Container box for framed pellicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example

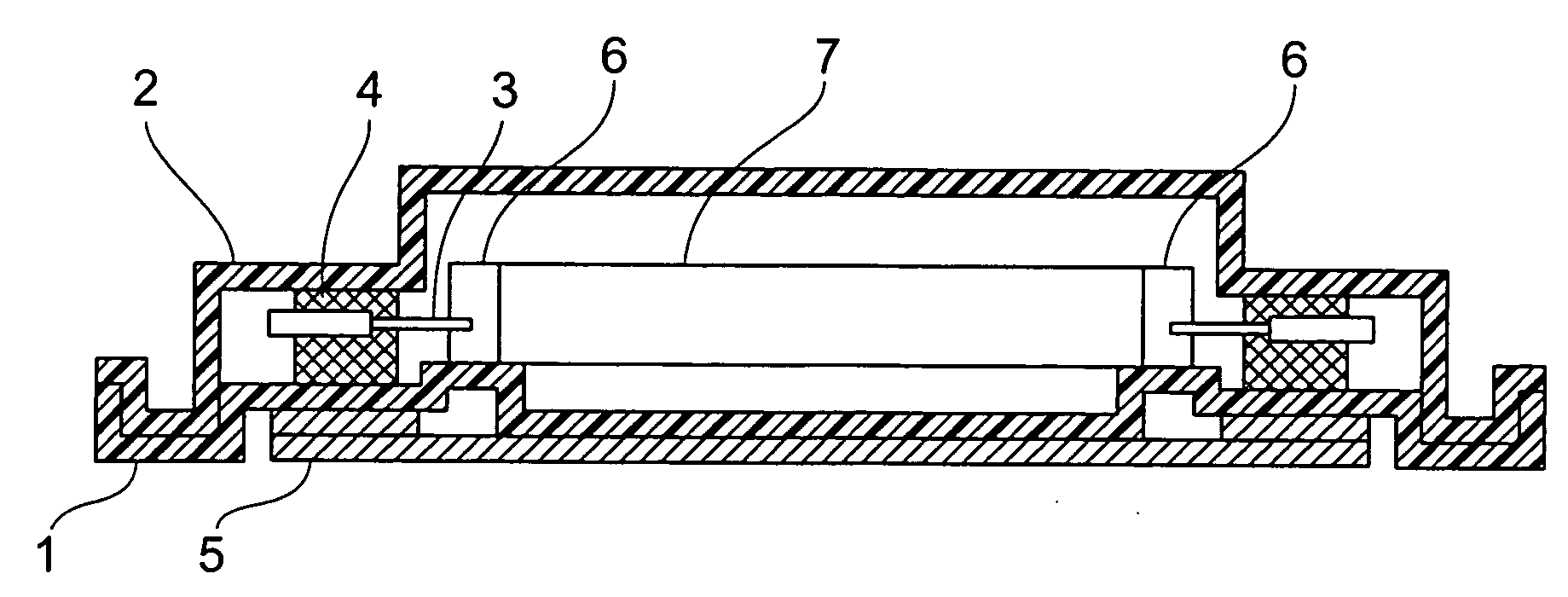

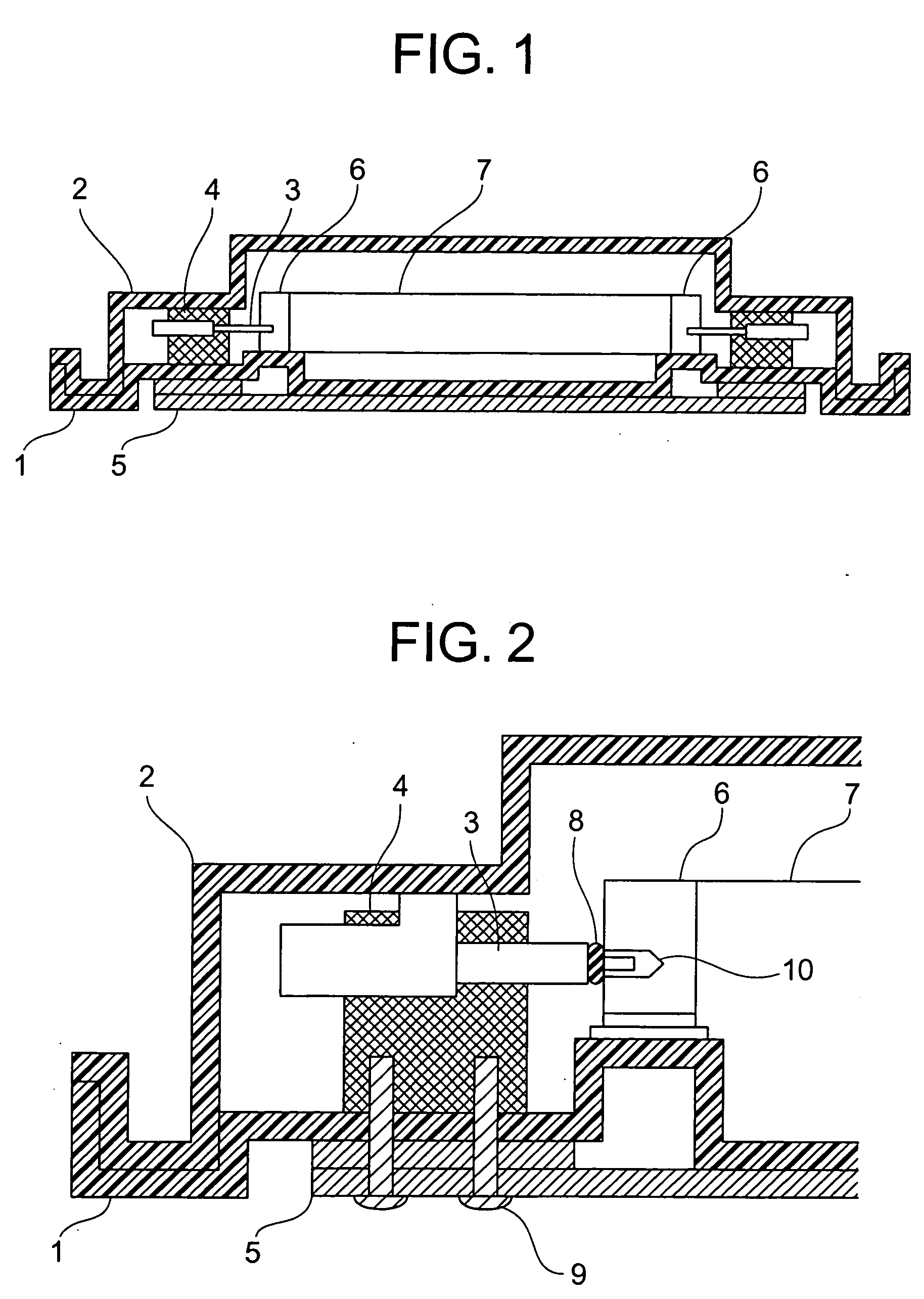

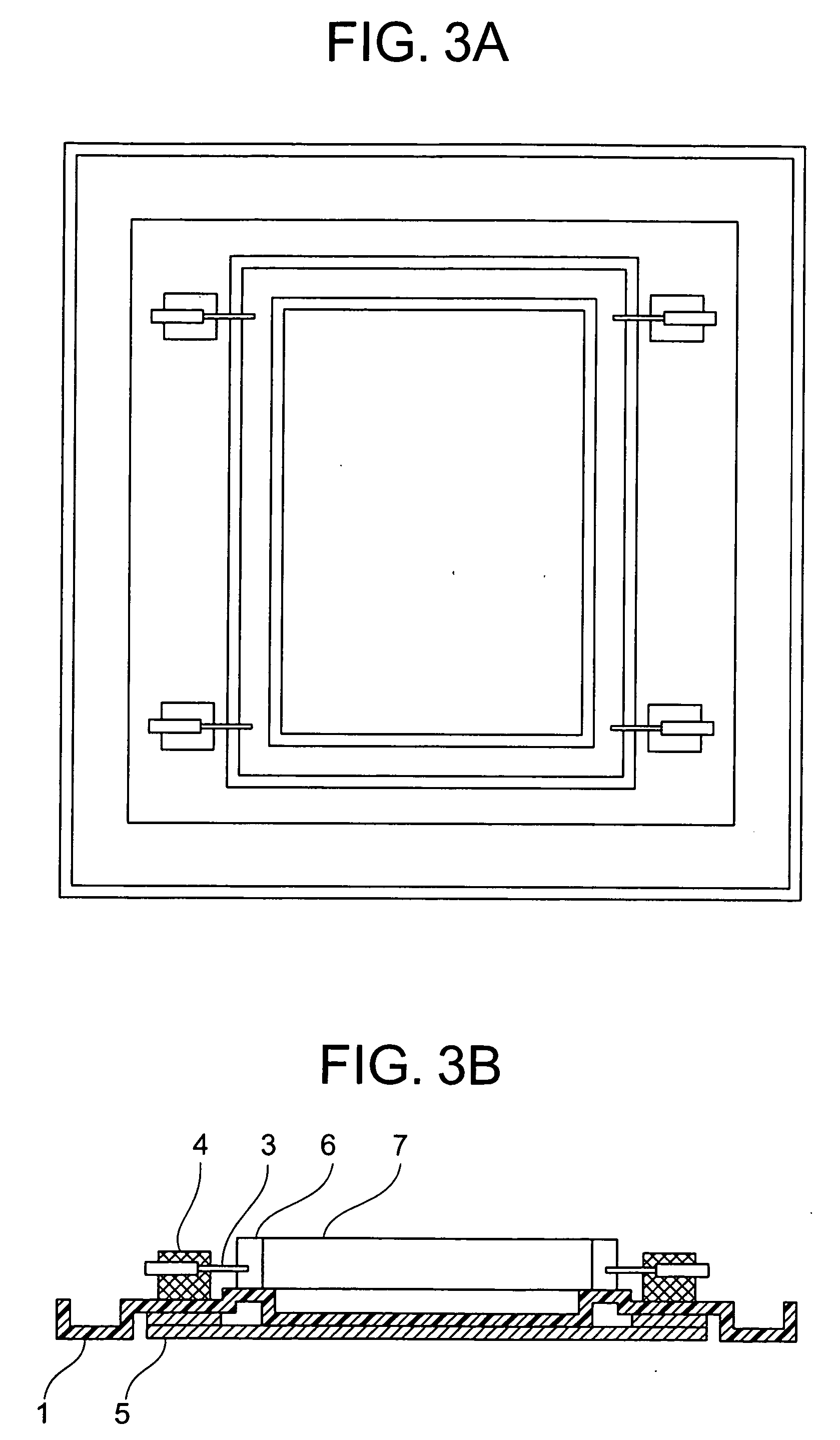

[0046] The pellicle containers illustrated in the drawings were constructed.

[0047] The pellicle container had a structure mainly composed of the container base 1, which was prepared by vacuum forming of an antistatic ABS resin (Toyolac Parrel TP10 (trade name of Toray); surface resistivity of 5×1011 ohms), and the covering body 2, which was prepared also by vacuum forming of an antistatic ABS resin (Toyolac Parrel TP10, supra); surface resistivity of 5×1011 ohms). The reinforcing metal components 5, which were made from aluminum and had a cross section of 40×6 mm, were disposed on the bottom surface of the container base and five of the reinforcing metal components 5 were connected in the down and across directions as shown in FIG. 4B.

[0048] Furthermore, the reinforcing metal components 5 disposed on the bottom surface of the container base, and the pin fixing components 4 disposed on the upper surface of the container base were mechanically connected by M4 screw bolts to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com