Substrate handling apparatus with lift pin assembly

A technology of substrate processing device and pin assembly, which is applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., and can solve the problem of enlarged stain area on the pin part on the substrate surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, referring to the above-mentioned problems to be solved, it may be explained with reference to the accompanying drawings of preferred embodiments of the present invention embodied in the present invention. Based on the description of the present embodiment, the same names and the same symbols are used for the same structures, and additional explanations thereof will be omitted below.

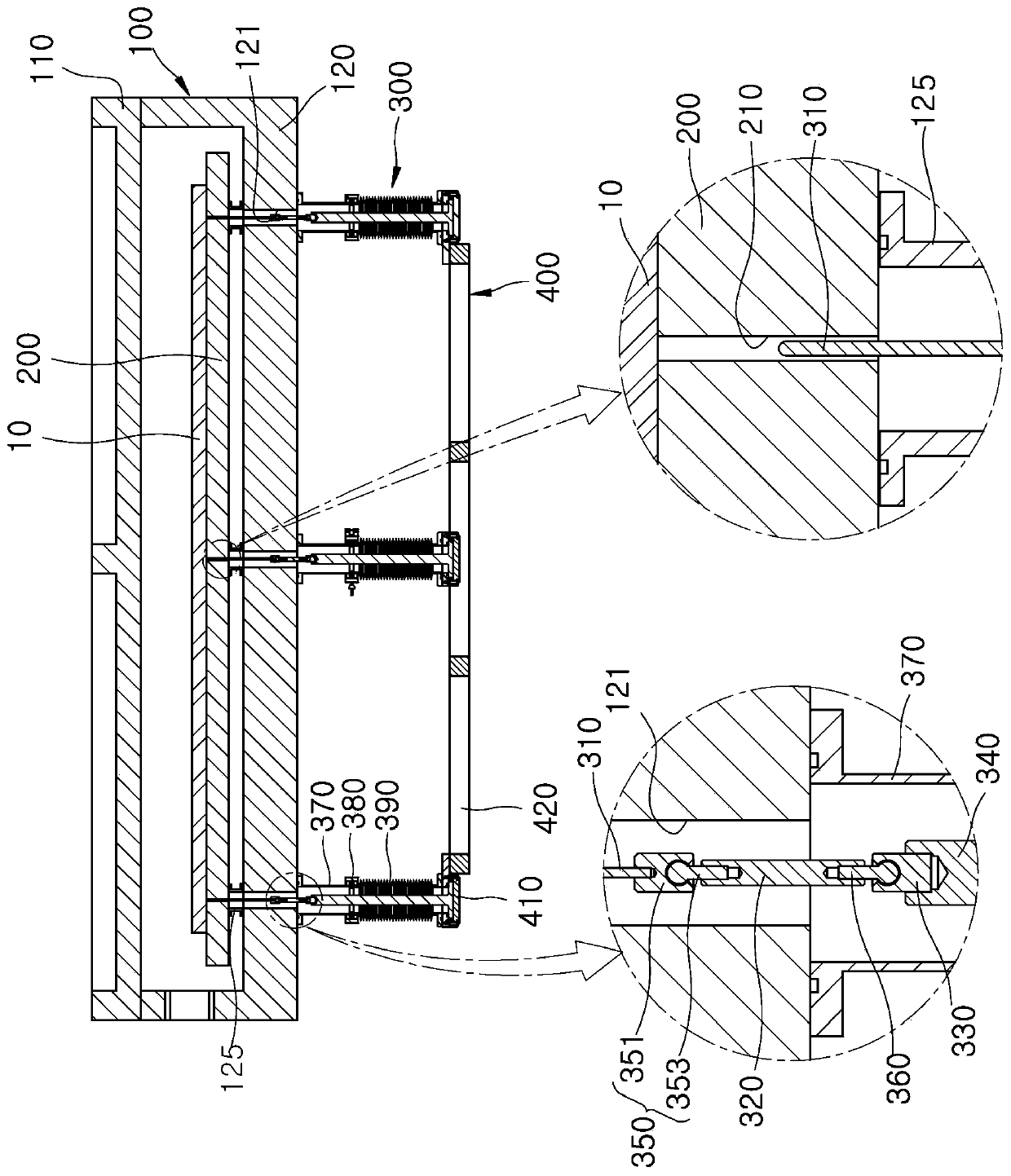

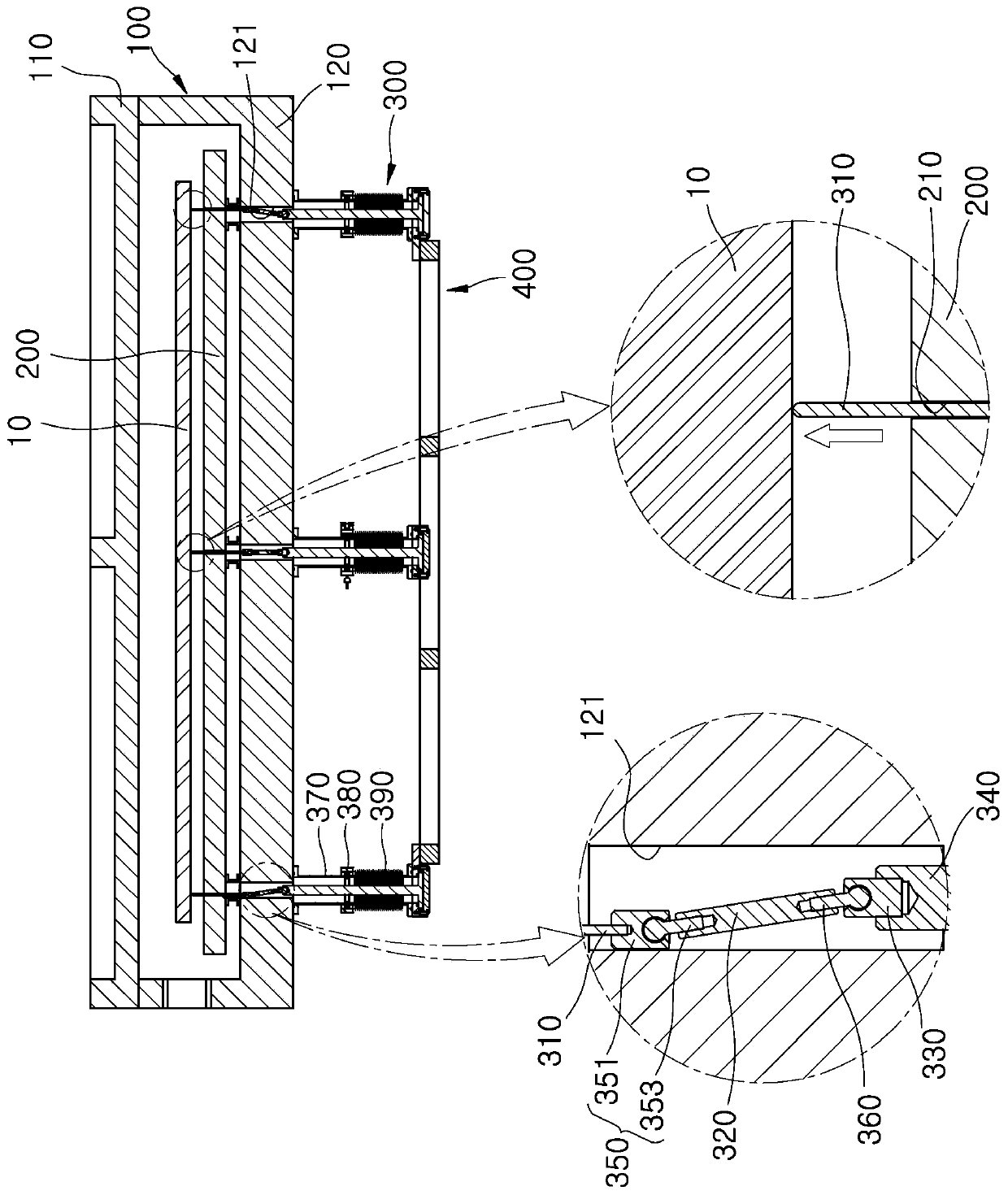

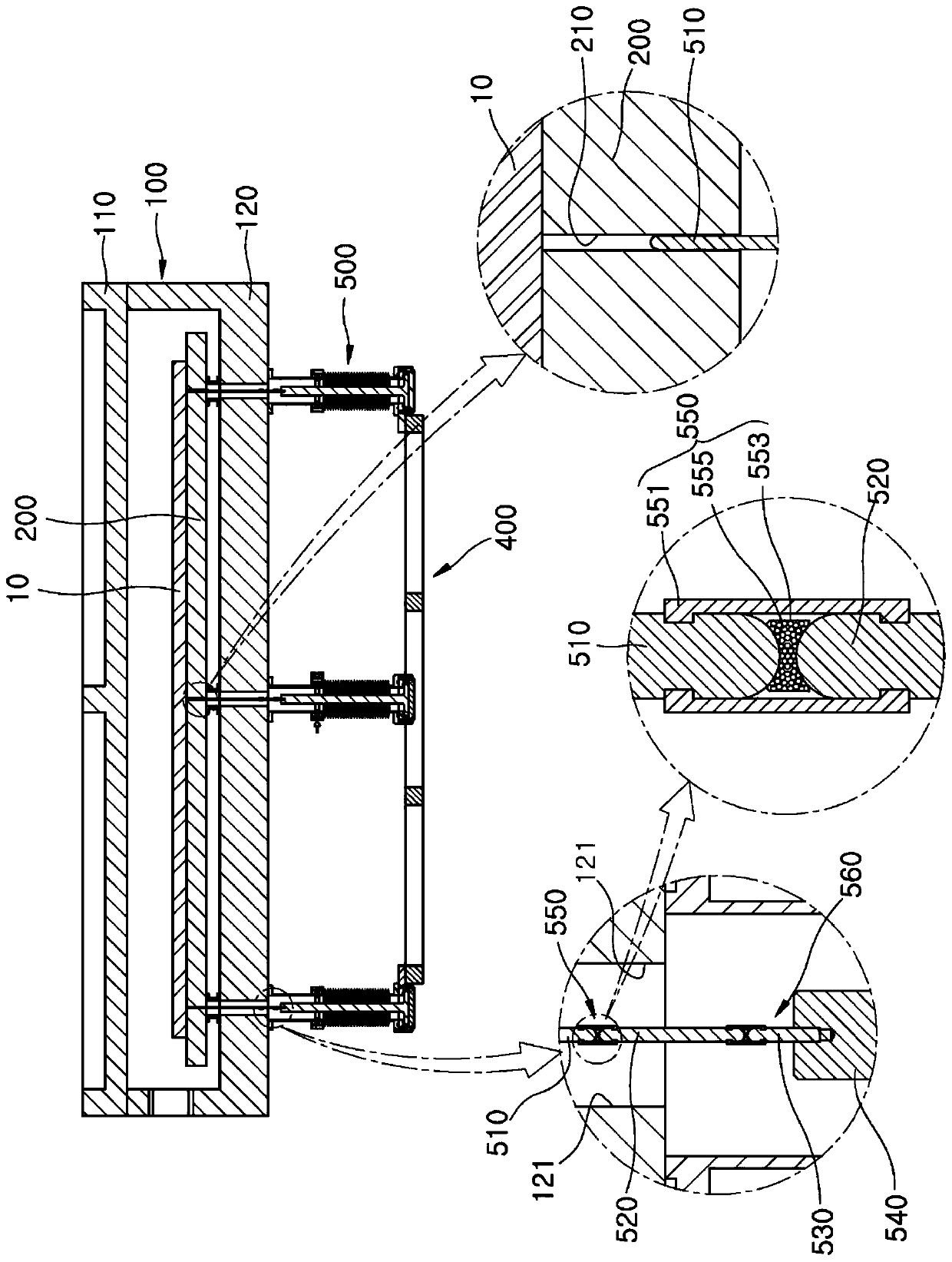

[0021] refer to figure 1 with figure 2 , a description of an embodiment of a substrate processing apparatus according to the present invention is as follows.

[0022] The substrate processing apparatus includes a chamber body 100 , a heater unit 200 , a lift pin assembly 300 and a main unit 400 .

[0023] An inner space is formed in the chamber main body 100 for accommodating the substrate 10 to be processed and the heater unit 200 . Specifically, the chamber body 100 includes: an upper frame 110 forming an upper wall based on the inner space, and a lower frame 120 combini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com