Modified thermosetting resin and preparation method thereof

A technology of thermosetting and curing resin, applied in the field of modified thermosetting resin and its preparation, can solve the problem of not involving dielectric properties, etc., and achieve the effects of not harsh molding conditions, good toughness, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

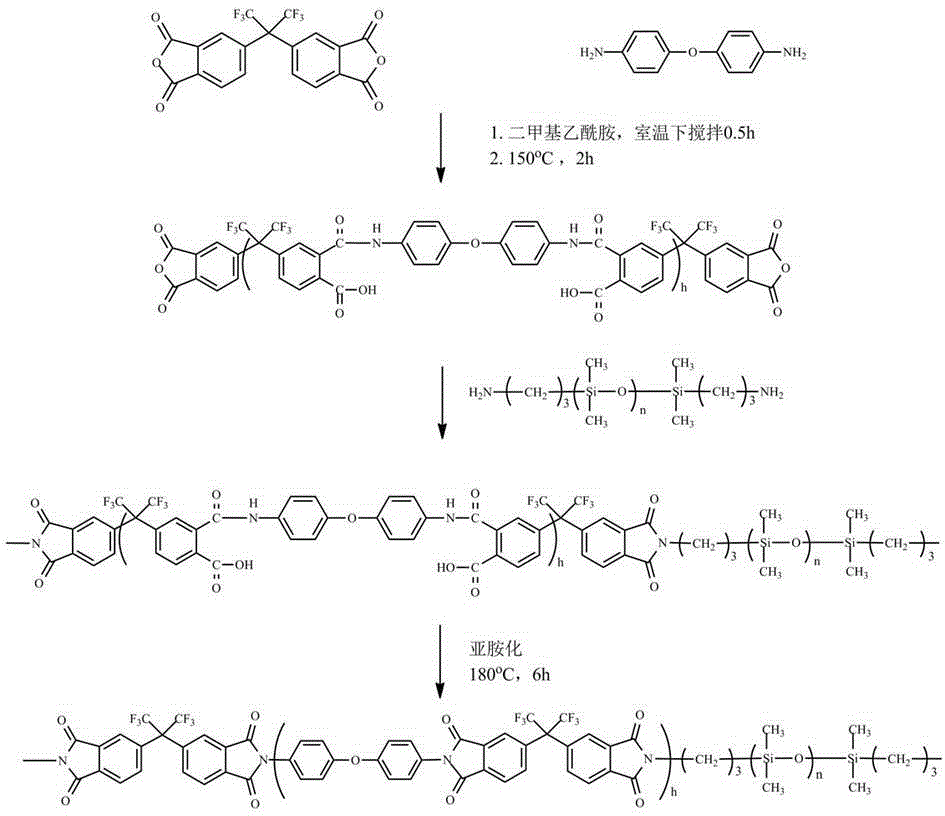

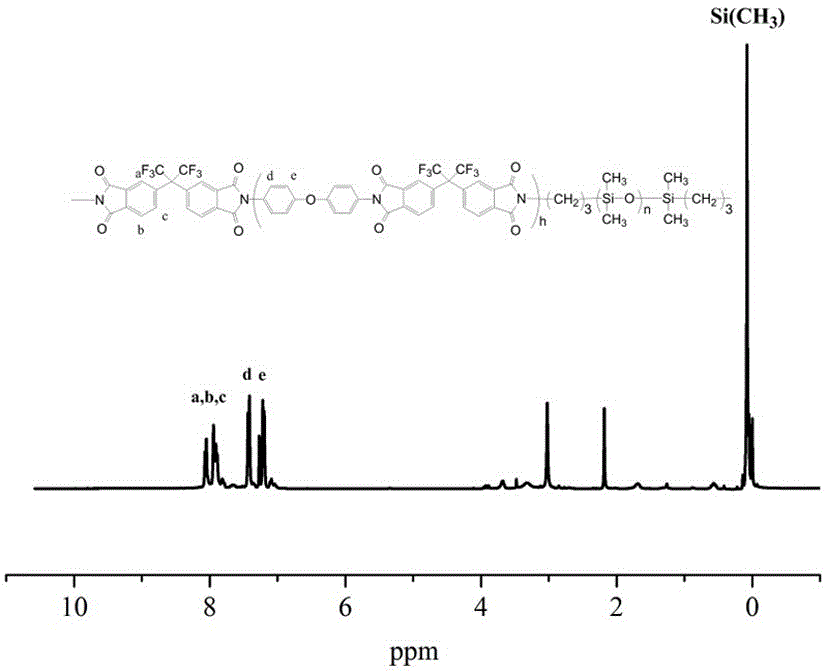

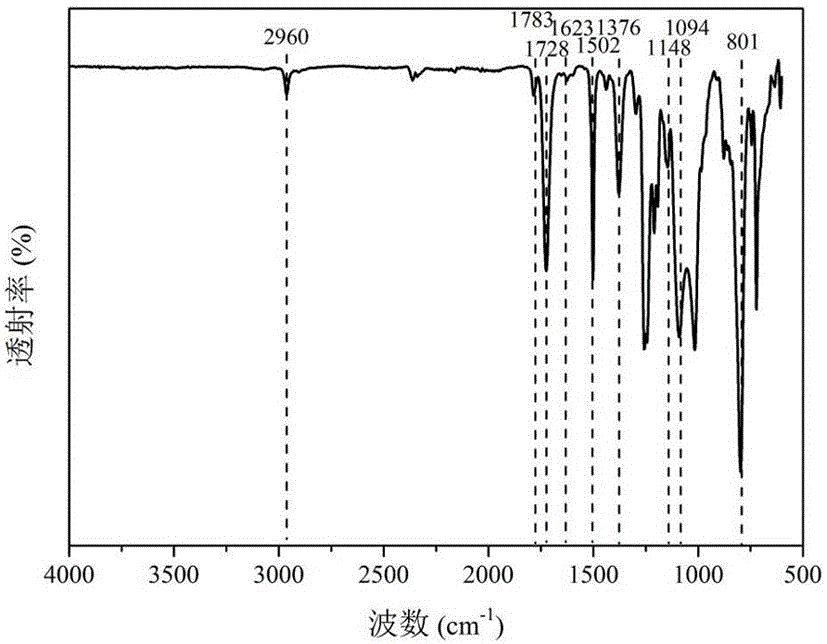

[0038] (1) Fluorinated polyimide -b- Preparation of polysiloxane block copolymer copolymer

[0039] N 2 Under protection, at 25°C, 0.6726g of 4,4'-diaminodiphenyl ether was dissolved in 15mL of N,N'-dimethylacetamide to obtain solution A; 1.5927g of hexafluorodianhydride was added to solution A, and then the temperature Raise to 150°C, and keep it warm for 2 hours to obtain solution B; 2 / g) dissolved in 2mL N,N'-dimethylacetamide to obtain solution C; at 150°C, add solution C dropwise to solution B, and then add 3mL toluene; heat up to 180°C and react for 4h to obtain reaction System D: lower the temperature of reaction system D to 25°C, slowly pour it into 100mL of methanol and stir, and precipitate a powdery product, which is dried to obtain crude product E. The crude product E was dissolved in 10 mL of dichloromethane and precipitated with 80 mL of methanol. After drying at 120°C for 5h and at 80°C for 10h, a fluorine-containing polyimide was obtained -b- Polysiloxane...

Embodiment 2

[0047] (1) Fluorinated polyimide -b- Preparation of Polysiloxane Block Copolymer

[0048] N 2 Under protection, at 25°C, 0.5381g of 4,4'-diaminodiphenyl ether was dissolved in 13mL of N,N'-dimethylacetamide to obtain solution A; 1.3439g of hexafluorodianhydride was added to solution A; then the temperature Raise to 150°C, and keep it warm for 2 hours to obtain solution B; 2 / g) was dissolved in 3mL N, N'-dimethylacetamide to obtain solution C. At 150°C, add solution C dropwise to solution B, then add 2.5mL toluene, raise the temperature to 180°C, and react for 4 hours to obtain reaction system D; lower the temperature of reaction system D to 25°C, and slowly pour it into 80mL In methanol and stirring, the powdery product precipitated out, and after drying, the crude product E was obtained, which was dissolved in 8 mL of dichloromethane, and precipitated with 65 mL of methanol again. After drying at 120° C. for 5 hours and at 80° C. for 10 hours, a fluorine-containing polyi...

Embodiment 3

[0053] (1) Fluorinated polyimide -b- Preparation of Polysiloxane Block Copolymer

[0054] N 2 Under protection, at 25°C, dissolve 0.4484g of 4,4'-diaminodiphenyl ether in 10mL of N,N'-dimethylacetamide to obtain solution A; add 1.1945g of hexafluorodianhydride to solution A; Afterwards, the temperature was raised to 150°C, and the reaction was kept for 2 hours to obtain solution B; 2 / g) was dissolved in 4mL N, N'-dimethylacetamide to obtain solution C. At 150°C, add solution C dropwise to solution B, then add 2mL of toluene, raise the temperature to 180°C, react for 4 hours, and obtain reaction system D; lower the temperature of reaction system D to 25°C, and slowly pour it into 70mL of methanol With stirring, the powdery product precipitated out, and after drying, the crude product E was obtained, which was dissolved in 7 mL of dichloromethane and precipitated again with 50 mL of methanol. After drying at 120° C. for 5 hours and at 80° C. for 10 hours, a fluorine-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com