Patents

Literature

54results about How to "Ensure rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

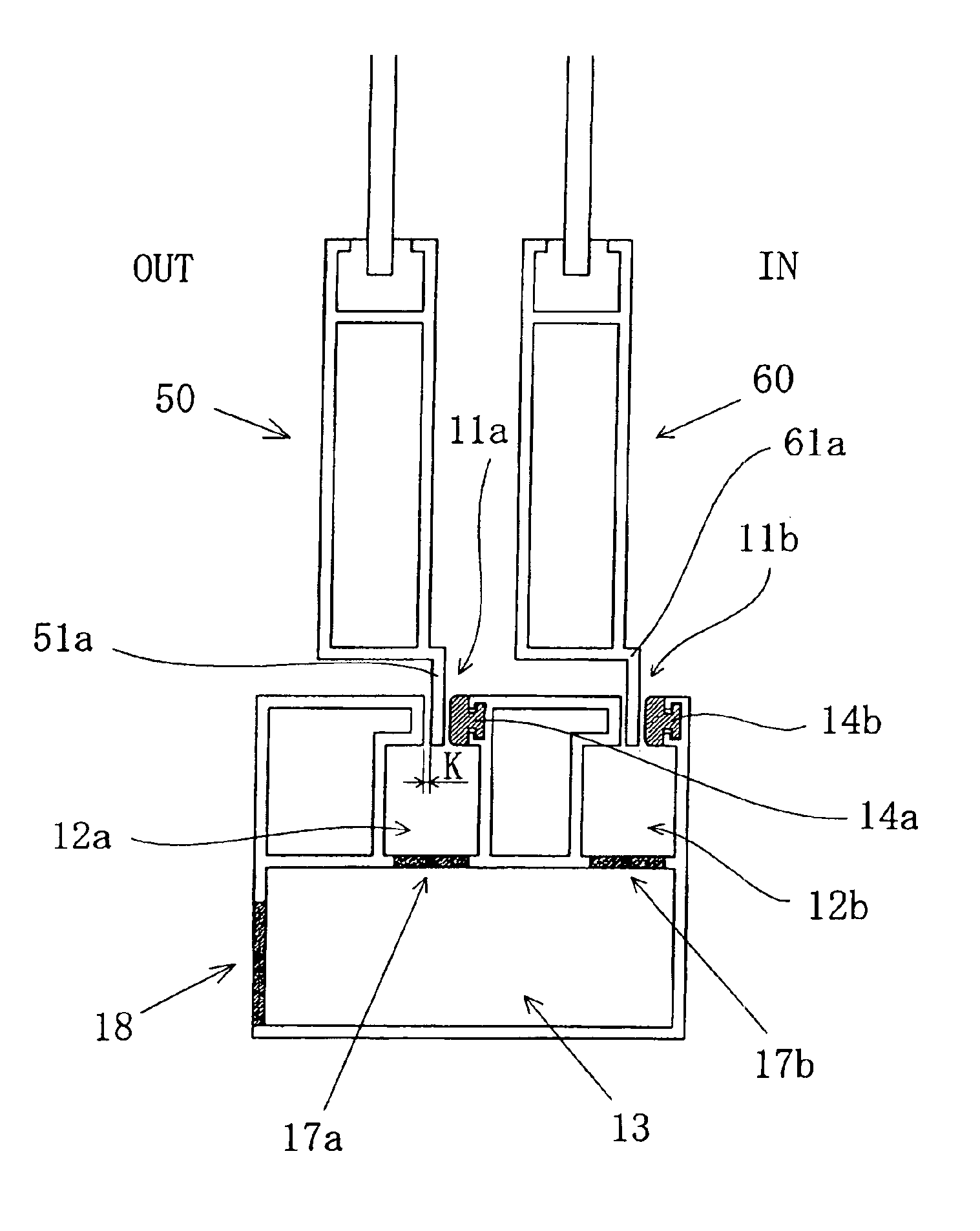

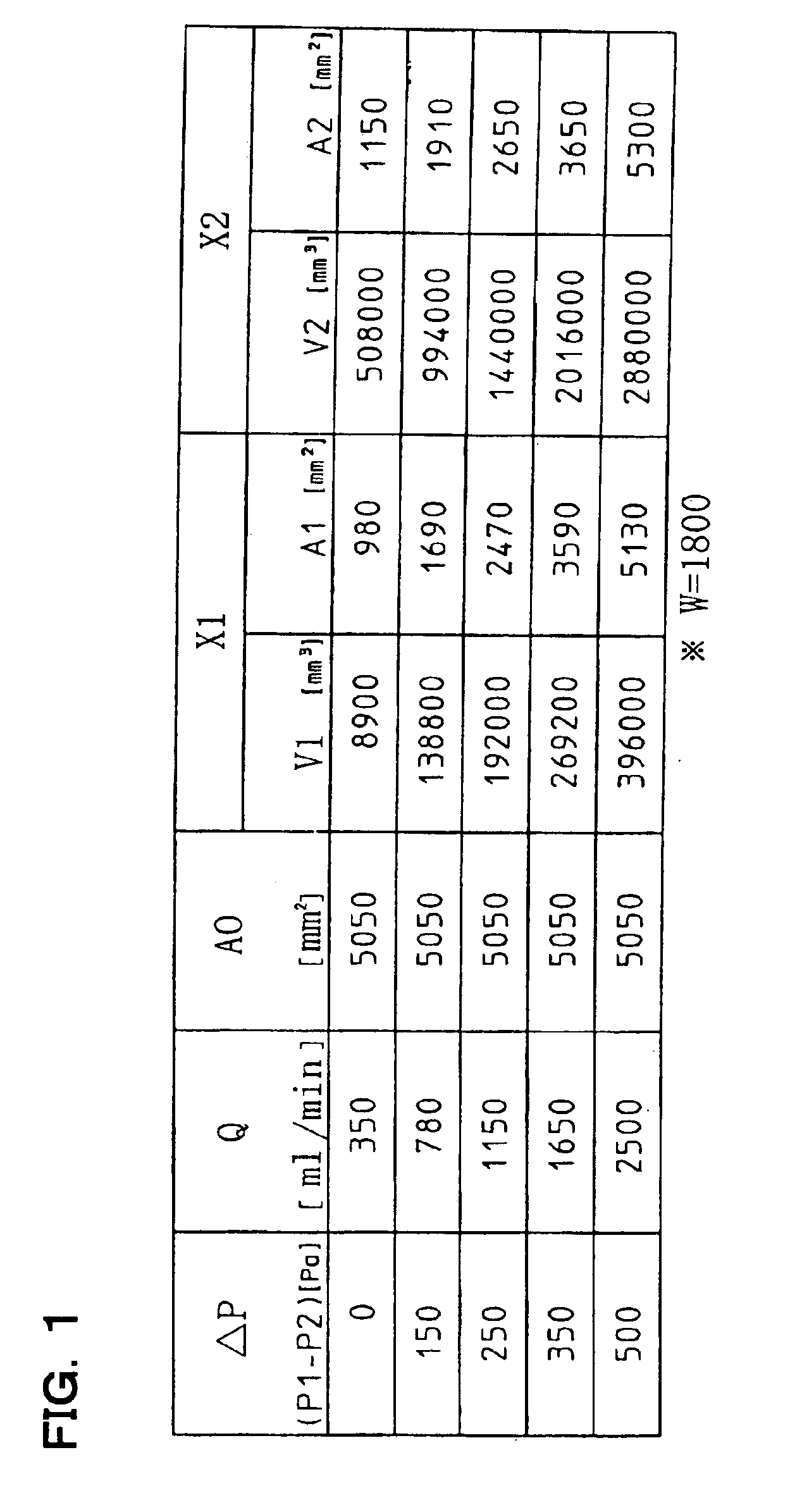

Outdoor window

InactiveUS6883279B2Superior in drainage of rainwaterHigh in watertightness against indoor water leakageCondensed water drain-offSealing arrangementsSash windowEngineering

Owner:TATEYAMA ALUMINUM IND

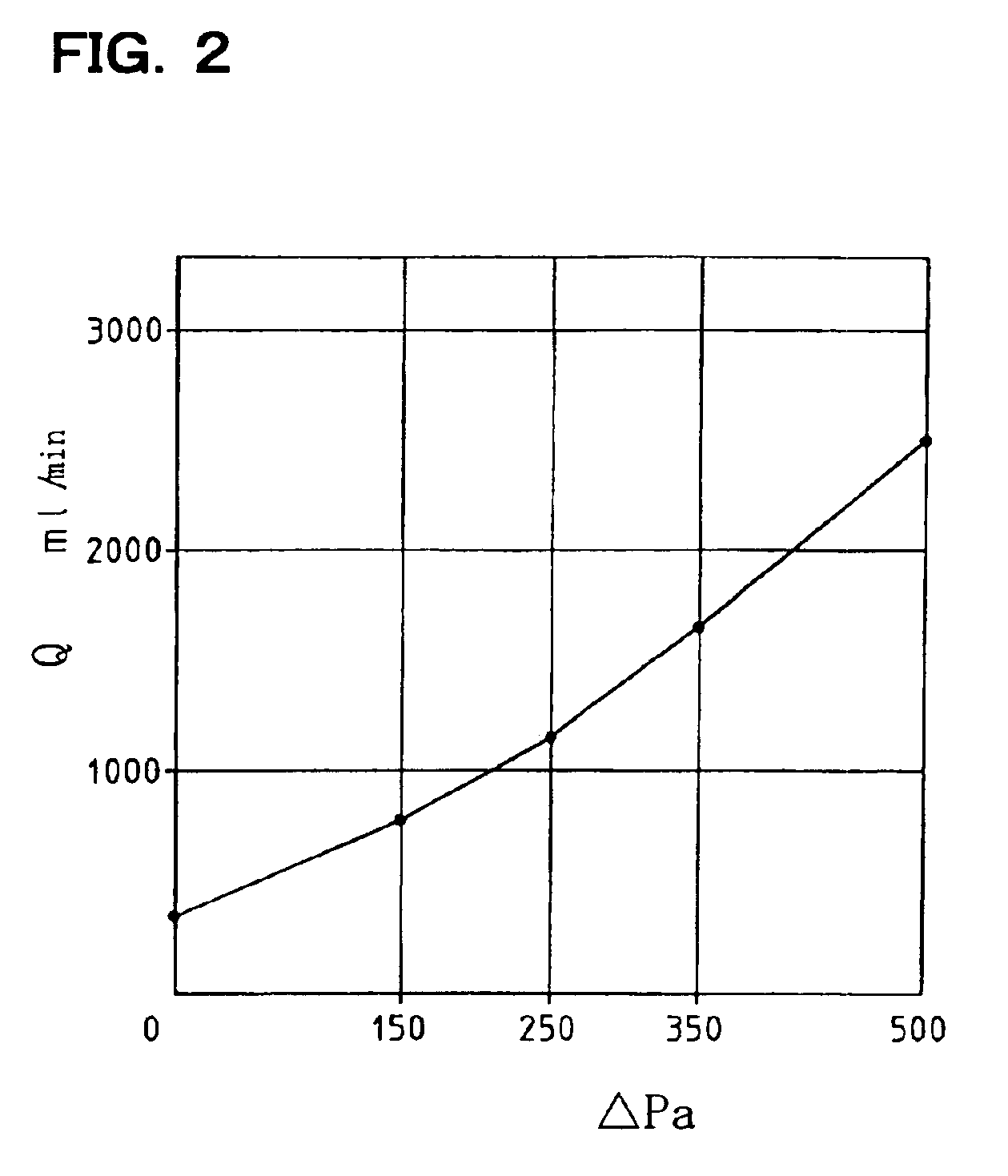

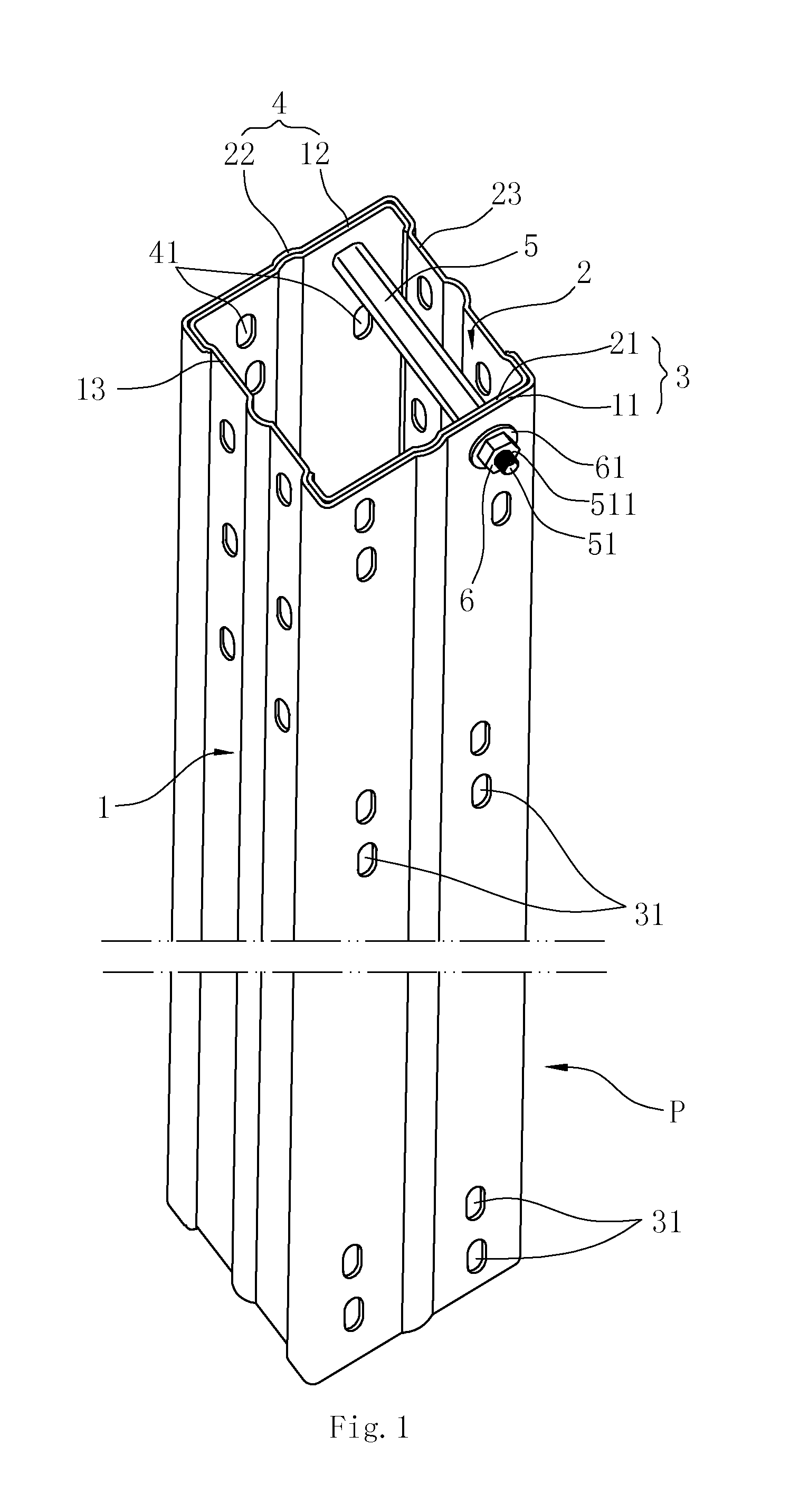

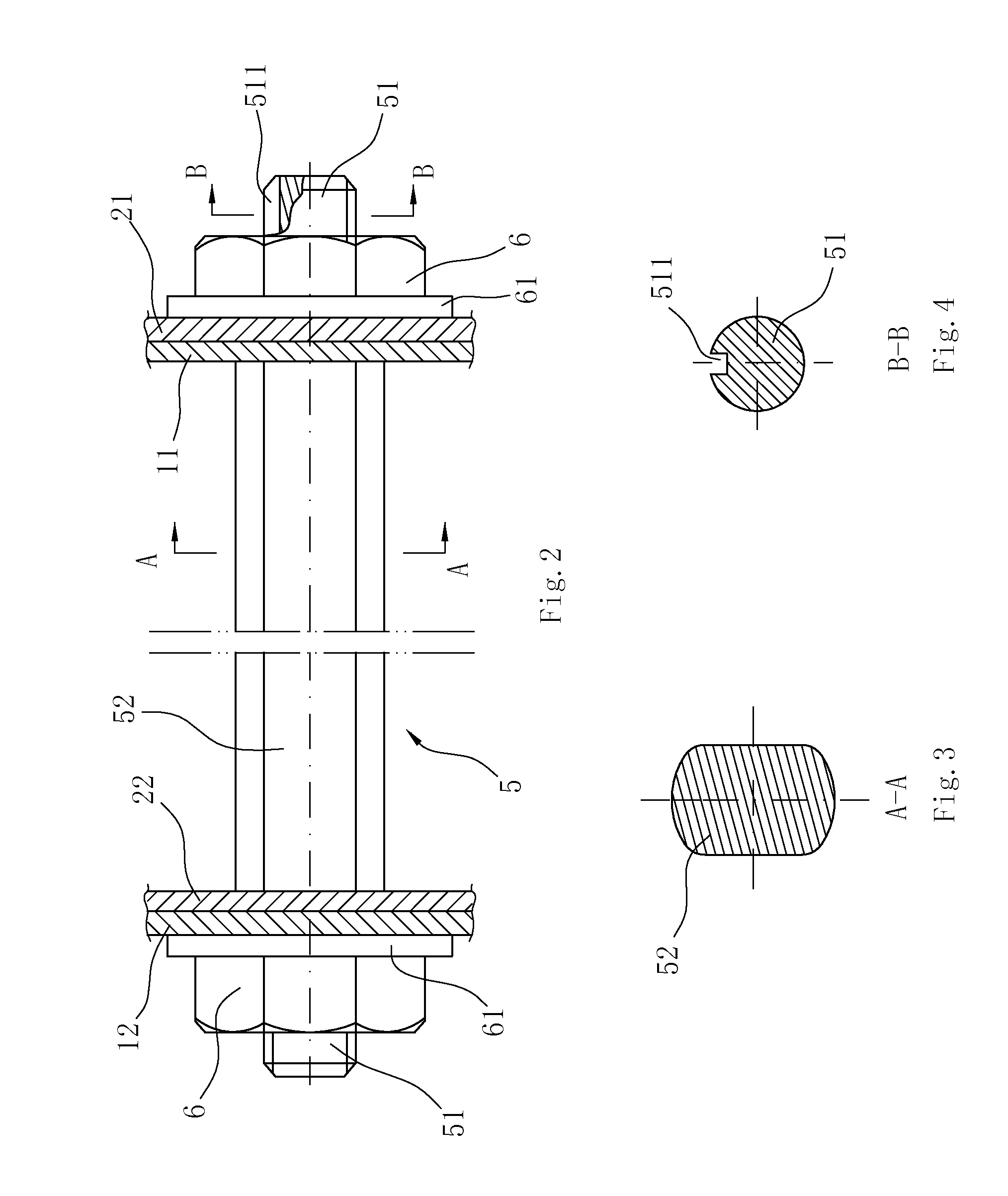

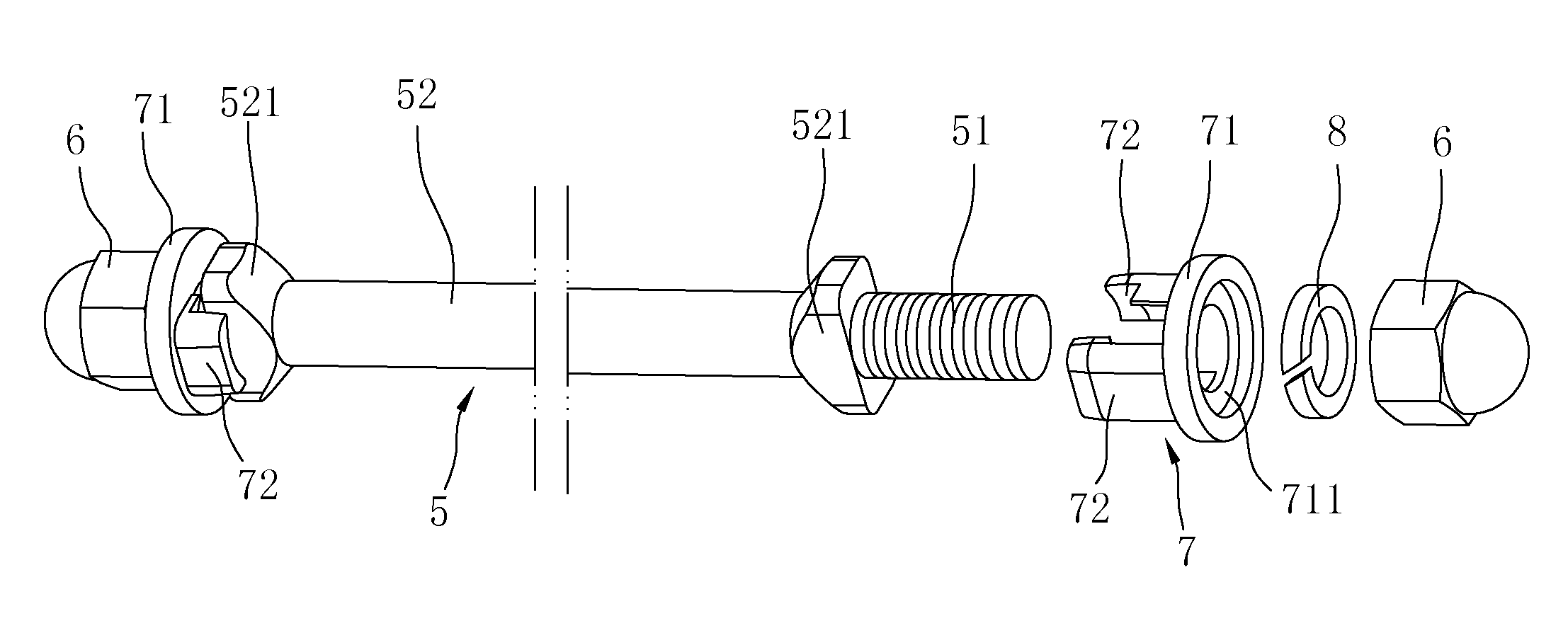

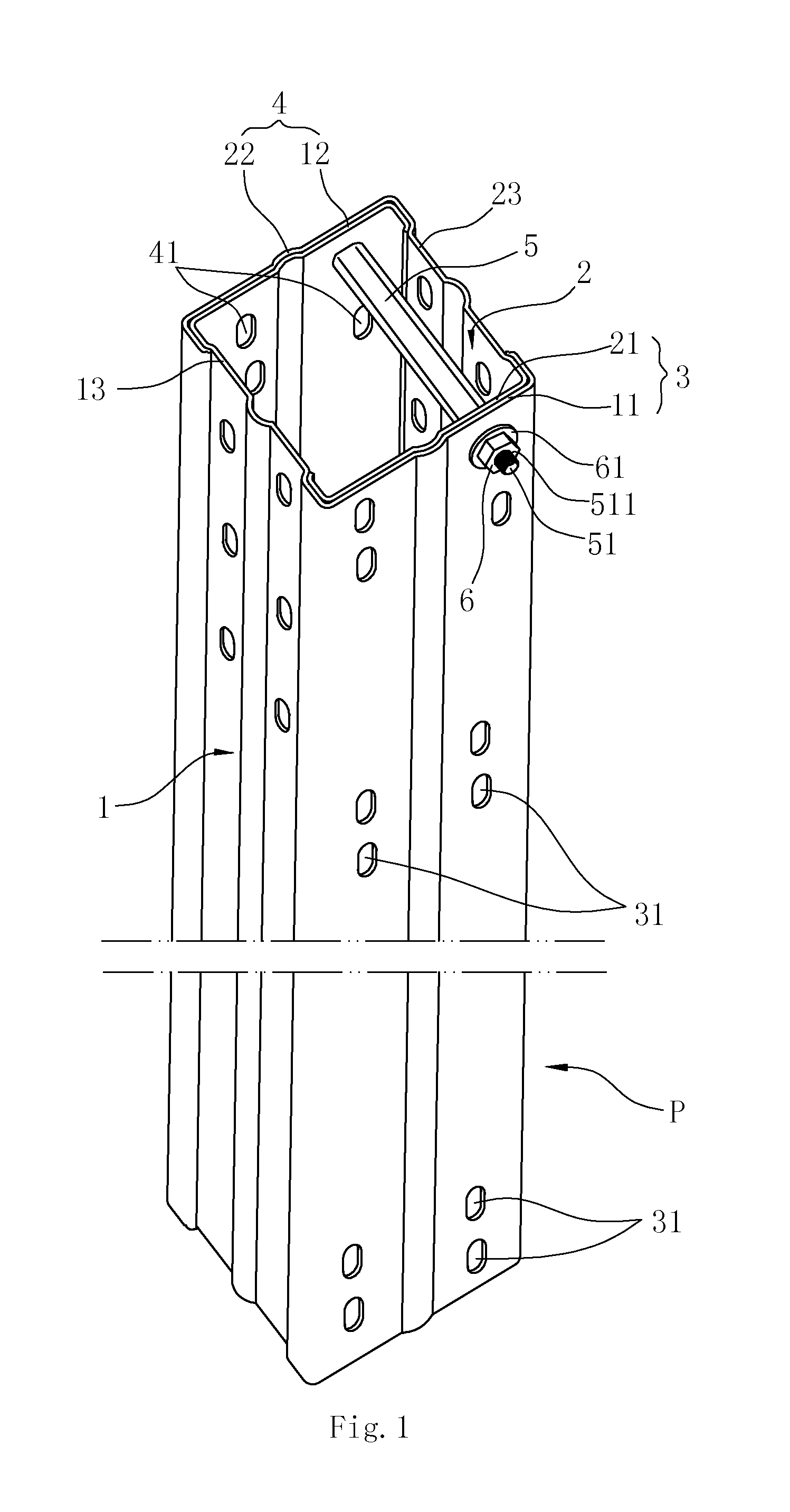

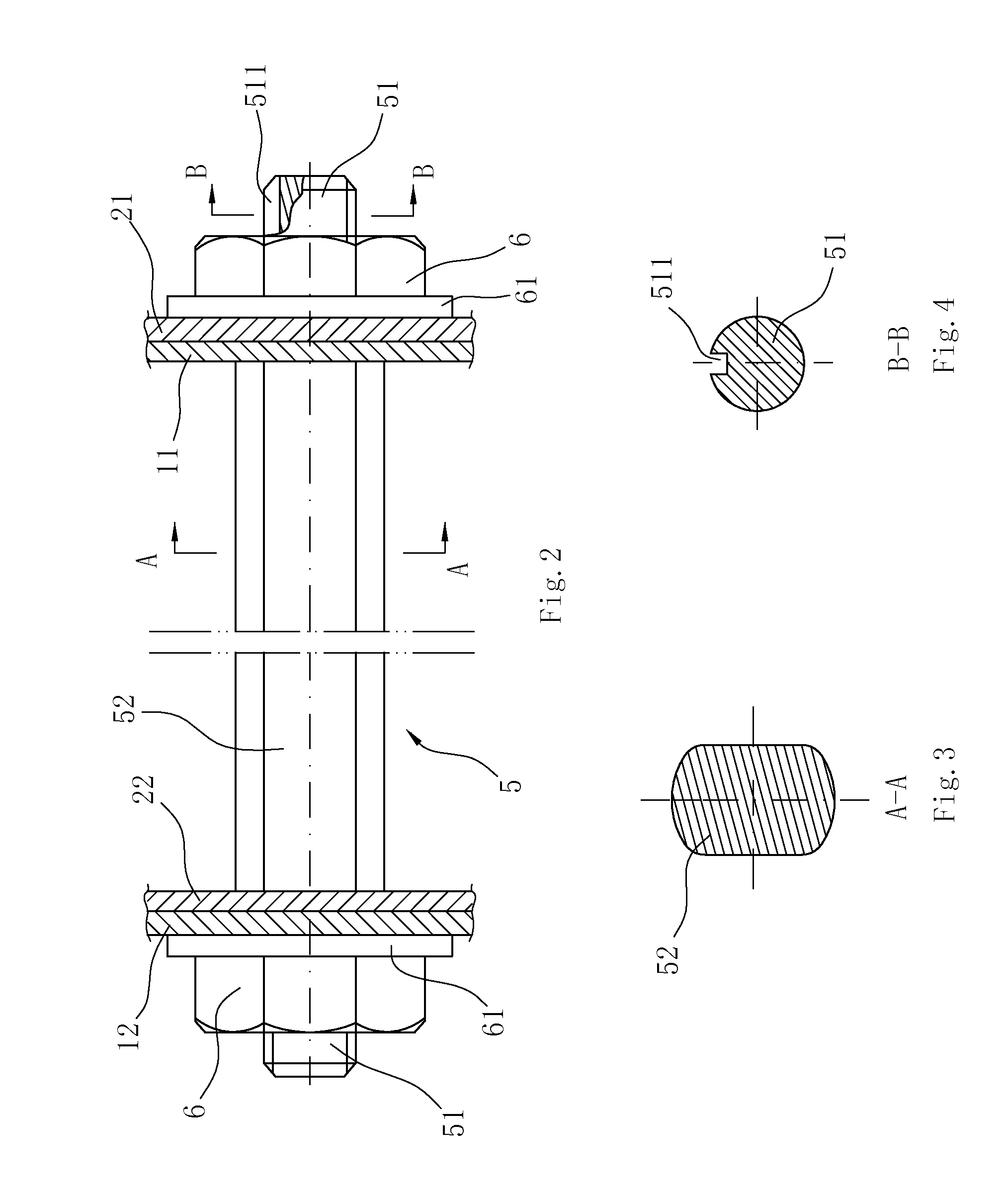

Unconventional Bolt and a Fastening Device Using the Unconventional Bolt Thereof

An unconventional bolt includes a main body having two heads, and two threaded rods respectively formed at the external surface of each head coaxially with the main body, wherein the cross section of each head has a noncircular shape, and the axial projection of the cross section of the middle of the main body is located in the noncircular axial projection of each head of the main body. The unconventional bolt has a simple structure and a convenient assembly, and can improve the strength and rigidity of the nested profiled components after the connection; and the fastening device using the unconventional bolt can not only support the component but also reinforce it, thus effectively preventing the nested profiled components from transforming.

Owner:NINGBO BANGDA INDAL

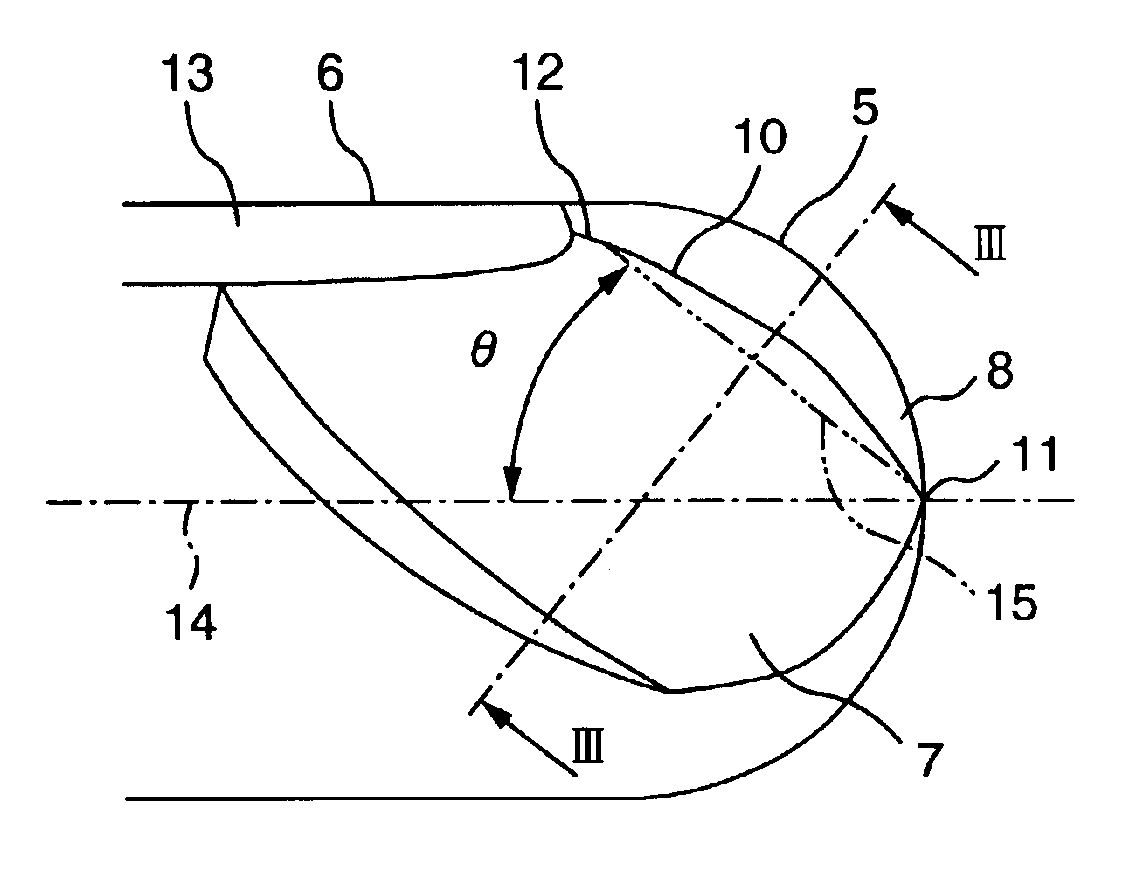

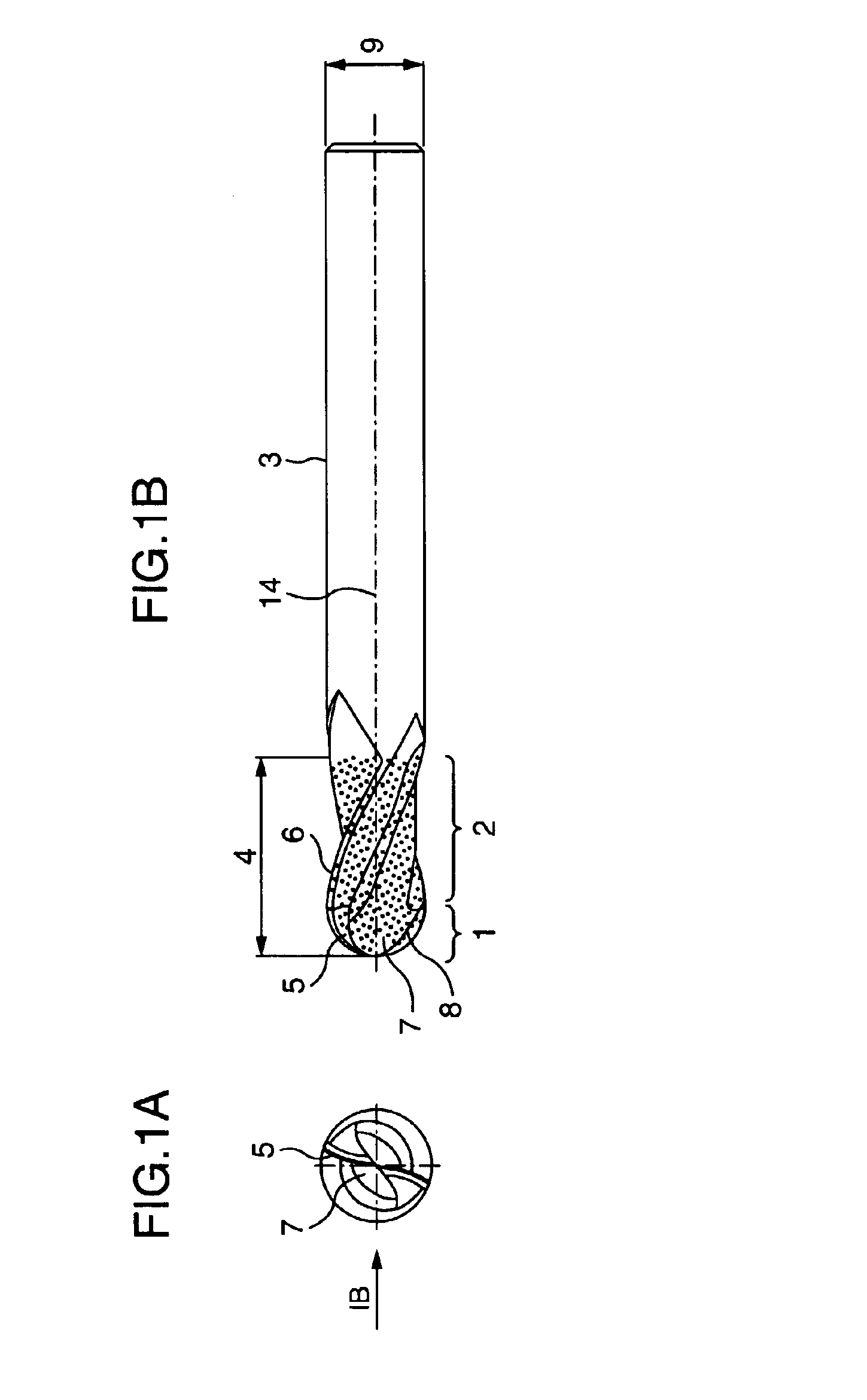

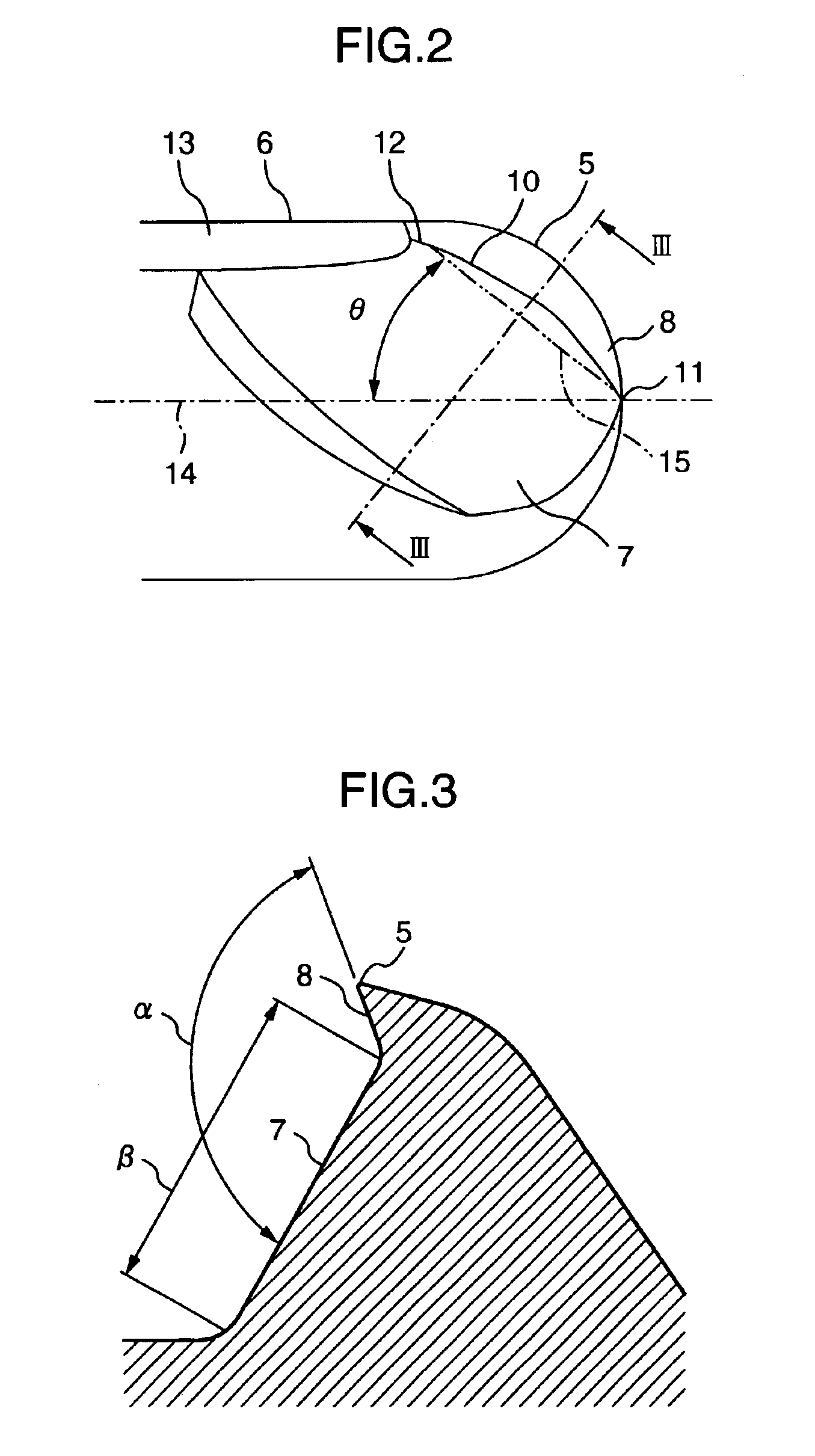

Cemented carbide ball end mill

InactiveUS6953310B2Improve machine performanceImprove performanceMilling cuttersWorkpiecesFluteCemented carbide

A cemented carbide ball end mill comprises a cutting portion with a semi-spherical ball portion at a tip thereof. The cutting edge portion has a cutting edge rake face and a chip evacuating flute at the ball portion. An angle formed by a straight line connecting a vertex of the ball portion, where an intersection line passes through, and another end of the intersection line with respect to the central axis, is from 30° to 50°. Further, and angle formed by the rake face and the chip evacuating flute is from 100° to 150°, and a width of the chip evacuating flute is 0.5 to 5 times as large as a radius of the ball portion.

Owner:NACHI-FUJIKOSHI

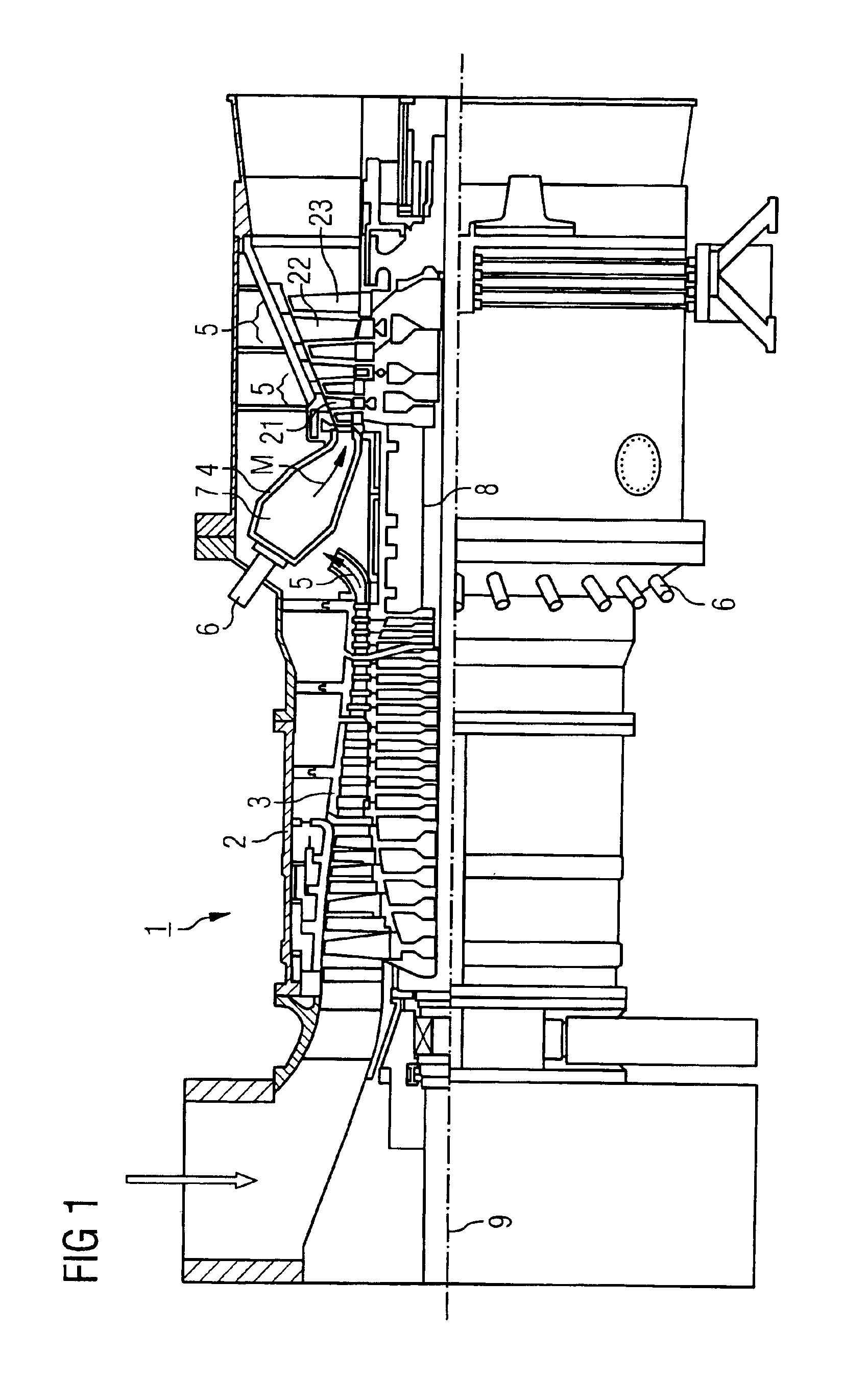

Annular combustion chambers for a gas turbine and gas turbine

ActiveUS6938424B2Increase rigidityEnsure rigidityContinuous combustion chamberGas turbine plantsEdge regionAerospace engineering

The invention relates to an annular combustion chamber for a gas turbine wherein the annular combustion chamber extends in an axial direction, encloses a combustor and has on its inside facing the combustor a bearing structure on which a lining element secured to this lines the annular combustion chamber. The object is to disclose an annular combustion chamber with a lining element that meets the mechanical requirements while at the same time taking account of the system's maintenance-friendliness. The object is achieved in that the annular combustion chamber has a lining element wherein on the rear side facing away from the combustor of two edge areas on the lining element a plurality of interlocking means are located which have a hook width and wherein the lining element is secured to the corresponding bearing structure such that in order to release the lining element from the bearing structure the lining element is moved by the extent of the hook width of the interlocking means in the axial direction.

Owner:SIEMENS AG

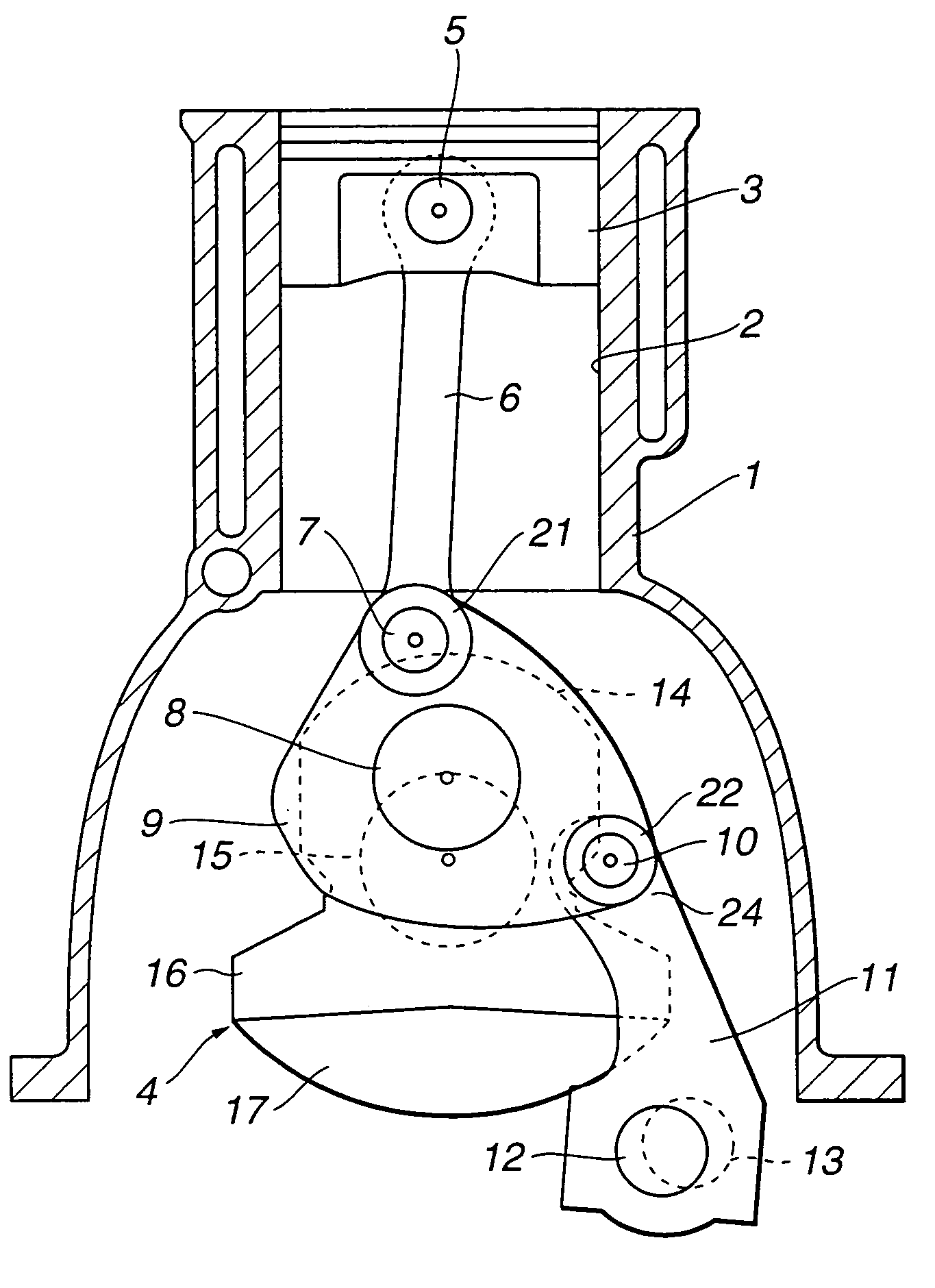

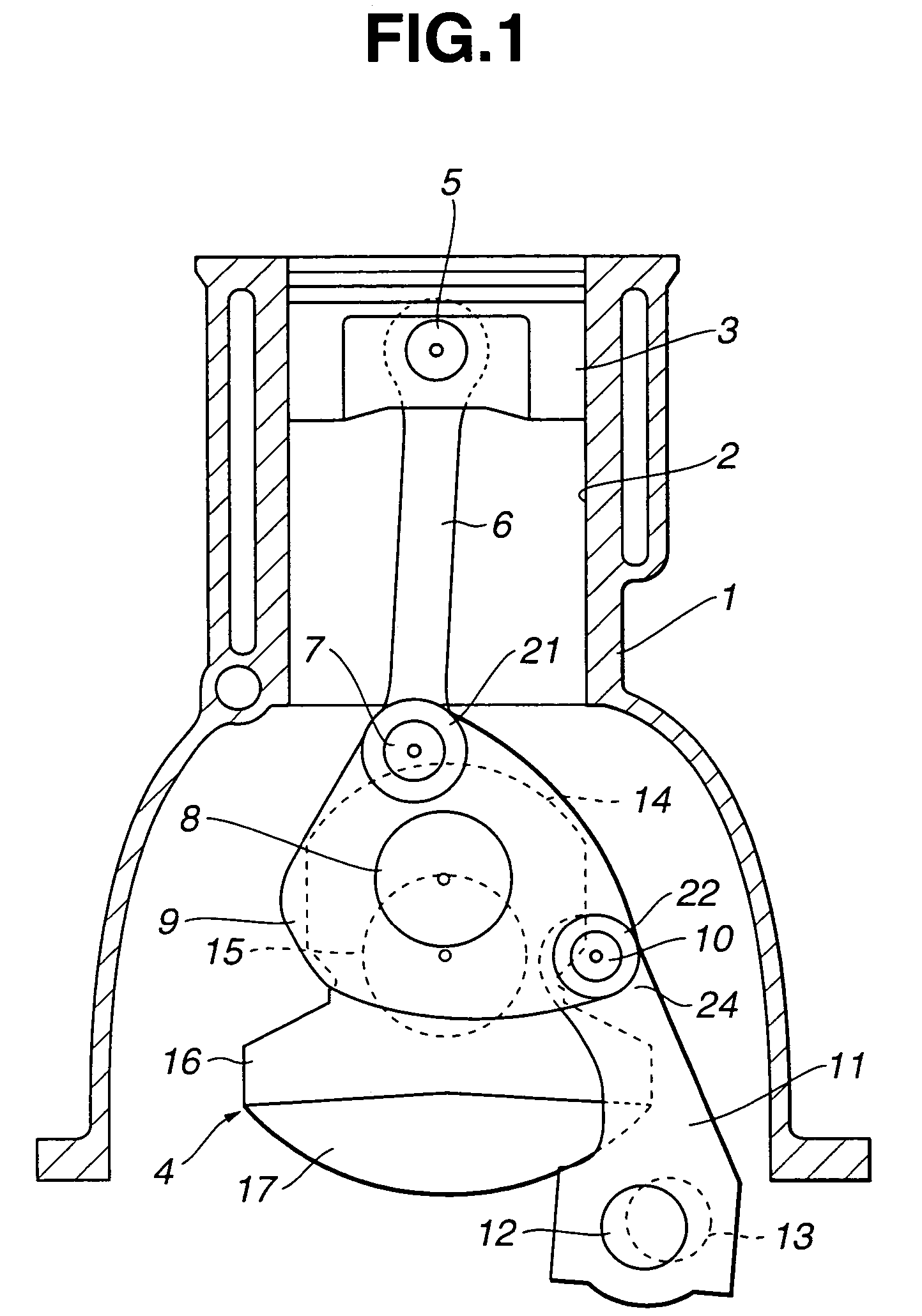

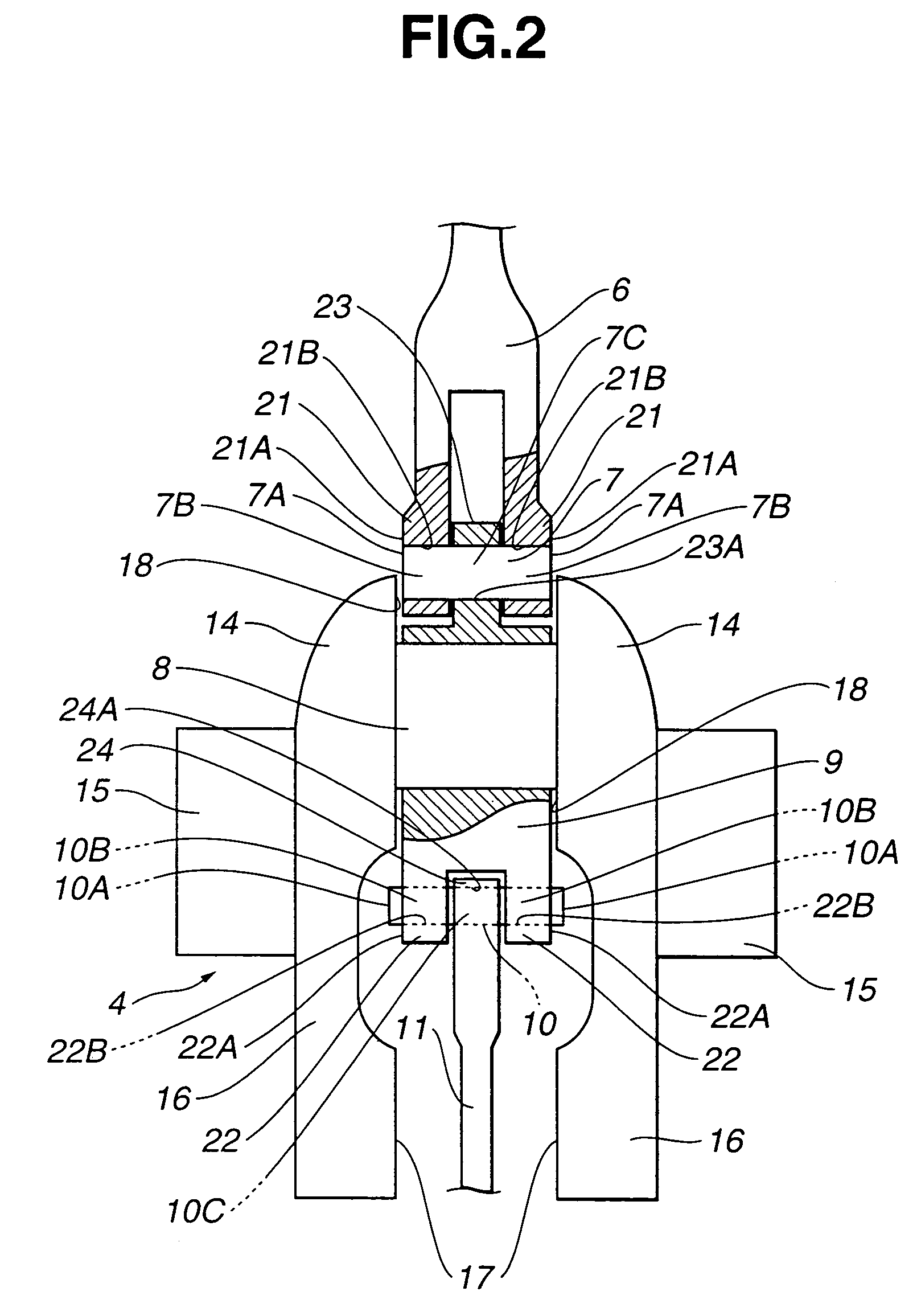

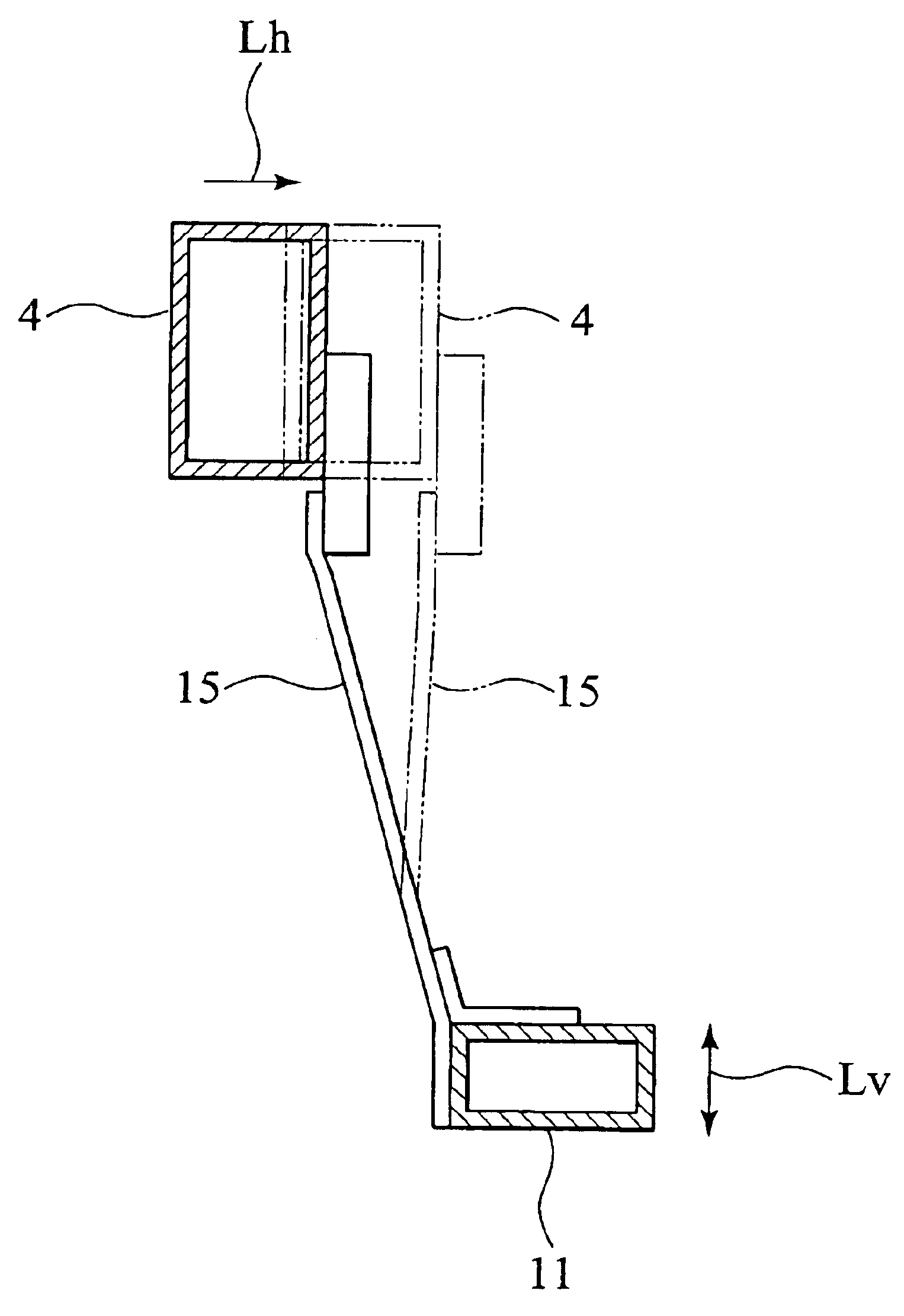

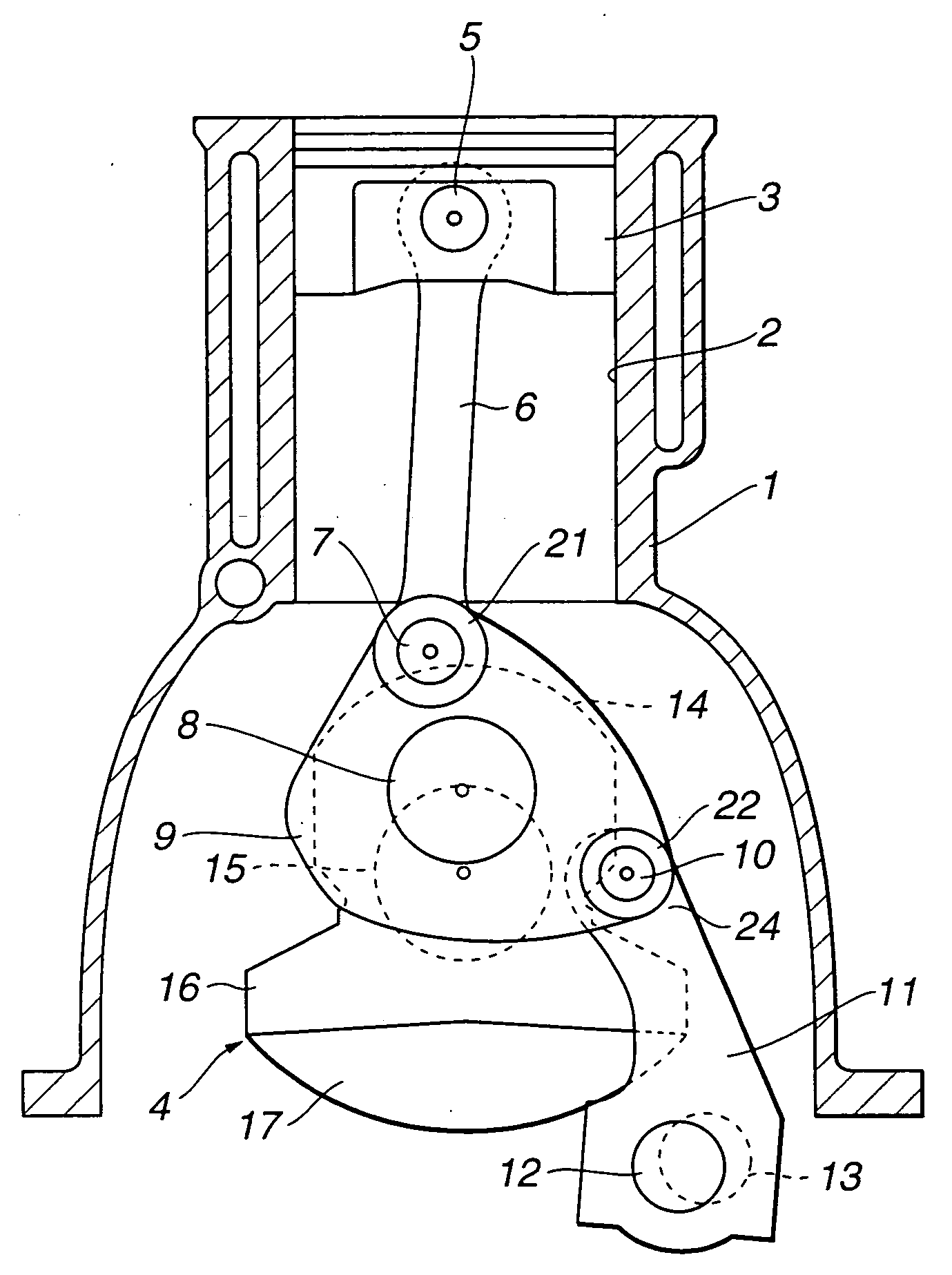

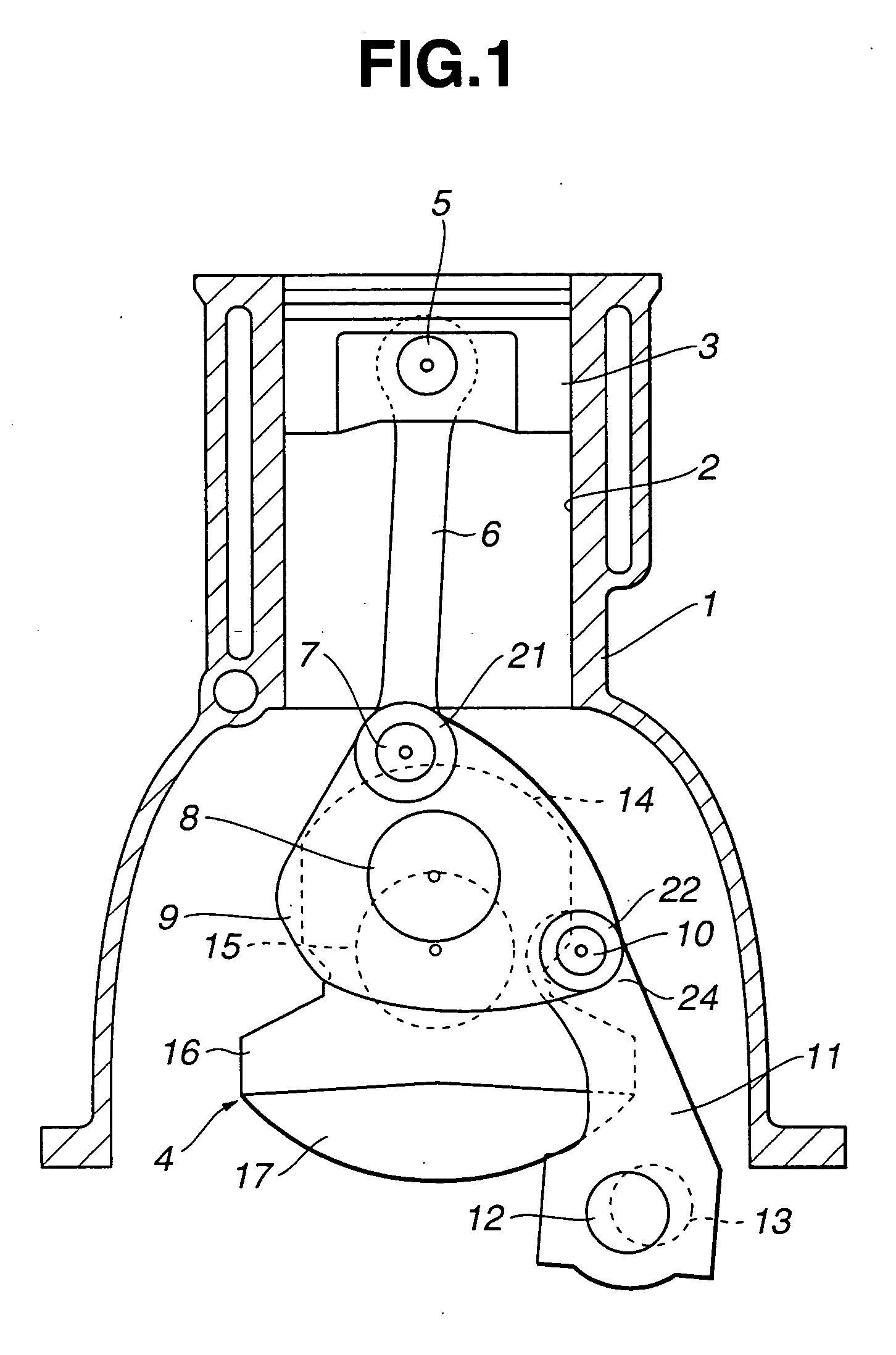

Multi-link piston crank mechanism for internal combustion engine

ActiveUS7121251B2Optimization mechanismAvoid interferenceConnecting rodsGearingMulti linkInternal combustion engine

A multi-link piston crank mechanism for an internal combustion engine, including a crankshaft having a crank pin, and crank webs connected with each other through the crank pin. A pair of thrust surfaces are formed on the crank webs so as to be opposed in a direction of a center axis of the crank pin. A first link pivotally supported on the crank pin is coupled to a second link through a connection pin located in a space between the thrust surfaces. The connection pin is moveable about the crank pin to form a circular trace along which the thrust surfaces extend. The end surfaces of the connection pin and the thrust surfaces come into mutual contact to prevent the connection pin from falling out of the space between the thrust surfaces.

Owner:NISSAN MOTOR CO LTD

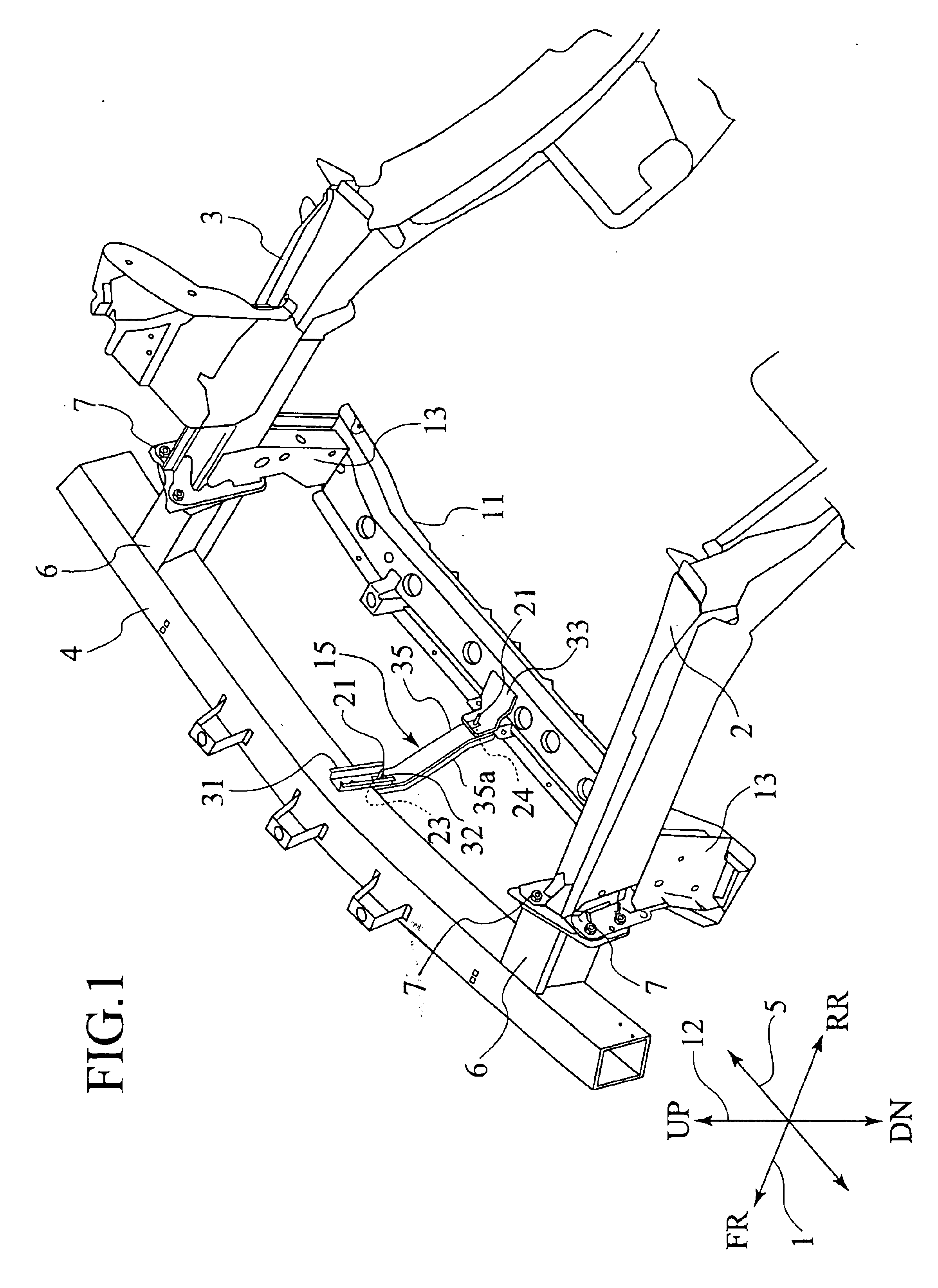

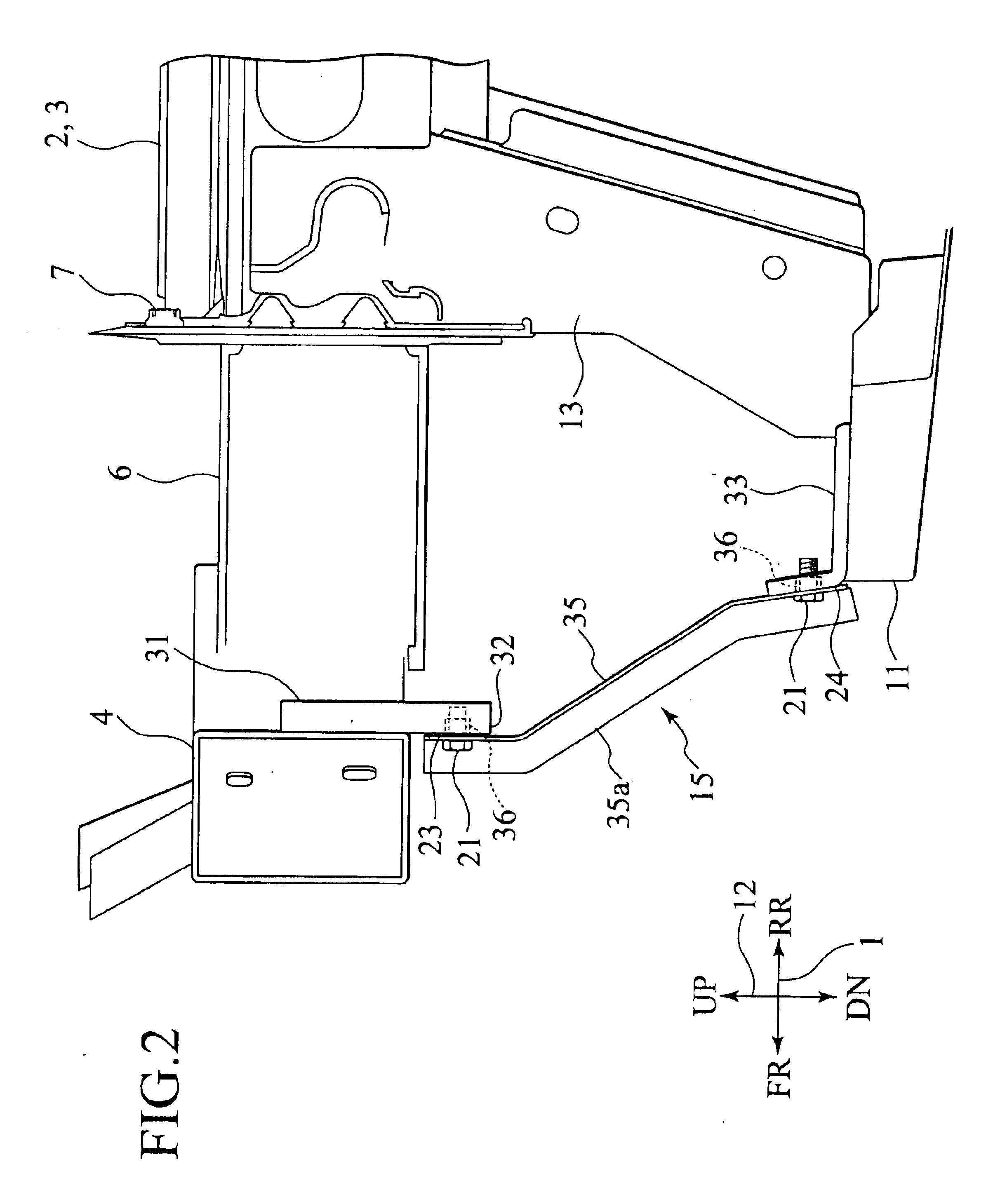

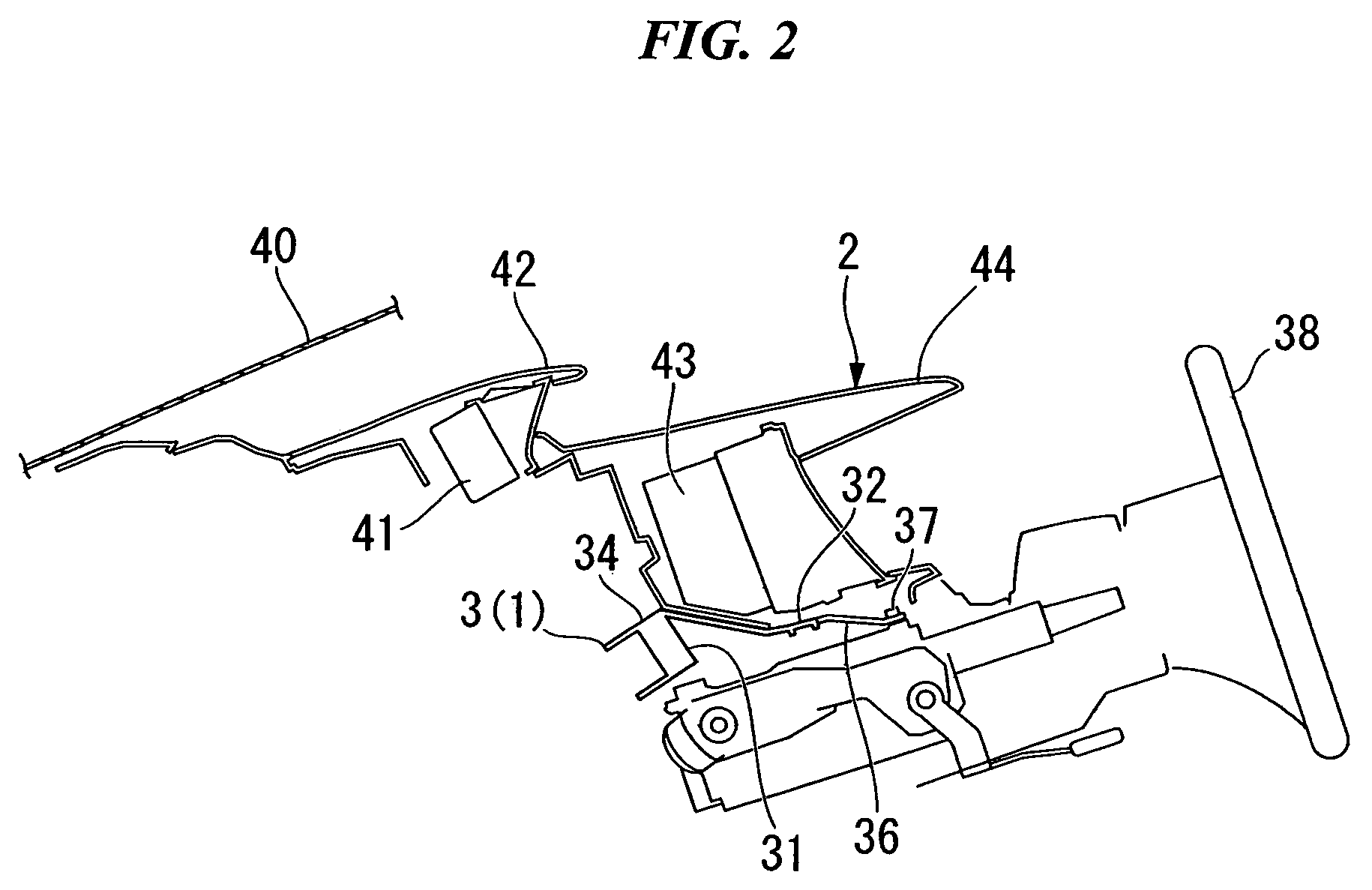

Vehicle front body structure

ActiveUS6866333B2Ensure strengthEnsure rigidityVehicle seatsUnderstructuresFlexural strengthEngineering

A vehicle front body structure which includes: a pair of side members extending in a vehicle longitudinal direction; a bumper reinforcing member connected to front ends of the side members; a cross member connected to bottoms of the side members in the vicinities of the front ends thereof; and a connecting member connected to the bumper reinforcing member and the cross member. Connection strength between the connecting member and the bumper reinforcing member in the vehicle longitudinal direction is lower than a flexural strength of the cross member in the vehicle longitudinal direction.

Owner:NISSAN MOTOR CO LTD

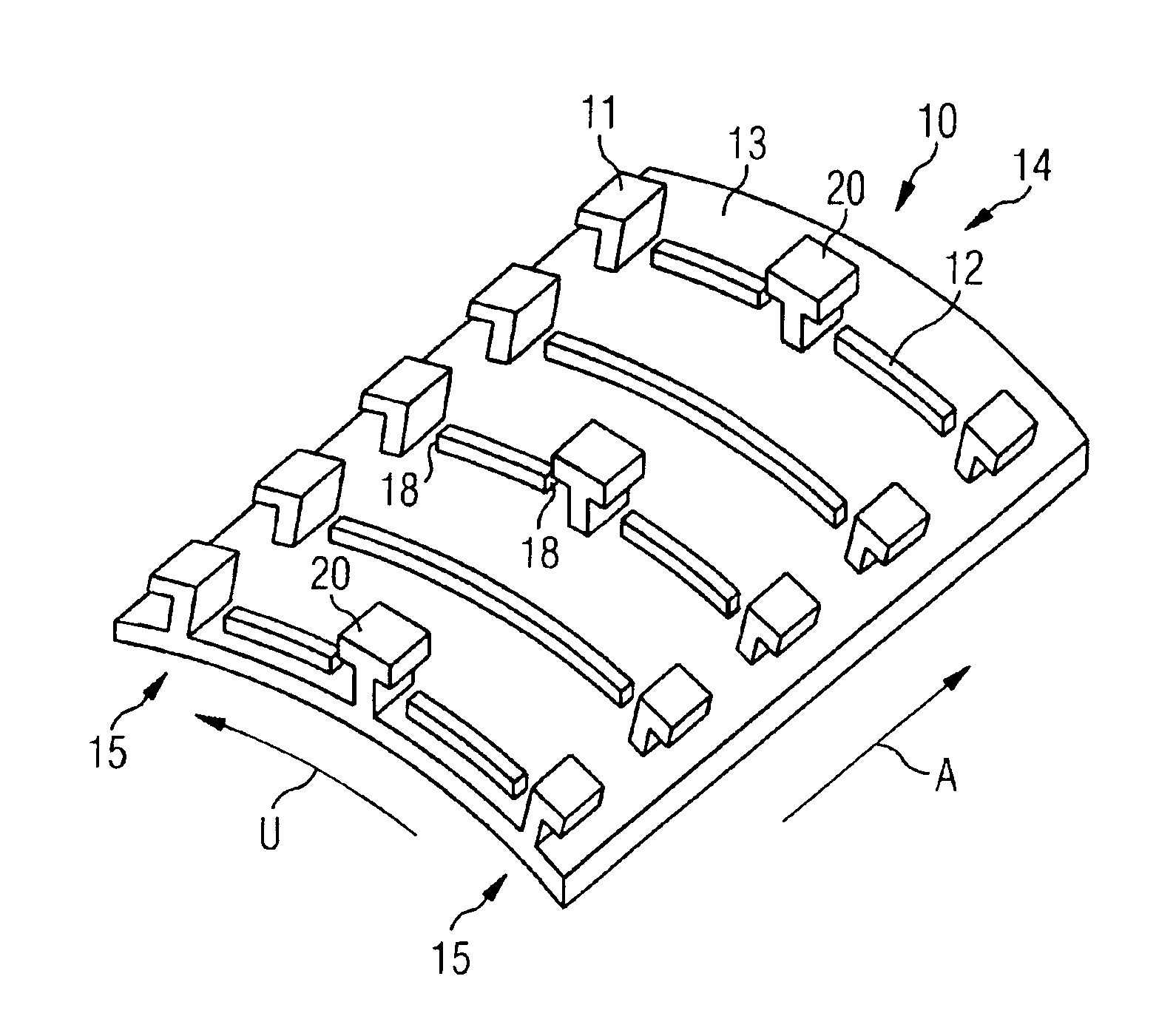

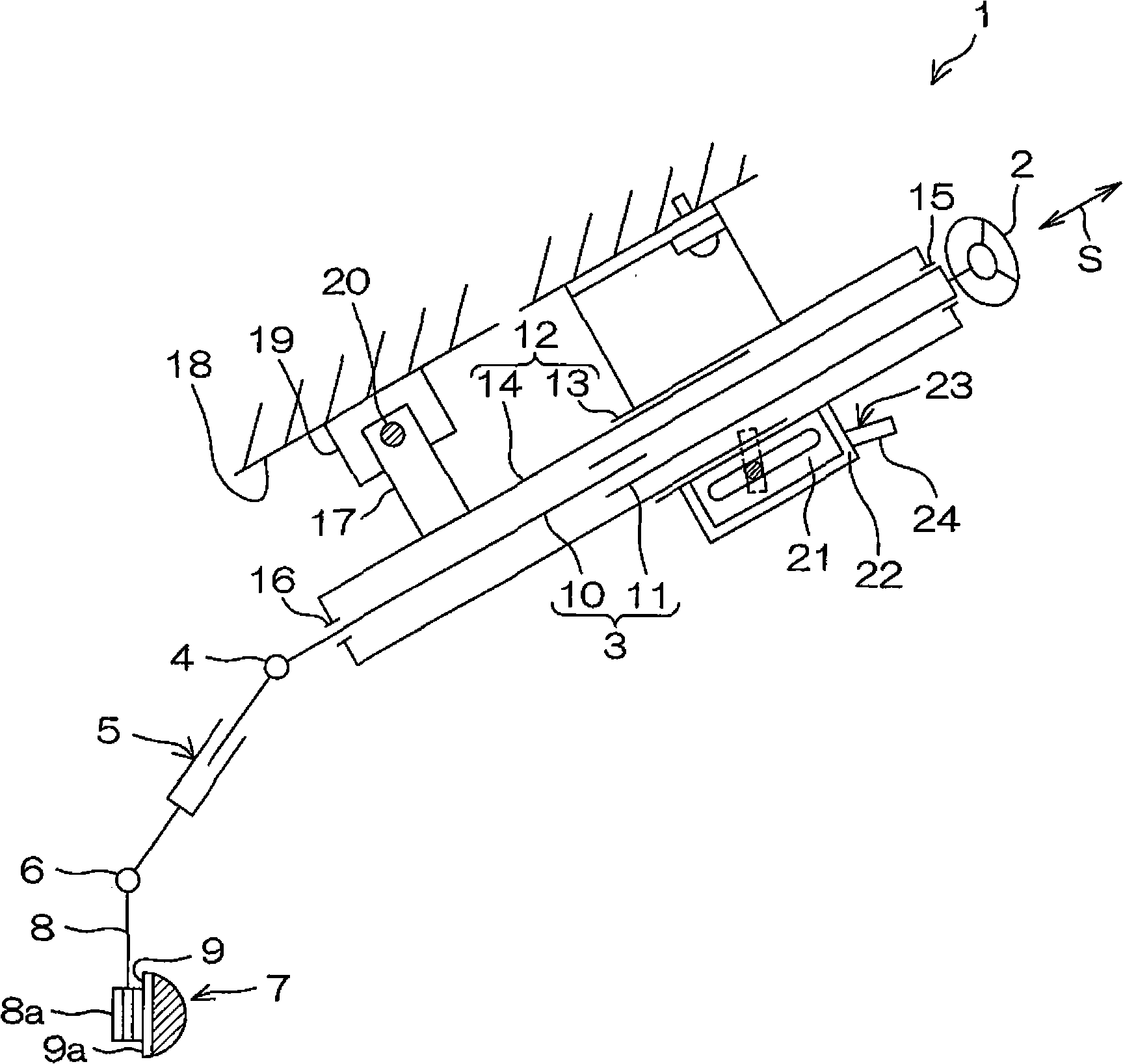

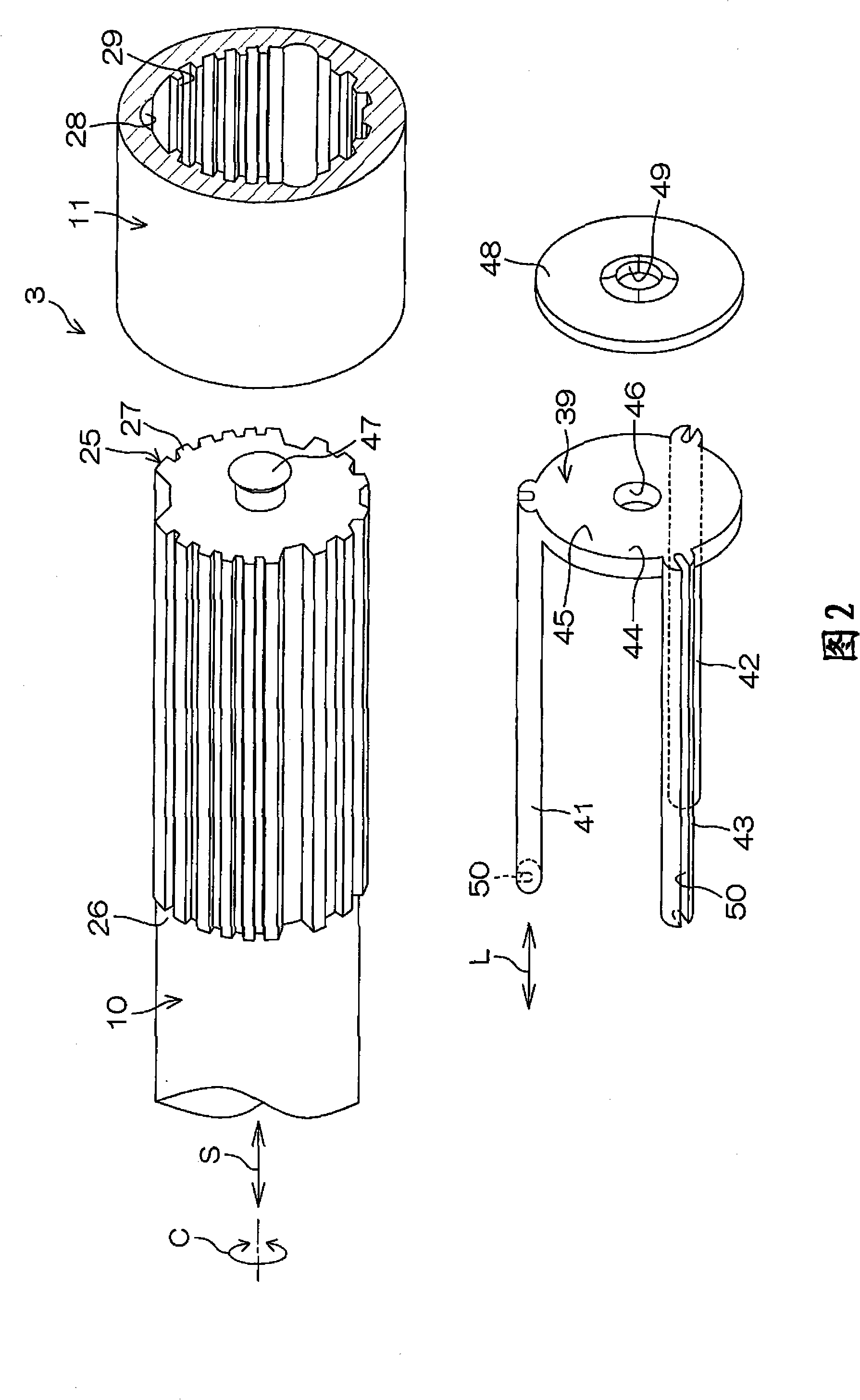

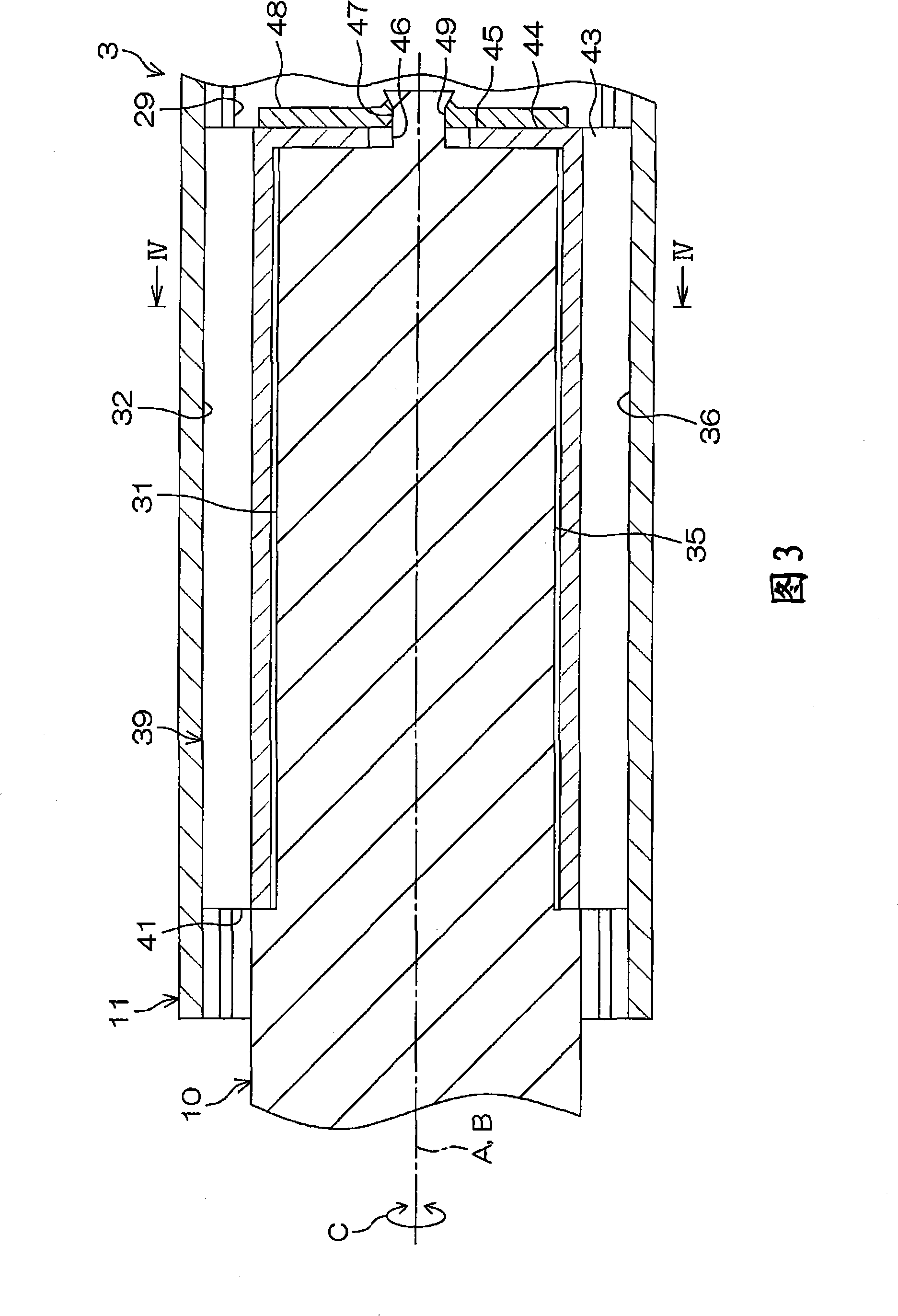

Telescopic shaft for steering a vehicle and motor vehicle steering system

InactiveCN101332828AAvoid plastic deformationSmooth slidingLinear bearingsShaftsRelative phaseCoupling

A telescopic shaft for vehicle steering includes: an inner shaft and a tubular outer shaft fitted with each other; at least three pairs of axial grooves formed on an outer periphery of the inner shaft and an inner periphery of the outer shaft; a rigid coupling element for rigidly connecting the inner shaft and the outer shaft in a circumferential direction (C) of the inner shaft when a relative phase of the inner shaft and the outer shaft with respect to the circumferential direction (C) exceeds a predetermined range; and a plurality of elongate resin rods as elastic coupling elements for elastically connecting the inner shaft and the outer shaft in the circumferential direction (C) when the relative phase is in the predetermined range. Each of the plural resin rods is formed with a groove. A section of the groove is shaped like U opening toward the outside in a radial direction (U) of the inner shaft.

Owner:JTEKT CORP +1

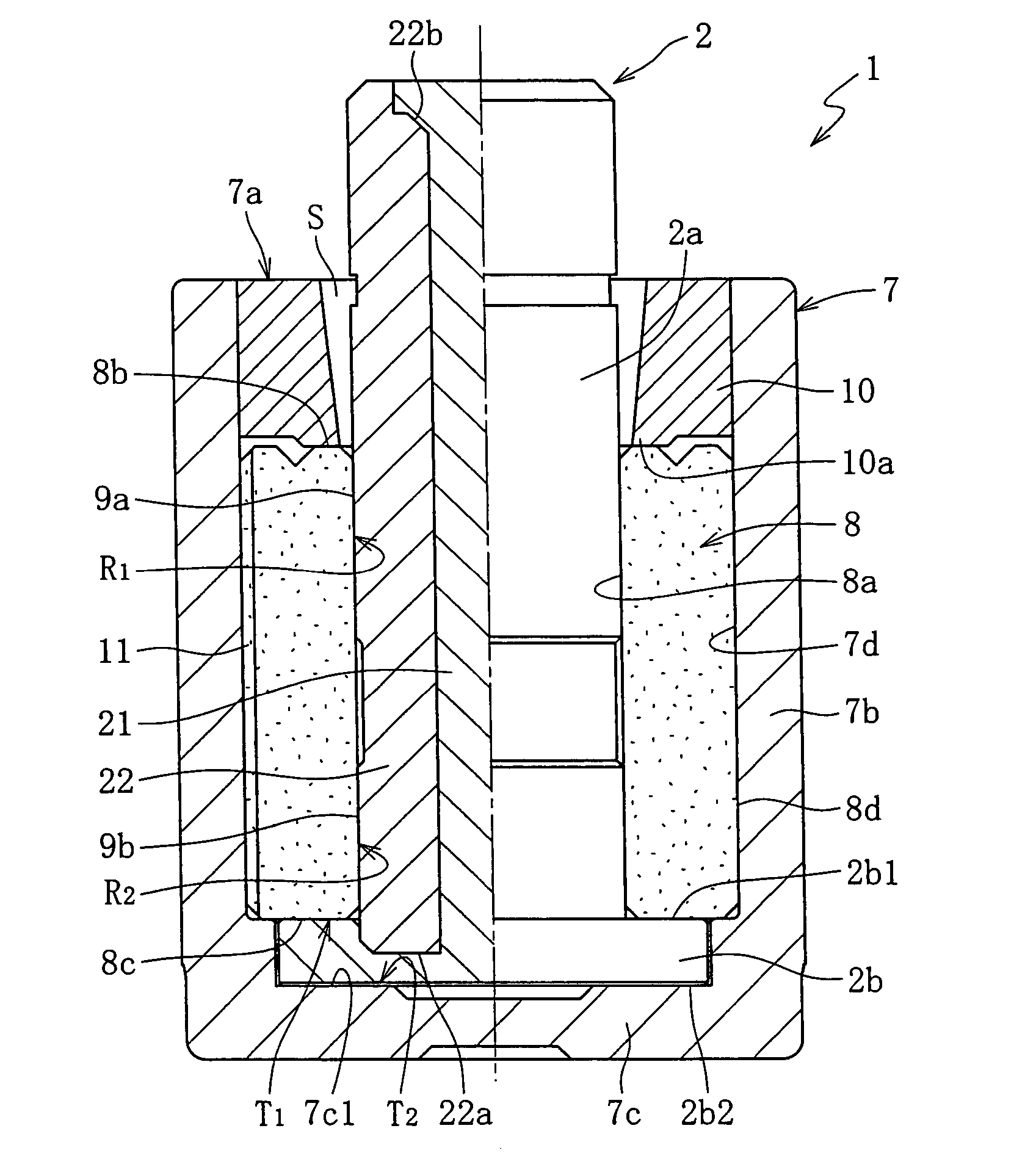

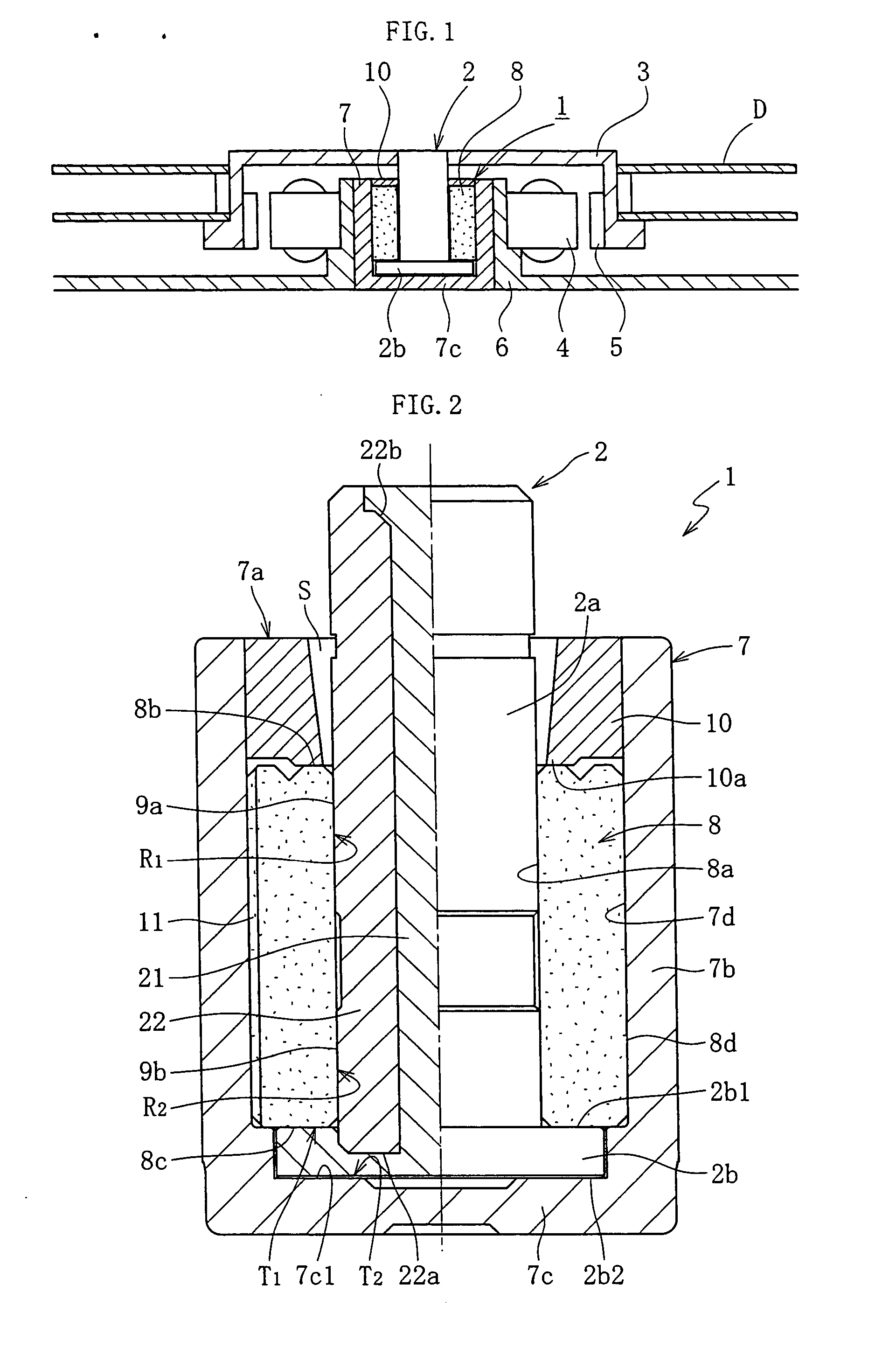

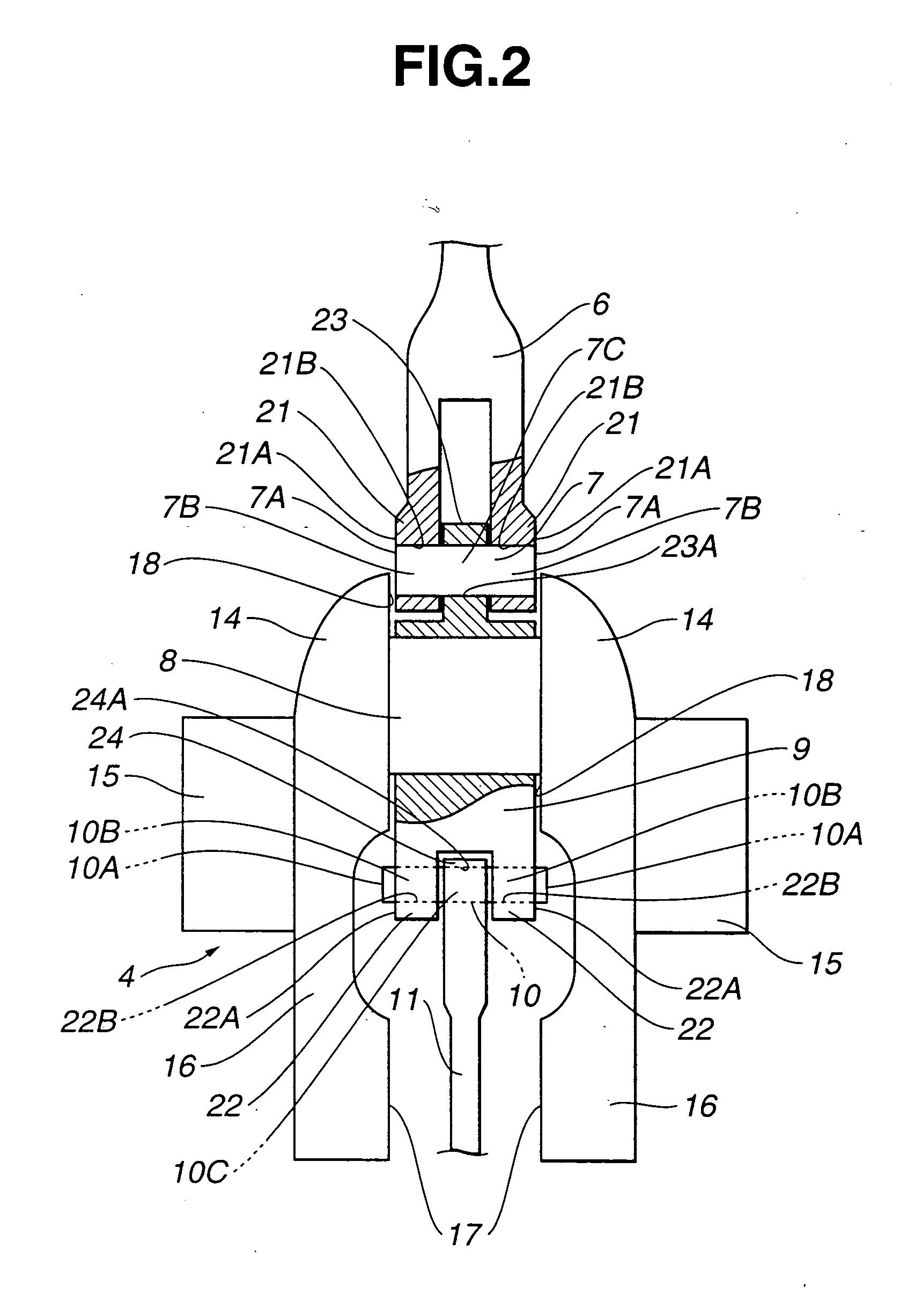

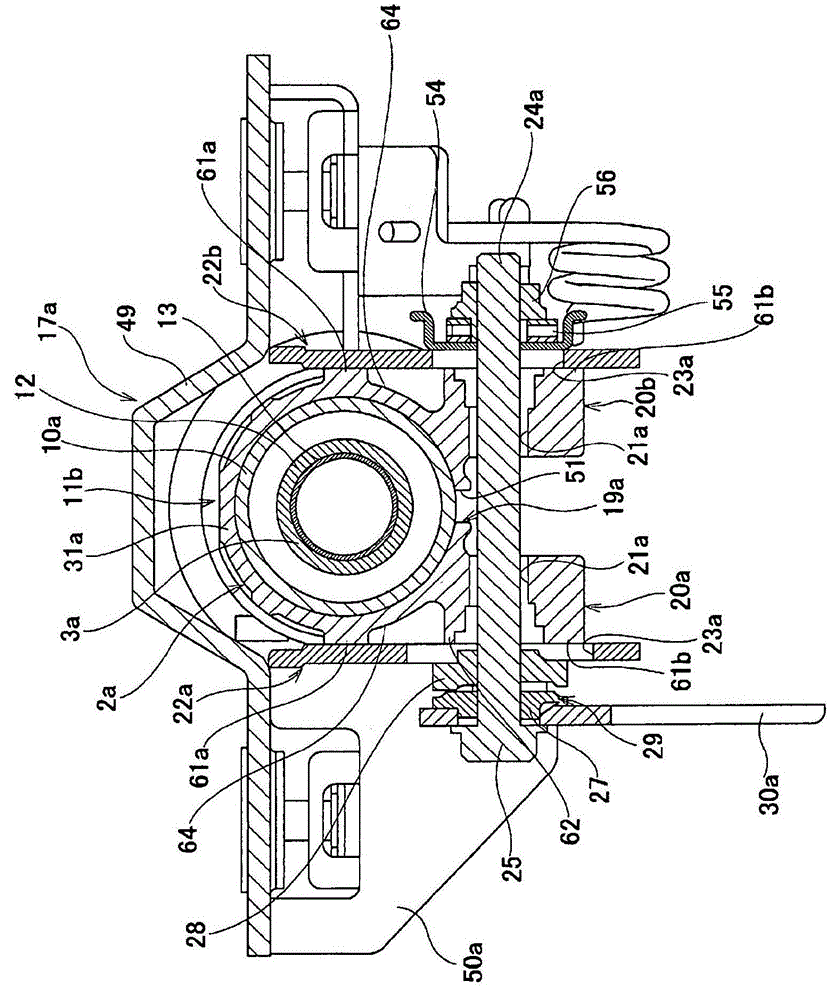

Dynamic bearing device

InactiveUS20070104400A1Ensure strengthEnsure rigidityShaftsRecord information storageThrust bearingEngineering

It is an object to improve bearing rigidity in a thrust direction at high temperatures and reduce a torque at low temperatures. An axial member 2 is arranged in such a manner that an outer circumferential surface of an axial part 2a is opposed to an inner circumferential surface of a bearing sleeve with a radial bearing gap interposed therebetween, and both end faces 2b1 and 2b2 of a flange part 2b are opposed to one end face of the bearing sleeve and a bottom face of a housing with thrust bearing gaps interposed therebetween, respectively. In this manner, the axial member 2 is supported by dynamic pressures generated in the respective bearing gaps in the thrust direction in a non-contact manner. The flange part of the axial member 2 is formed of a resin in such a manner that its linear expansion coefficient in its axial direction is equal to or larger than that of the housing 7.

Owner:NTN CORP

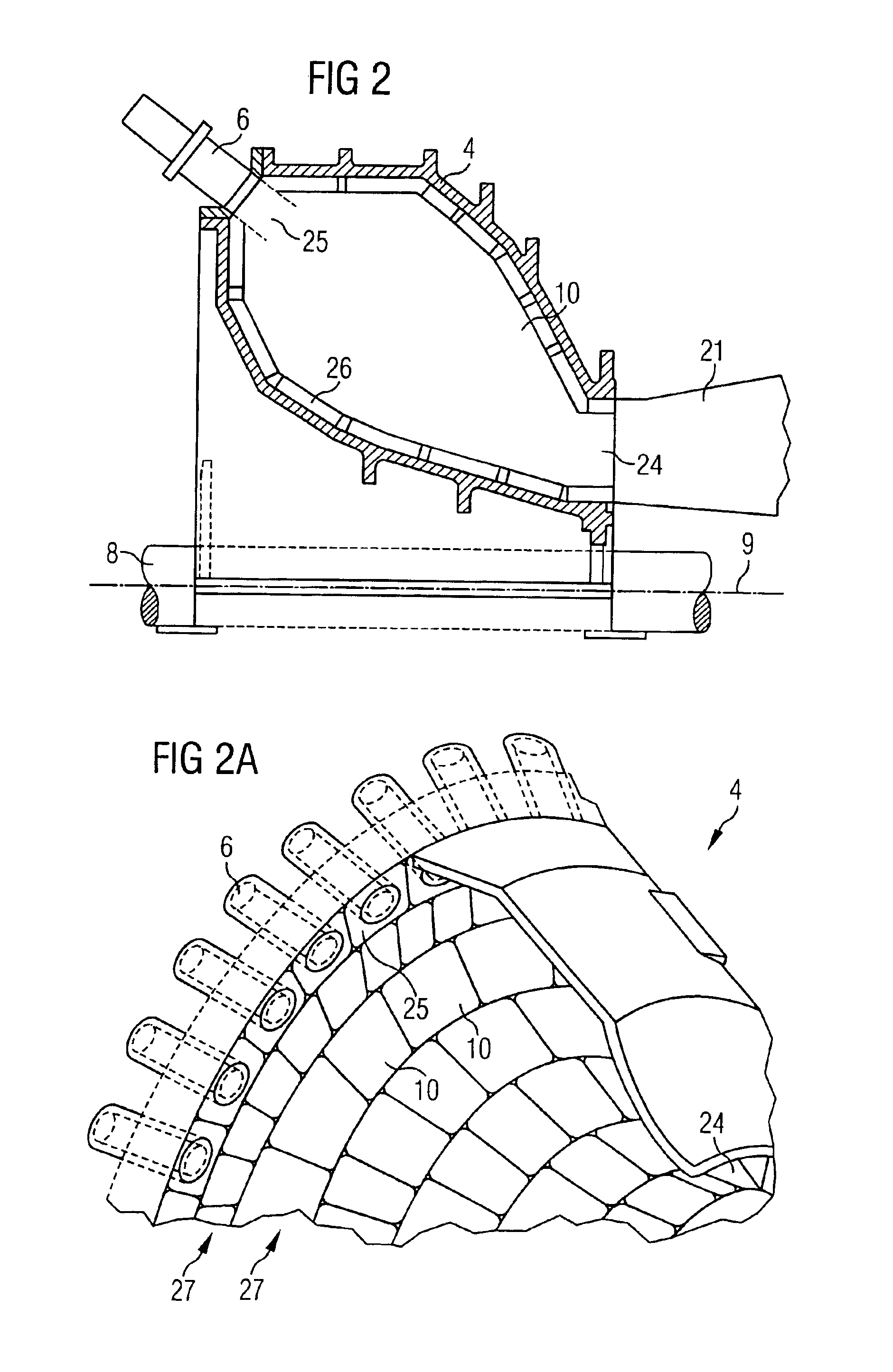

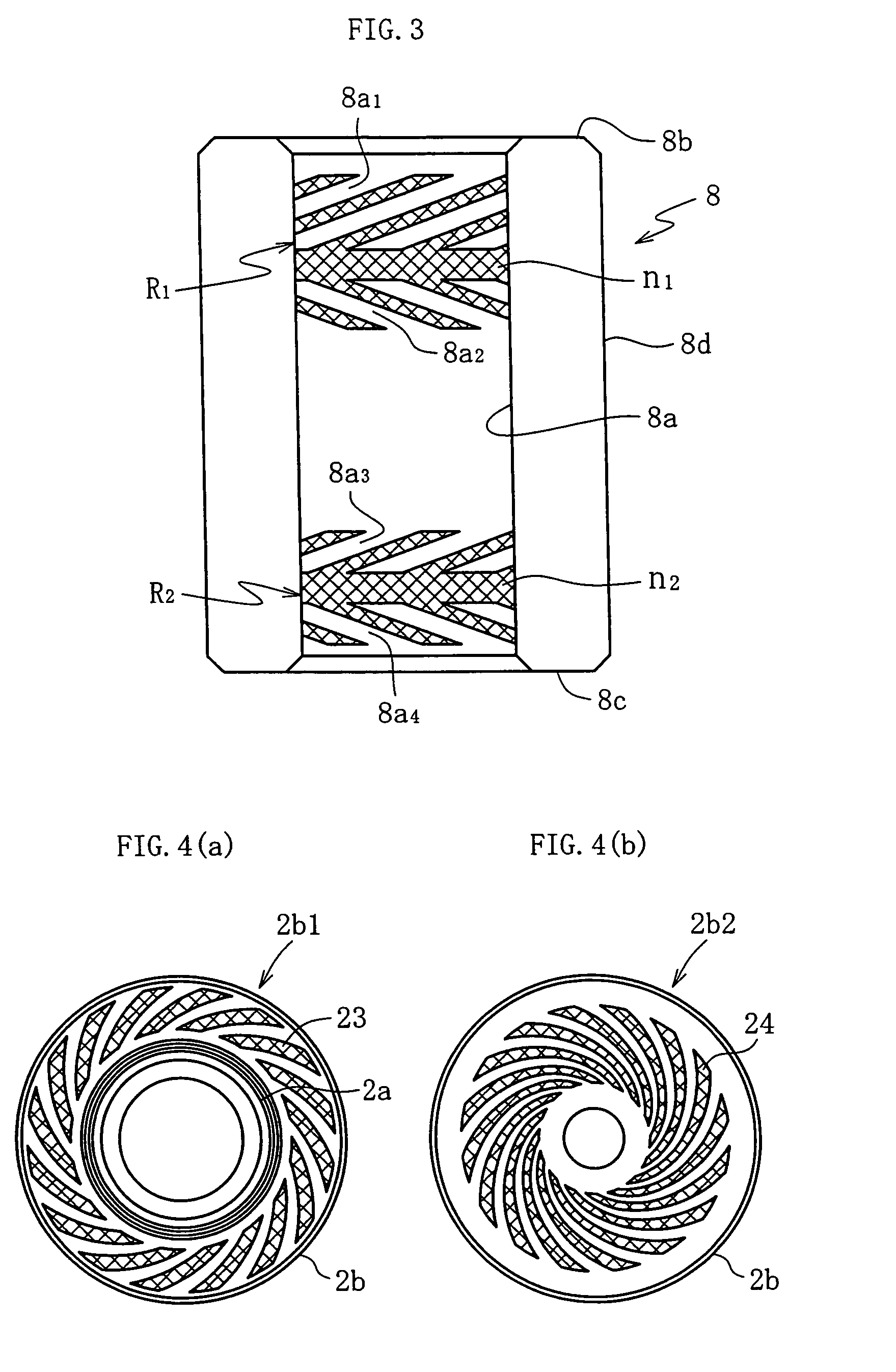

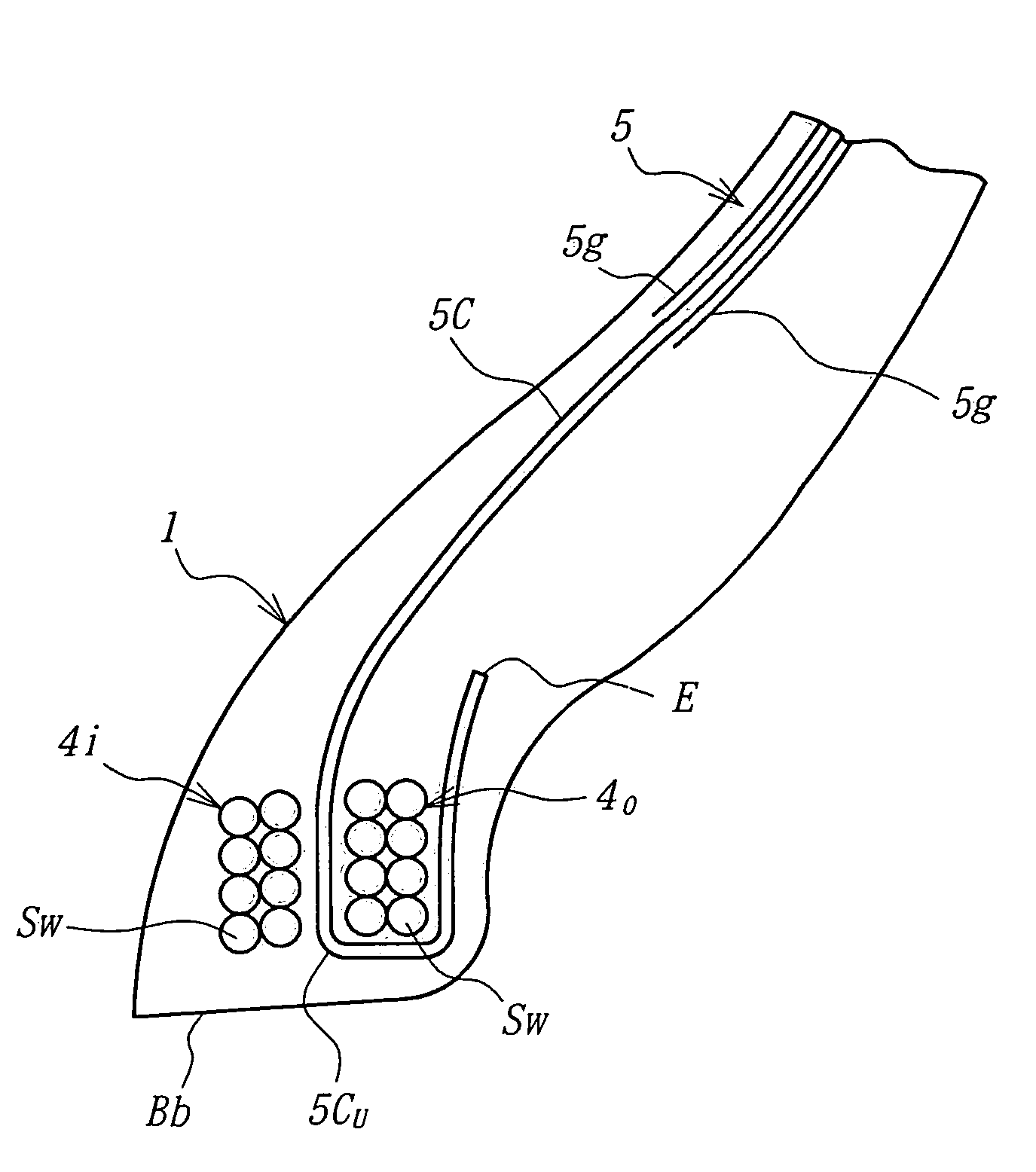

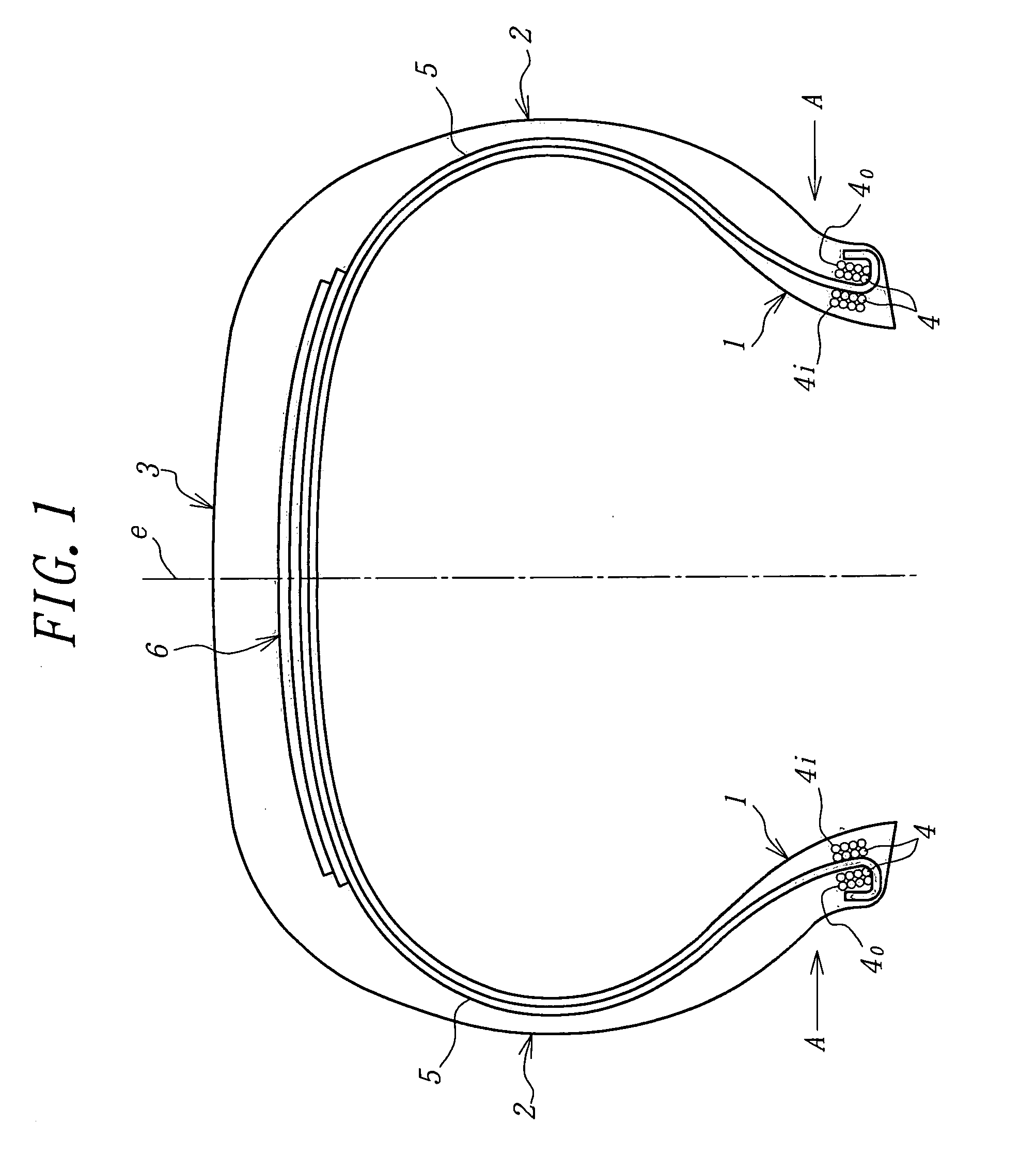

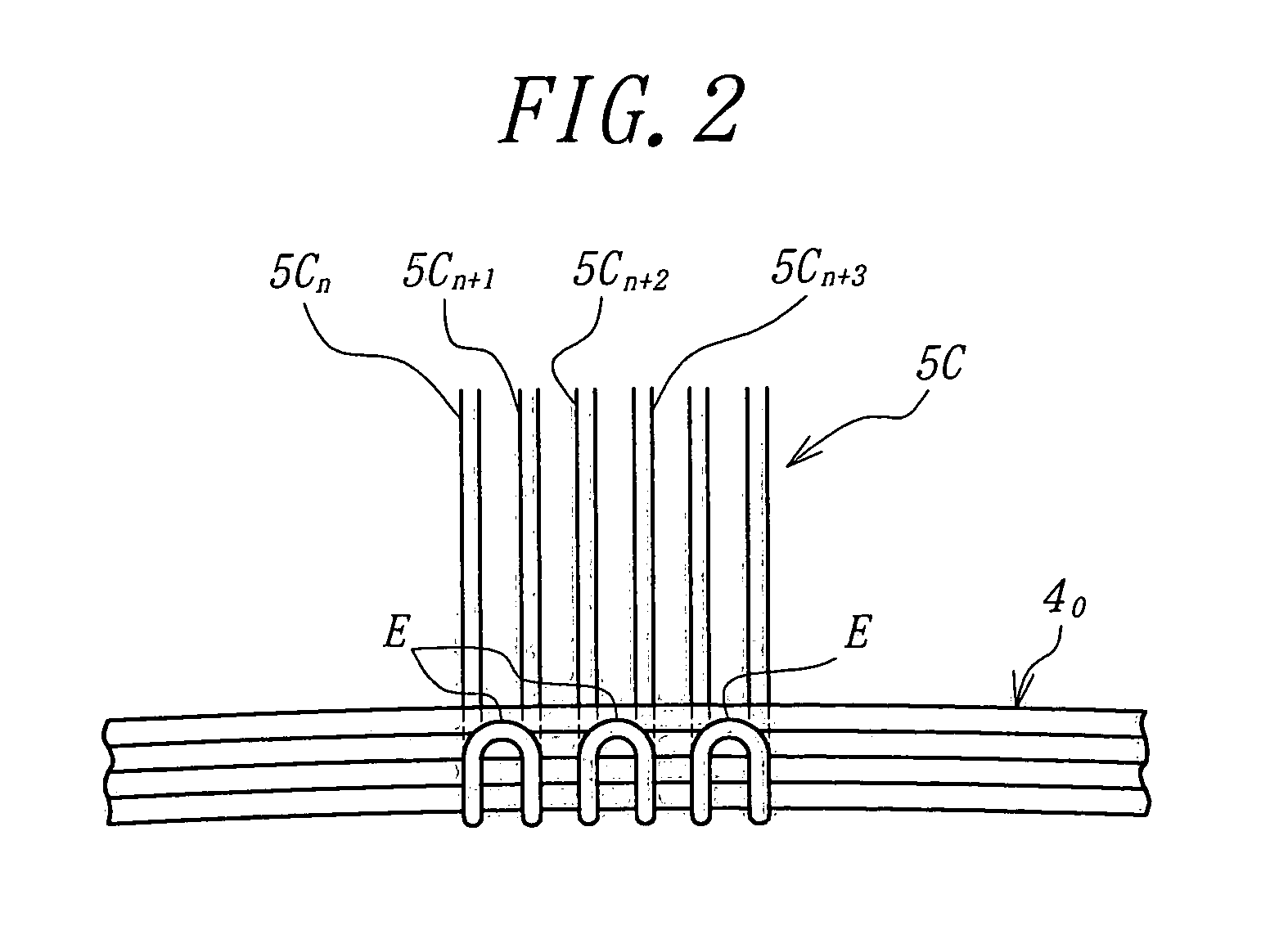

Pneumatic radial tires

InactiveUS6929045B1Ensure rigidityEnsure strengthPneumatic tyre reinforcementsTyre beadsMechanical engineeringRadial tire

A pneumatic radial tire comprises a radial carcass extending between a pair of bead portions each including two bead cores therein and reinforcing a pair of sidewall portions and a tread portion, wherein the radial carcass is comprised of a rubberized ply of a continuous cord successively repeating round trip in at least one of the two bead cores as a pair between the pair of the bead portions along a circumference of the bead portion and a roundtrip return portion of the cord is existent in both the bead portions. In this case, at least one of the two bead cores has such a structure that one or more steel wires are arranged lengthwise and widthwise in radial and widthwise directions of the tire, and the cord of the carcass ply has a roundtrip return portion located through a side face of the bead core having the above structure so as to cover at least an innermost steel wire arrangement in the radial direction from an inner side in the radial direction of the tire.

Owner:BRIDGESTONE CORP

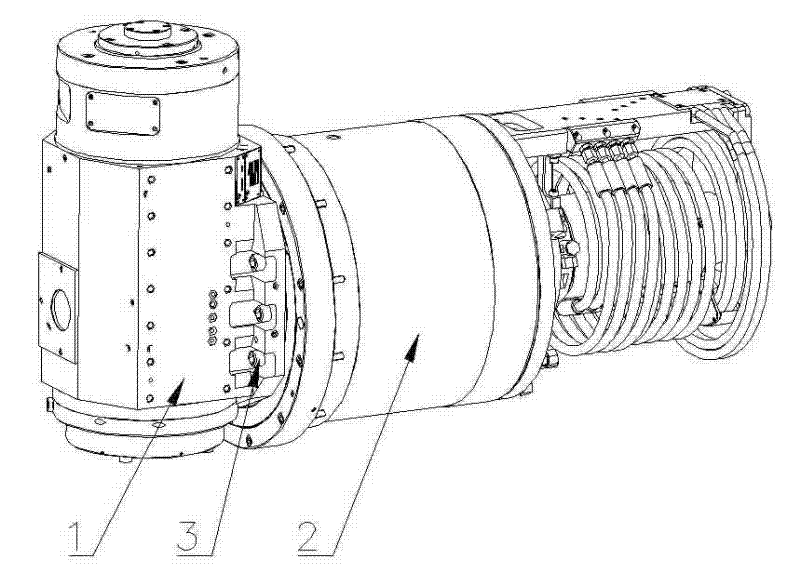

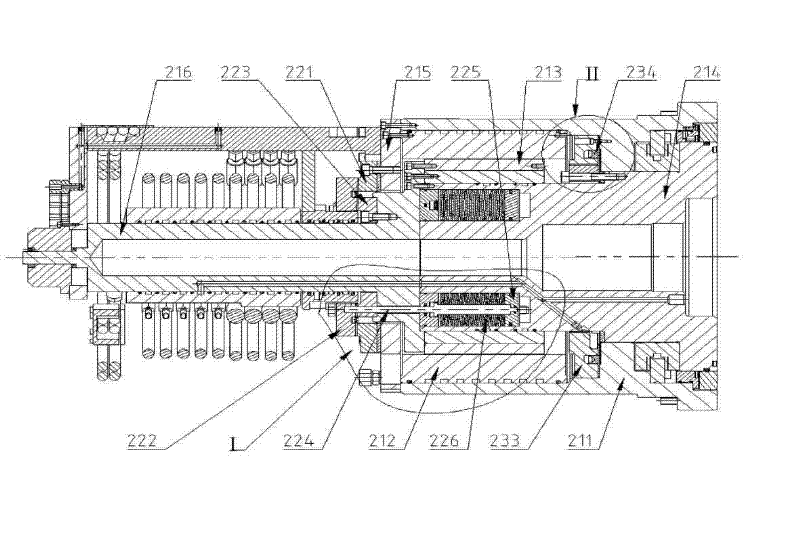

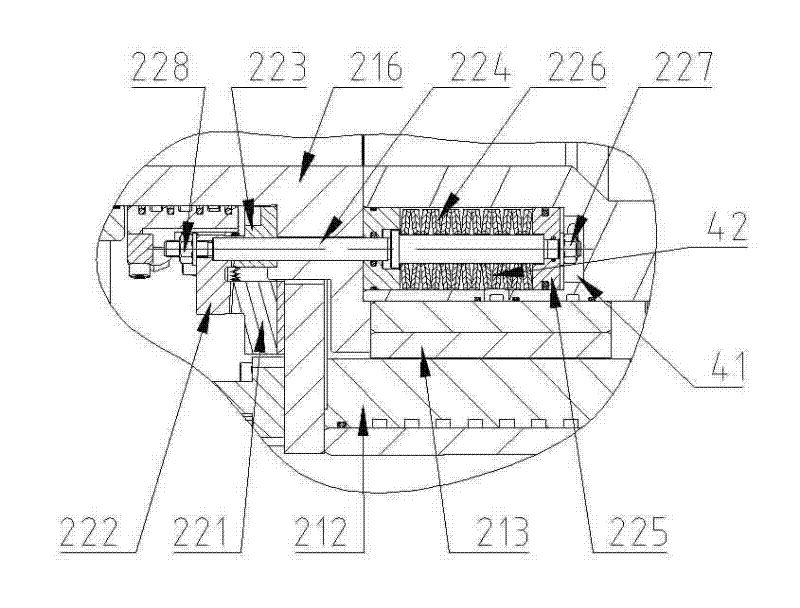

Modularized B-axis turning and milling composite functional unit

InactiveCN102398154AHazard reduction issuesEnsure rigidityFeeding apparatusOther manufacturing equipments/toolsNumerical controlMotor drive

The invention relates to a turning and milling composite functional unit for a numerical control machine, in particular to a modularized B-axis turning and milling composite functional unit, which comprises a B-axis module and a turning and milling head module, wherein the B-axis module comprises a driving device, a three-fluted-disc indexing structure and a brake structure, the turning and milling head module comprises a motor driving device and a three-fluted-disc fixing device, the turning and milling head module id driven by a built-in motor, and is provided with a three-fluted-disc locking structure, during turning, three fluted discs are locked to ensure structure rigidity, during milling or drilling, the three fluted discs are loosened, and a main shaft rotates to drive a cutter to carry out processing. The B-axis module is driven by the built-in motor, during indexing processing, the three-fluted-disc locking structure is adopted to ensure the structure rigidity and the indexing accuracy; and during processing at any angle, the brake mechanism is adopted to ensure the processing rigidity. The B-axis module and the turning and milling head module are connected through screws, and according to processing requirements, different turning and milling heads are replaced so as to expand processing capability.

Owner:SHENYANG MACHINE TOOLGRP RES & DESIGN INST CO LTD SHANGHAI BRANCH

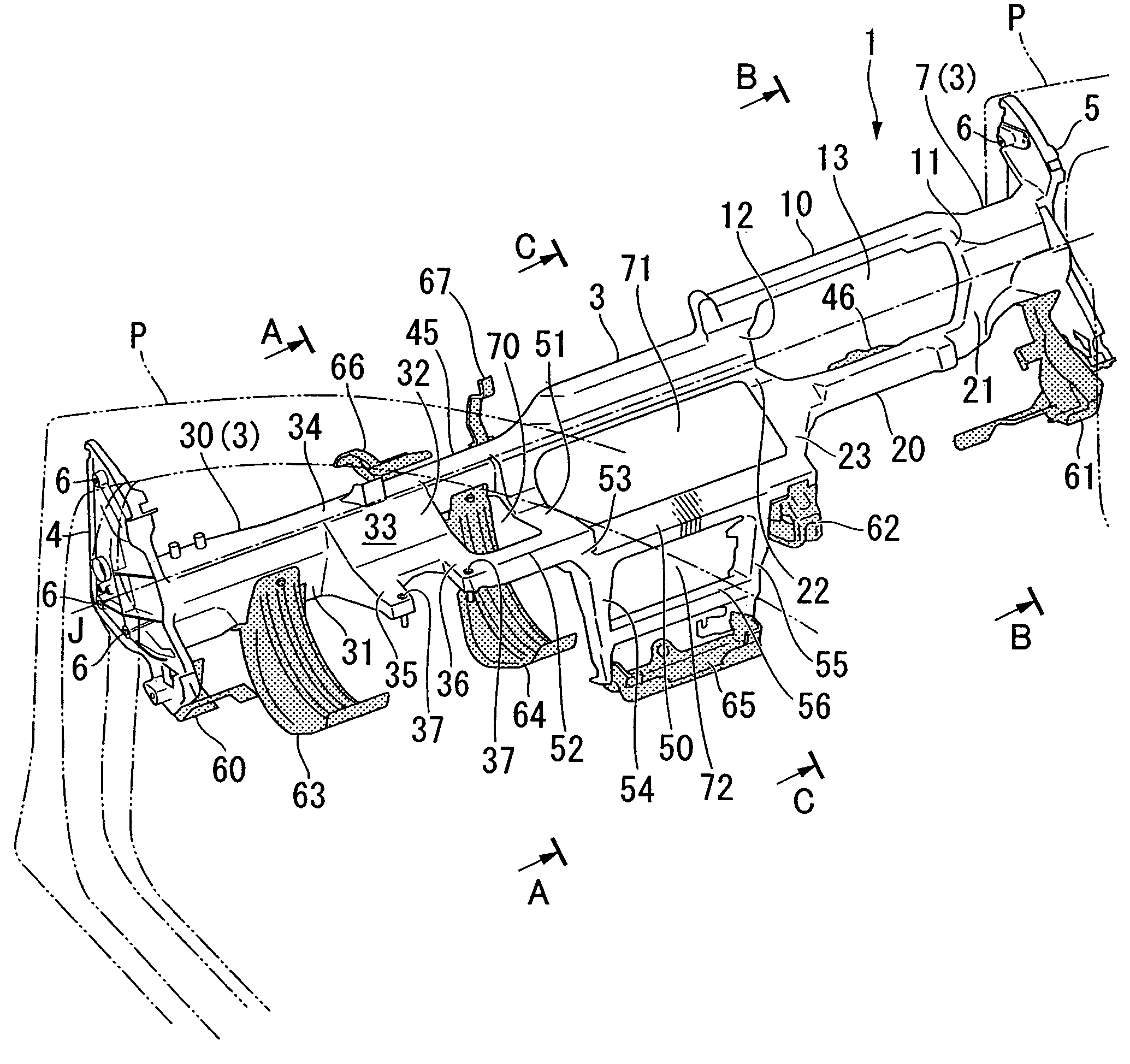

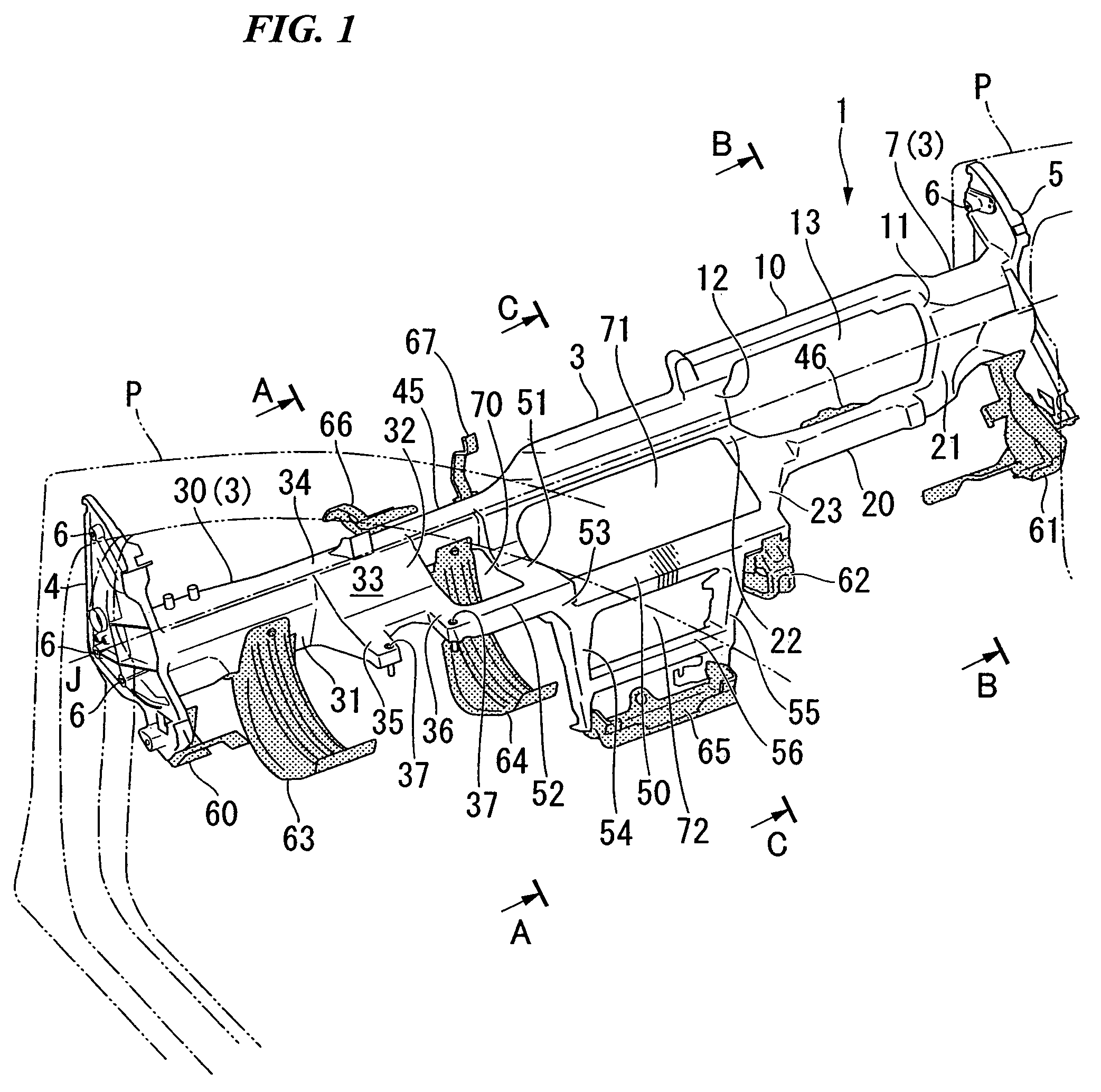

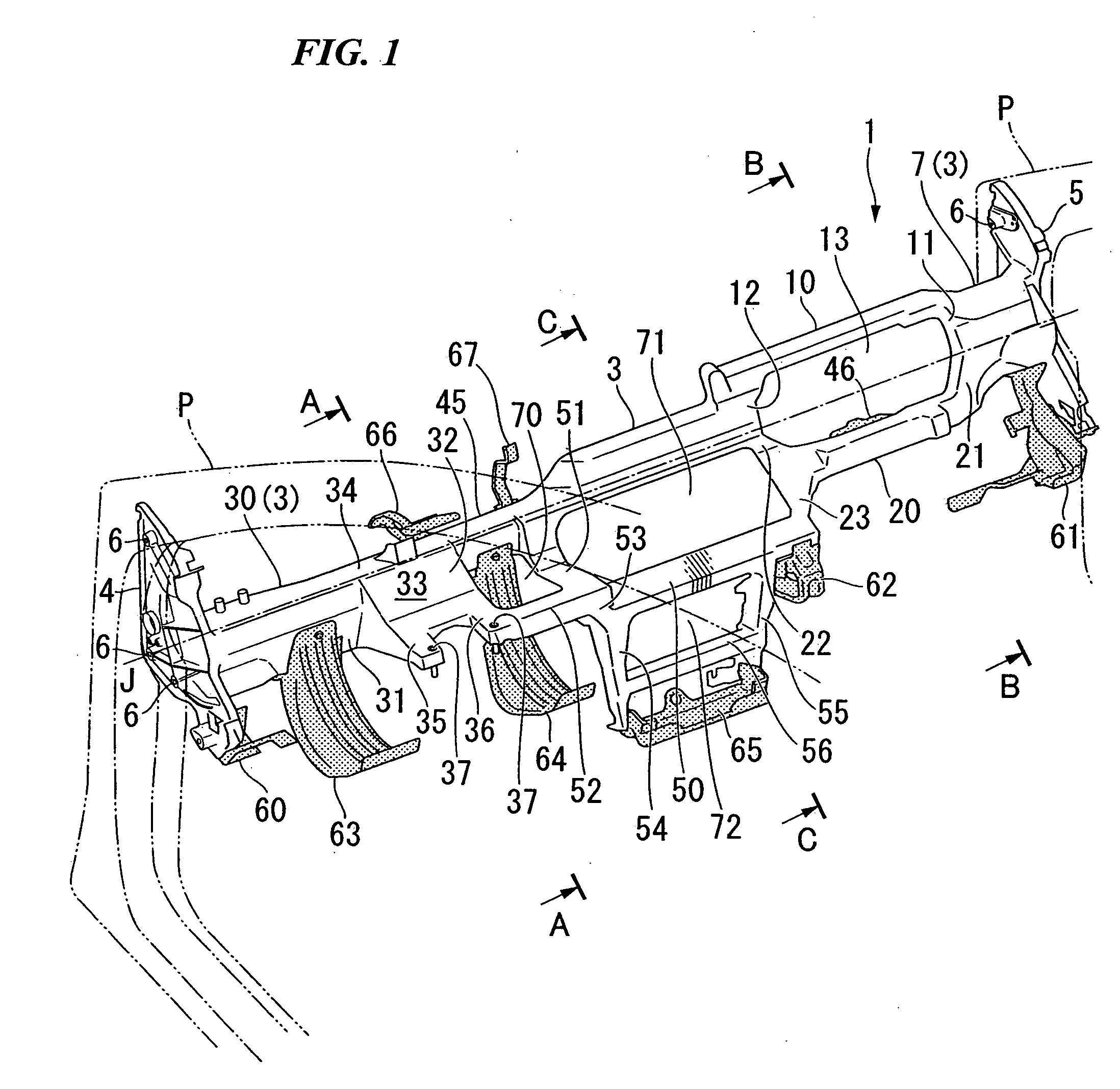

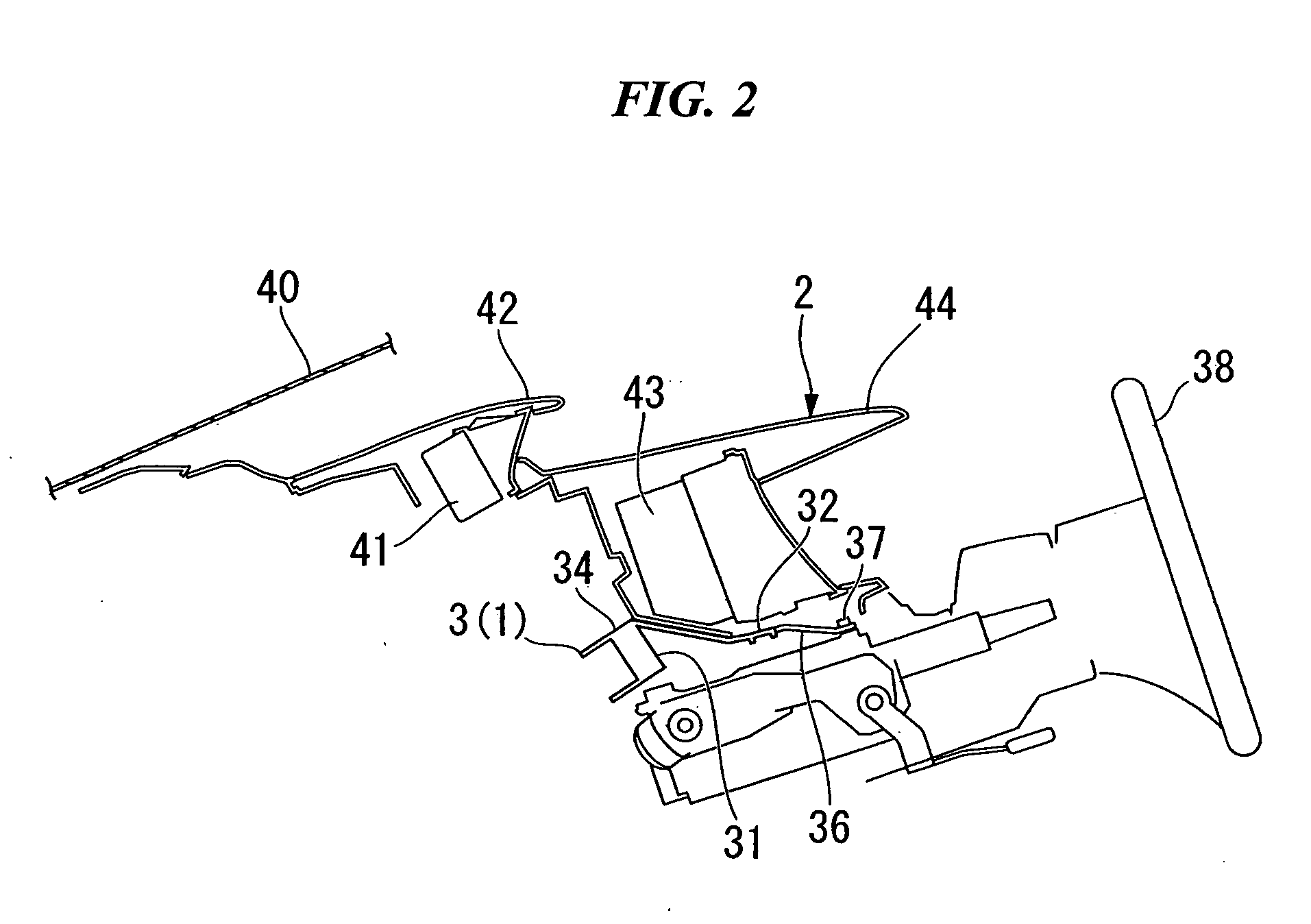

Steering hanger beam

InactiveUS7891707B2Reduce the overall heightIncrease freedomVehicle seatsUnderstructuresEngineeringMechanical engineering

The steering hanger beam extending in a width direction of a vehicle and connected to left and right vehicle-body members, is provided with: a main member which supports a steering device; a pair of front and rear transverse beam portions connected to the main member in the width direction of the vehicle so as to be offset from an axis of the main member to front and rear; and an opening which is formed between the pair of front and rear transverse beam portions so as to penetrate in substantially a vertical direction.

Owner:HONDA MOTOR CO LTD

Multi-link piston crank mechanism for internal combustion engine

ActiveUS20050045120A1Optimization mechanismAvoid interferenceConnecting rodsGearingMulti linkEngineering

A multi-link piston crank mechanism for an internal combustion engine, including a crankshaft having a crank pin, and crank webs connected with each other through the crank pin. A pair of thrust surfaces are formed on the crank webs so as to be opposed in a direction of a center axis of the crank pin. A first link pivotally supported on the crank pin is coupled to a second link through a connection pin located in a space between the thrust surfaces. The connection pin is moveable about the crank pin to form a circular trace along which the thrust surfaces extend. The end surfaces of the connection pin and the thrust surfaces come into mutual contact to prevent the connection pin from falling out of the space between the thrust surfaces.

Owner:NISSAN MOTOR CO LTD

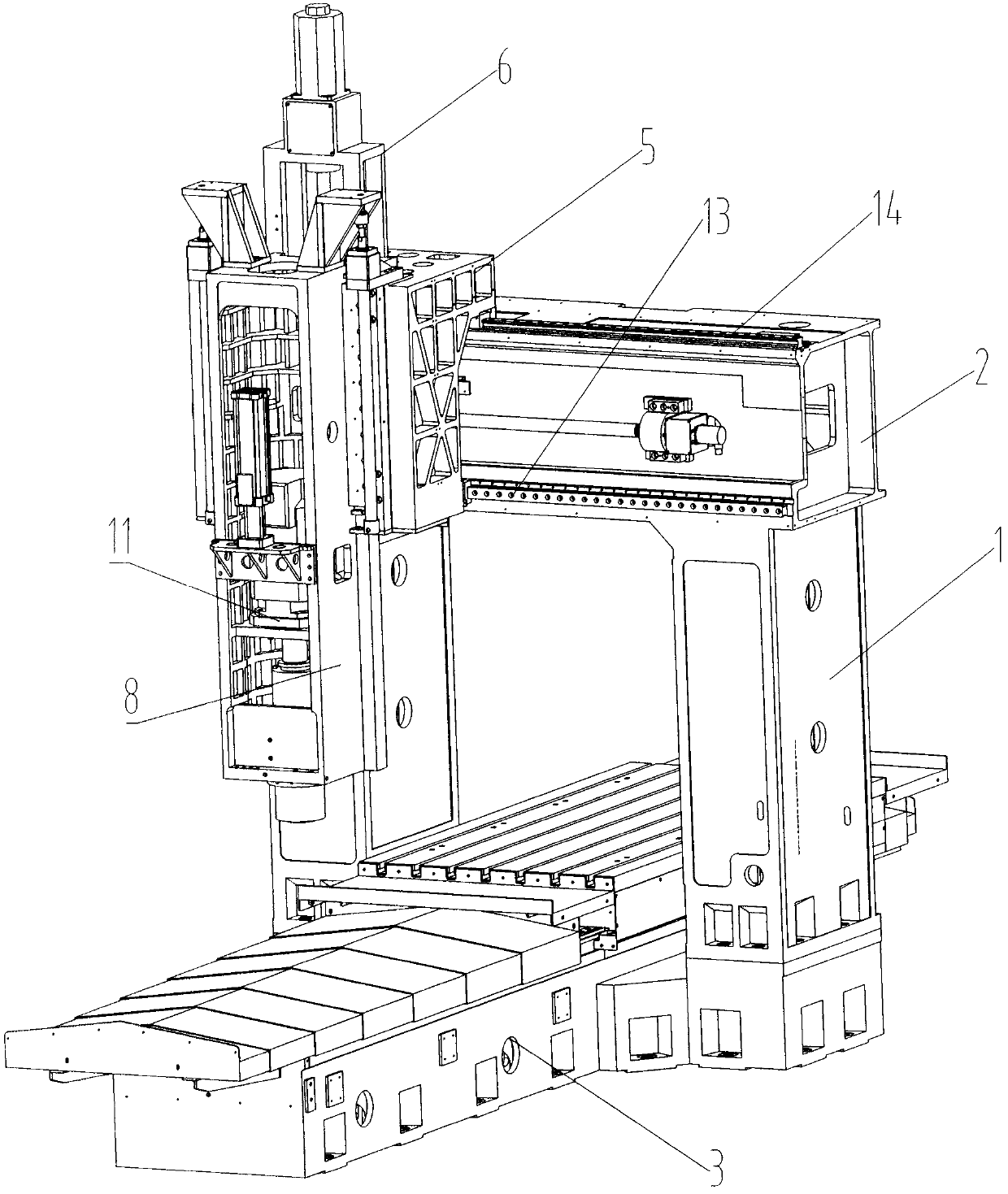

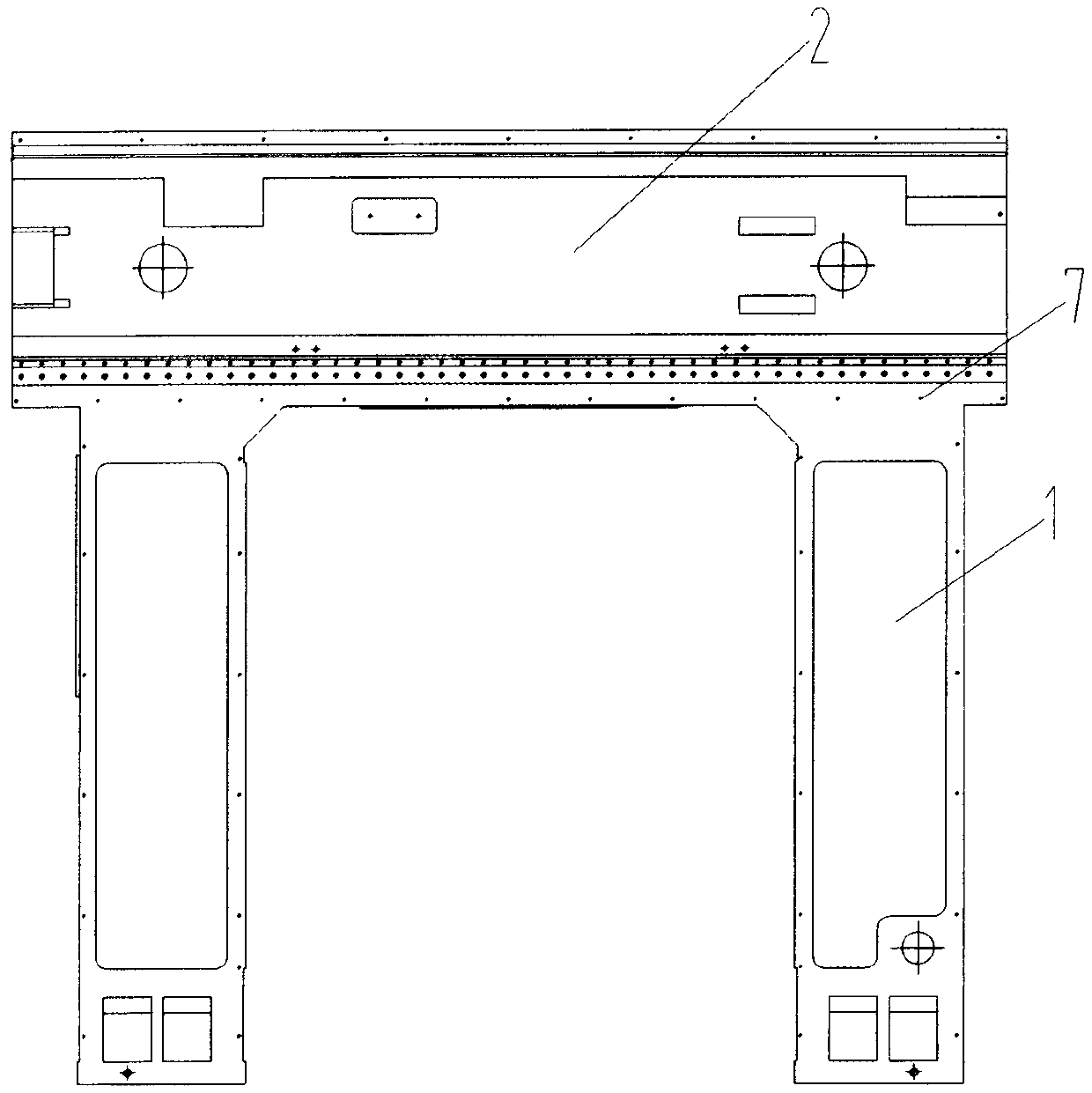

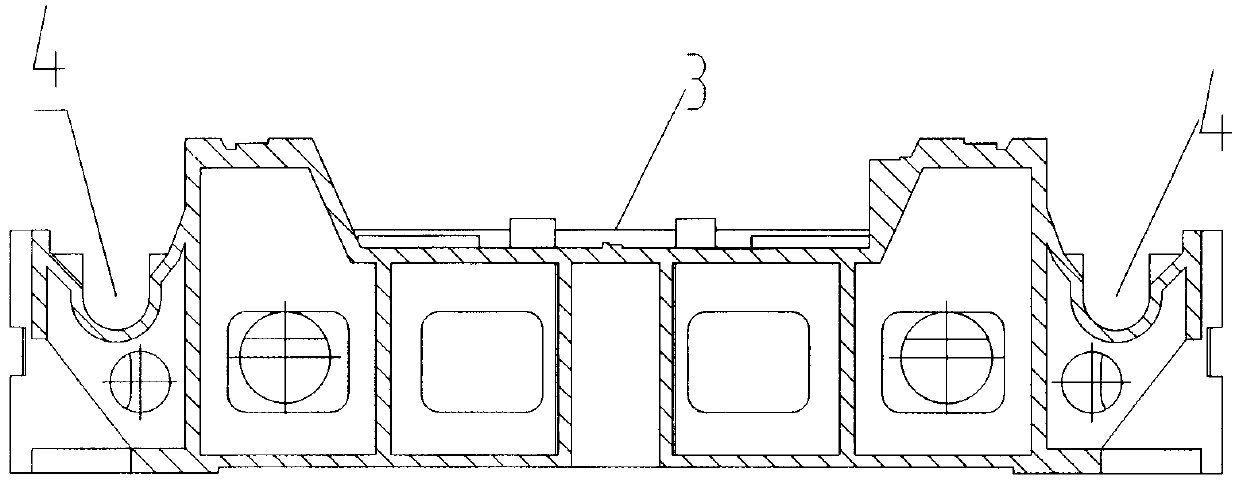

Novel gantry machining center

InactiveCN103624553AEnsure rigidityEnsure strengthLarge fixed membersDriving apparatusEngineeringUltimate tensile strength

The invention discloses a novel gantry machining center which comprises a stand column, a beam, a lathe bed body, casting chip removal device grooves, a sliding base body, a sliding base support and the like. The novel gantry machining center is characterized in that the stand column and the beam are of an integrated structure which is one-time formed by cast iron, the casting chip removal device grooves are formed in the two sides of the lathe bed body, the casting chip removal device grooves and the lathe bed body are of an integrated structure which is one-time formed by castings, the sliding base body and the sliding base support are of a split structure and are fixedly connected together through bolts. According to the novel gantry machining center, the partial integrated structure or the split structure is adopted, the rigidity and strength of the whole gantry machining center are improved, and assembling efficiency and production efficiency are improved.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

Unconventional bolt and a fastening device using the unconventional bolt thereof

An unconventional bolt includes a main body having two heads, and two threaded rods respectively formed at the external surface of each head coaxially with the main body, wherein the cross section of each head has a noncircular shape, and the axial projection of the cross section of the middle of the main body is located in the noncircular axial projection of each head of the main body. The unconventional bolt has a simple structure and a convenient assembly, and can improve the strength and rigidity of the nested profiled components after the connection; and the fastening device using the unconventional bolt can not only support the component but also reinforce it, thus effectively preventing the nested profiled components from transforming.

Owner:NINGBO BANGDA INDAL

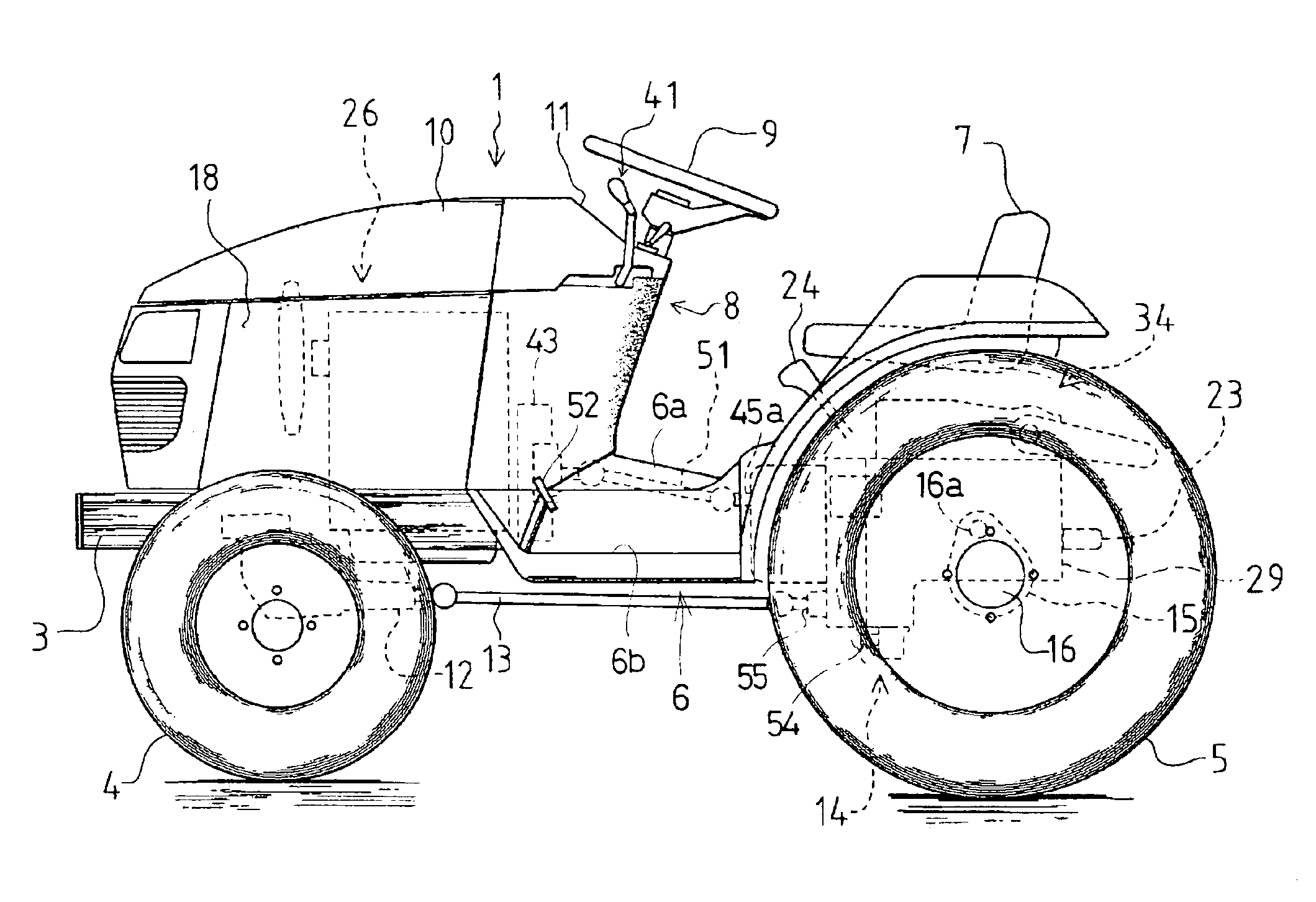

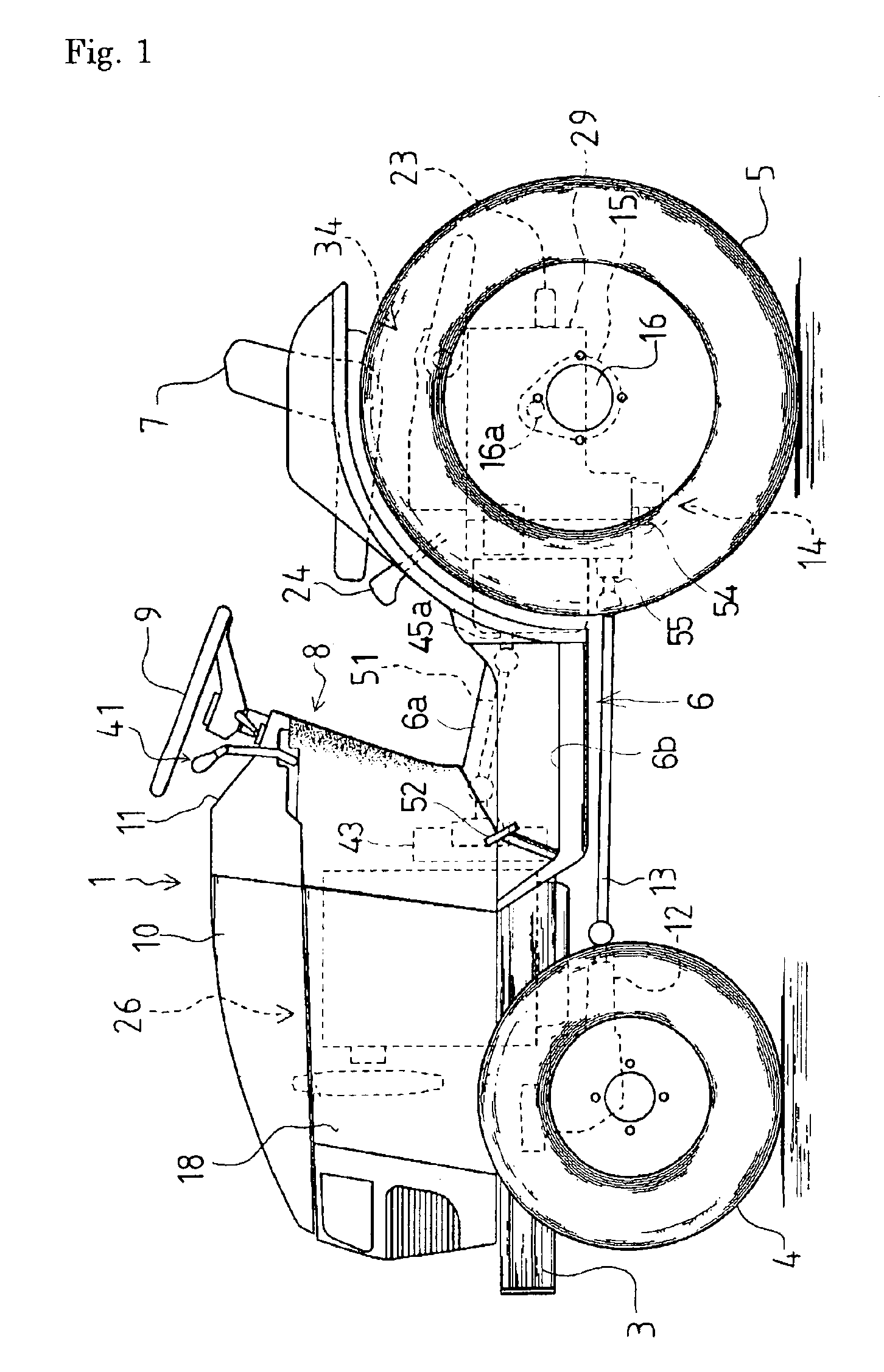

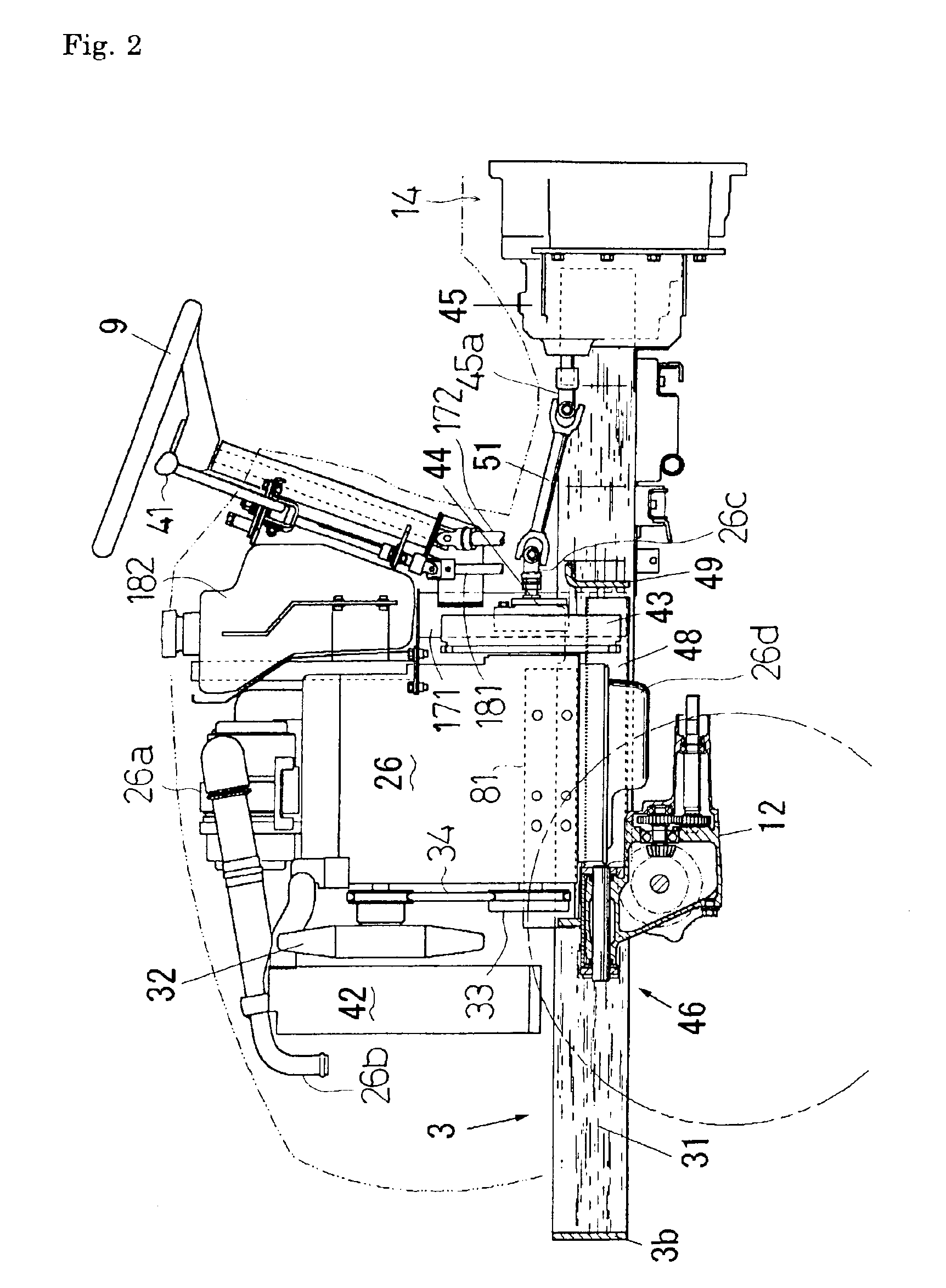

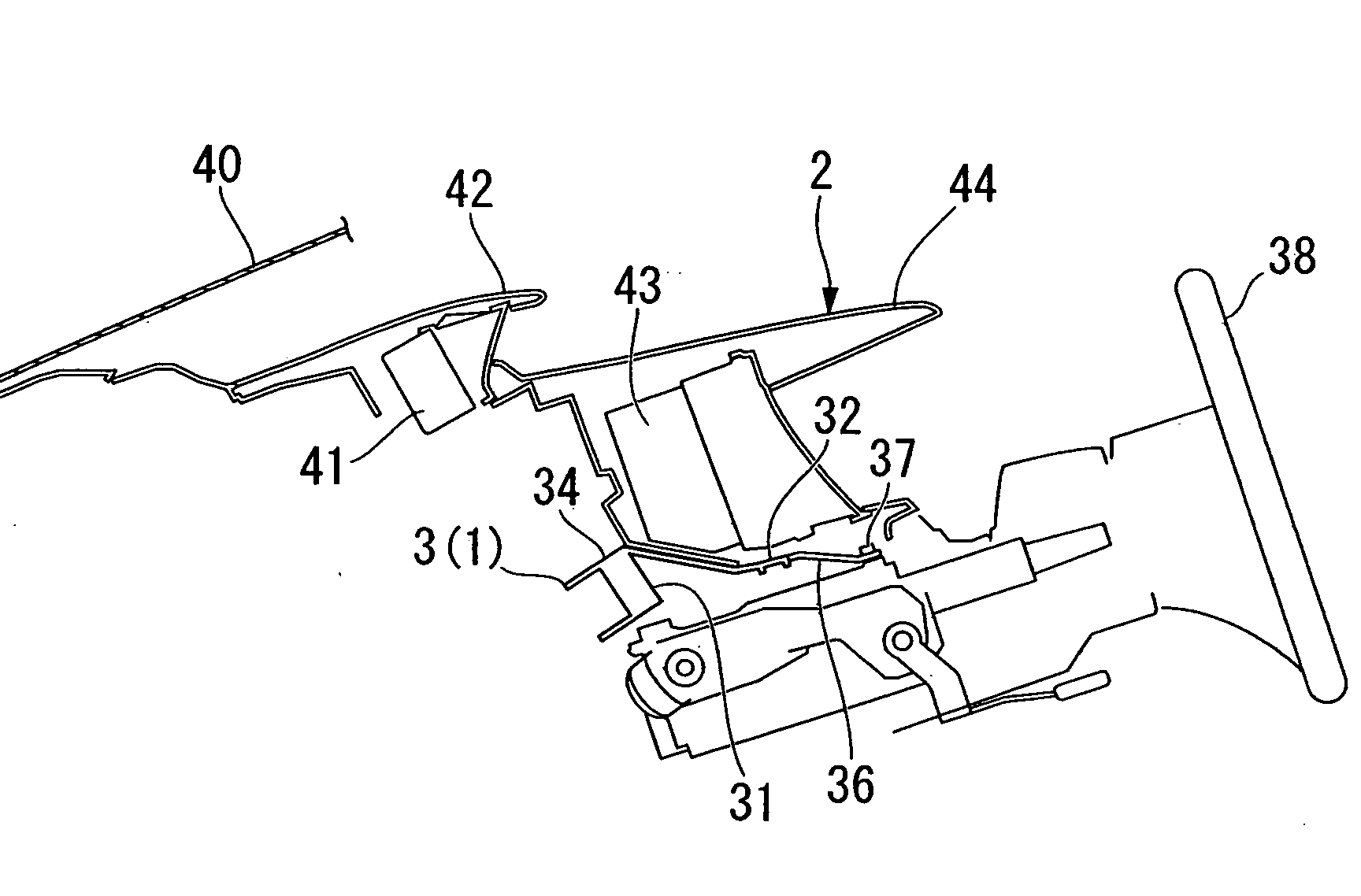

Body frame of a riding tractor

InactiveUS6935457B2Ensure rigidityEnsures rigidityUnderstructuresSuperstructure subunitsVehicle frameFlywheel

A body frame is provided for a riding tractor. An axis of an engine mounted on the body frame is oriented lengthwise along the tractor and a flywheel is provided on the axis of the engine. The body frame comprises a pair of left and right side members extending lengthwise along the tractor, cross members disposed in front and rear of the engine, respectively, so as to connect the left and right side members to each other, and reinforcing members provided on inside portions of the respective side members. The reinforcing members are disposed laterally inward from the lateral outermost end of the flywheel in a space between the engine and each of the side members.

Owner:KANZAKI KOKYUKOKI MFG

Steering hanger beam

InactiveUS20090090211A1Reduce the overall heightIncrease freedomUnderstructuresSuperstructure subunitsEngineeringMechanical engineering

The steering hanger beam extending in a width direction of a vehicle and connected to left and right vehicle-body members, is provided with: a main member which supports a steering device; a pair of front and rear transverse beam portions connected to the main member in the width direction of the vehicle so as to be offset from an axis of the main member to front and rear; and an opening which is formed between the pair of front and rear transverse beam portions so as to penetrate in substantially a vertical direction.

Owner:HONDA MOTOR CO LTD

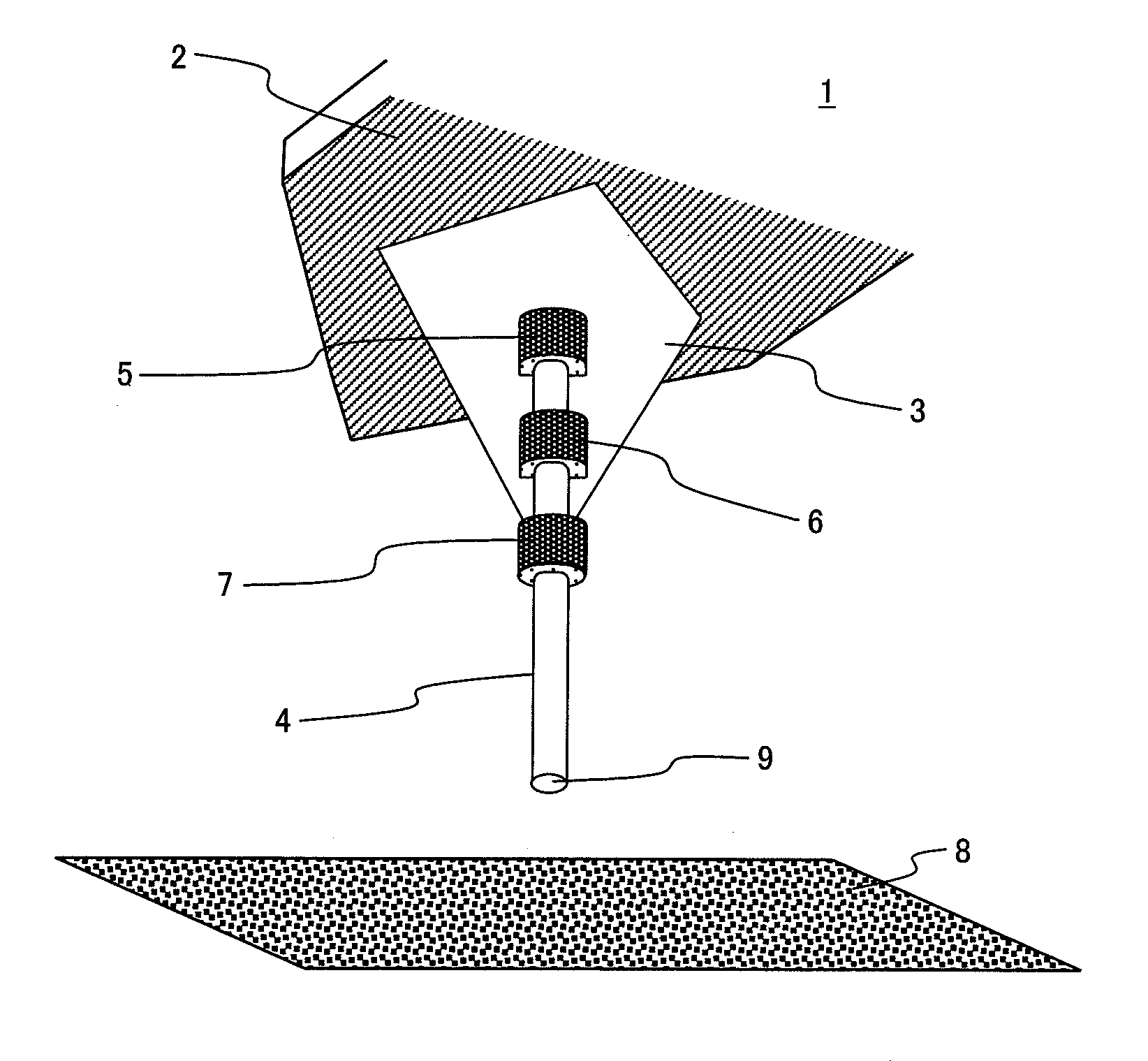

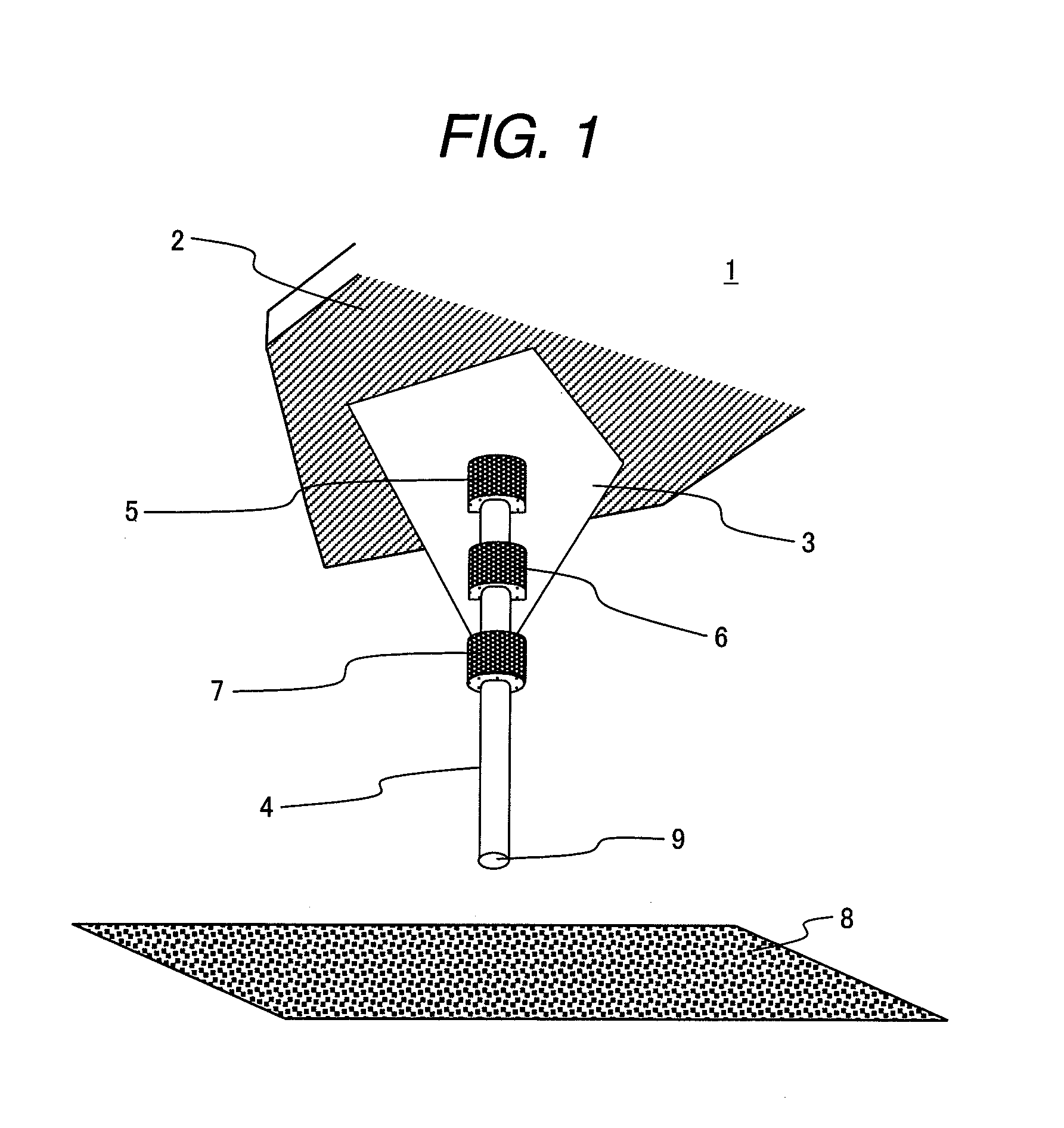

Probe for scanning probe microscope

InactiveUS20100043108A1Improve reliability and reproducibilityEnsure rigidityNanosensorsMechanical roughness/irregularity measurementsPhysicsExtremity Part

In a tip having a carbon nanotube tip used to a scanning probe microscope, its length of the tip is adjusted in a several order of 10 nm and the tip maintains cylindrical shape up to the extremity portion.

Owner:HITACHI CONSTR MASCH CO LTD +1

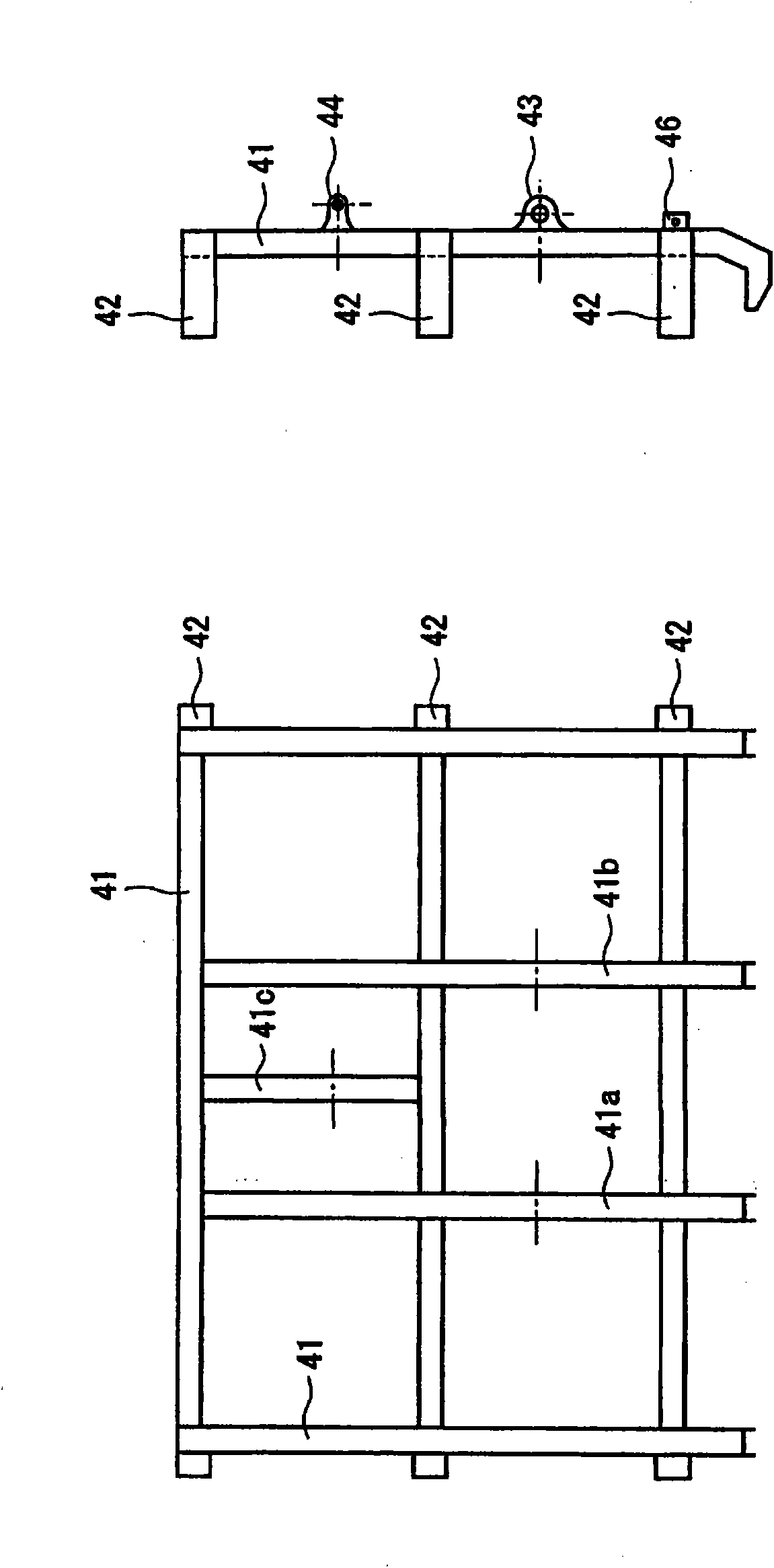

Container of type having wing doors, used to transport plate-like goods, and trailer for carrying the container

InactiveCN101970261ASmall sizeIncrease the number ofGlass plate transportationLarge containersEngineeringMechanical engineering

A container of type having wing doors is used carried on a vehicle. The container has the wing doors adapted to swing open and closed and constructed as integral parts functioning as side faces and the roof of the container, a base mounted inside the container and on which plate-like goods are fixed, and a base supporting device for supporting the base such that the base can be set to either a tilted state or a horizontal state. The floor surface of the container has, in a lateral cross-section of the floor surface, a shape of a hat in which the center portion of the shape is high in height along the entire length in the front-rear direction of the floor surface with side portions on opposite sides of the center portion formed to be low in height. The base supporting device is mounted on the center portion of the floor surface. The lower part of the base enters either of the side portions of the floor surface when the base supporting device supports the base in a tilted state.

Owner:ASAHI GLASS CO LTD

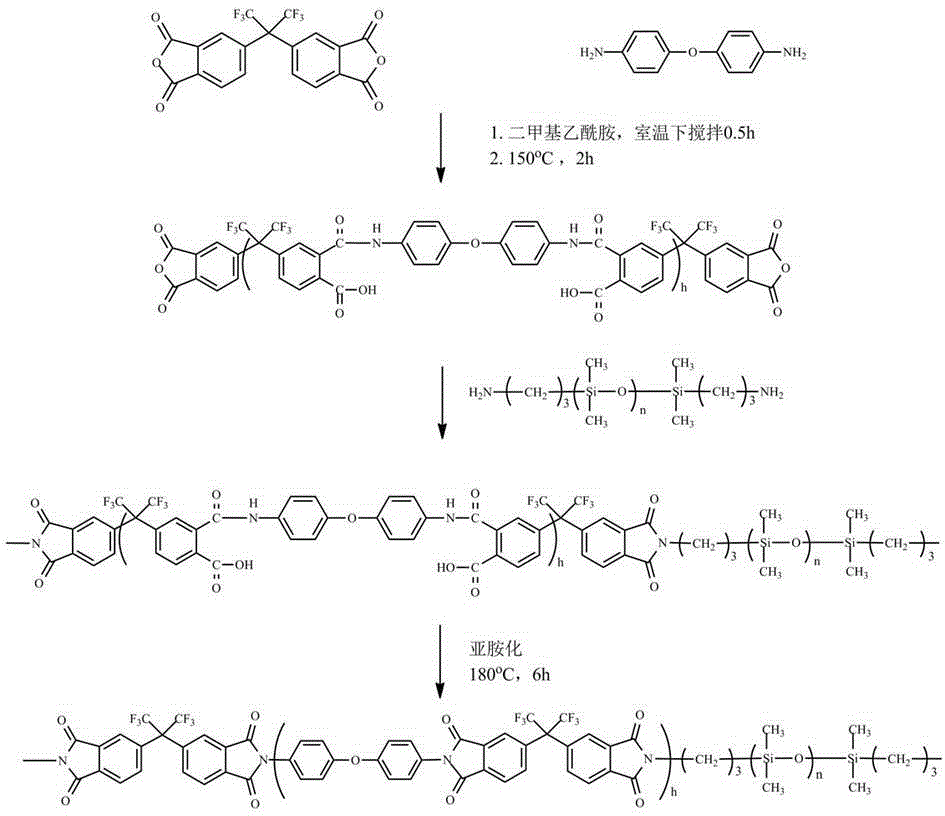

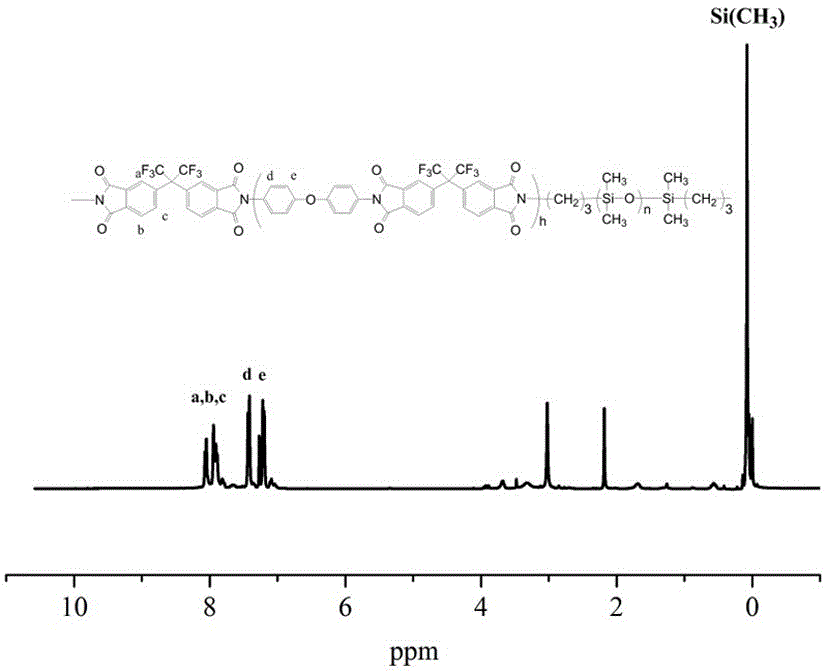

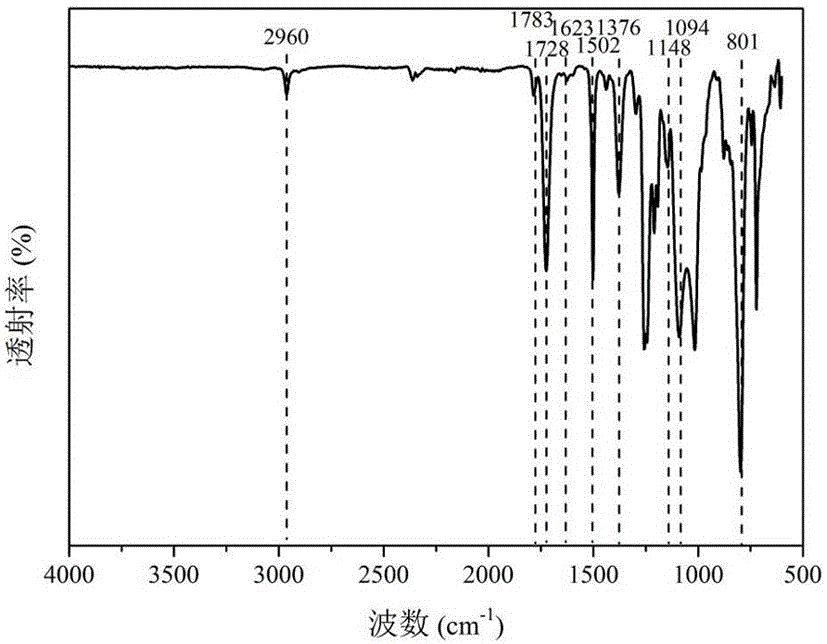

Modified thermosetting resin and preparation method thereof

The invention discloses modified thermosetting resin and a preparation method thereof. 100 parts of molten state thermosetting resin and 1-20 parts of fluorine-containing-polyimide-b-polysiloxane rigid-flexible segmented copolymer with amino end groups are evenly mixed and undergo a curing and postprocessing process to obtain fluorine-containing-polyimide-b-polysiloxane rigid-flexible segmented copolymer modified thermosetting resin. The modified thermosetting resin has high heat resistance, high toughness, low dielectric constant and good curing manufacturability. The method for preparing the modified thermosetting resin is simple and practical, no solvent is used, and the modified thermosetting resin undergoes large-scale and cleaning production easily.

Owner:太湖华强科技有限公司

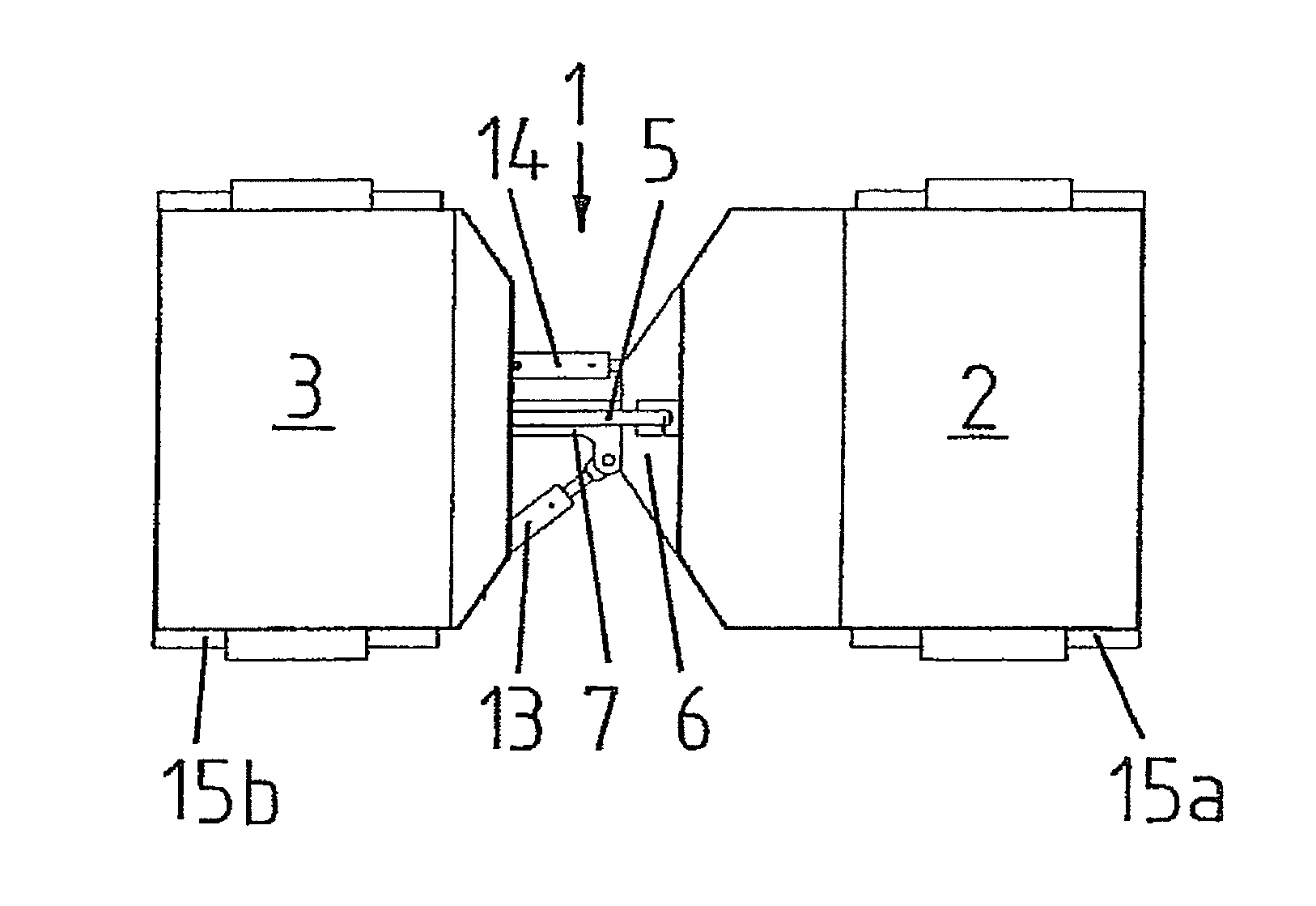

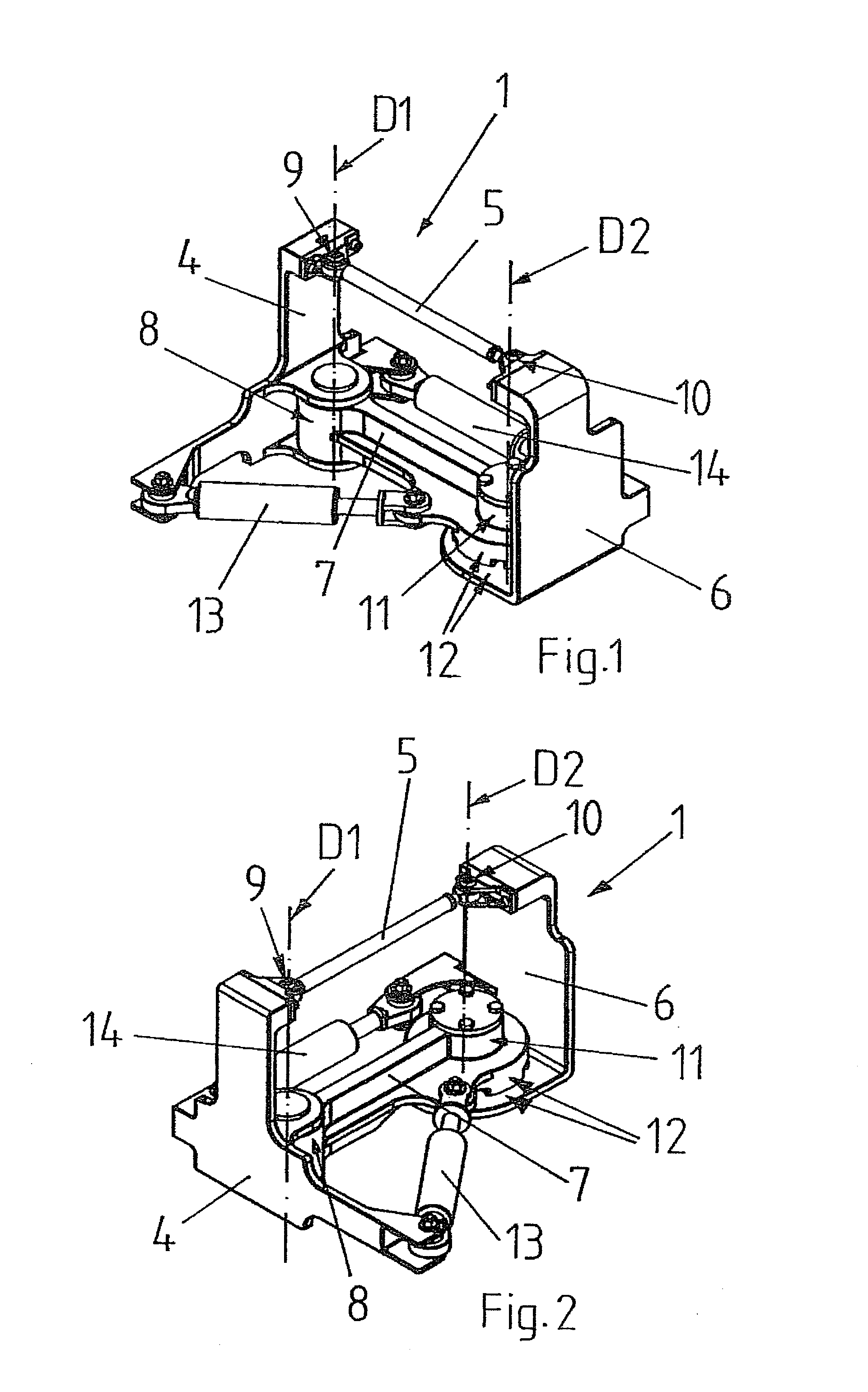

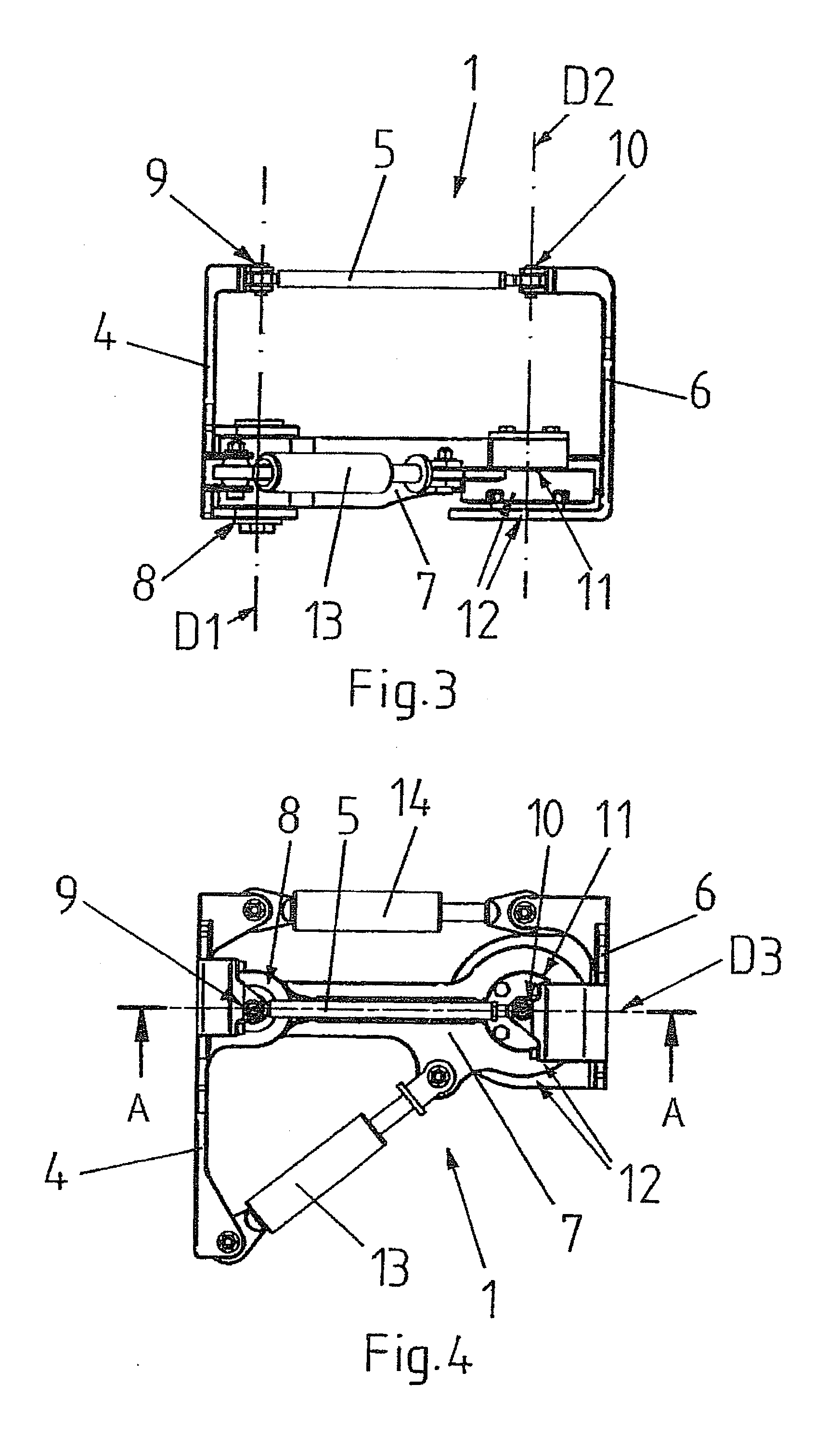

Hinge assembly for connecting two vehicle parts to a vehicle with articulated frame steering

InactiveUS20120000723A1Ensure rigidityLow costTractor-trailer combinationsPin hingesVehicle frameRotational axis

Owner:AMMANN SCHWEIZ

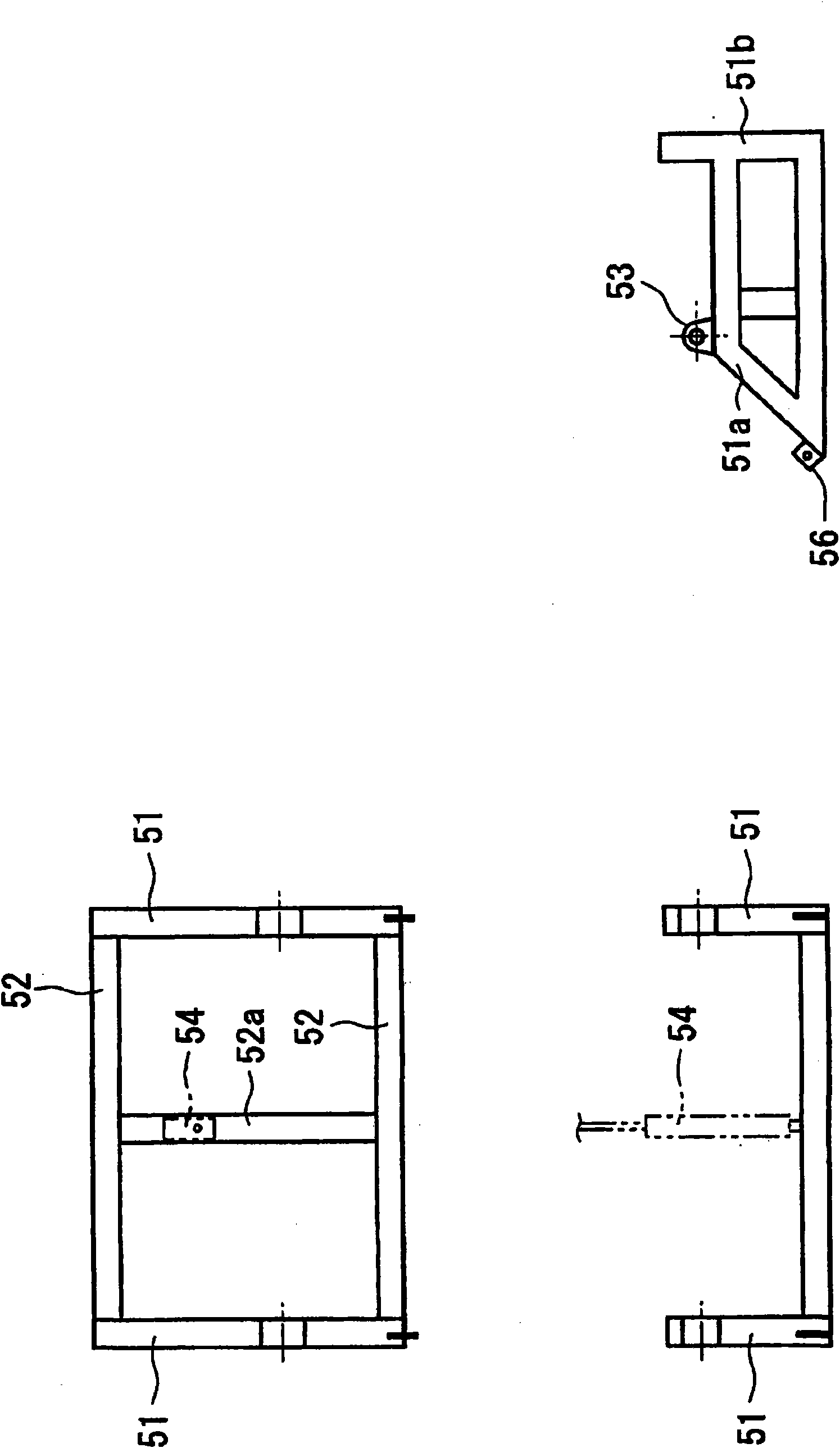

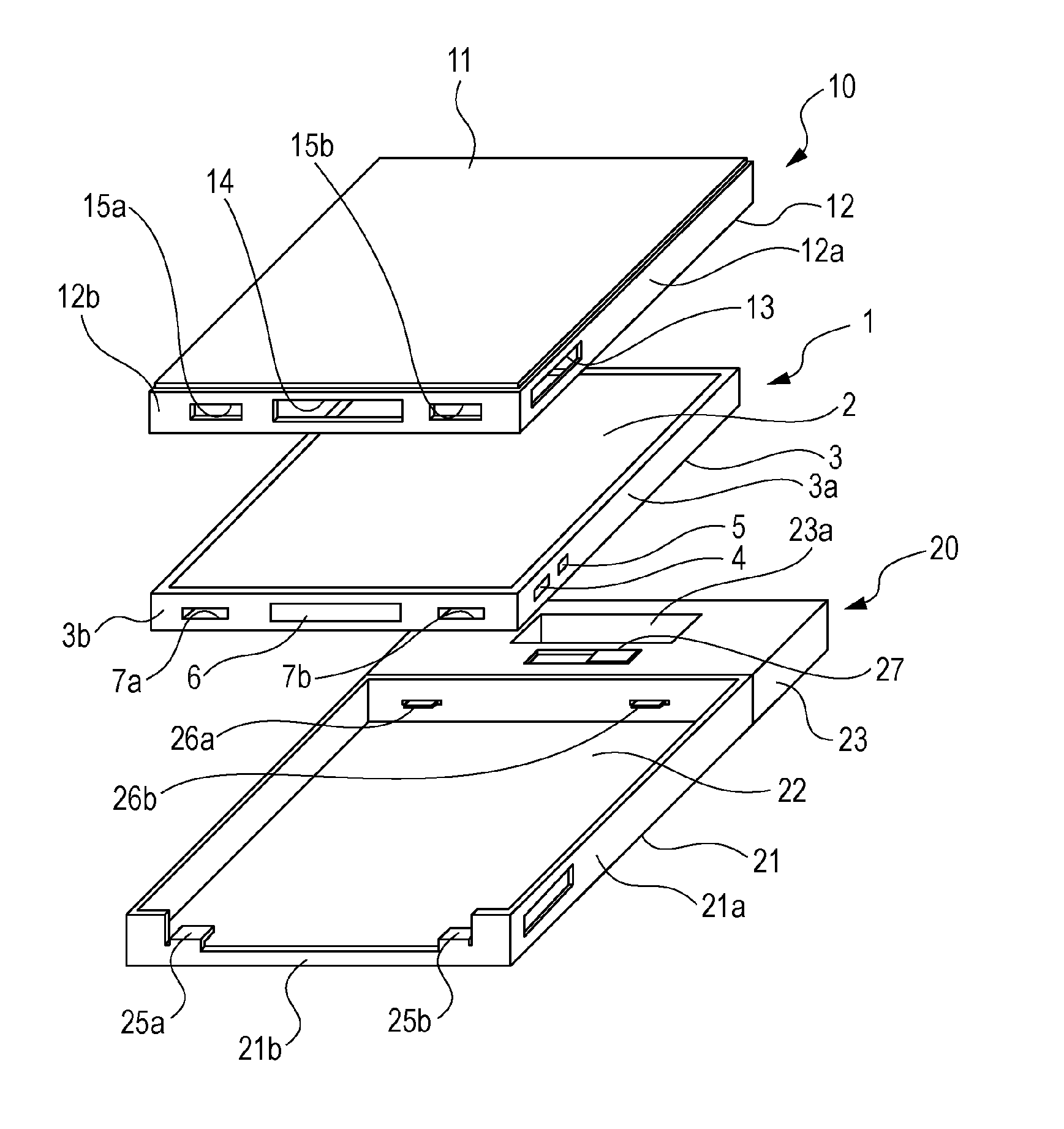

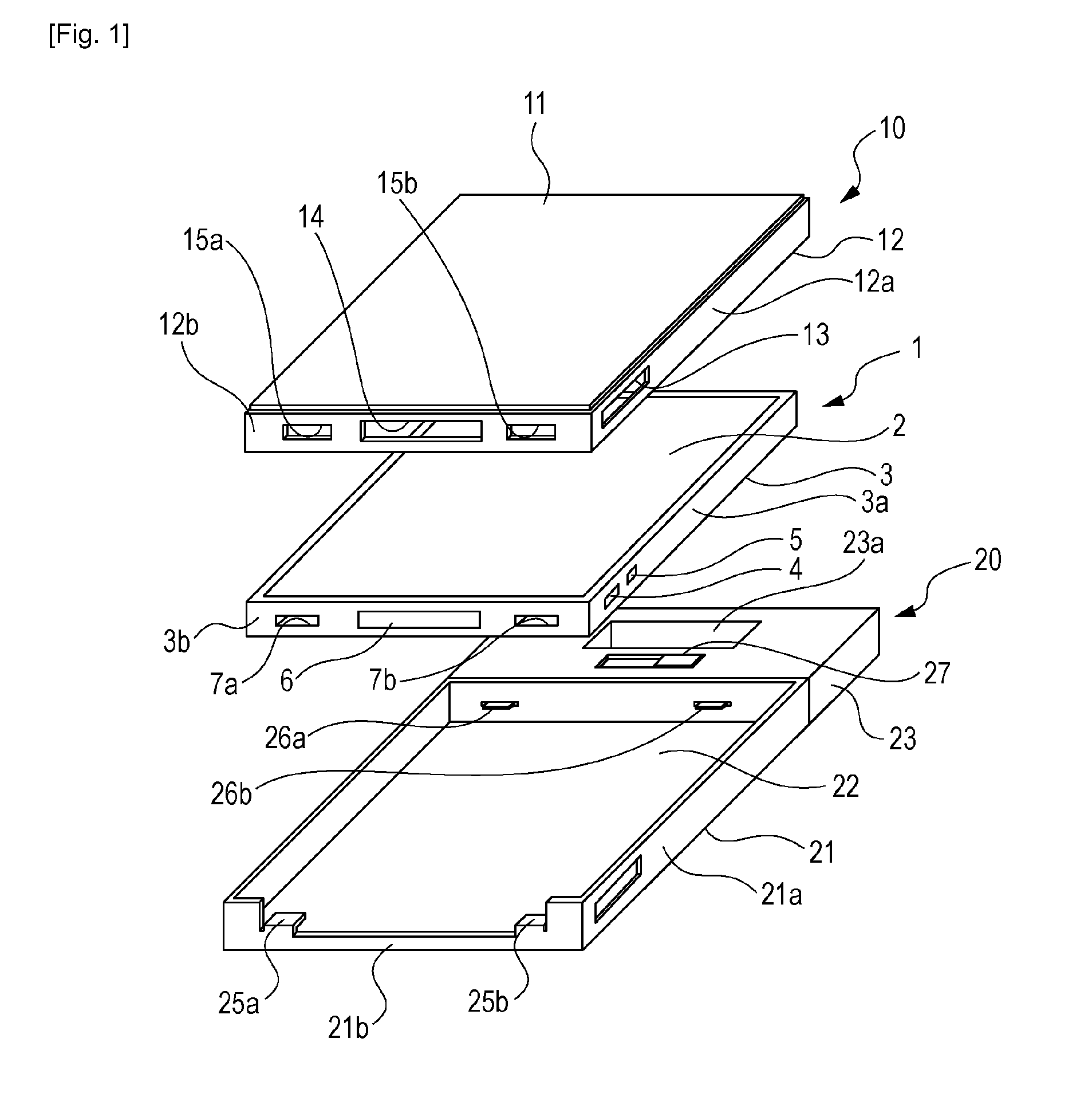

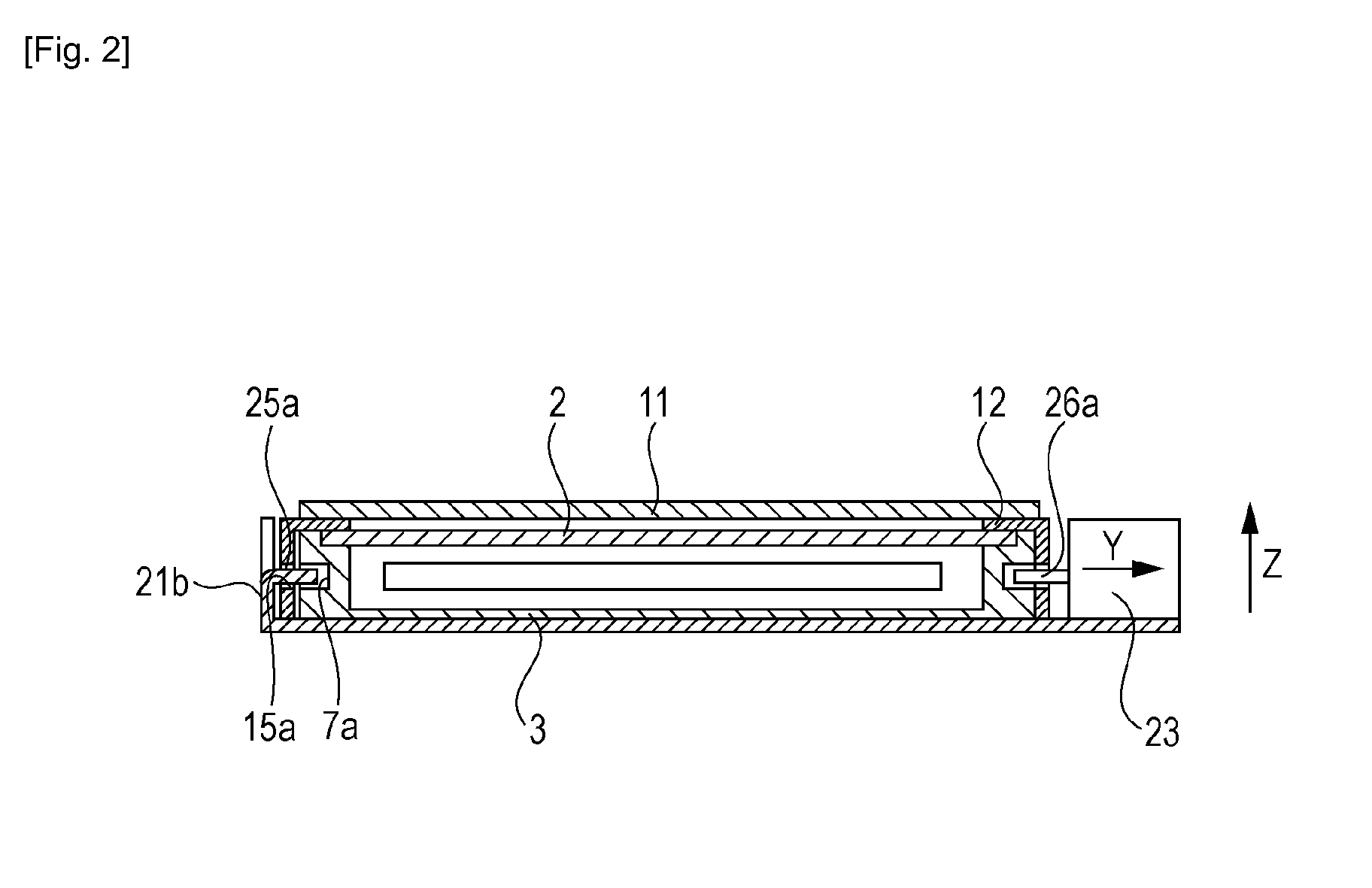

Container apparatus

InactiveUS20120280601A1Ensure portabilityEnsure rigidityFurniture partsCabinetsEngineeringStress radiography

A container apparatus that is able to contain a radiographic imaging apparatus having a rectangular parallelepiped shape. The container apparatus includes a container portion into which the radiographic imaging apparatus is insertable in a direction perpendicular to a radiation detecting surface of the radiographic imaging apparatus and a protecting member that covers side surfaces of the radiographic imaging apparatus contained in the container portion, the side surfaces of the radiographic imaging apparatus being adjacent to the radiation detecting surface. The container apparatus also includes a holding portion that engages with the radiographic imaging apparatus contained in the container portion in order to hold the radiographic imaging apparatus in the container portion.

Owner:CANON KK

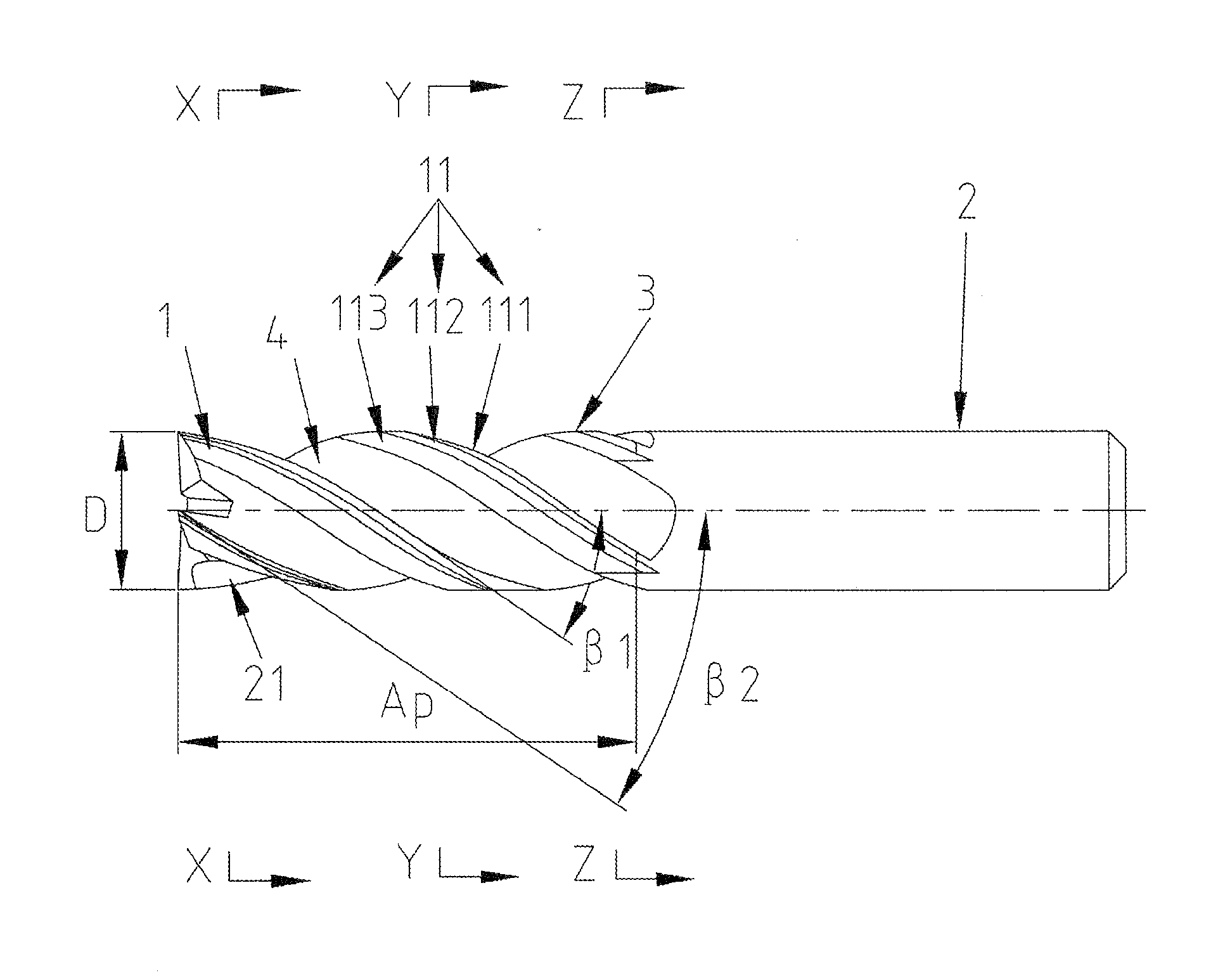

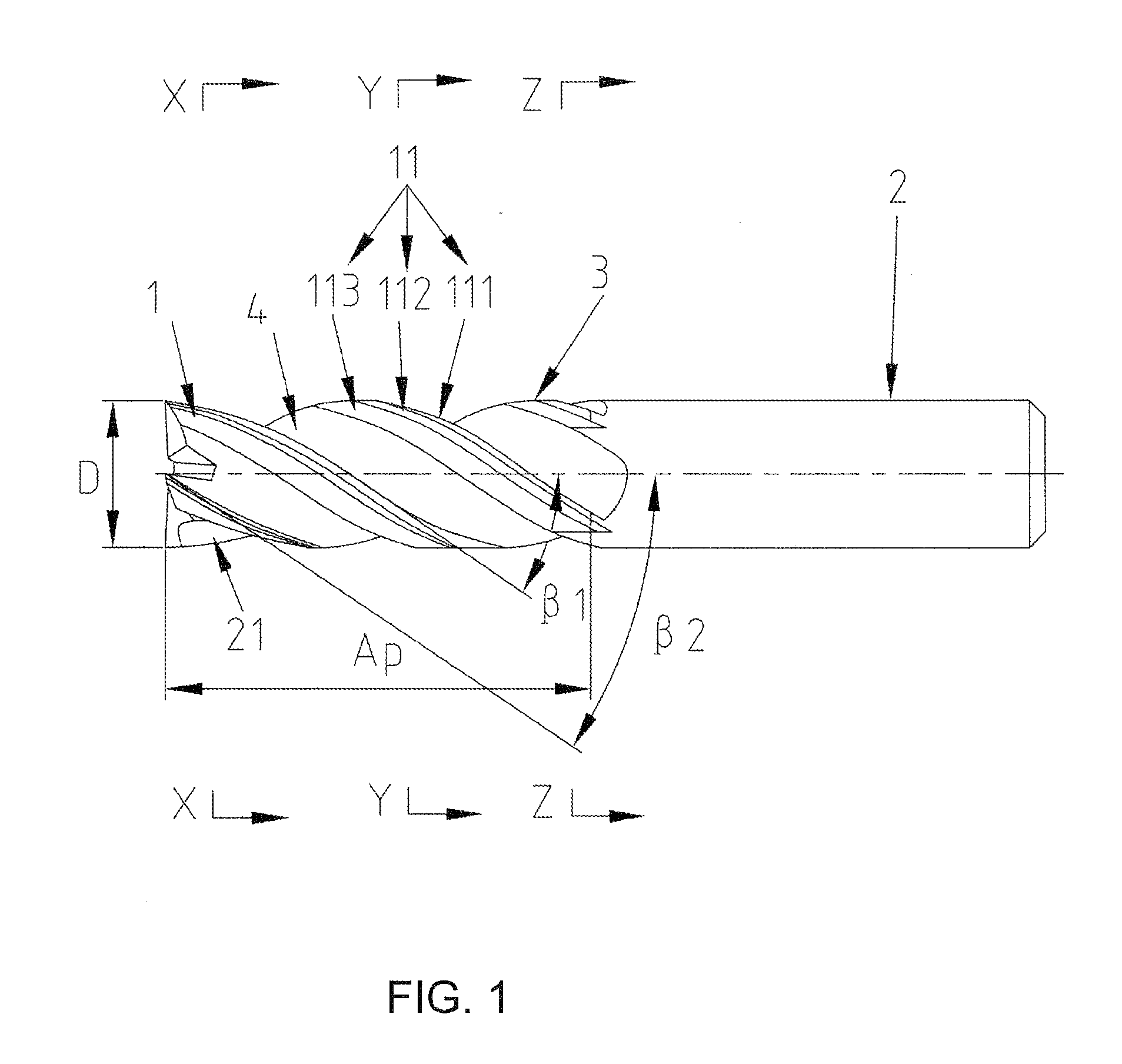

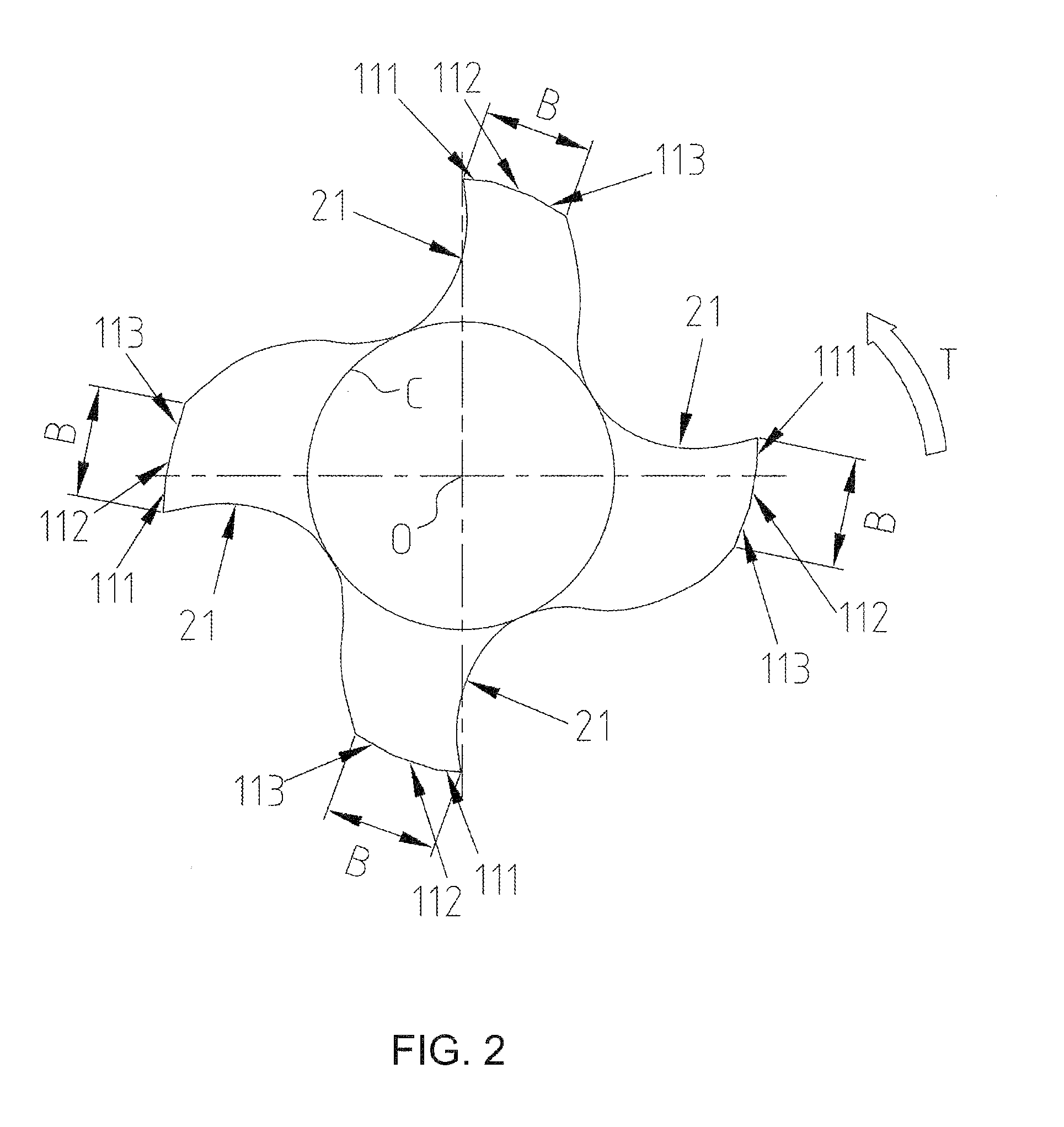

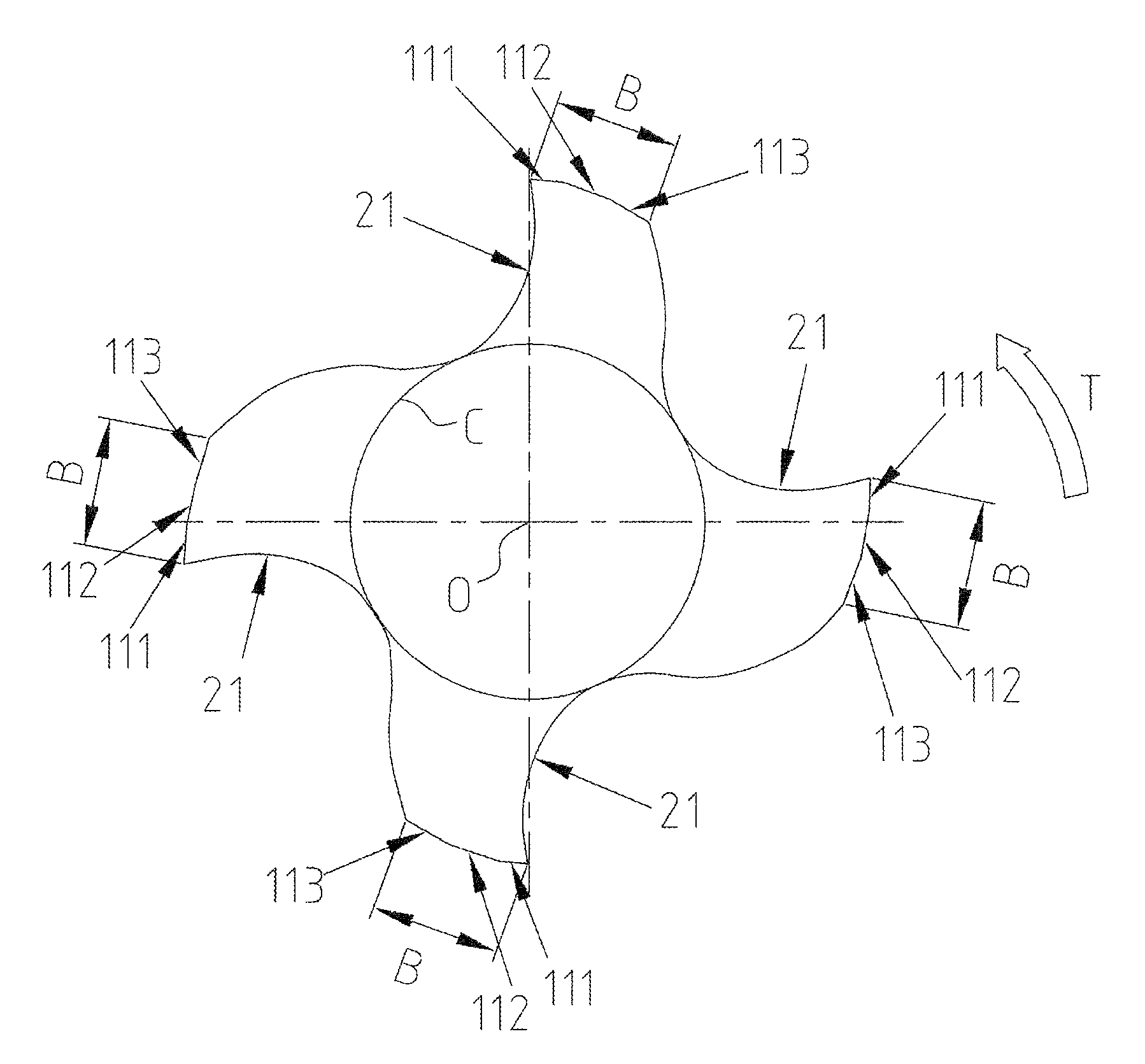

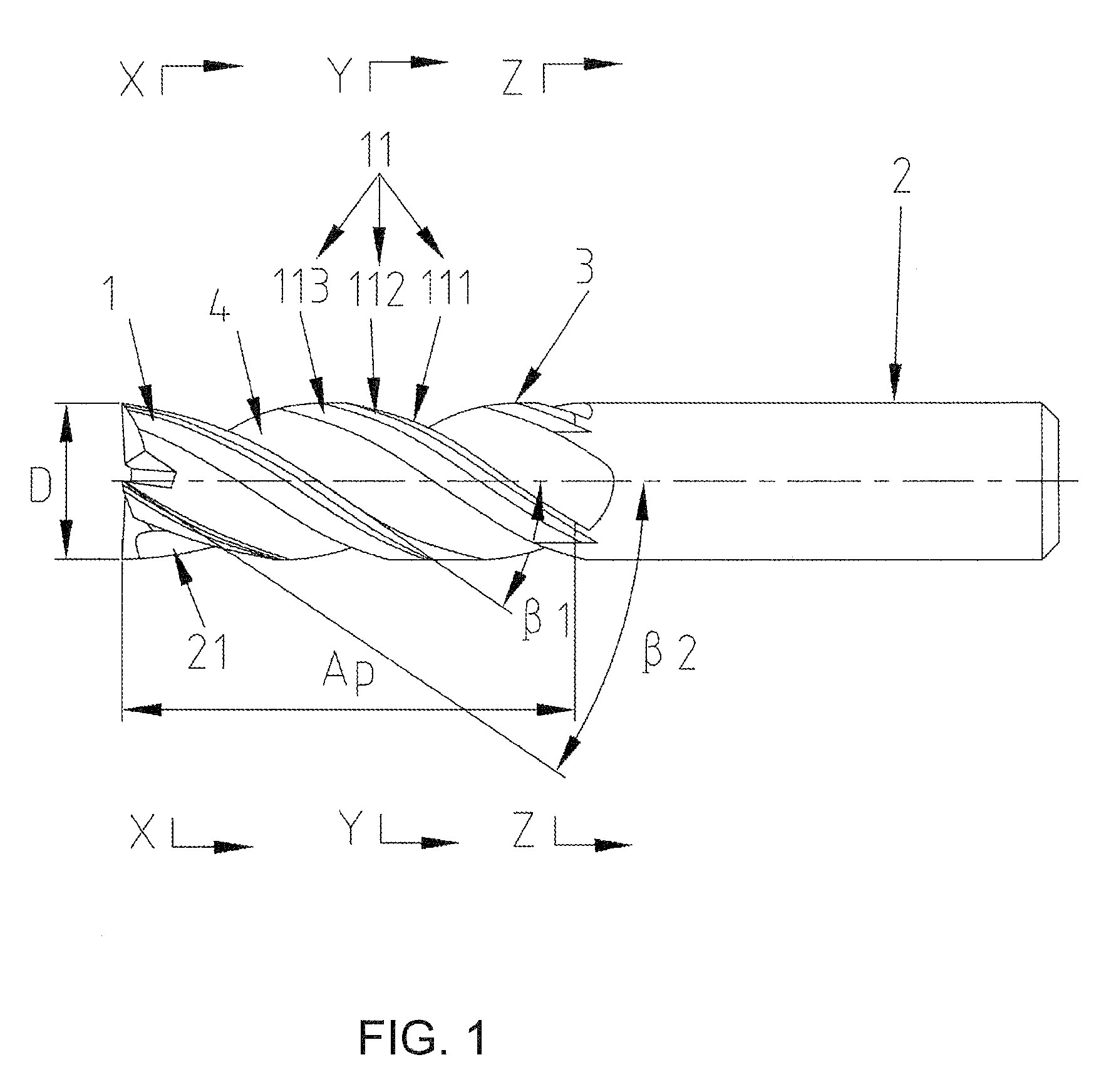

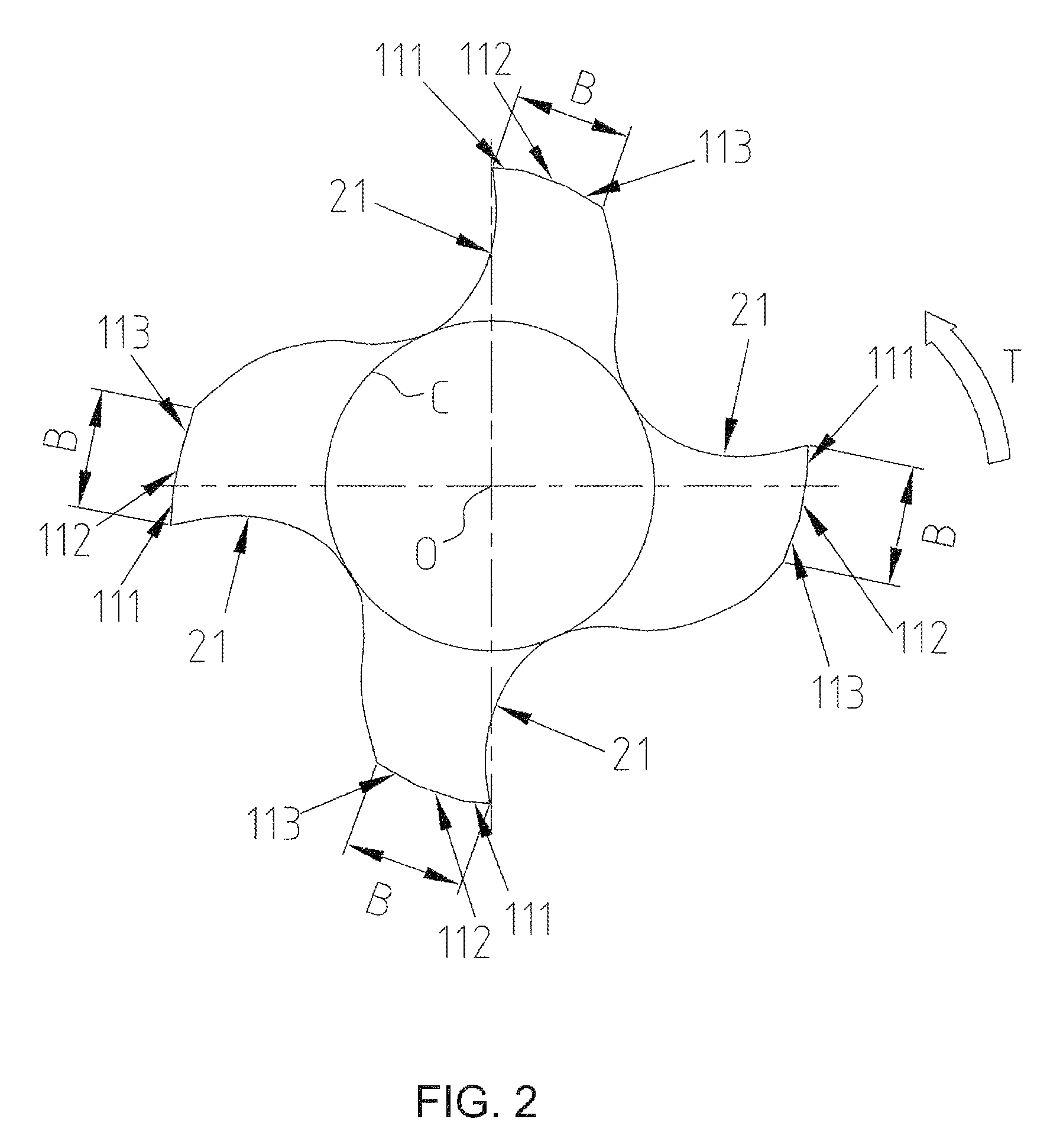

Unequal Helix-Angle End Mill

ActiveUS20130170916A1High strengthIncreased depth of cutMilling cuttersShaping cuttersFluteMilling cutter

An unequal helix-angle end mill includes a cutting part and a handle part. The cutting part is provided with a plurality of flutes, each spirally extending from the bottom end to the handle part. The face of each flute facing the cutting rotation direction is a rake face, wherein the rake face and an outer peripheral face of the cutting part are intersected to form an outer peripheral blade, and the helix-angle of at least one of the peripheral blades is different from those of the other peripheral blades. A face joined with the peripheral blade among the outer peripheral face of the cutting part is a rear face. The width B of the edge flap of each peripheral blade is equal on a plane orthogonal to a rotating axis of the end mill. The unequal helix-angle end mill has high strength, and enhances the cutting depth and durability.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Unequal helix-angle end mill

ActiveUS9346109B2High strengthIncreased depth of cutMilling cuttersShaping cuttersFluteMilling cutter

An unequal helix-angle end mill includes a cutting part and a handle part. The cutting part is provided with a plurality of flutes, each spirally extending from the bottom end to the handle part. The face of each flute facing the cutting rotation direction is a rake face, wherein the rake face and an outer peripheral face of the cutting part are intersected to form an outer peripheral blade, and the helix-angle of at least one of the peripheral blades is different from those of the other peripheral blades. A face joined with the peripheral blade among the outer peripheral face of the cutting part is a rear face. The width B of the edge flap of each peripheral blade is equal on a plane orthogonal to a rotating axis of the end mill. The unequal helix-angle end mill has high strength, and enhances the cutting depth and durability.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

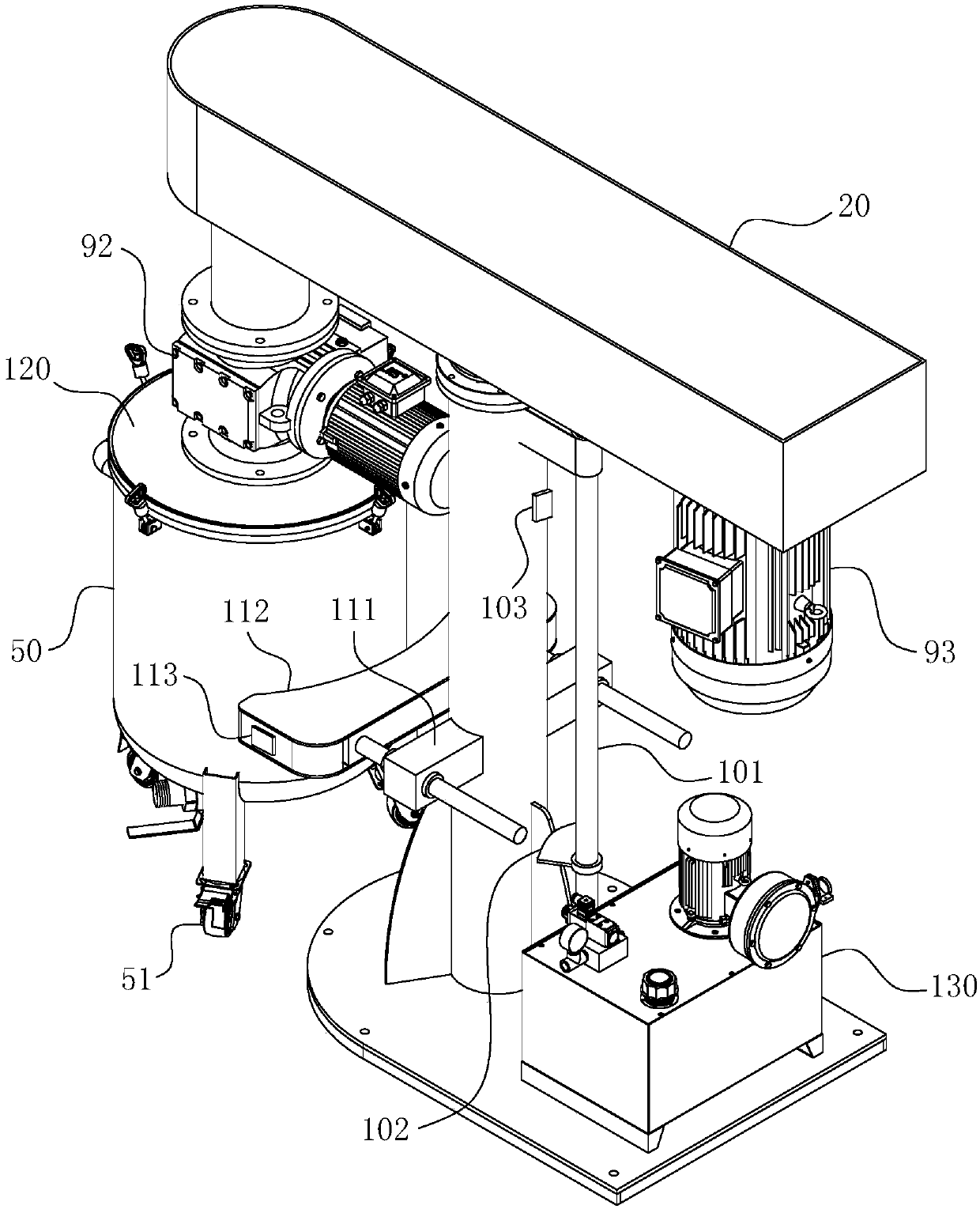

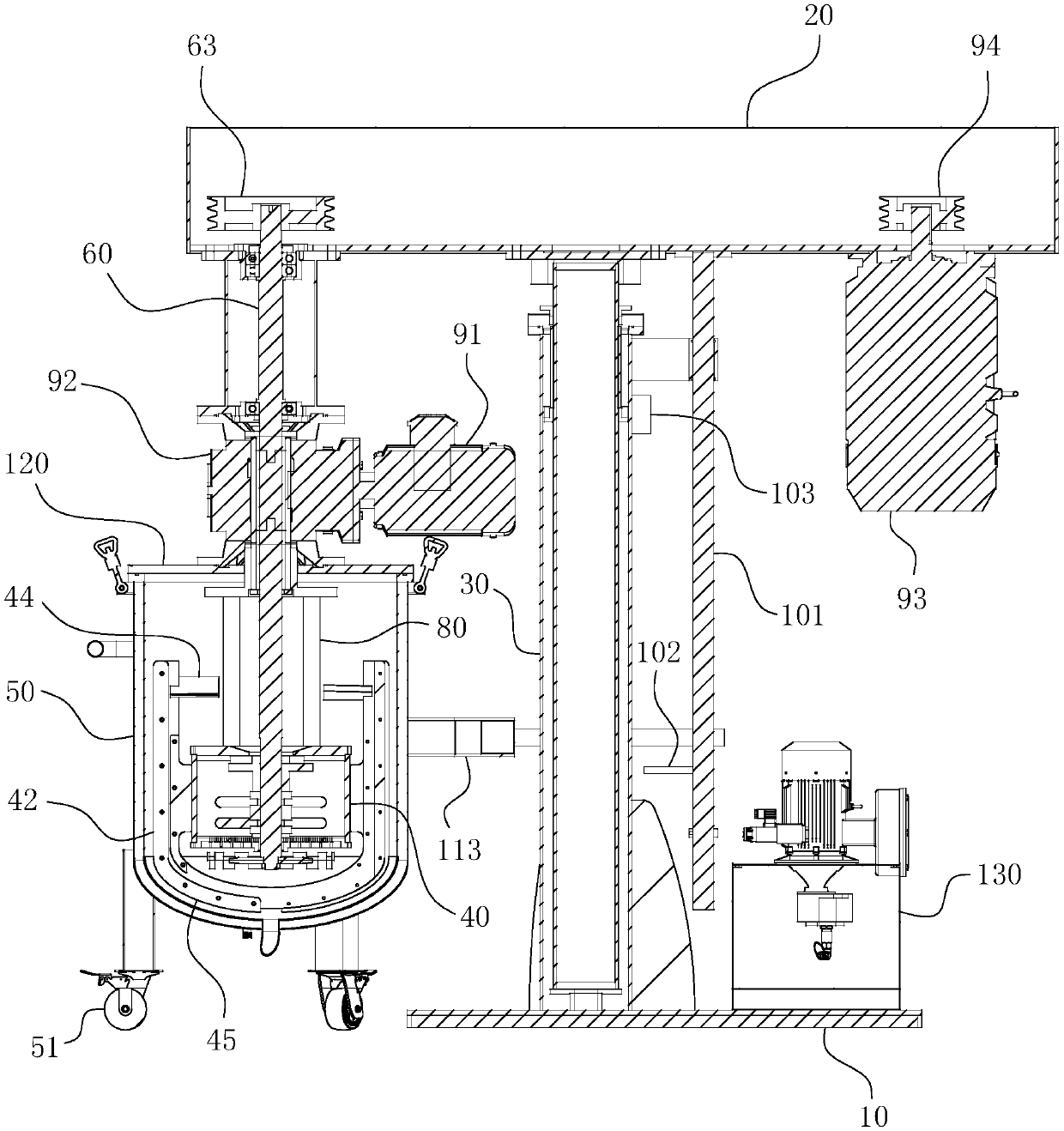

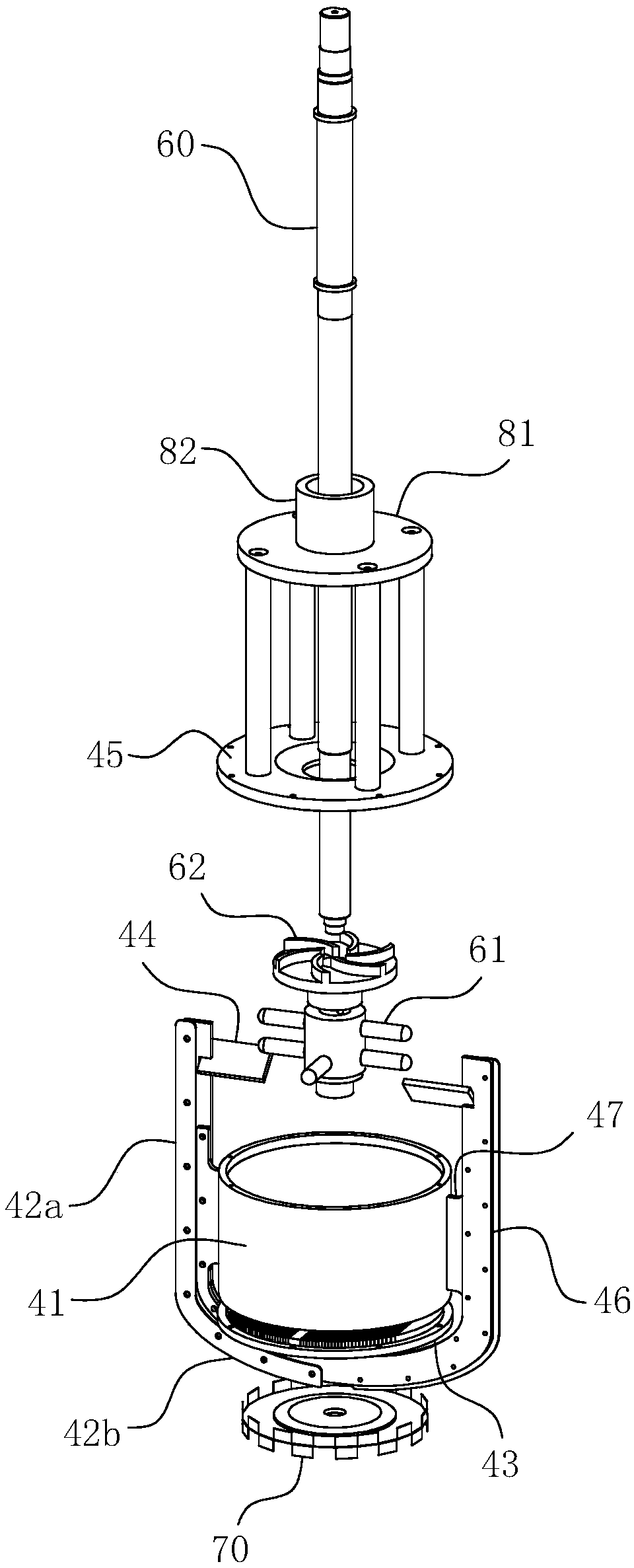

Concentric double-axis vacuum hydraulic basket grinding machine

ActiveCN109590078AEfficient mixingEfficient grindingGrain treatmentsCantileverMechanical engineering

The invention belongs to the field of grinding equipment, in particular to a concentric double-axis vacuum hydraulic basket grinding machine. The grinding machine comprises a base, a frame, a liftingassembly, a grinding basket and a cylinder. The grinding basket comprises a cylinder body, an end cap and a filter plate. The end cap and the filter plate are vertically coaxially penetrated by a stirring shaft and the stirring shaft is respectively rotatably matched with the end cap and the filter plate. A basket support is coaxially arranged with the stirring shaft but dose not interfere the stirring shaft. The top end of the basket support is matched with the output end of a second power source, and the bottom end of the basket support is coaxially fixed at the end cap for driving the grinding basket to produce a coaxial rotating action opposite to the turning direction of the stirring shaft. A cantilever extends radially outwardly at the outer wall of the grinding basket, and the extending end of the cantilever arm is fixedly connected with a scraper for scraping the attachment at the wall of a cylinder chamber. The invention has the advantages of high grinding efficiency, good stirring effect, good product fineness, convenient and reliable operation.

Owner:费曹民

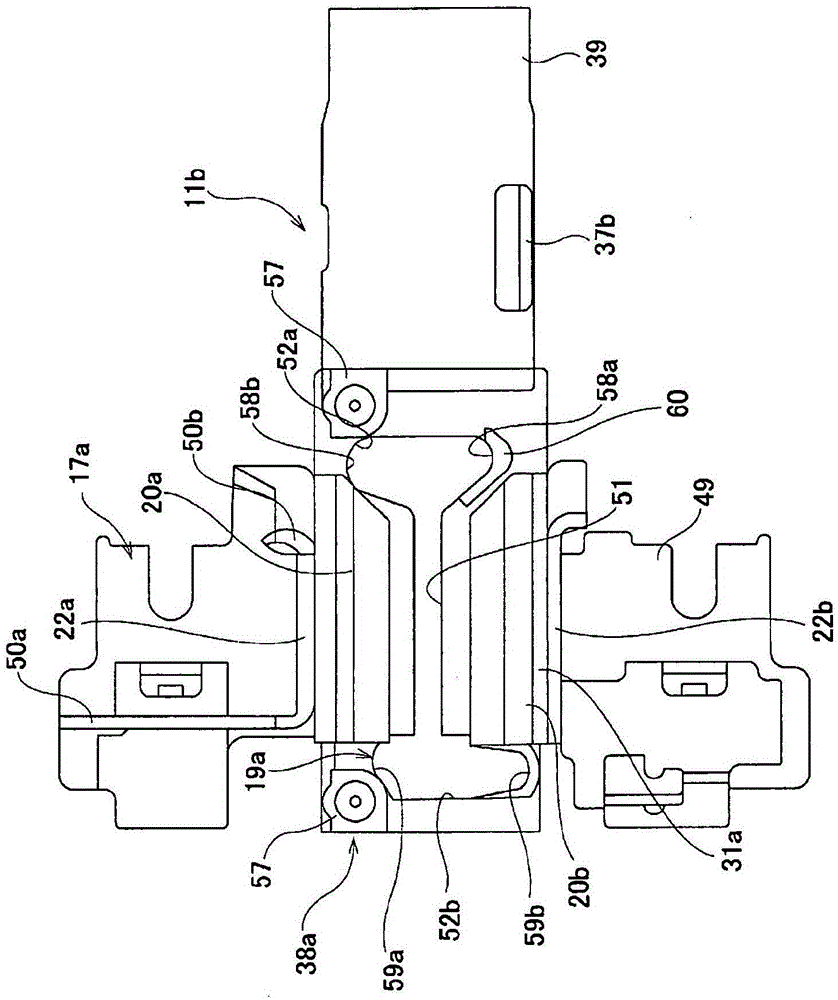

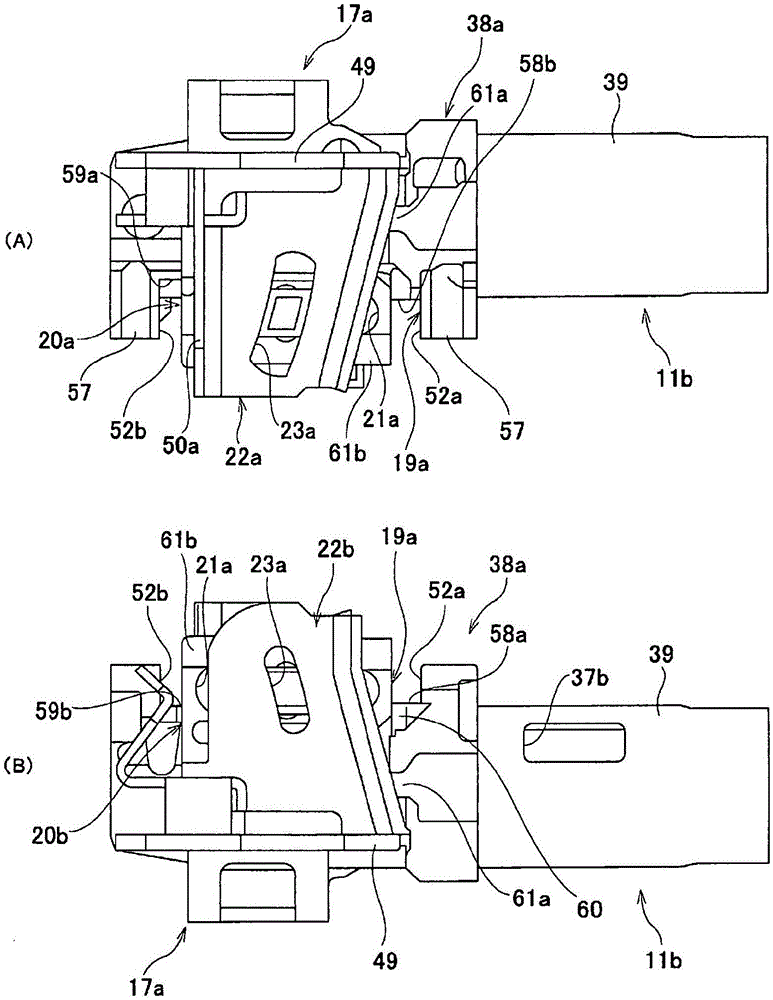

Telescopic steering device and outer column

ActiveCN105026243AReduce stressGuaranteed durabilityAnti-theft devicesSteering controlsSteering wheelDiagonal

Construction of an outer column for a telescopic steering apparatus is achieved in which sufficient strength is maintained even when a steering lock apparatus is assembled, and smooth operation is maintained when making it possible to adjust the forward / backward position of a steering wheel, and when maintaining the adjusted position. Of the end sections 58a, 58b, 59a, 59b of the sub slit sections 52a, 52b of an approximately H-shaped slit 19a for expanding or contracting the inner diameter of a fitting support portion 31a of an outer column 11b, the rigidity of the nearest end section 58a portion that exists in the location closest to a lock through hole 37a and of the furthest end section 59a portion that exists in a location diagonally from the nearest end section 58a, is greater than the rigidity of the end sections 58b, 59b in the remaining two locations. Moreover, convex sections 61a, 61b are provided at two locations in the up / down direction on the outside surfaces of each of a pair of held plate sections 20a, 20b.

Owner:NSK LTD

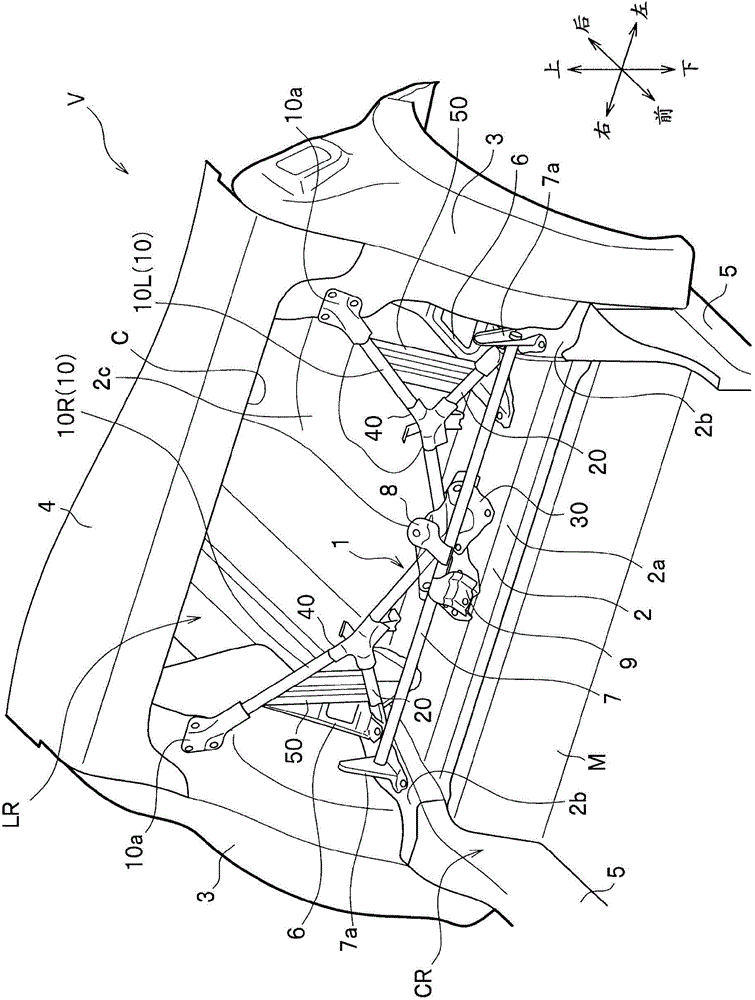

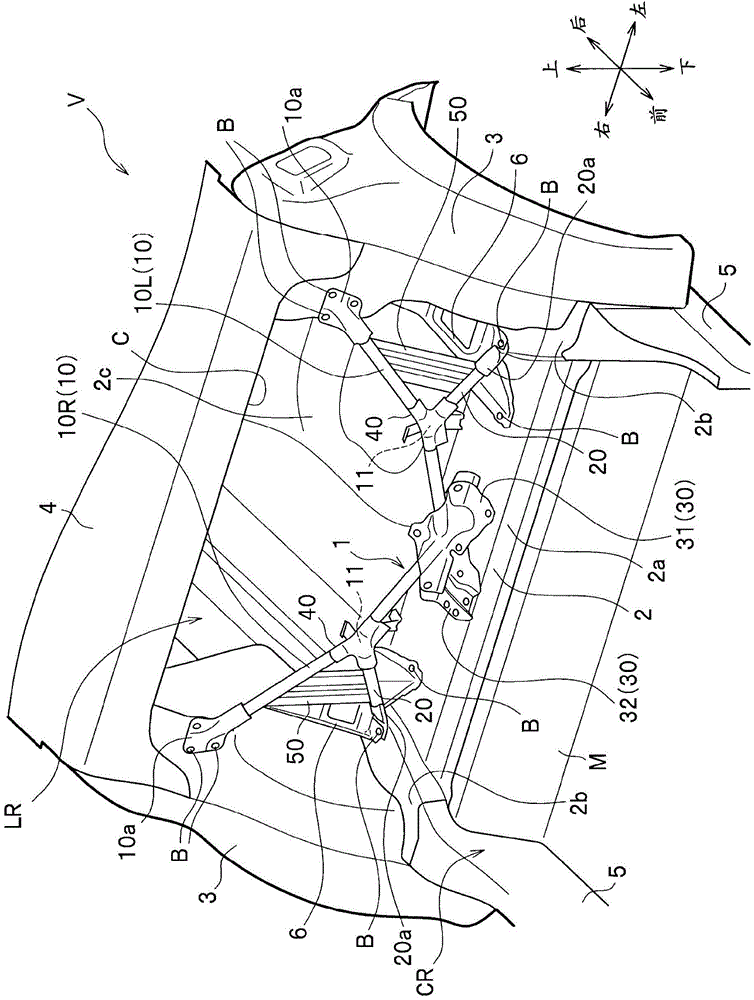

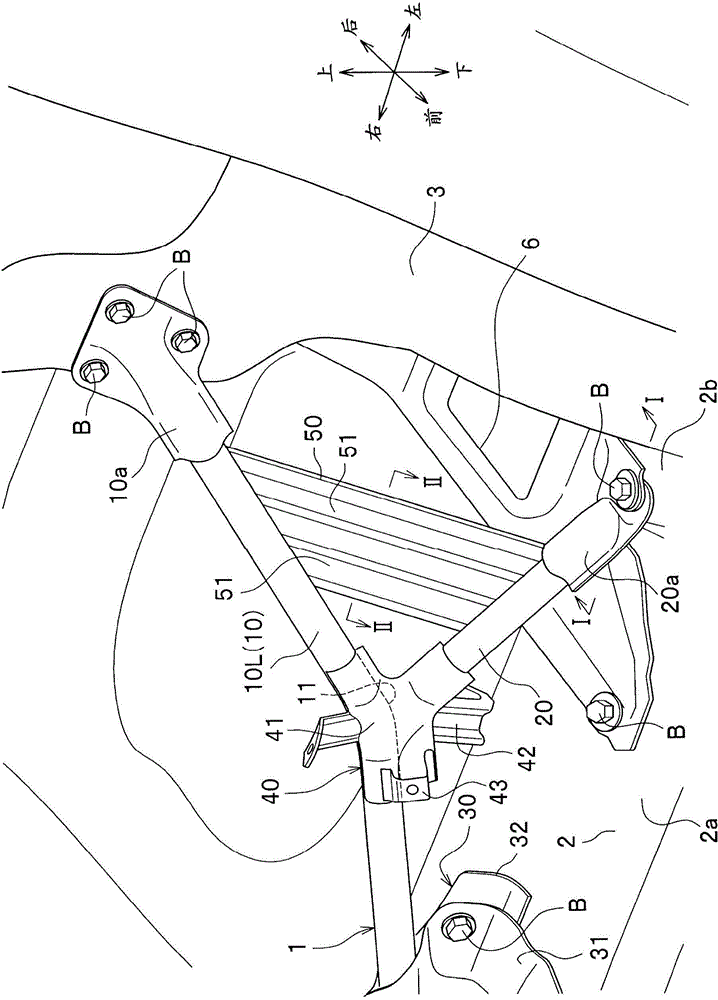

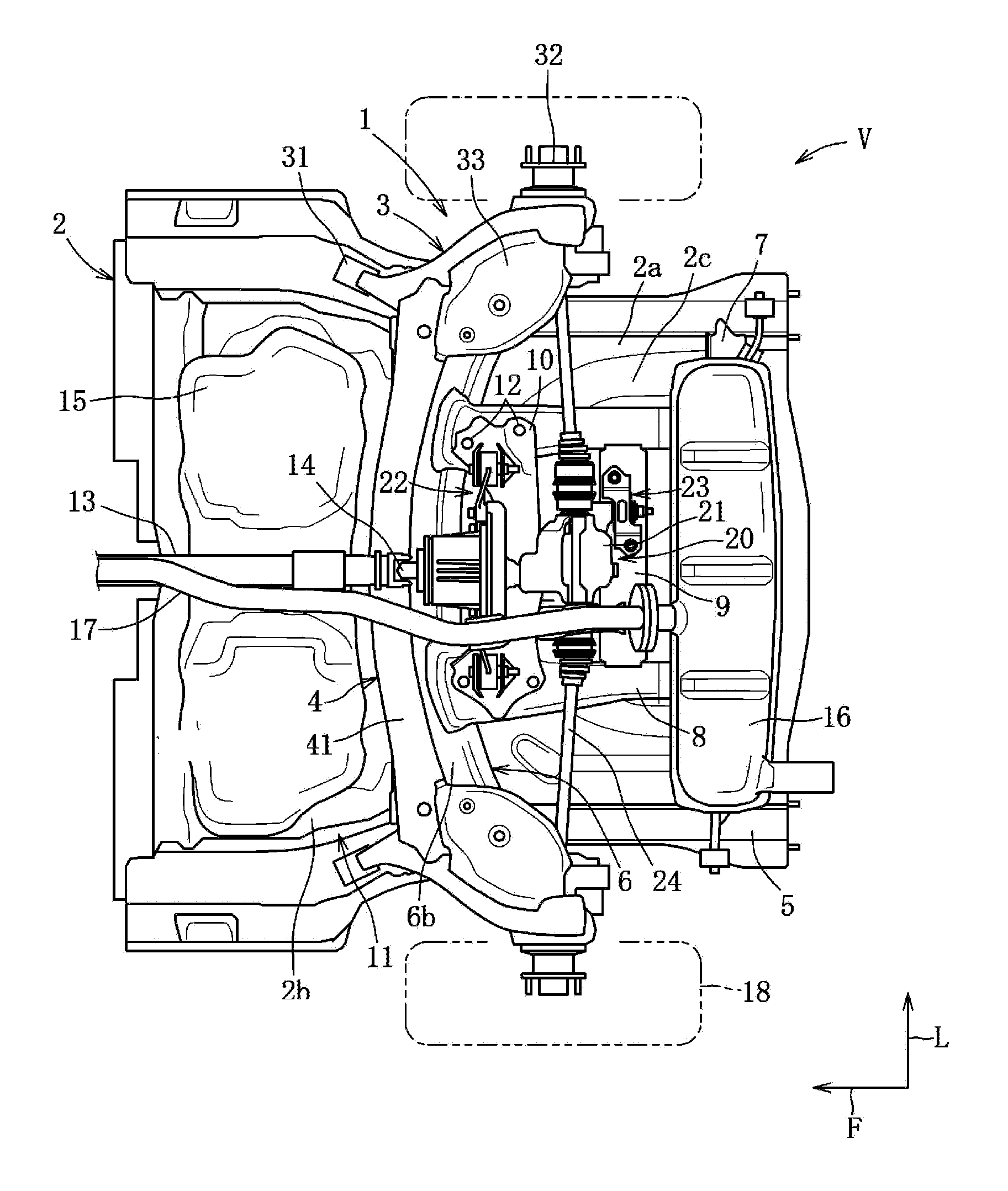

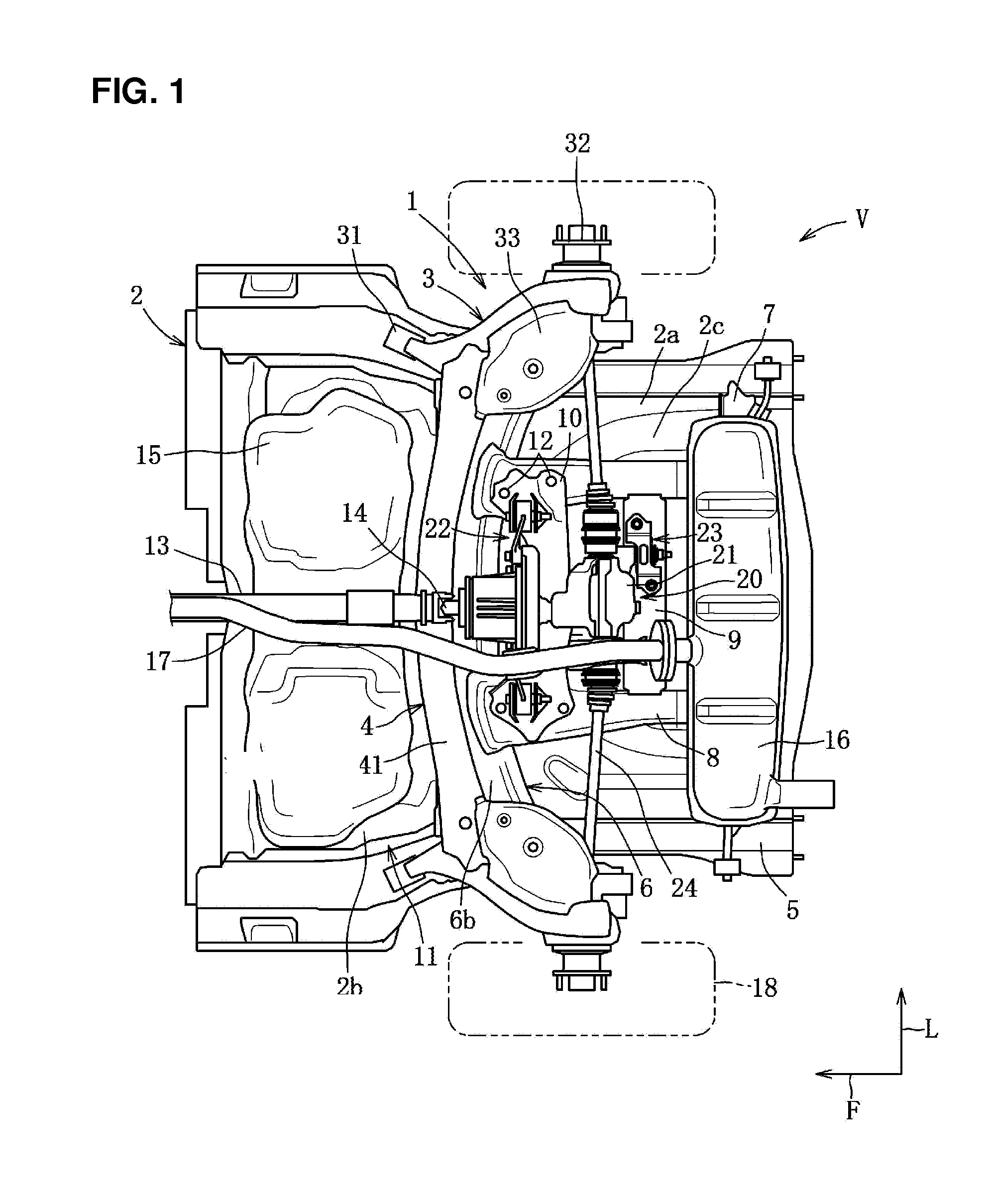

Vehicle body rear structure

ActiveCN104015809AHigh degree of freedom of shapeEnsure rigiditySuperstructure subunitsEngineeringUltimate tensile strength

The invention provides a vehicle body rear structure which does not interfere with a connection function of a trunk and ensures rigity and strength of the rear part of a vehicle body. The vehicle body rear structure is provided with a baseplate panel (2), a pair of rear-wheel covers (3) standing on two ends of a vehicle width direction of the baseplate panel (2), a rear parcel shelf (4) making the upper ends of the rear-wheel covers (3) extend along a vehicle width direction in a connected manner, a trunk connected opening portion (C) which is formed by the baseplate panel (2), the rear-wheel covers (3), and the rear parcel shelf (4), and a first reinforcing component (10) and a second reinforcing component (20) reinforcing the trunk connected opening portion (C). The first reinforcing component (10) is connected with the baseplate panel (2) and the upper end side of the rear-wheel covers (3), and is provided with a bending portion (11) on the middle of a length direction. The second reinforcing component (20) is connected with the baseplate panel (2) and the bending portion (11).

Owner:HONDA MOTOR CO LTD

Suspension of vehicle

ActiveUS9132713B1Ensure productivityEnsure rigidityInterconnection systemsResilient suspensionsEngineeringFront edge

A torsion beam is configured in an arch shape and comprised of an open cross-section member including an arch lower-half portion and an arch upper-half portion. A sectional shape of the arch lower-half portion in a cross section perpendicular to a longitudinal direction of the arch lower-half portion is configured to be substantially horizontal when a vehicle is in a standard state, and a central portion, in the vehicle width direction, of the torsion beam is configured such that a front edge portion of the arch lower-half portion and a front edge portion of the arch upper-half portion are located substantially at the same position in a vehicle longitudinal direction when the vehicle is in a full-rebound state. Thereby, the rigidity and the productivity can be endured, attaining low floor-level of the vehicle.

Owner:MAZDA MOTOR CORP

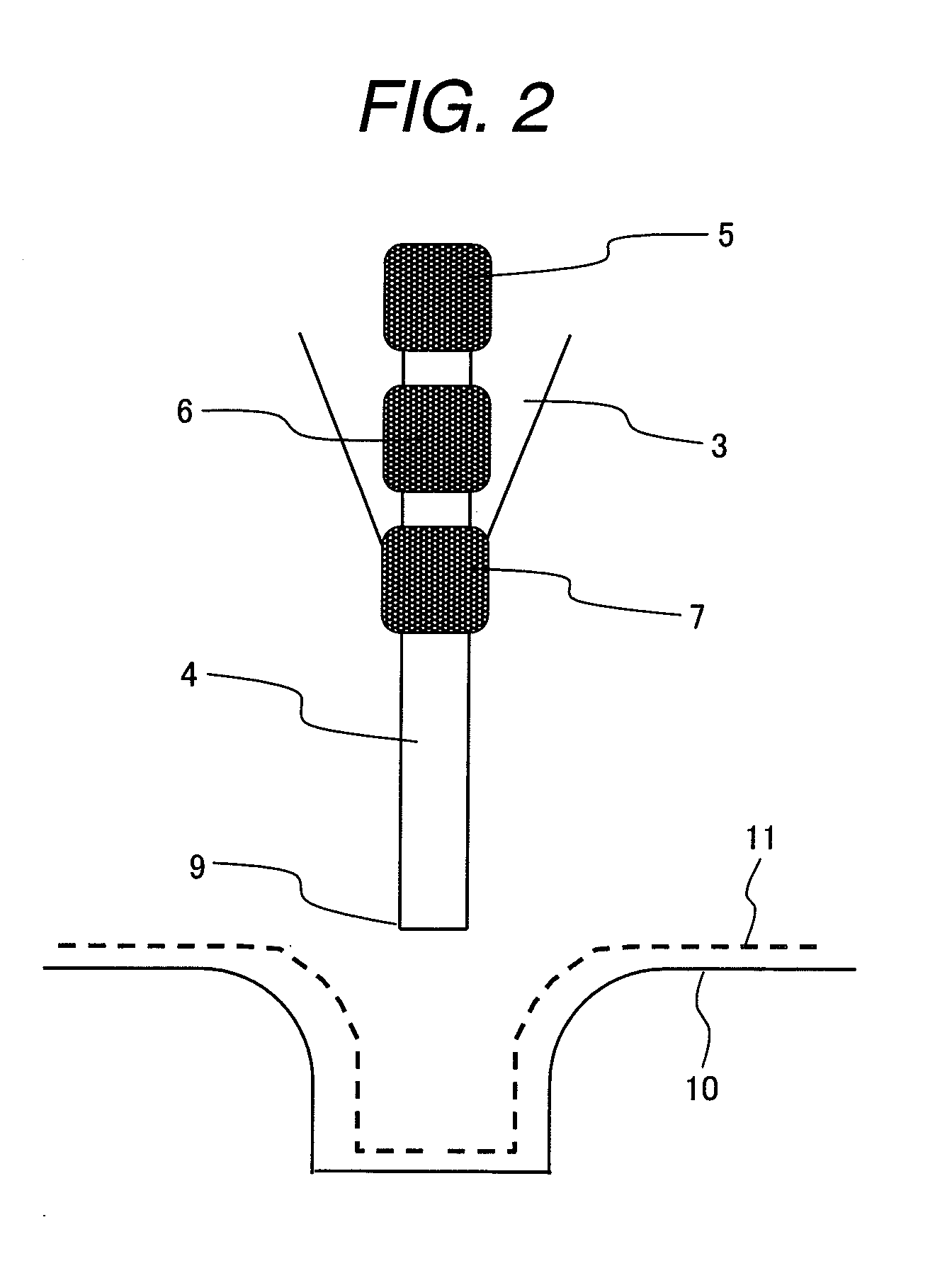

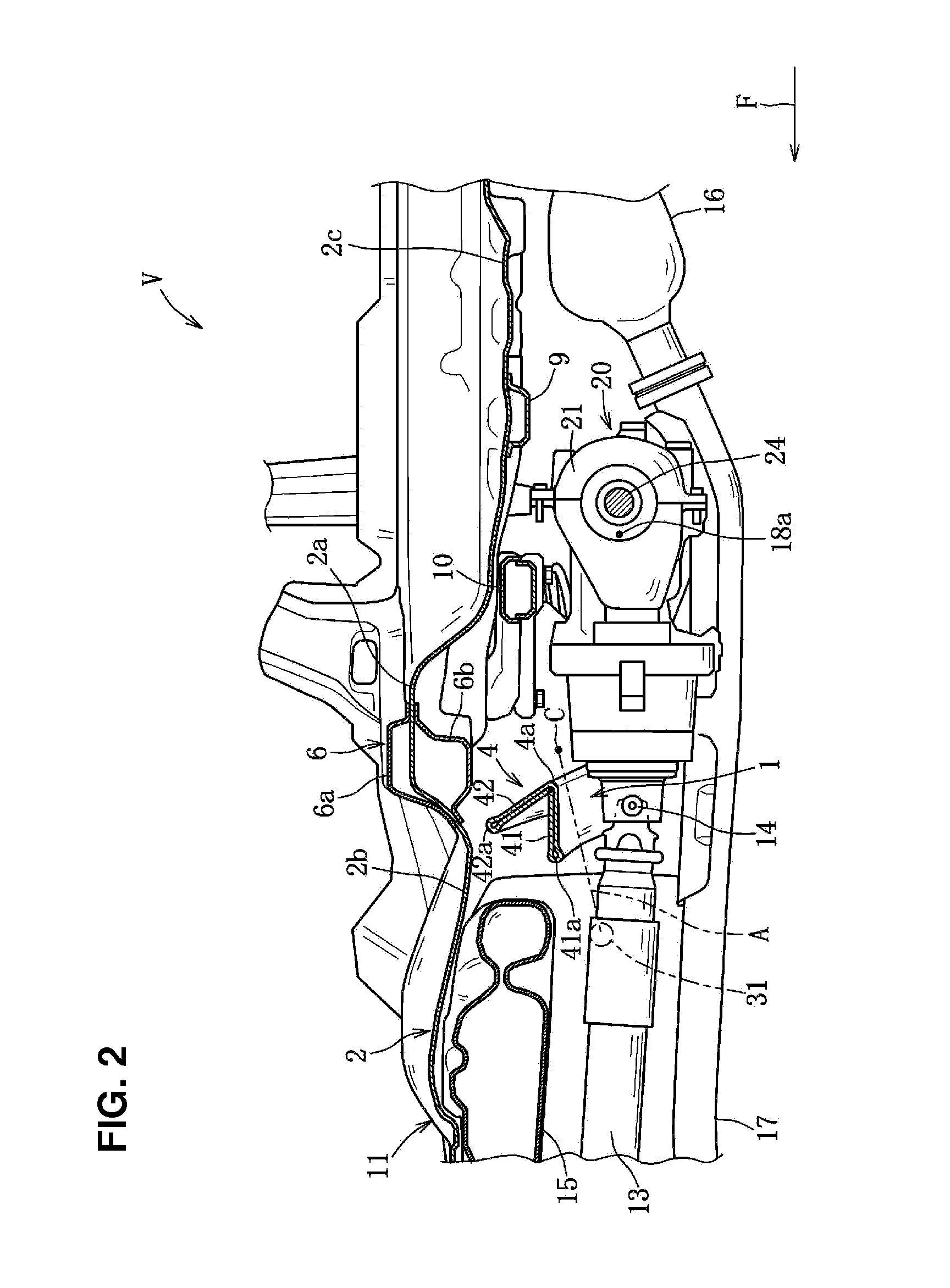

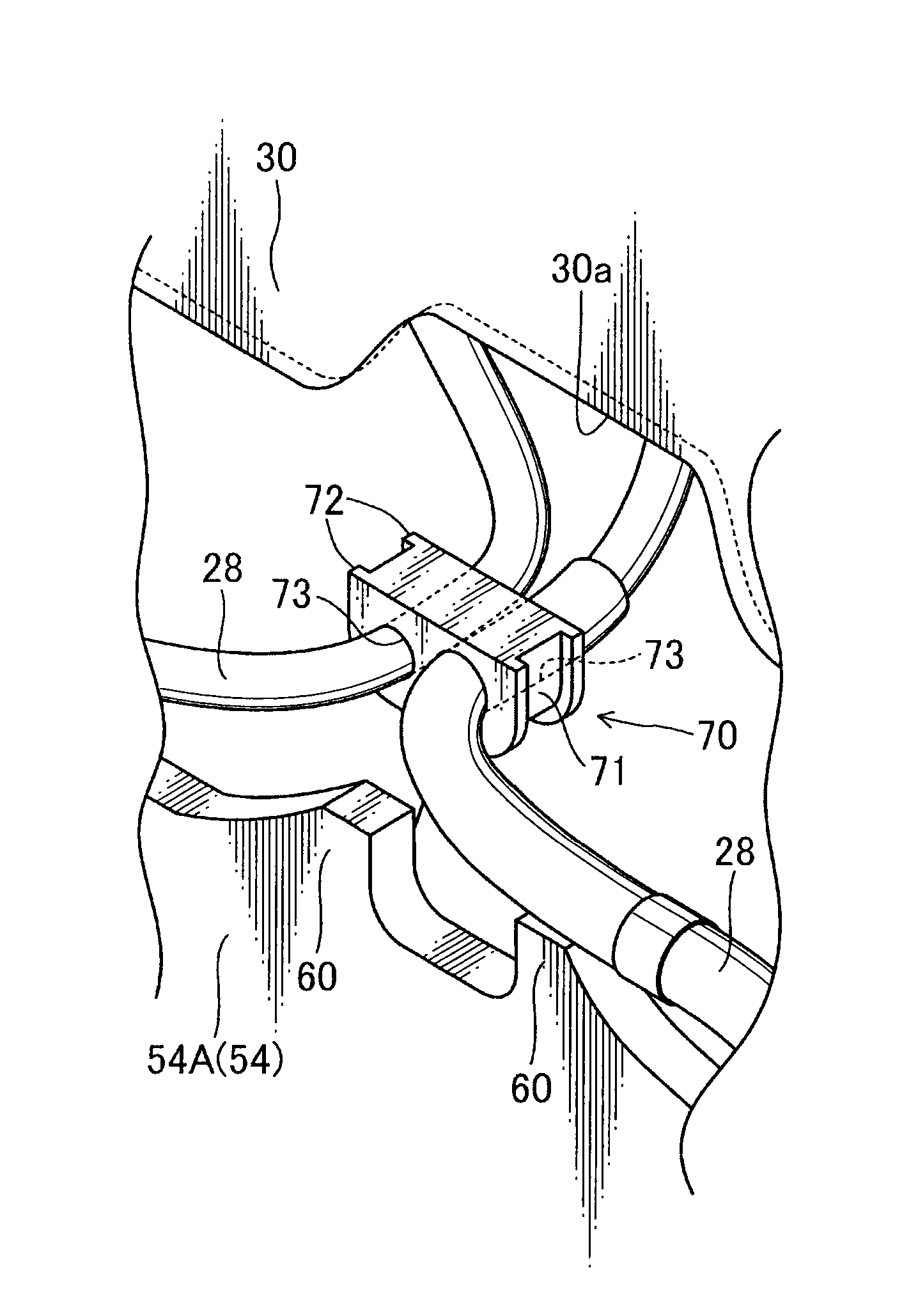

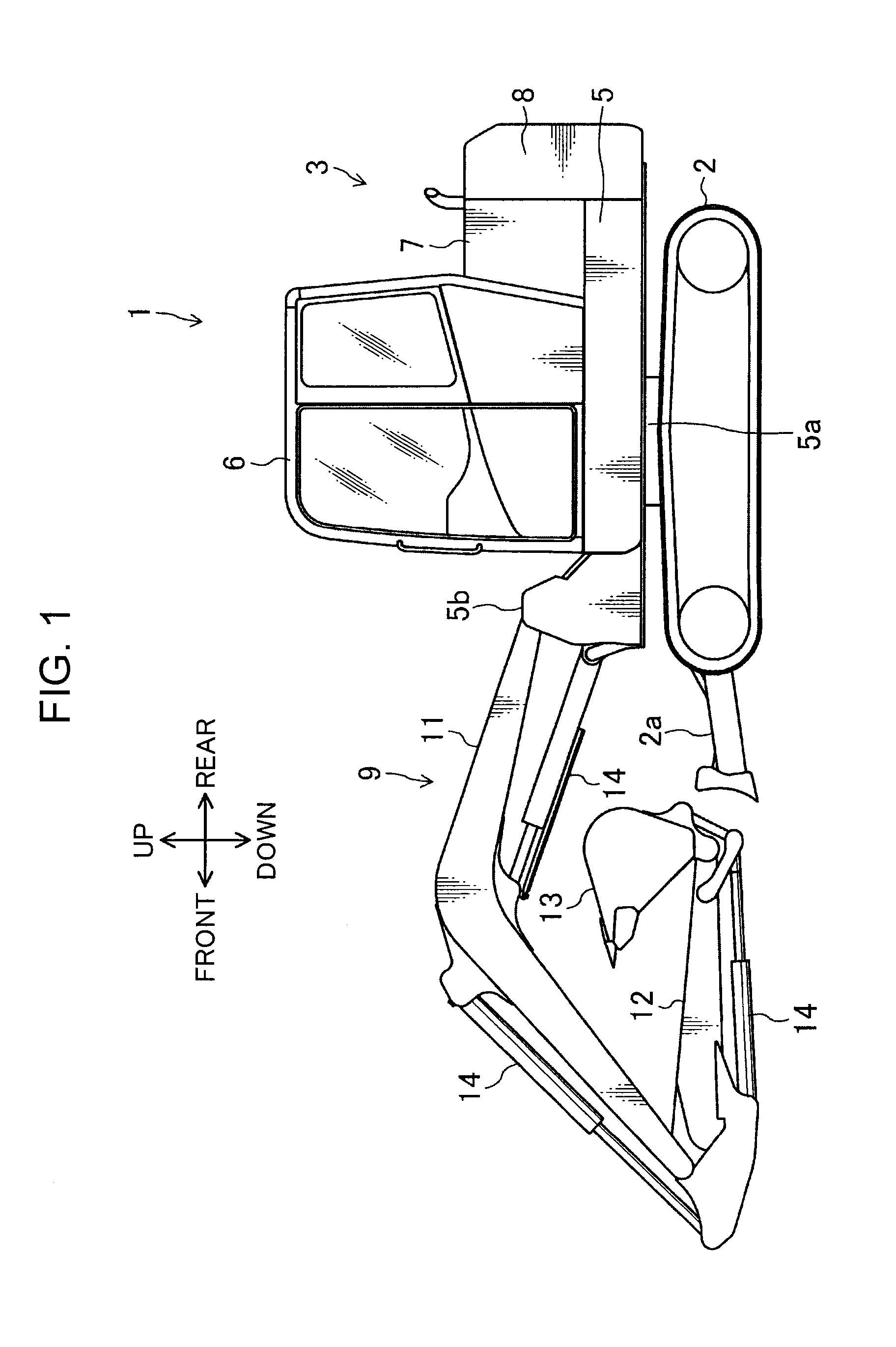

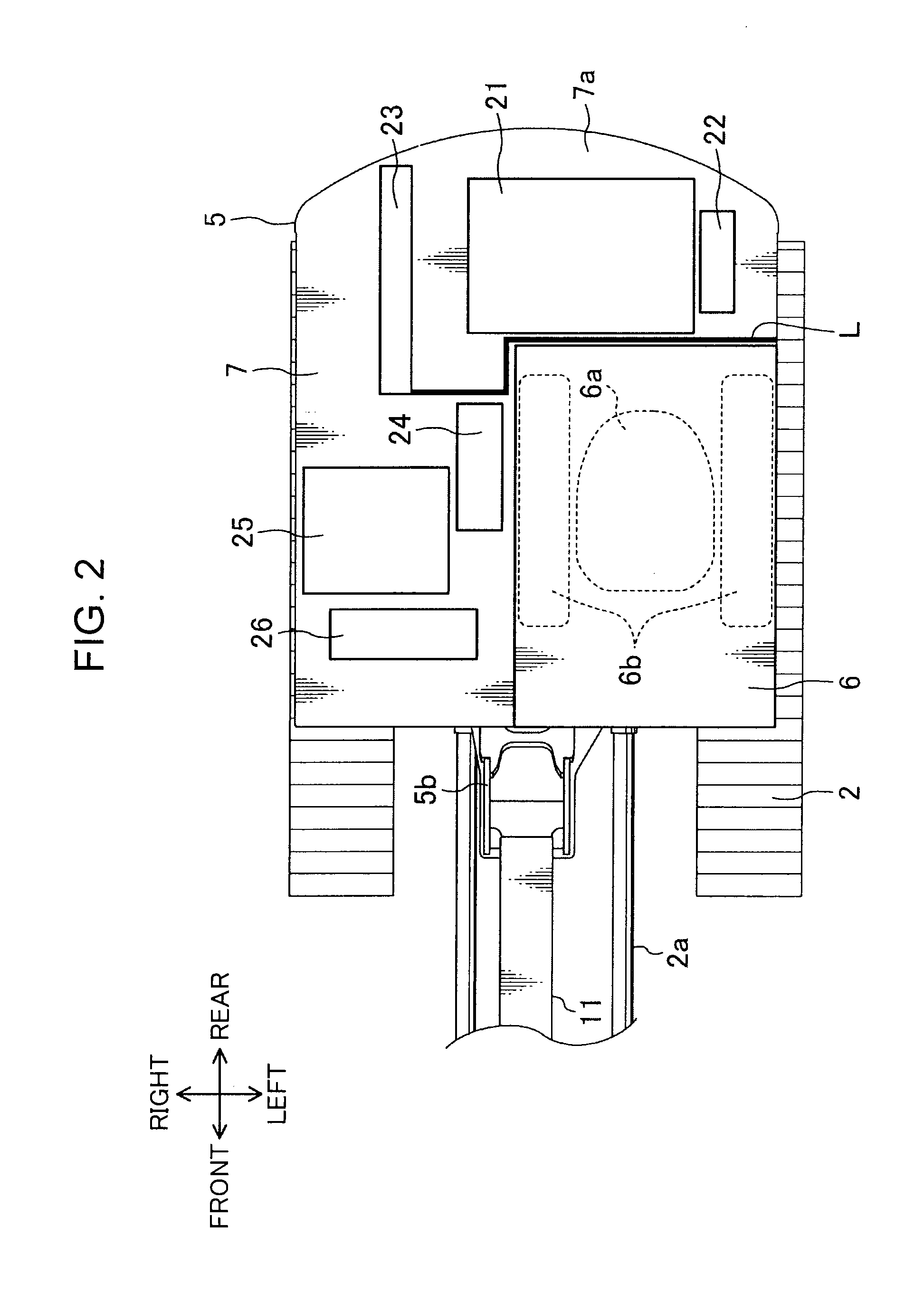

Operating machine

InactiveUS8820821B2Improve efficiencyEnsure rigidityVehicle seatsUnderstructuresLeft directionTransverse plane

An operating machine comprises a machine body mounted on a lower propelling body. The machine body comprises an upper frame, and a line member mutually connecting a plurality of devices installed to the upper frame. The upper frame has a bottom plate, a pair of longitudinal plates each provided to stand on the bottom plate and extend in a front-rear direction, while being disposed in spaced-apart relation to each other in a right-left direction, and a transverse plate provided to stand on the bottom plate and extend in the right-left direction, while being joined to each of the longitudinal plates. A specific plate consisting of at least one of the pair of longitudinal plates and the transverse plate has an upper edge on which a pair of protrusions are provided in opposed relation to each other, and the line member is set to pass through between the pair of protrusions.

Owner:KOBELCO CONSTR MASCH CO LTD

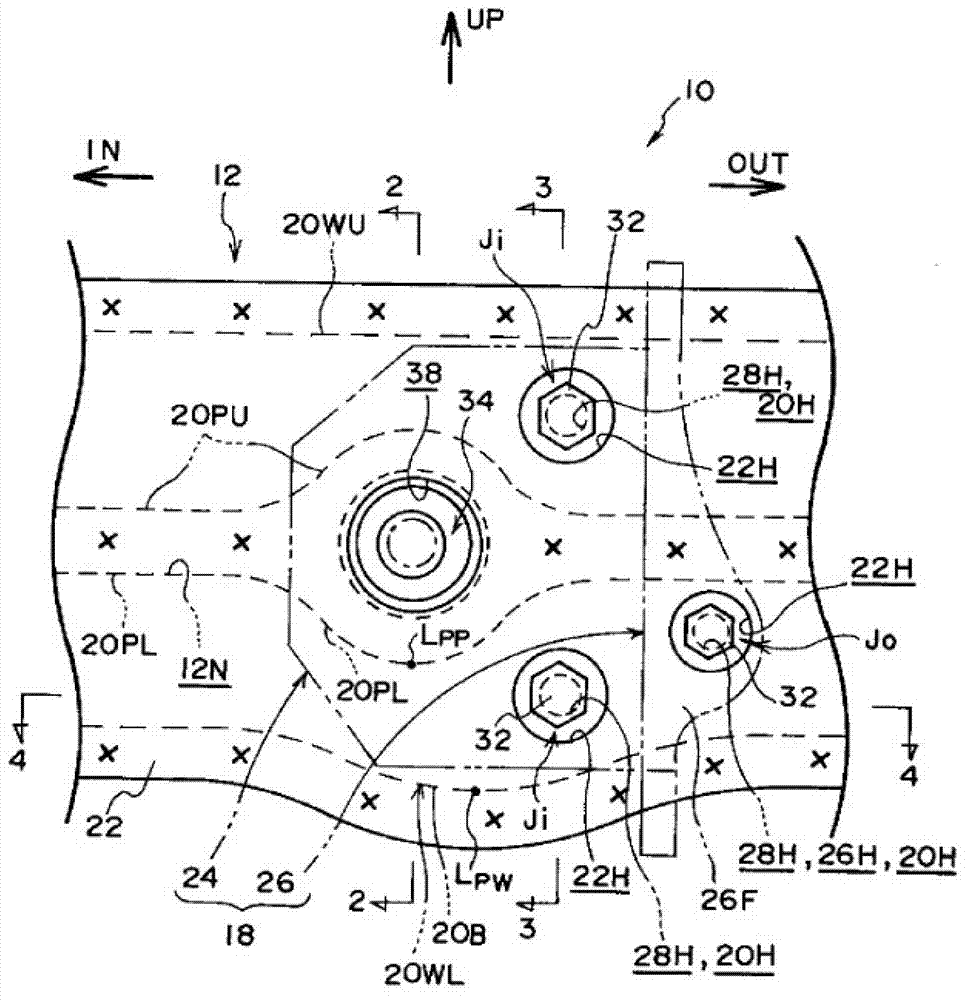

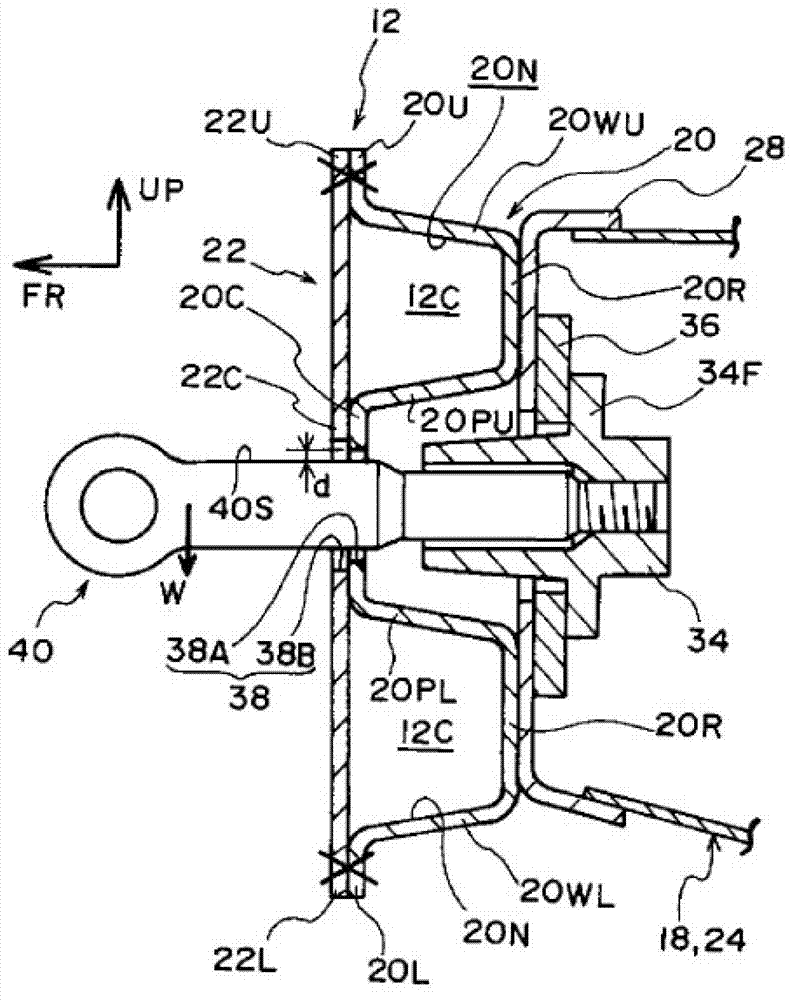

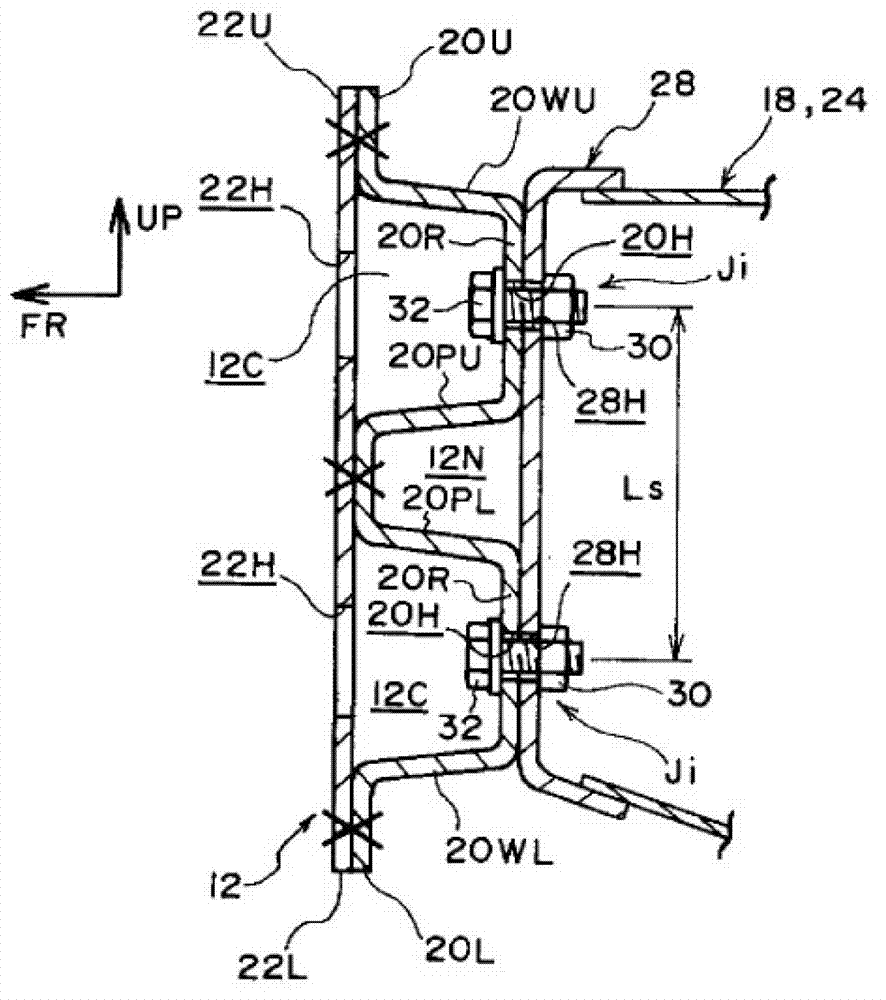

Structure of vehicle end section

Provided is a structure of a vehicle end section for ensuring combination stiffness at a joint which is located between a bumper reinforcement part and a structural part and at which a hook attaching part is disposed. A front vehicle body structure (10) comprises: a bumper reinforcement part (12) which has a B-shaped cross section where a concave portion (12N) opened backwards is disposed between a pair of upper and lower closed cross sections (12C); a crush box (18) disposed at a rear portion of an edge in a length direction of the bumper reinforcement part (12); a bolt (32) and a weld nut (30) which connect the upper and lower closed cross sections (12C) of the bumper reinforcement part (12) to a closed cross section of the crush box (18) in a front-back direction; and a pipe nut (34) which is fixed to the crush box (18) in the closed cross section of the crush box (18) in the front-back direction and is disposed oppositely to the concave portion (12N) for access of a hook member (40) through an access hole (38).

Owner:TOYOTA JIDOSHA KK

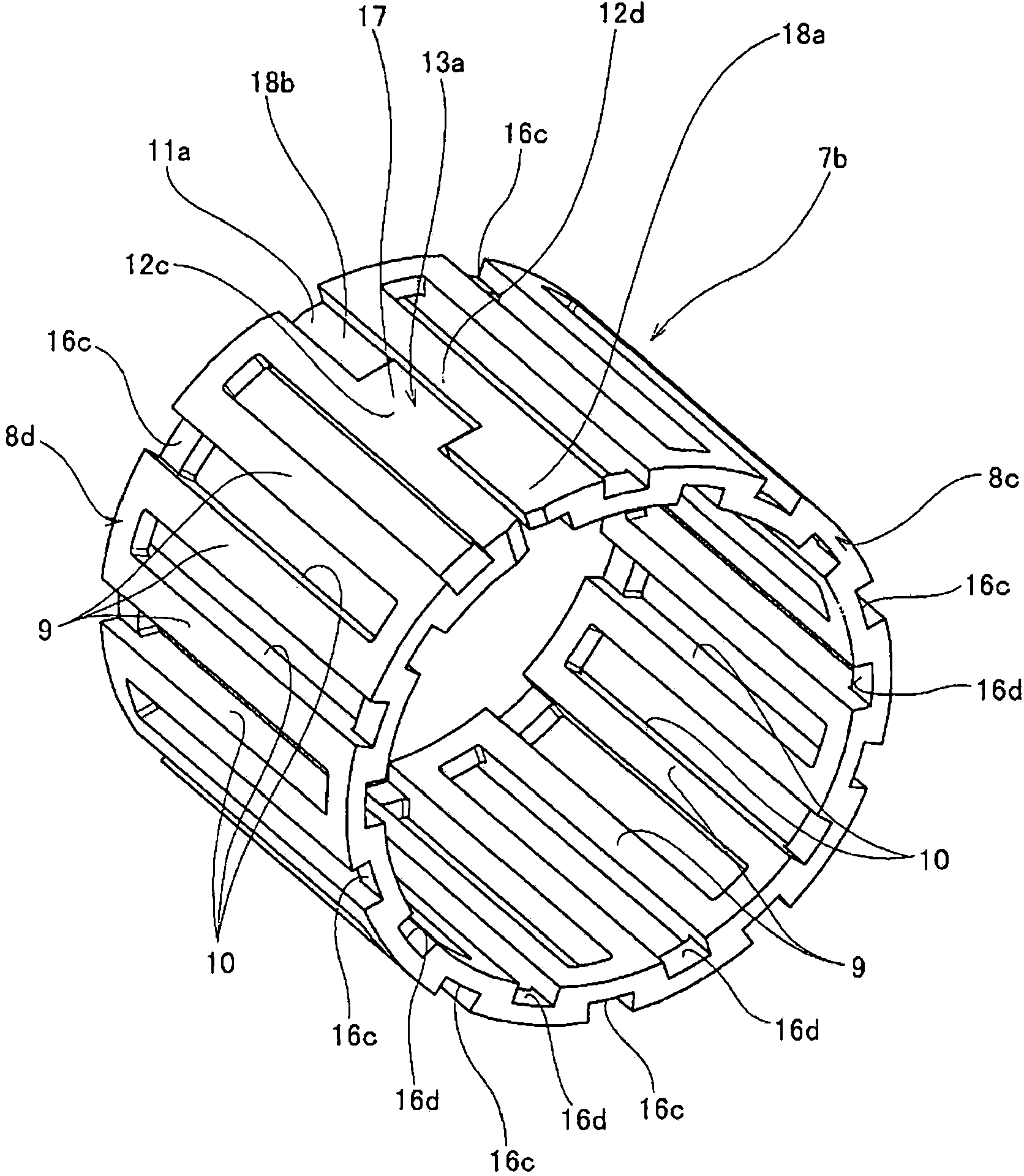

Radial roller bearing cage

ActiveCN104204576AScale smoothlyAvoid wear and tearRoller bearingsBearing assemblyRelative displacementMechanical engineering

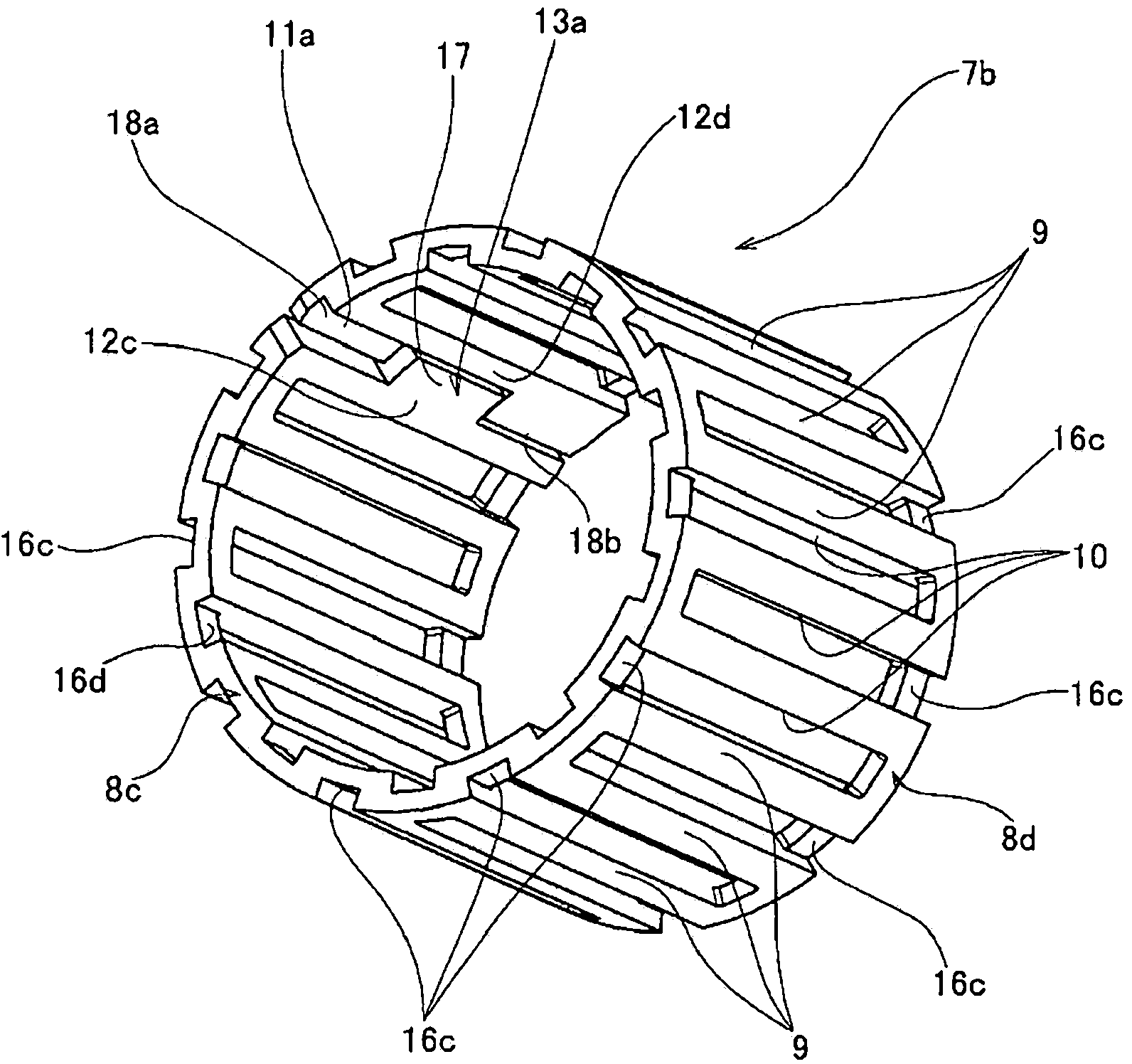

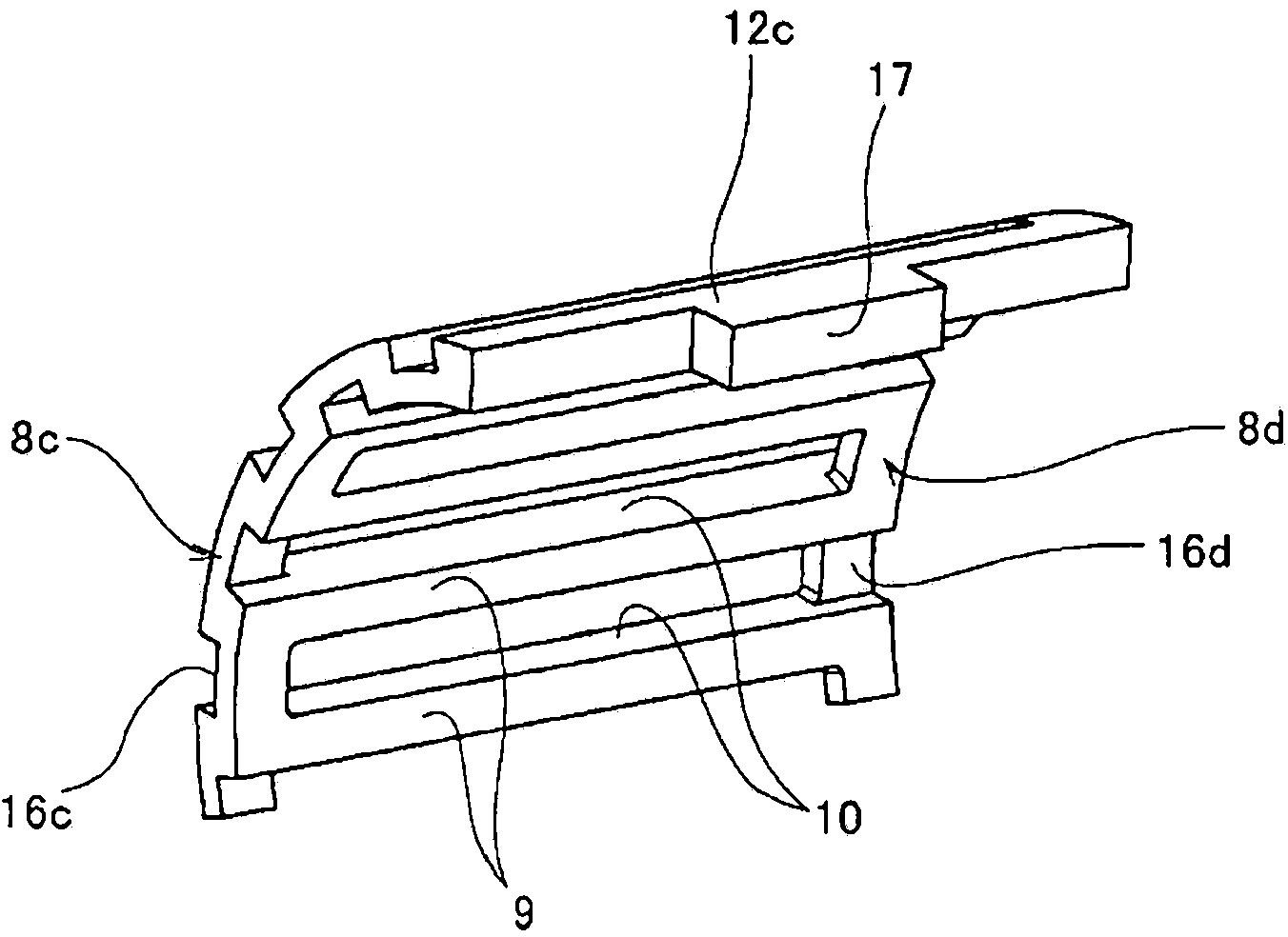

[Problem] To provide a radial roller bearing cage (7b) which can be manufactured by axial draw molding, and which allows ends (12c, 12d) provided to both sides of a discontinuous part (11a) to be engaged so as to allow the relative displacement thereof in the radial direction and disallow the relative displacement thereof in the axial direction. [Solution] An engagement section (13a) for the engagement of the ends (12c, 12d) is configured from an inner engagement piece (17) provided at the axial center of one of the ends (12c), and a pair of outer engagement pieces (18a, 18b) provided to both sides of the other end (12d) at positions that are separated in the axial direction and do not overlap in the axial direction. By arranging the inner engagement piece (17) at a position between the outer engagement pieces (18a, 18b) when incorporated into the radial roller bearing, the inner engagement piece (17) and the outer engagement pieces (18a, 18b) are each engaged in the axial direction without the inner engagement piece (17) and the outer engagement pieces (18a, 18b) overlapping in the radial direction.

Owner:NSK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com