Secondary battery with improved film-like electrode structure

A secondary battery, film technology, applied in secondary batteries, secondary battery manufacturing, winding/folding electrodes, etc., can solve the problems of being very complicated, unusable, and limiting the tightness of electrode winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

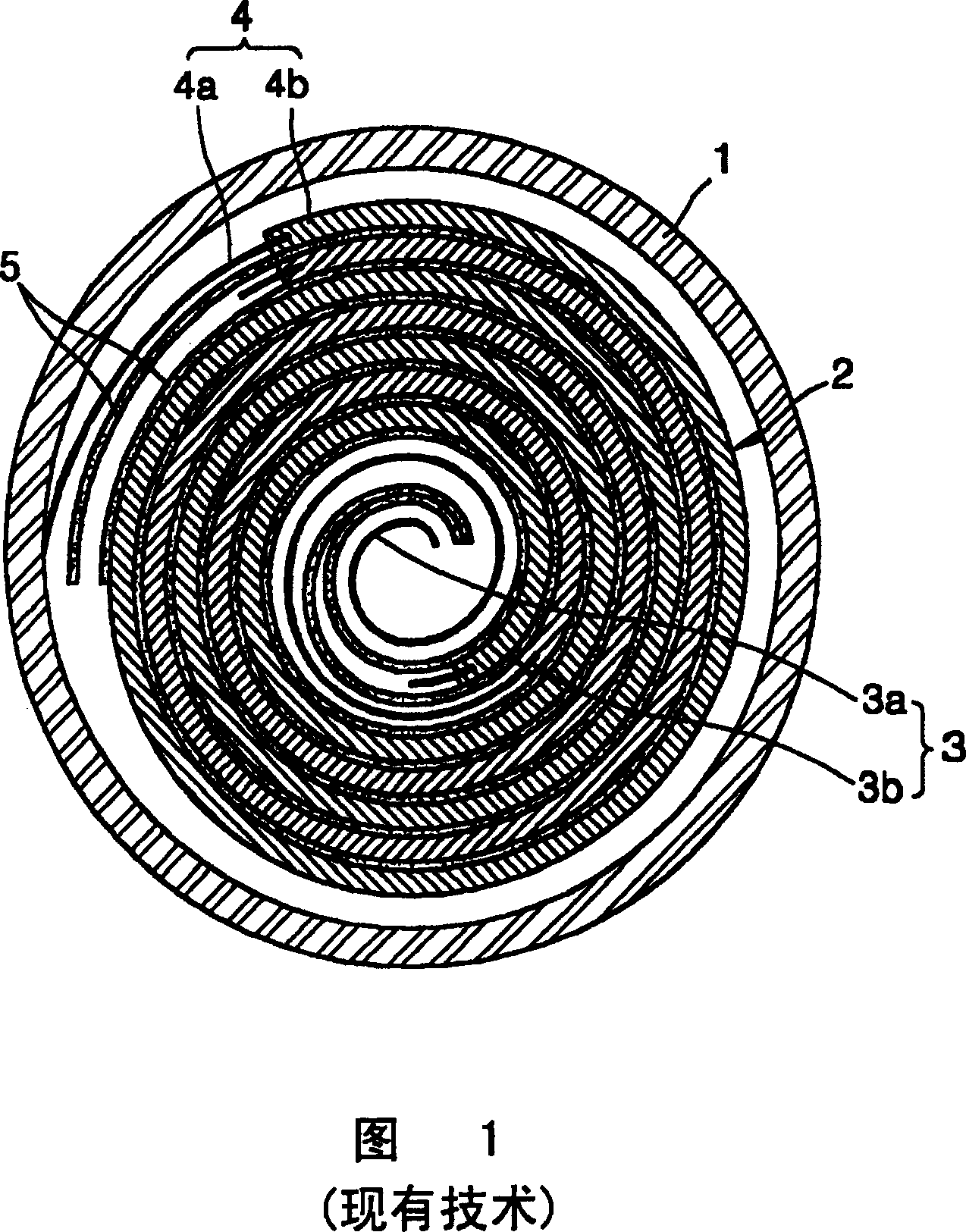

[0032] Accompanying drawing 1 is a sectional view of a cylindrical secondary battery, which shows the structure of the jelly-roll electrode of the secondary battery.

[0033] An electrode such as a positive electrode and a negative electrode can be manufactured in different ways depending on the type of electrode. Usually, as shown in Figure 1, the positive electrode 4 and the negative electrode 3 are coated with the binding liquid containing the positive electrode active material 4b and the negative electrode active material 3b on both sides of their respective base layers 4a and 3a, then it is dried, rolled and stamped And cut the base layers 3a and 3b according to the predetermined size. A separator 5 was inserted between the positive electrode 4 and the negative electrode 3 to prevent the positive electrode 4 from being electrically connected to the negative electrode 3, and finally they were wound up.

[0034] The obtained jelly-roll electrode 2 is placed in the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com