Radial roller bearing cage

A roller bearing and cage technology, applied in the field of cages for radial roller bearings, can solve the problems of increasing the number and increasing the manufacturing cost, and achieve the effects of improving work efficiency, preventing fretting wear and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] [the first example of embodiment]

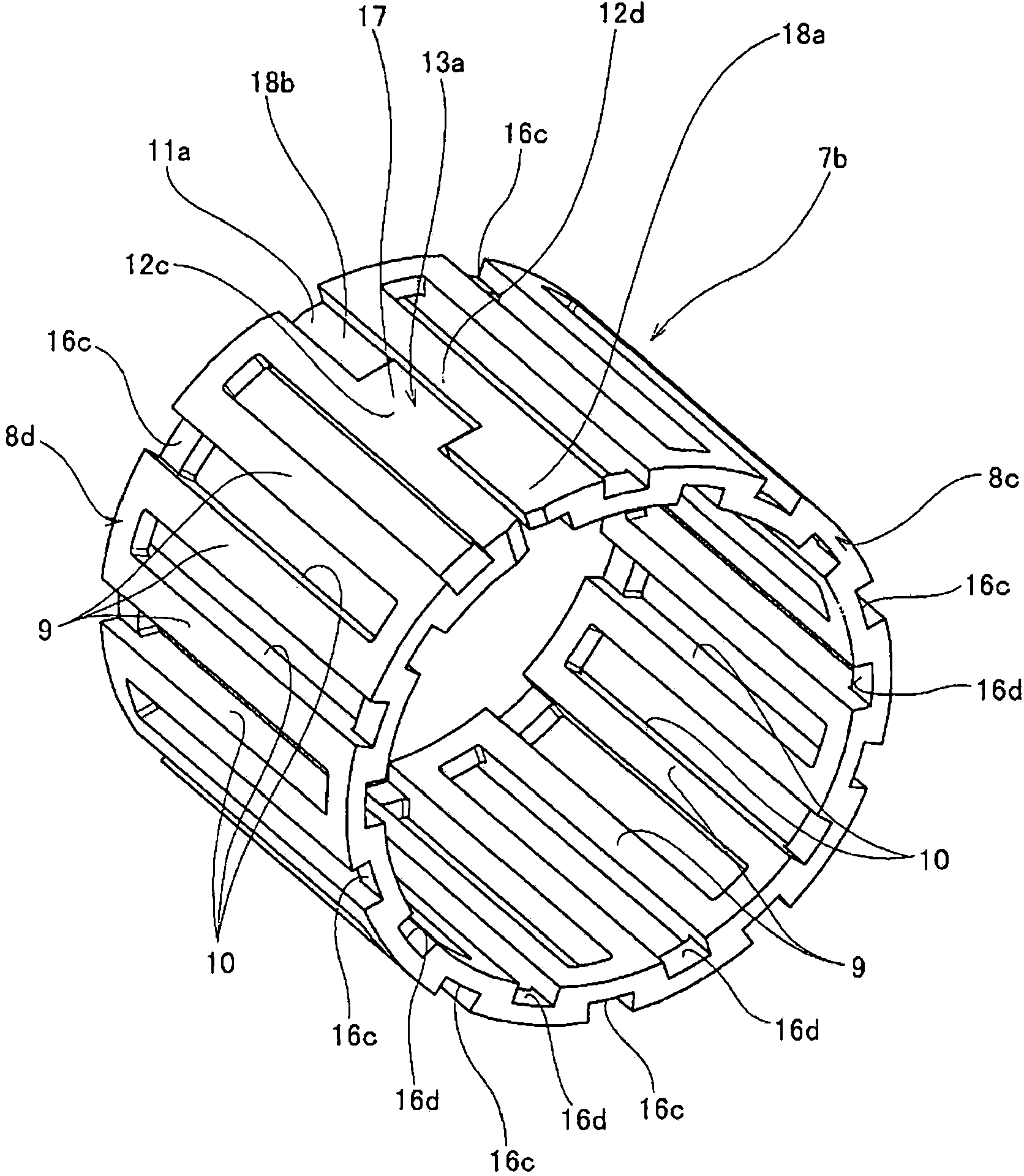

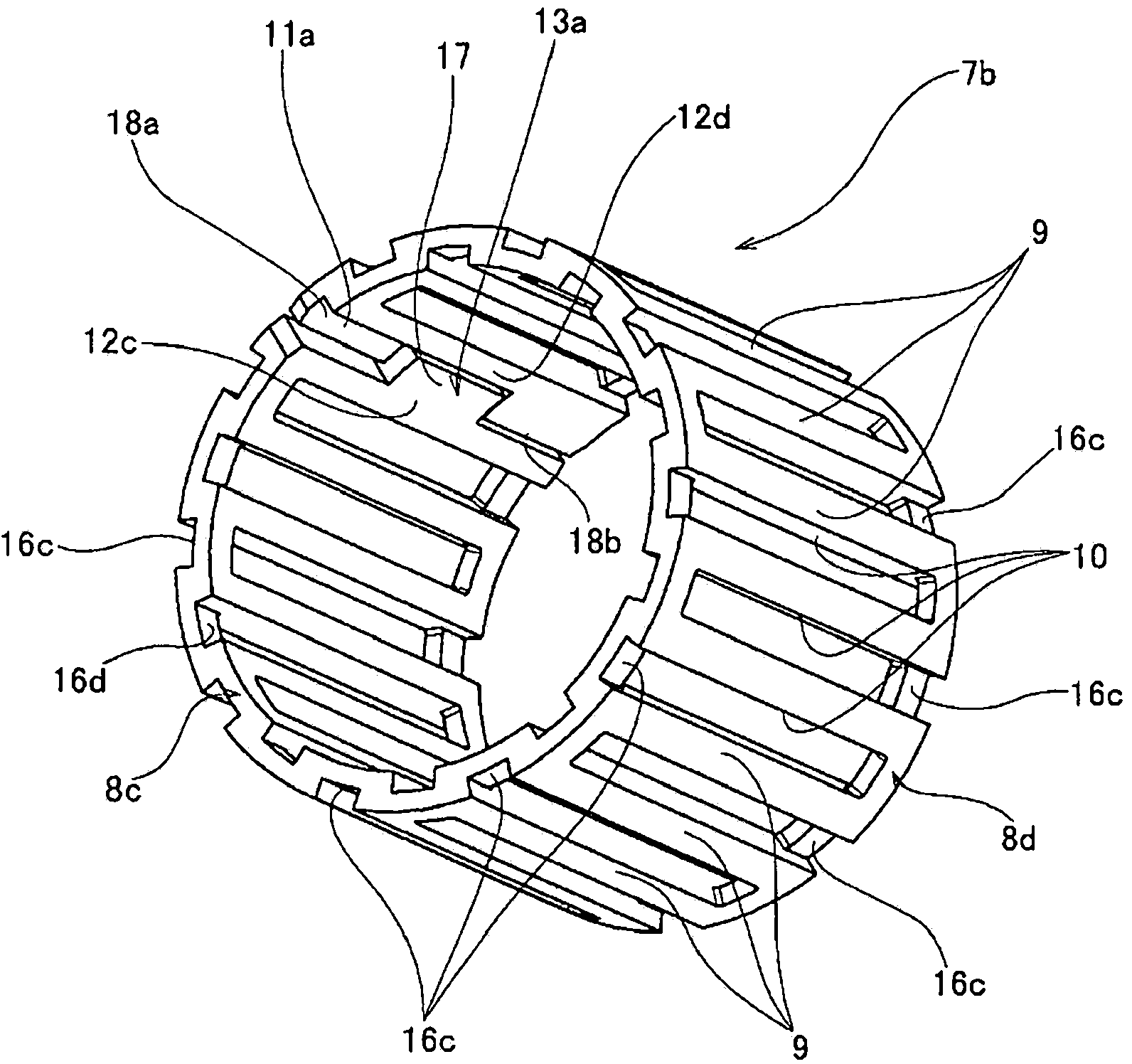

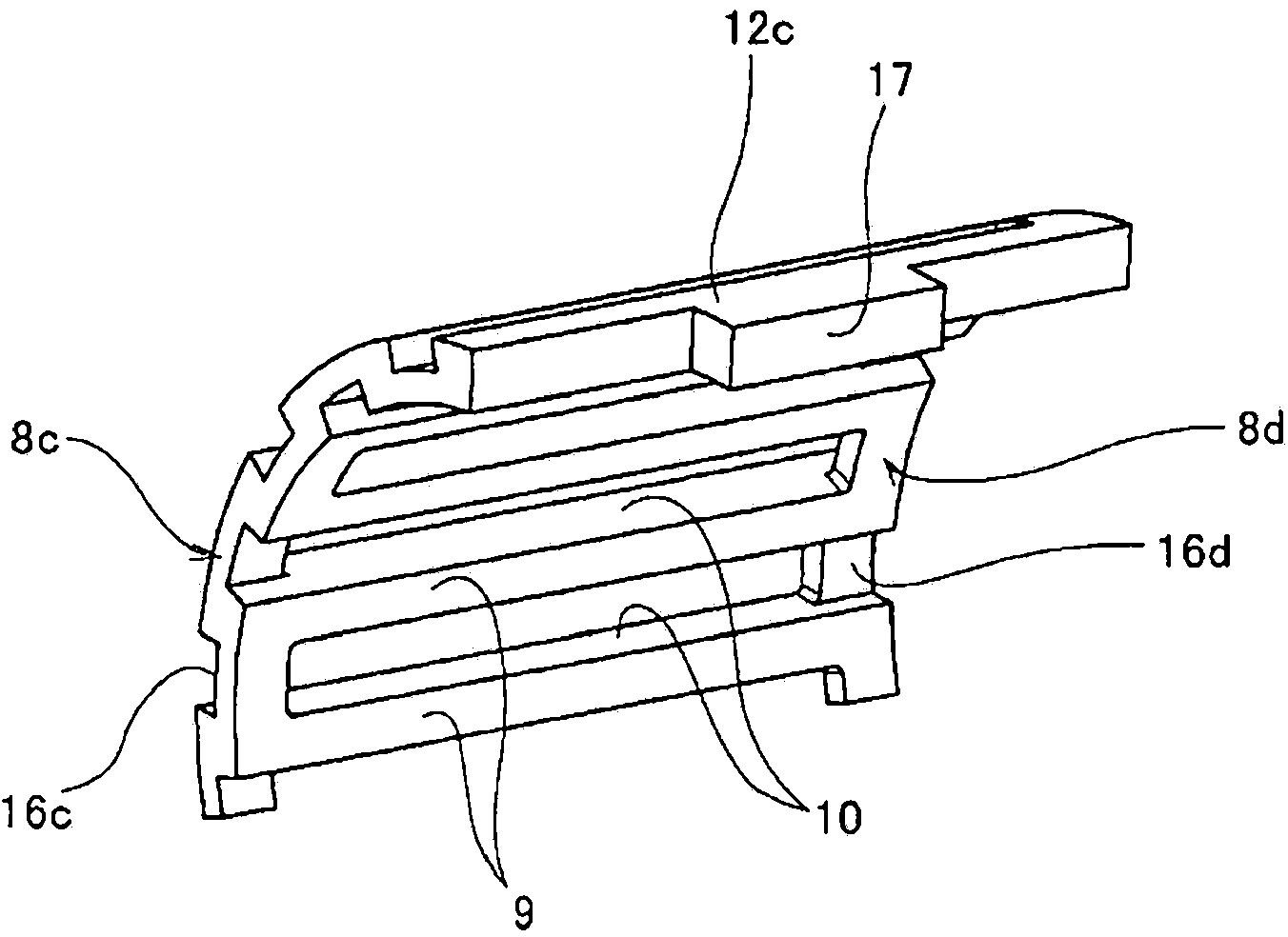

[0065] Figure 1 ~ Figure 4 This is the first example showing the embodiment of the present invention. The radial roller (needle) bearing cage 7b of this example is provided with a pair of ring-shaped rim portions 8c and 8d which are arranged concentrically with each other at intervals in the axial direction, and are intermittently spaced throughout the circumferential direction. The plurality of column parts 9 are provided in a state of being bridged between these rim parts 8c and 8d. Moreover, each of the four-sided portions surrounded by the adjacent column portion 9 in the circumferential direction and the rim portions 8c, 8d is made to freely hold the roller 6 for rolling (see Figure 23 ) pocket 10.

[0066] On the peripheral surfaces of the rim portions 8c, 8d, the portions matching the pockets 10 in the axial direction are alternately formed in the circumferential direction, and concave portions dented inward in the radial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com