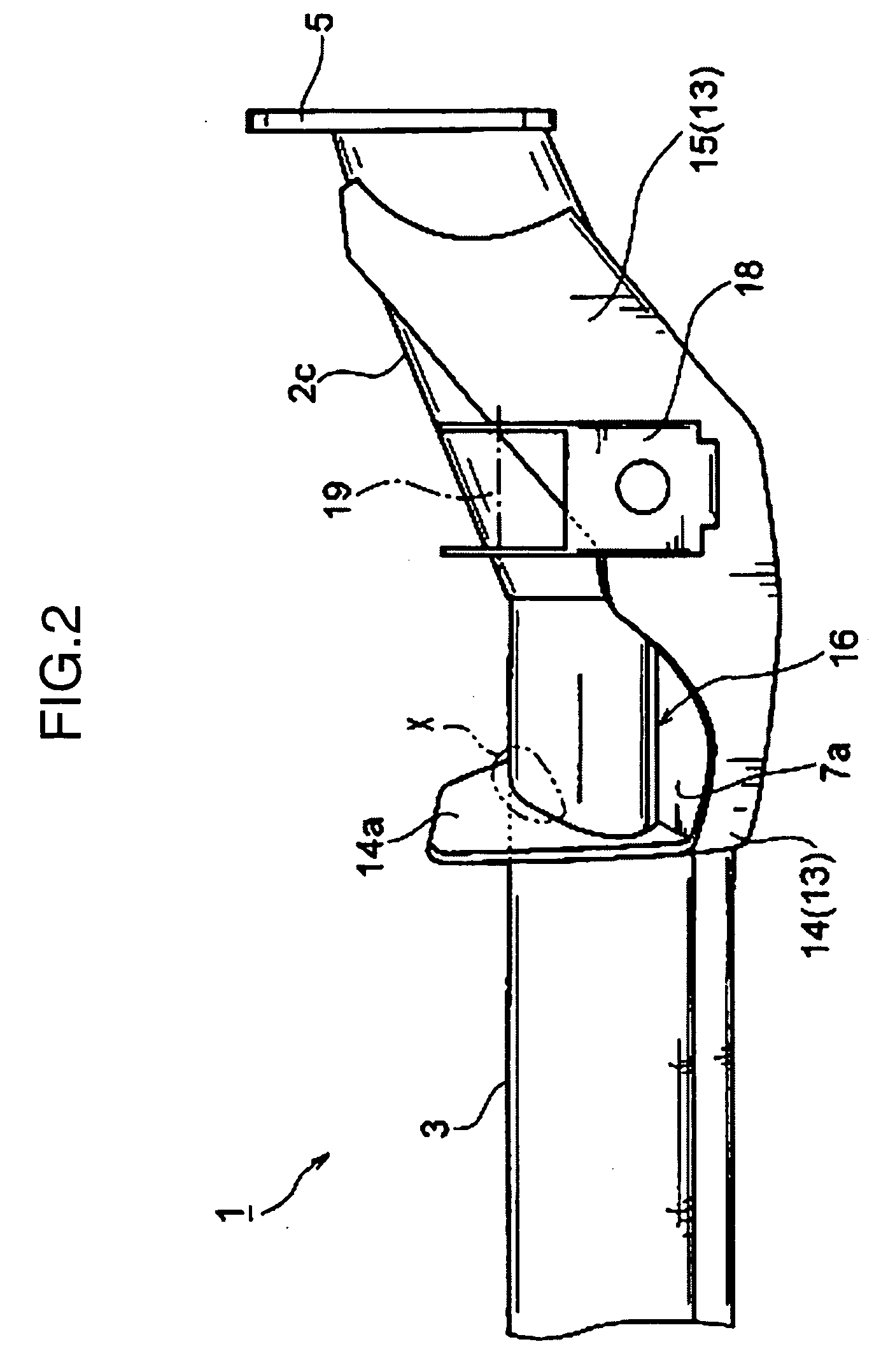

Torsion beam type rear suspension

InactiveUS20060220339A1Improve supportIncrease rigidityInterconnection systemsWheel manufactureEngineeringCoil spring

Disclosed is a torsion beam type rear suspension which comprises a pair of right and left trailing arms (2), a torsion beam (3), and a spring seat (6) disposed in a corner region defined at a junction between each of the lateral ends of the torsion beam and a rear portion (2c) of a corresponding one of the trailing arms to form a mounting seat for a coil spring (8). A vertical flange (13) is formed along a laterally inner edge (12) of the spring seat to have a longitudinally front edge extending vertically along a rear side surface of the torsion beam. The spring seat has a first region (7b) of disposed opposed to the corresponding trailing arm and fixed thereto approximately in its entirety, and a second region (16) disposed opposed to the torsion beam and fixed thereto only through the vertical flange. The torsion beam type rear suspension of the present invention can improve the supporting rigidity of the spring seat relative to a coil spring without increasing the rigidities of the spring seat and trailing arm themselves, while allowing the risk of stress concentration occurring at an end of the torsion beam to be reduced, so as to achieve increased chassis rigidity and adequately maintain suspension functions.

Owner:MAZDA MOTOR

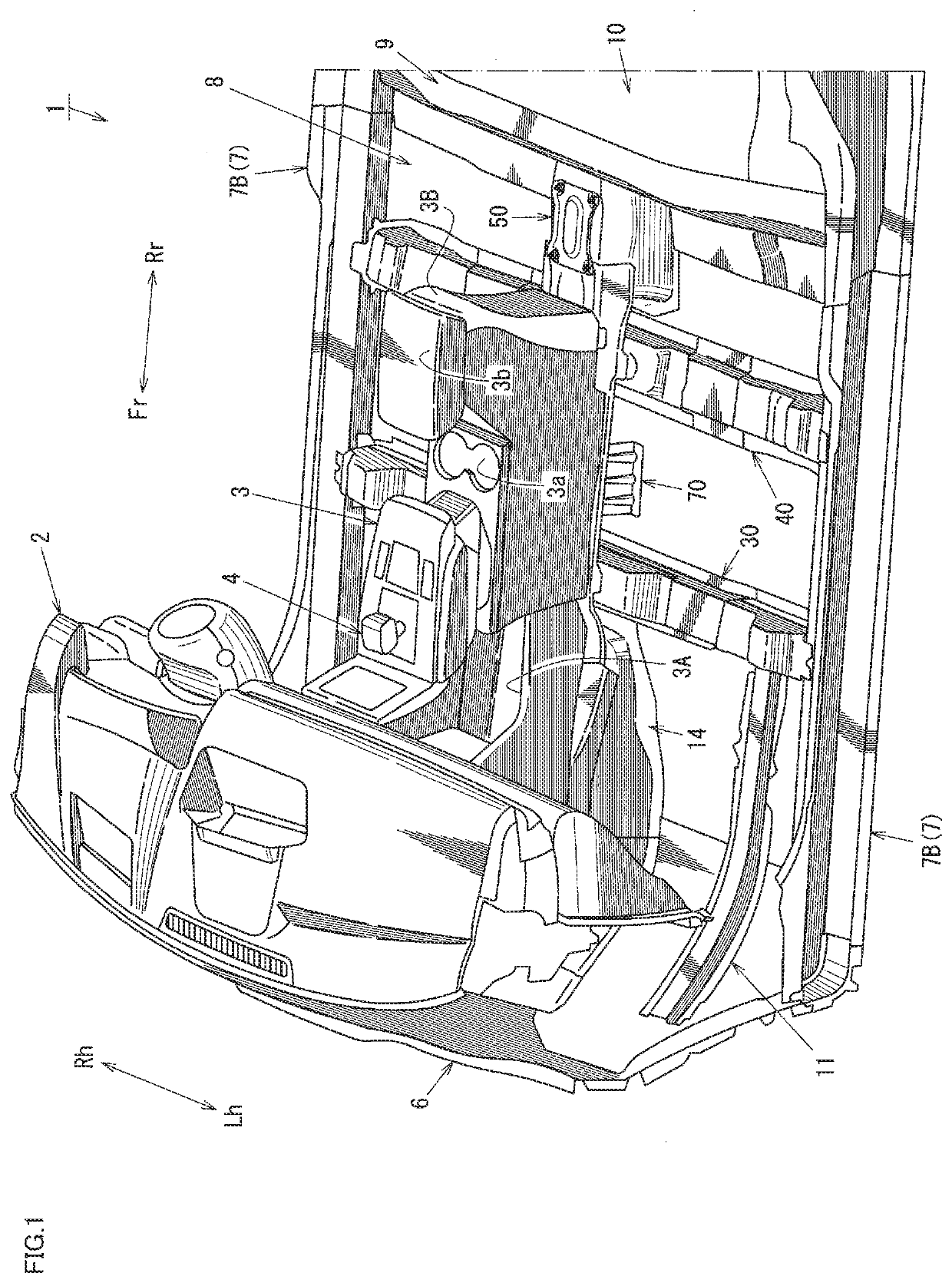

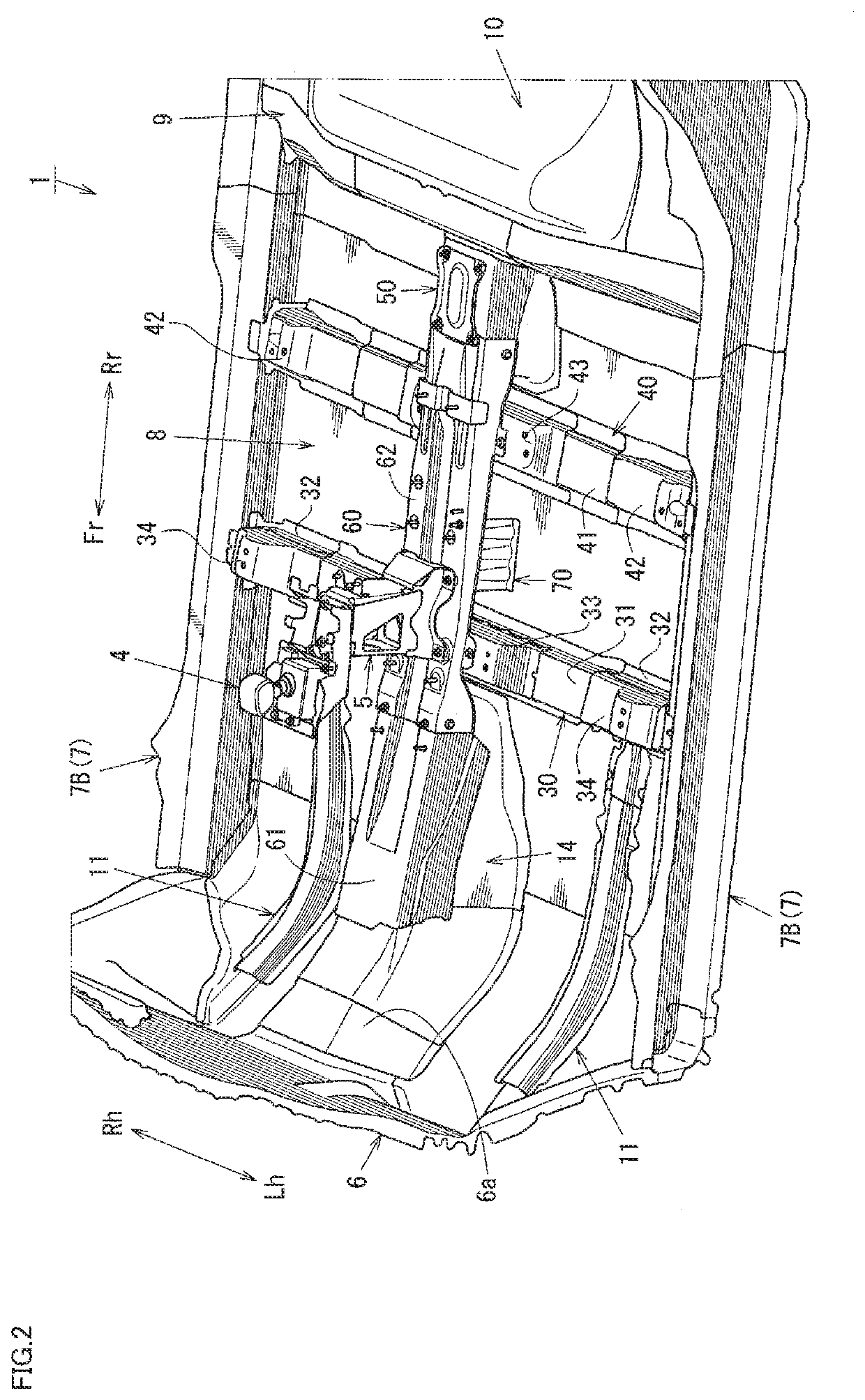

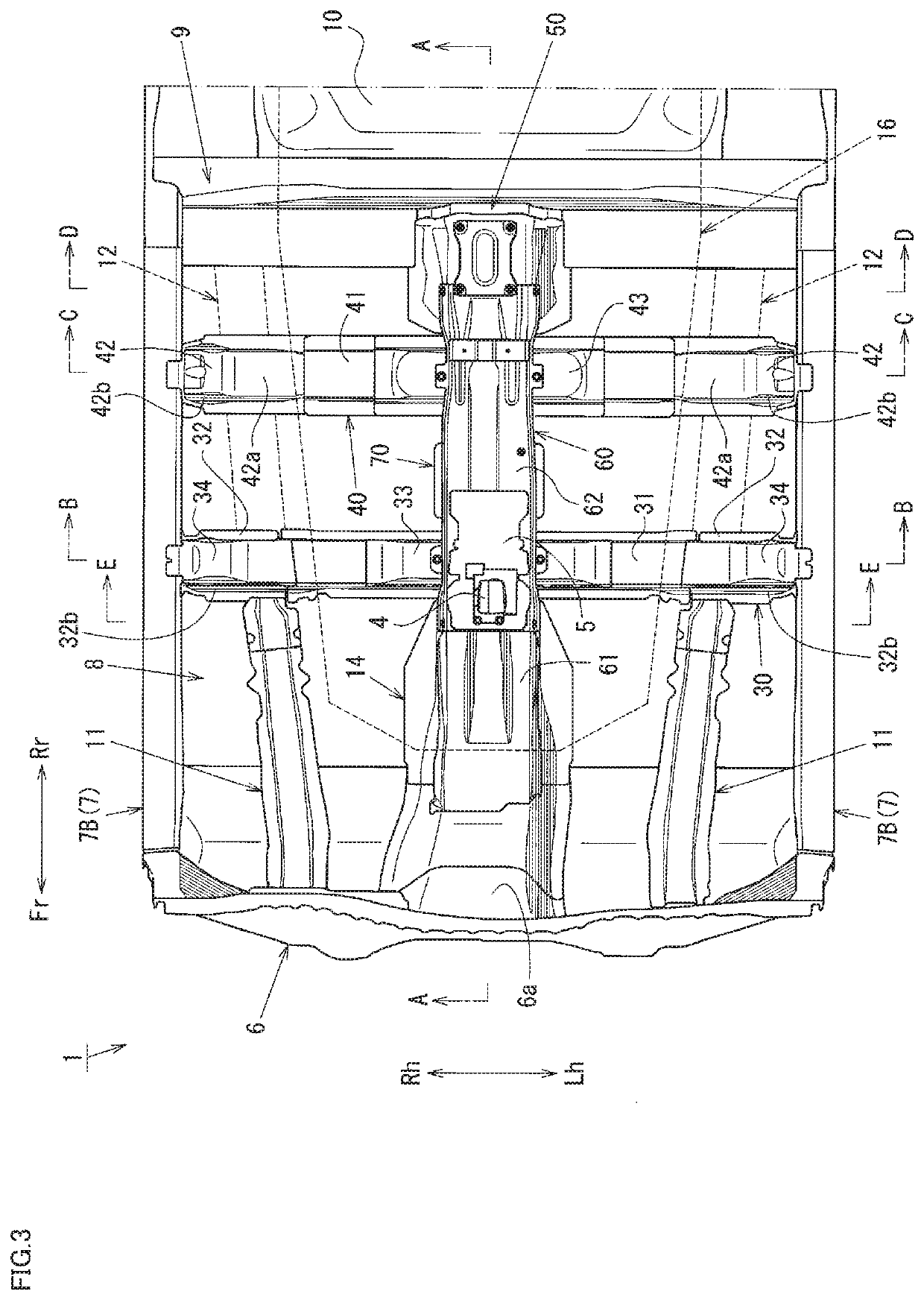

Lower vehicle-body structure of electric vehicle

ActiveUS20200361542A1Increase rigidityIncrease in numberElectric propulsion mountingUnderstructuresAutomotive engineeringElectric vehicle

A lower vehicle-body structure of an electric vehicle that can ensure desired resistance to rear-end collision even if a tunnel of a front floor panel is eliminated. The lower vehicle-body structure of the electric vehicle includes a pair of left and right side sills; a substantially flat front floor panel; a first floor cross member and a second floor cross member connecting the left and right side sills in a vehicle-width direction. The lower vehicle-body structure further includes a kick-up portion raised from a rear end of the front floor panel toward a vehicle upper side; a rear floor panel connected to a vehicle rear side of the kick-up portion; and a kick-up reinforcing element connecting a substantial middle of the kick-up portion in the vehicle-width direction and the front floor panel in front of the substantial middle of the kick-up portion.

Owner:MAZDA MOTOR CORP

Crimped electric wire with terminal and method for producing the same

InactiveUS20110034091A1Hard be roundIncrease rigidityConnections effected by permanent deformationConnection formation by deformationEngineeringAluminium alloy

A crimped electric wire with a terminal, includes: an electric wire having a core wire made of aluminum or aluminum alloy; and a terminal fitting having an electric wire crimping section for crimping the core wire partly exposed from the electric wire, wherein: a value obtained by dividing the height of the electric wire crimping section by the width of the electric wire crimping section after the crimping of the electric wire crimping section is set to 0.5 or more and 0.6 or less; and the value obtained by dividing the gross cross-sectional area of the core wire after the crimping of the electric wire crimping section by the gross cross-sectional area of the core wire before the crimping of the electric wire crimping section is set to 55% or more and 65% or less.

Owner:AUTONETWORKS TECH LTD +2

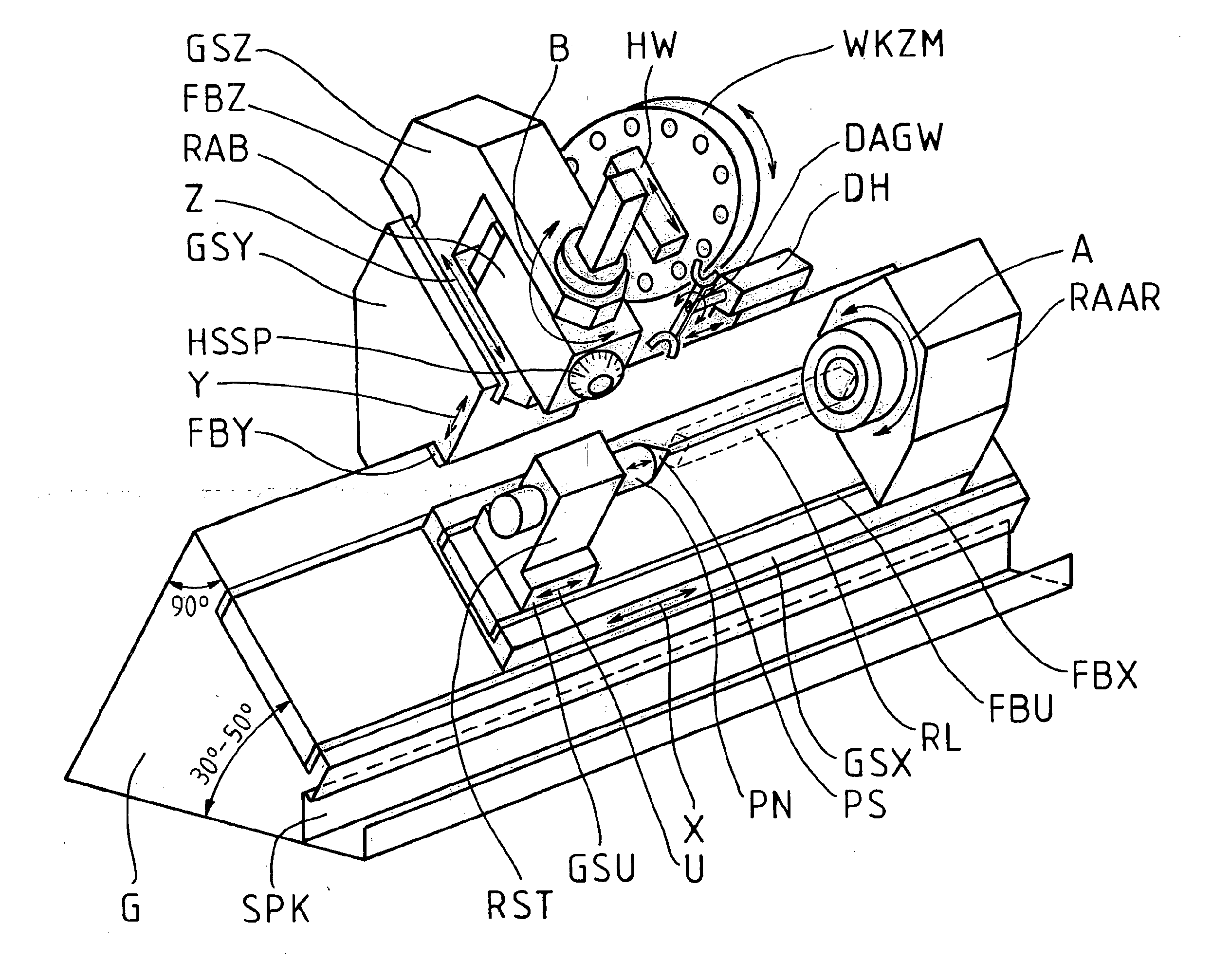

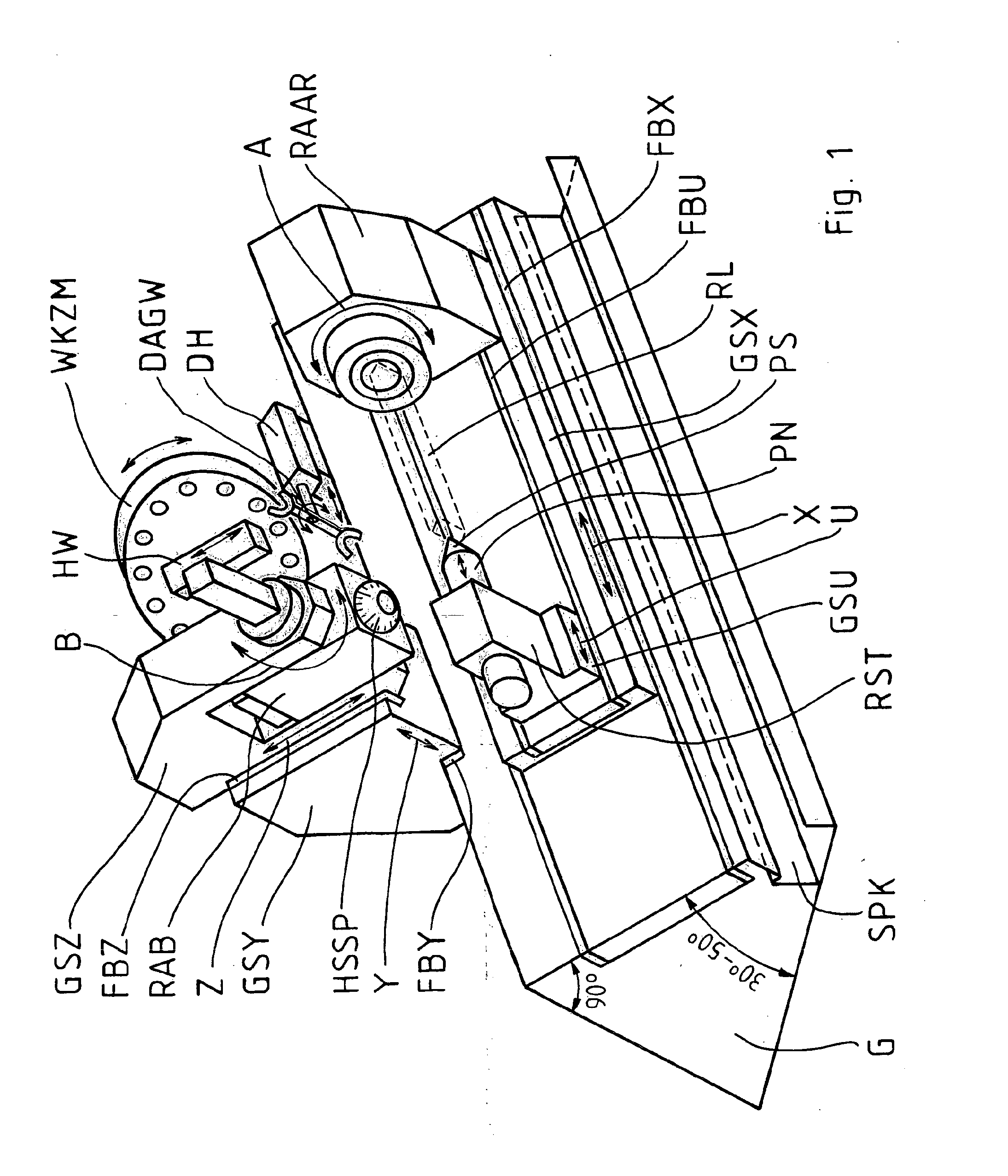

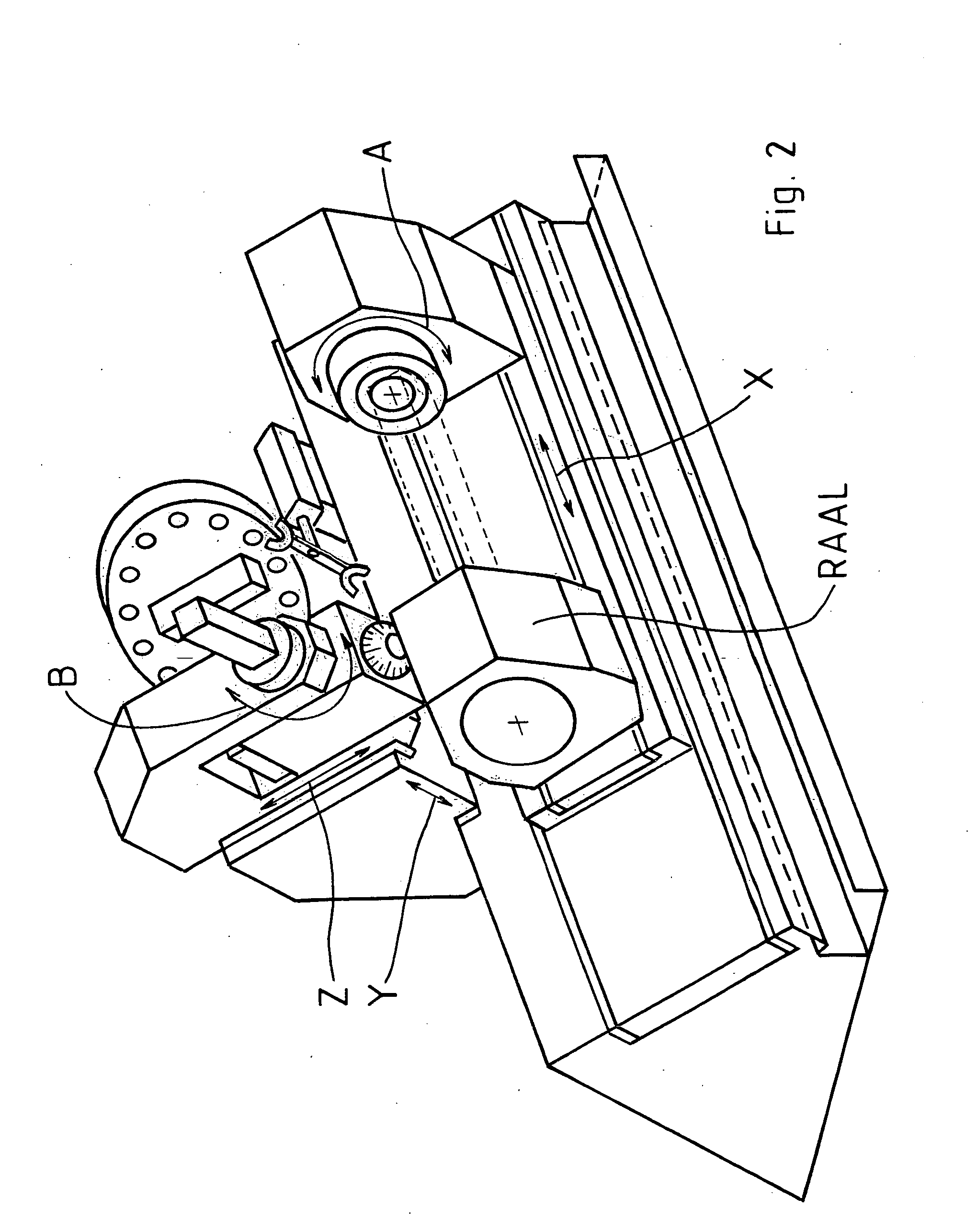

Method for machining blanks in a clamp

InactiveUS20100092260A1Increase rigidityIncrease precisionAutomatic/semiautomatic turning machinesWorkpiecesTurbine bladeMachine tool

In order to carry out complete machining of a blank on a machine tool, such as, for example, a rotary miller, the blank is held in at least one clamp during a machining step. All the functional surfaces of the workpiece (circumference and both end faces of the blank) are brought into the final required form corresponding to final use by the machine tool, in particular, the rotary miller. The blank is a blank made from metal or a ceramic material, of cylindrical, square, or polyhedral cross-section, in particular, a rectangular block or any shaped cast or forged blank. The required form is the head of a turbine blade, the blade region of the turbine blade, and the root of the turbine blade, wherein the functional surfaces of the head and root are prepared during a clamped phase on the machine tool.

Owner:HAMUEL MASCHENBAU

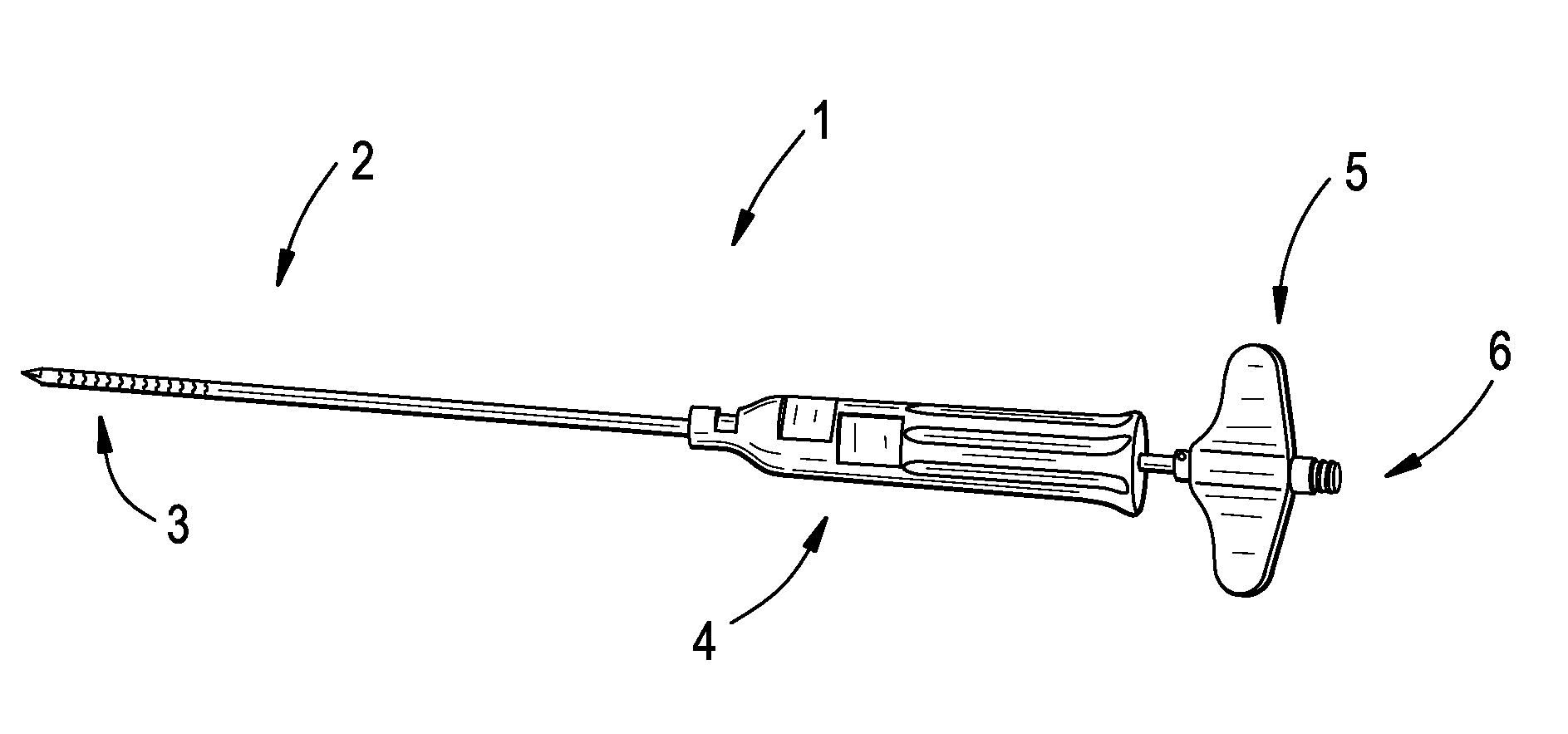

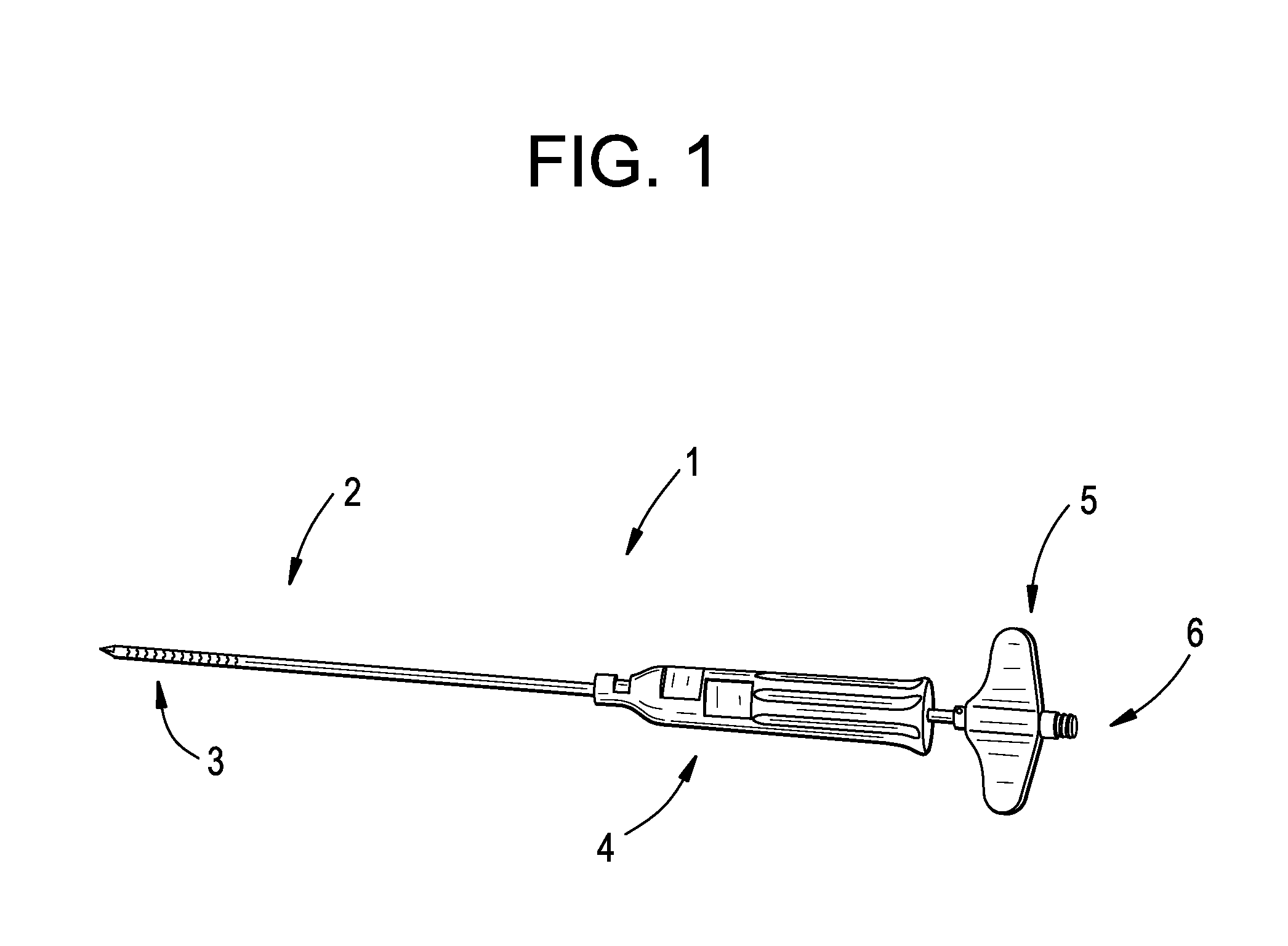

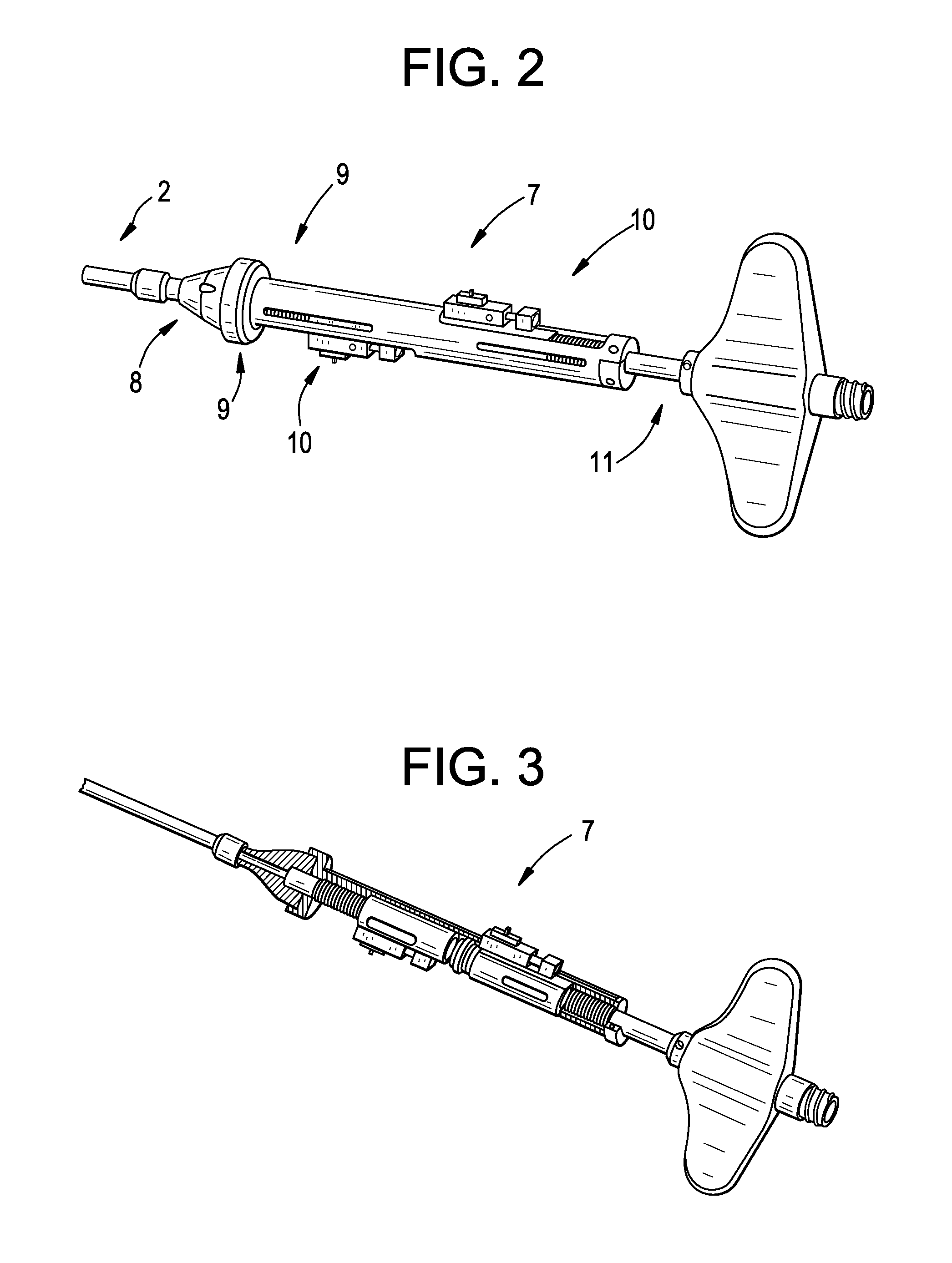

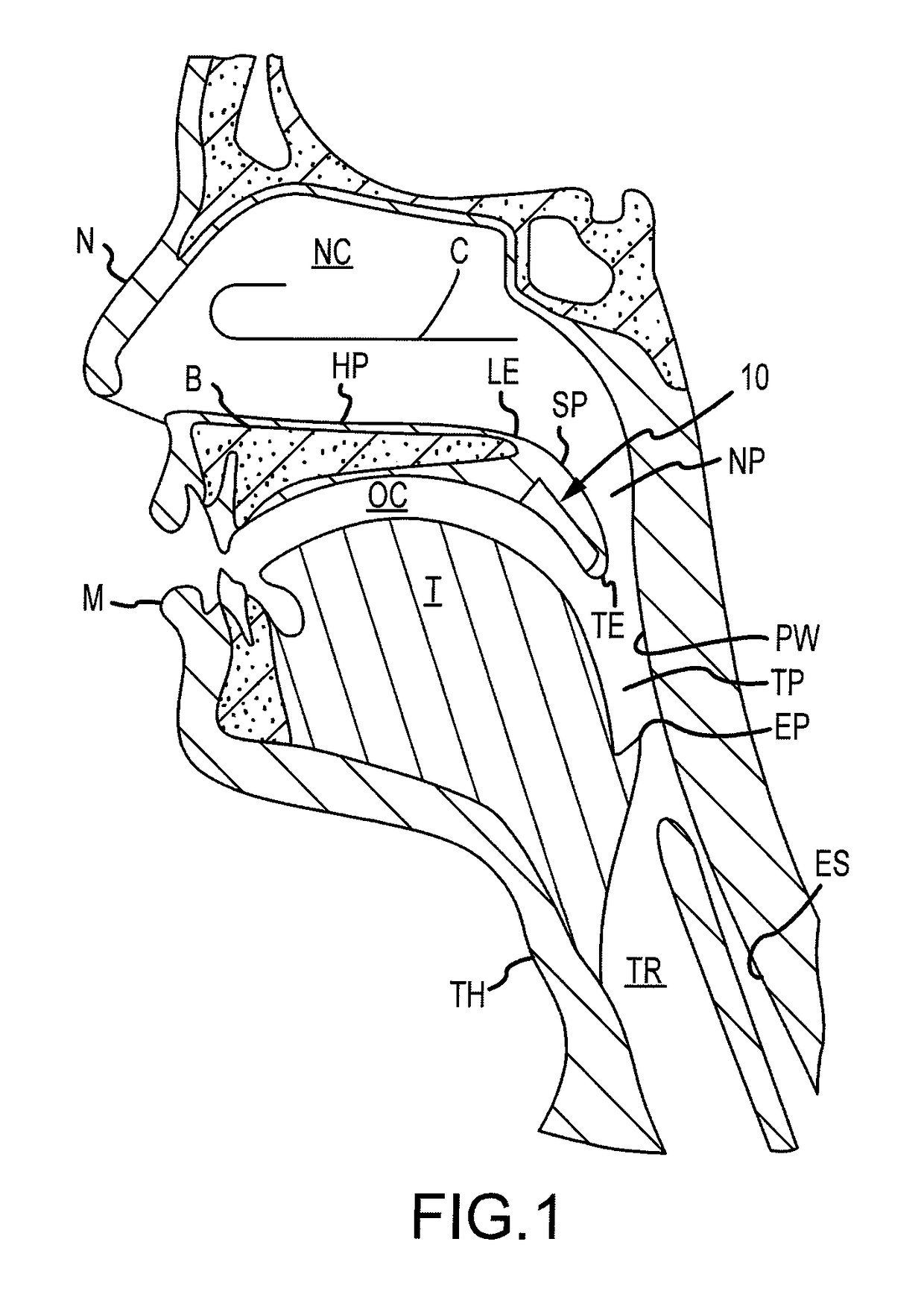

Vertebroplasty Curved Needle

InactiveUS20120265210A1Increase rigidityDecrease fatigue stressSurgical needlesProsthesisBone structureCentral region

Devices, systems and methods for delivering a curable, stabilizing material into a central region of a bone structure. Precise placement of the curable substance into a central region of a bone structure through a unipedicular approach. One primary advantage is its ability to create a central cavity in a vertebral body (or to centrally deliver bone cement) through a unipedicular approach. A curved needle having increased rigidity in its flexible end when the end is disposed in its straight position. This increased rigidity is due to a novel tensioning mechanism and to a segmented tube design (as opposed to the conventional longitudinally-slotted tube design).

Owner:DEPUY SYNTHES PROD INC

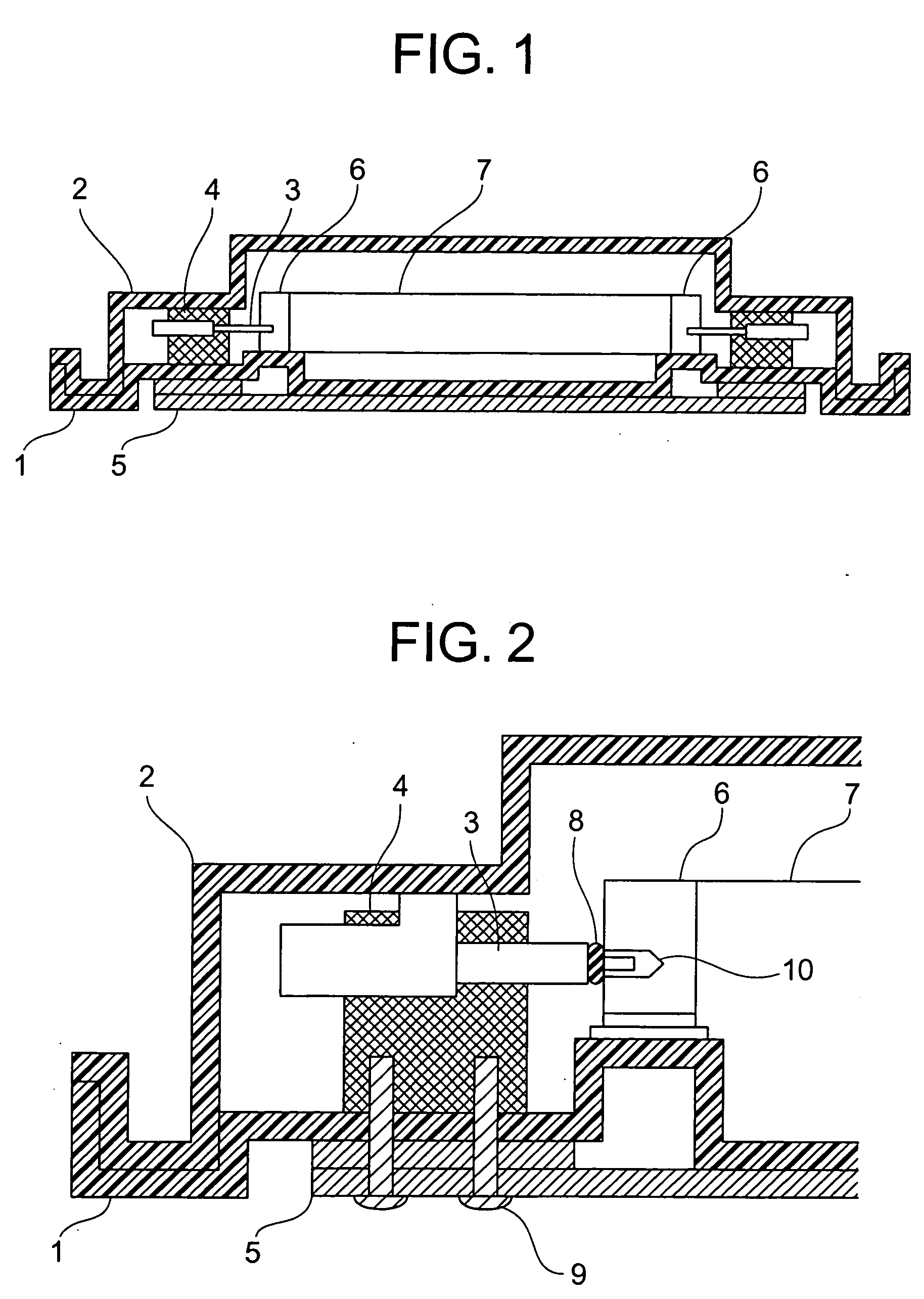

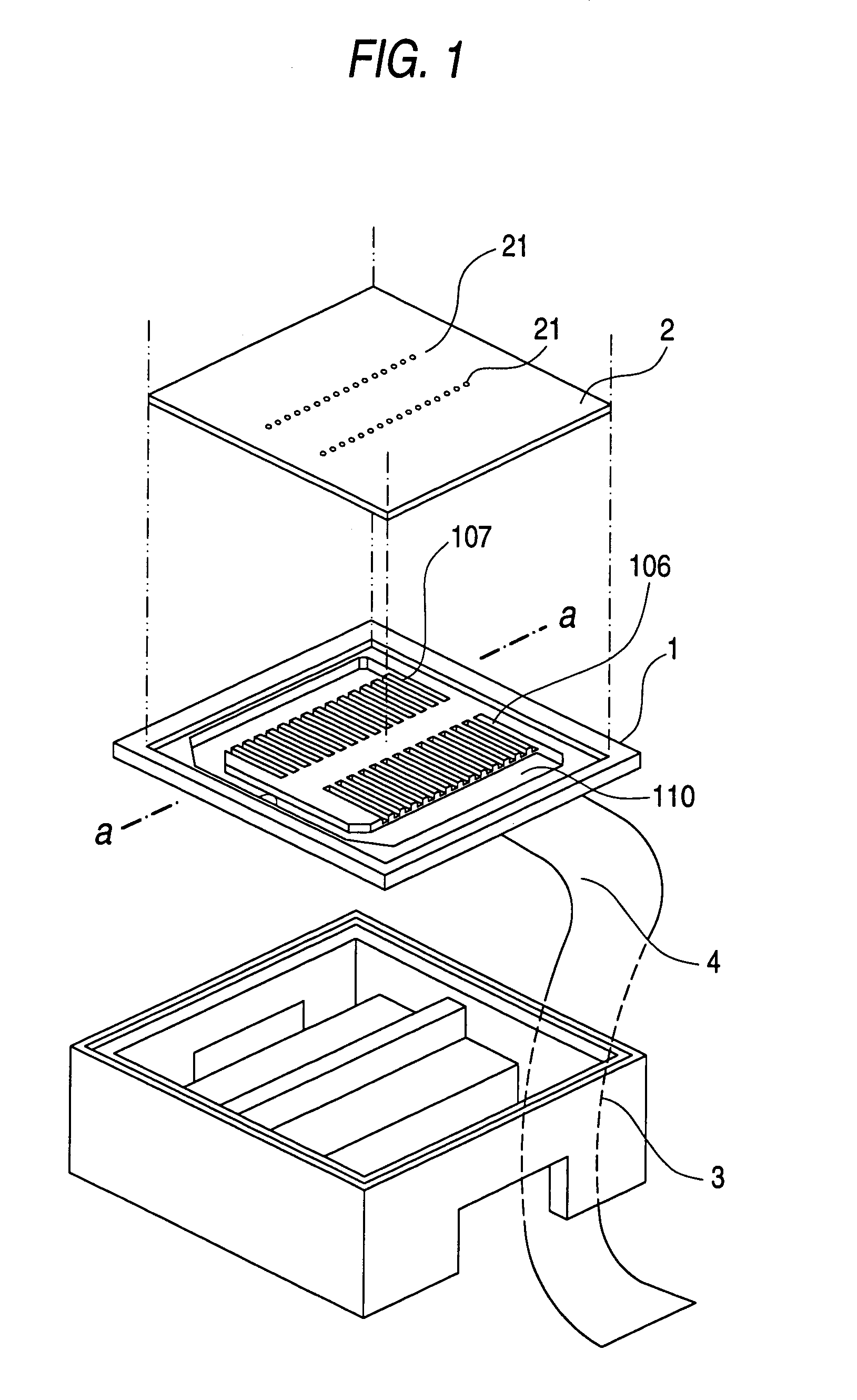

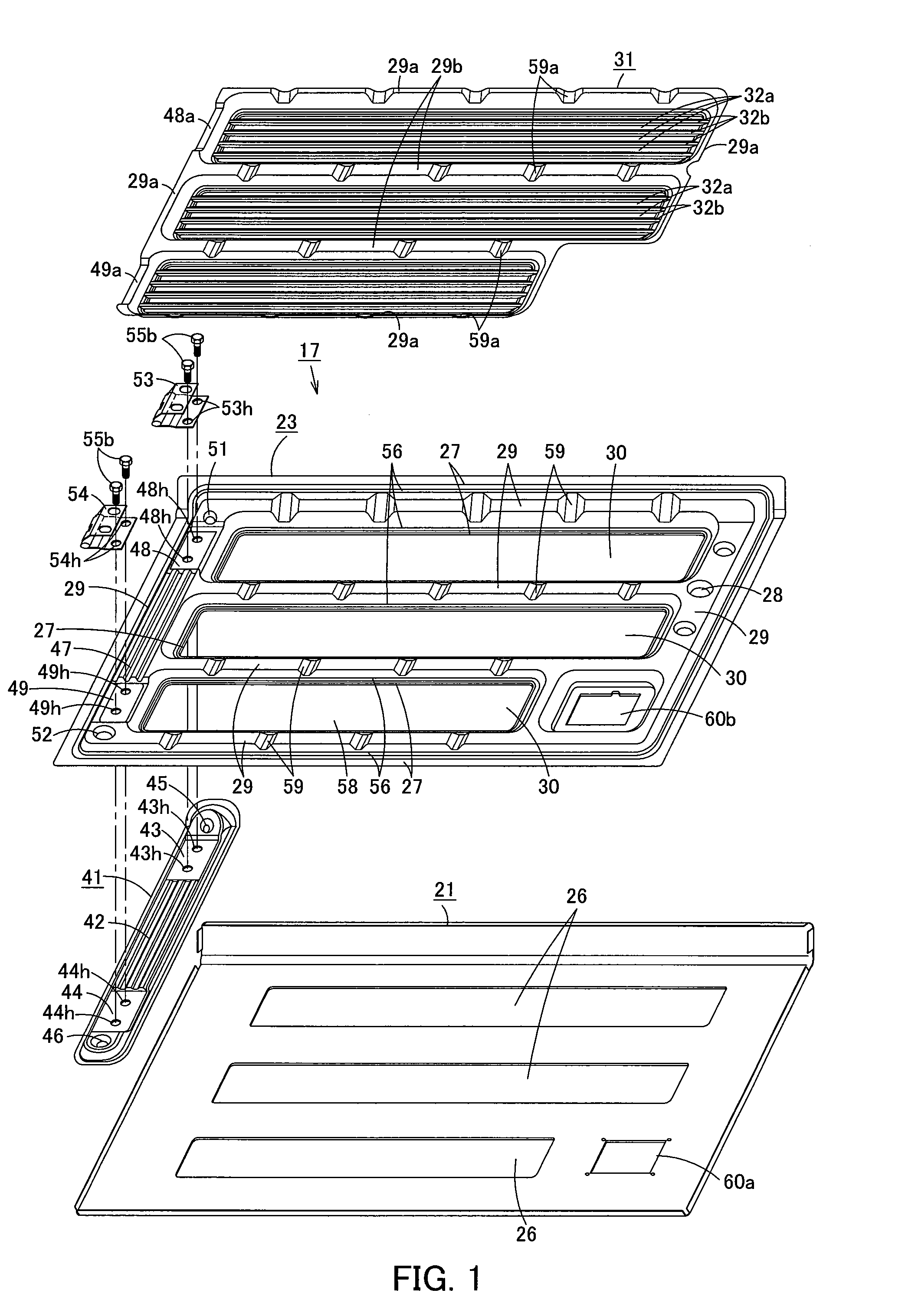

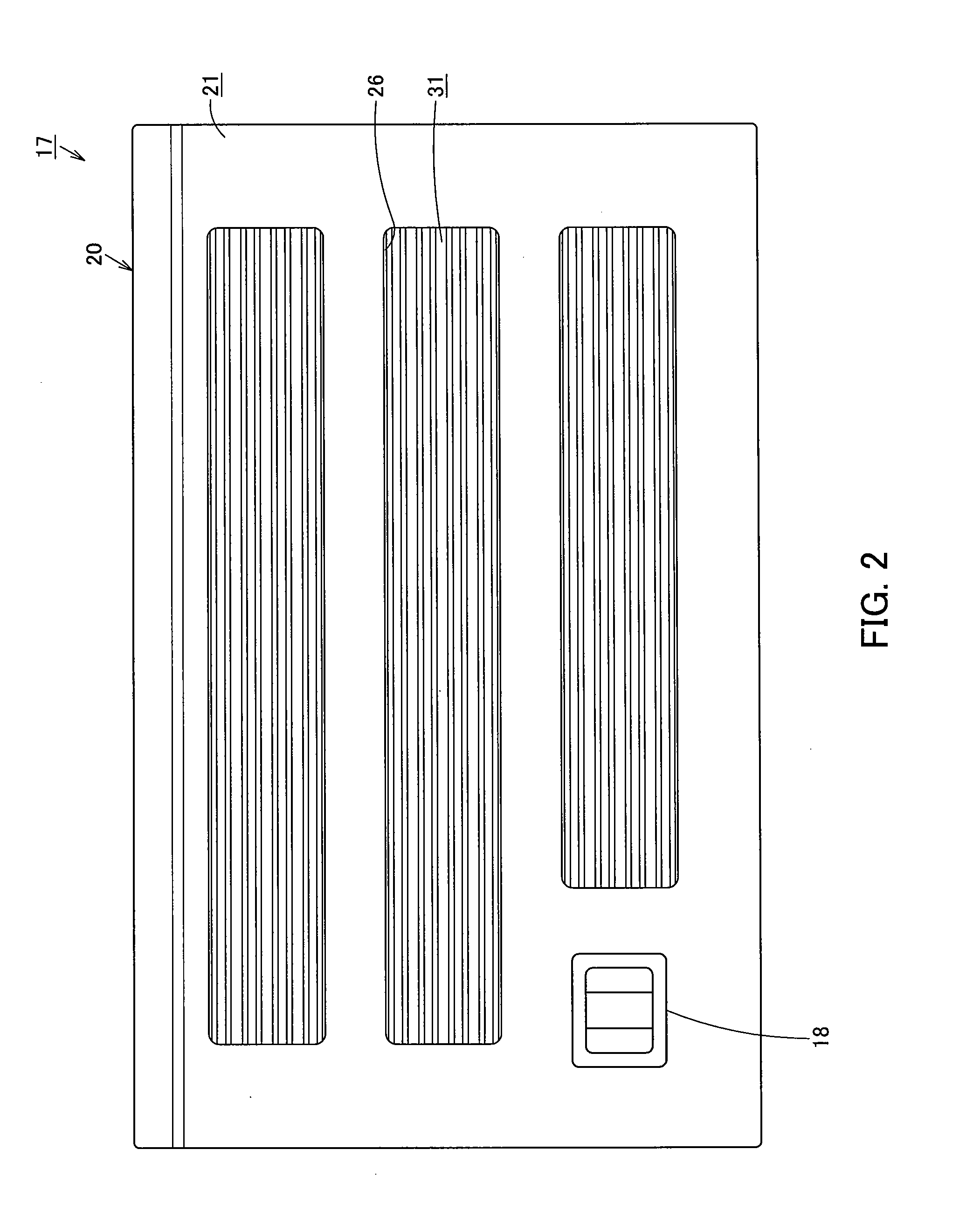

Method of producing an ink-jet printing head

InactiveUS7003857B1Prevent crosstalkIncrease rigidityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringInkjet printing

An ink-jet printing head comprises: a pressurizing chamber substrate having first and second sides opposing each other; a plurality of pressurizing chambers formed on the first side of the pressurizing chamber substrate; channels formed on the second side of the pressuring chamber substrate to be opposite to the pressuring chambers, respectively; oscillating plate films for pressurizing ink within the respective pressurizing chambers; and piezoelectric thin-film elements, each having upper and lower electrodes and a piezoelectric film sandwiched between the upper and lower electrodes, the piezoelectric thin-film being formed in the channel, wherein at least the upper electrode is formed to have a narrower width than that of the pressurizing chamber. And a method for producing the ink-jet head.

Owner:SEIKO EPSON CORP

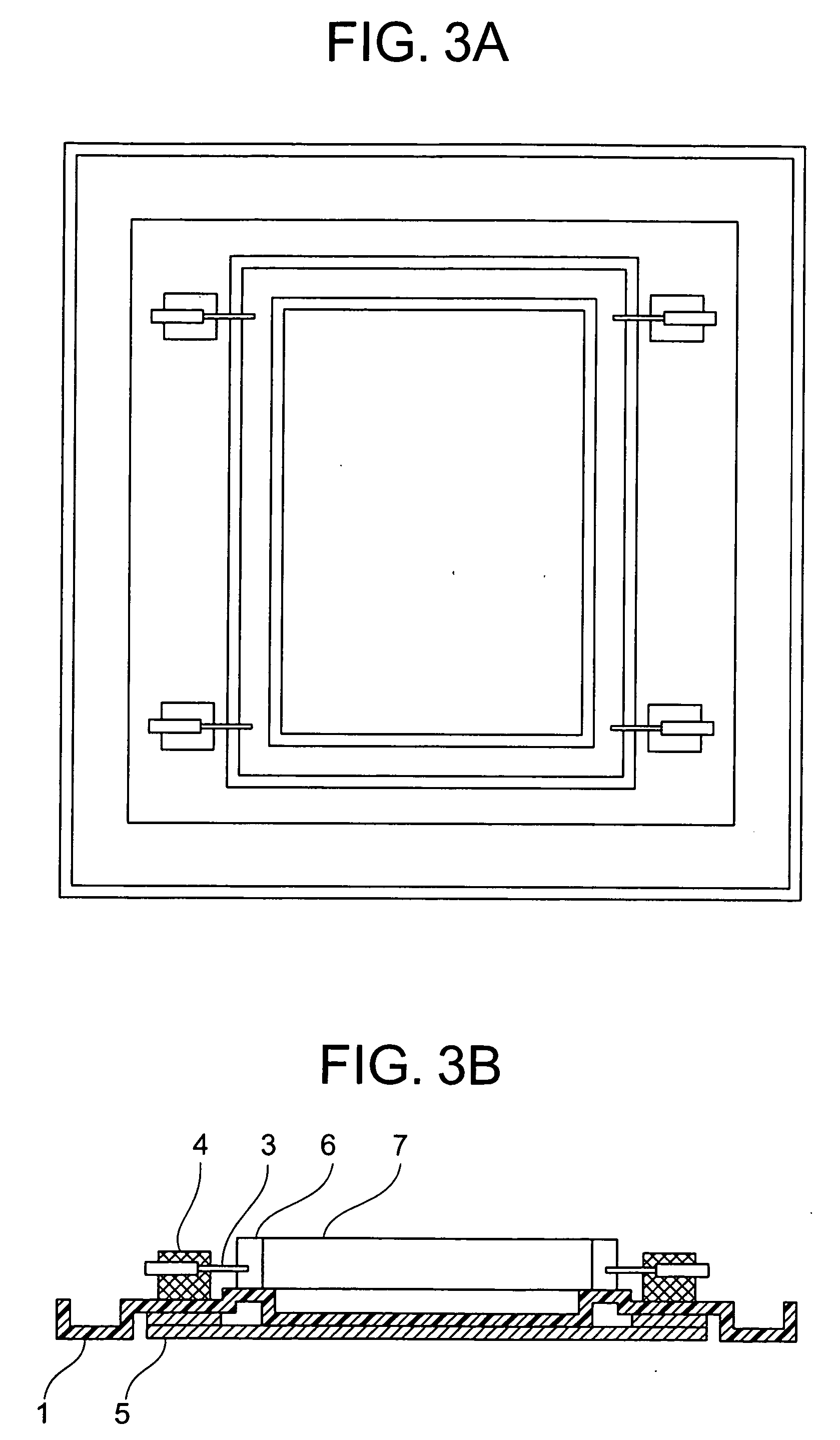

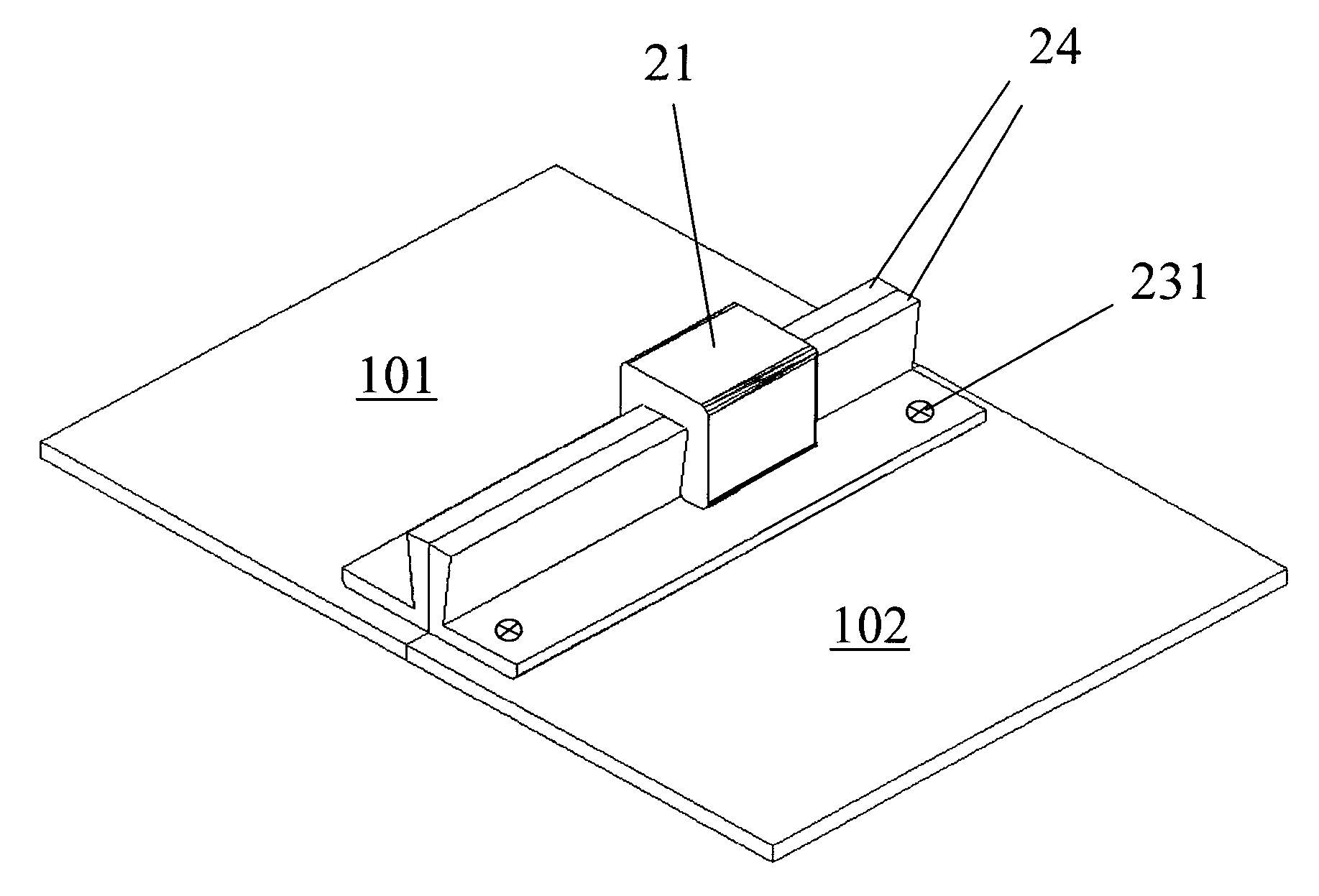

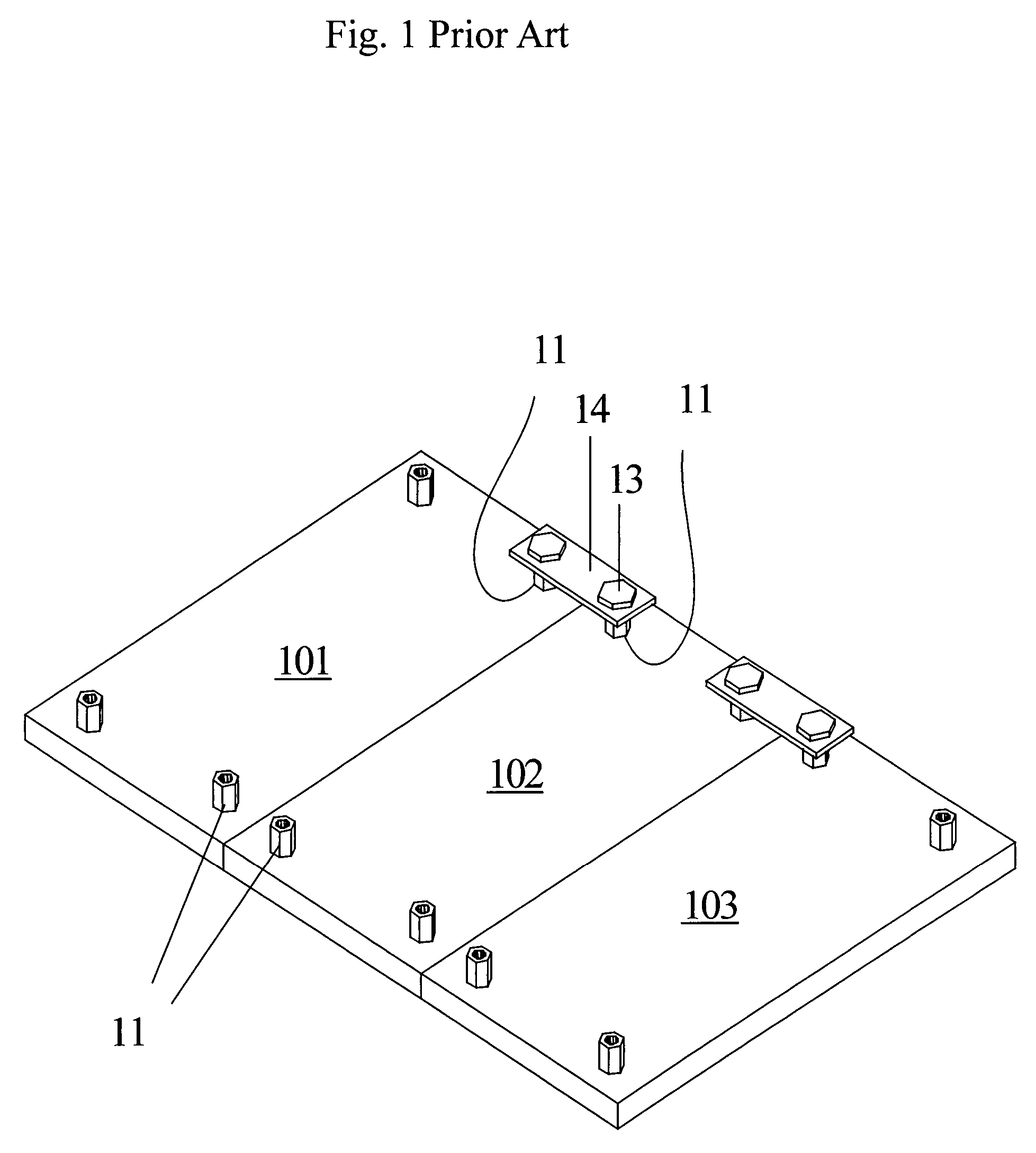

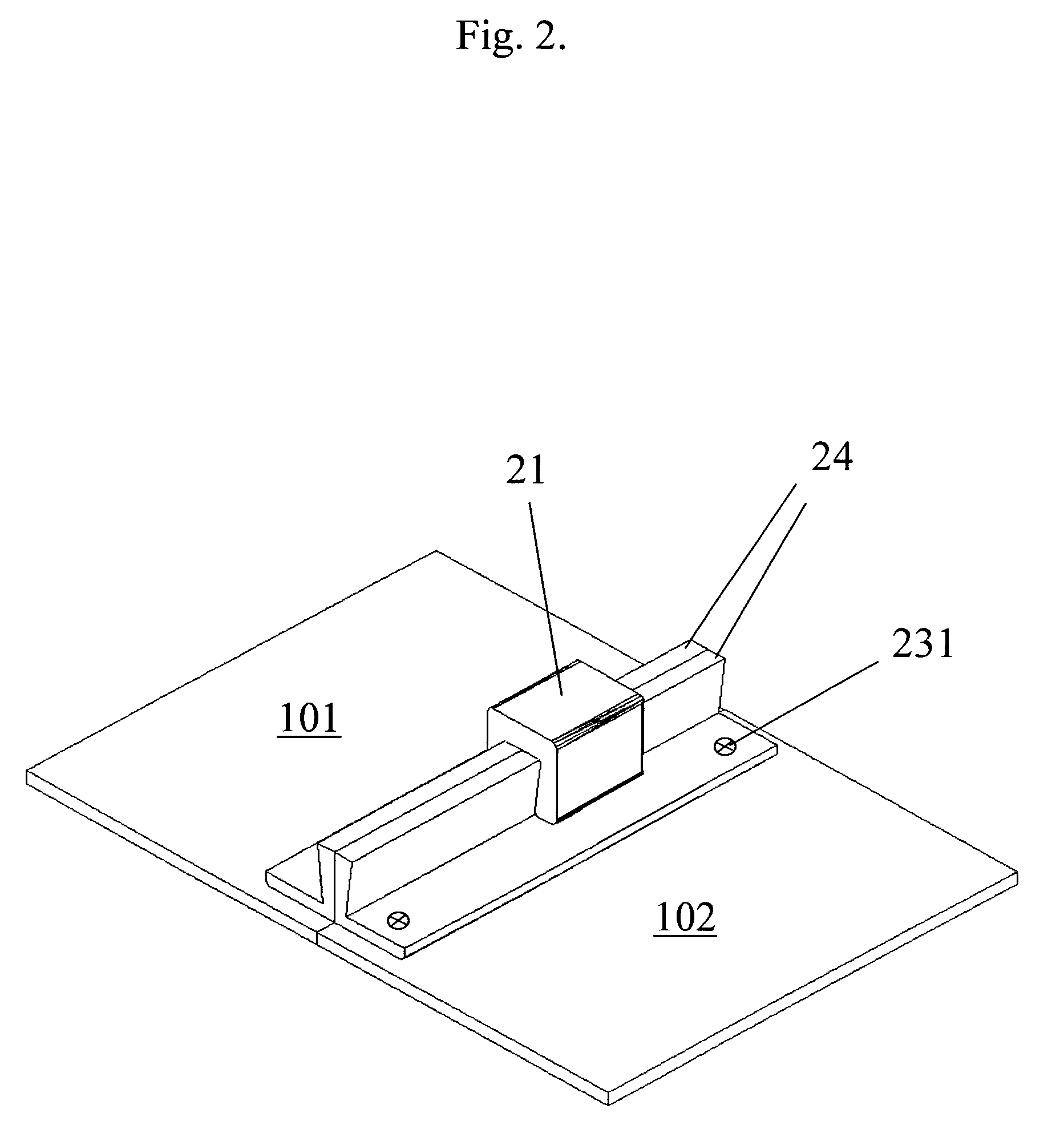

Circuit board for large screen LED matrix array display

InactiveUS20050083275A1Increase rigidityImprove rigidityMachine supportsDigital data processing detailsEngineeringMatrix Array

Multiple LED matrix array circuit boards are pieced together a form a display panel. L-shape brackets are mounted on the bottom sides of the circuit boards and aligned with the butting edges of the circuit boards. The vertical butting walls are pressed together by clamps. A set screw is inserted in one jaw of the clamp to tighten the pressure between butting edges of the circuit boards. Another set screw is inserted on top of the clamp to align the adjacent boards vertically.

Owner:HARVATEK CORPORATION

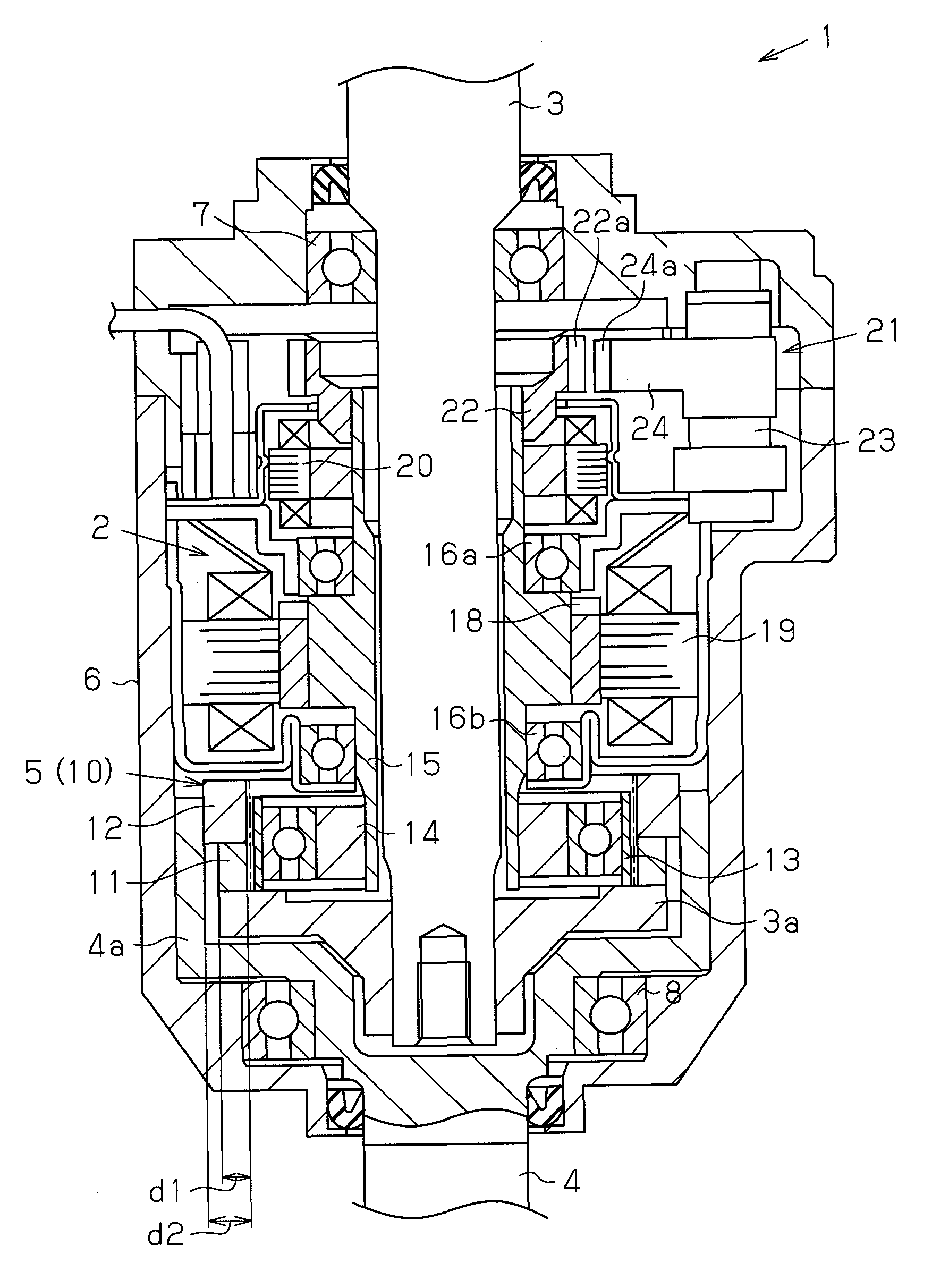

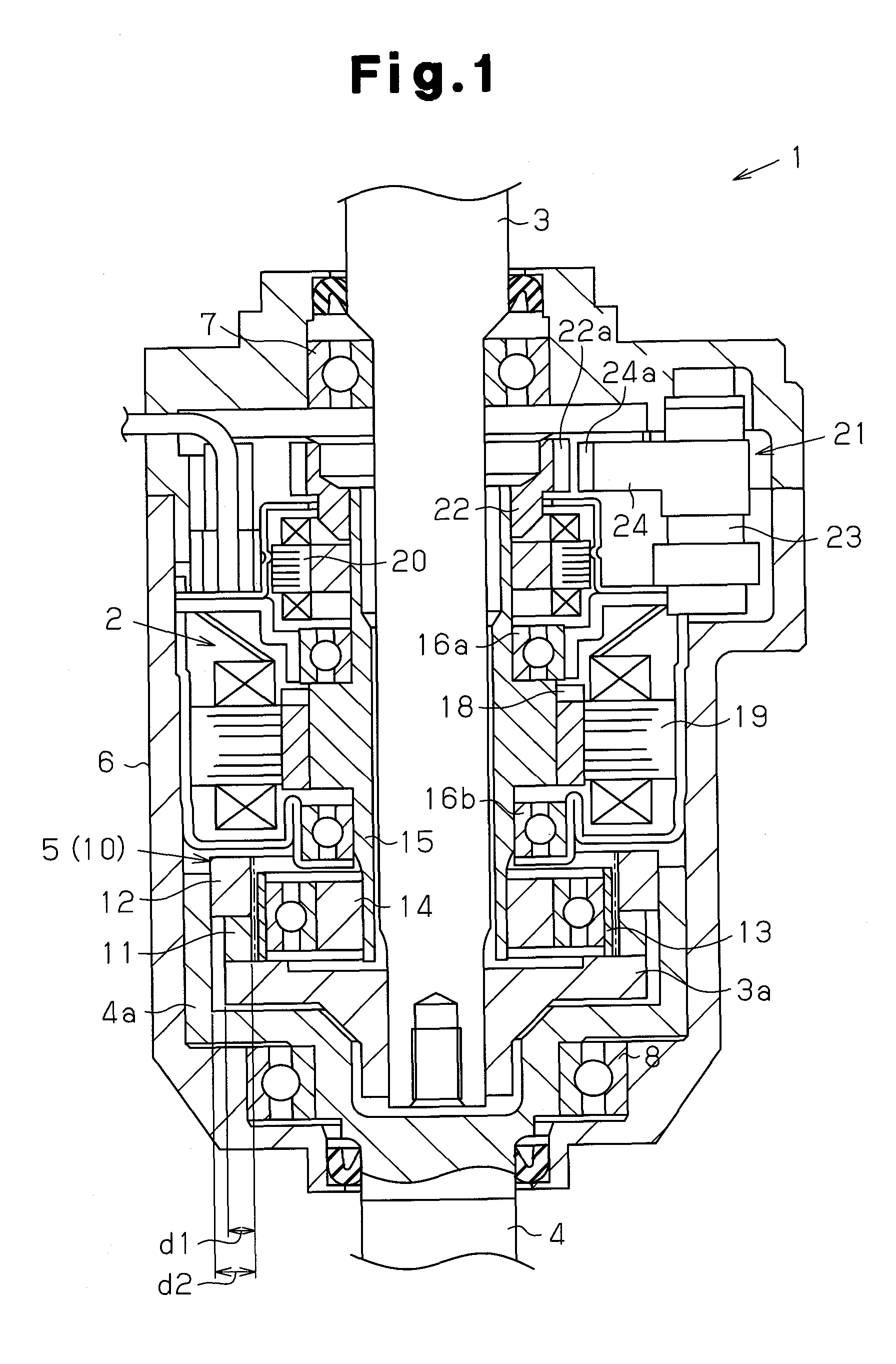

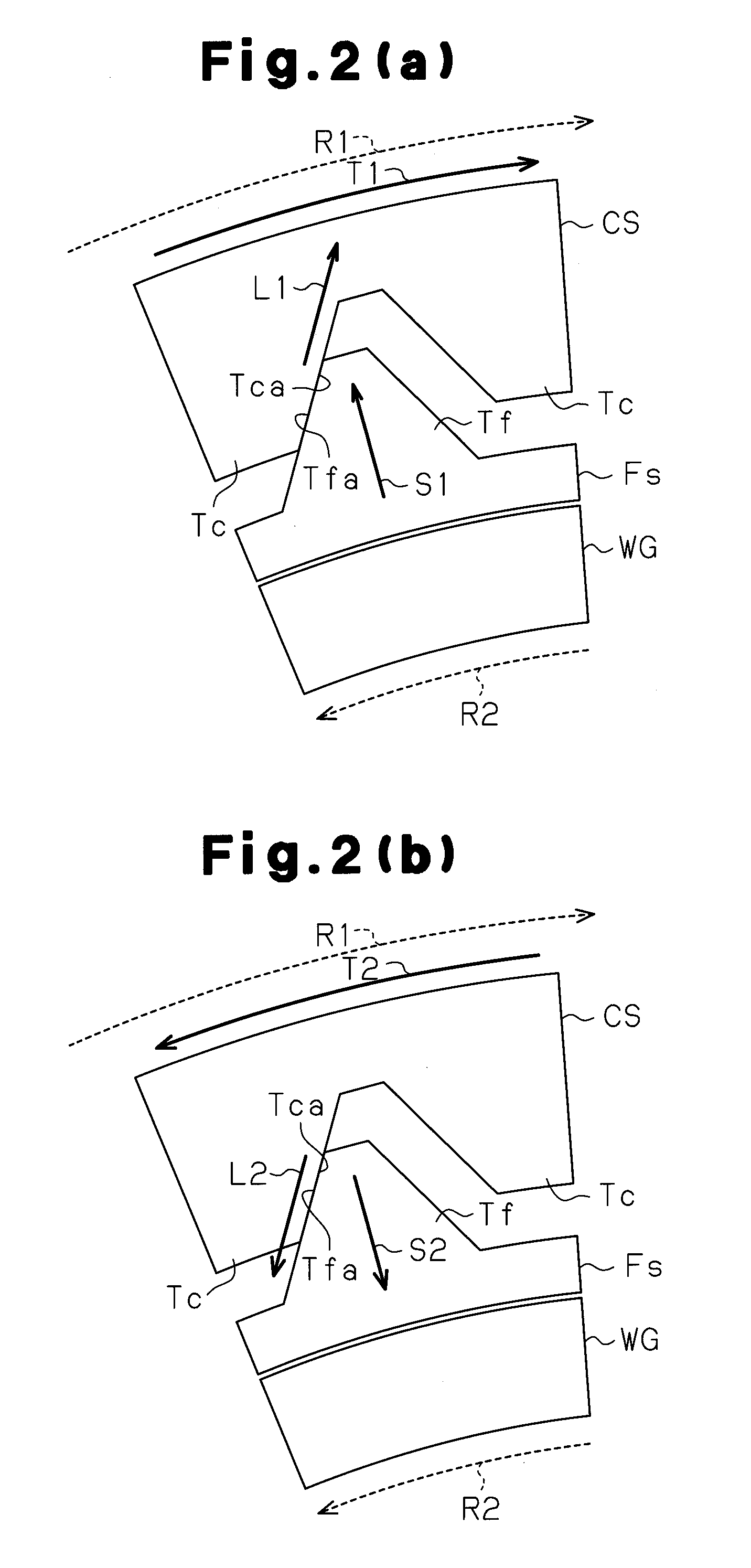

Transmission ratio variable device and steering gear

InactiveUS20090031852A1Increase rigidityEffectively prevents the ratcheting phenomenon from occurringDifferential gearingsElectrical steeringMotor shaftEngineering

A variable transmission ratio apparatus for effectively preventing ratcheting between a flexible spline and a circular spline caused by a steering operation performing in a locked state. A variable transmission ratio apparatus includes a strain wave gear mechanism for adding rotation resulting from motor drive to rotation from an input shaft resulting from a steering operation and transmitting the added rotation to an output shaft, a housing accommodating the strain wave gear mechanism and the motor and fixed to a non-rotating portion, and a lock device for locking the housing and a motor shaft in a manner prohibiting relative rotation therebetween. Among the circular splines forming the strain wave gear mechanism, the number of teeth of the circular spline connected to the output shaft is greater than the number of teeth of the circular spline connected to the input shaft.

Owner:JTEKT CORP

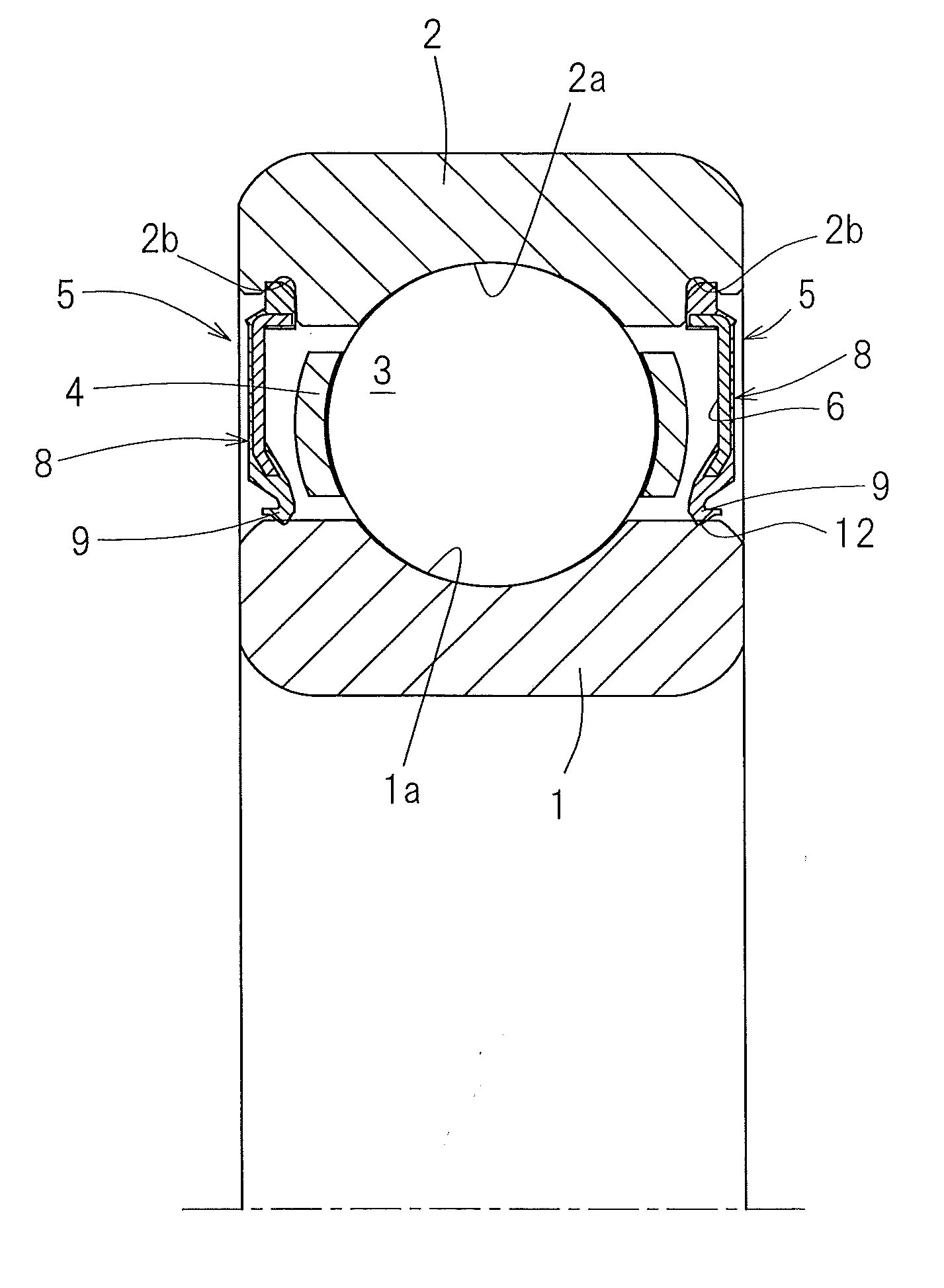

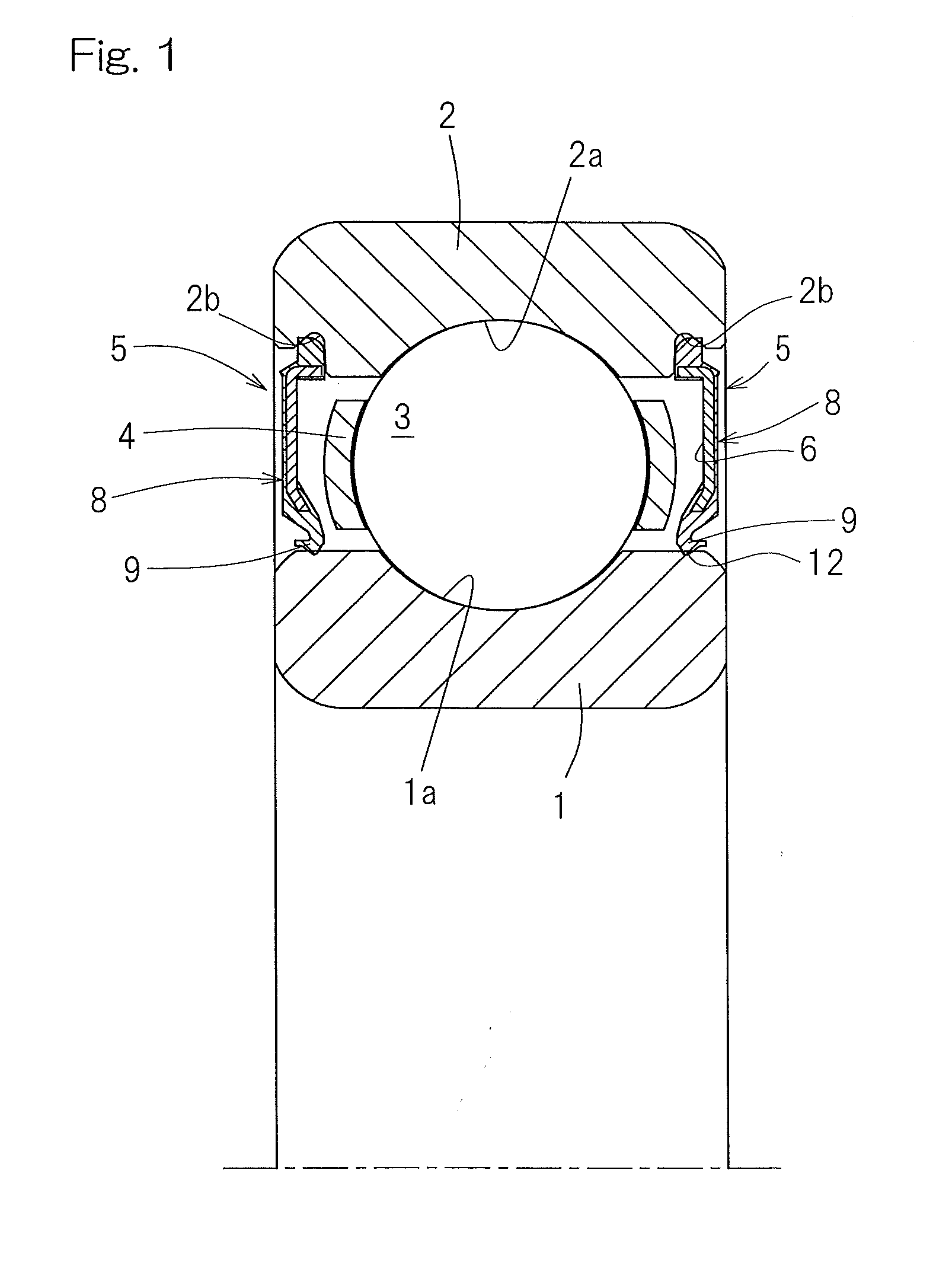

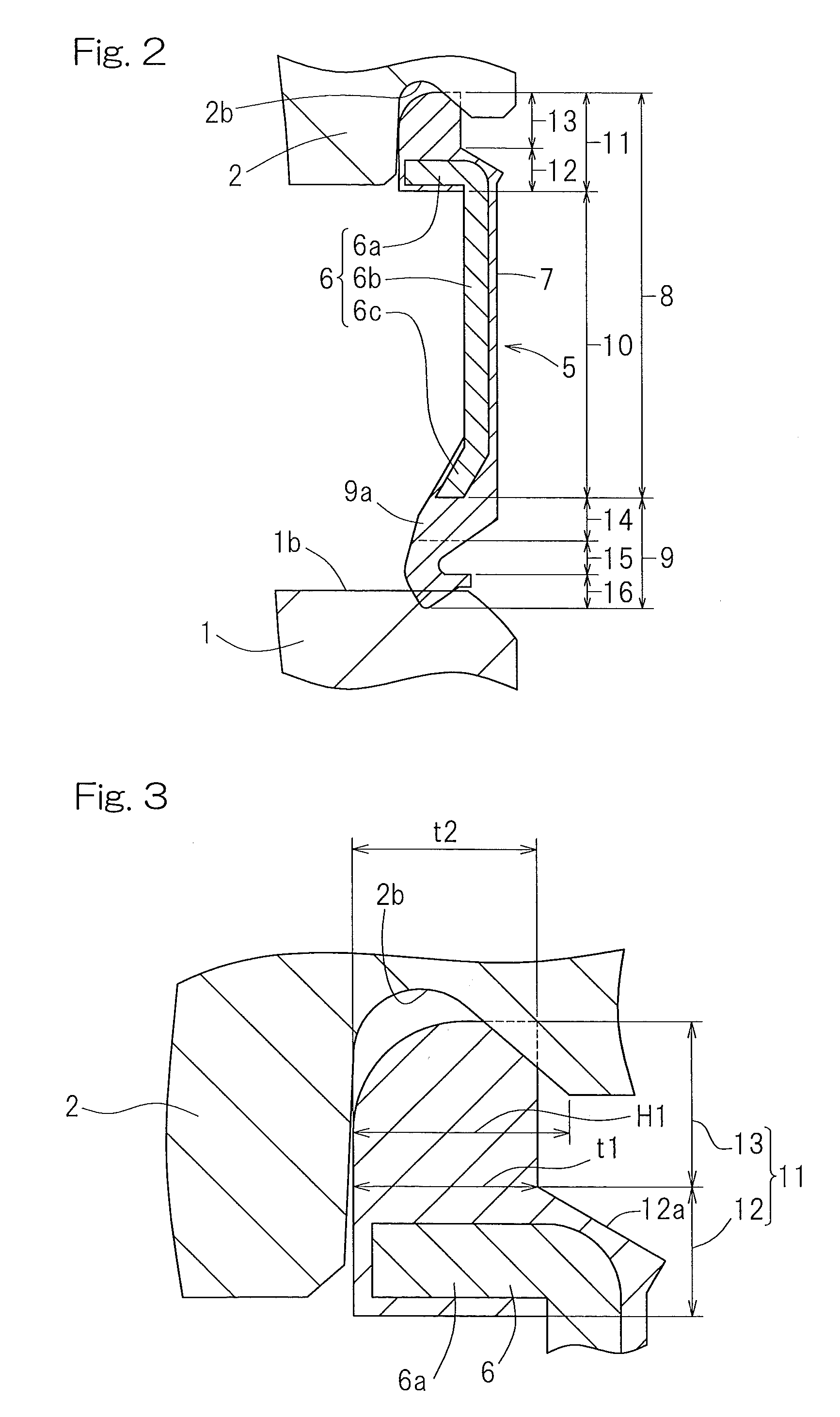

Rolling bearing

InactiveUS20150049972A1Constrain force of be increaseIncrease rigidityBall bearingsBearing componentsRolling-element bearingFriction force

A seal lip portion 9 includes a lip main body (9a) and a projecting section (16) protruding from a peripheral edge of the lip main body (9a) and slidingly engageable with an inner ring (1), and this projecting section (16) is made of a highly frictionally wearable material which allows the projecting section (16), when frictionally worn, to establish a non-contact or a light contact to such an extend as to result in a contact pressure that can be regarded as zero. A fitting section (13) fitted into a seal mounting groove (2b) in a seal member main body (8) is held in a drag-rotation preventive structure that prevents circumferential movement due to a drag-rotation relative to an outer ring (2).

Owner:NTN CORP

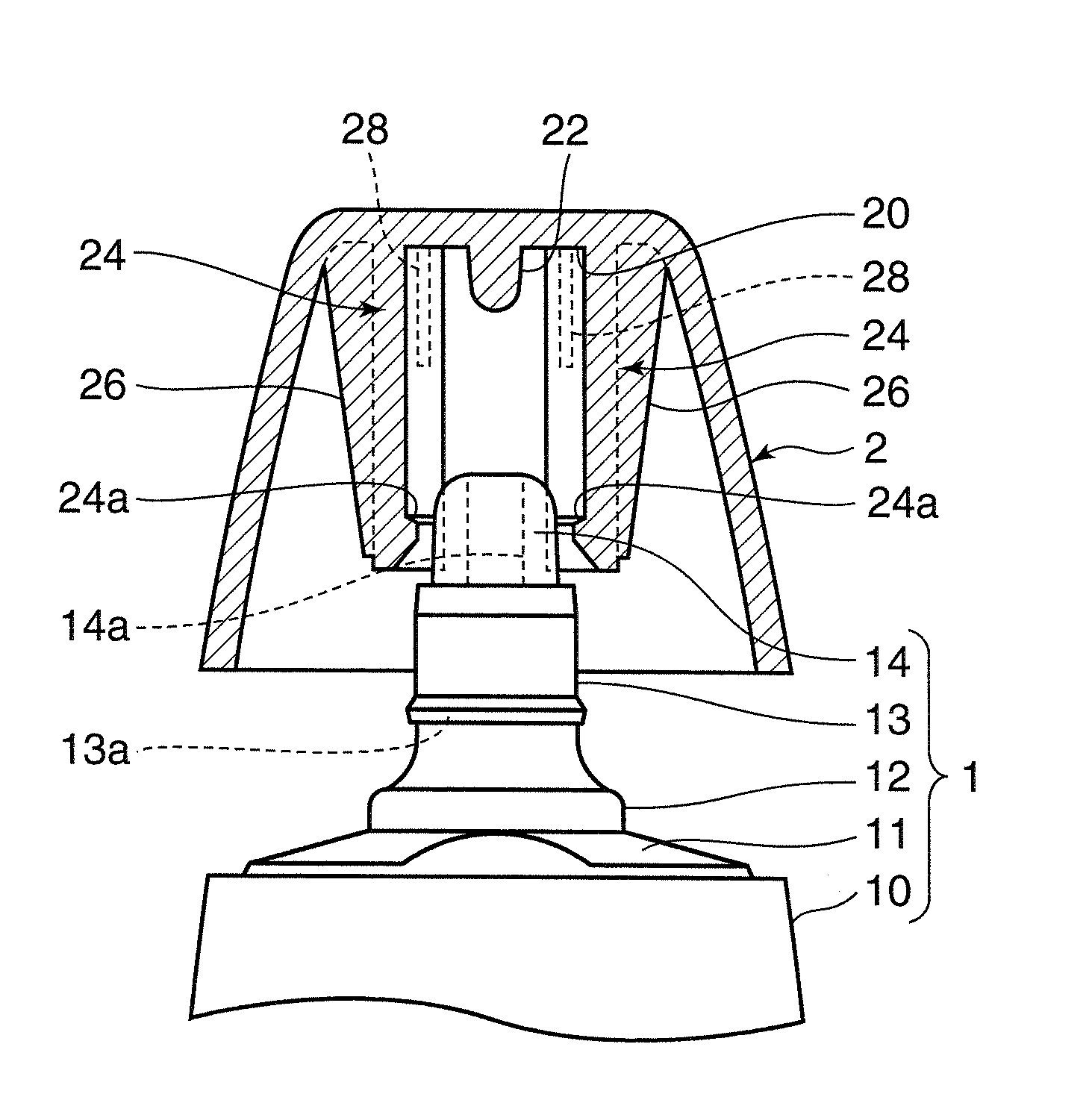

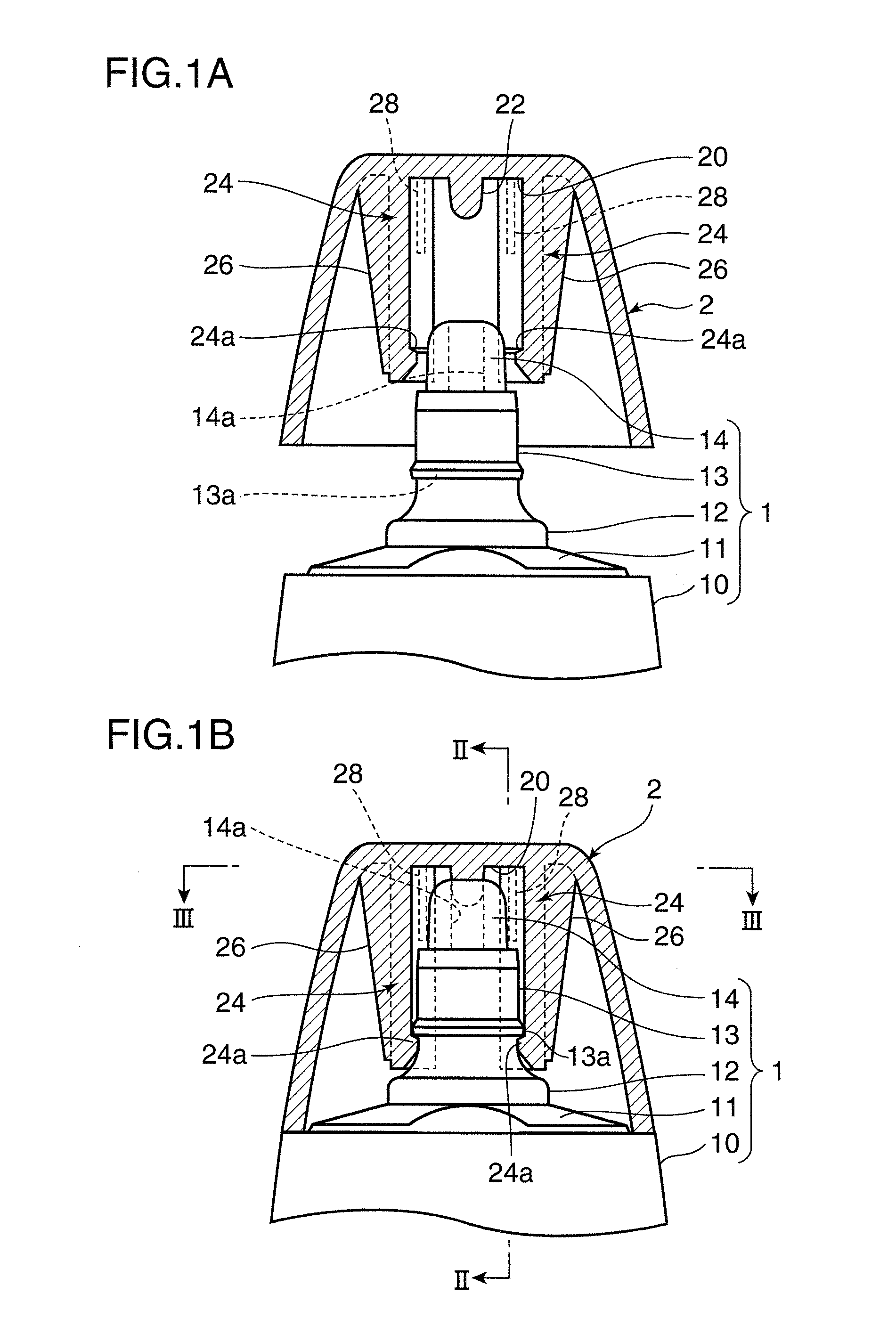

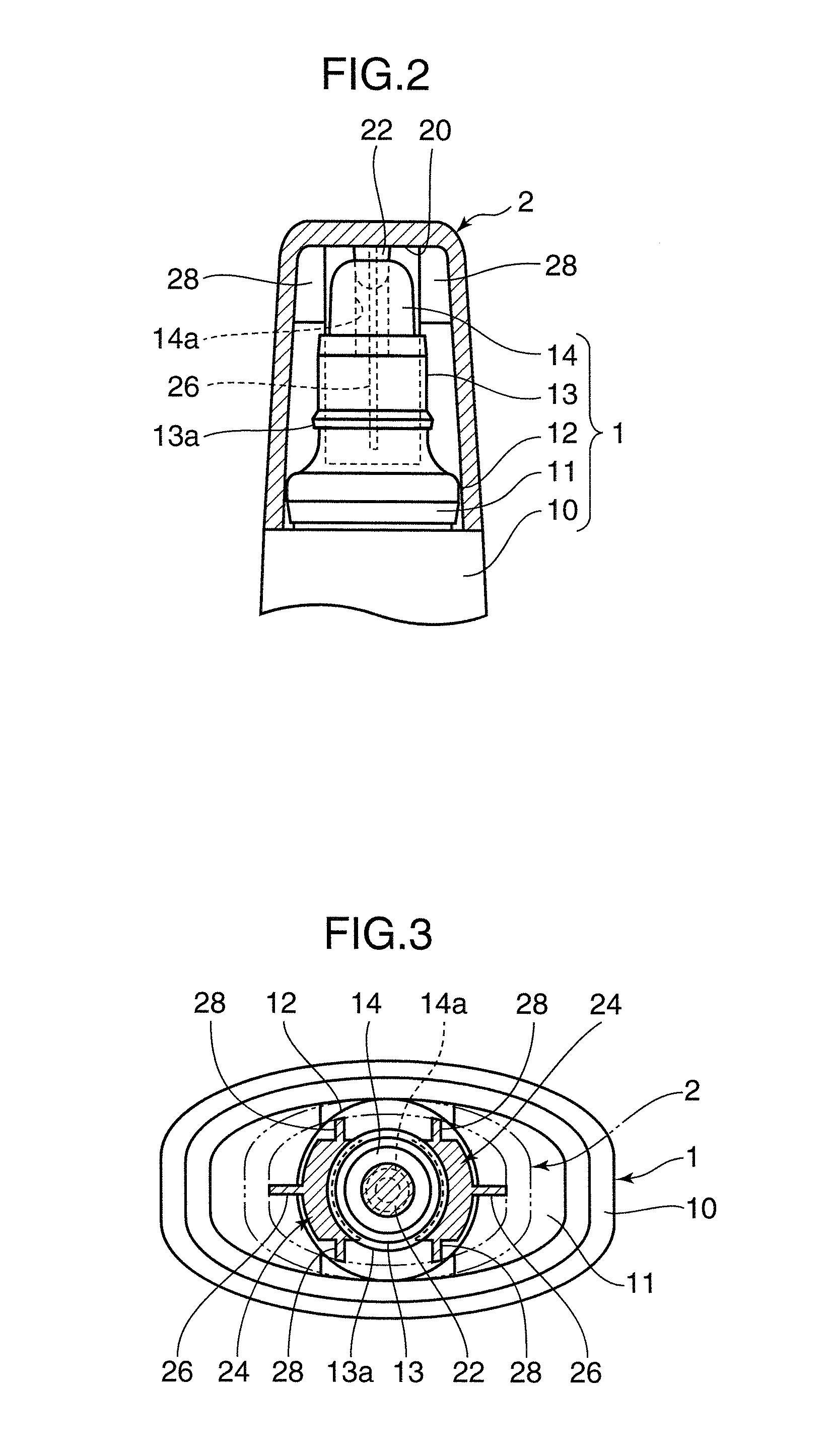

Liquid container

InactiveUS20110031207A1Increase rigidityImprove rigidityClosure capsBottlesEngineeringMechanical engineering

A liquid container comprises a container body (1) and a cap (2). The container body (1) has a circular tubular neck portion (13) with an outer peripheral surface provided with a protrusion (13a) for locking the cap (2). The cap (2) has a pair of lockable arms (24) arranged in a lateral direction and each provided with a hook portion (24a) adapted, during an operation of attaching the cap (2) to the container body (1), to be engaged with the locking protrusion (13a). Further, the cap (2) internally has a pair of first reinforcing ribs (26) each adapted to restrict a flexural displacement of a respective one of the lockable aims (24) in the lateral direction, and a pair of second reinforcing ribs (28) each connecting an inner surface of the cap and a respective one of the lockable arms (24) in a frontward-rearward direction.

Owner:ROHTO PHARM CO LTD

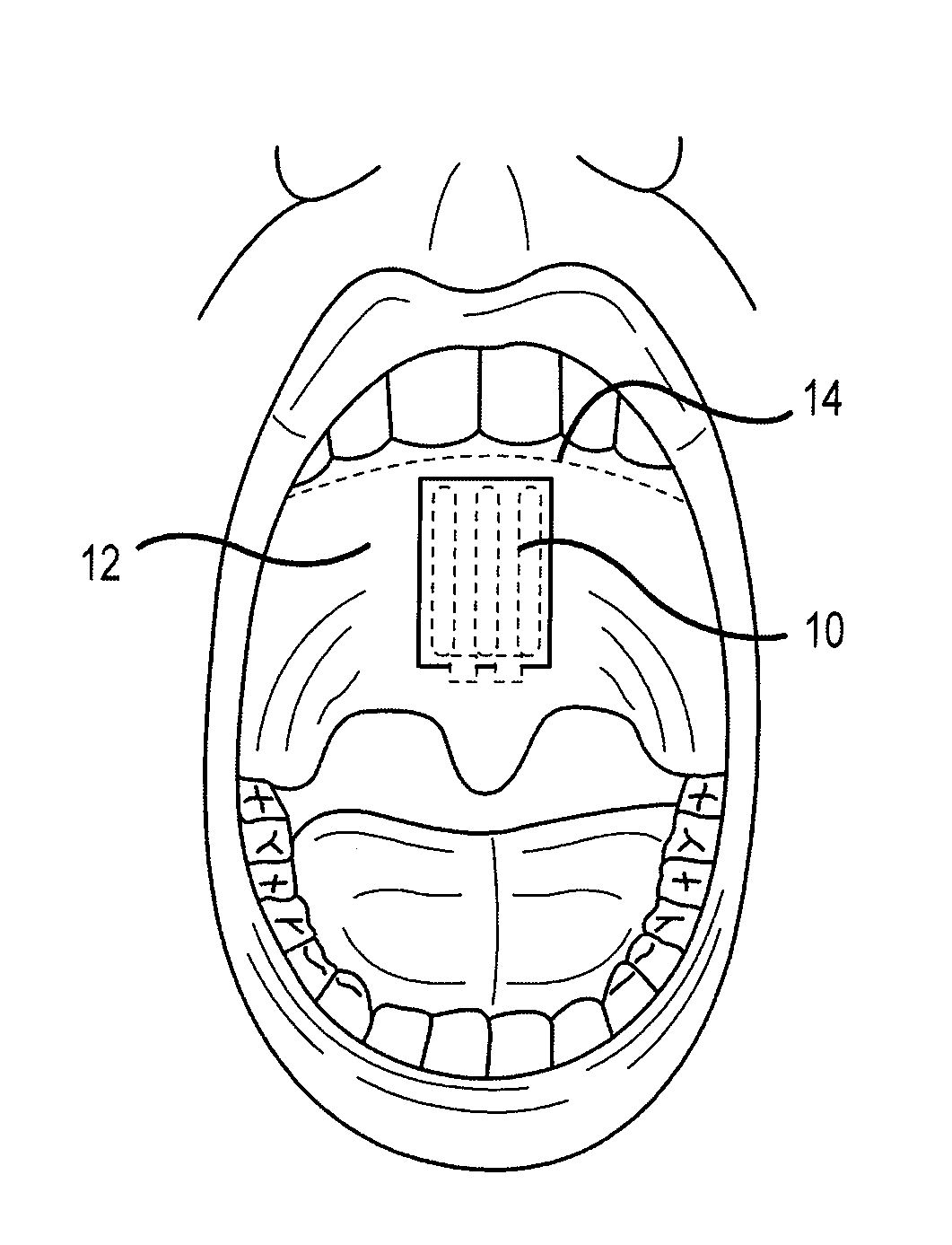

Bioadhesive Strip and Method of Using Same

A bioadhesive strip includes material that is removable or dissolvable in the oral cavity and adheres to the mucosal tissue of a person's oral cavity, with preferred embodiments including a specially textured surface on at least the outer side of an adhesive strip that faces away from the mucosal tissue to which it is attached and that has anti-microbial characteristics, bioluminescent expressions, etc. and a surface topography that resists bioadhesion of undesired bacteria that are typically present in a human's mouth. Methods of using the bioadhesive strip include treating snoring, sore throat conditions, GERD, NAFLD, Alzheimer's Disease, cachexia and migraines.

Owner:KOVARIK JOSEPH E +1

Label with bendable part

A label has a part that is to stand out at a defined angle from a curved surface to which the label is applied. There is a reinforcement area that has an edge curvature at the transition part of the label, between the part that is to be raised up and the part that is attached to the curved surface. The edge curvature is implemented such that it fixes the part to be raised up at a defined angle during or after placement of the label on a specific object.

Owner:SCHREINER GRP GMBH & CO KG

Door panel

InactiveUS20100031604A1Easily provideIncrease rigidityDoors/windowsSoil-shifting machines/dredgersHoneycombRidge

A door panel that permits formation of small ventilation holes therein while ensuring adequate rigidity is provided. The door panel includes an outer panel, an inner panel, and a perforated ridge-and-furrow plate. The outer panel has openings, and the inner panel has openings. The inner panel is formed by means of press molding so as to have an uneven surface with recessed portions and a raised portion, with the raised portion protruding away from the outer panel and the recessed portions recessed towards and fixed to the inner surface of the outer panel. The perforated ridge-and-furrow plate is attached to the reverse side of the inner panel. The perforated ridge-and-furrow plate is a punching plate that is already provided with numerous small, circular ventilation holes, or with ventilation holes arranged in a mesh or a honeycomb shape. The perforated ridge-and-furrow plate includes alternating furrow portions and ridge portions formed in the region that corresponds to the openings of the inner panel.

Owner:KEJTERPILLAR R L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com