Patents

Literature

42results about How to "Ensure thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

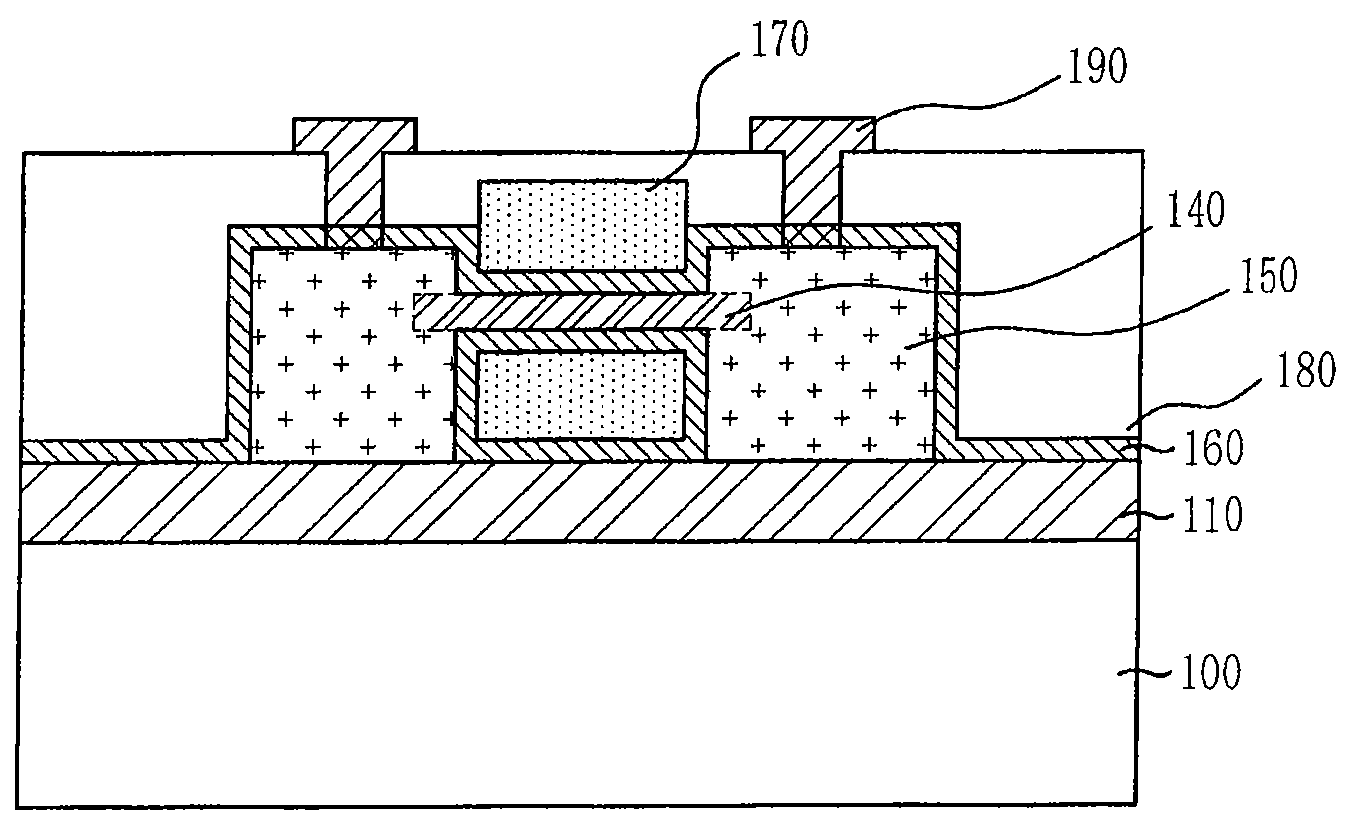

Schottky barrier nanowire field effect transistor and method for fabricating the same

InactiveUS20080128760A1Easy to makeEnsure thermal stabilityNanoinformaticsSolid-state devicesSalicideInsulation layer

Provided is a Schottky barrier nanowire field effect transistor, which has source / drain electrodes formed of metal silicide and a channel formed of a nanowire, and a method for fabricating the same. The Schottky barrier nanowire field effect transistor includes: a channel suspended over a substrate and including a nanowire; metal silicide source / drain electrodes electrically connected to both ends of the channel over the substrate; a gate electrode disposed to surround the channel; and a gate insulation layer disposed between the channel and the gate electrode.

Owner:ELECTRONICS & TELECOMM RES INST

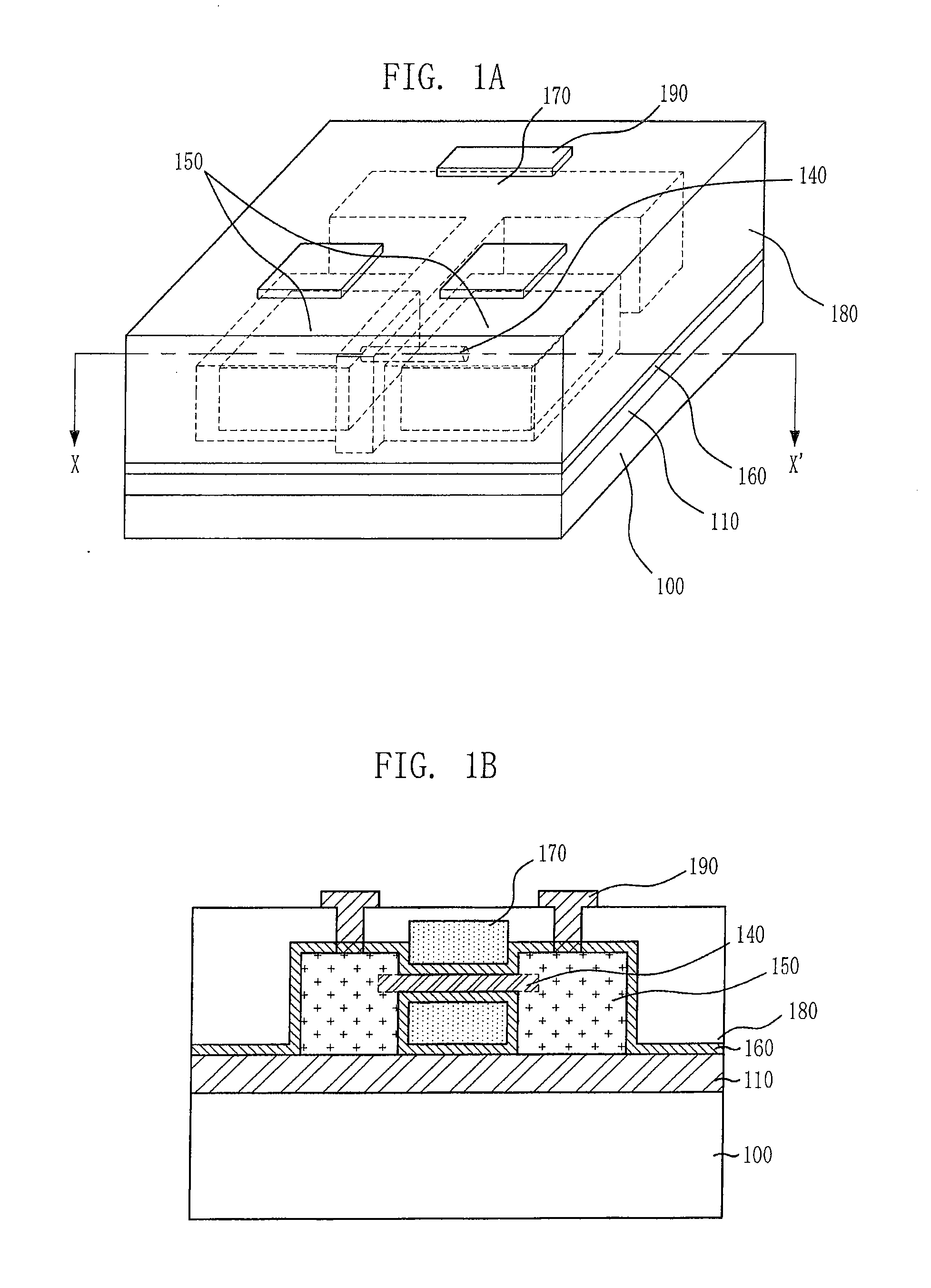

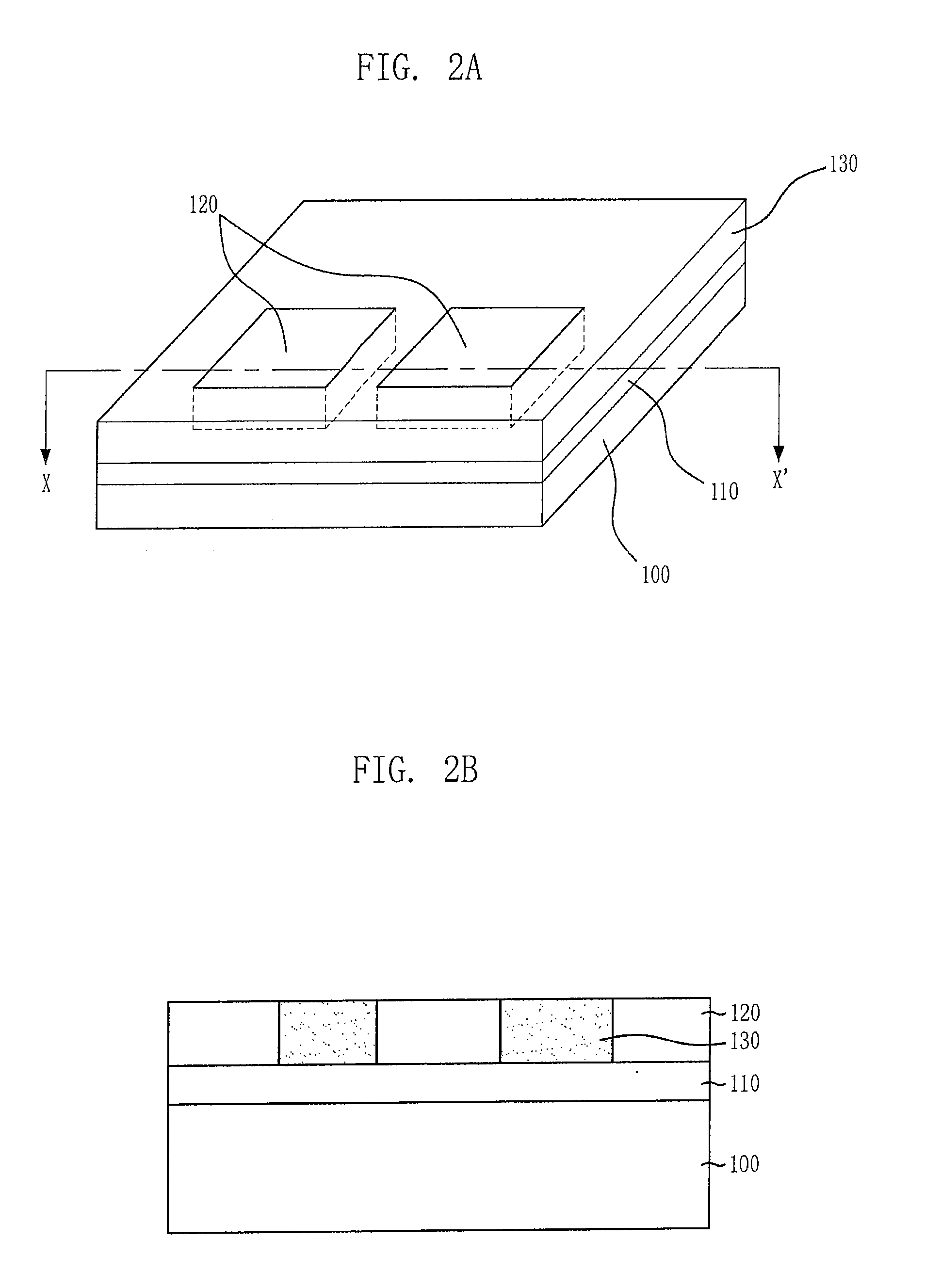

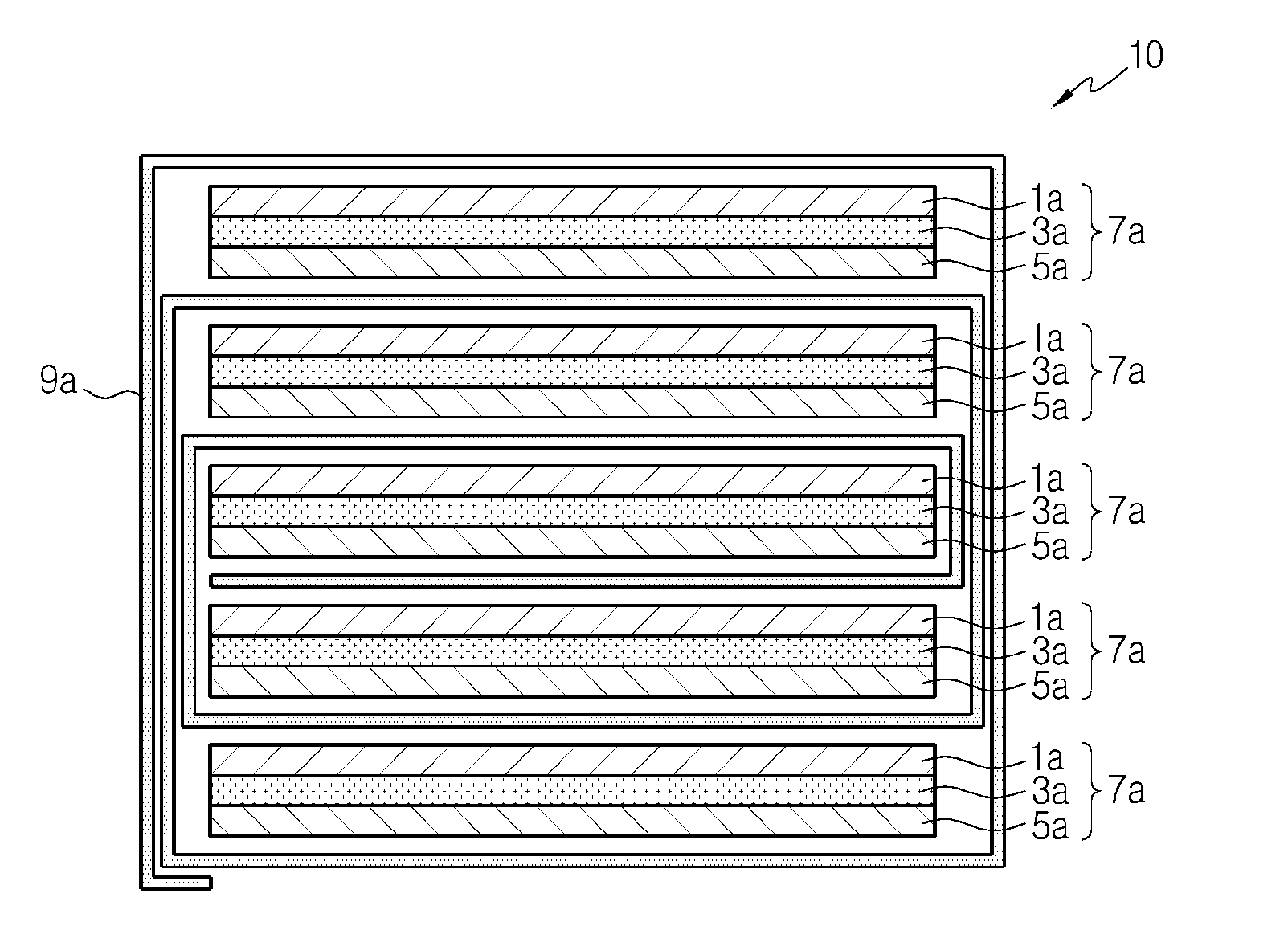

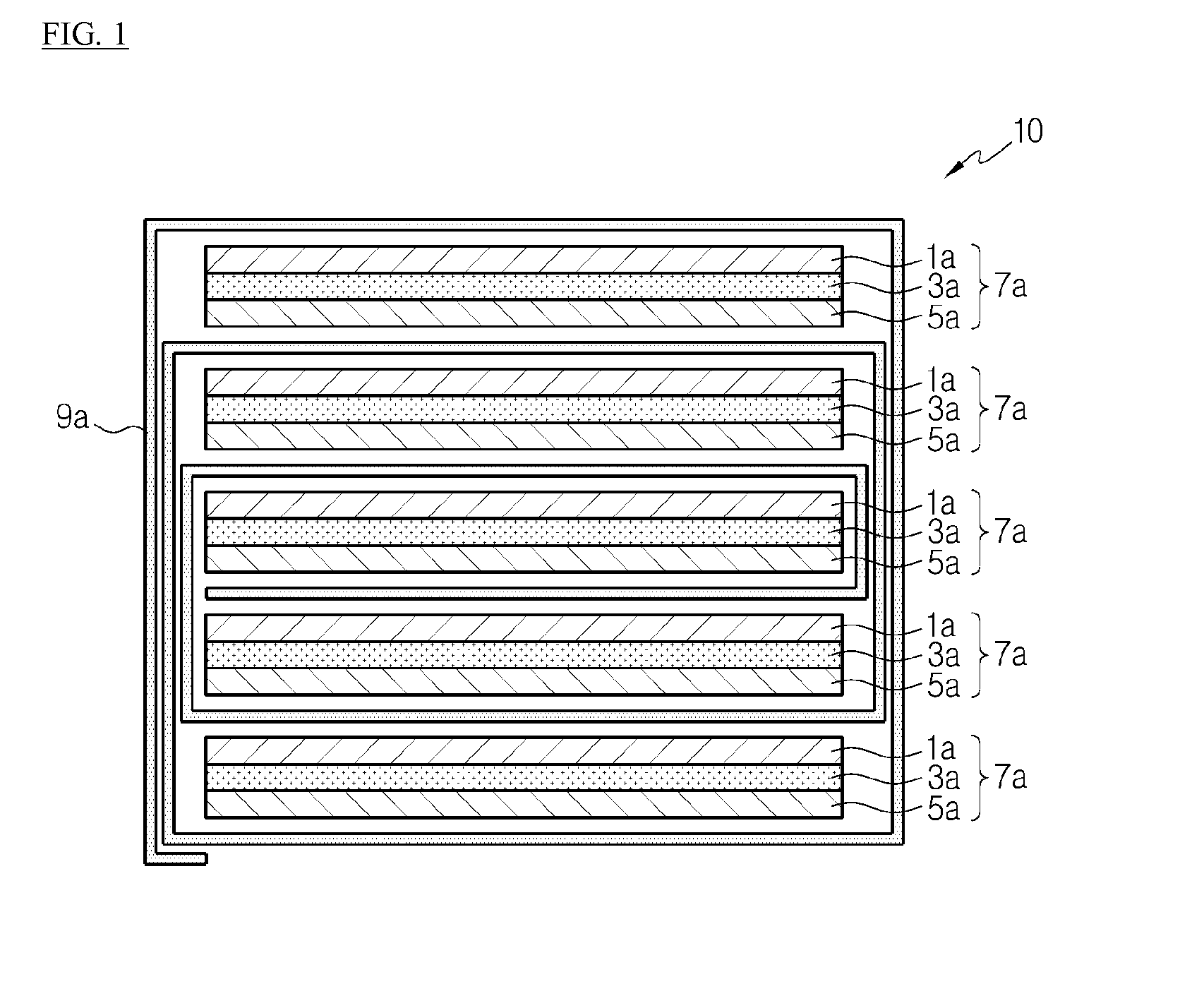

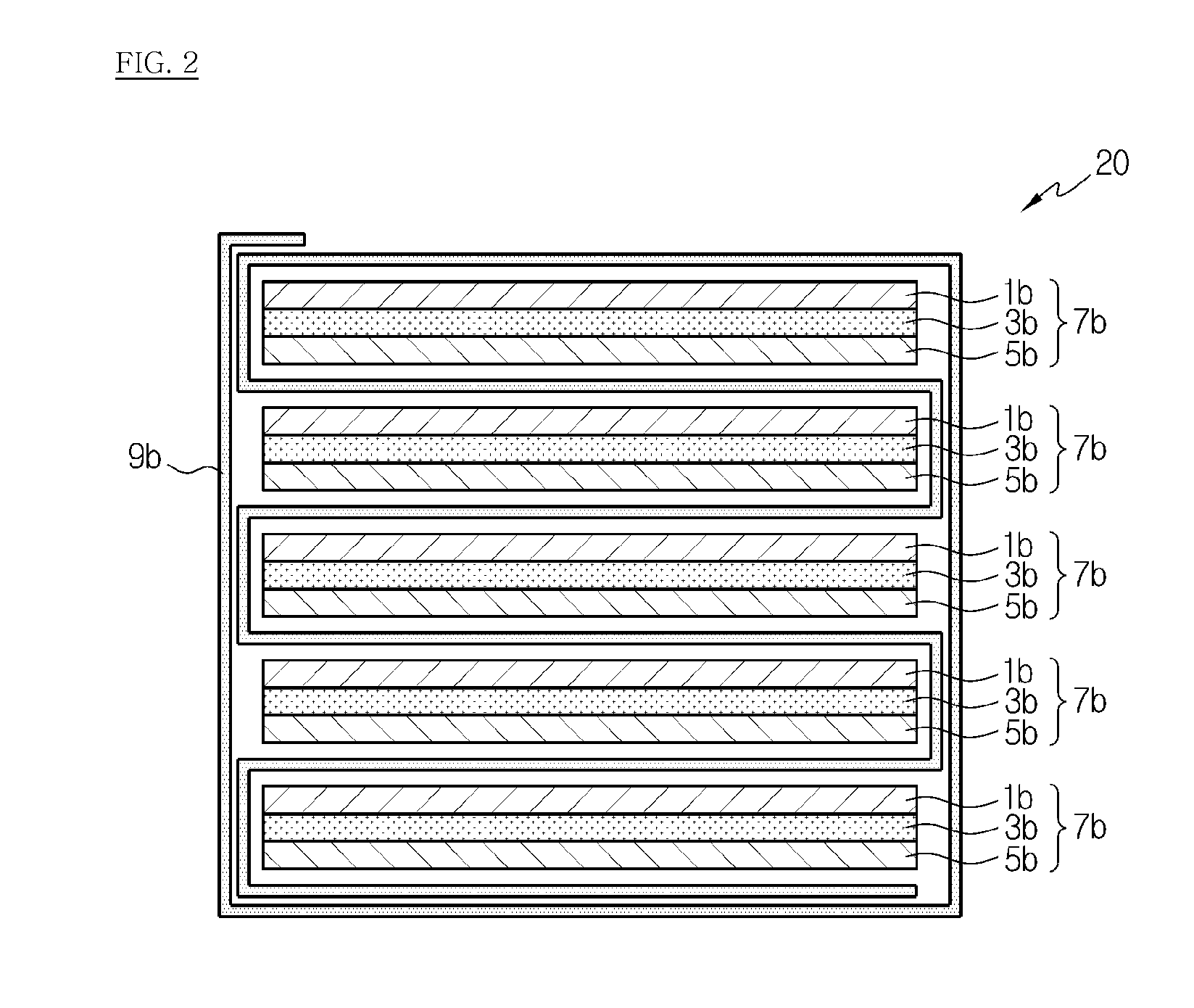

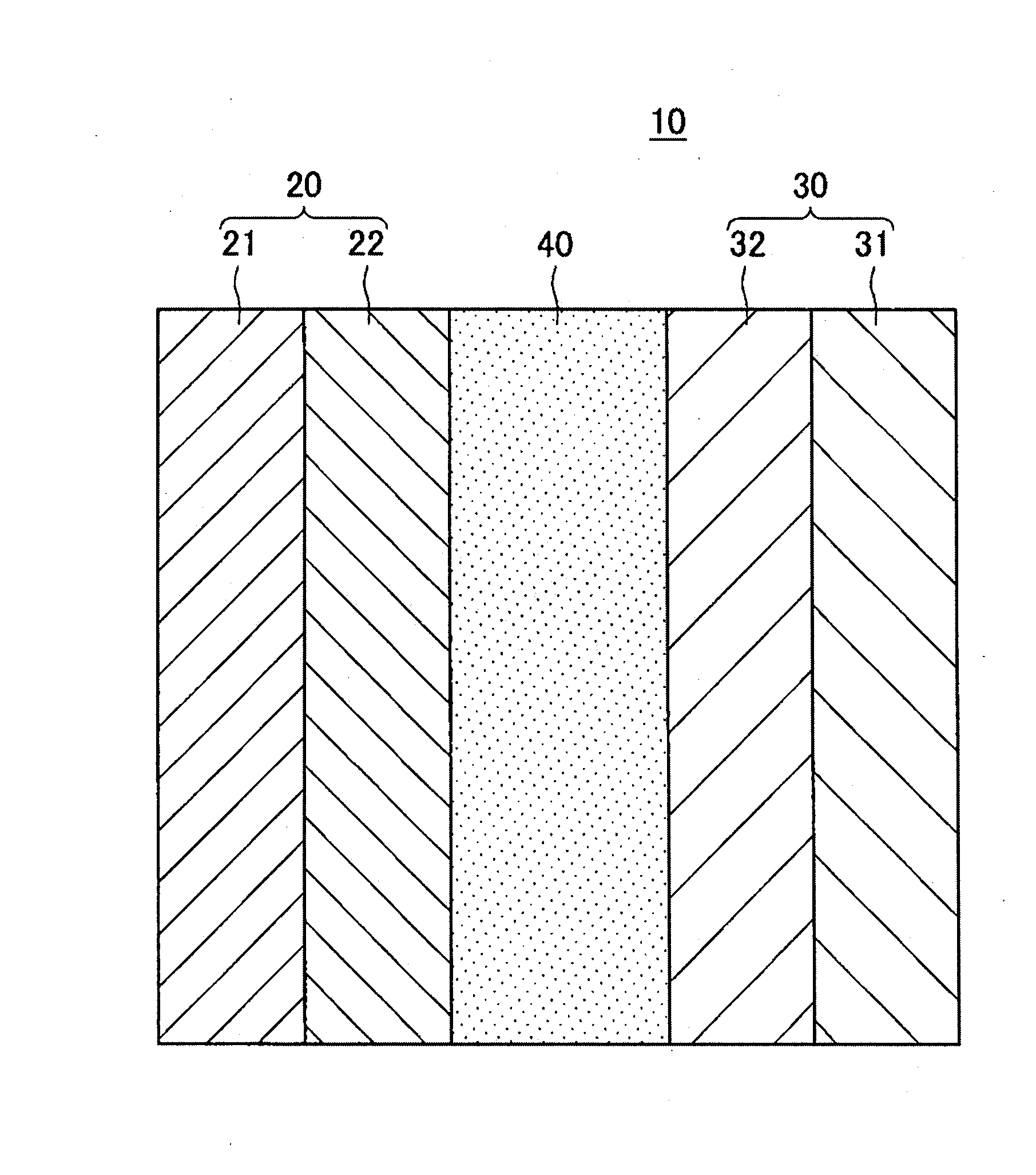

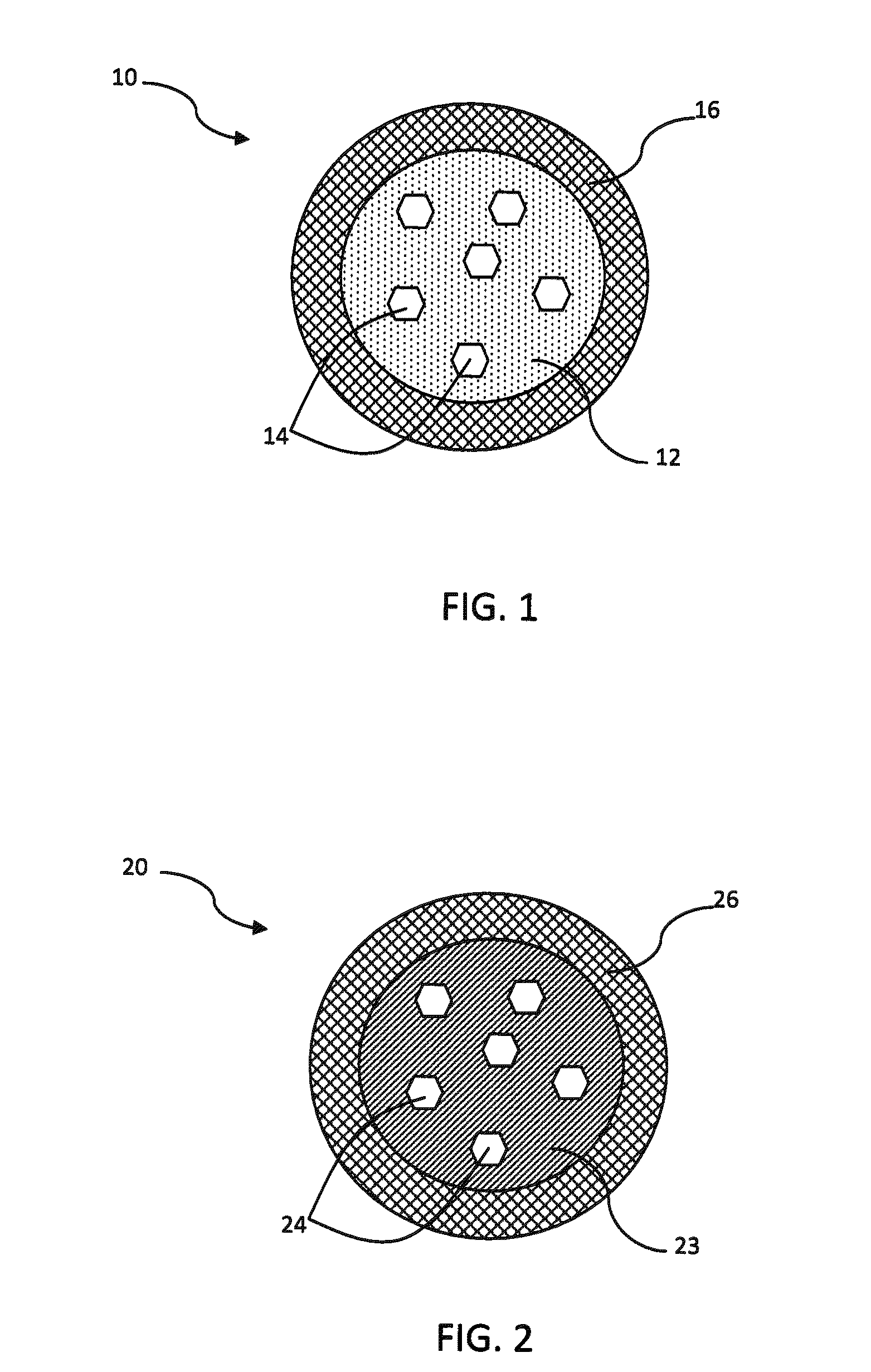

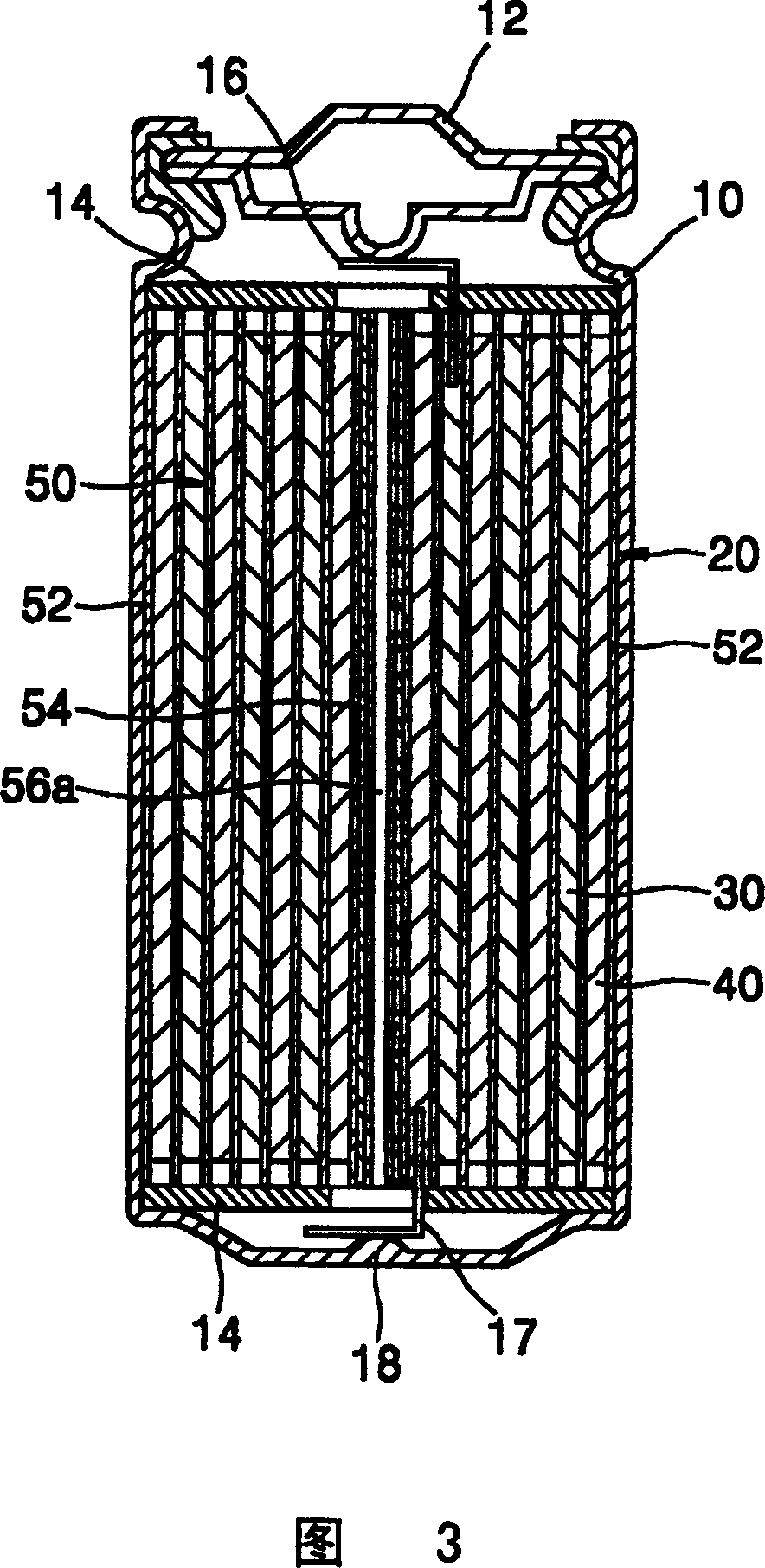

Electrochemical device having different kinds of separators

ActiveUS20100261047A1Prevent ignition and explosionReduce temperature increase rateFinal product manufactureJackets/cases materialsPolyolefinPorous coating

An electrochemical device includes a plurality of unit cells, each having a first separator and a cathode and an anode positioned at both sides of the first separator, and a continuous single second separator interposed between adjacent unit cells in correspondence with each other in a laminated pattern and arranged to surround each unit cell. The first separator includes a heat-resisting porous substrate having a melt point of 200° C. or above and a first porous coating layer formed on at least one surface of the heat-resisting porous substrate and made of a mixture of a plurality of inorganic particles and a binder polymer. The second separator includes a polyolefin porous substrate and a second porous coating layer formed on at least one surface of the polyolefin porous substrate and made of a mixture of a plurality of inorganic particles and a binder polymer.

Owner:LG ENERGY SOLUTION LTD

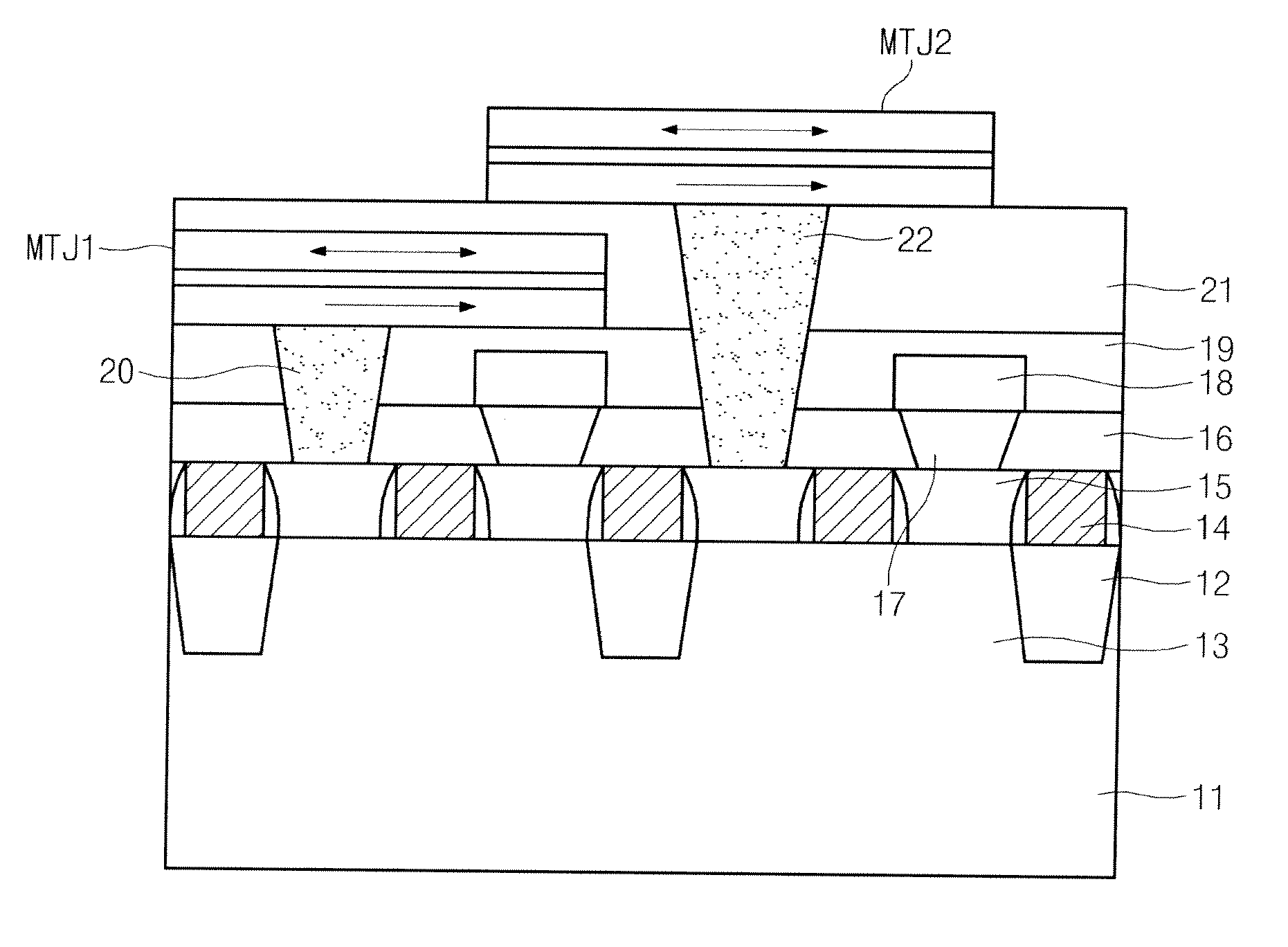

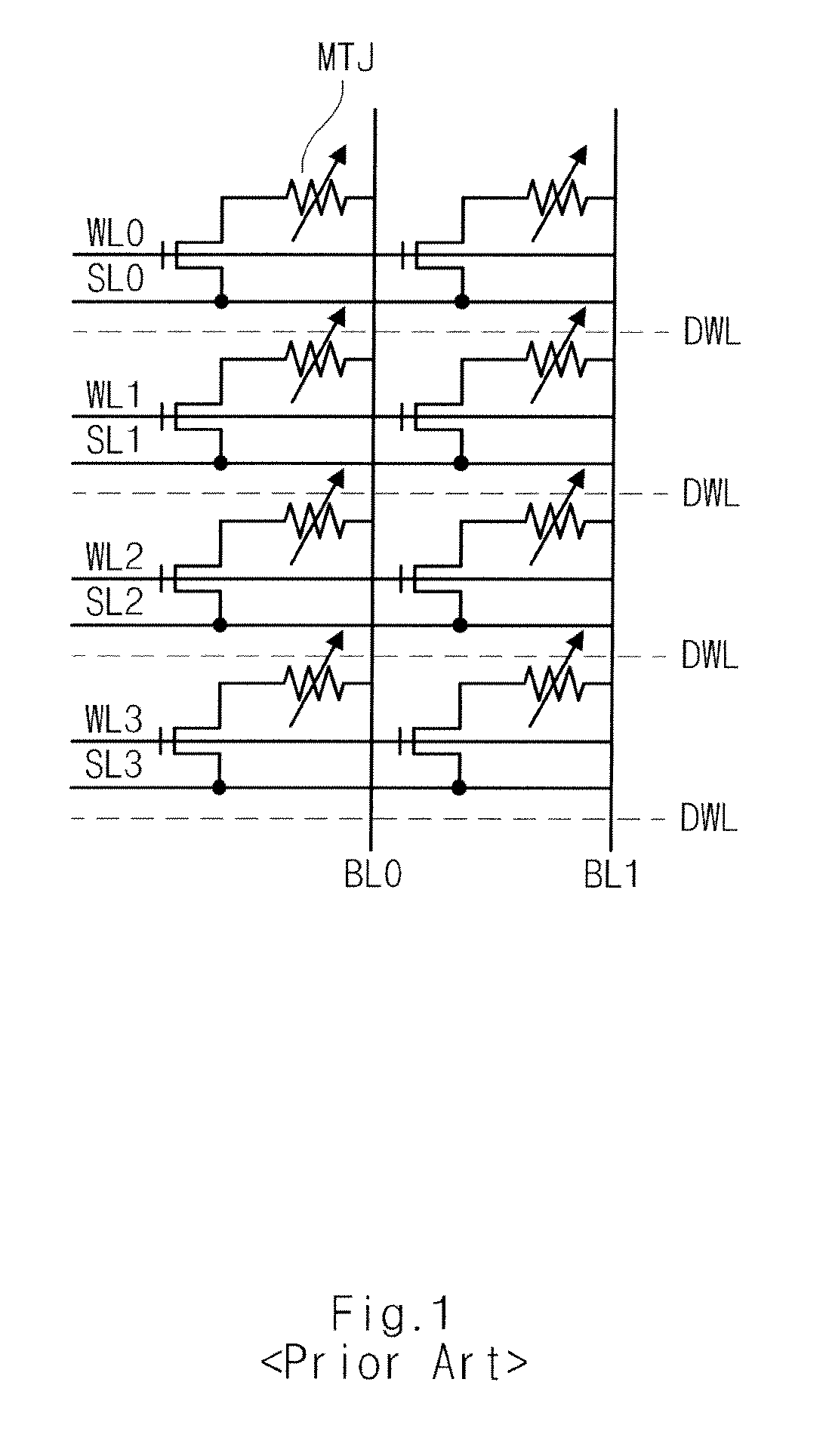

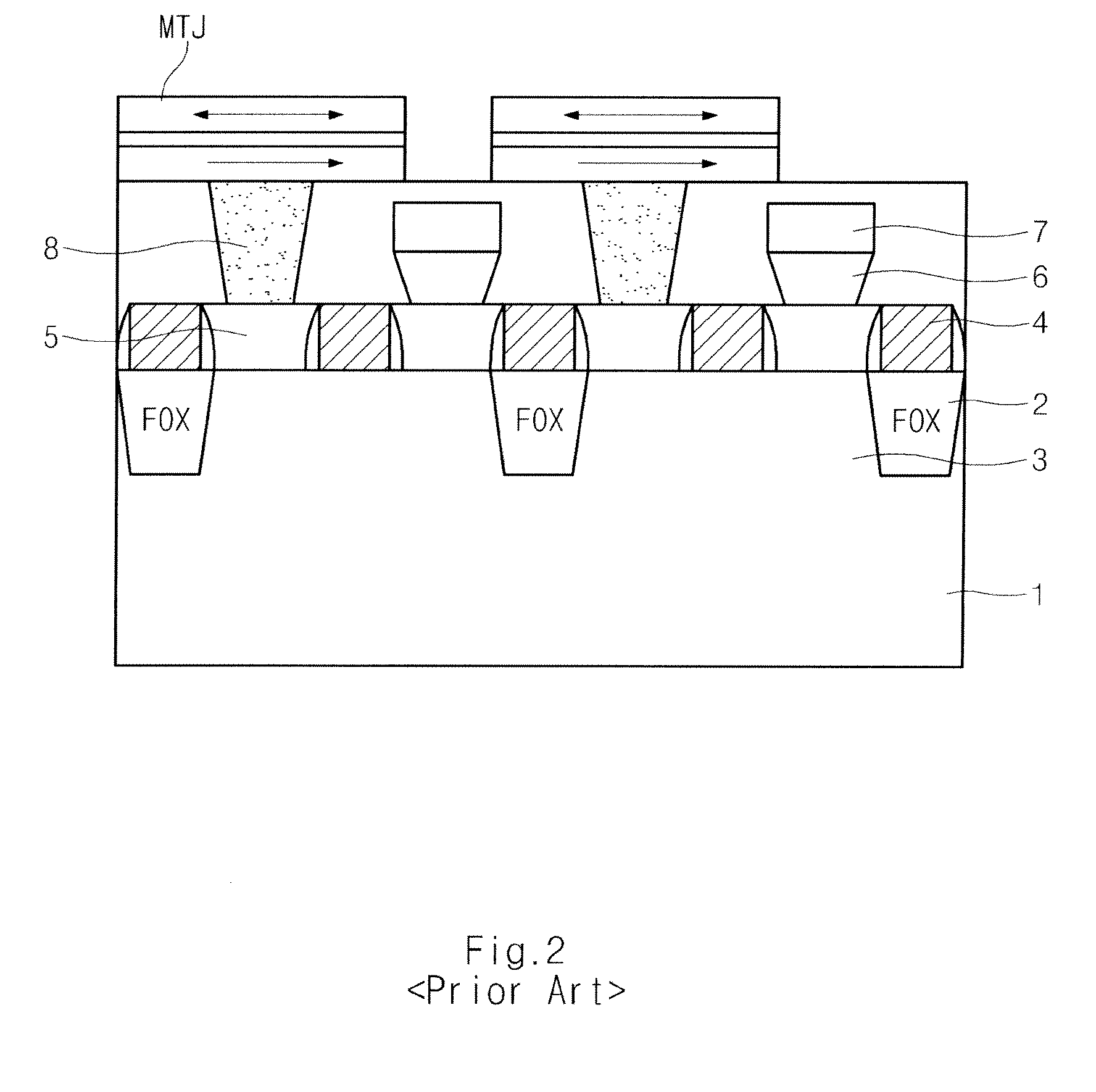

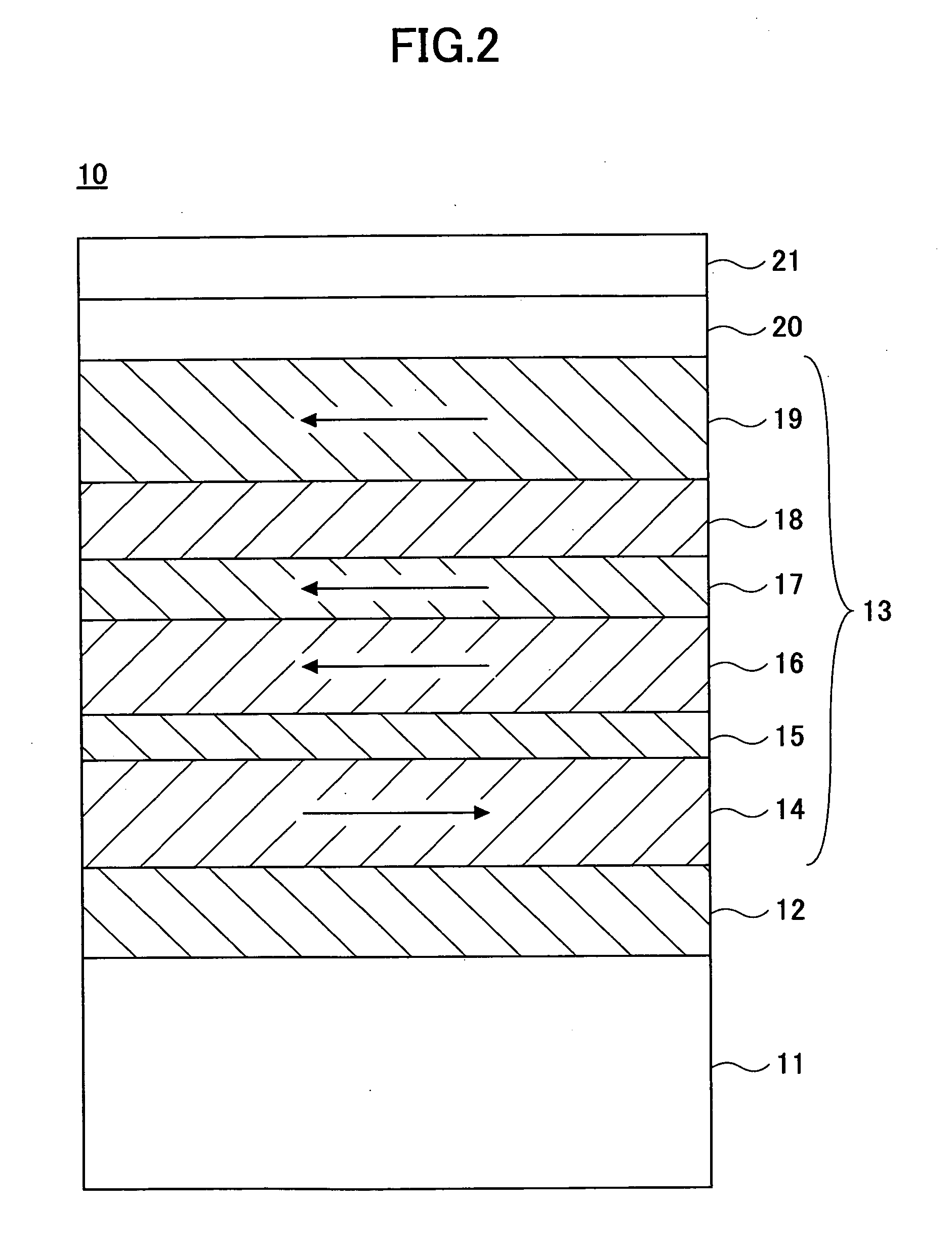

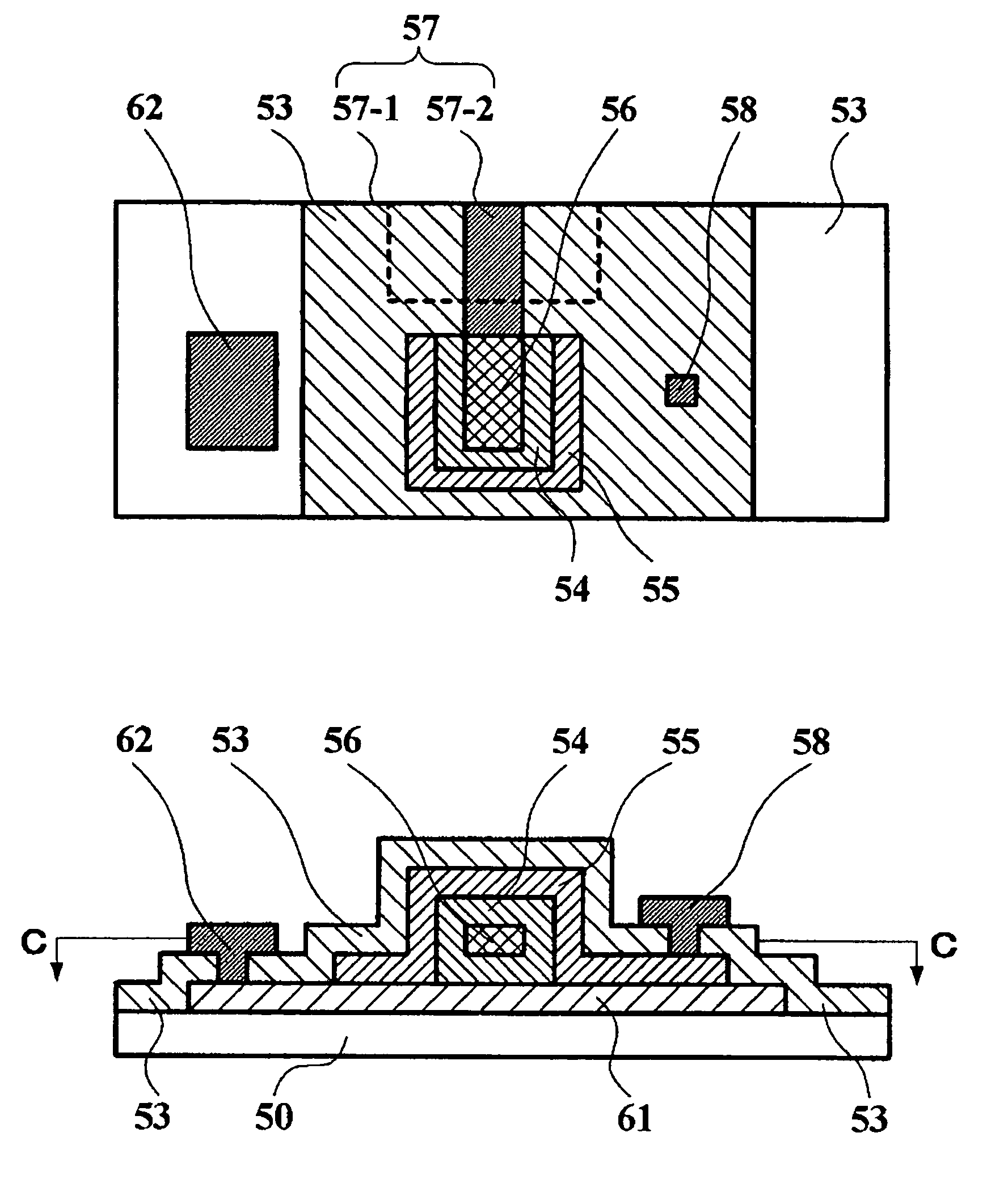

Multi-Stacked Spin Transfer Torque Magnetic Random Access Memory and Method of Manufacturing the Same

InactiveUS20100019297A1Improve cell structureEnsure thermal stabilityMagnetic-field-controlled resistorsSolid-state devicesSpin-transfer torqueRandom access memory

A spin transfer torque magnetic random access memory (STT-MRAM) device comprises adjacent magnetic tunneling junctions (MTJ), respectively, formed in different layers, thereby preventing interference between the MTJs and securing thermal stability.

Owner:SK HYNIX INC

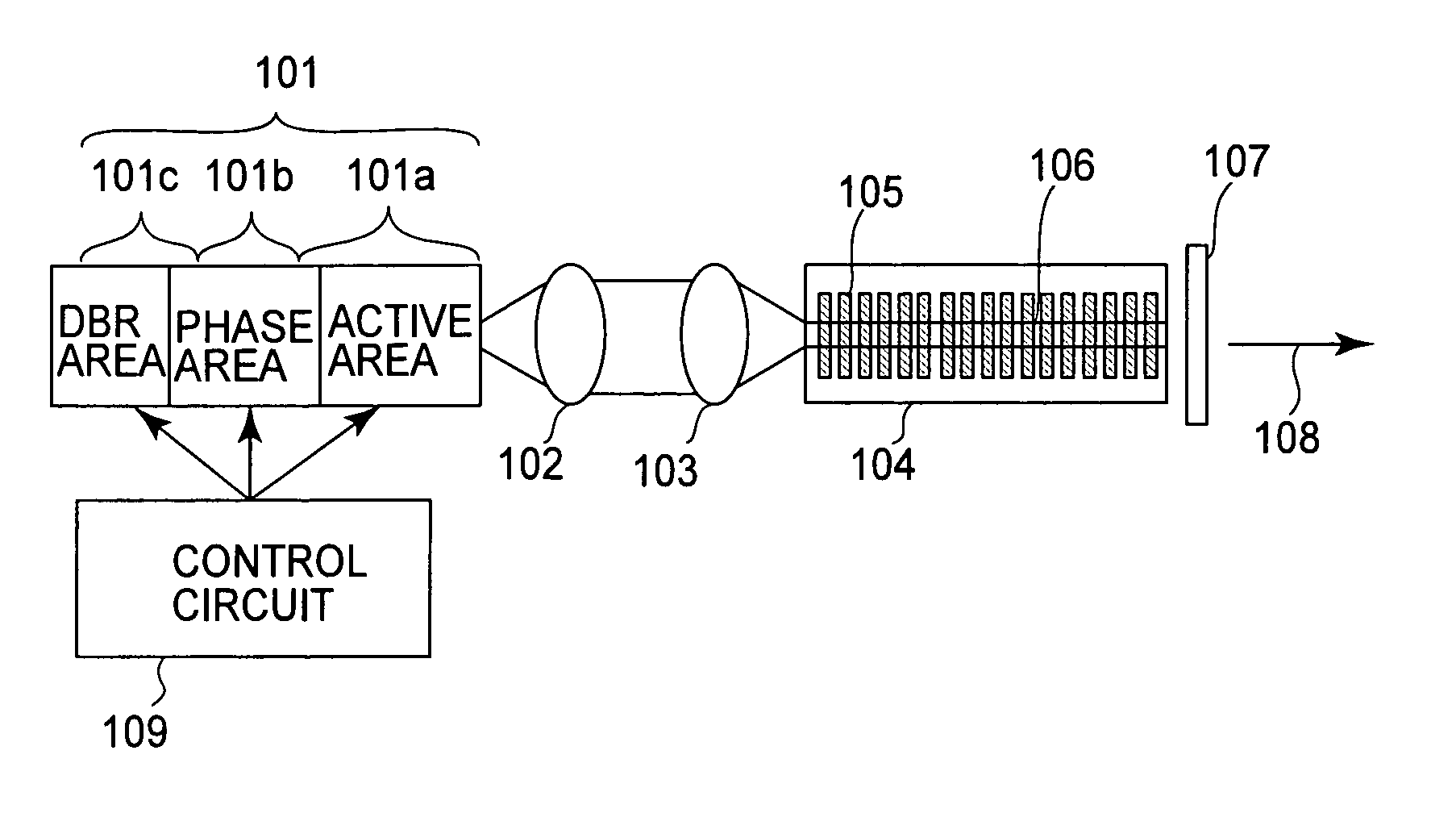

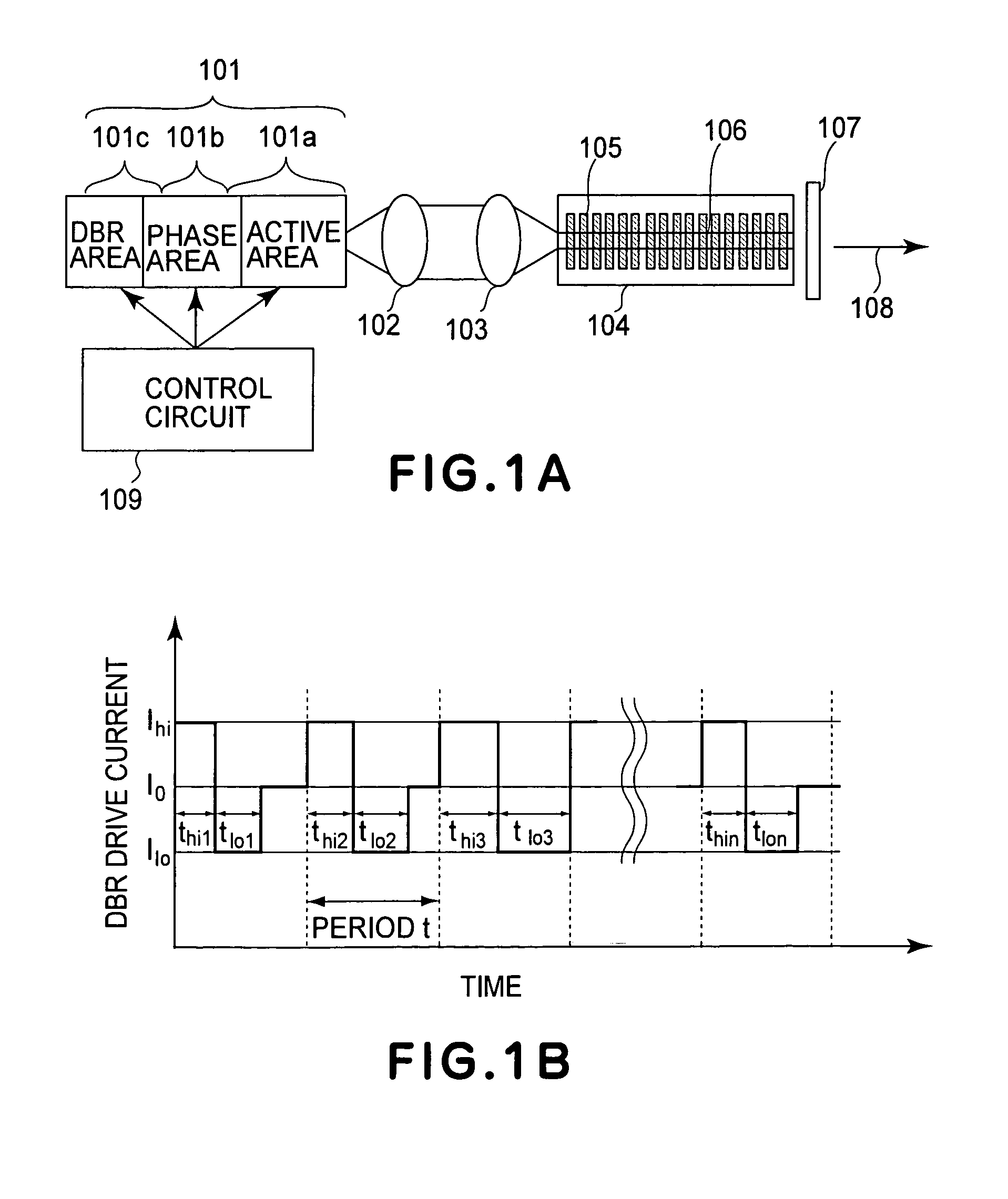

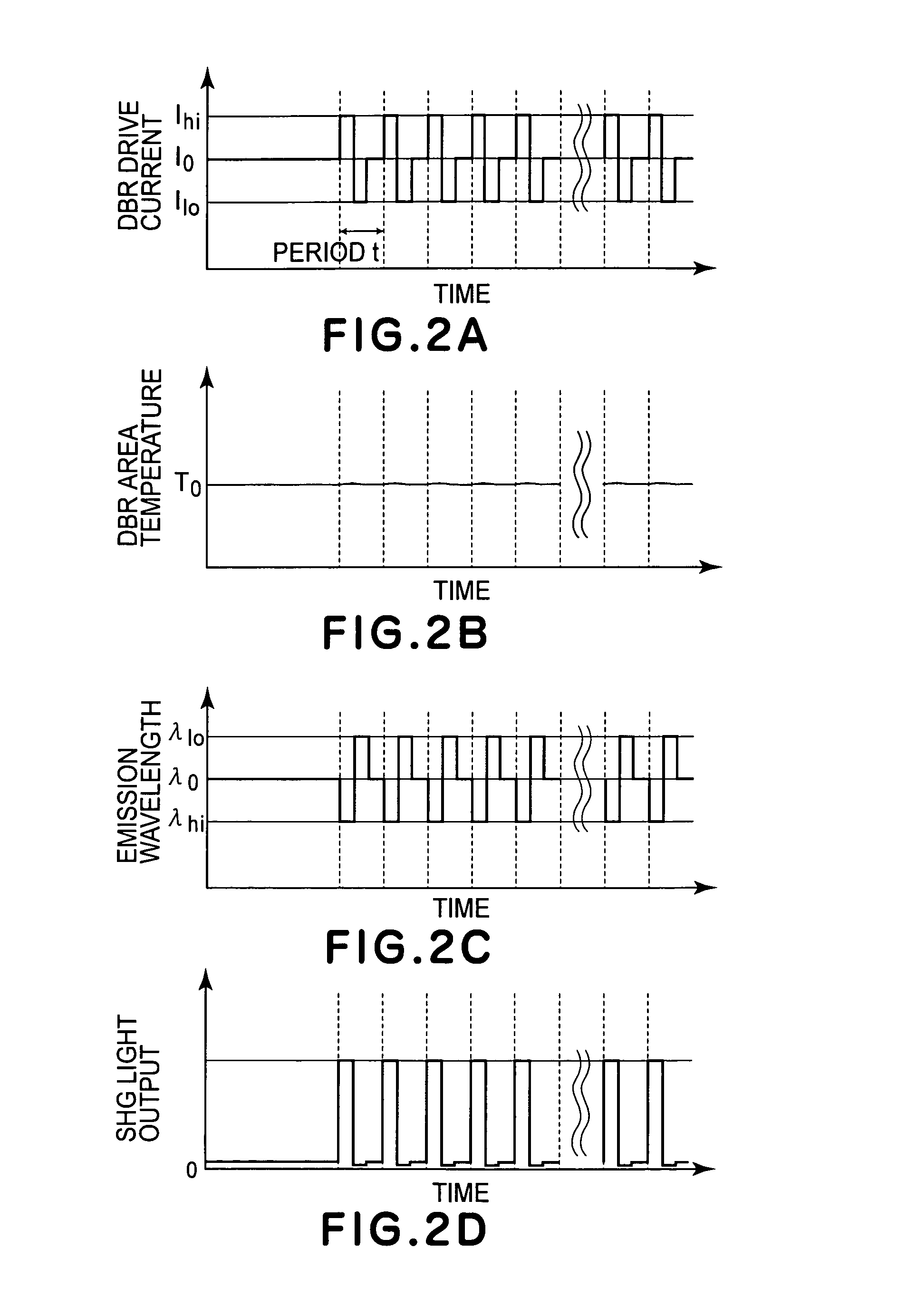

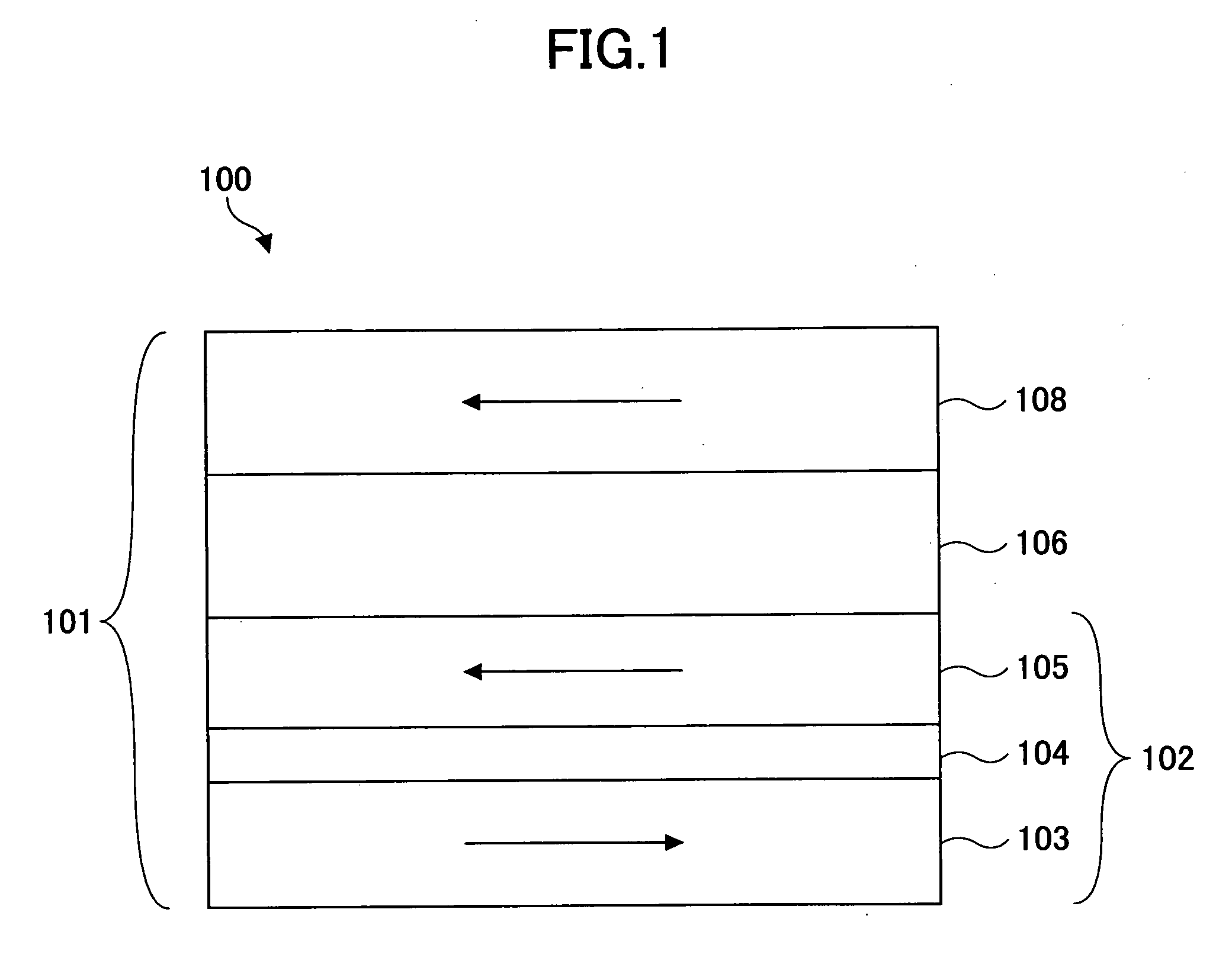

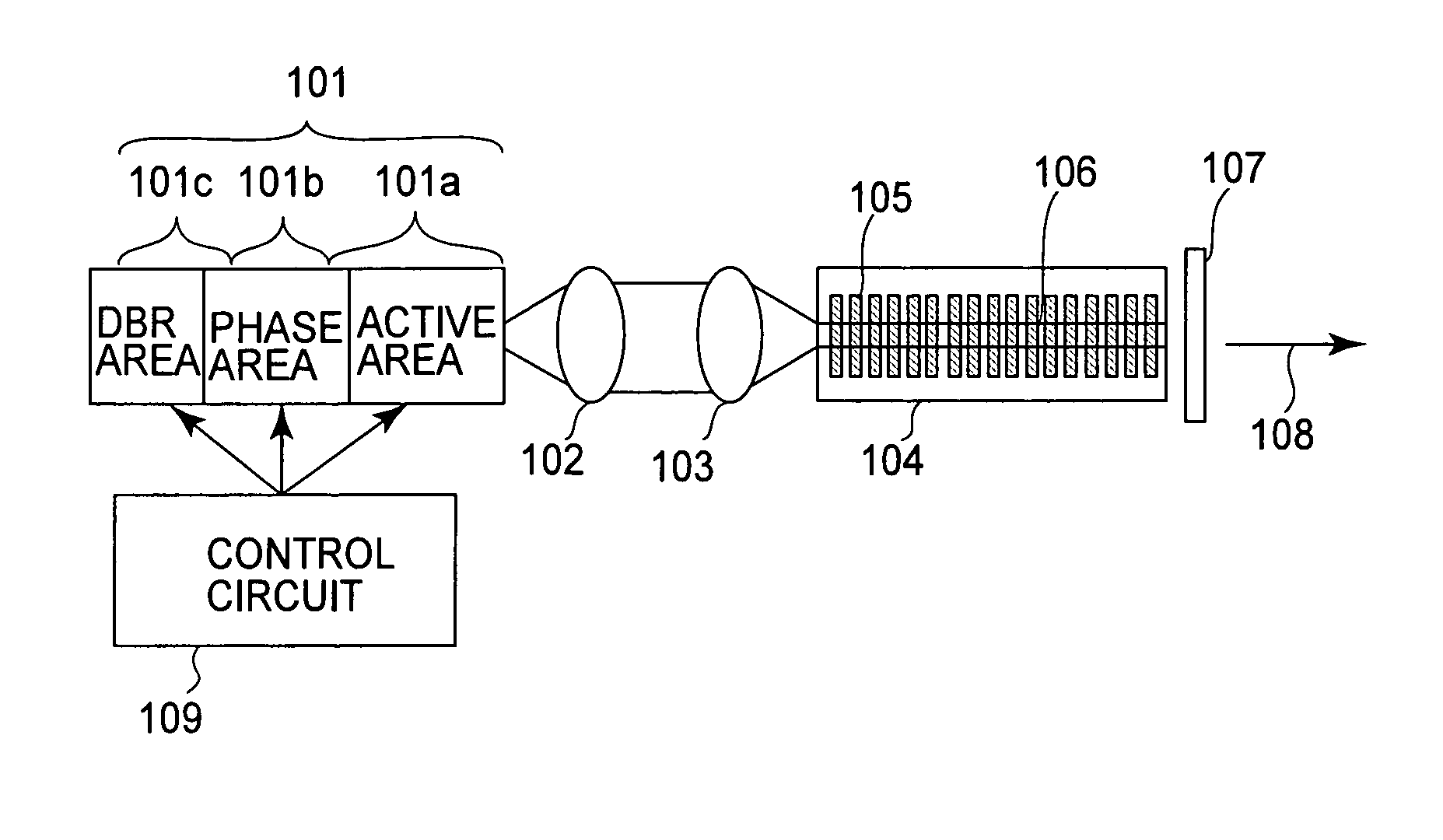

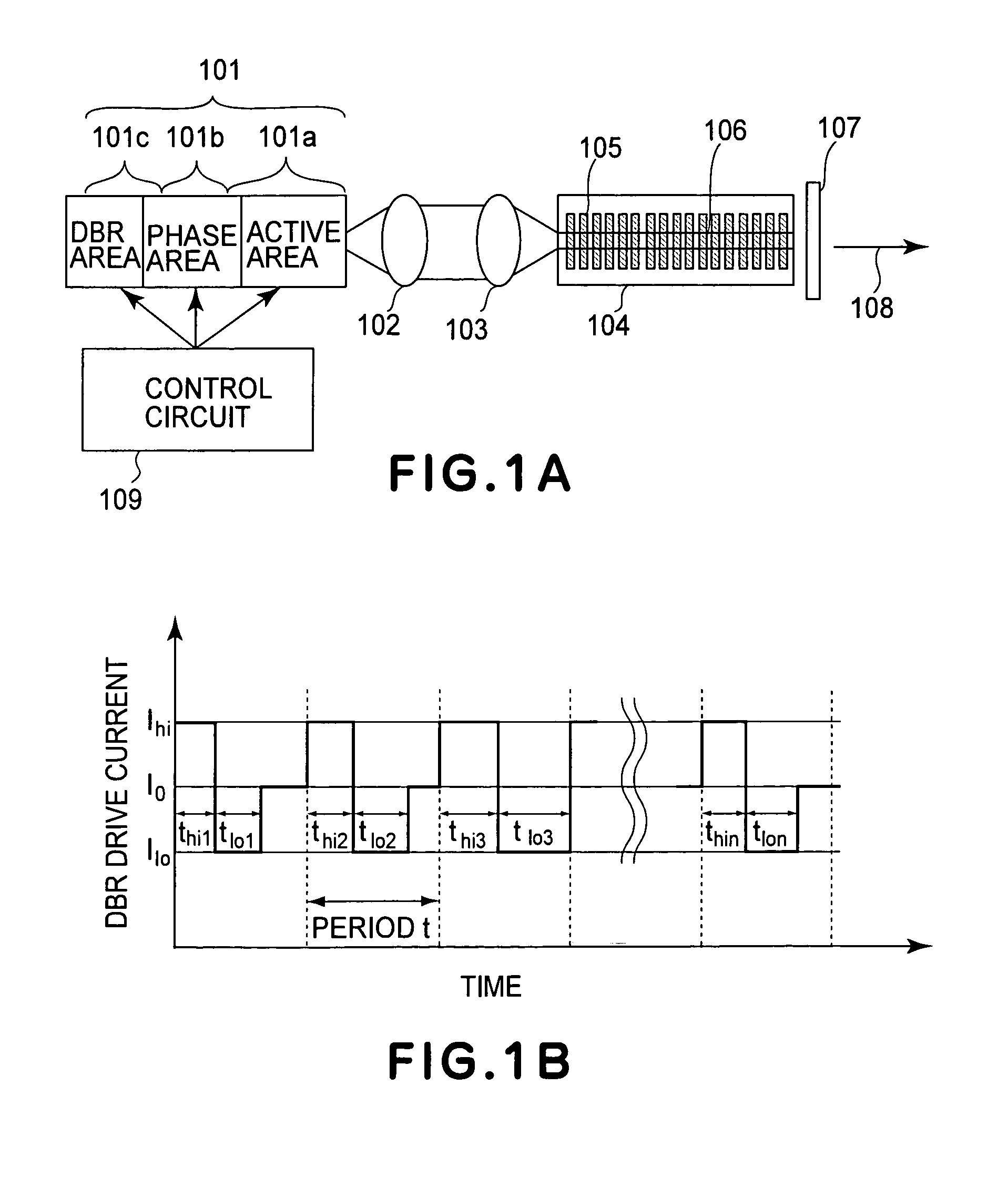

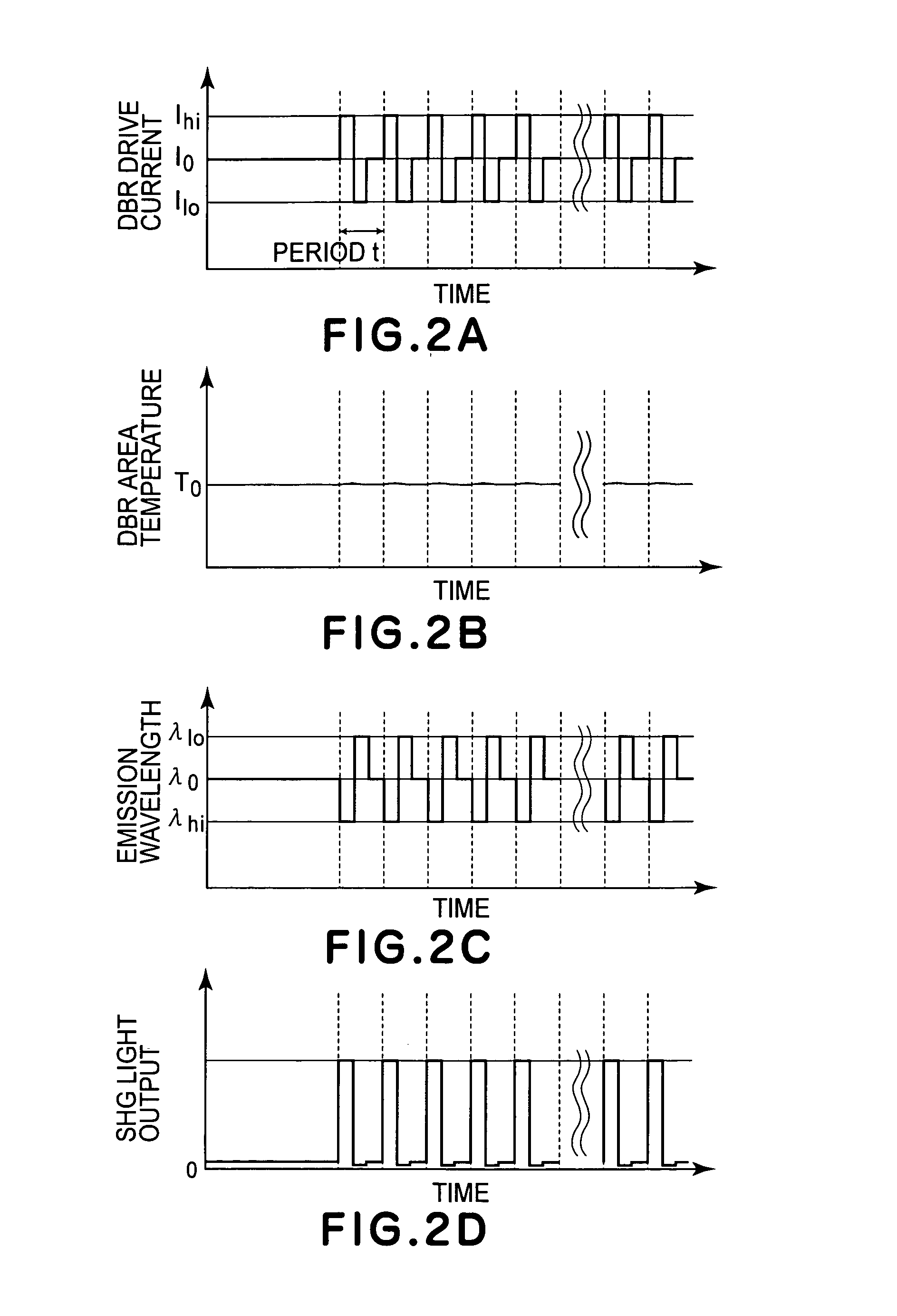

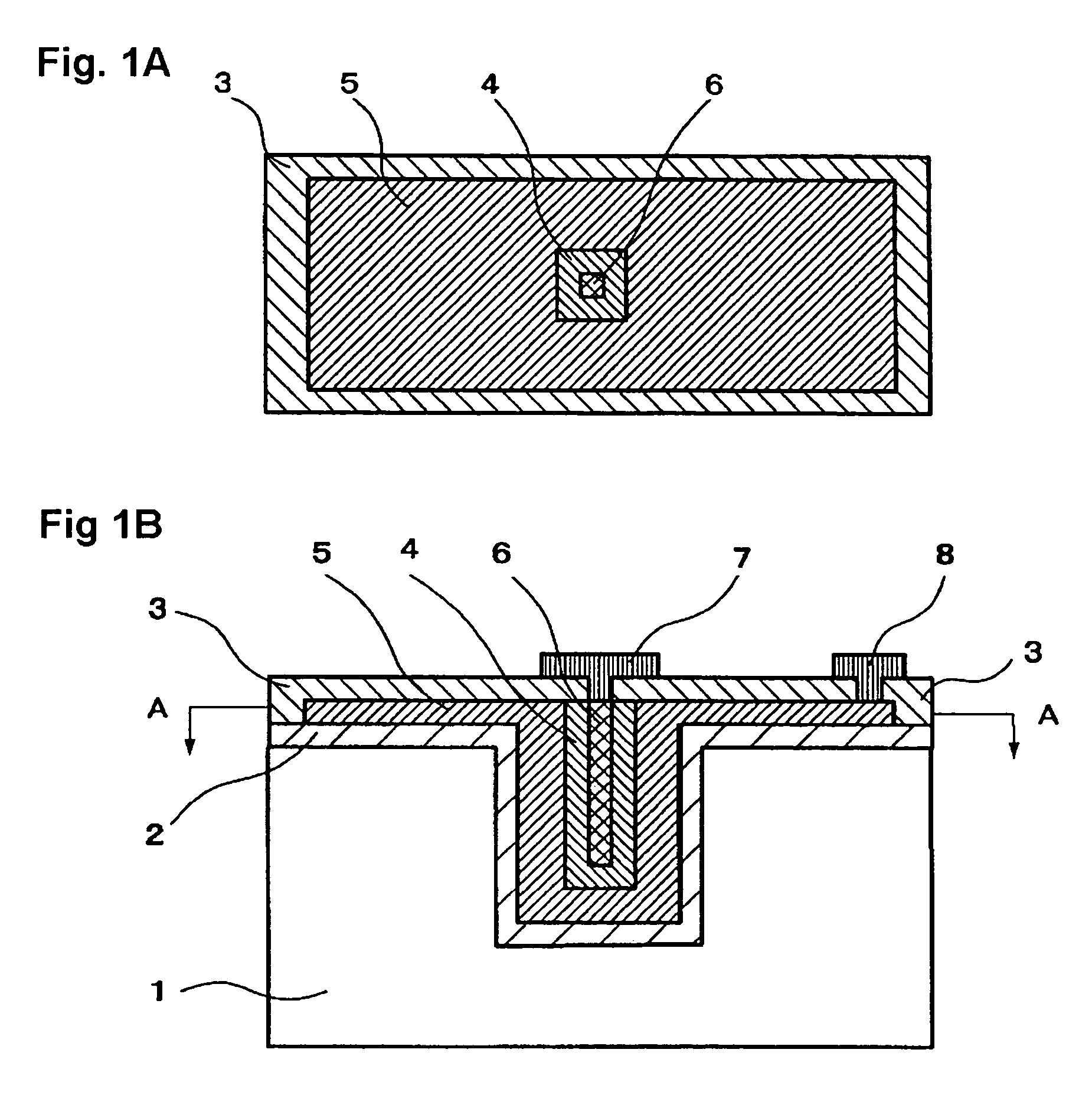

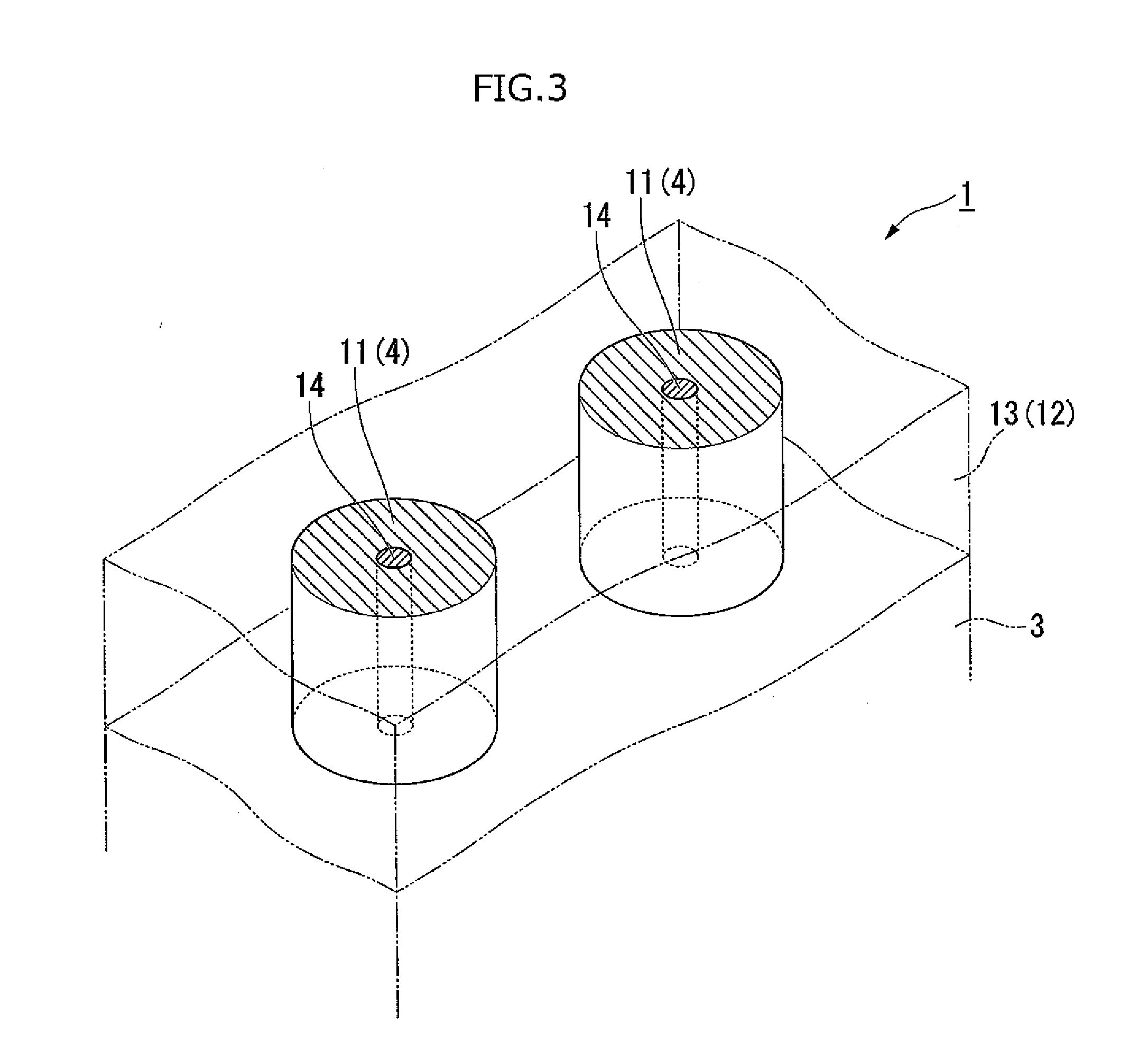

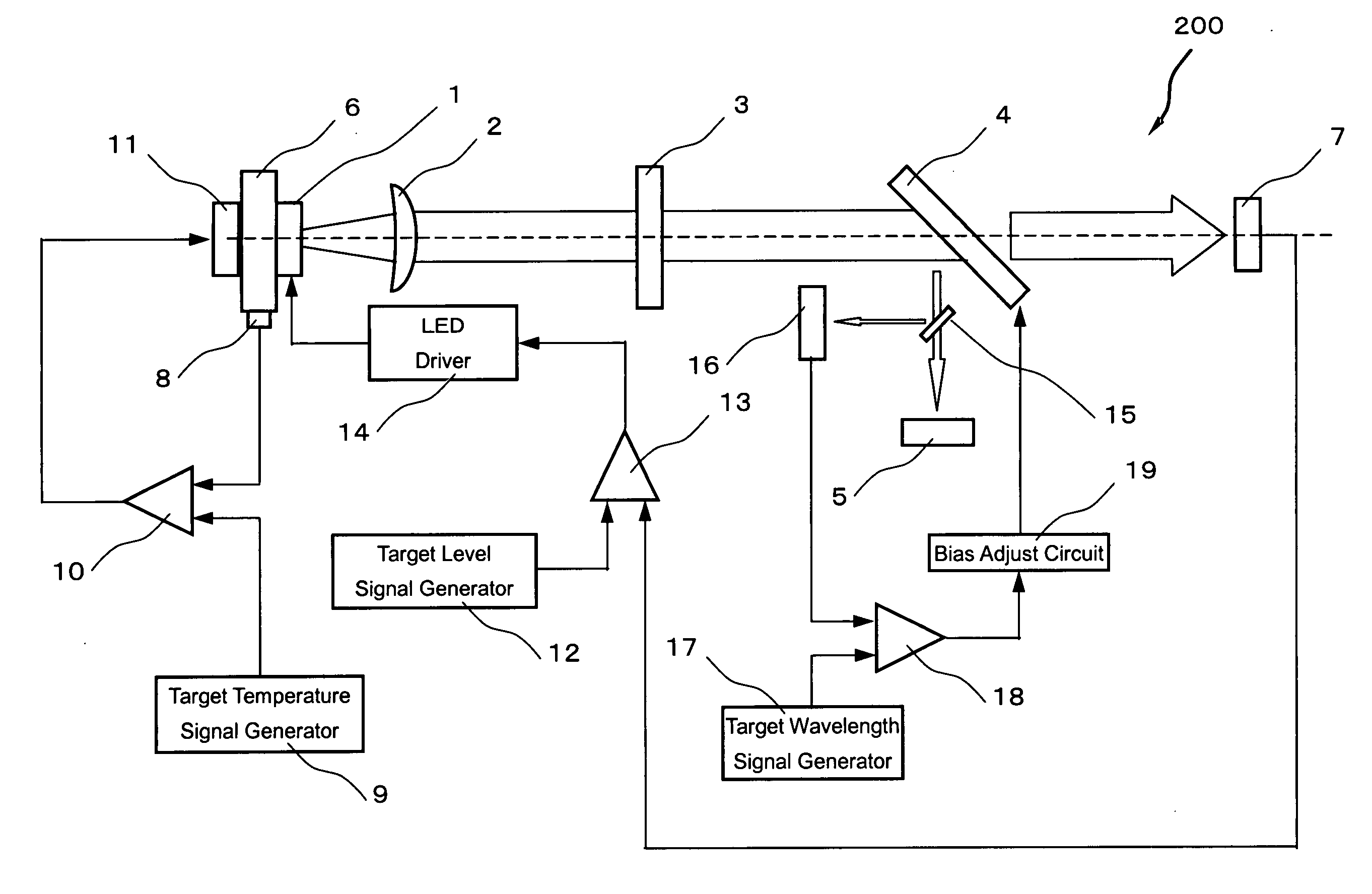

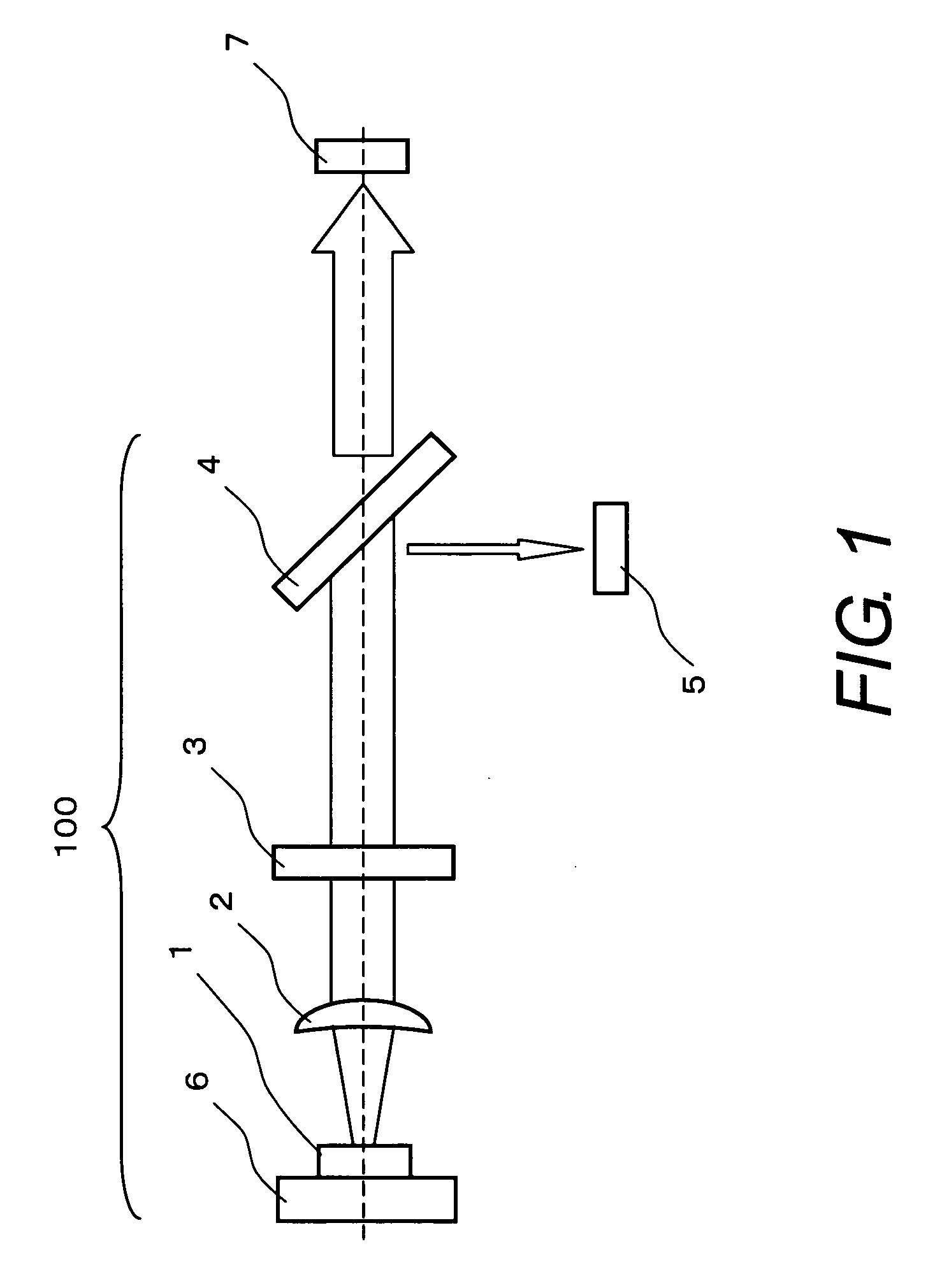

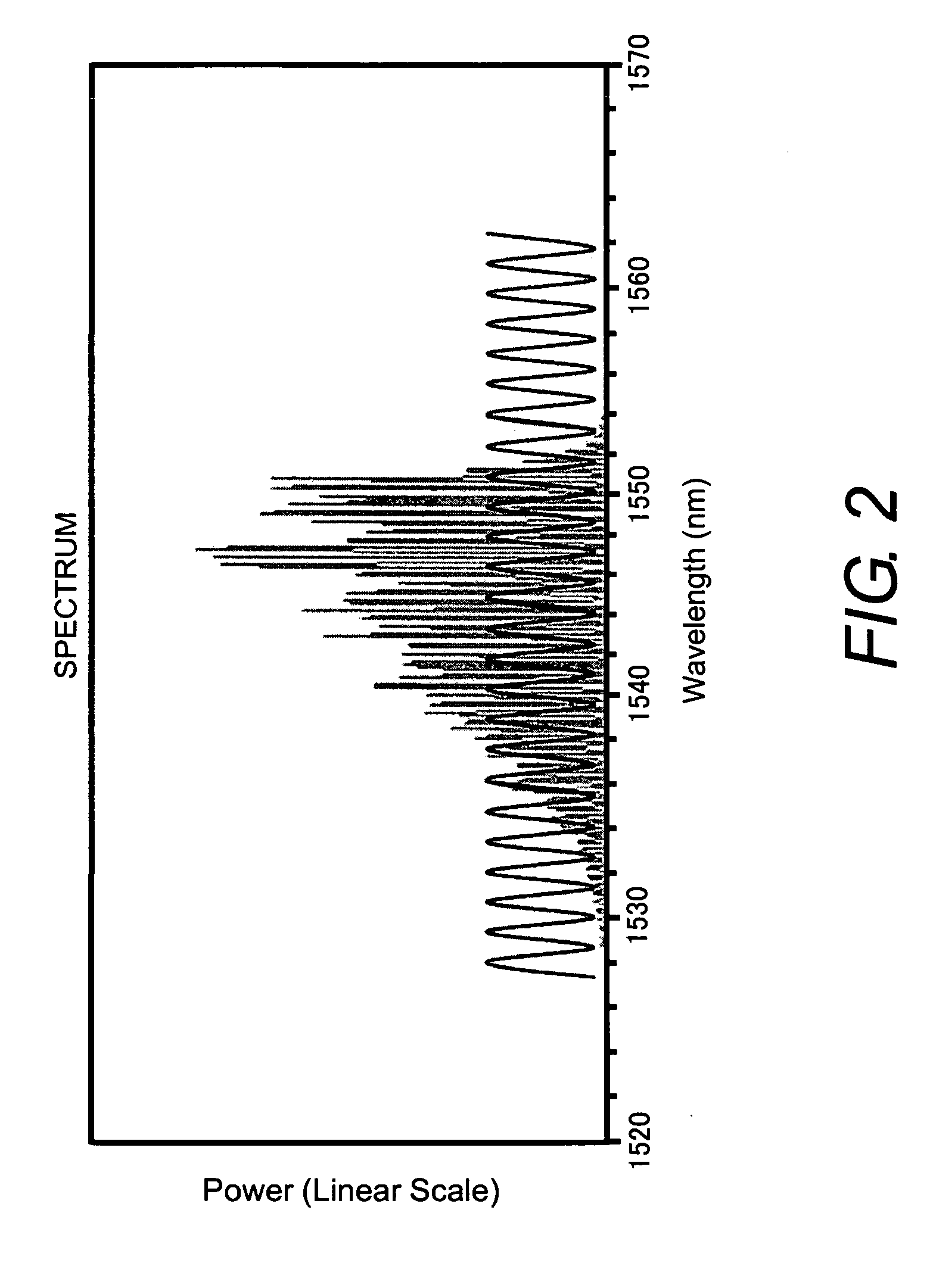

Optical wavelength converter and image forming apparatus using the same

InactiveUS7330490B2Ensure thermal stabilitySimple control methodLaser detailsSemiconductor laser optical deviceDistributed Bragg reflector laserLight energy

An optical wavelength converter includes a distributed Bragg reflector laser having an active area, a phase area, and a distributed Bragg reflector area in which a distributed Bragg reflector is formed; an optical wavelength conversion device for receiving fundamental wave light emitted from said distributed Bragg reflector laser and outputting second harmonic wave light of the fundamental wave light; and a control circuit for controlling an emission wavelength and a light output by controlling an injection current to be injected into the distributed Bragg reflector laser for each period. The control circuit controls the injection current to be injected into the distributed Bragg reflector laser while satisfying a condition for controlling a light output mode of the distributed Bragg reflector laser so that light energy to be inputted into the optical wavelength conversion device in each period is constant and satisfying a condition for injecting a current into each of an active area, a phase area, and a distributed Bragg reflector area in each of periods in a mode of constant amount of generated heat so that an injection current-emission wavelength characteristic in the distributed Bragg reflector area is constant.

Owner:CANON KK

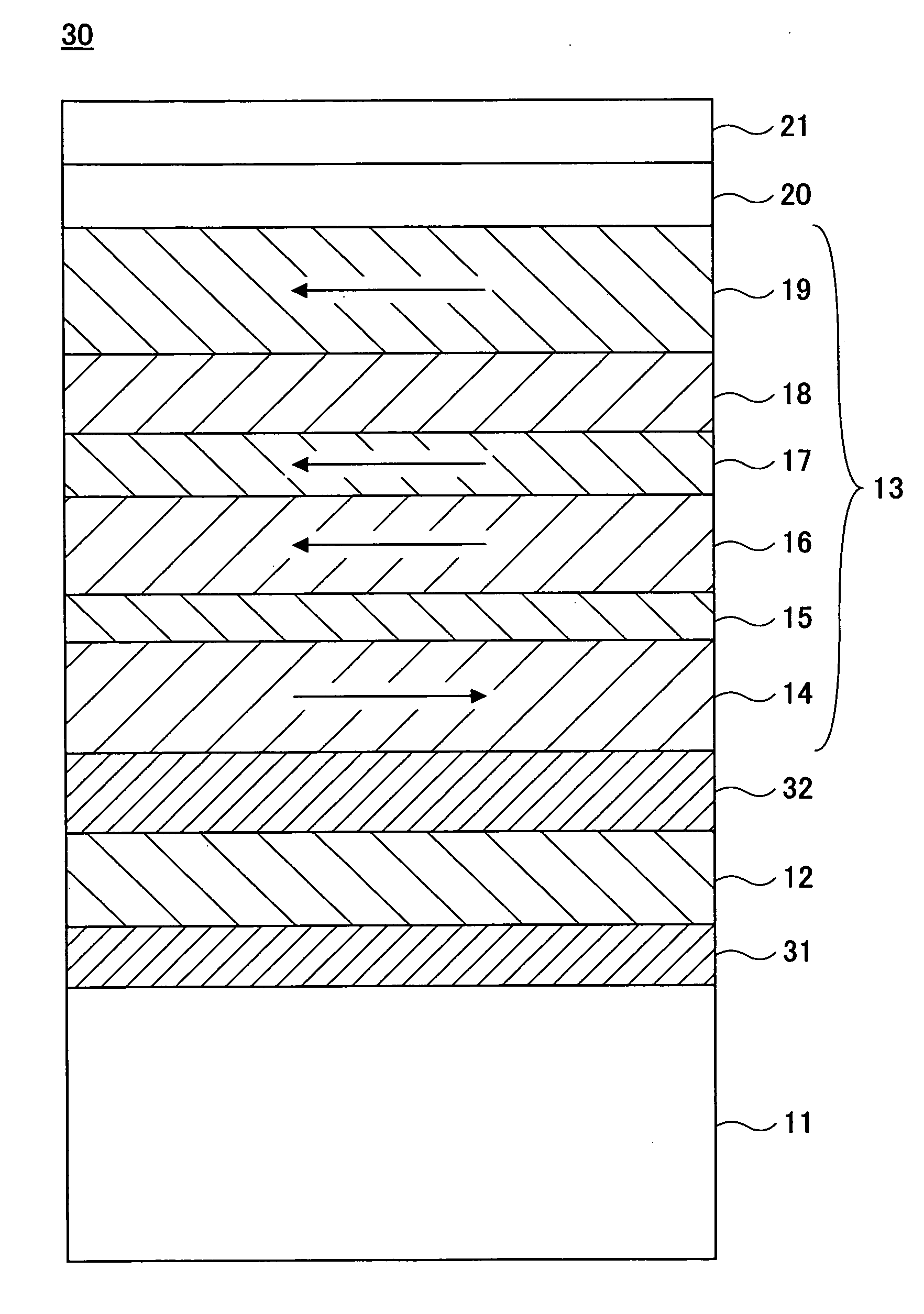

Magnetic recording medium and magnetic storage unit

InactiveUS20070275269A1Eliminate the problemGood coverageRecord information storageMagnetic recordingMagnetic storageCoupling

A magnetic recording medium is disclosed that includes a substrate; and an underlayer, a first magnetic layer, a non-magnetic coupling layer, a second magnetic layer, a third magnetic layer, a non-magnetic separation layer, and a fourth magnetic layer stacked in this order on the substrate. The first magnetic layer and the second magnetic layer are antiferromagnetically exchange-coupled, and the second magnetic layer and the third magnetic layer are ferromagnetically exchange-coupled. The third magnetic layer has an anisotropic magnetic field smaller than the anisotropic magnetic field of the second magnetic layer, and has a saturation magnetization greater than the saturation magnetization of the second magnetic layer.

Owner:SHOWA DENKO KK

Optical wavelength converter and image forming apparatus using the same

InactiveUS20070002909A1Ensure thermal stabilitySimple control methodLaser detailsSemiconductor laser optical devicePhysicsControl circuit

An optical wavelength converter includes a distributed Bragg reflector laser having an active area, a phase area, and a distributed Bragg reflector area in which a distributed Bragg reflector is formed; an optical wavelength conversion device for receiving fundamental wave light emitted from said distributed Bragg reflector laser and outputting second harmonic wave light of the fundamental wave light; and a control circuit for controlling an emission wavelength and a light output by controlling an injection current to be injected into the distributed Bragg reflector laser for each period. The control circuit controls the injection current to be injected into the distributed Bragg reflector laser while satisfying a condition for controlling a light output mode of the distributed Bragg reflector laser so that light energy to be inputted into the optical wavelength conversion device in each period is constant and satisfying a condition for injecting a current into each of an active area, a phase area, and a distributed Bragg reflector area in each of periods in a mode of constant amount of generated heat so that an injection current-emission wavelength characteristic in the distributed Bragg reflector area is constant.

Owner:CANON KK

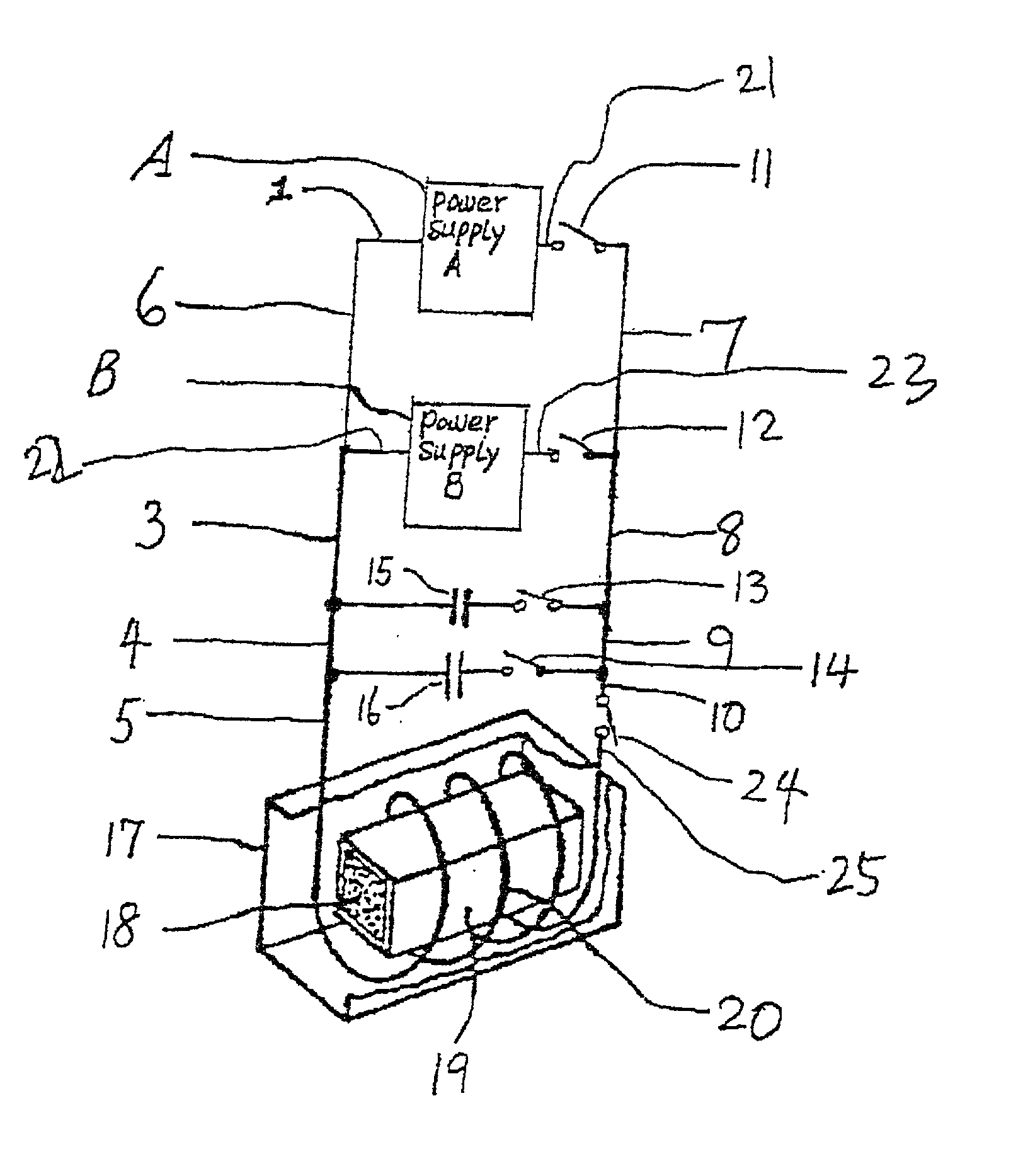

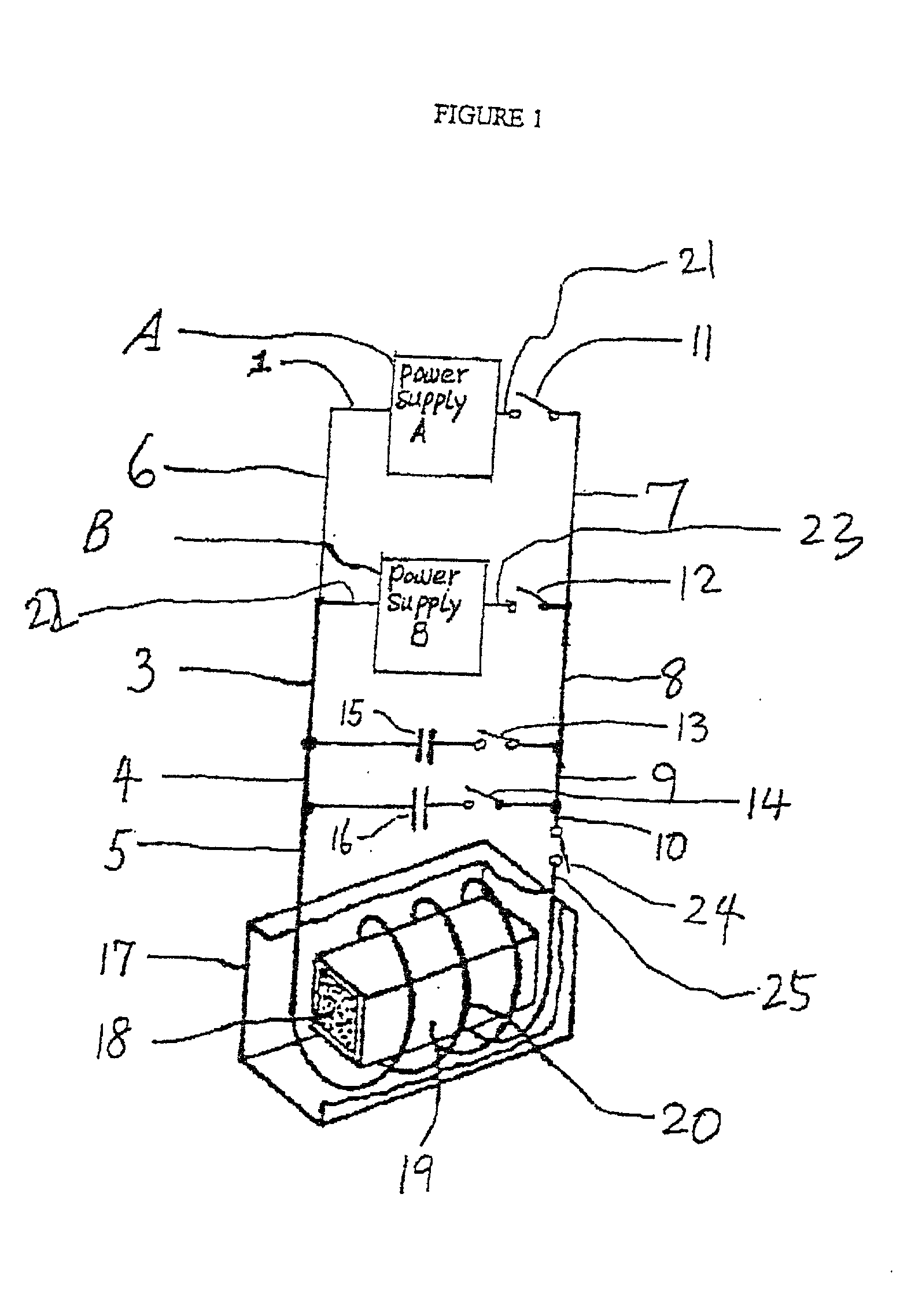

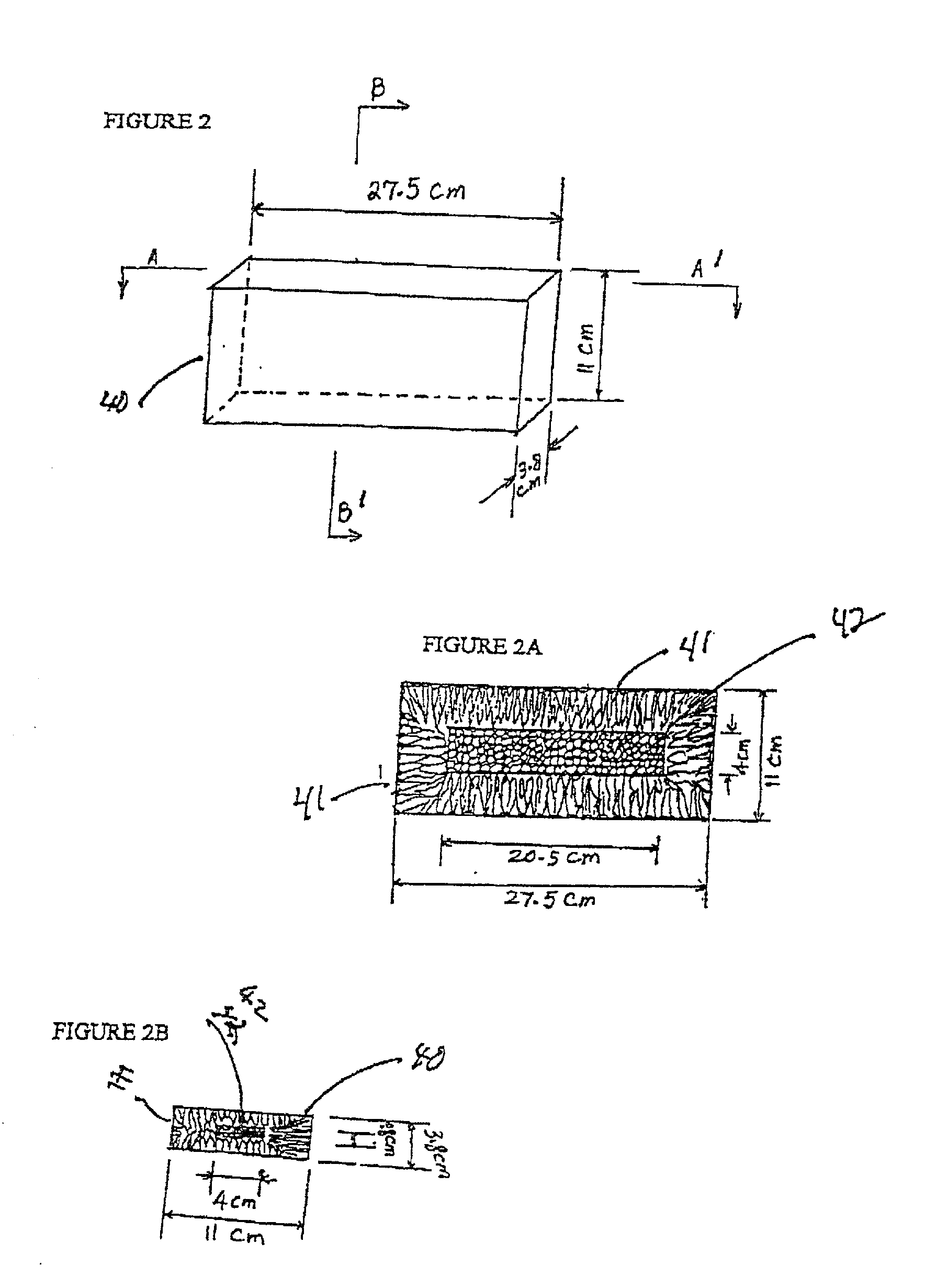

Method for producing & manufacturing density enhanced, DMC, bonded permanent magnets

InactiveUS20020036367A1Improve compatibilityHigh mechanical strengthElectrotherapyInorganic material magnetismParticulatesVoid ratio

Disclosed is a method of manufacturing density enhanced, bonded permanent magnets having the following properties: a. maximum energy product (BH)max up to 40% greater than that of traditional, mechanical, compacted, bonded permanent magnets, b. (BH)max up to 99% of theoretical, c. void ratio approaching 0 volume %, and d. use temperature from room temperature up to about 550° C., said method comprising the step of compacting a mixture of permanent magnet particulates and a binder using pulsed electromagnetic forces, where each pulse has a pulse time less than the thermal time constant of the permanent magnet particulate, and wherein said compaction is achieved without adversely affecting the binder or the structure of the permanent magnet particulates.

Owner:ELECTRON ENERGY CORP

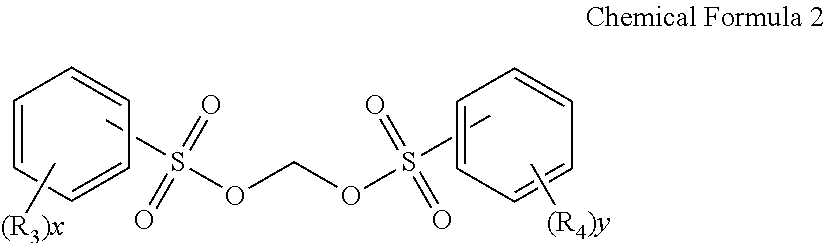

Rechargeable lithium ion battery

ActiveUS20150125742A1Ensure thermal stabilityExcellent battery characteristicsCell electrodesSecondary cellsLithium compoundLithium-ion battery

The rechargeable lithium ion battery includes a positive active material including a lithium compound, a non-aqueous electrolyte including at least one disulfonate ester selected from a cyclic disulfonate ester represented by Chemical Formula 1 and a linear disulfonate ester represented by Chemical Formula 2, and includes at least one carbonate having an unsaturated bond selected from vinylene carbonate and vinylethylene carbonate. The non-aqueous electrolyte may include about 0.05 wt % to about 0.5 wt % of the disulfonate ester based on the total weight of the non-aqueous electrolyte, and about 0.2 wt % to about 1.5 wt % of the carbonate having the unsaturated bond based on the total weight of the non-aqueous electrolyte.

Owner:SAMSUNG SDI CO LTD

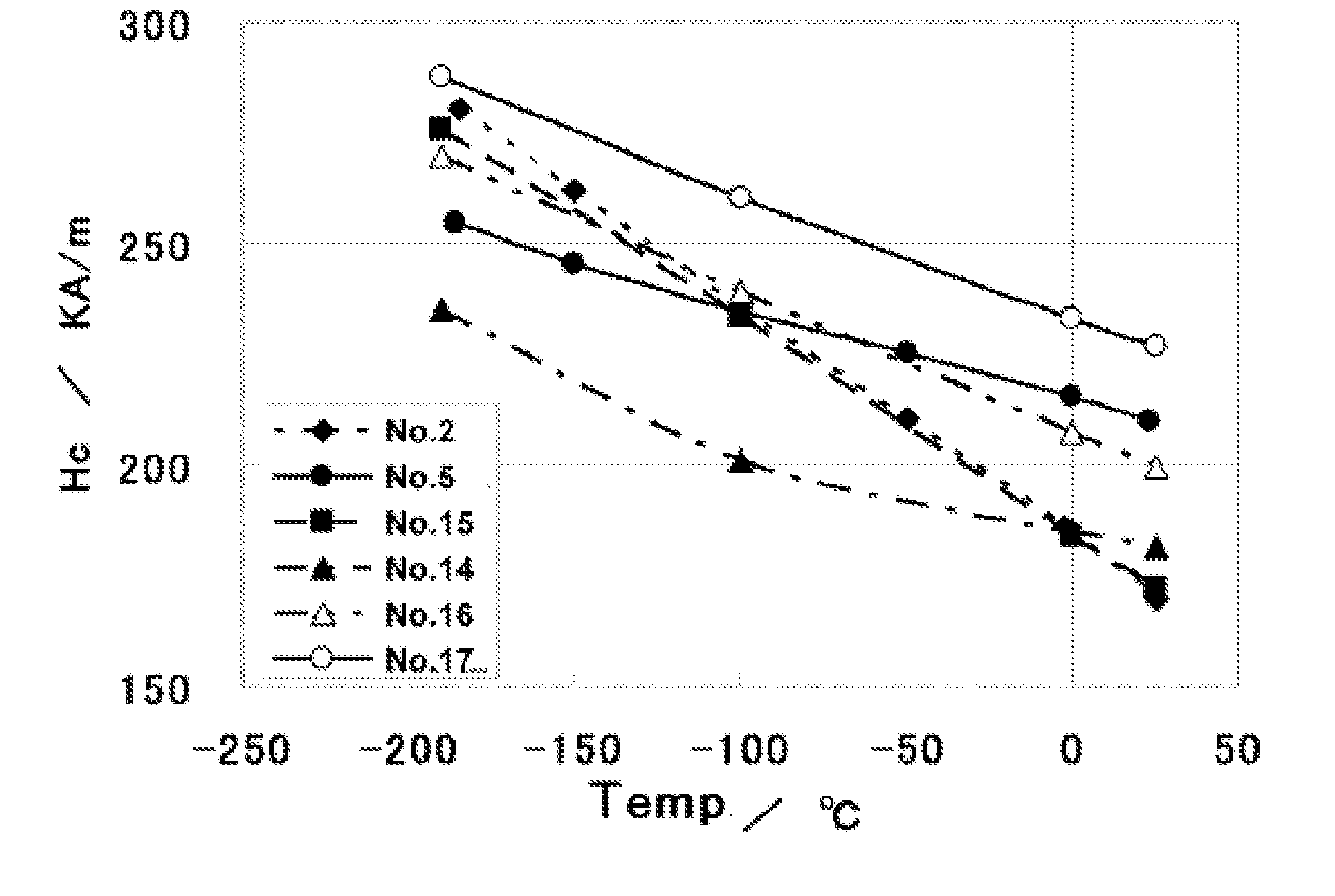

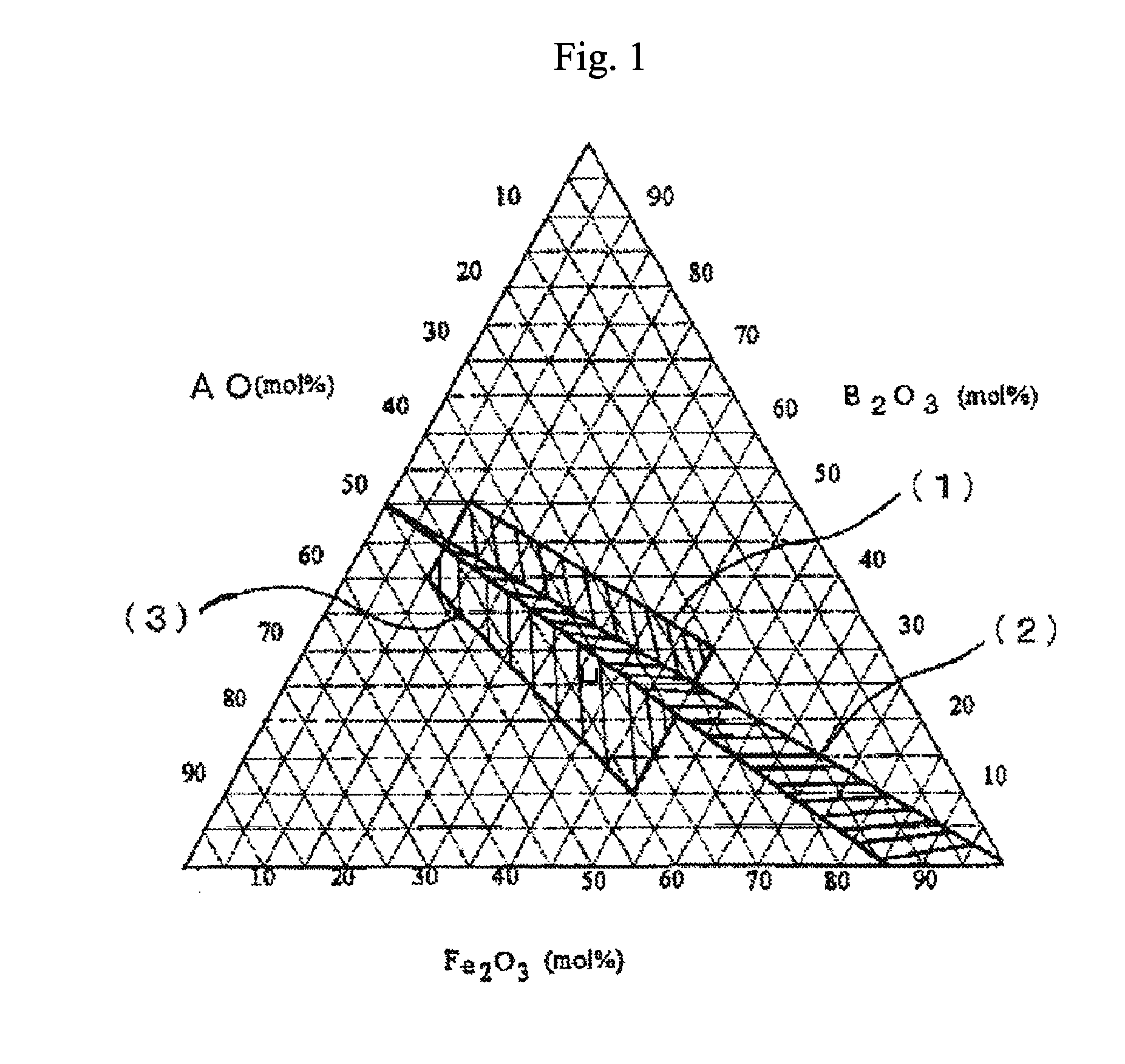

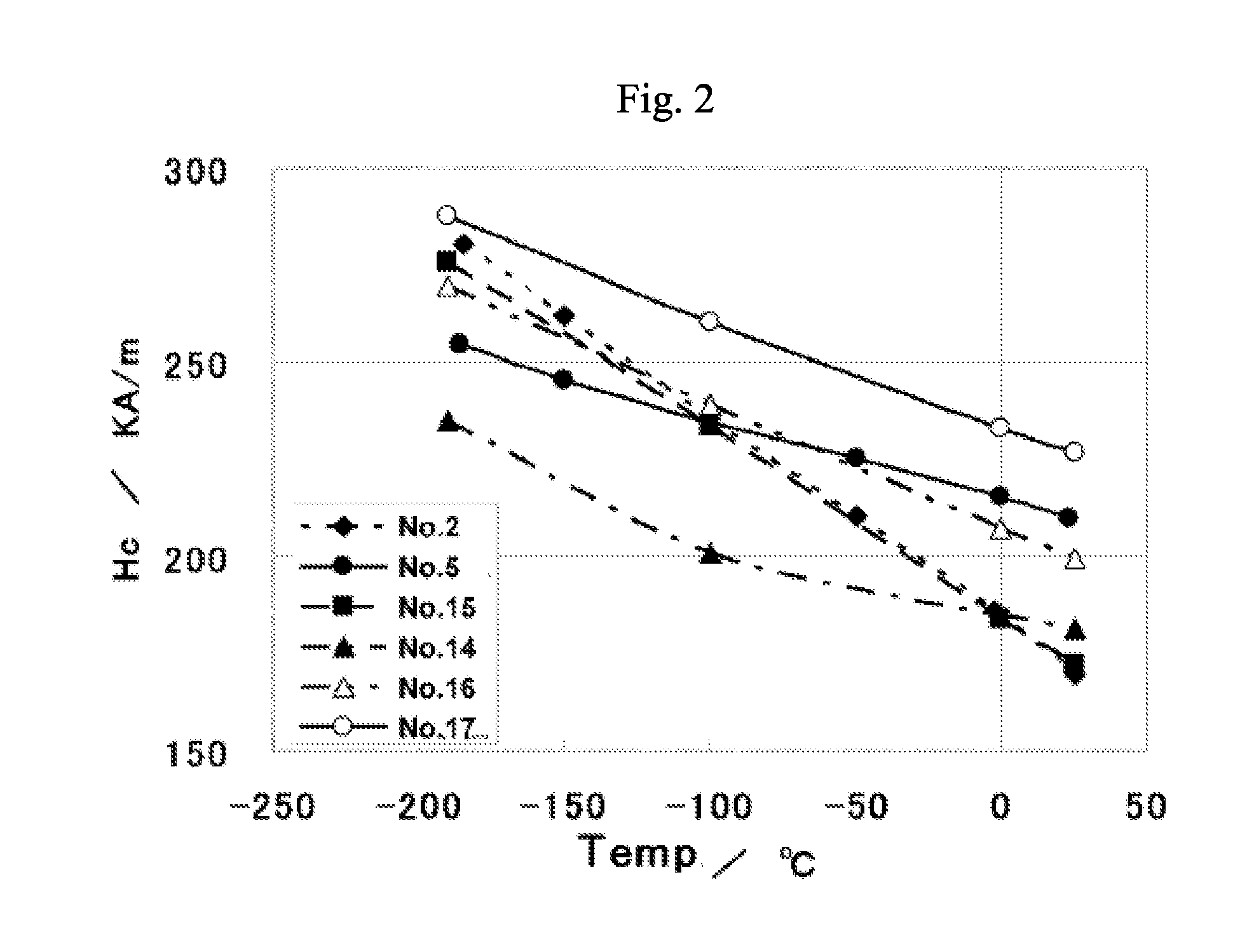

Magnetic recording powder and method of manufacturing the same, and magnetic recording medium

InactiveUS20120251844A1Improve recording densityImprove stabilityMagnetic materials for record carriersRecord information storageBiological activationMaterials science

An aspect of the present invention relates to magnetic recording powder, which comprises hexagonal ferrite magnetic particles, the hexagonal ferrite magnetic particle comprising 0.5 to 5.0 atomic percent of an Fe substitution element in the form of just a divalent element per 100 atomic percent of a content of Fe and having an activation volume ranging from 1,200 to 1,800 nm3.

Owner:FUJIFILM CORP

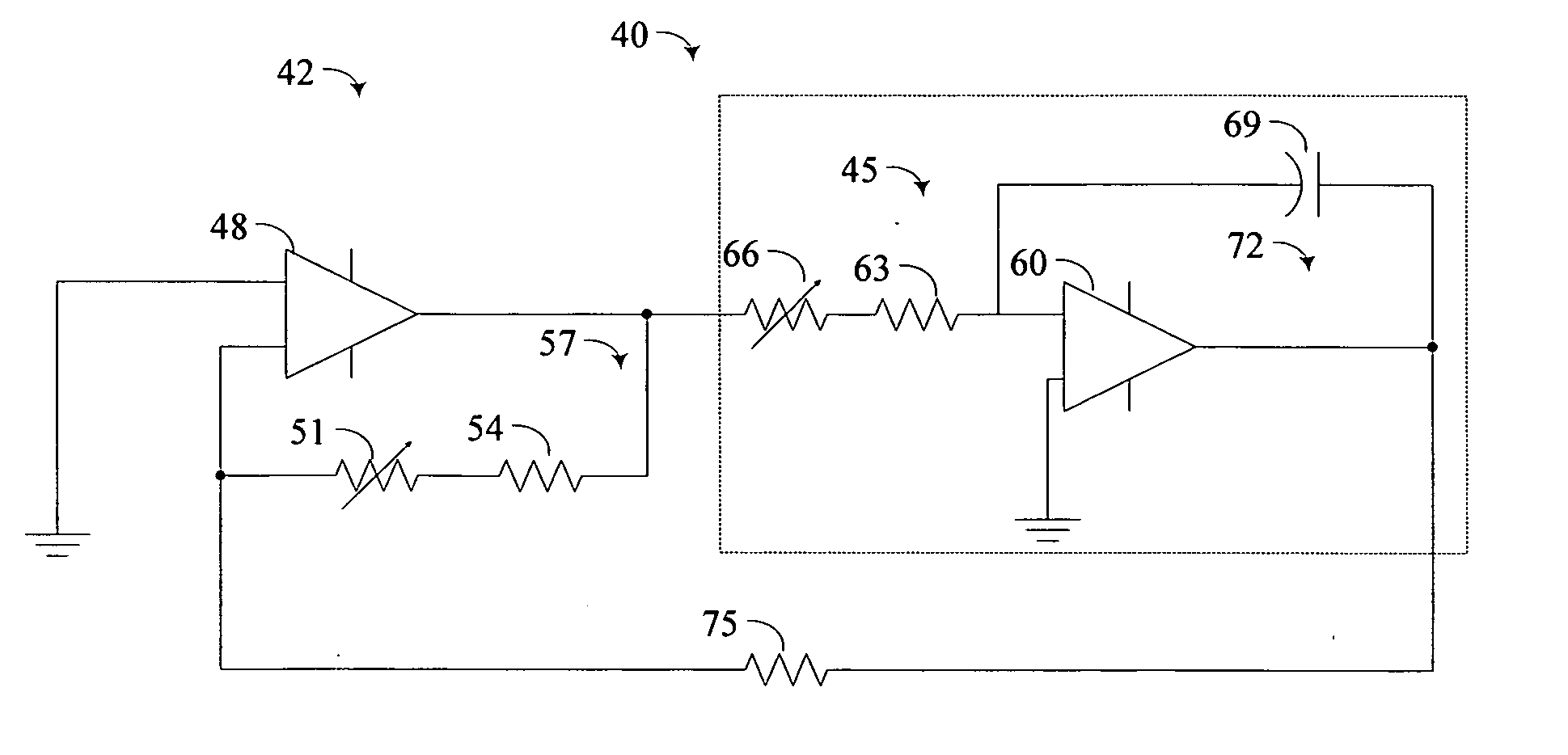

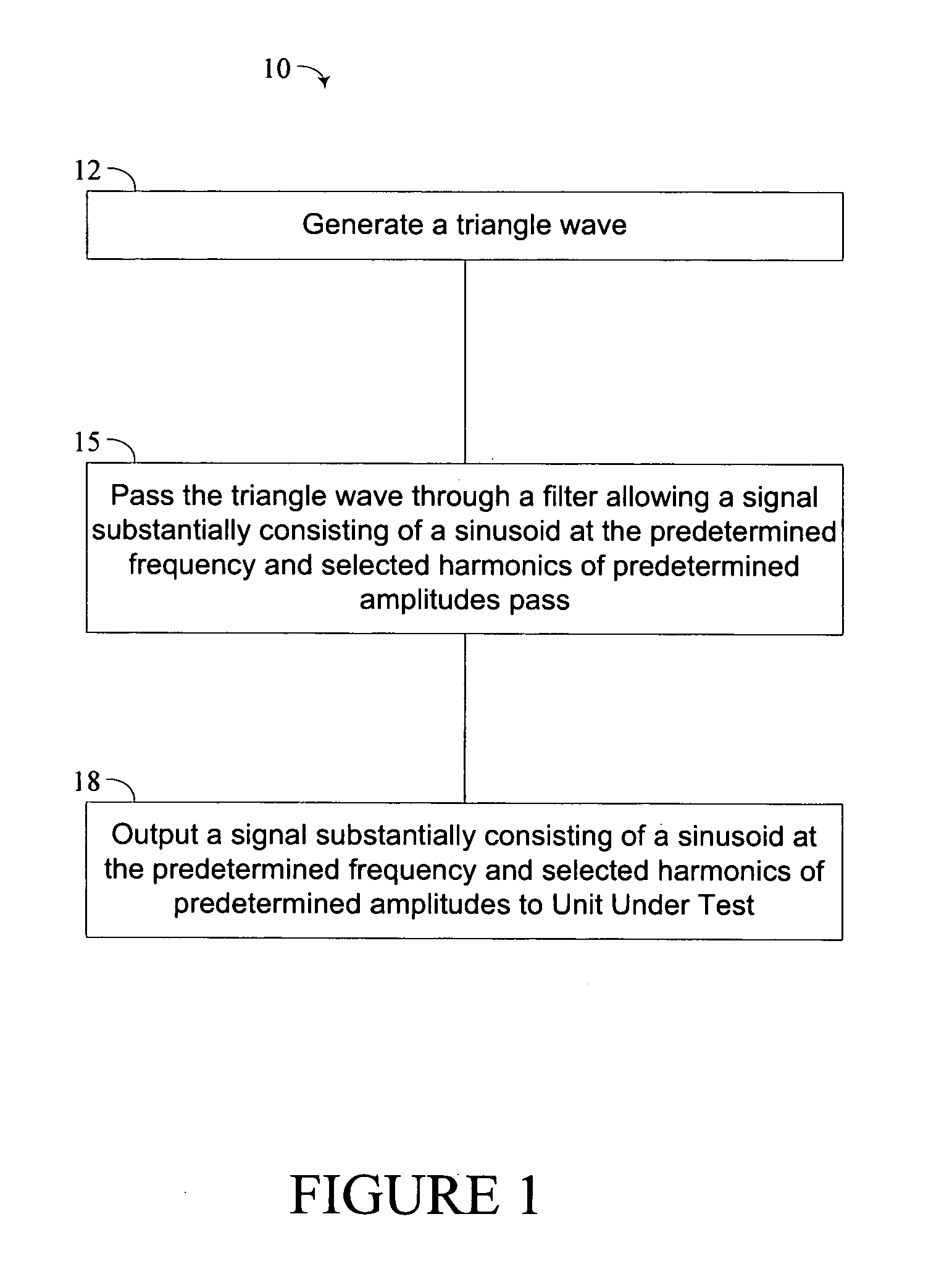

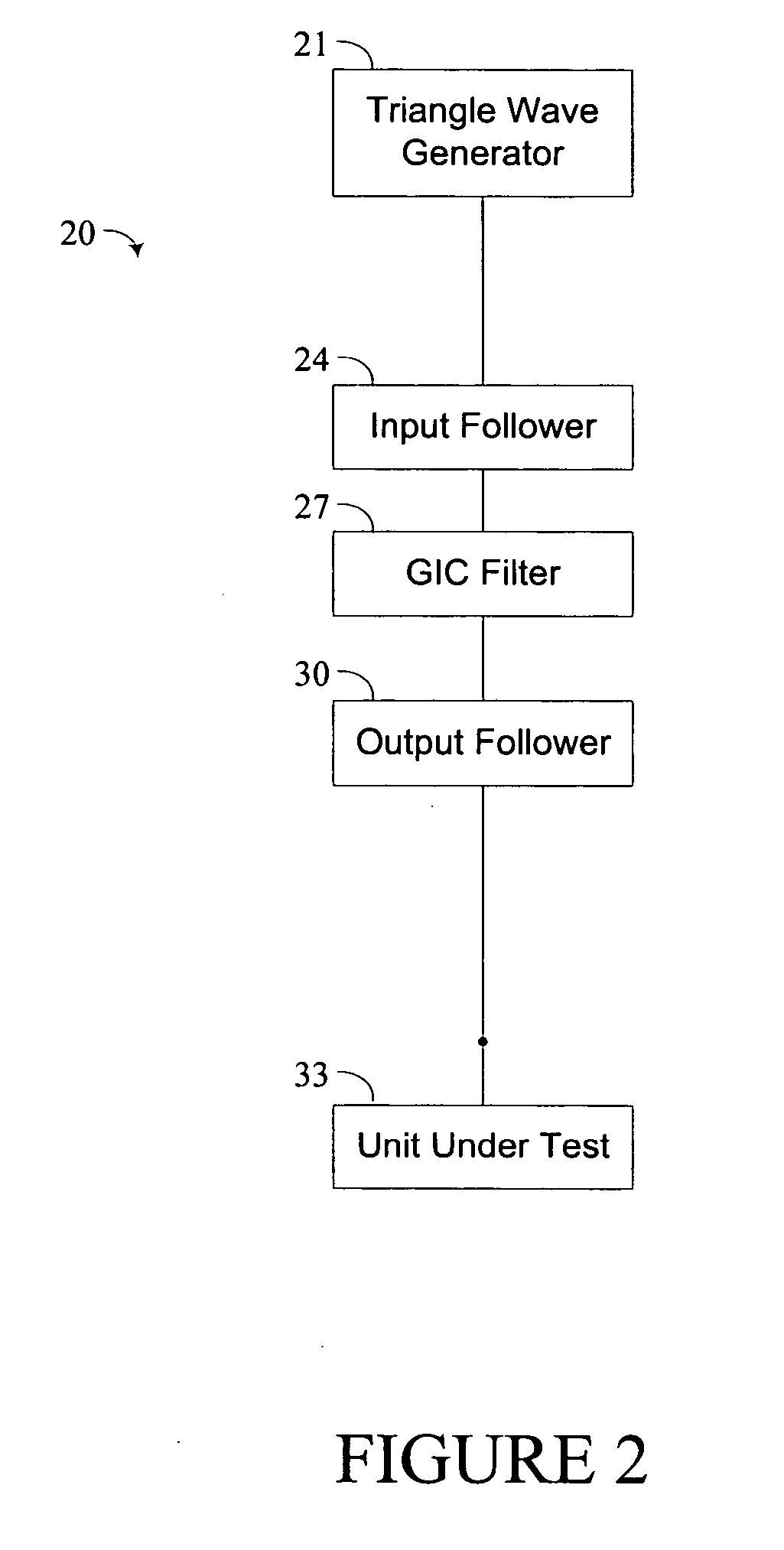

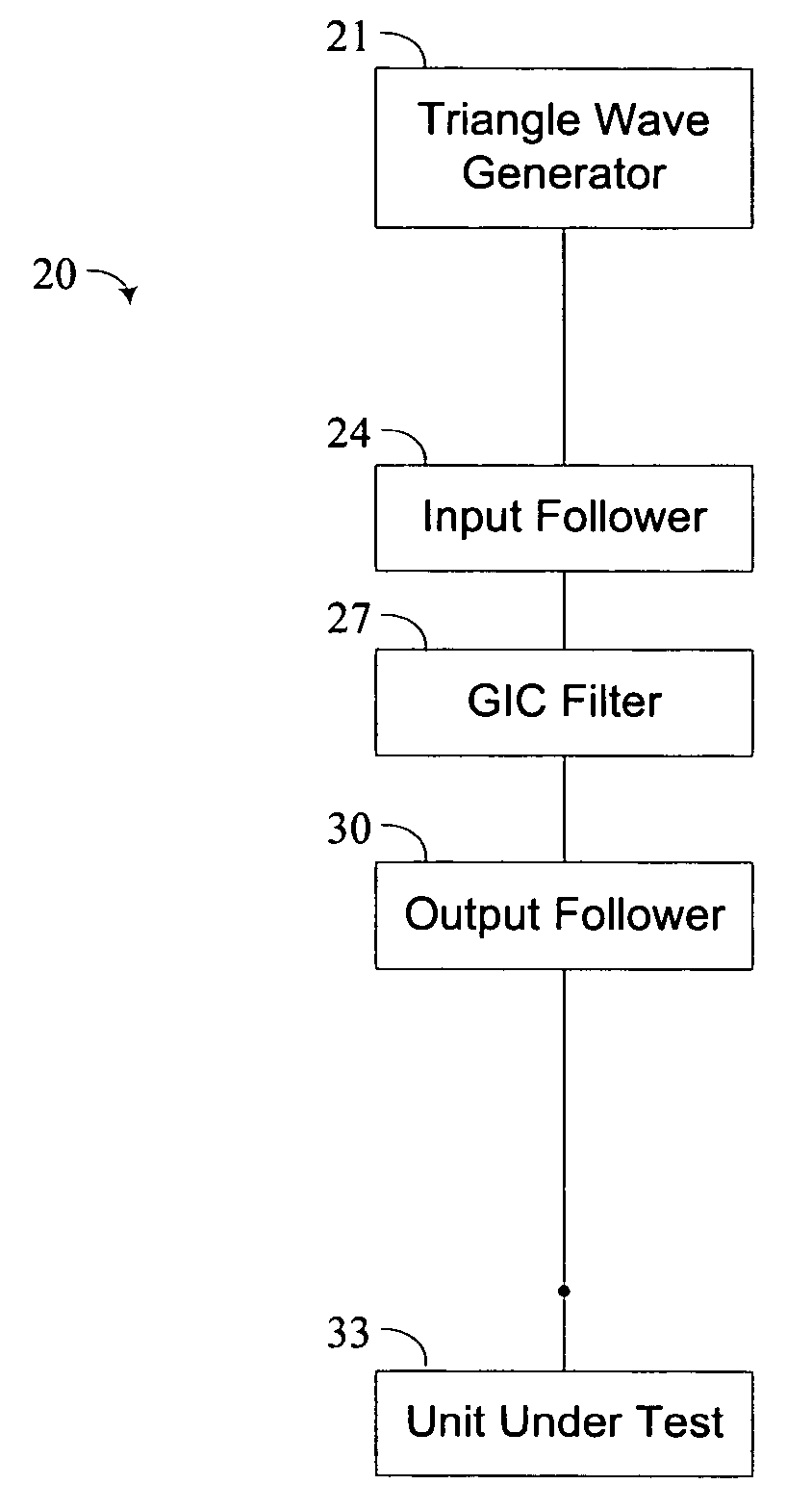

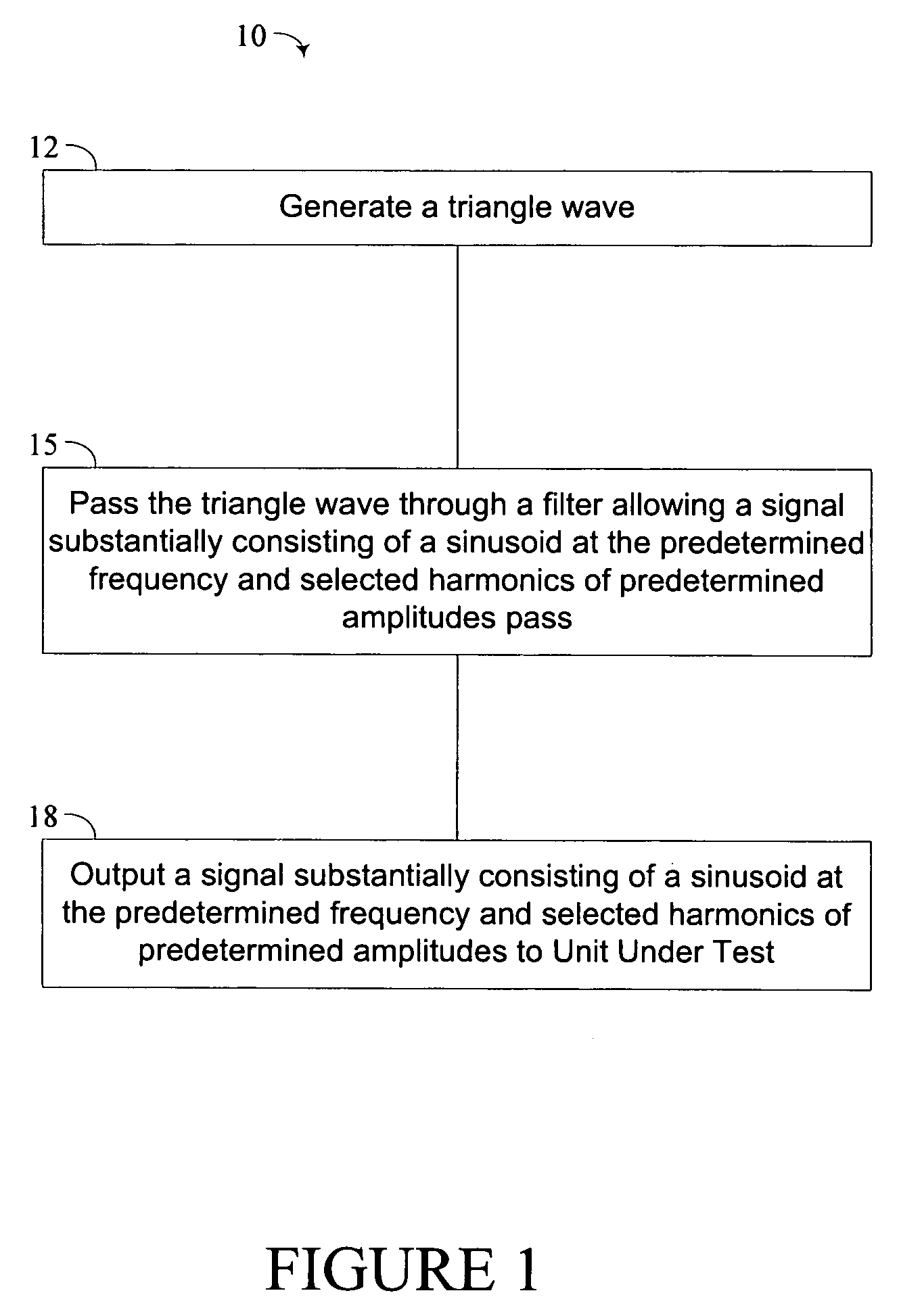

Total harmonic distortion standard

InactiveUS20050189969A1Stable and reliableReliable signalPulse generatorOscillations generatorsTotal harmonic distortionTriangle wave

Embodiments of the invention provide a method and an apparatus for generating a total harmonic distortion reference signal. A triangle wave having a predetermined frequency and a predetermined amplitude is generated. The triangle wave is filtered to produce a signal substantially consisting of a sinusoid at the predetermined frequency and selected harmonics of predetermined amplitudes.

Owner:THE BOEING CO

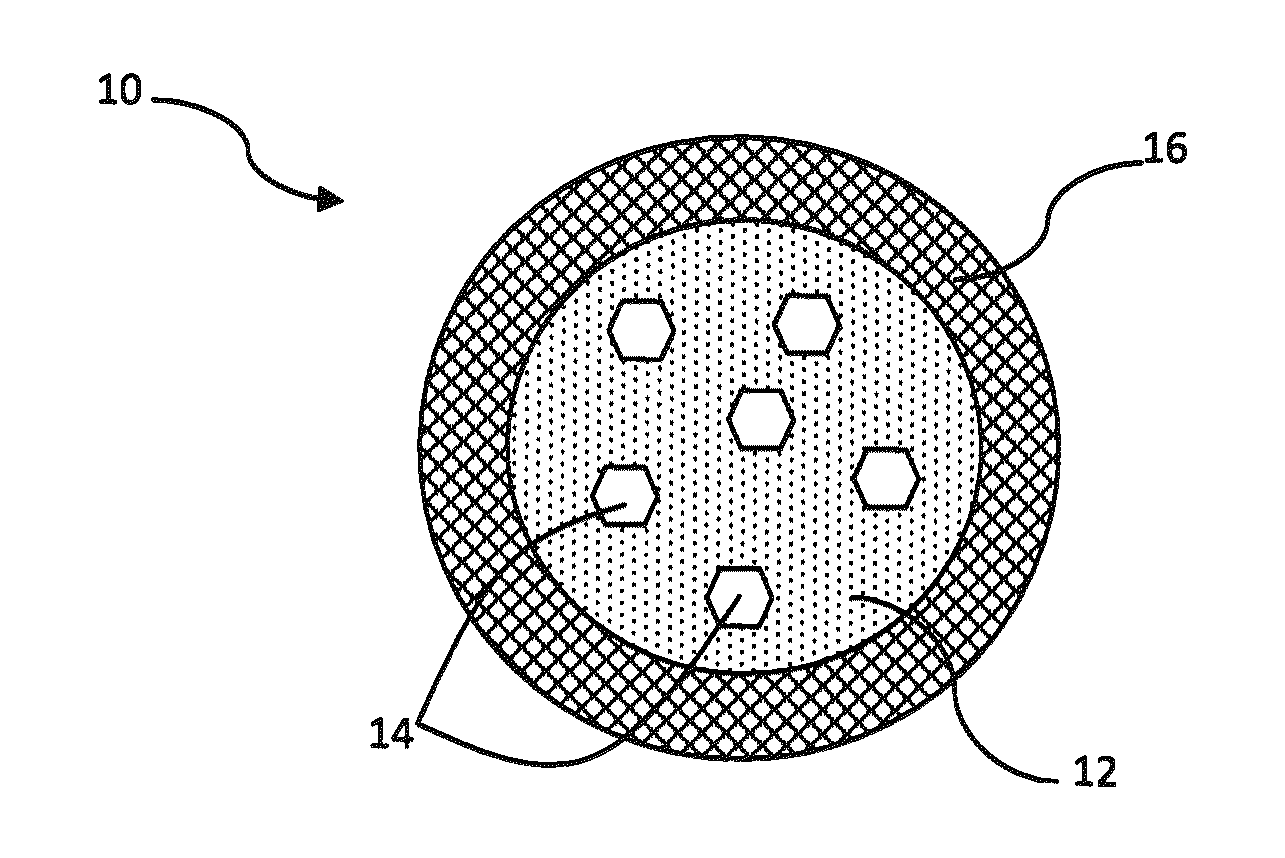

Composite detergent granules and laundry compositions comprising the same

InactiveUS20150291913A1Maximizing water hardness toleranceImprove protectionInorganic/elemental detergent compounding agentsAnionic surface-active compoundsSulfonateActive agent

This relates to a composite detergent granule having a core particle covered by a coating layer, as well as a granular detergent composition containing the same. The core particle contains a mixture of silica, a C10-C20 linear alkyl benzene sulphonate (LAS) and optionally a C10-C20 linear or branched alkylethoxy sulfate (AES). The coating layer contains AES. Such a composite detergent granule is characterized by high surfactant activity, improved water hardness tolerance, fast surfactant release, and superior dissolution profile.

Owner:THE PROCTER & GAMBLE COMPANY

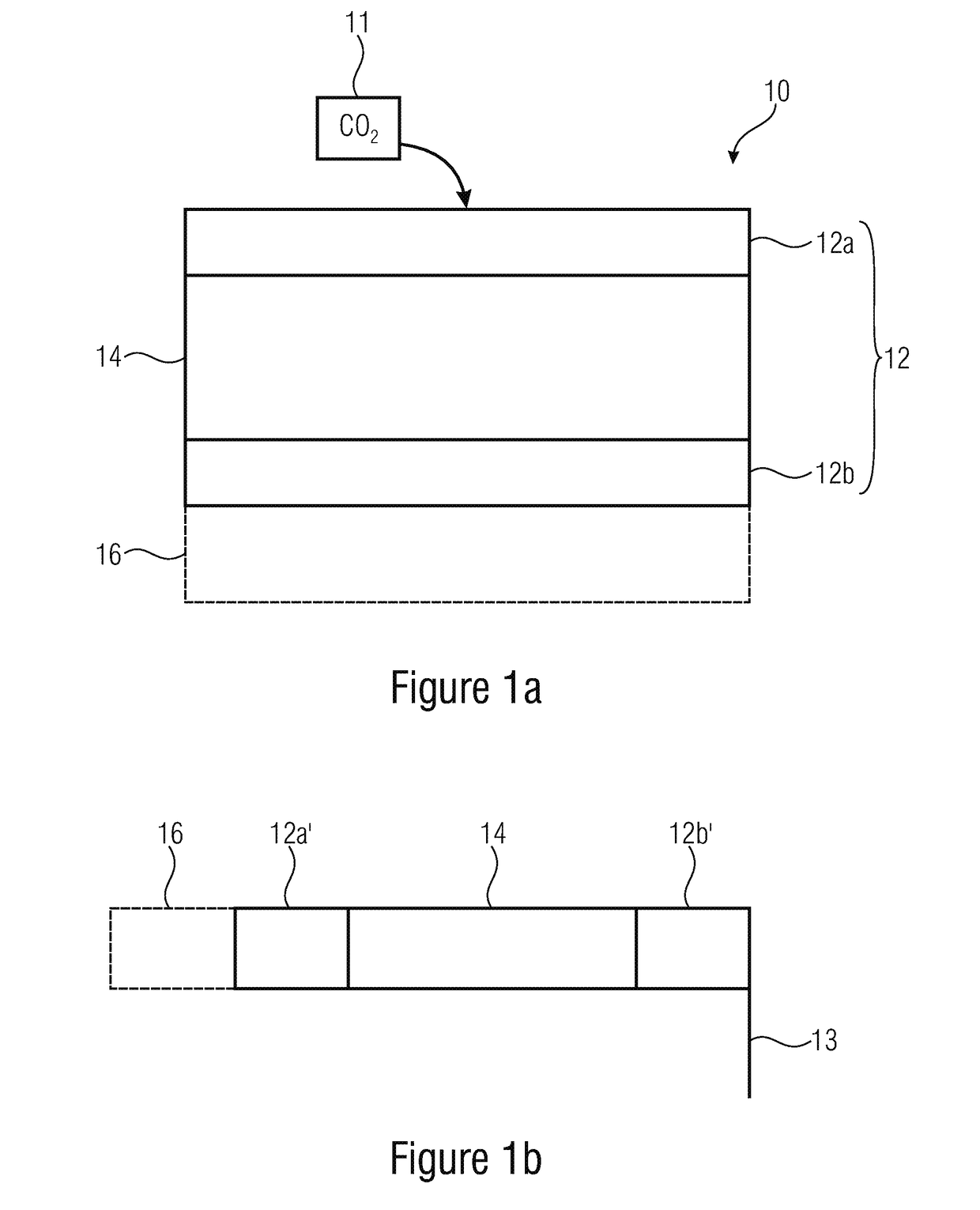

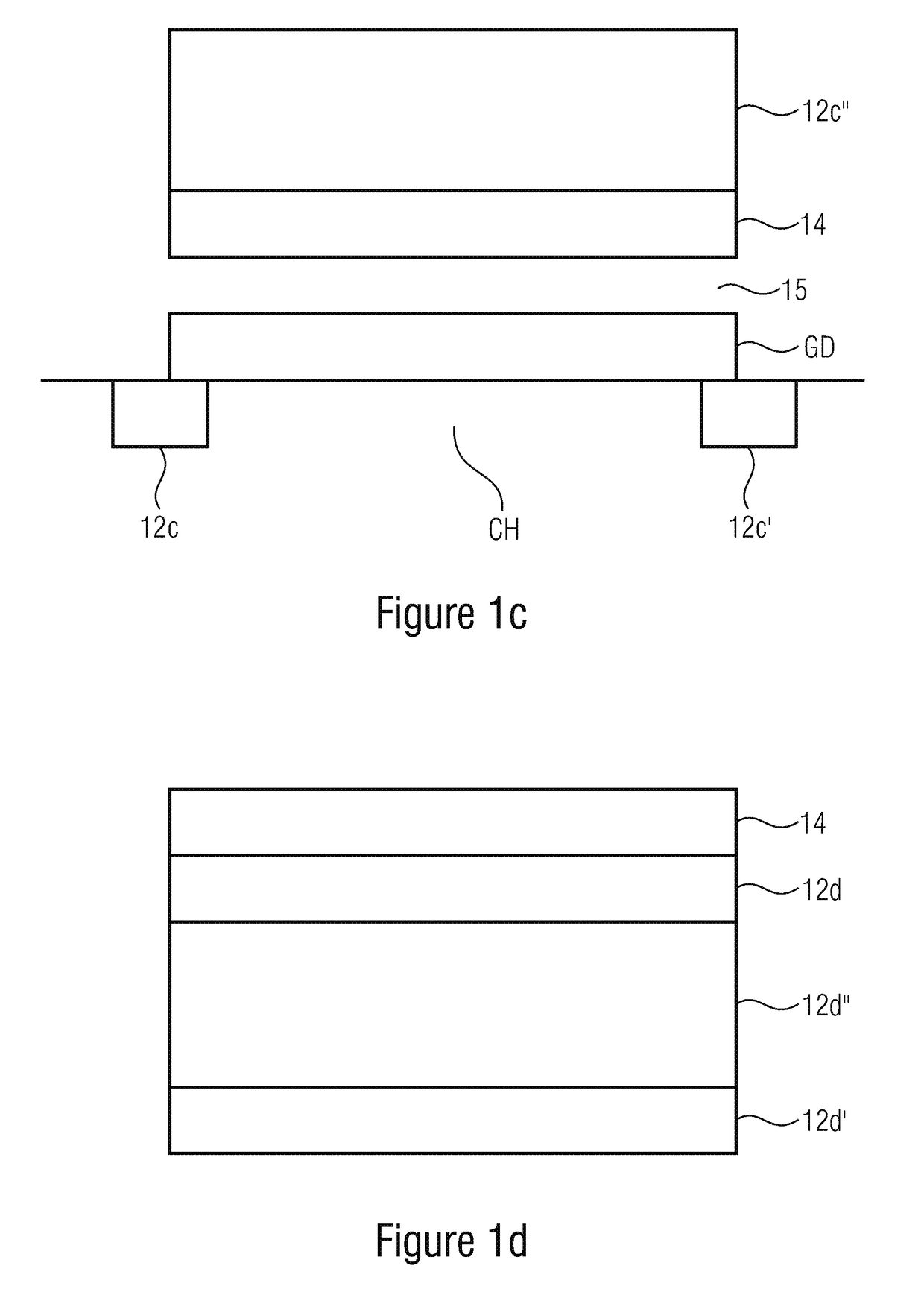

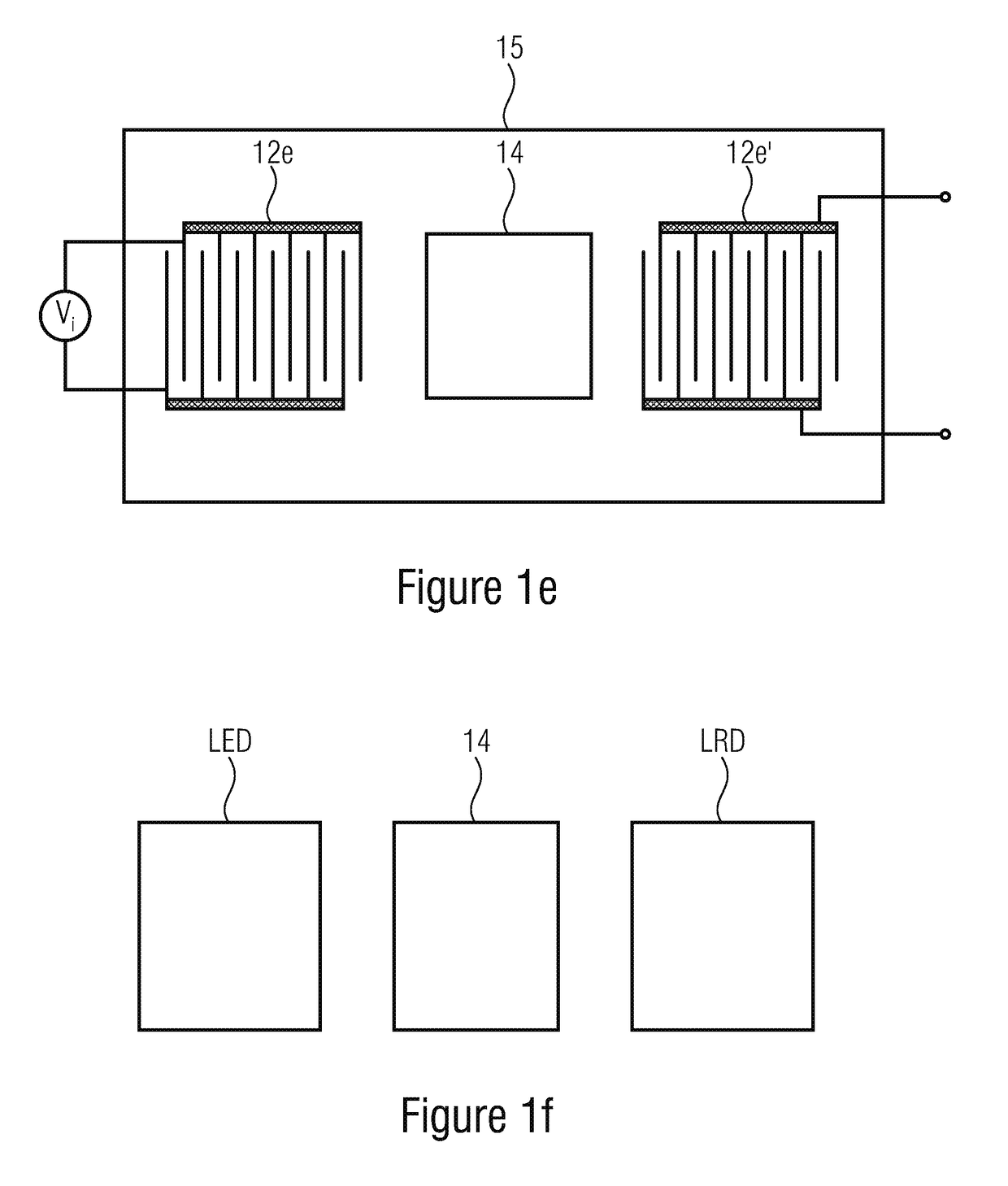

CO2 Sensor and Method for Manufacturing Same

ActiveUS20180372662A1Heavy loadEnsure thermal stabilityMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansElectricityNanoparticle

A sensor device for sensing CO2 comprises a hybrid sensing material and a transducer. The hybrid sensing material comprises at least amines and nanoparticles, wherein the hybrid sensing material has a property and is configured to change the property dependent on a current CO2 concentration in the surrounding. The transducer is configured to output an electrical sensor signal dependent on the property of the hybrid sensing material.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

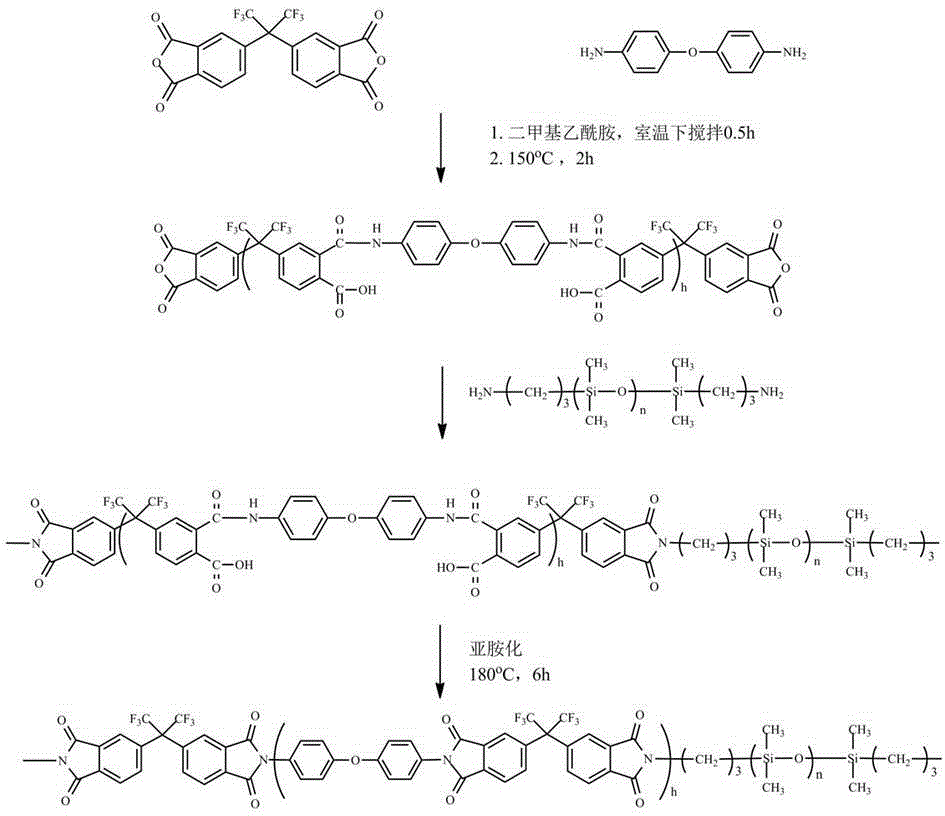

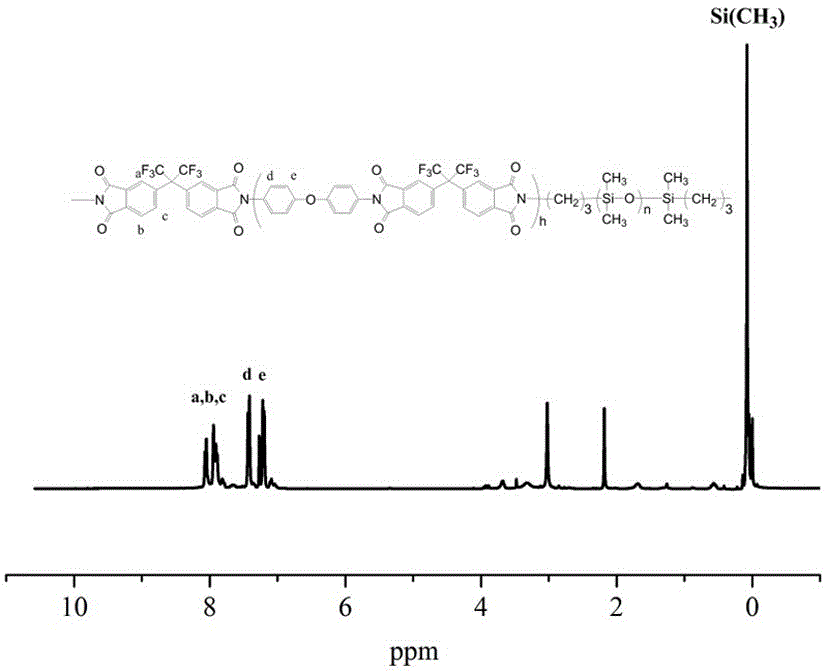

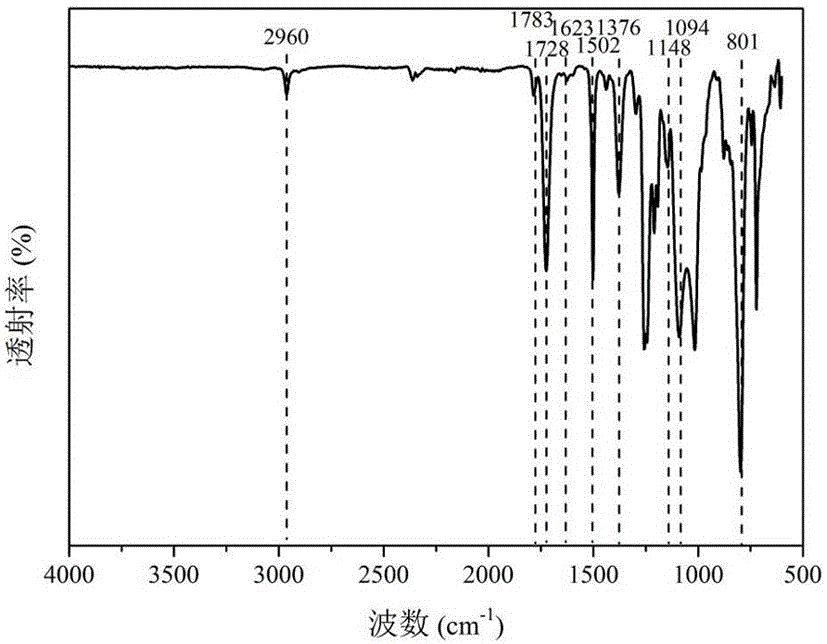

Modified thermosetting resin and preparation method thereof

The invention discloses modified thermosetting resin and a preparation method thereof. 100 parts of molten state thermosetting resin and 1-20 parts of fluorine-containing-polyimide-b-polysiloxane rigid-flexible segmented copolymer with amino end groups are evenly mixed and undergo a curing and postprocessing process to obtain fluorine-containing-polyimide-b-polysiloxane rigid-flexible segmented copolymer modified thermosetting resin. The modified thermosetting resin has high heat resistance, high toughness, low dielectric constant and good curing manufacturability. The method for preparing the modified thermosetting resin is simple and practical, no solvent is used, and the modified thermosetting resin undergoes large-scale and cleaning production easily.

Owner:太湖华强科技有限公司

Spin injection magnetization reversal element

InactiveUS7501688B2Efficiently injected and reflectedImprove efficiencyMagnetic-field-controlled resistorsDigital storageIsolation layerFerromagnetism

A spin injection magnetization reversal element includes a ferromagnetic fixed layer, an isolation layer and a ferromagnetic free layer. The area of contact between the ferromagnetic fixed layer and the isolation layer is larger than an area of contact between the ferromagnetic free layer and the isolation layer. The ferromagnetic fixed layer may be divided into ferromagnetic first fixed layer and ferromagnetic second fixed layer, and the isolation layer may be divided into first isolation layer and second isolation layer. The ferromagnetic first fixed layer may be arranged on one of opposed principal surfaces of the ferromagnetic free layer with the first isolation layer in between, and the ferromagnetic second fixed layer may be arranged on the other of the opposed principal surfaces of the ferromagnetic free layer with the second isolation layer in between. The element holds recorded magnetization and can reverse magnetization with a small current density.

Owner:FUJI ELECTRIC CO LTD

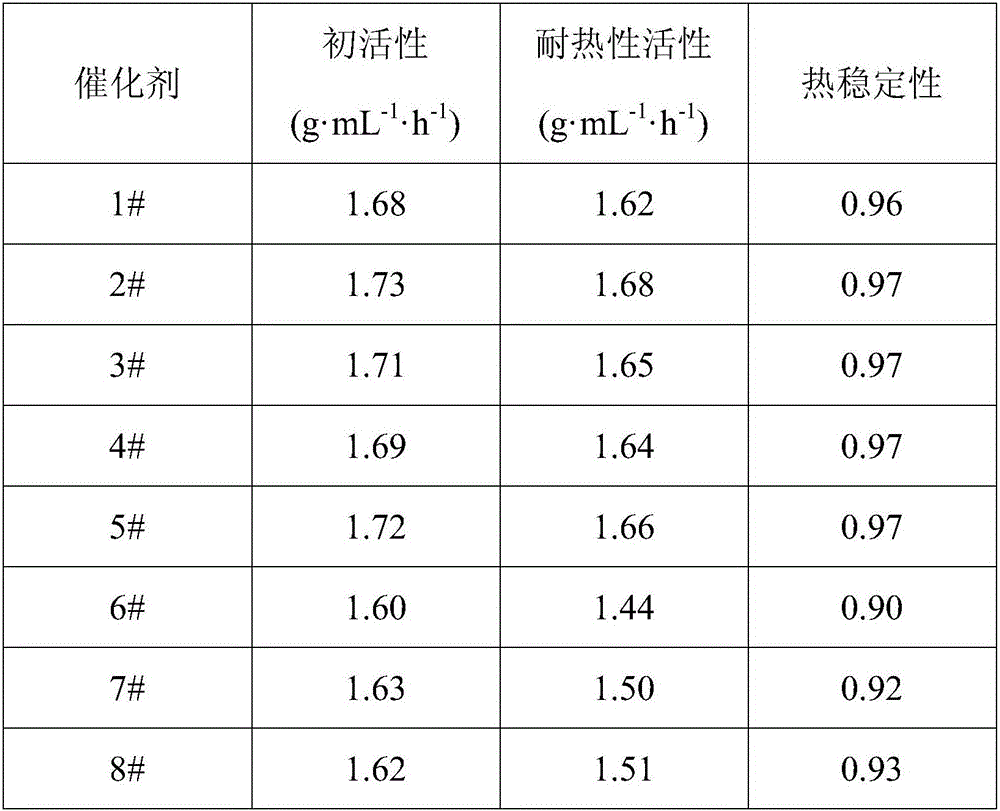

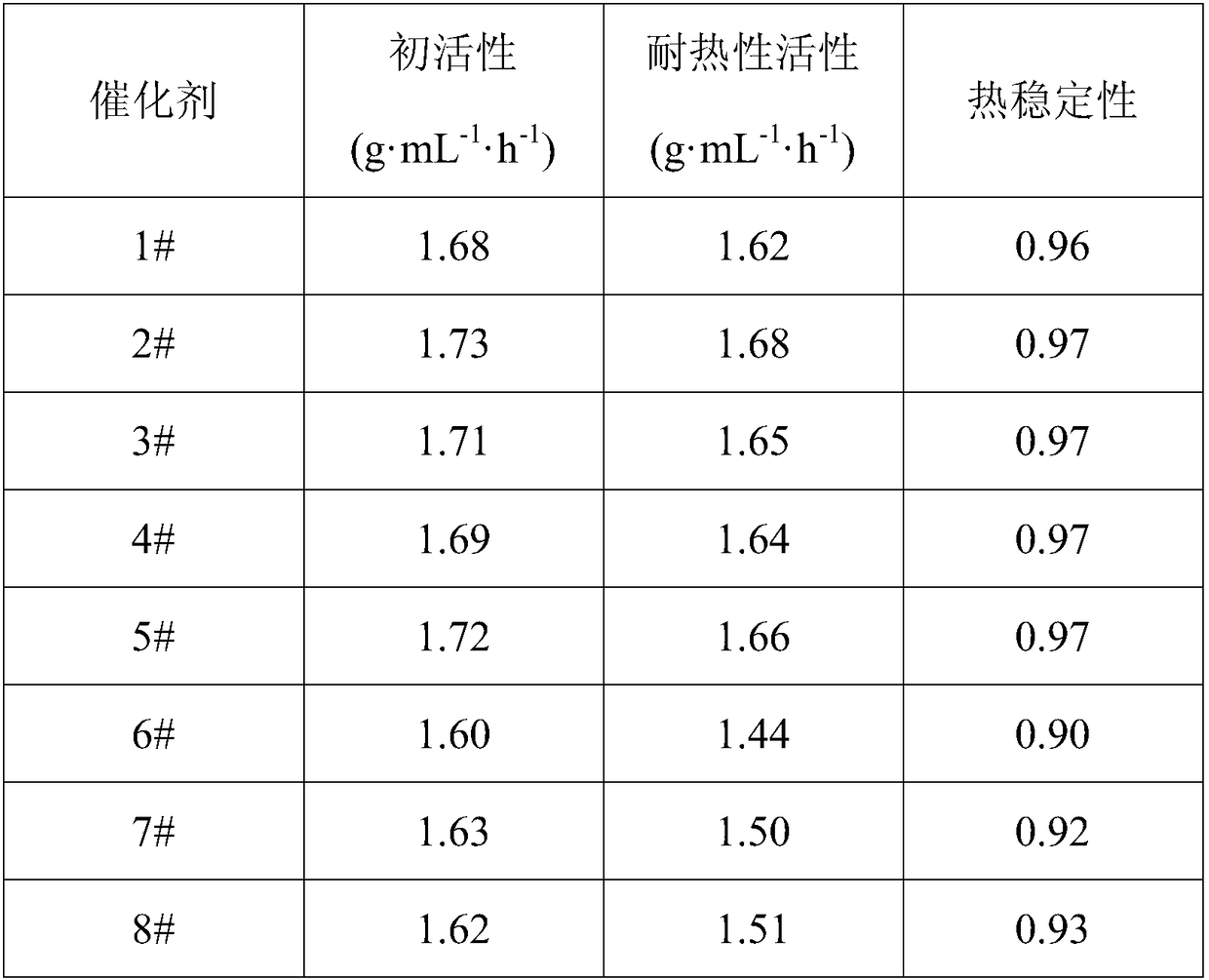

Copper-based methanol synthesis catalyst and preparation method thereof

ActiveCN105964267AEnsure activity stabilityEnsure thermal stabilityOrganic compound preparationHydroxy compound preparationSyngasHeat stability

The invention provides a copper-based methanol synthesis catalyst and a preparation method thereof. The method includes the steps that copper-zinc mixed liquor is mixed with a first precipitator aqueous solution in a parallel flow mode, the pH is controlled to be 7-8, standing is performed for ageing, and slurry A is formed; a second precipitator aqueous solution is added into a soluble aluminum salt aqueous solution, the pH is controlled to be 7-8, the temperature is controlled to be 40-50 DEG C, standing is performed for ageing, and slurry B is obtained; the slurry A and the slurry B are mixed and filtered, a solid phase is washed, dried, roasted and formed, and the copper-based methanol synthesis catalyst is obtained. According to the preparation method, the steps are simple, the controllability is high, the raw material source is wide, and industrialization is easy to achieve; by the adoption of the preparation method, the copper-based methanol synthesis catalyst with high catalytic activity and heat stability can be obtained and is suitable for producing methanol with synthesis gas containing CO, CO2 and H2 under the low temperature and low pressure conditions; besides, the catalyst does not need reduction before use and can be conveniently applied and popularized on a large scale.

Owner:SHENYANG SANJUKAITE CATALYST +1

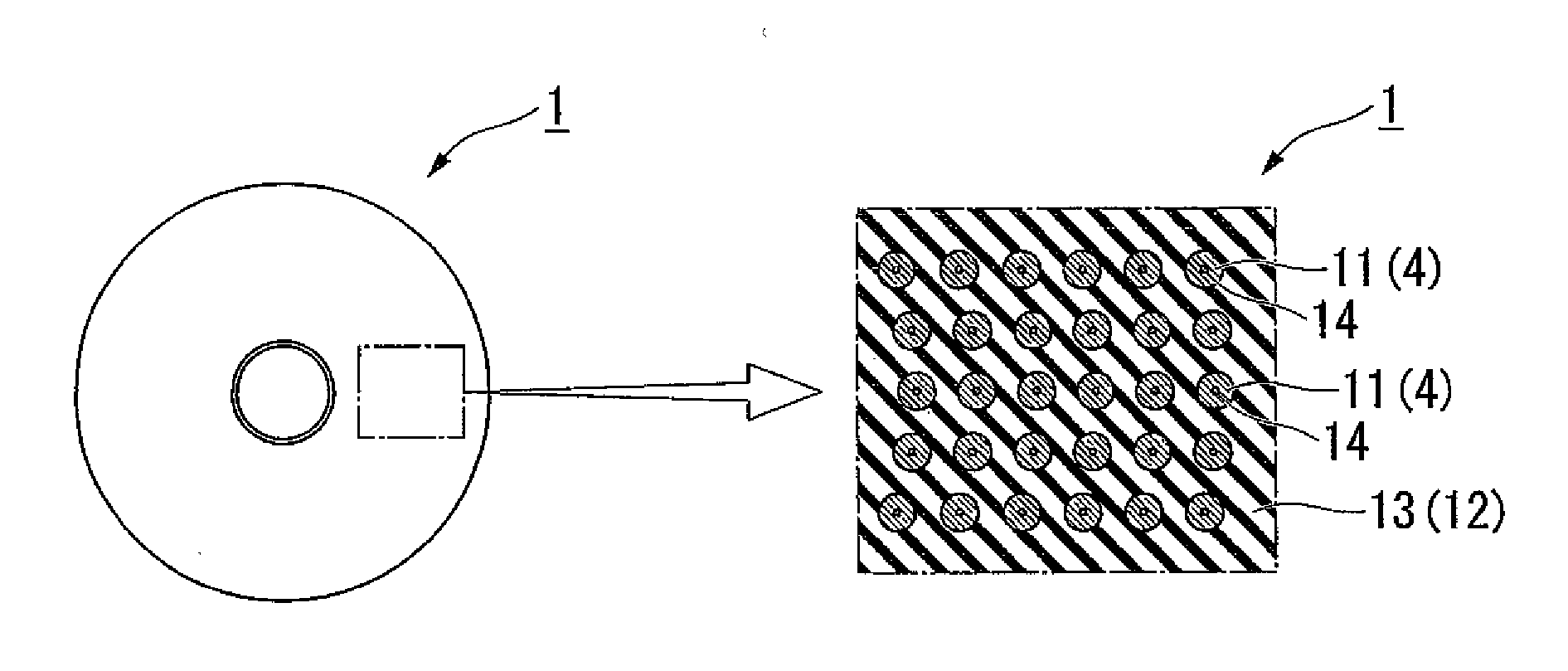

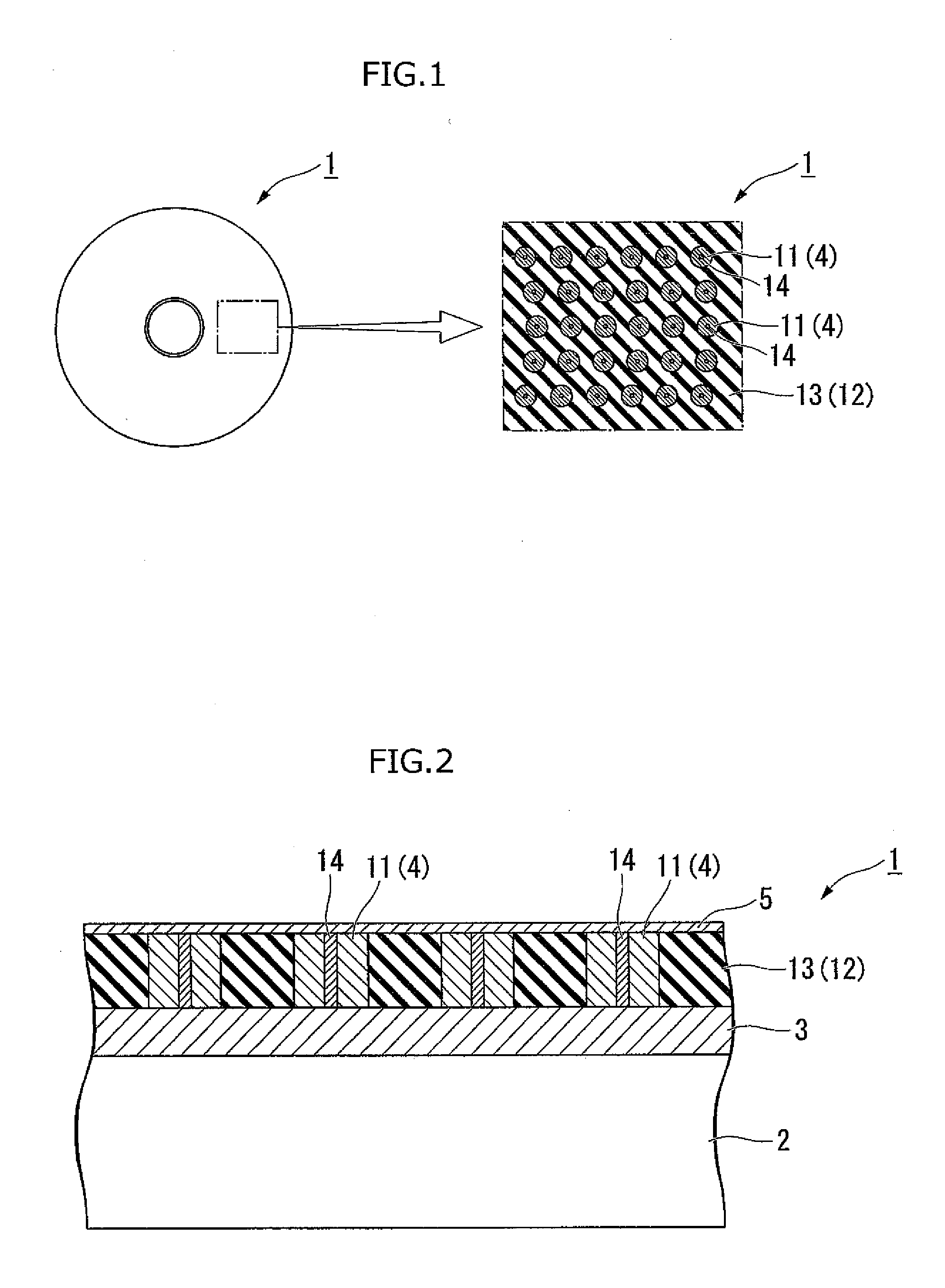

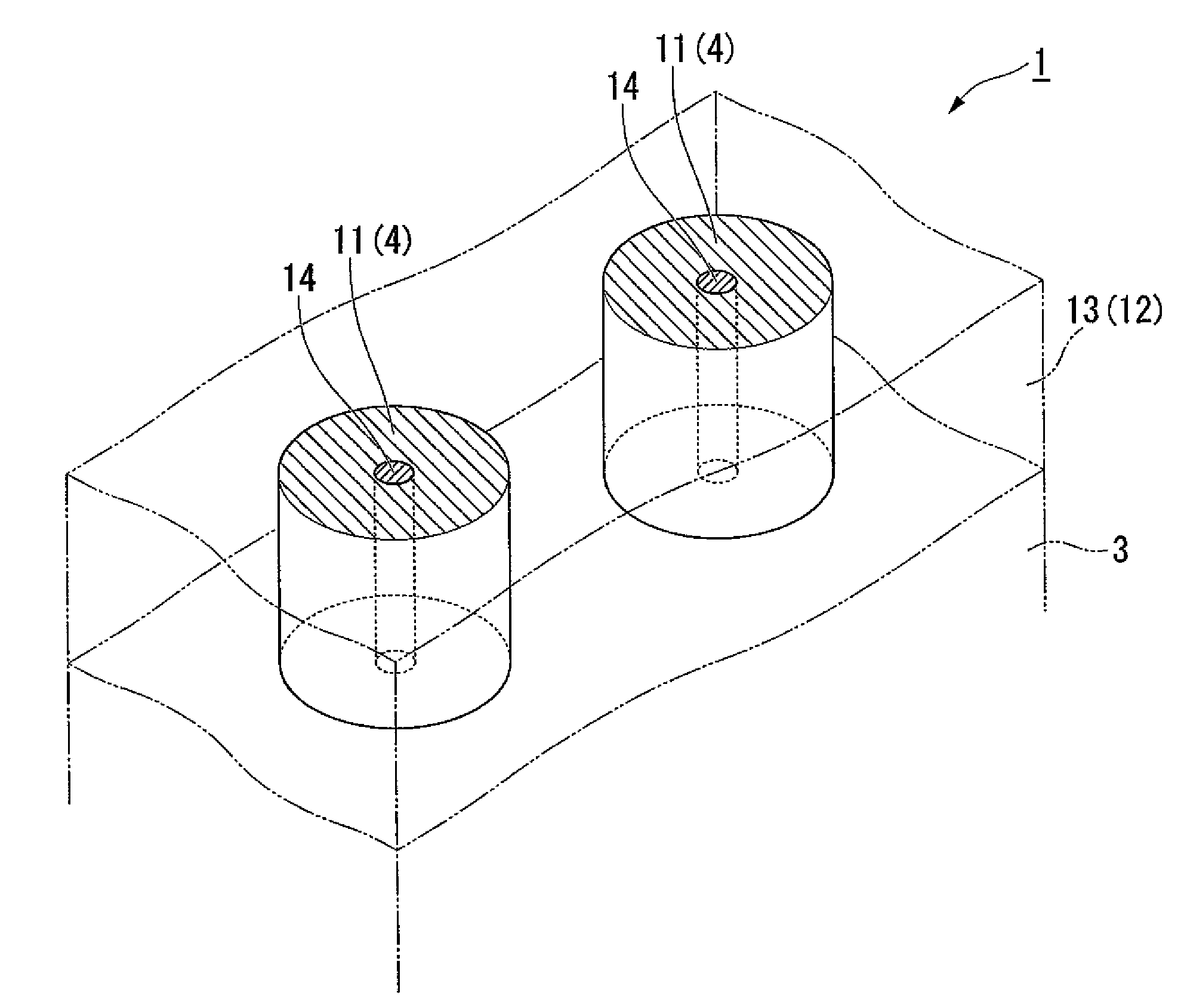

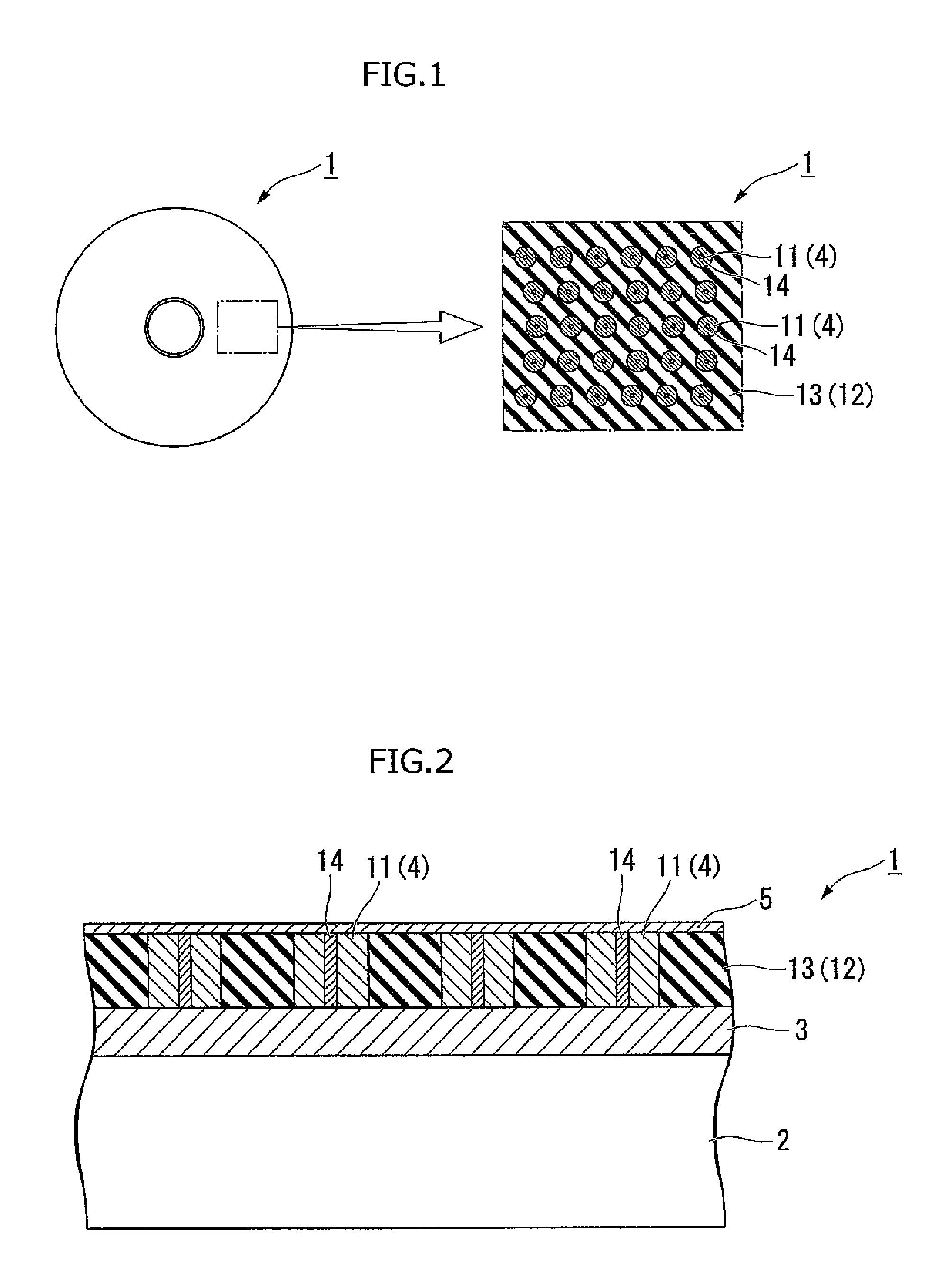

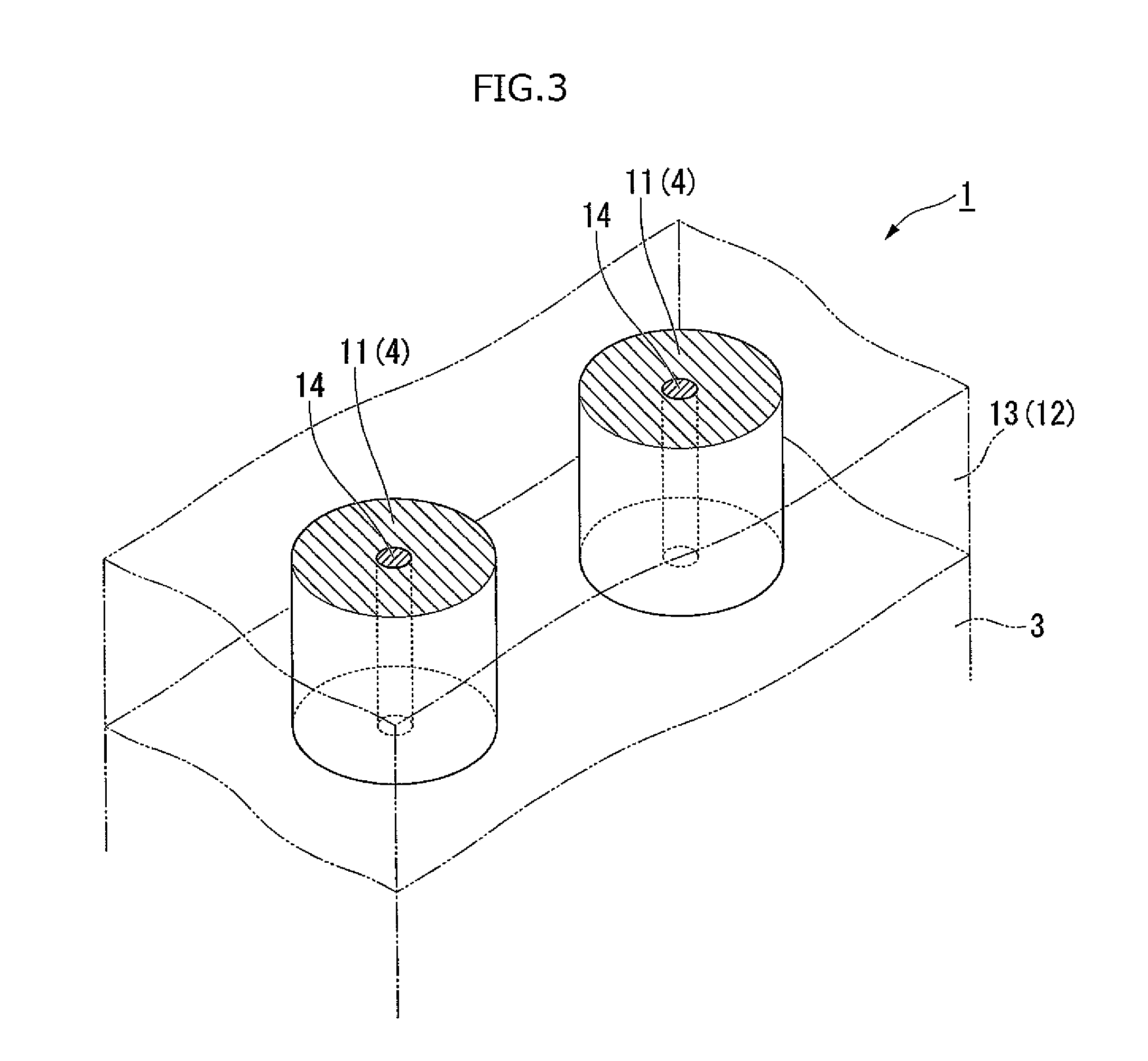

Magnetic recording medium

InactiveUS20120237797A1Precise positioningEasy to implementMagnetic materials for record carriersPatterned record carriersRecording layerThermal transmittance

A recording layer is formed on a substrate, and a high thermal conductor having a thermal conductivity higher than that of the recording layer is disposed inside a plurality of recording bit regions constituting the recording layer, respectively. Furthermore, the recording layer is formed with a separating portion which divides the recording layer into the plurality of recording bit regions. The separating layer is filled with a low thermal conductor having a thermal conductivity lower than that of the recording layer.

Owner:SEIKO INSTR INC

Tunable LED module

InactiveUS20090140278A1Avoid difficult choicesReduce partElectromagnetic transmissionSemiconductor devicesLength waveOptical coupler

The objective of the invention is to provide with a tunable LED module capable of easily selecting a wavelength and reducing particular parts, comparing to that of prior art. The tunable LED module according to the present invention is applicable to a certain short range communication. The module comprises: an LED 1 capable of emitting a light with a certain wavelength band including a desire wavelength; a collimator 2 for collimating the divergent light from the LED 1; an etalon 3 working as a wavelength selector for selecting a light with a plurality of wavelengths including the desired wavelength from the light emitted from the LED 1; a BRF 4 working as an optical tuner selectively tunable the desired wavelength within the wavelengths selected by the wavelength selector; an optical coupler 5, which the light rejected by the BRF 4 enters to and couples with; a LED mounting element 6 made from a material with a high thermal conductivity, such as cupper, cupper alloy, and the like, the element 6 for mounting the LED 1; and an optical receiver 7 for detecting the power of the light with wavelengths excluding the tuned wavelength and then generating light level monitor signal representing the power of the detected light.

Owner:TEKUDAIYA

Production method of medical artificial skin

InactiveCN107362393ASimple production processEasy and practical to processProsthesisEnvironmentally friendlyOrganic solvent

The invention discloses a production method of a medical artificial skin. The method comprises the following steps: according to steps A-E, feeding a component A and a component B of injecting and forming liquid silicone rubber according to a certain mass ratio under a certain condition, separately mixing the component A and the component B with purified water uniformly at first, then mixing the component A and the component B uniformly under a certain condition, feeding the mixture into a slobbering machine and carrying out slobbering film forming, curing and evaporating at the specifically selected temperature and for a specifically selected time, and then carrying out steps such as puncturing, slitting and rolling to obtain the finished medical artificial skin. The method is simple, convenient and practical, is short in preparation period and high in efficiency, does not use organic solvents in a production process, is safe and environmentally friendly, meanwhile can provide a wet environment for a wound to facilitate healing of the wound, and is not adhered to the wound when used, so that pain of a patient when the medical artificial skin is changed is relieved; and moreover, the produced medical artificial skin is good in resistance of bacteria and breathability.

Owner:江西高大生物医疗科技有限公司

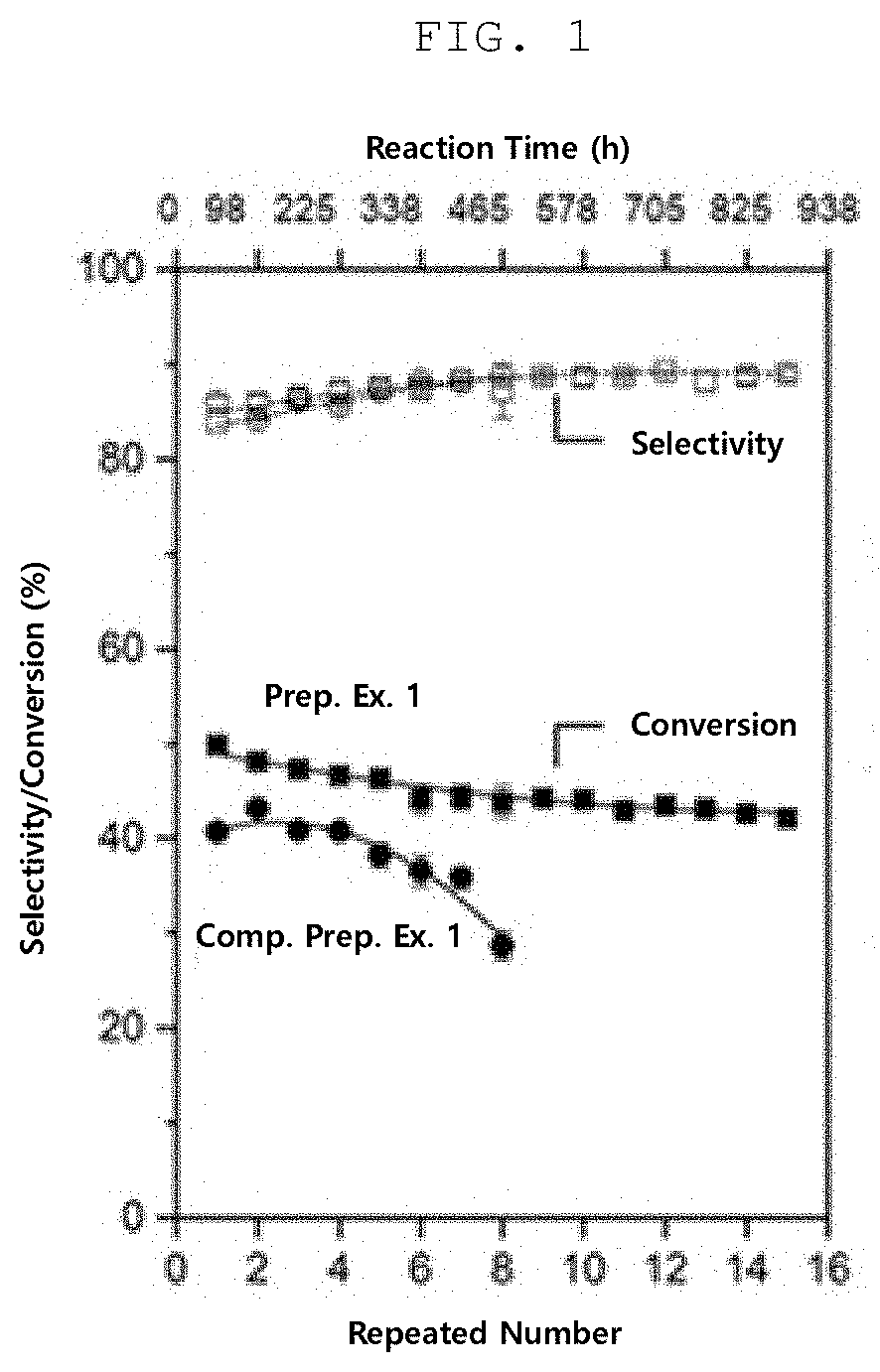

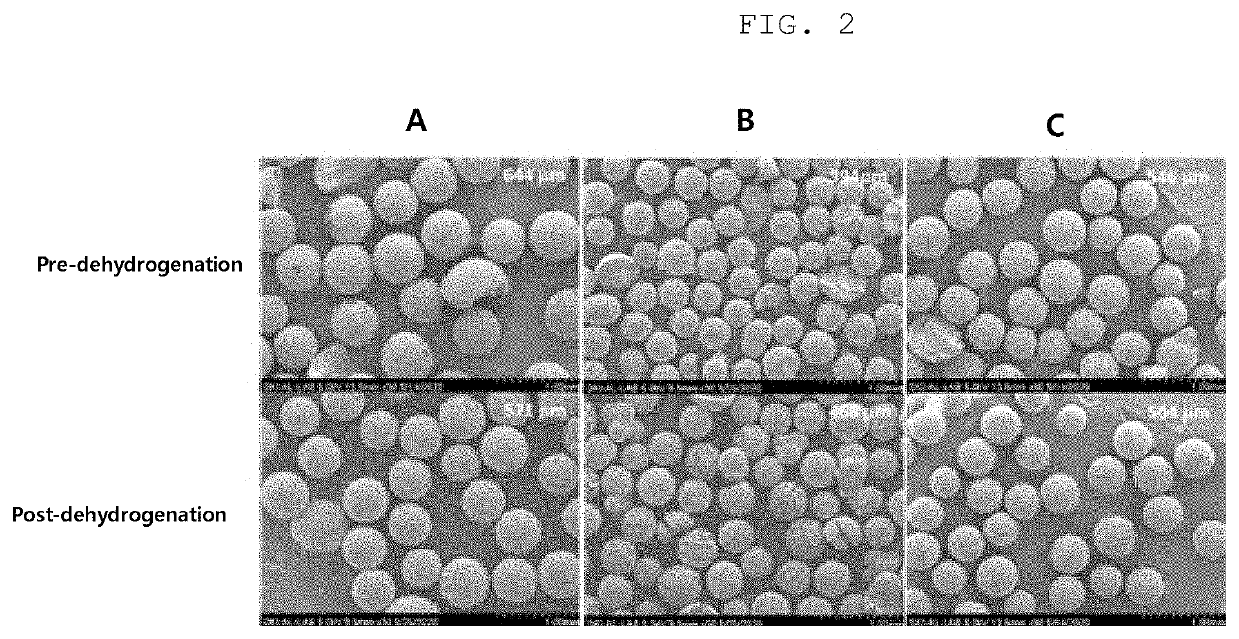

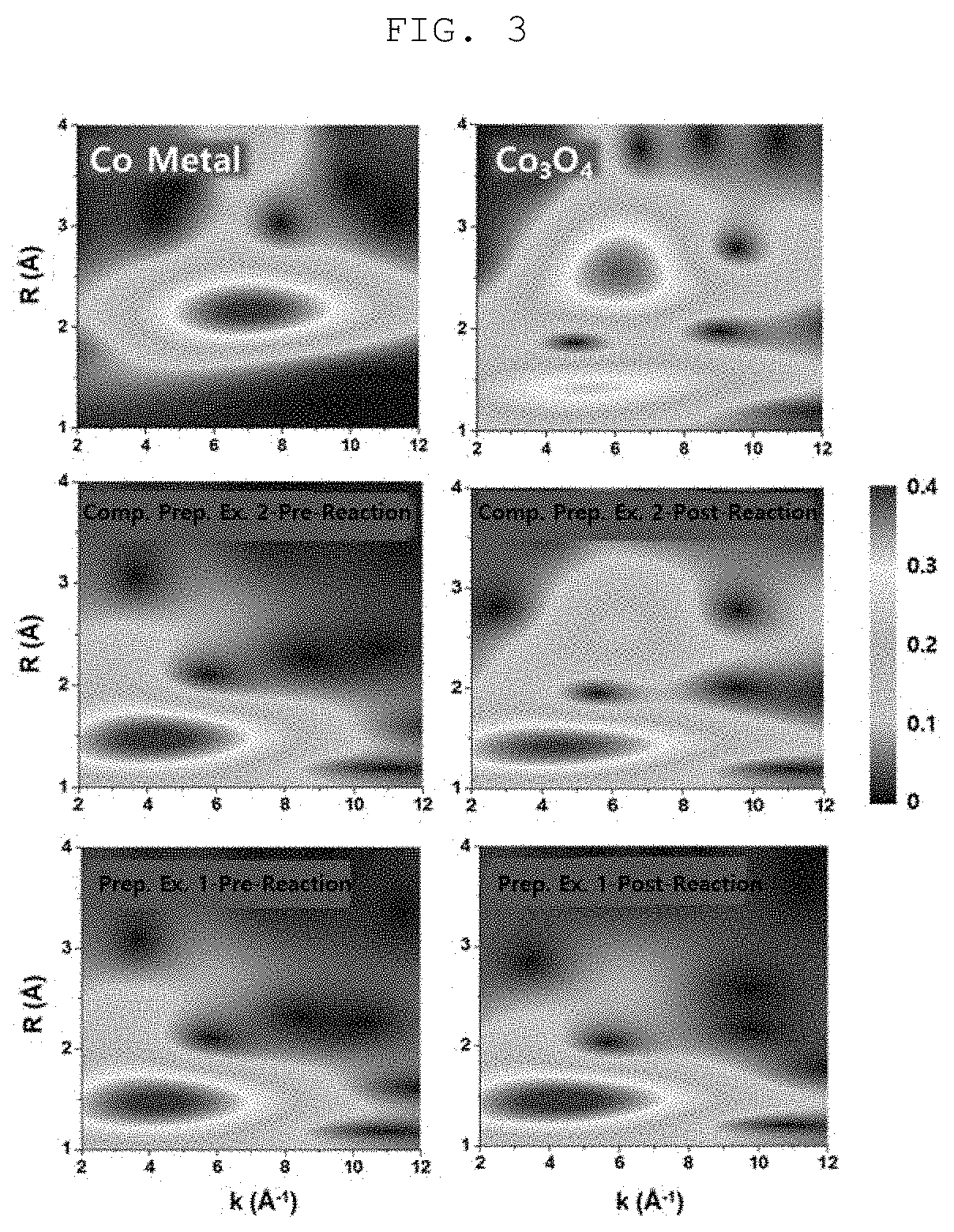

Cobalt-Based Single-Atom Dehydrogenation Catalysts Having Improved Thermal Stability and Method for Producing Olefins From Corresponding Paraffins by Using the Same

ActiveUS20210402379A1Guaranteed heat resistanceRetain activityCatalystsHydrocarbon preparation catalystsAlkanePtru catalyst

Disclosed herein are a dehydrogenation catalyst having single-atom cobalt loaded onto a silica support that has undergone pretreatment including a thermal treatment and a high-temperature aqueous treatment (reaction), a preparation method therefor, and a method for producing olefins by dehydrogenating corresponding paraffins, particularly light paraffins in the presence of the dehydrogenation catalyst.

Owner:SK INNOVATION CO LTD

A kind of copper-based methanol synthesis catalyst and preparation method thereof

ActiveCN105964267BAvoid successive precipitationFully turbulentOrganic compound preparationHydroxy compound preparationPtru catalystPhysical chemistry

The invention provides a copper-based methanol synthesis catalyst and a preparation method thereof. The method comprises: mixing the copper-zinc mixed solution and the first precipitant aqueous solution in parallel, controlling the pH to be 7-8, and standing for aging to form a slurry A ; Add the second precipitant aqueous solution to the soluble aluminum salt aqueous solution, control the pH to 7-8, and the temperature to 40-50°C, leave it to age to obtain slurry B; mix slurry A and slurry B, filter, and pass through the solid phase Washing, drying, roasting, molding treatment, that is, the copper-based methanol synthesis catalyst is obtained. The above preparation method has simple steps, strong controllability, wide sources of raw materials, and easy industrialization. The preparation method of the present invention can obtain a copper-based methanol synthesis catalyst with high catalytic activity and thermal stability, which is suitable for the synthesis of methanol containing CO, CO2, H2 The synthesis gas can produce methanol under the condition of low temperature and low pressure, and the catalyst of the invention does not need to be reduced before use, which is convenient for large-scale popularization and application.

Owner:SHENYANG SANJUKAITE CATALYST +1

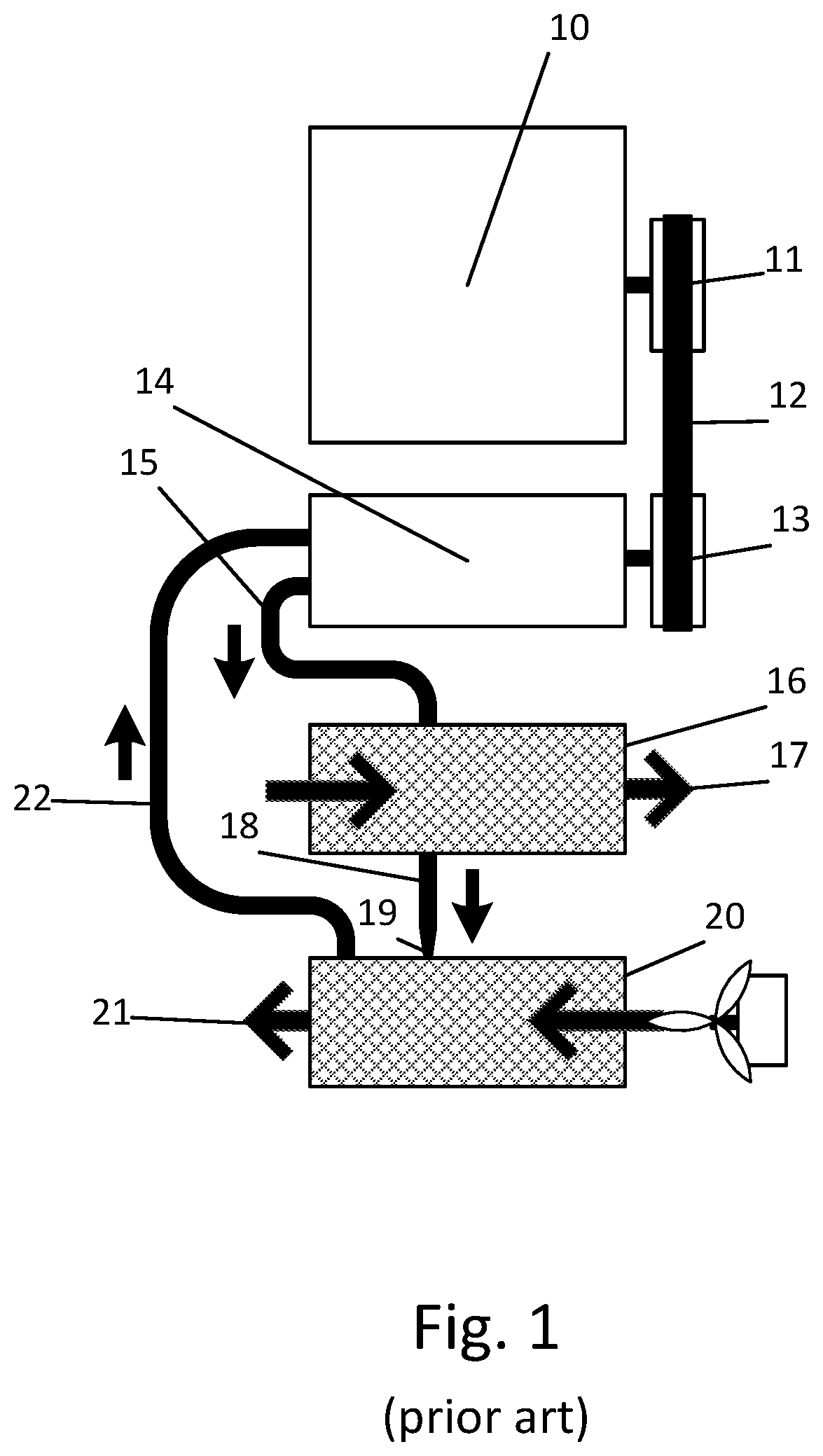

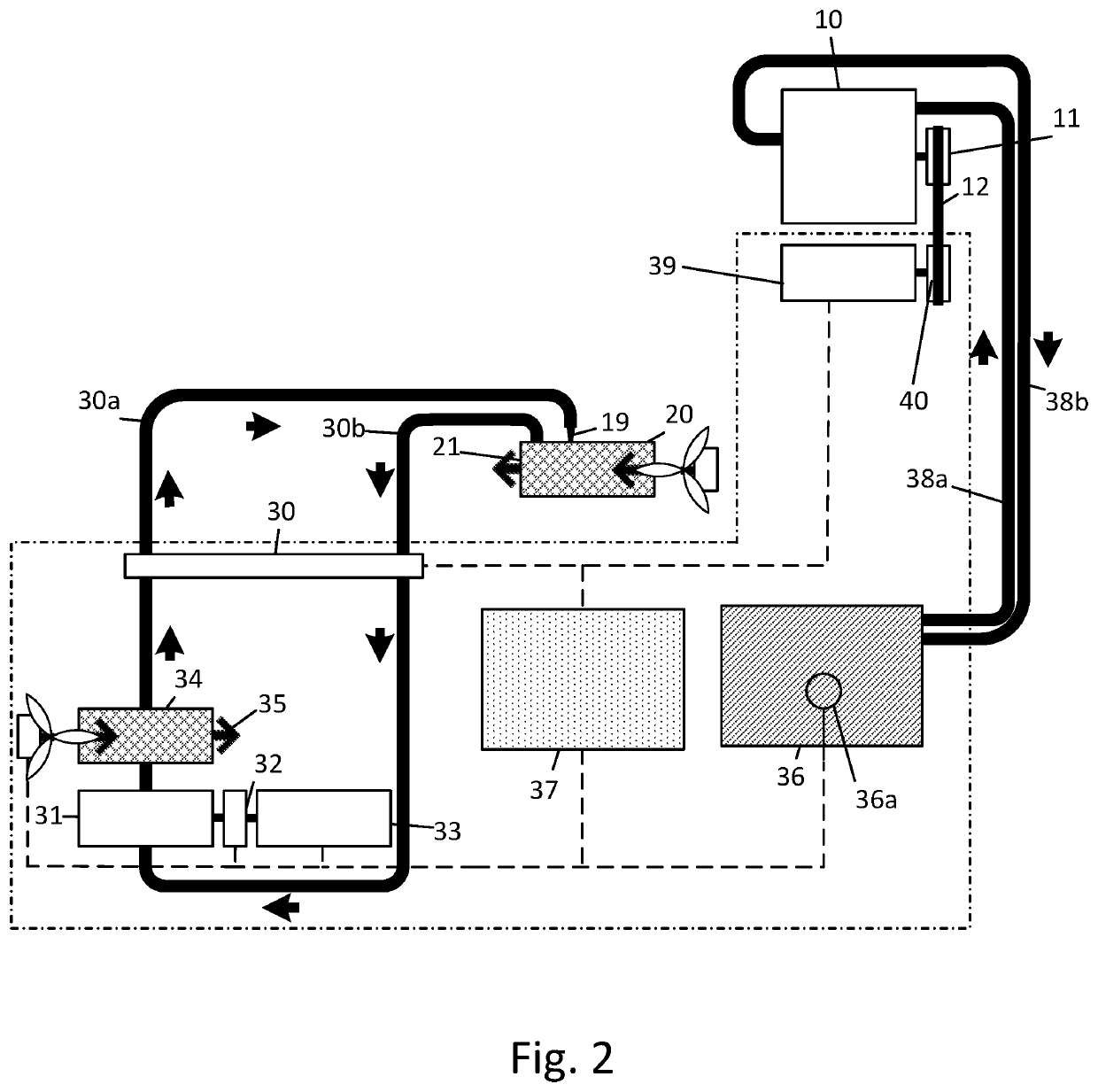

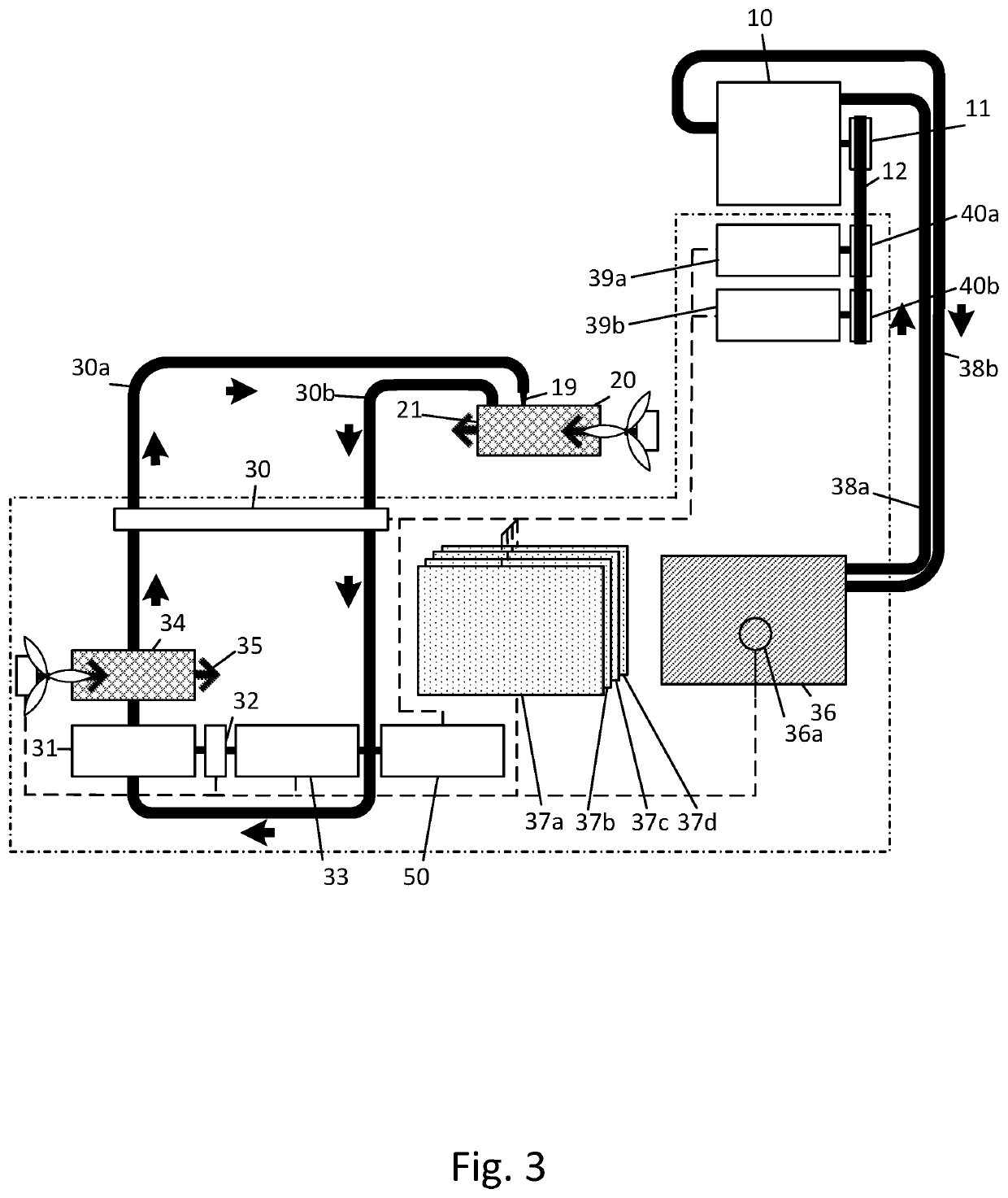

Auxiliary Air-Conditioning System for Over-the-Road Trucks

InactiveUS20210188040A1Ensure thermal stabilityEasy to startAir-treating devicesVehicle heating/cooling devicesAlternatorIn vehicle

The invention relates to a system that is added to a standard vehicle installed air-conditioning system that allows the standard vehicle installed air-conditioning system to cool and condition the air inside the vehicle without operating the engine of the vehicle. This allows the vehicle to be air-conditioned without polluting the air via continuous operation of the vehicle's (usually) diesel engine. Also, a thermal heating tank is included to warm the electrical components of the system and to ensure improved morning starting of the vehicle's engine. Also, an interiorly operating alternator recaptures some of the energy generated by the system when the air conditioning compressor is disconnected from the electric motor that powers it, but the electric motor remains activated.

Owner:FIERRO FR

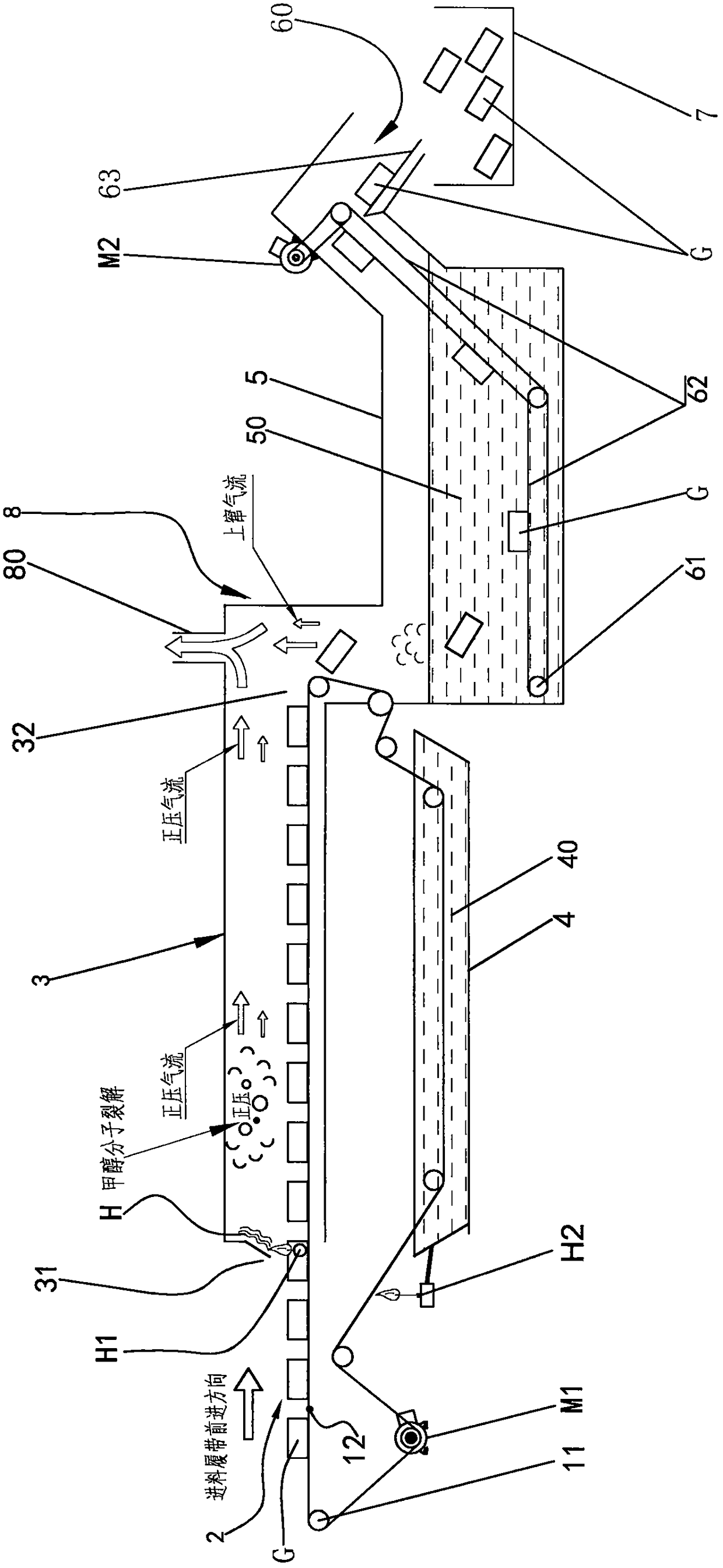

Continuous quenching device for jacking chain wheel workpiece

PendingCN108330269APrevent oxidationEnsure thermal stabilityFurnace typesHeat treatment furnacesQuenchingSprocket

The invention discloses a continuous quenching device for jacking a chain wheel workpiece. The continuous quenching device for jacking the chain wheel workpiece comprises a feeding motor, a feeding caterpillar band, a feeding roller, a feeding area, a heating furnace area, a cooling groove, a quenching groove and a discharging hoisting part arranged in the quenching groove; the quenching groove isadjacent to the outlet side of the heating furnace area; the feeding motor drives a feeding transmission part to drive the feeding caterpillar band to continuously march to cyclically pass through the feeding area, the heating furnace area and the cooling groove; a discharging motor drives a discharging roller to drive a discharging caterpillar band to continuously march to conveying the workpiece to be discharged; the inlet side of the heating furnace area is provided with a methanol first spraying port, and after ignition, a fire curtain scouring the whole inlet side can be formed; and theside, where the feeding caterpillar band moves out of the cooling groove, on the cooling groove is provided with a methanol second spraying port, and after ignition, it is used for drying the feedingcaterpillar band under high temperature. After the scheme is adopted, production is efficient, the formed fire curtain prevents oxygen-containing air from entering the heating furnace area, it is avoided that oxygen-containing water vapor enters the heating furnace area along with the feeding caterpillar band, and therefore oxidization of the workpiece in a furnace is effectively avoided.

Owner:ZHEJIANG SHUANGNIAO MACHINERY

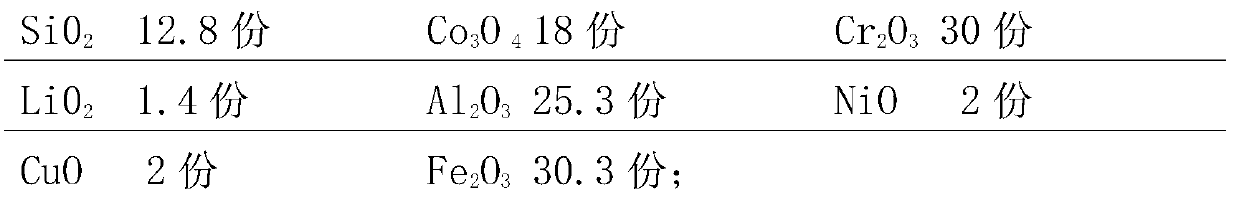

Whole-body dry-pressed porcelain induction cooker heating panel material and preparation method thereof

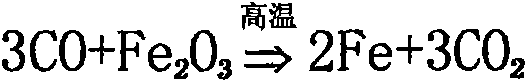

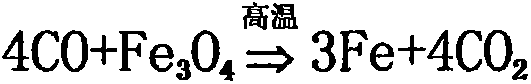

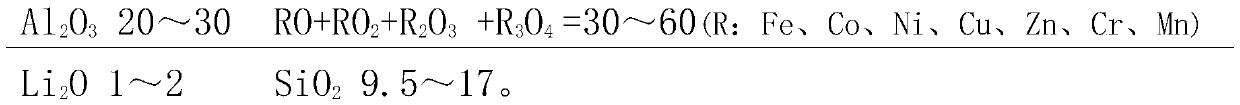

ActiveCN110668785AGood electromagnetic wave penetration performanceImprove molding abilityClaywaresOxide zincFrit

The invention relates to a whole-body dry-pressed porcelain induction cooker heating panel material and a preparation method thereof. The whole-body dry-pressed porcelain induction cooker heating panel material comprises: a blank material comprising, by weight, 30-60 parts of spodumene, 0-20 parts of cordierite, 0-20 parts of flint clay, 0-20 parts of calcined kaolin, 10-30 parts of kaolin, 0-20 parts of fused quartz, 0-4 parts of alkaline earth metal minerals and 0.5-6 parts of a pigment; a panel pigment comprising, by weight, 15-30 parts of spodumene, 20-30 parts of aluminum oxide, 0-5 partsof a mineralizing agent and 30-60 parts of transition metal oxide; and a panel glaze comprising, by weight, 0-60 parts of spodumene, 0-70 parts of petalite, 0-10 parts of calcined zinc oxide, 0-10 parts of barium carbonate, 0-10 parts of calcite, 15-35 parts of fused quartz, 4-10 parts of kaolin, 0-25 parts of frit and 0.5-6 parts of the pigment. The panel pigment is respectively added into the panel blank and the panel glaze according to the coloring requirement, the adding amount is 0.5-6%, and the panel glaze is applied to the panel blank to form a layered structure.

Owner:刘江义

Magnetic recording medium

InactiveUS8945733B2Efficient heatingEnsure thermal stabilityMagnetic materials for record carriersPatterned record carriersElectrical conductorHeat-assisted magnetic recording

Owner:SEIKO INSTR INC

Total harmonic distortion standard

InactiveUS7046053B2Reliable signalMinimizes variabilityPulse generatorOscillations generatorsTotal harmonic distortionTriangle wave

Embodiments of the invention provide a method and an apparatus for generating a total harmonic distortion reference signal. A triangle wave having a predetermined frequency and a predetermined amplitude is generated. The triangle wave is filtered to produce a signal substantially consisting of a sinusoid at the predetermined frequency and selected harmonics of predetermined amplitudes.

Owner:THE BOEING CO

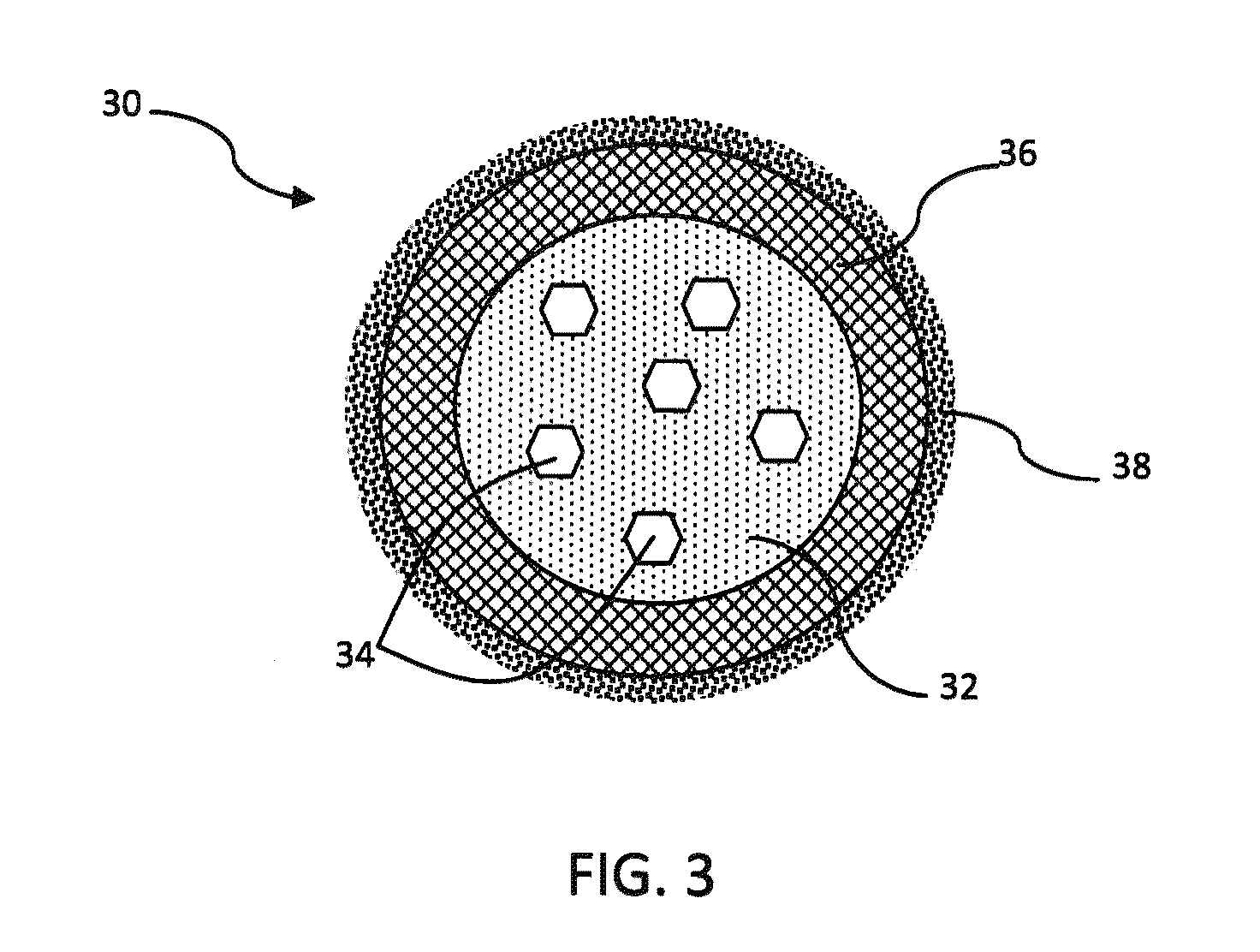

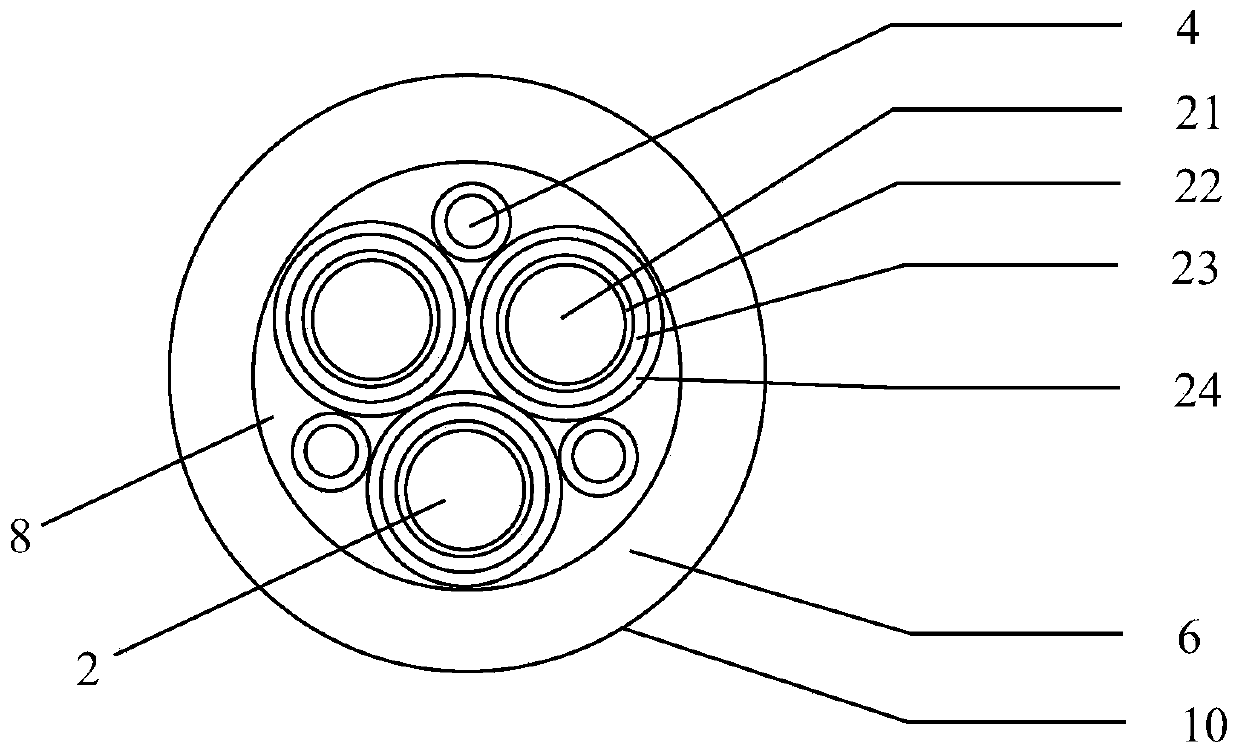

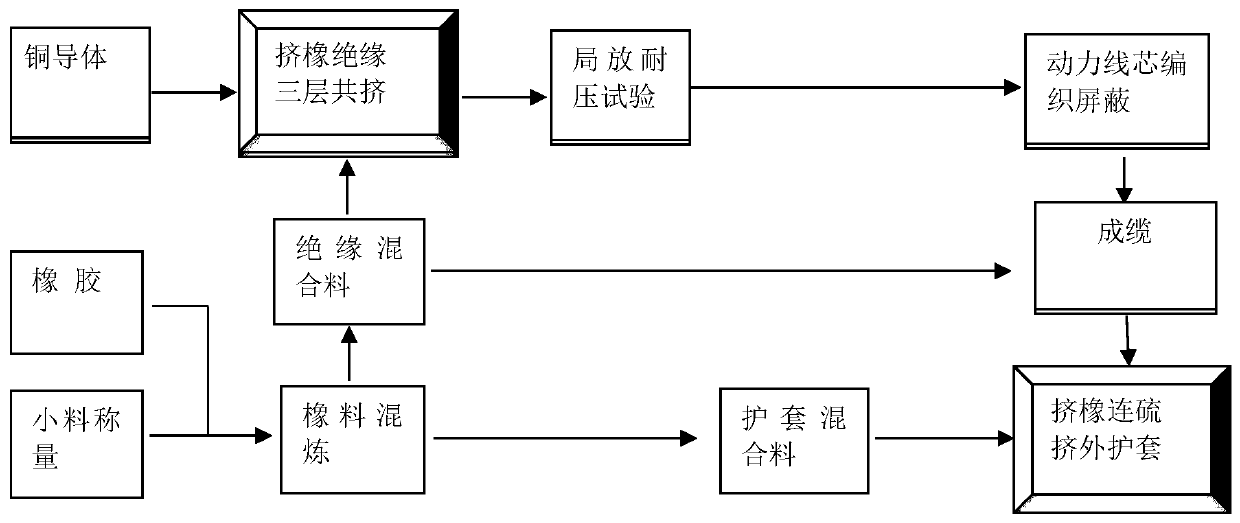

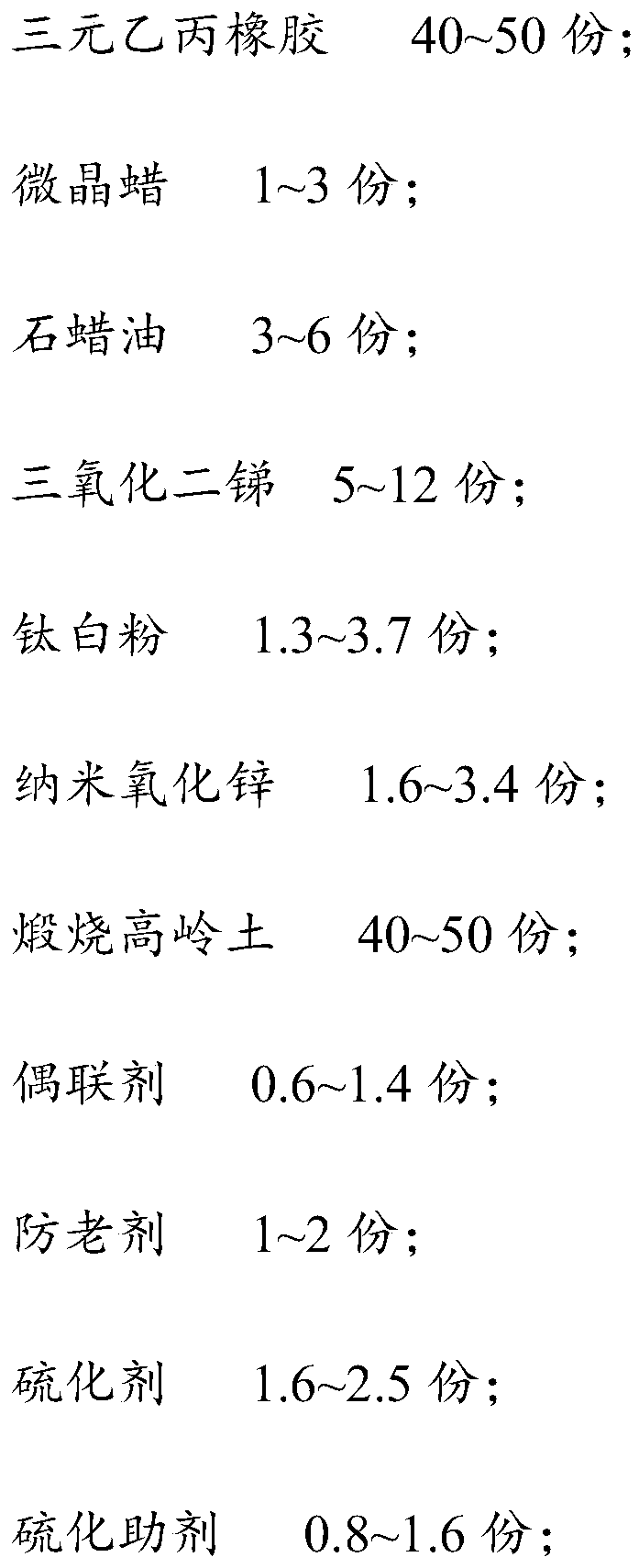

Medium-pressure torsion-resistant power cable for wind generating set

ActiveCN110504053ASolve long-term high current carrying capacitySolve bending fatigueRubber insulatorsPlastic/resin/waxes insulatorsWear resistantAntimony trioxide

The invention discloses a medium-pressure torsion-resistant power cable. The power cable comprises at least one power cable core, at least one grounding cable core twisted with the power cable core, and a sheath layer wrapping the power cable core and the grounding cable core, wherein the power cable core comprises a conductor and an insulating layer covering the conductor; the insulating layer comprises the following components: ethylene propylene diene monomer rubber, microcrystalline wax, paraffin oil, antimony trioxide, titanium dioxide, nano zinc oxide, calcined kaolin, a coupling agent,an anti-aging agent, a vulcanizing agent and a vulcanizing assistant; and the sheath layer comprises the following components: chlorinated polyethylene, magnesium hydroxide, white carbon black, modified calcined kaolin, a thermoplastic elastomer, the anti-aging agent, red lead masterbatch, the antimony trioxide, light magnesium oxide, a calcium-zinc stabilizer, stearic acid, high-wear-resistant carbon black, a plasticizer, a cold-resistant plasticizer, the coupling agent, the vulcanizing agent and a vulcanization accelerator. The problem of the reduced service life of the torsion-resistant power cable of the 8MW offshore wind generating set due to long-term high-load flow, bending fatigue, aging, tearing and the like can be solved.

Owner:JIANGSU HENGTONG POWER CABLE

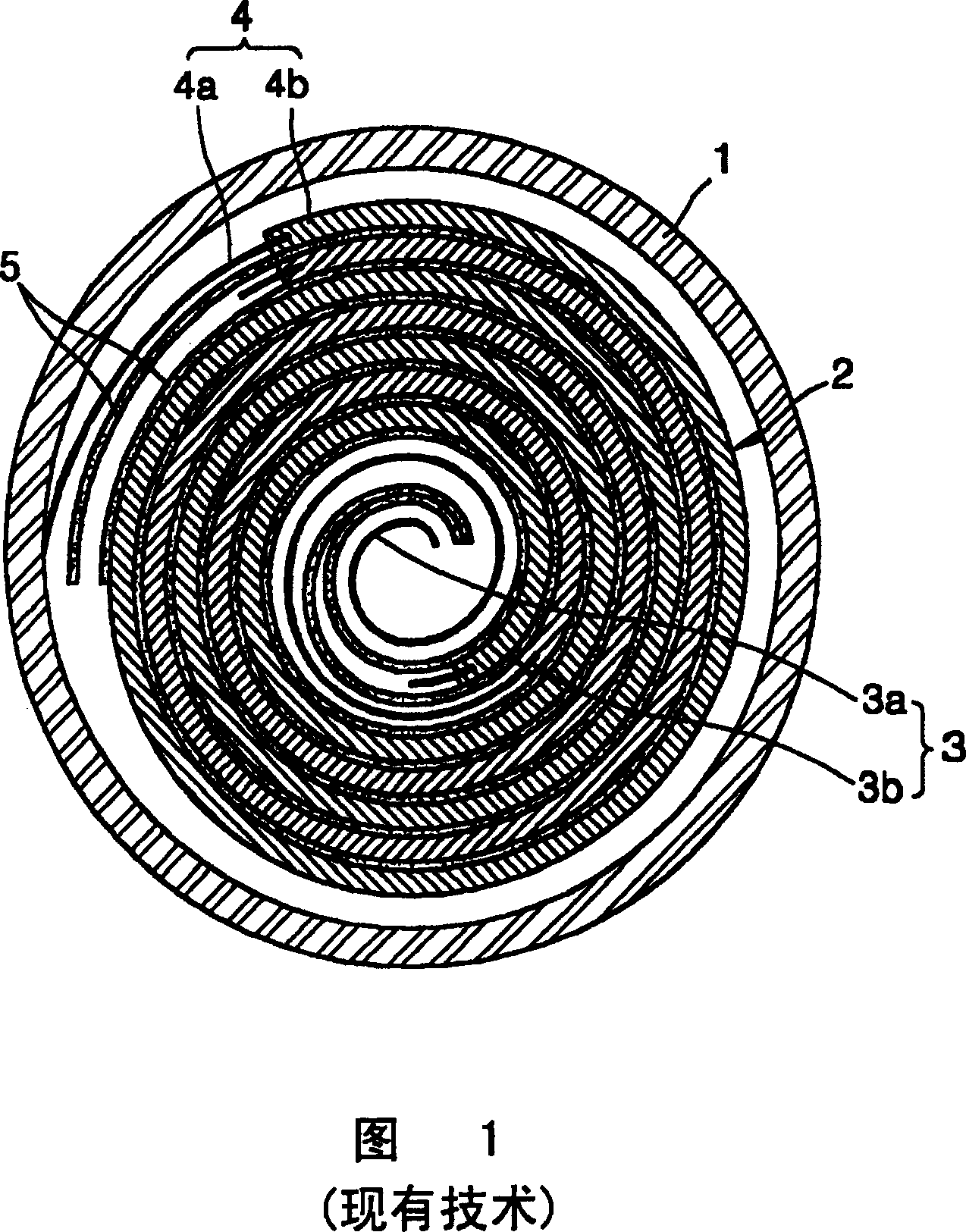

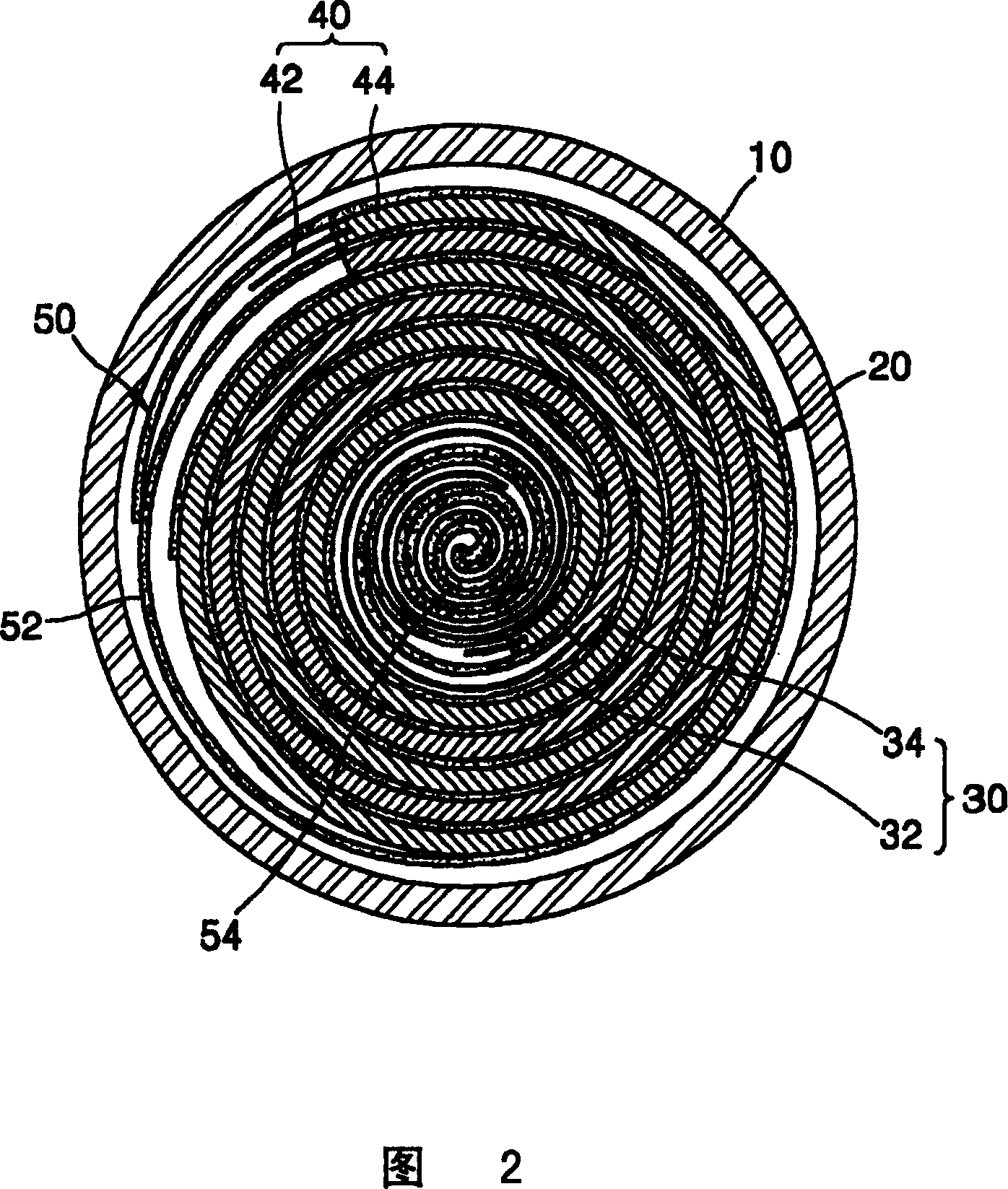

Secondary battery with improved film-like electrode structure

InactiveCN1302574CIncrease capacityEnsure thermal stabilityCell seperators/membranes/diaphragms/spacersFinal product manufactureMechanical stabilityEngineering

A secondary cell capable of ensuring thermal and mechanical stabilities required for a high-capacity cell with a simple structure is provided. The secondary cell includes: a can; and an electrode jelly-roll wound with two different electrodes and a separator interposed between the electrodes therein and accommodated in the can, the outer surface of the electrode jelly-roll being wound around one more turn with the separator. Only the separator is wound at the core of the electrode jelly-roll to form a rod-like stability member which is cured by absorbing heat generated from the cell. The separator wound at the core of the electrode jelly-roll is continuous from a portion of the separator which is stacked with the two different electrodes.

Owner:SAMSUNG SDI CO LTD

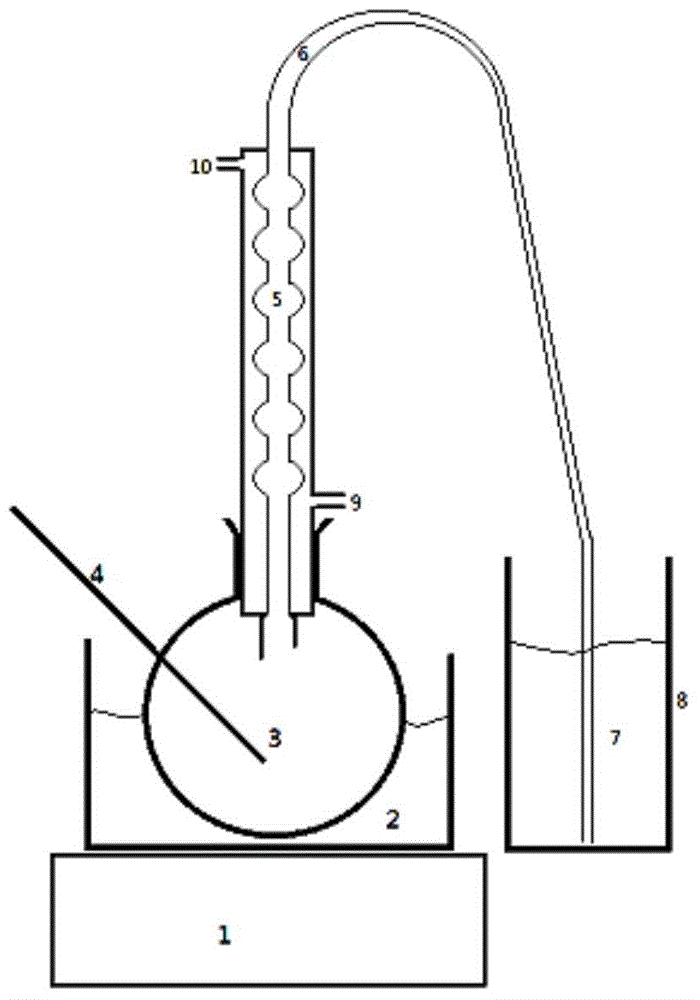

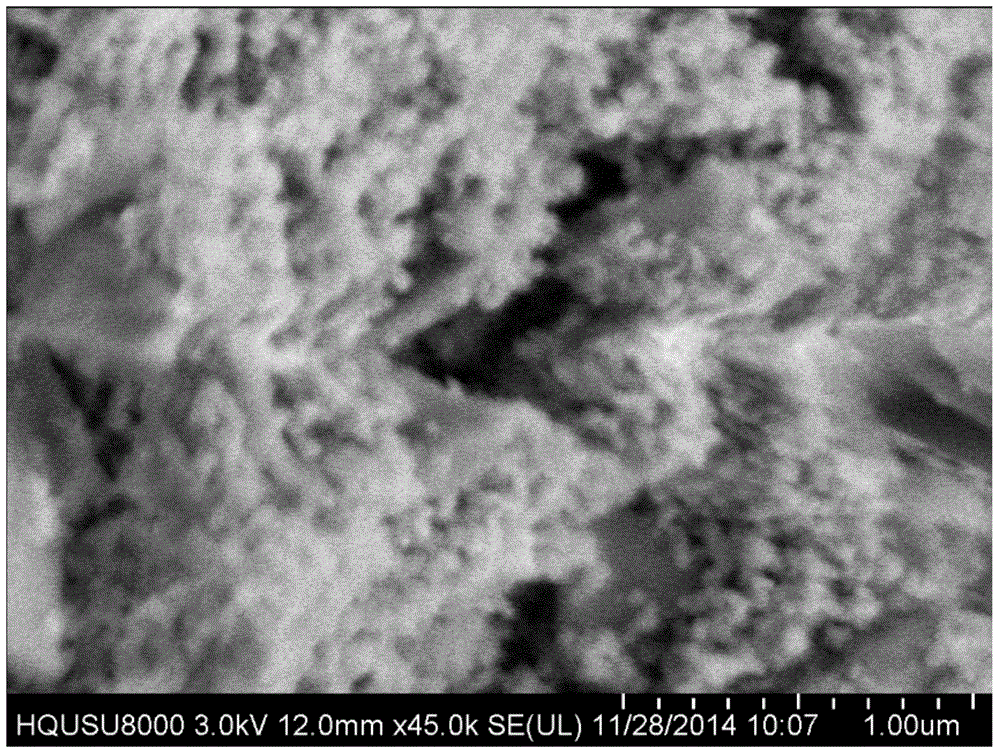

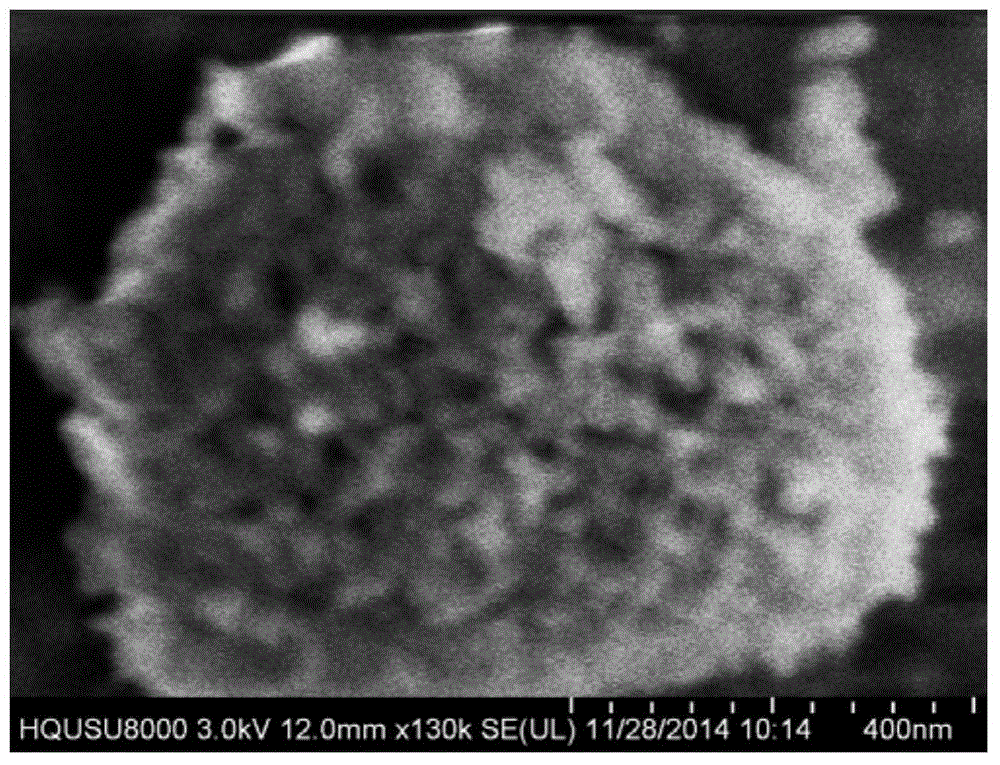

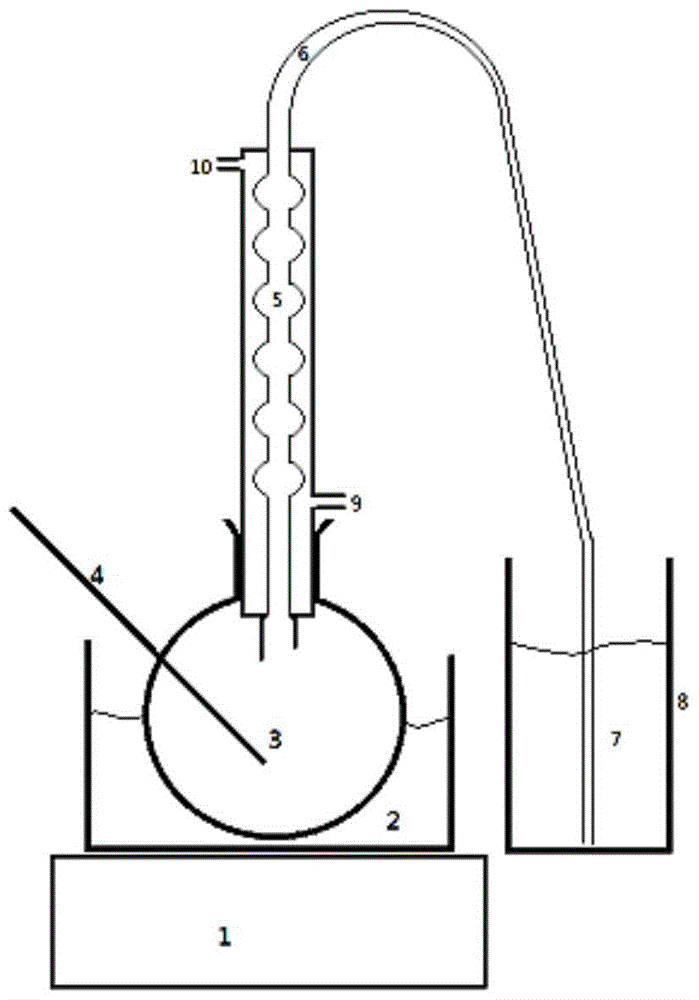

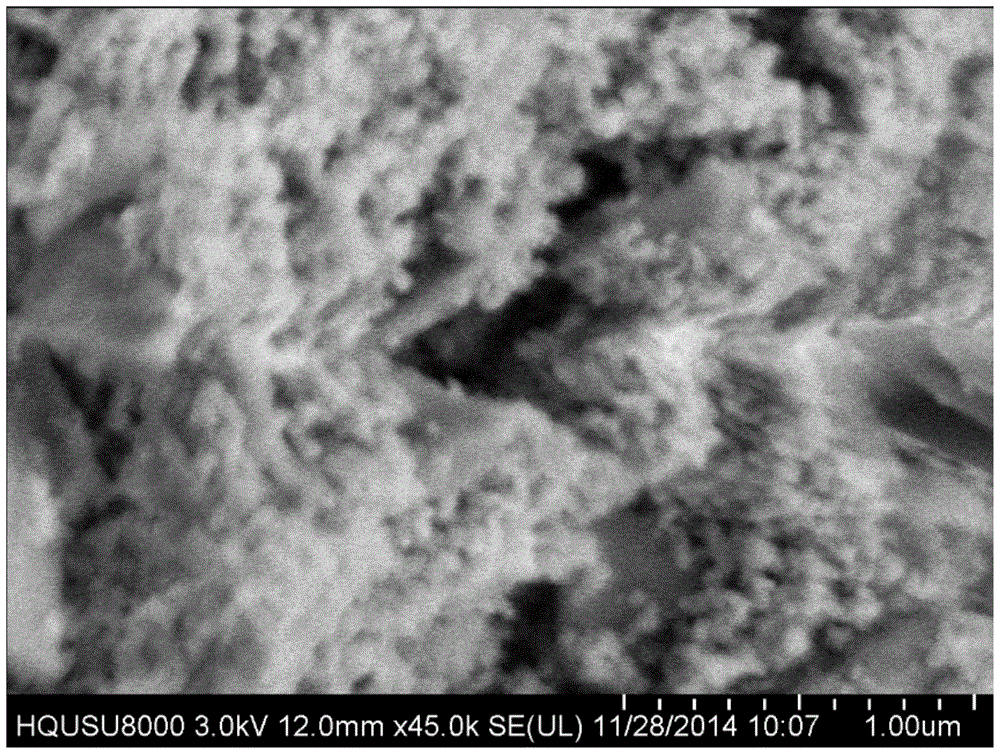

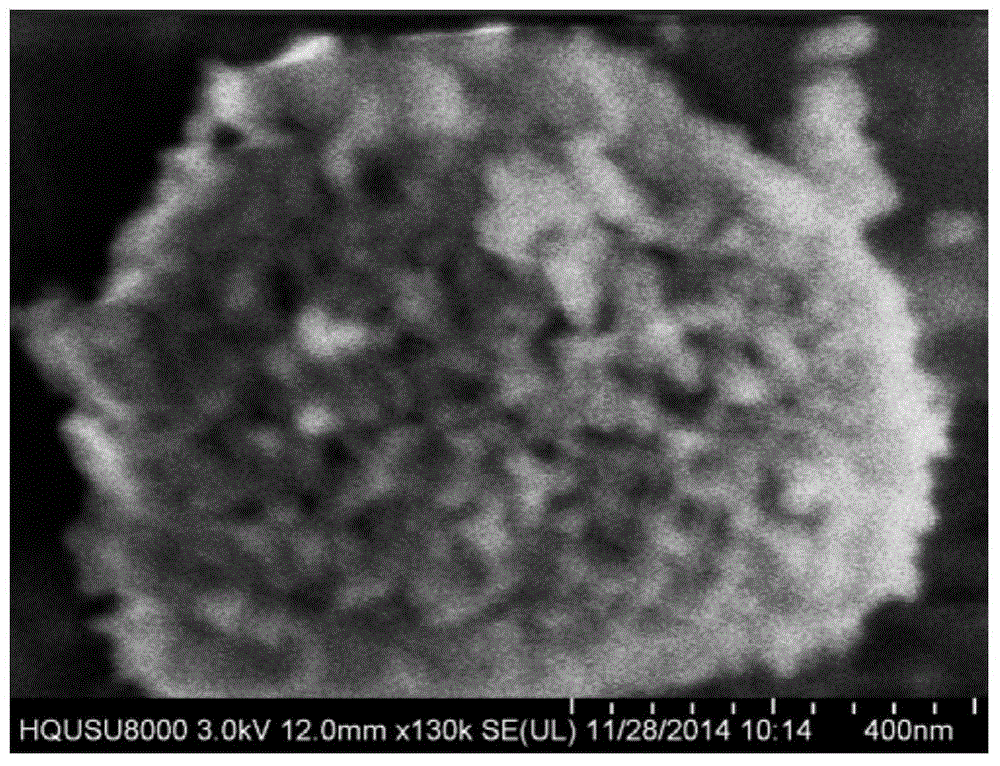

Selective catalytic reduction (SCR) nanofilm denitration catalyst, and preparation method and applications thereof

InactiveCN104971718AIncrease profitReduce volumeDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureEthylenediamineAdditive ingredient

The invention discloses a SCR nanofilm denitration catalyst, and a preparation method and applications thereof. According to the preparation method, industrial-grade common ceramic with changeable flow morphology is taken as a nanofilm catalyst carrier; a nanoparticle is taken as an auxiliary carrier; a mixture obtained via combination of V2O5 with at least one ingredient selected from PdO, MnO2, and NiO is taken as an active component; CeO2 is taken as a catalytic active ingredient; WO3 is taken as an accessory ingredient; the carrier is subjected to cleaning and drying, and then is delivered into a reflux unit filled with ethidene diamine for surface modification; the auxiliary carrier is prepared into a solution, the modified carrier is added into the solution for pulling film forming; the film-formed carrier obtain via the former step is delivered into a vacuum drying oven so as to realize chemical bond connection of the carrier with the nanoparticle; an obtained product is delivered into a mixed solution of CeO2 and WO3 for pulling film forming; and at last the SCR nanofilm denitration catalyst is obtained via drying. The SCR nanofilm denitration catalyst can be used for removing nitrogen oxides generated in combustors; turbulent flow, rotational flow, and cross flow are caused when air flow is delivered through the SCR nanofilm denitration catalyst; catalyst surface utilization rate is increased by changing flow morphology of the air flow, and catalytic efficiency is increased.

Owner:厦门宇净环保科技有限公司

A kind of scr nano membrane denitration catalyst and its preparation method and application

InactiveCN104971718BIncrease profitReduce volumeDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureBULK ACTIVE INGREDIENTVacuum drying

The invention discloses a SCR nanofilm denitration catalyst, and a preparation method and applications thereof. According to the preparation method, industrial-grade common ceramic with changeable flow morphology is taken as a nanofilm catalyst carrier; a nanoparticle is taken as an auxiliary carrier; a mixture obtained via combination of V2O5 with at least one ingredient selected from PdO, MnO2, and NiO is taken as an active component; CeO2 is taken as a catalytic active ingredient; WO3 is taken as an accessory ingredient; the carrier is subjected to cleaning and drying, and then is delivered into a reflux unit filled with ethidene diamine for surface modification; the auxiliary carrier is prepared into a solution, the modified carrier is added into the solution for pulling film forming; the film-formed carrier obtain via the former step is delivered into a vacuum drying oven so as to realize chemical bond connection of the carrier with the nanoparticle; an obtained product is delivered into a mixed solution of CeO2 and WO3 for pulling film forming; and at last the SCR nanofilm denitration catalyst is obtained via drying. The SCR nanofilm denitration catalyst can be used for removing nitrogen oxides generated in combustors; turbulent flow, rotational flow, and cross flow are caused when air flow is delivered through the SCR nanofilm denitration catalyst; catalyst surface utilization rate is increased by changing flow morphology of the air flow, and catalytic efficiency is increased.

Owner:厦门宇净环保科技有限公司

Whole-body dry-pressed porcelain induction cooker heating panel material and preparation method thereof

ActiveCN110668785BAdapt to different powerGood electromagnetic wave penetration performanceClaywaresAlkaline earth metalGlaze

The invention relates to a whole-body dry-pressed porcelain induction cooker heating panel material and a preparation method thereof. Parts by weight: blank: 30-60 parts of spodumene; 0-20 parts of cordierite; 0-20 parts of burnt gem; 0-20 parts of calcined kaolin; 10-30 parts of kaolin; 0-4 parts of minerals; 0.5-6 parts of colorants; panel colorants: 15-30 parts of spodumene; 20-30 parts of alumina; 0-5 parts of mineralizers; 30-60 parts of transition metal oxides; Panel glaze: 0-60 parts of spodumene; 0-70 parts of petalite; 0-10 parts of calcined zinc oxide; 0-10 parts of barium carbonate; 0-10 parts of calcite; 15-35 parts of fused quartz; kaolin 4 to 10 parts; 0 to 25 parts of frit; 0.5 to 6 parts of coloring material; panel coloring material is added to panel blank and panel glaze respectively according to the coloring requirements, and the addition amount is 0.5 to 6%, and the panel glaze is applied to the panel blank. form a layered structure.

Owner:刘江义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com