Architectural pavements in elevated exterior deck applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

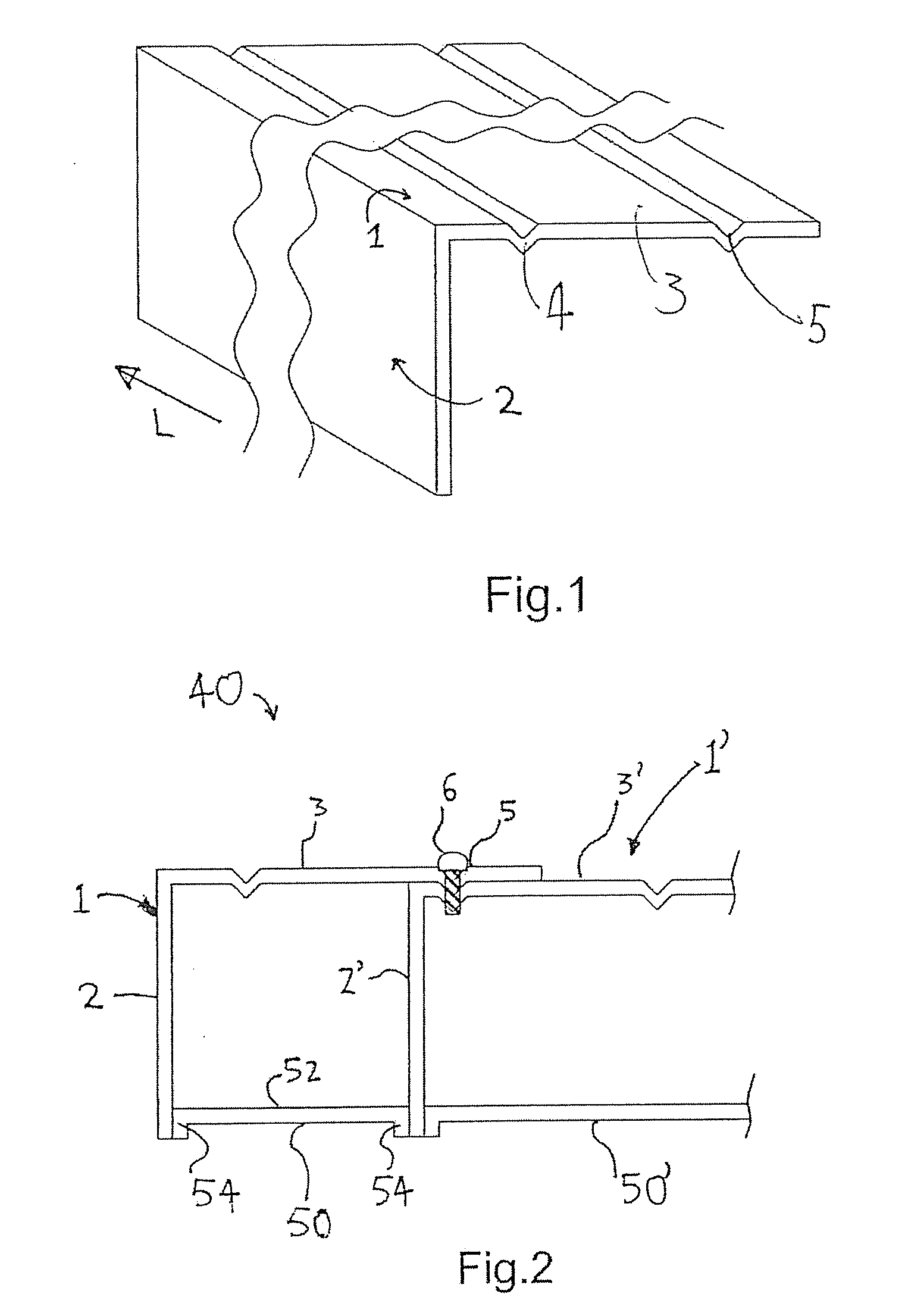

[0046]Referring to FIG. 1, a joist 1 for use in a deck assembly 40 comprises a web portion 2 and a deck portion 3. It will be appreciated that the joists are of indeterminate length L and may be customized to the length required. The deck portion 3 extends outwardly from the web portion 2 and the included angle between the deck portion 3 and web portion 2 is typically 90°, although other angles may be incorporated. The deck portion 3 is provided with a pair of V-shaped recesses 4, 5 at spaced locations that are proximal to and distal from the web portion 2 respectively. The joist 1 is formed from a rolled steel strip of appropriate gauge and the joists 1 may be pre-finished by painting, powder coating or galvanising to inhibit corrosion.

[0047]A plurality of joists 1, 1′ of FIG. 1 are assembled as shown in FIG. 2 to form a deck assembly 40. The web portions 2, 2′ of each joist are aligned vertically in parallel with the deck portions 2, 2′ overlapping. The distal V-shaped recess 5 en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com