Concentric double-axis vacuum hydraulic basket grinding machine

A basket grinder with concentric double-shaft technology, applied in grain processing, etc., can solve the problems of reduced material grinding quality, increased use cost, troublesome cleaning operation, etc., to achieve efficient shoveling operation, efficient mixing and grinding, and intensified rapids and the effect of turbulent motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

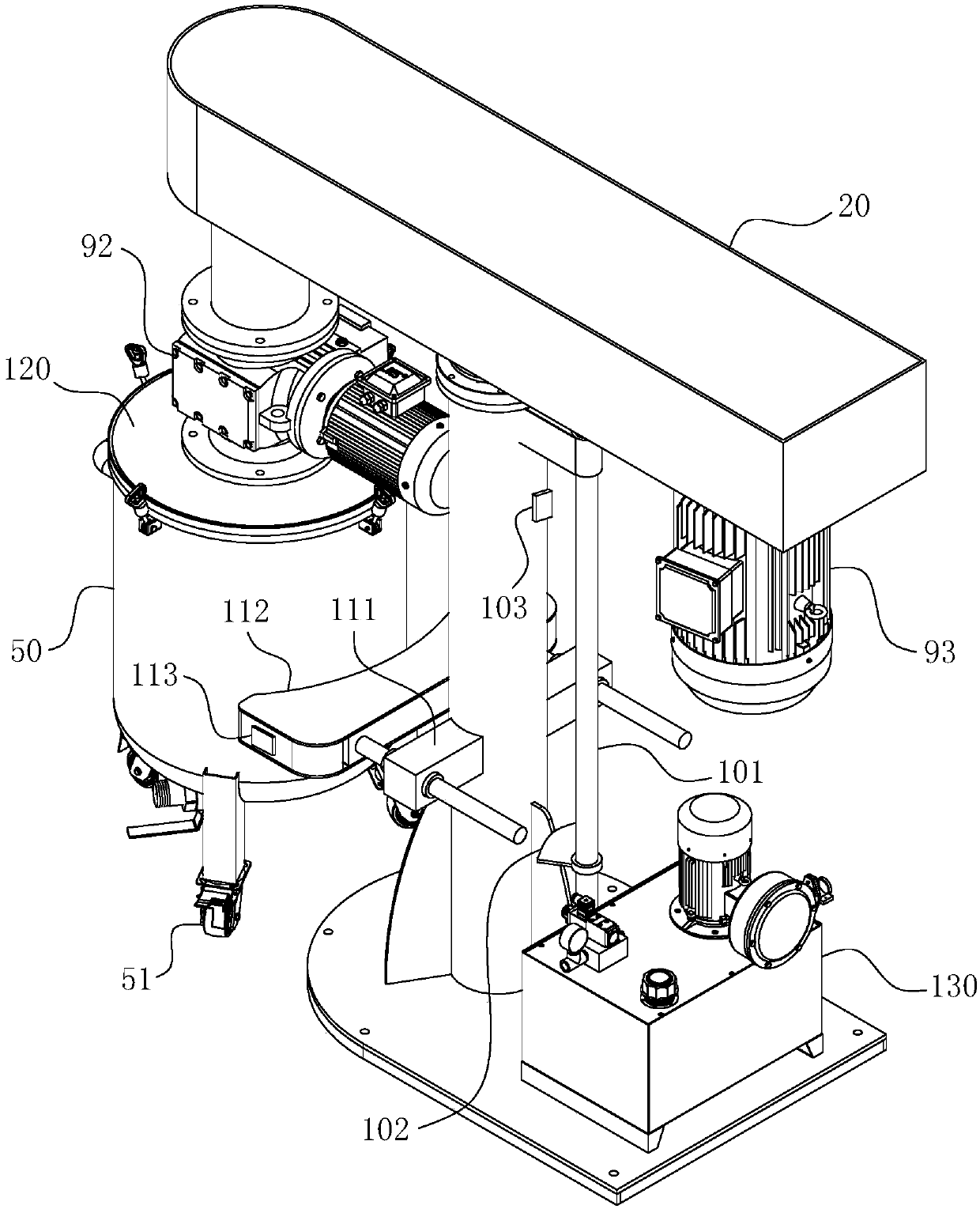

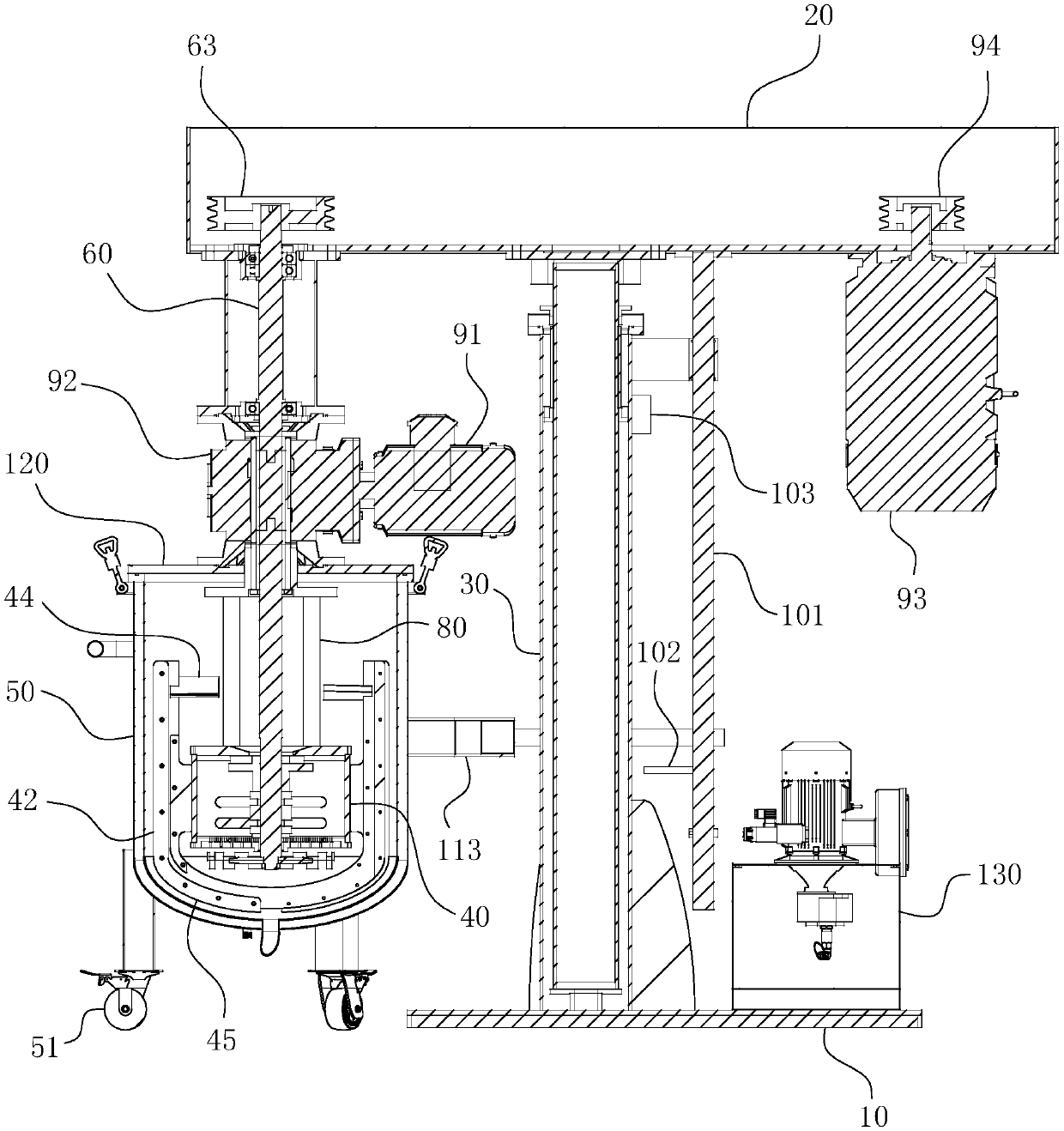

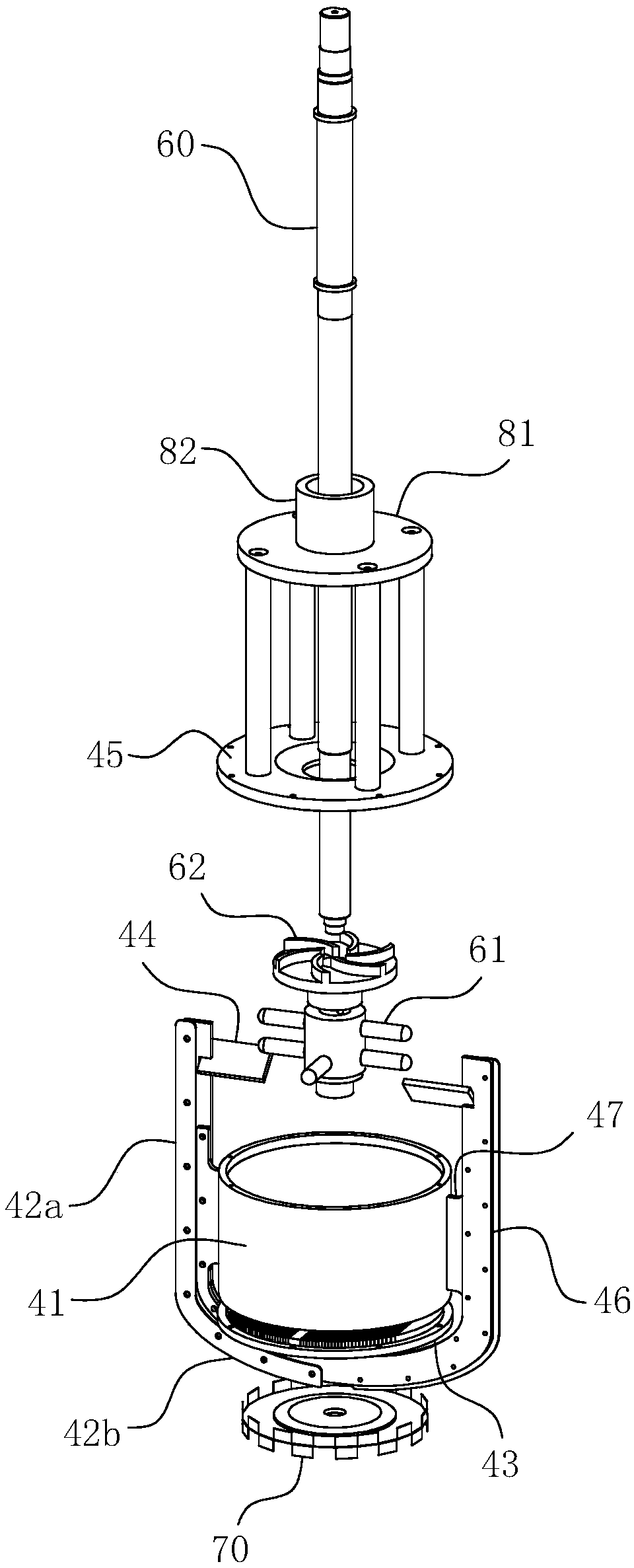

[0043] For ease of understanding, here in conjunction with accompanying drawing, the concrete structure of the present invention and working mode are further described as follows:

[0044] The invention is a product developed on the basis of a single-shaft grinder with powerful dispersing, grinding and stirring functions. The invention has good adaptability to medium-high viscosity and thixotropic materials, and various stirring methods are optional, such as conventional anchor type, butterfly type, frame type, etc., dispersing grinding and stirring can be carried out at the same time, strong adaptability, and can be According to the characteristics of customers' materials and production process requirements, non-standard customization is carried out. When the present invention is used in practice, it can even have a vacuum-tight cylinder head matching the cylinder body. The inner milling groove of the cylinder head flange is attached with a corrosion-resistant elastic sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com