Patents

Literature

159results about How to "Improve cell structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamed thermoplastic polyurethanes

InactiveUS7202284B1Improve cell structureExcellent surface appearanceCoatingsPolymer scienceMicrosphere

Process for the preparation of foamed thermoplastic polyurethanes characterized in that the foaming of the thermoplastic polyurethane is carried out in the presence of thermally expandable microspheres.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

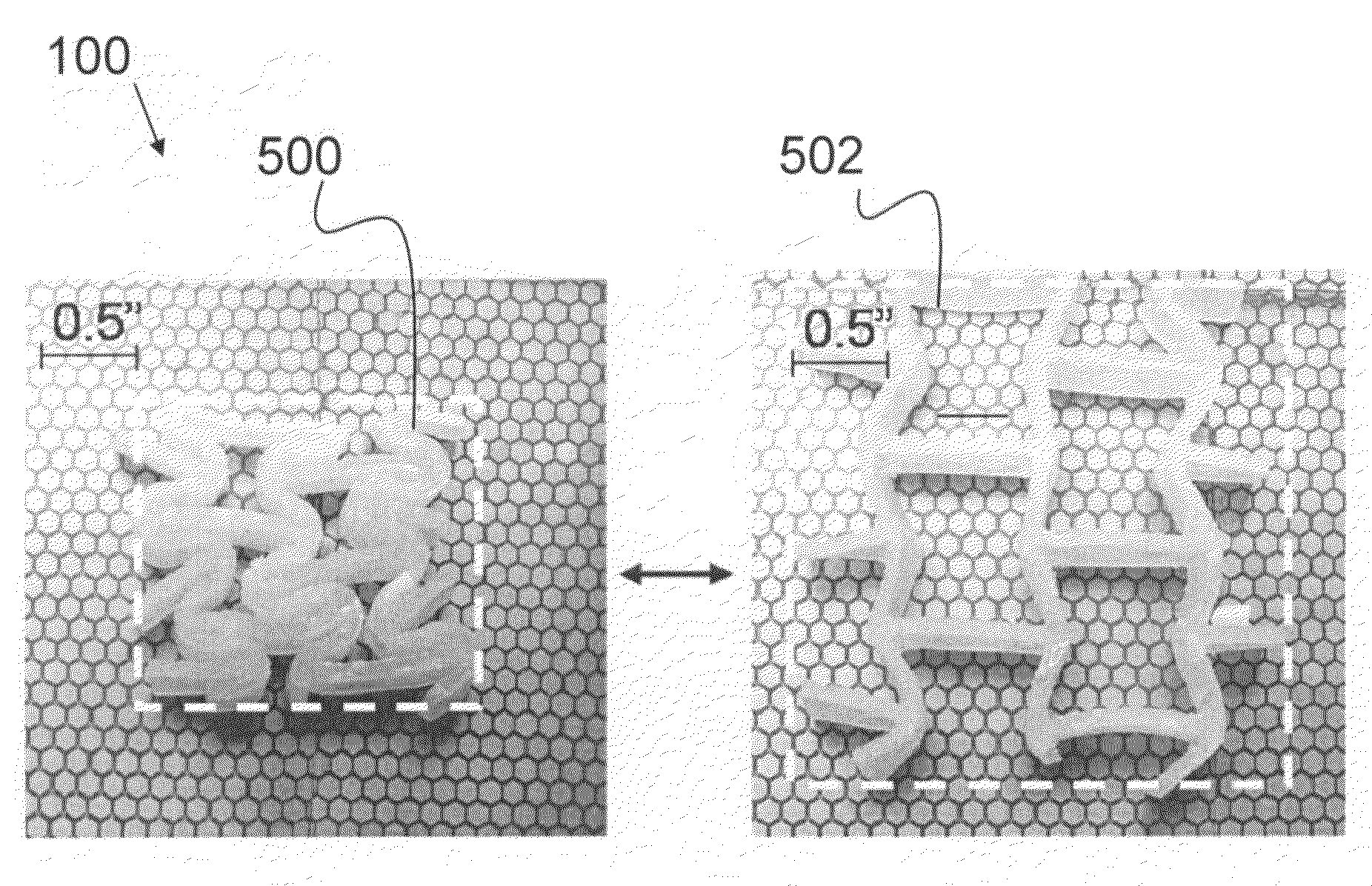

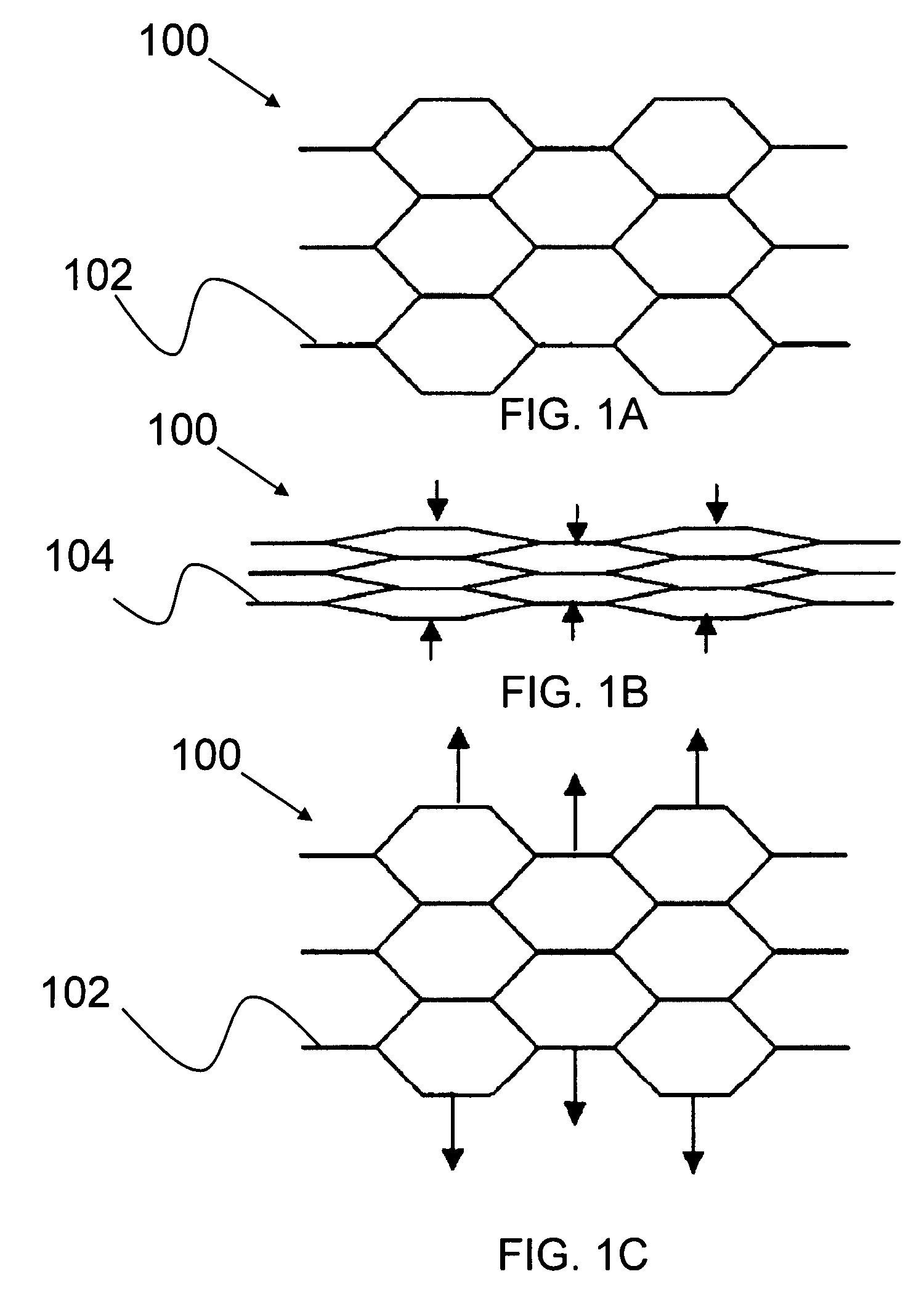

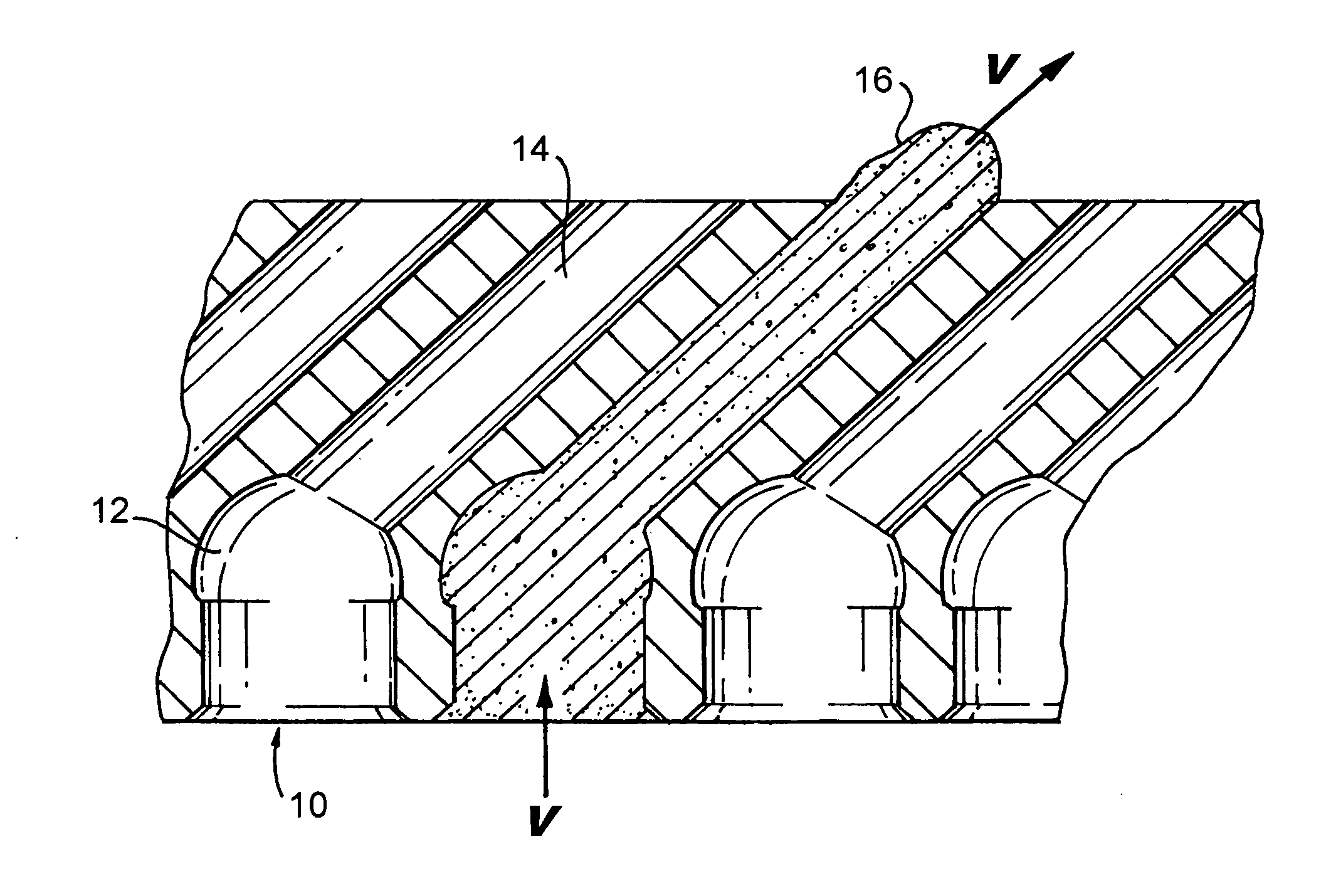

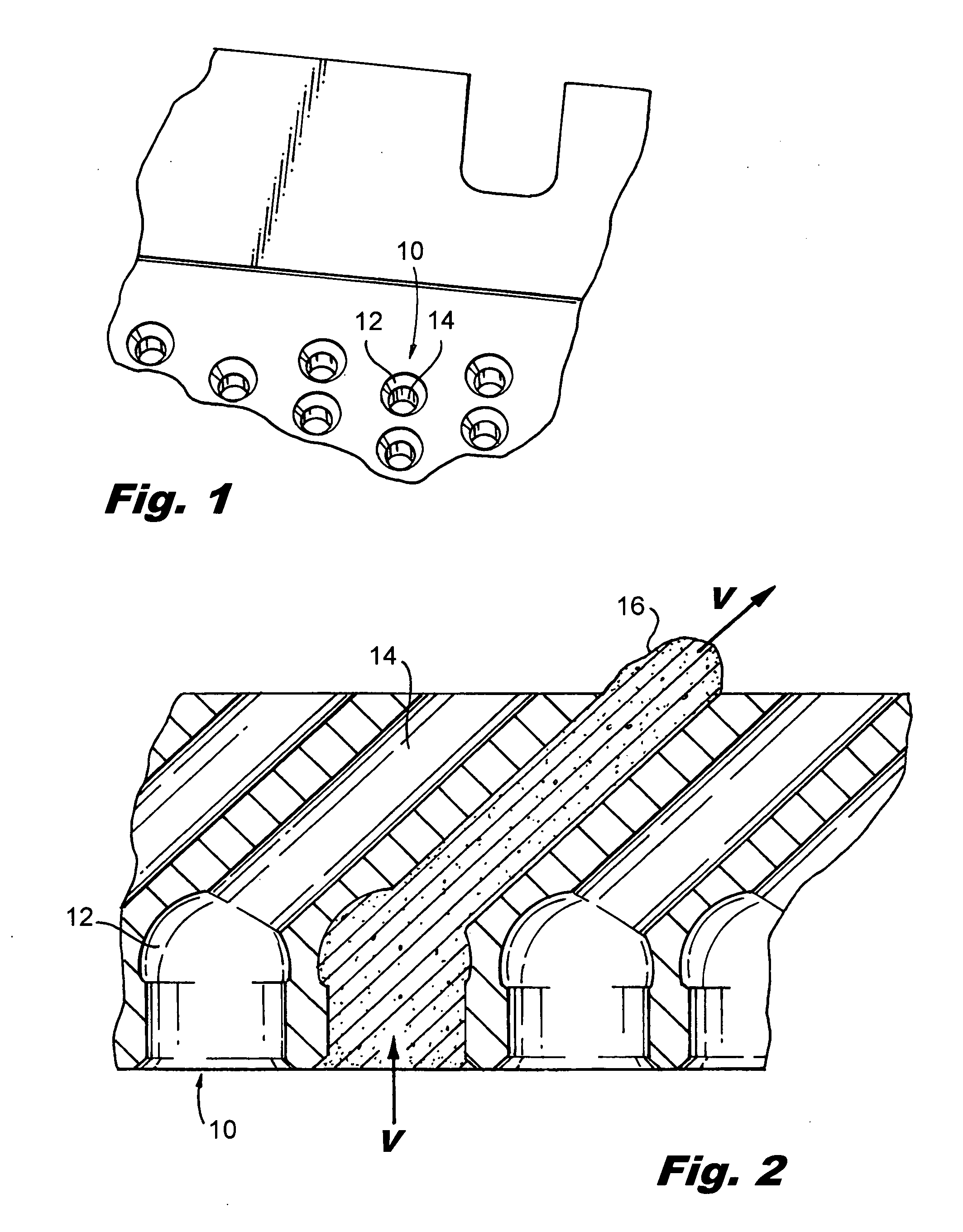

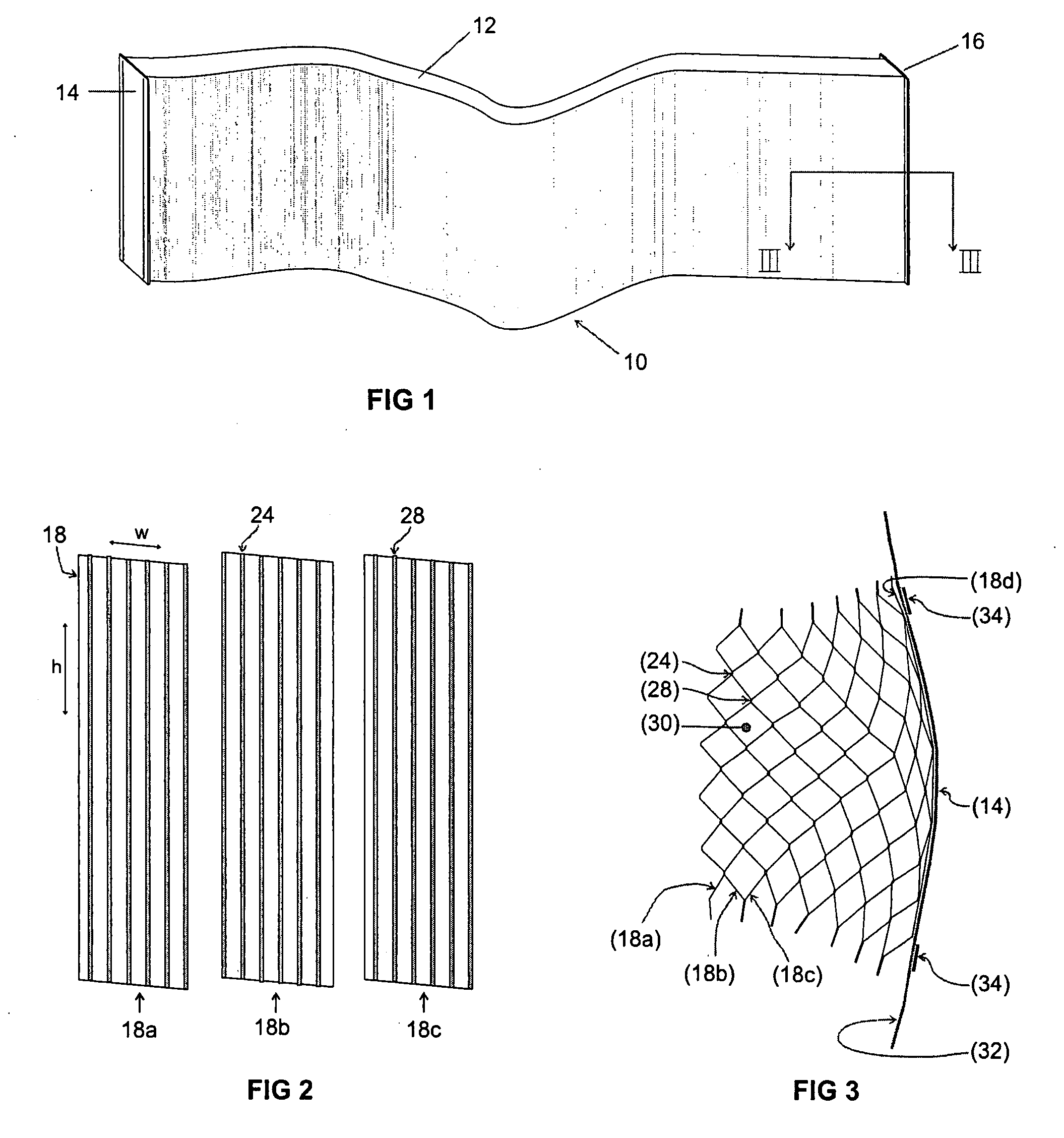

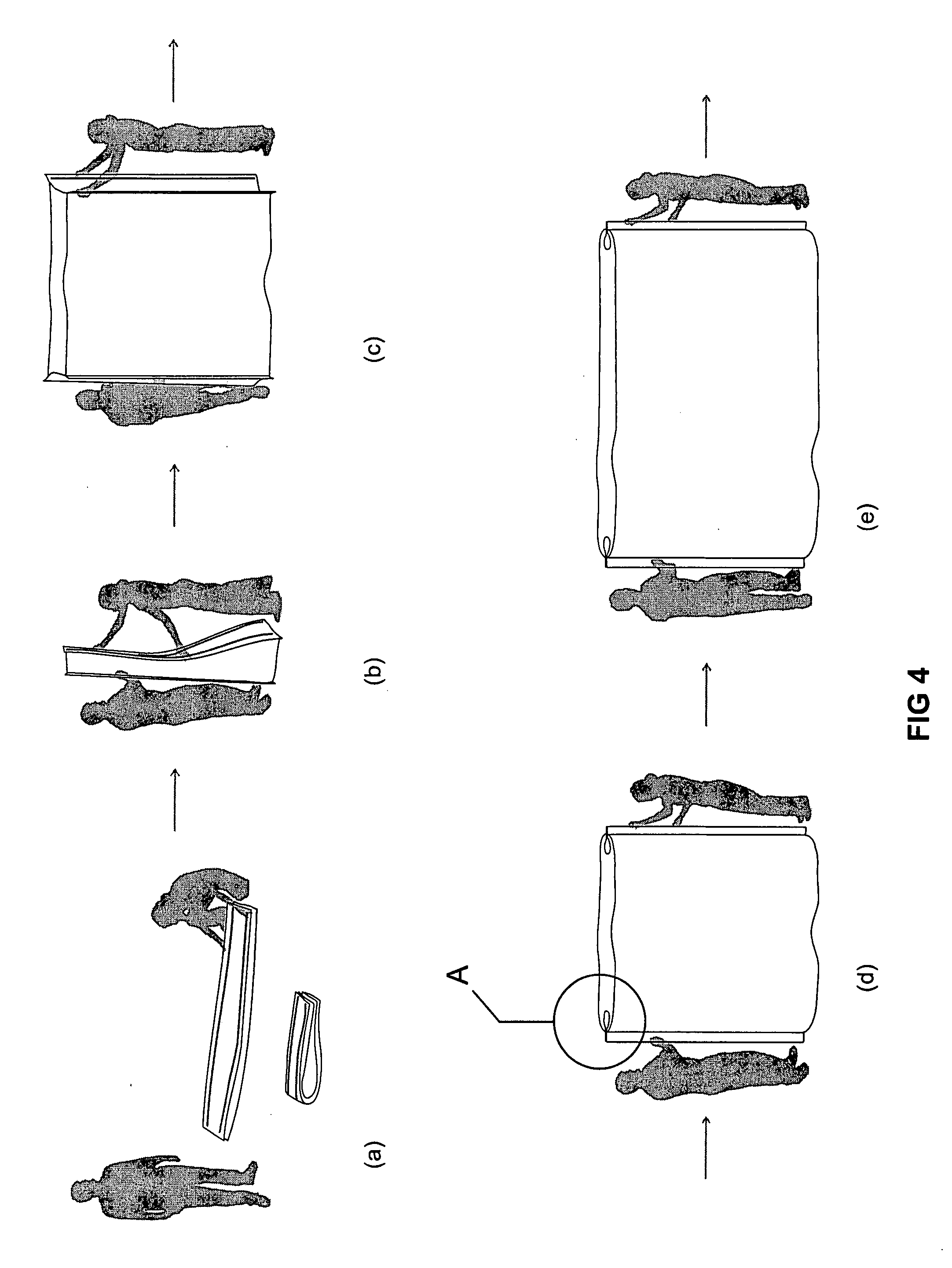

Deformable variable-stiffness cellular structures

ActiveUS7678440B1Assist shapeAssist strainLayered productsCeramic shaping apparatusVariable stiffnessHoneycomb structure

Described is a deformable, variable-stiffness cellular structure. The cellular structure a group of unit cells with each unit cell having a cellular geometry. The group of unit cells are formed of a variable-stiffness composite material (VSM). The VSM has a first stiffness state and a second stiffness state. Additionally, the cellular structure has a first shape and a second shape, with a gradation of shapes between the first shape and second shape. The transition from the first shape to the second shape occurs through using an actuation signal to actuate the VSM to change the stiffness of the cellular structure, thereby allowing the cellular structure to be deformed from the first shape to the second shape, and any shape therebetween. The cellular structure can be locked in the second shape through actuating the VSM from the second stiffness state to the first stiffness state.

Owner:HRL LAB

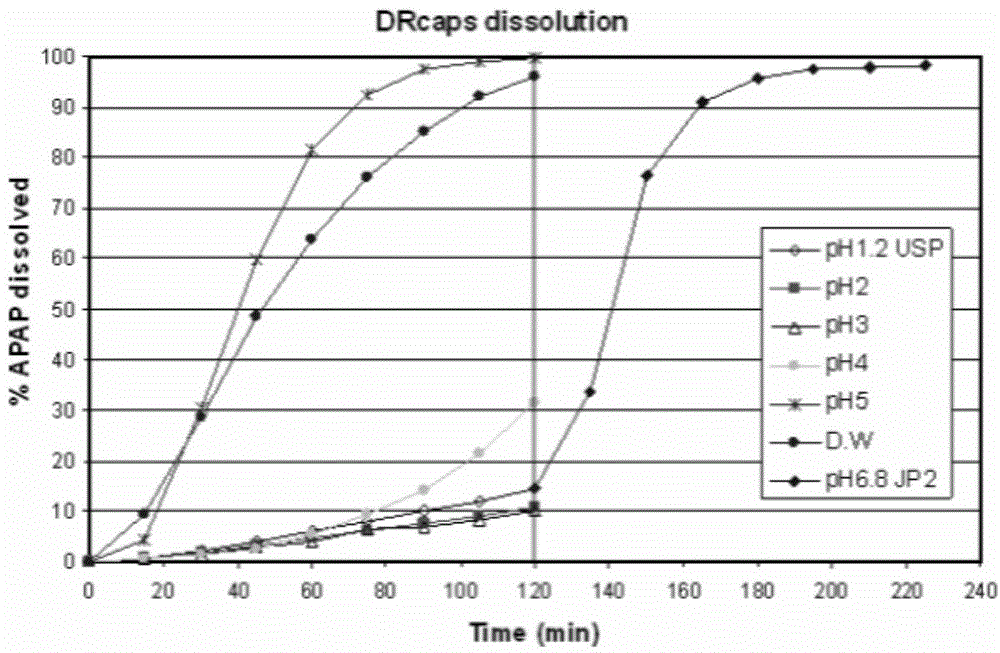

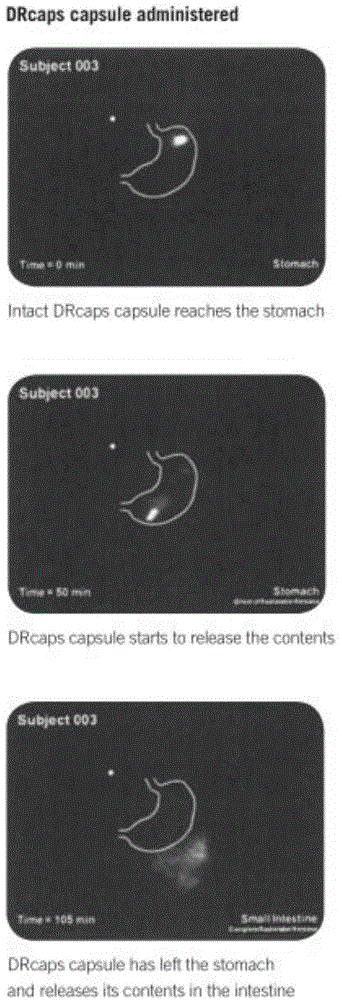

Fecal microbiota capsule, as well as preparation method and application thereof

The invention belongs to the technical field of fecal microbiota transplantation, and particularly relates to a fecal microbiota capsule, as well as a preparation method and application of the fecal microbiota capsule. The preparation method comprises the following steps: (1) a fecal microbiota solution is prepared; (2) the fecal microbiota solution, obtained in the step (1), is added with a freeze-drying protective additive, and freeze drying is performed to obtain fecal microbiota freeze-dried powder; (3) a capsule is filled with the fecal microbiota freeze-dried powder, obtained in the step (2), to obtain the fecal microbiota capsule. Through adoption of the fecal microbiota capsule, flora is enabled to be comparatively concentrated and can be preserved for a long time at a low temperature; implementation of flora transplantation is facilitated, and invasive implementation manners, such as a gastroscope, an enteroscope and a nasointestinal feeding tube, are not needed; when the fecal microbiota capsule is applied to weak patients, the safety is increased.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

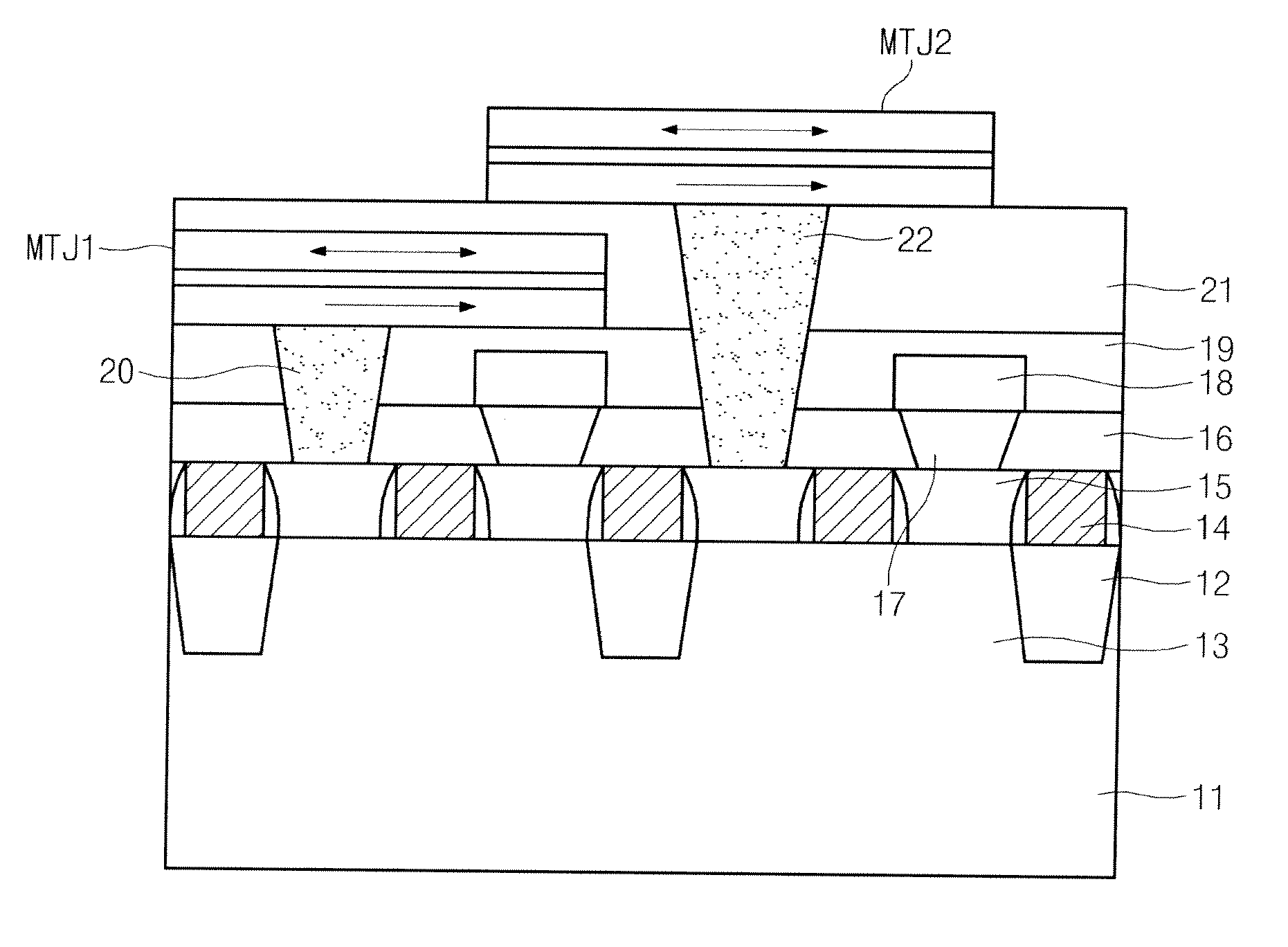

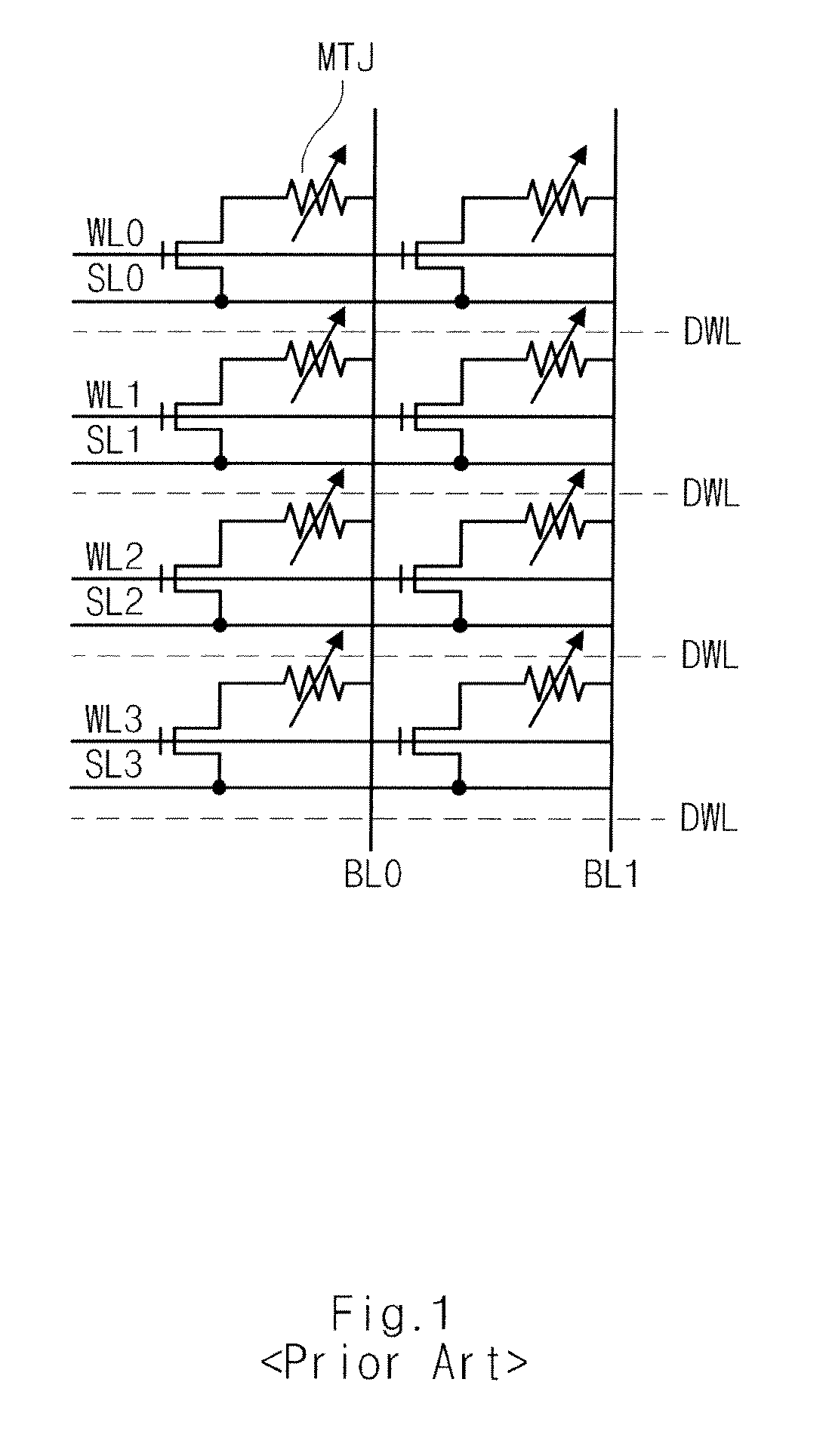

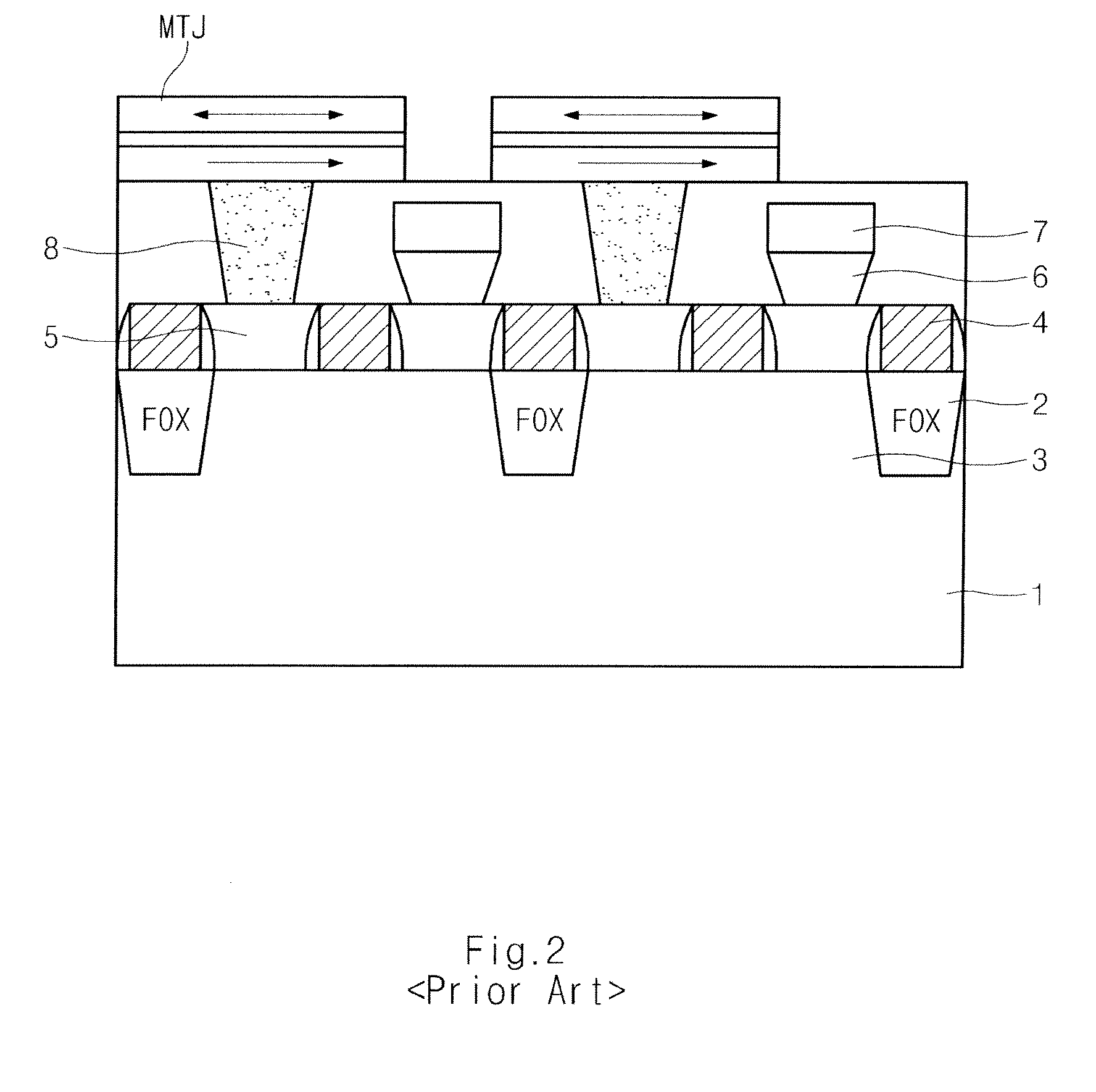

Multi-Stacked Spin Transfer Torque Magnetic Random Access Memory and Method of Manufacturing the Same

InactiveUS20100019297A1Improve cell structureEnsure thermal stabilityMagnetic-field-controlled resistorsSolid-state devicesSpin-transfer torqueRandom access memory

A spin transfer torque magnetic random access memory (STT-MRAM) device comprises adjacent magnetic tunneling junctions (MTJ), respectively, formed in different layers, thereby preventing interference between the MTJs and securing thermal stability.

Owner:SK HYNIX INC

Isocyanate-based polymer foams with nano-scale materials

Isocyante-based polymer foams containing functionalized nano-scale materials in which the functional groups are OH, NH2, COOH or NCO groups. The incorporation of such functionalized nano-scale materials into the isocyanate-based polymer foams provides foams with improved properties such as insulation values, mechanical properties and flame retardancy performance properties, including but not limited to k-factor and dimensional stability.

Owner:HONEYWELL INT INC

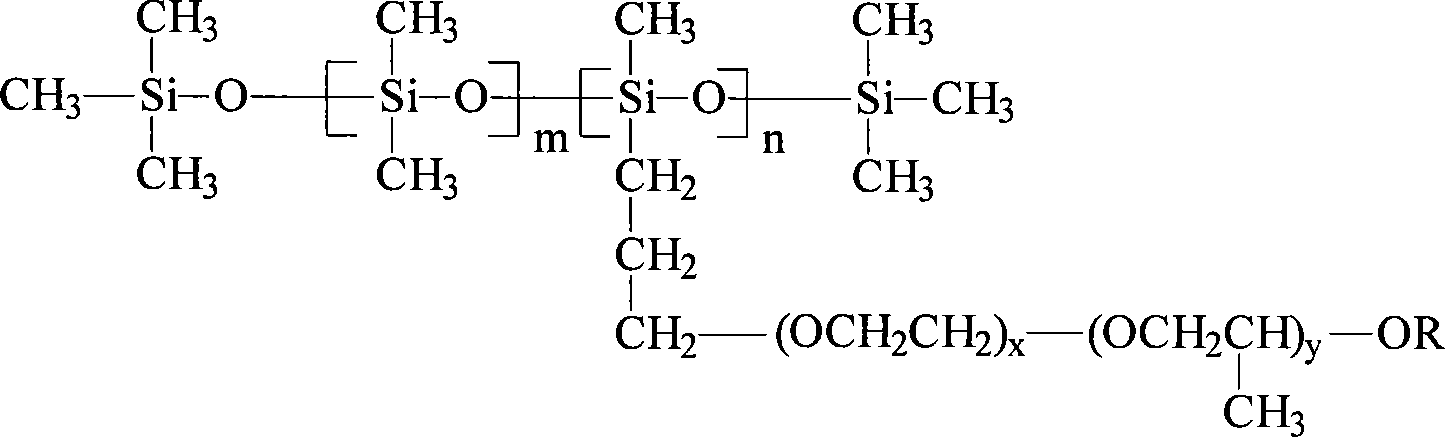

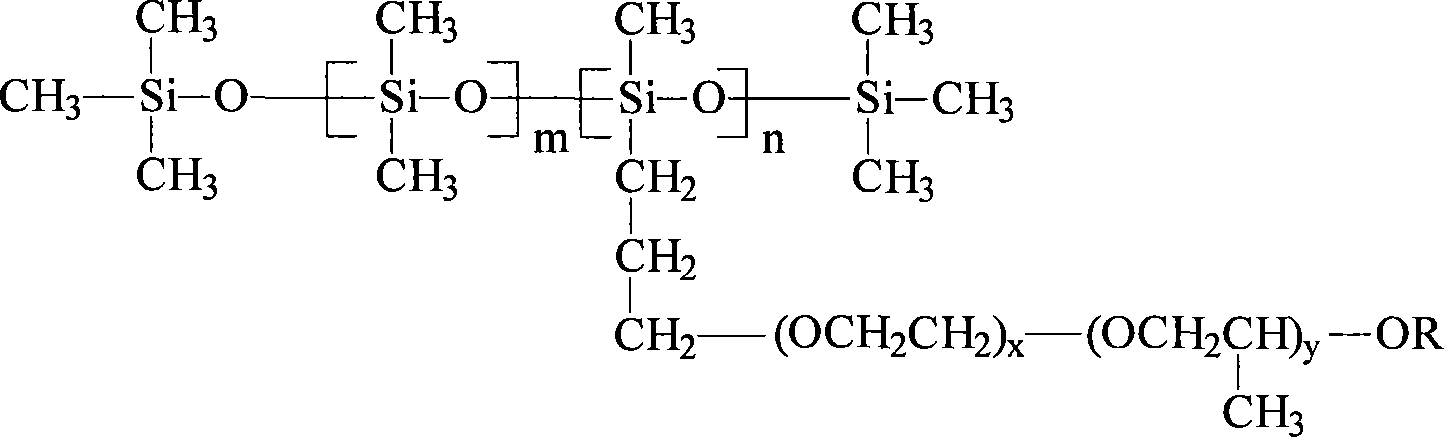

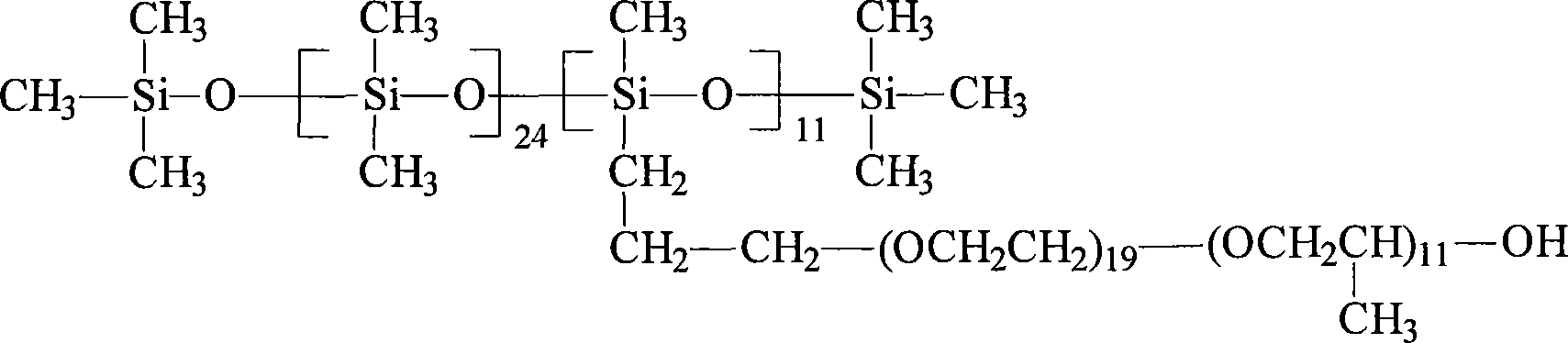

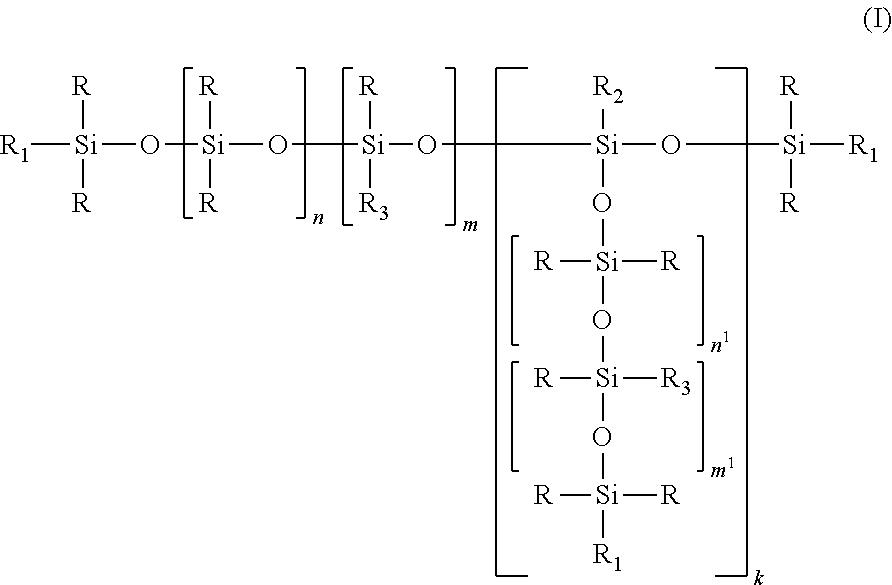

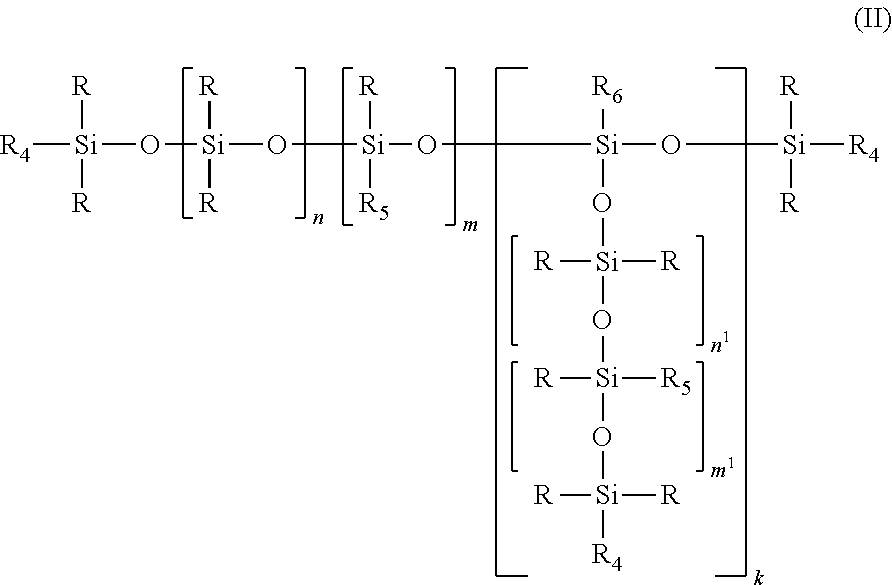

Polyurethane foam stabilizer with low density and low thermal conductivity factor and preparation method thereof

The invention discloses a low-density and low thermal-conduction-index polyurethane foam stabilizer and a preparation method thereof. The stabilizer can be widely used in polyurethane blowing technique, and enable the thermal conduction index of the pentane-blowing polyurethane foam to be lowered down to 0.0195-0.0200W / m.K, and has excellent functions of heat protection and heat preservation. The low-density and low thermal-conduction-index polyurethane foam stabilizer of the invention is provided with the structures: wherein, the figure of m is 10-80, the figure of n is 1-10, the figure of x is 10-70, the figure of y is 0-30, and m plus n is 11-90, x plus y is 10-100; R can be paraffin, radical aromatic, acyloxy or hydrogen atom that contains 1-4 carbon atoms.

Owner:JIANGSU MAYSTA CHEM

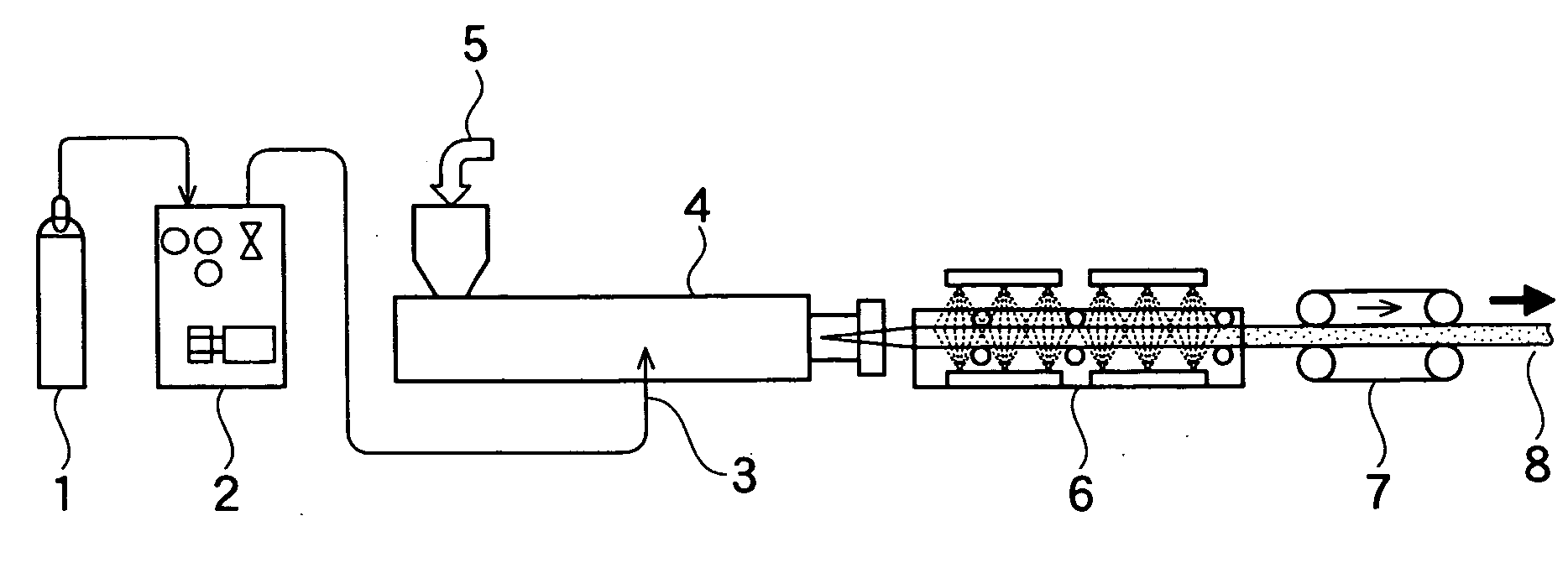

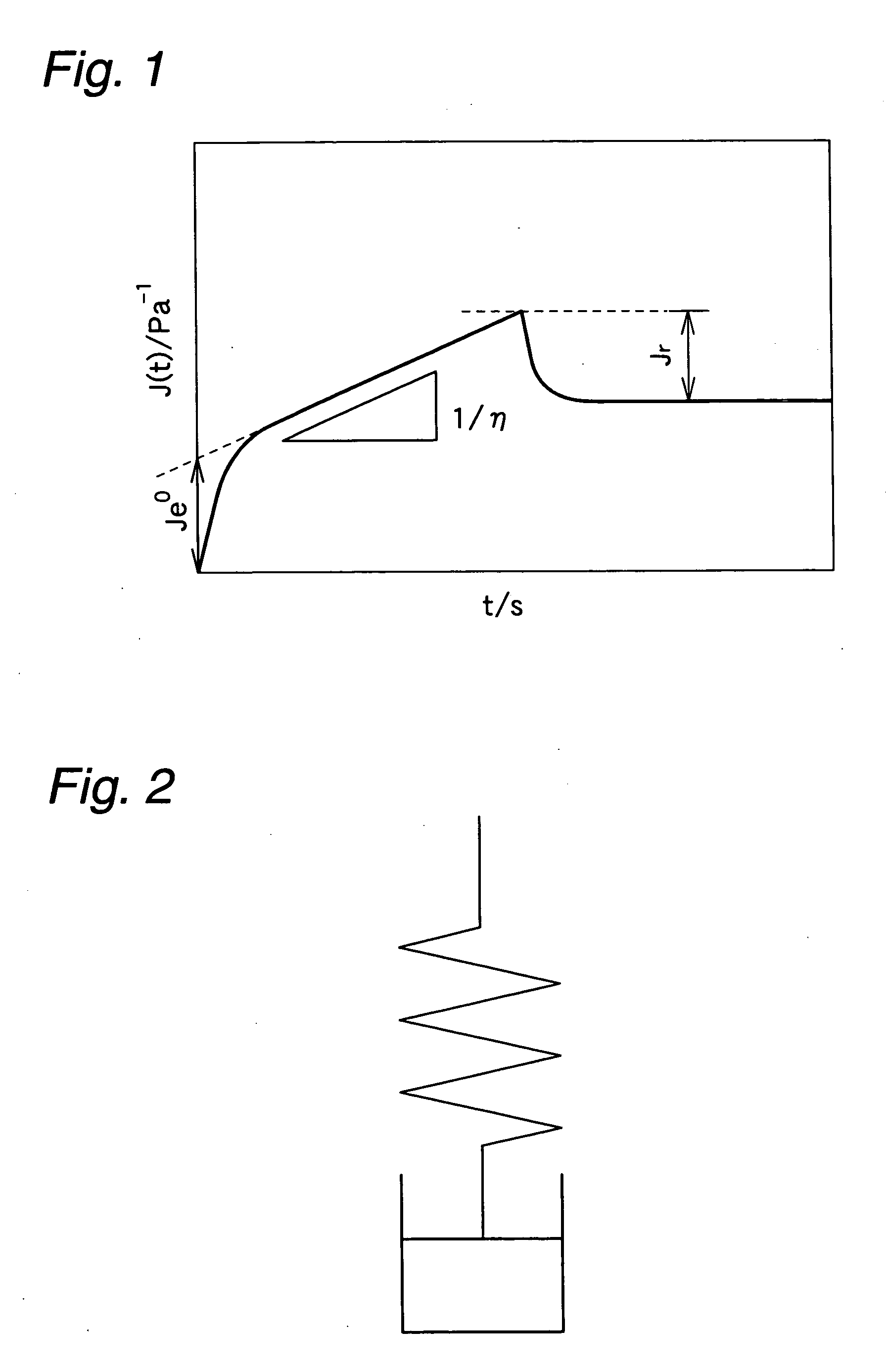

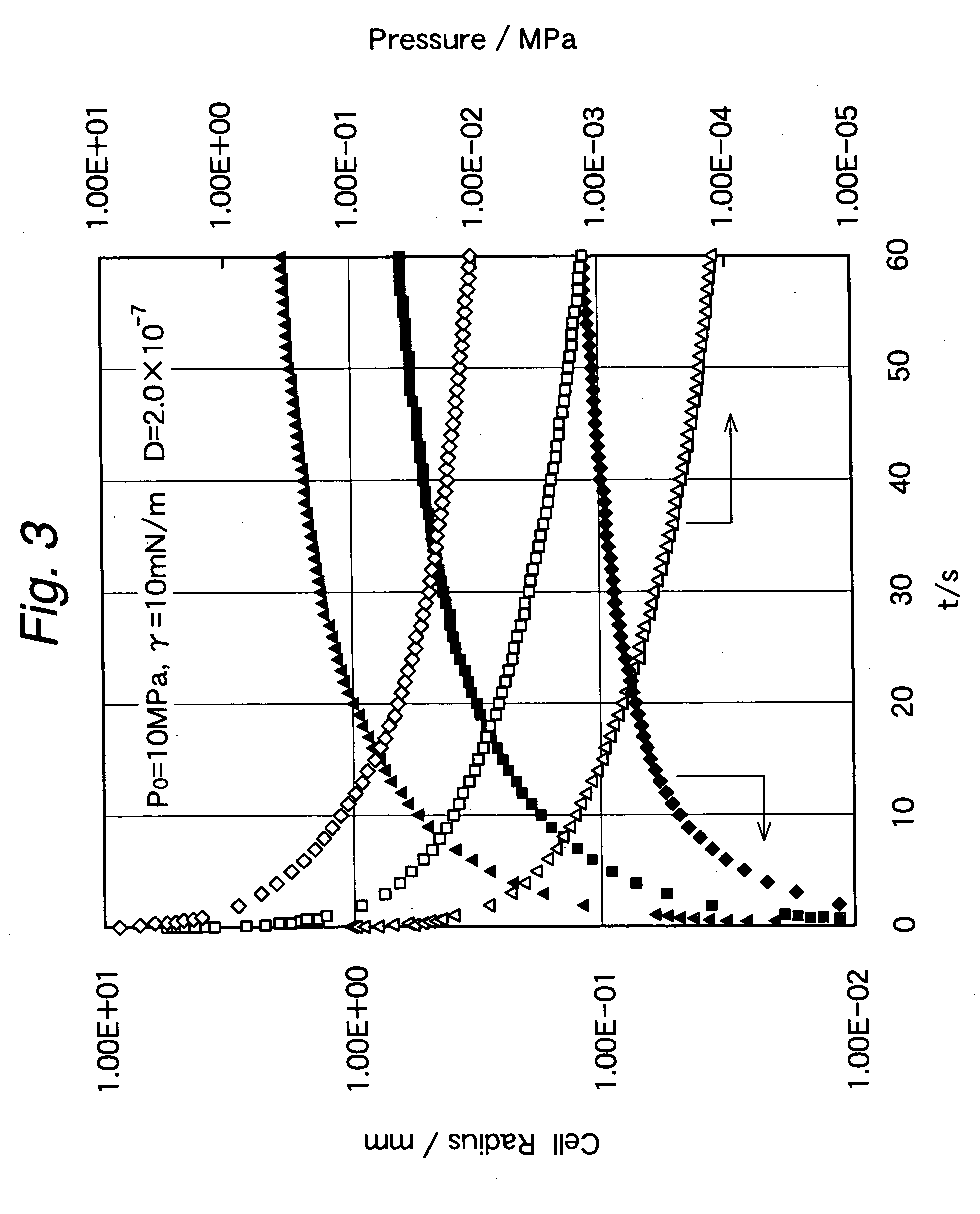

Olefin-base thermoplastic elastomer foam and olefin-base thermoplastic elastomer composition for the form

An olefinic thermoplastic elastomer foam of the present invention has a density of less than 700 kg / m<3>, a compression set of less than 60% and a density of elastically effective chains v of preferably 3.0x10<-5 >to 2.0x10<-4 >(mol / cm<3>). An olefinic thermoplastic elastomer composition for preparing the above foam has an equilibrium creep compliance Je<0 >of 1.0x10<-6 >to 5.0x10<-4 >(Pa<-1>) and contains a crosslinked olefin rubber and an olefin plastic in a specific proportion. The olefinic thermoplastic elastomer composition can be prepared by melt kneading a specific crosslinked olefinic thermoplastic elastomer and a specific olefin plastic. The olefinic thermoplastic elastomer composition is preferably foamed by at least one foaming agent selected from an organic or inorganic thermally decomposable foaming agent, carbon dioxide and nitrogen, together with a specific foaming auxiliary such as citric acid. The olefinic thermoplastic elastomer foam is particularly suitable to use as an automotive sponge weatherstrip, a clearance-filling foamed sheet, a building sash sponge seal, a pipe-joint sponge seal, a protect sponge or a thermal insulating sponge tube. The olefinic thermoplastic elastomer composition according to the invention can provide the foams which have no surface roughness, a low density and a low compression set, preferably a good appearance and a kink resistance. The olefinic thermoplastic elastomer foams can be used as substitutes for vulcanized rubbers.

Owner:MITSUI CHEM INC

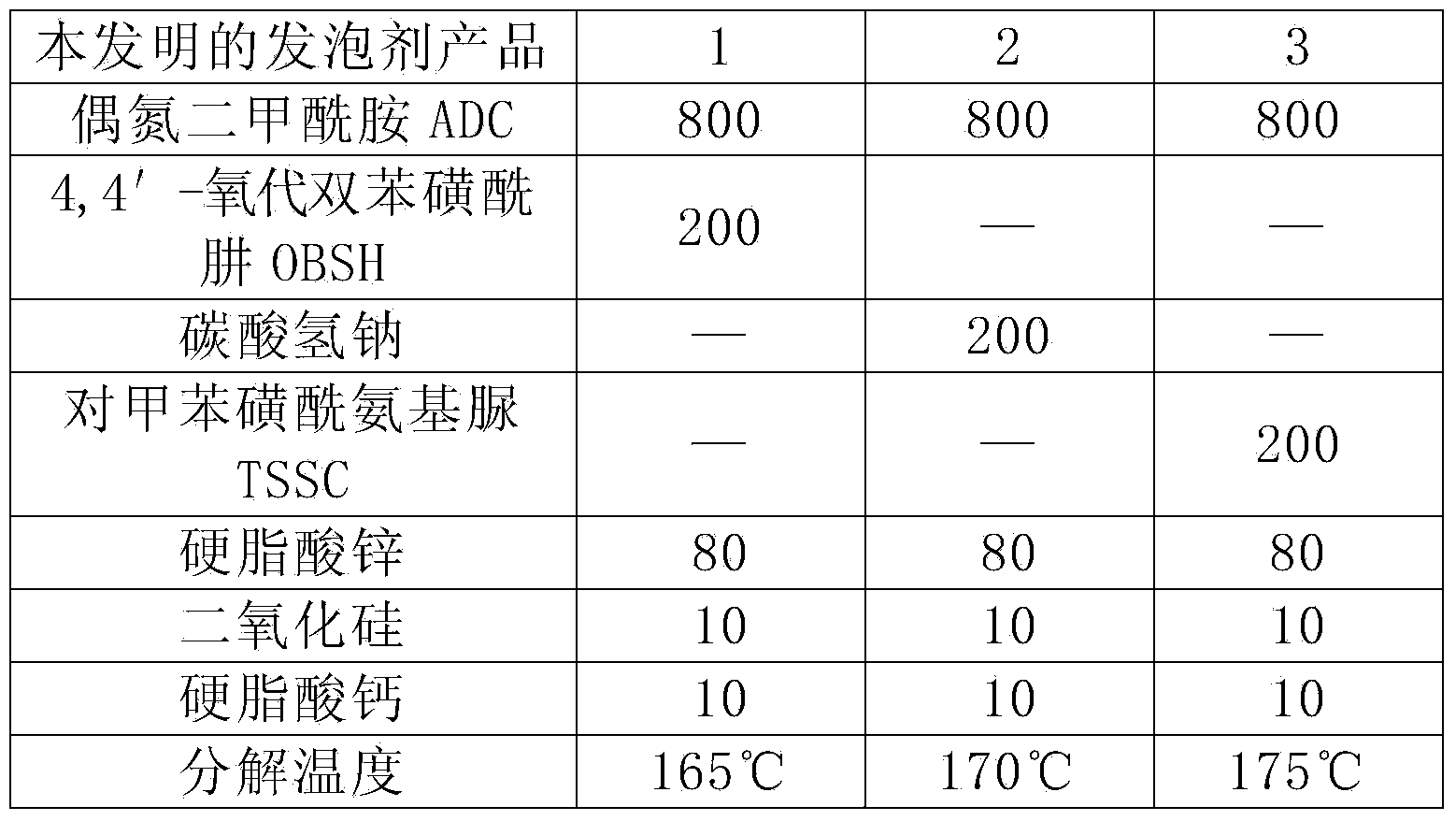

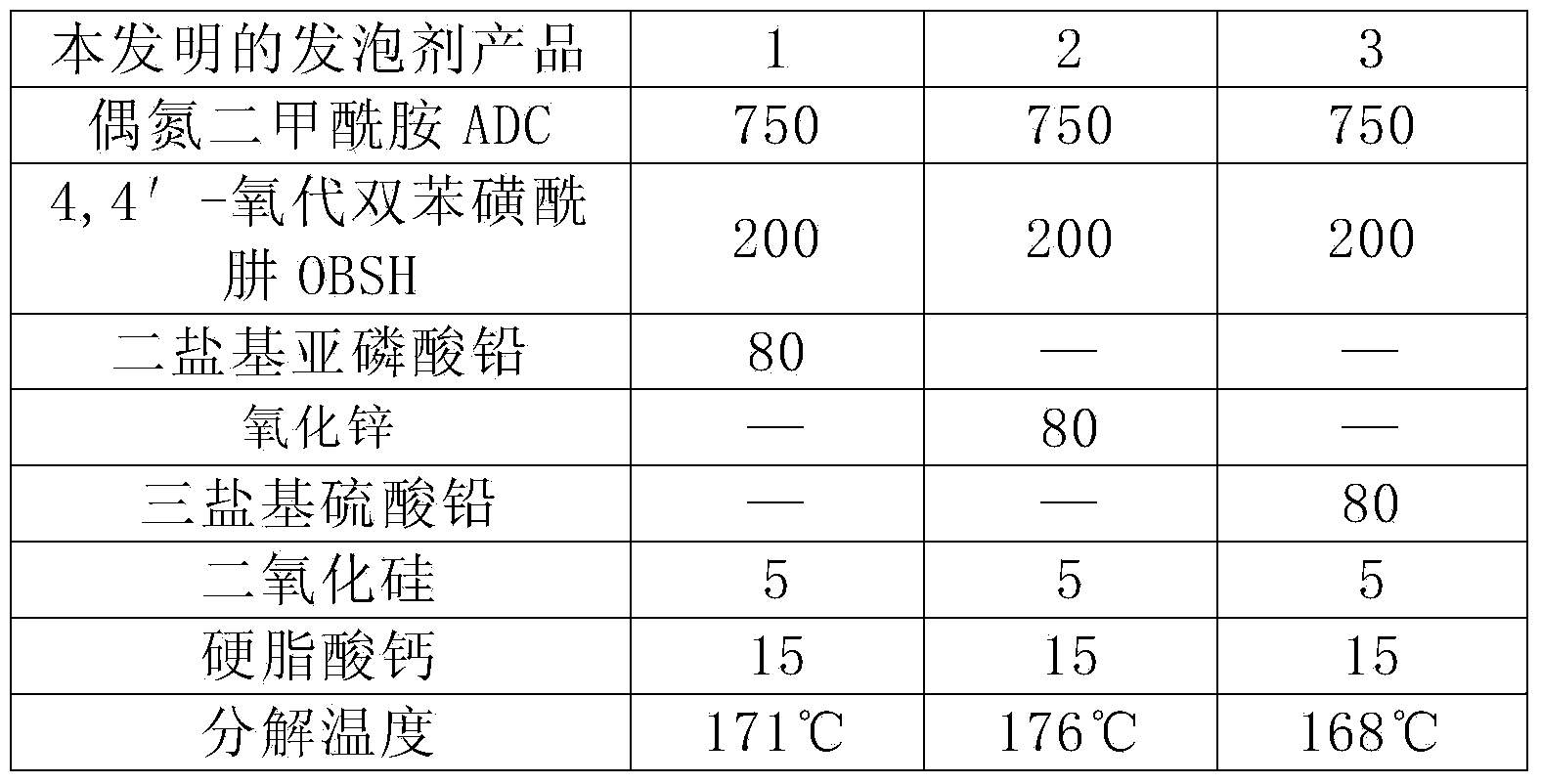

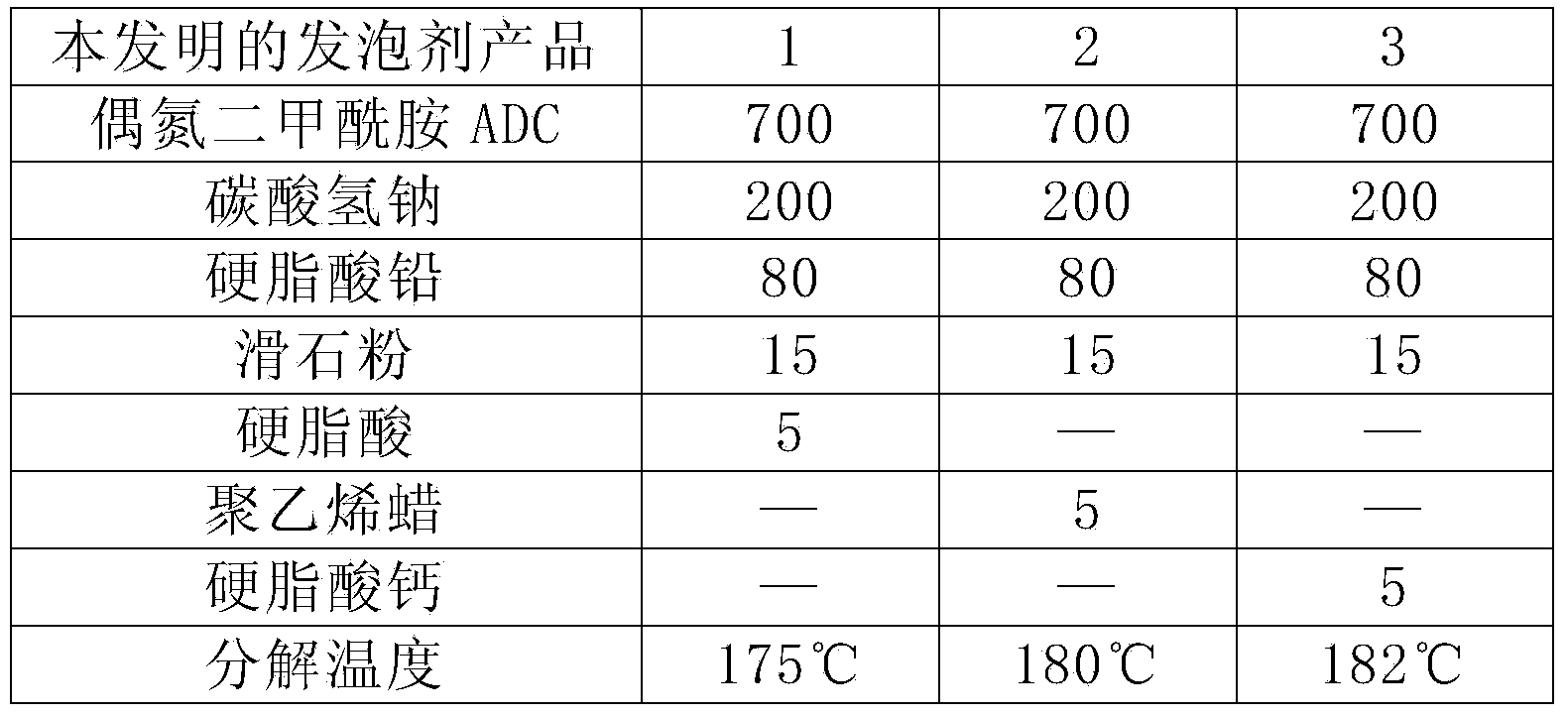

Special foaming agent for hard PVC (polyvinyl chloride) low-foaming material and preparation method thereof

The invention discloses a special foaming agent for a hard PVC (polyvinyl chloride) low-foaming material and a preparation method thereof. The special foaming agent comprises the following materials in parts by weight: 20-80 parts of azodicarbonamide (ADC), 20-80 parts of auxiliary foaming agent, 1-20 parts of activating agent, 0.2-10 parts of dispersing agent and 0.2-5 parts of processing agent. The preparation method comprises the steps: adding the dispersing agent and the processing agent in a mixer, mixing for 3-7 minutes, and sequentially uniformly mixing the ADC, the auxiliary foaming agent and the activating agent in the mixer to prepare the special foaming agent. The special foaming agent is suitable for hard PVC low-foam materials such as PVC crushing and low-foaming sectional bars, tubular products and sheets, a wood-plastics low-foaming material and the like. The special foaming agent has the positive effects that 1, the decomposition temperature is 160-190 DEG C, and is within a processing temperature range of the hard PVC low-foaming material; 2, the foaming process is short in induction period, the decomposition is performed without mutation, and the foaming process is easily controlled; 3, the hard PVC low-foaming material is used on a hard PVC low-foaming product, and has a smooth surface and has no discoloring and ageing phenomena; and 4, the special foaming agent is low in cost and good in comprehensive performance, and accords with the use requirement.

Owner:WEIFANG YAXING GRP CO LTD

Polyimide porous body and method for producing same

InactiveUS20140127494A1Excellent mechanical strength and propertyFine cell structureLayered productsPretreated surfacesChemistryPolyamide

An object of the present invention is to provide a polyimide porous body having an excellent heat resistance, a fine cell structure, and a low relative dielectric constant, and a method for producing the polyimide porous body. The present invention relates to a method for producing a polyimide porous body, comprising a step for applying a polymer solution containing a polyamide acid, a phase separation agent for separating the phases of the polyamide acid, an imidization catalyst, and a dehydrating agent, on a substrate, and drying the polymer solution to produce a phase-separated structure body having a microphase-separated structure; a step for producing a porous body by removing the phase separation agent from the phase-separated structure body; and a step for subjecting the polyamide acid in the porous body to imidization to synthesize a polyimide.

Owner:NITTO DENKO CORP

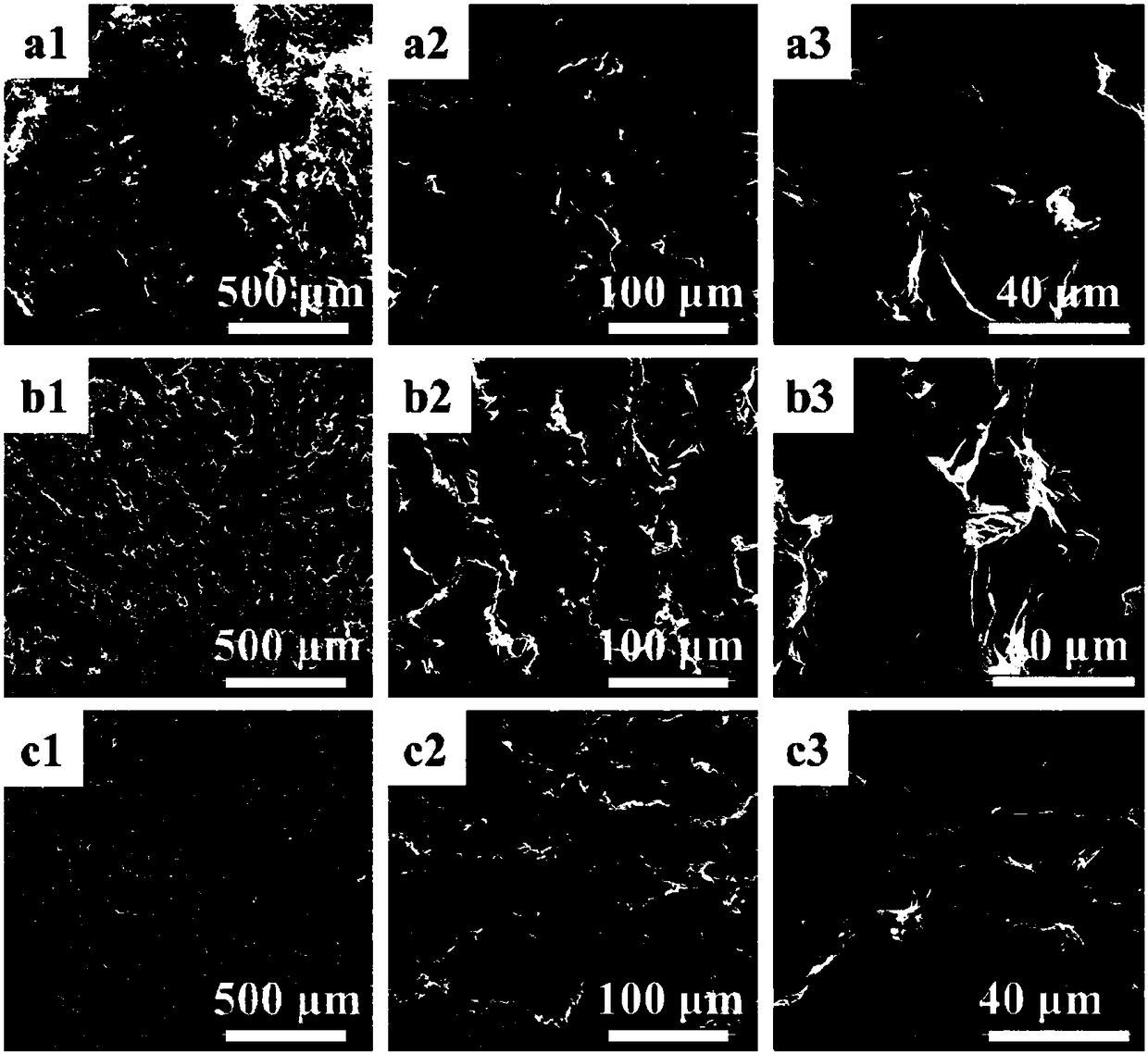

Polymer/graphene aerogel composite foam material and preparation method thereof

ActiveCN108250728AAvoid reunionAvoid uneven dispersionGraphenePolymer chemistryThermoplastic polymer

The invention provides a polymer / graphene aerogel composite foam material which is prepared from graphene aerogel and a thermoplastic polymer, wherein the graphene aerogel serves as a framework, the thermoplastic polymer is attached to the three-dimensional net structures of the graphene aerogel, and foam holes with closed pore structures are formed in the thermoplastic polymer. The composite foammaterial has mutually communicated three-dimensional net structures, and the content of the graphene aerogel in the composite foam material is 0.5%-10%. The invention also provides a preparation method of the composite foam material. The invention provides a new idea for solving the problem of agglomeration of graphene in polymer matrix materials.

Owner:SICHUAN UNIV

Room temperature crosslinked foam

Foams for filling cavities and crevasses and for forming foamed products are provided. The latex foam may include an A-side containing a functionalized latex and a B-side that contains a crosslinking agent and optionally a non-functionalized latex. The A- and / or B-side contain a blowing agent package or components forming the blowing agent package. The blowing agent package may be the combination of two or more chemicals that when mixed together form a gas or a chemical compound that, when activated by heat or light, forms a gas. In an alternate embodiment, the latex foam includes a functionalized latex, an acid, and an encapsulated crosslinking agent and base. Alternatively, the spray latex foam may include a functionalized latex, a crosslinking agent, and an encapsulated dry acid and dry base. The encapsulating agent may be a protective, non-reactive shell that can be broken or melted at the time of application.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

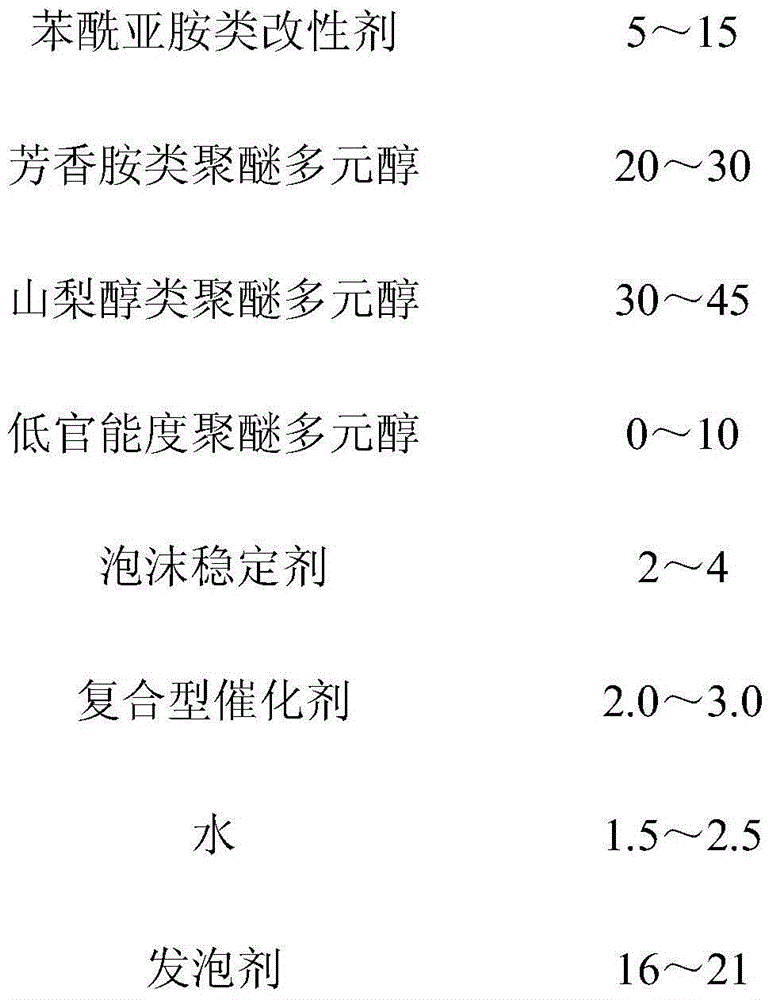

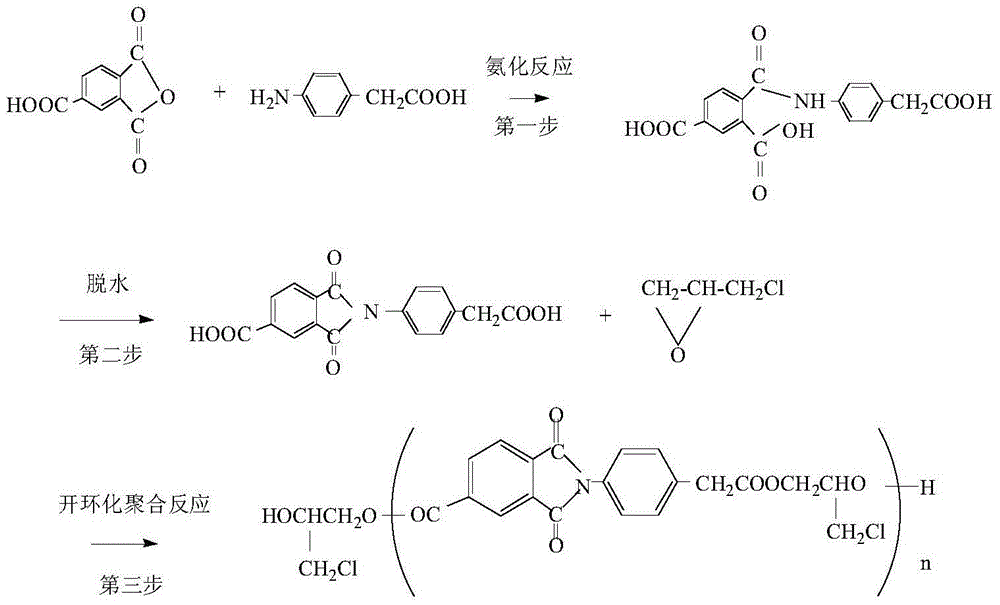

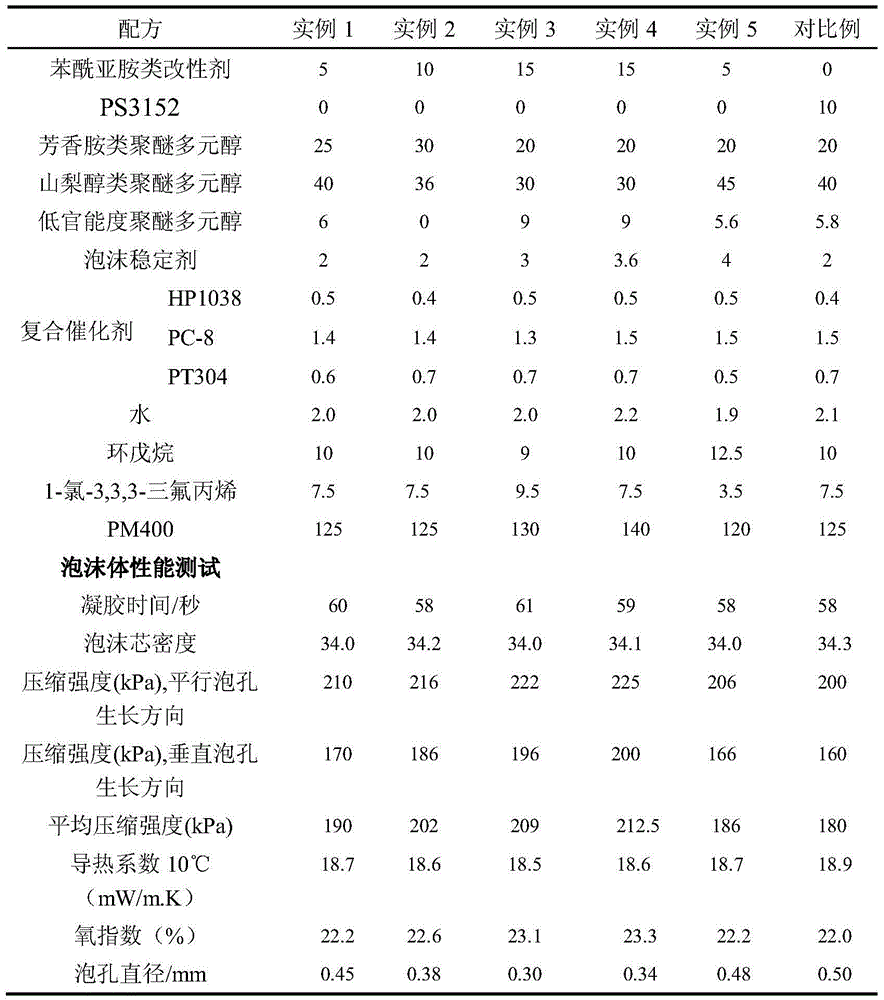

High-strength polyurethane rigid foam as well as preparation method and application thereof

ActiveCN104672420AIncrease internal rotation resistanceImprove rigidityRigid structureAromatic amine

The invention discloses high-strength polyurethane rigid foam, as well as a preparation method and application thereof. The invention introduces a benzoyl imide reinforced polyurethane modifier with a rigid structure; the benzoyl imide reinforced polyurethane modifier, the corresponding high-viscosity aromatic amine polyether polyol, low functionality polyether polyol, special silicon oil for increasing isotropy of the foam, a catalyst with a specific structure, water and a foaming agent are used for preparing the premixed polyether polyols and react with the polyisocyanates to generate the high-strength polyurethane foam. The polyurethane rigid foam provided by the invention has the characteristics of low batch charging density, high compressive strength, low heat conductivity coefficient and good size stability under low temperature, and can be used in the household appliance inside insulating materials such as the fridge, the refrigerator, the solar energy, the gas water heater and the disinfection cabinet.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

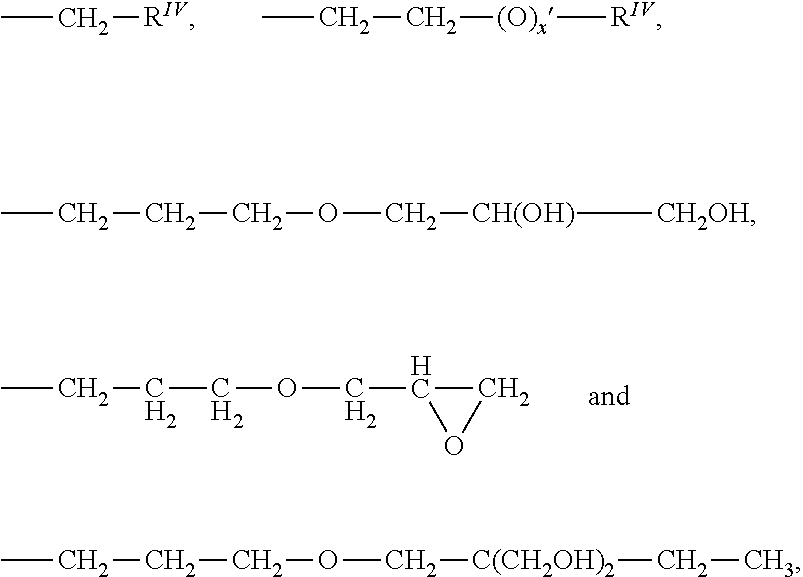

Polysiloxane polyether copolymers having (polyether)moieties comprising carbonate groups and their use as stabilizers for the production of polyurethane foams

InactiveUS20130035409A1Improve distributionBalanced property profileSilicon organic compoundsCopolymerCarbonate

The present invention relates to polysiloxane polyether copolymers which comprise at least one (polyether) moiety which comprises at least one unit —O—C(O)—O—, to a process for the production of the polysiloxane polyether copolymers, and also to the use of the polysiloxane polyether copolymers as stabilizers in the production of polyurethane foams, and also to polyurethane foams and items therefrom which are obtainable through the process.

Owner:EVONIK OPERATIONS GMBH

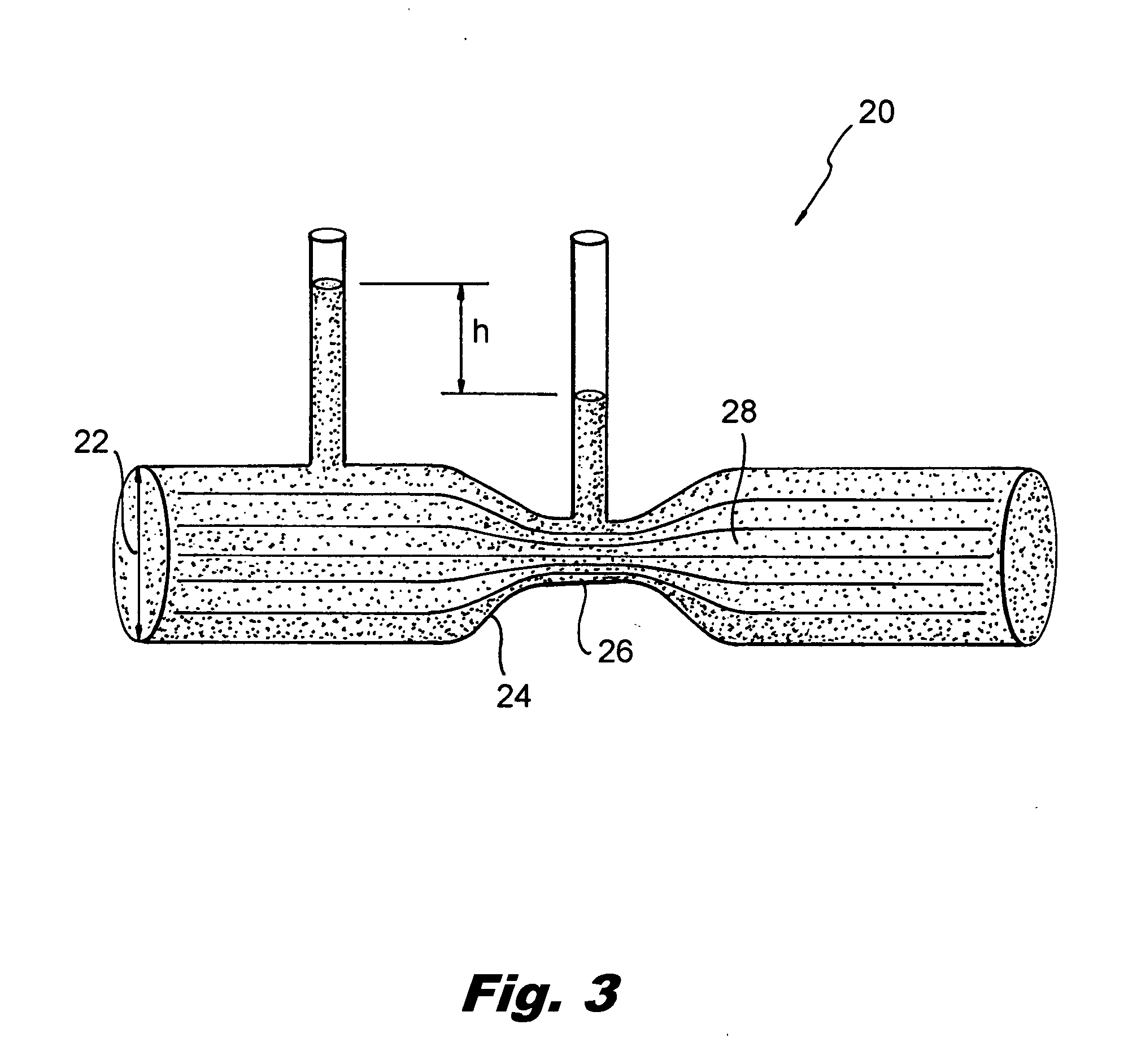

System and method for creating a venturi effect within an orifice

InactiveUS20130164425A1Reduce frictionIncrease pressureConfectioneryMeat processingEngineeringVenturi effect

Owner:FORMTEC

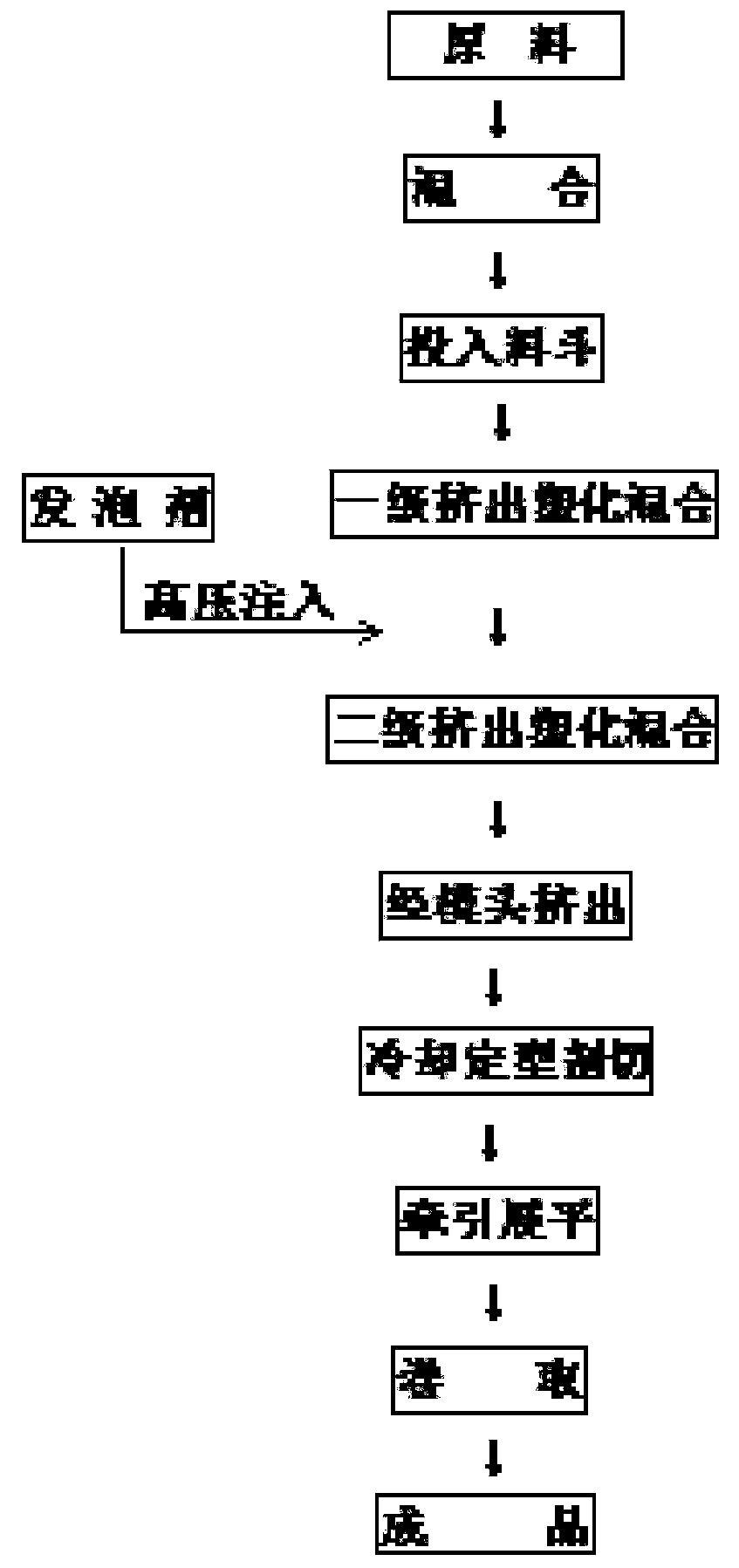

Polylactic acid foamed sheet and preparation method thereof

The invention relates to a polylactic acid foamed sheet and a preparation method thereof. The foaming ratio of the polylactic acid foamed sheet is 20 to 30 times; the pore density is 10.2-13.4*10<9> pores for each cubic centimeter; the diameter of pores is 4 to 15 [mu]m, and the thermal deformation temperature is 95 to 105 DEG C. According to the preparation method, polylactic acid is taken as thematrix, a nucleating agent and a chain extender are added to obtain a mixture; the mixture is extruded in a double screw extruder to obtain polylactic acid foamed modified resin; then the modified resin and optionally picked color master batch are added into the hopper of a foaming extruder composed of two extrusion systems, which are serially connected; the mixture is melted and plasticized in the primary extruding system, then a foaming agent is added, then the mixture is mixed and cooled in the secondary extruding system to obtain low temperature homogenous melt; the melt is extruded fromthe head of a controllable foaming machine, and finally the foamed sheet is obtained after sizing cooling, part spreading, and rolling. The provided polylactic acid foamed sheet has the advantages ofhigh foaming ratio, good foaming performance, good heatproof property, good pore structure, simple technology, and controllable cost.

Owner:COFCO GROUP +2

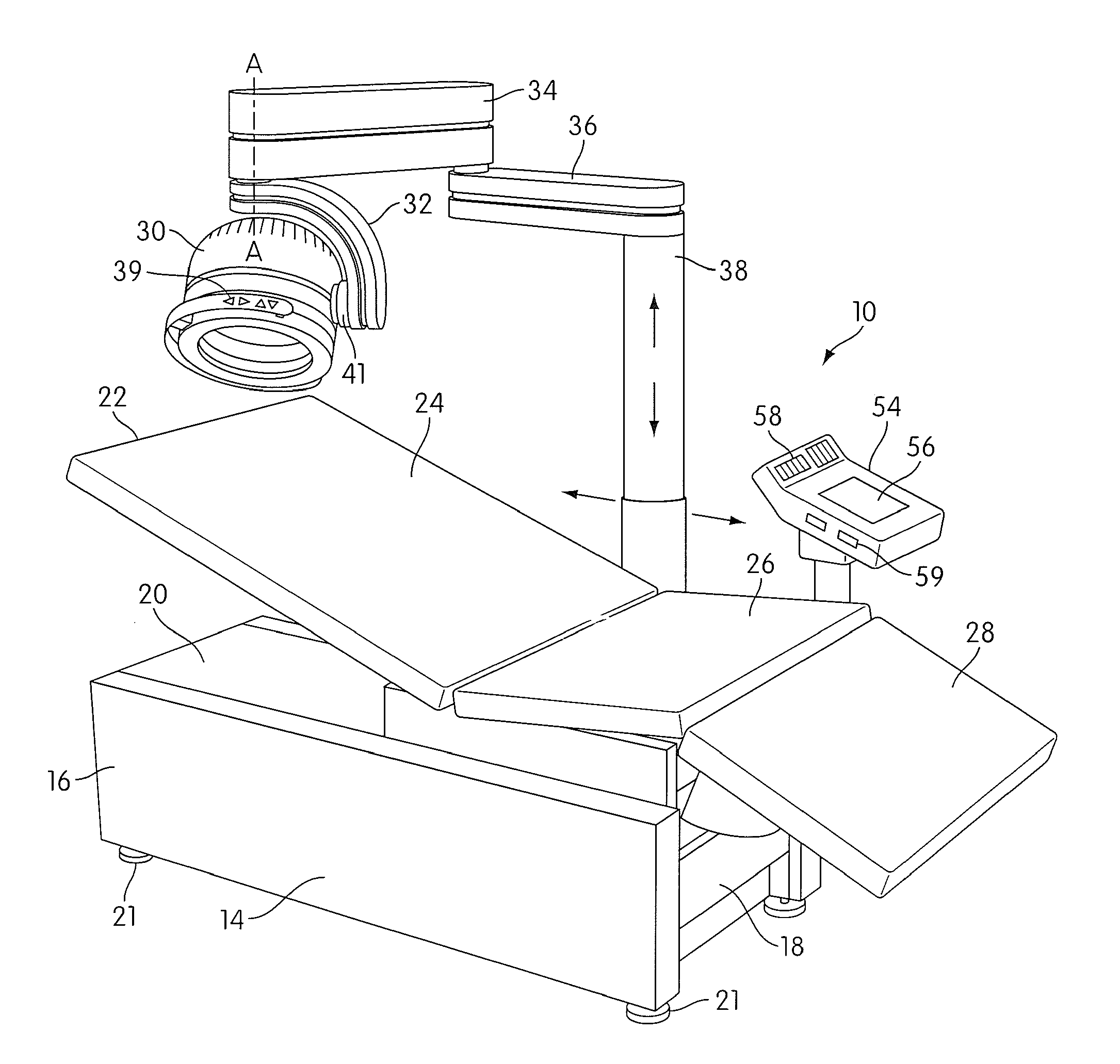

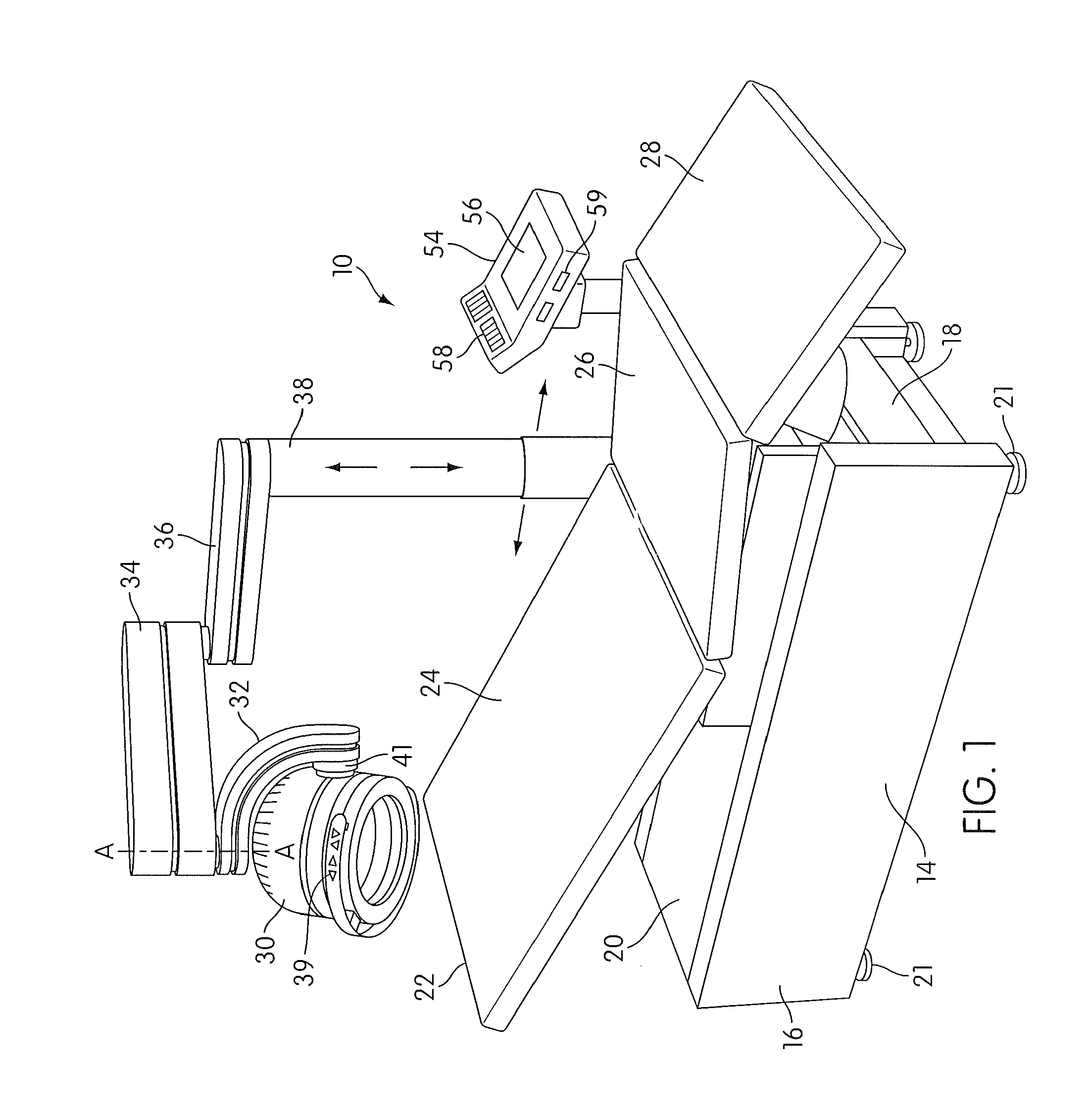

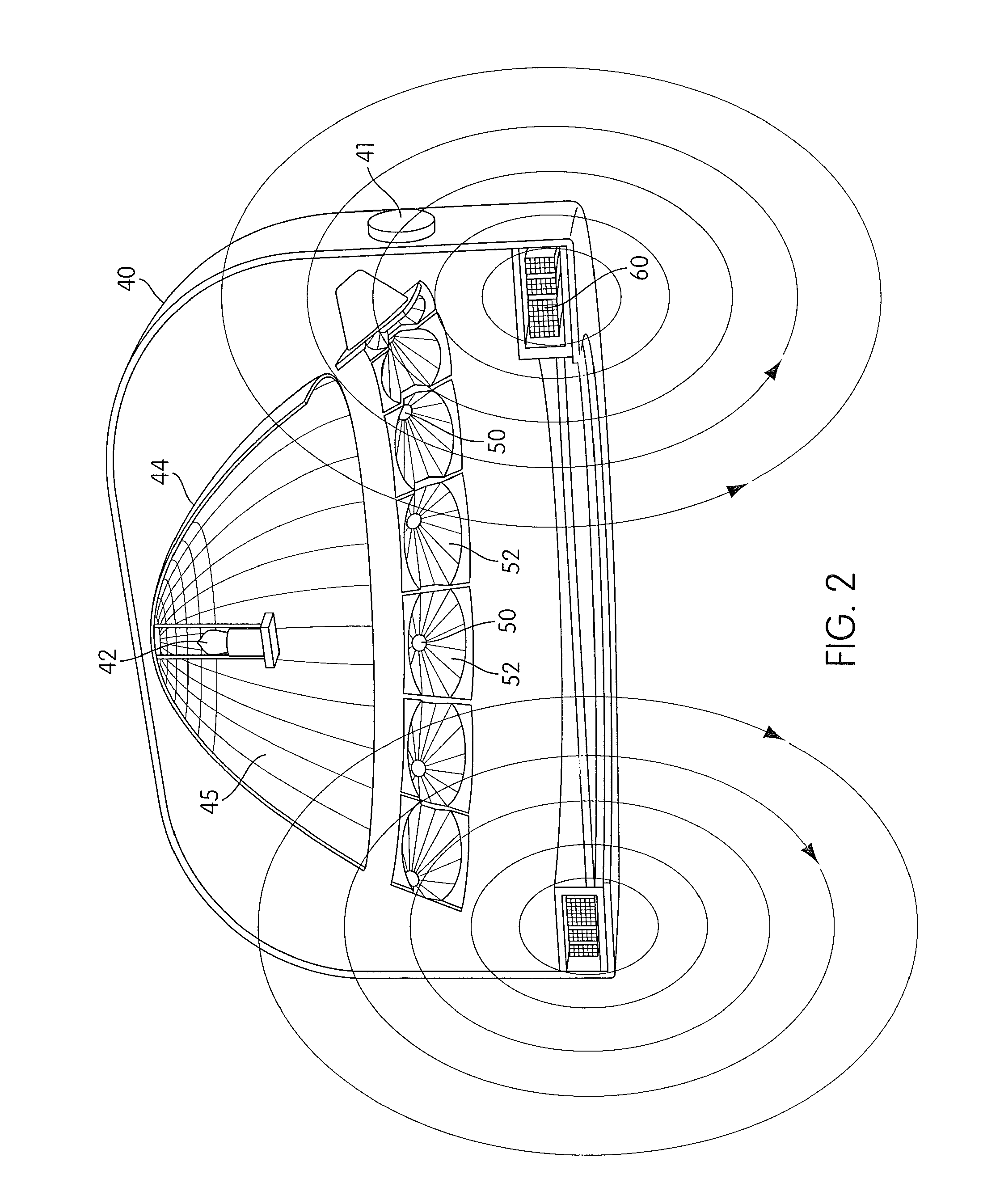

System and apparatus for treatment of biological cellular structure with electromagnetic wave energy and electromagnetic field energy sources

InactiveUS20120078328A1Maximum flexibilityMaximum efficacyLight therapyLight energyCritical position

A system and apparatus for treatment of cellular structure anomalies, principally in human patients, utilizes precisely controlled electromagnetic wave energy and electromagnetic field energy. The former energy is generated from a combination of coherent and incoherent light energy which is joined and focused on patients thru a unique arrangement of faceted coated reflectors and filters. The latter energy is generated in part by unique coils surrounding the light sources which include coils wound with bifilar wire. The disclosed apparatus also includes a platform, preferably segmented, that facilitates alignment of a patient's bodily area needing treatment. Additional coils are placed in the platform in strategic locations proximate the area of the patient to be treated. A digital control module can be programmed to regulate the frequency, duration, phase, duty cycle, pulse and amplitude of all energy sources in the claimed systems.

Owner:LETEC

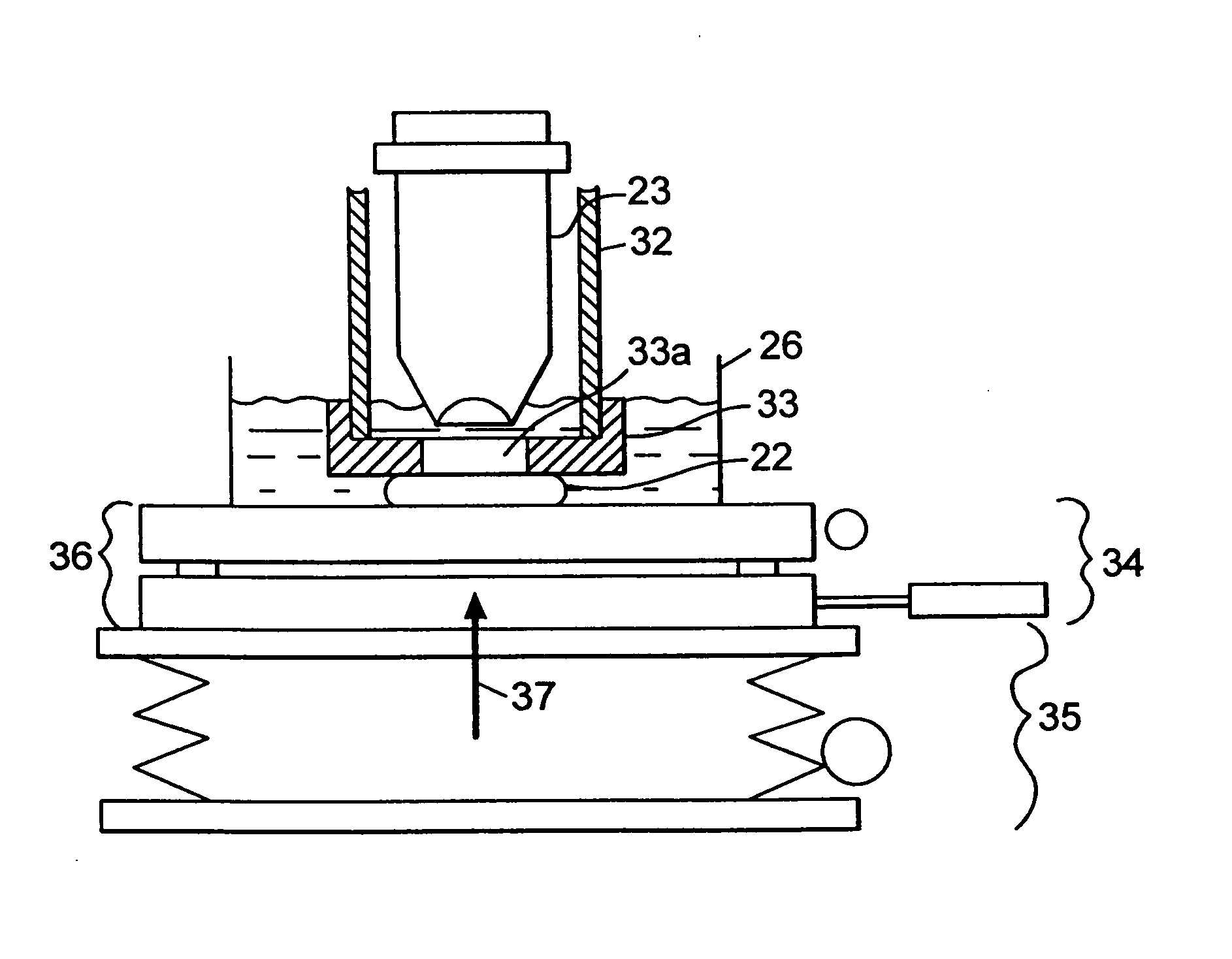

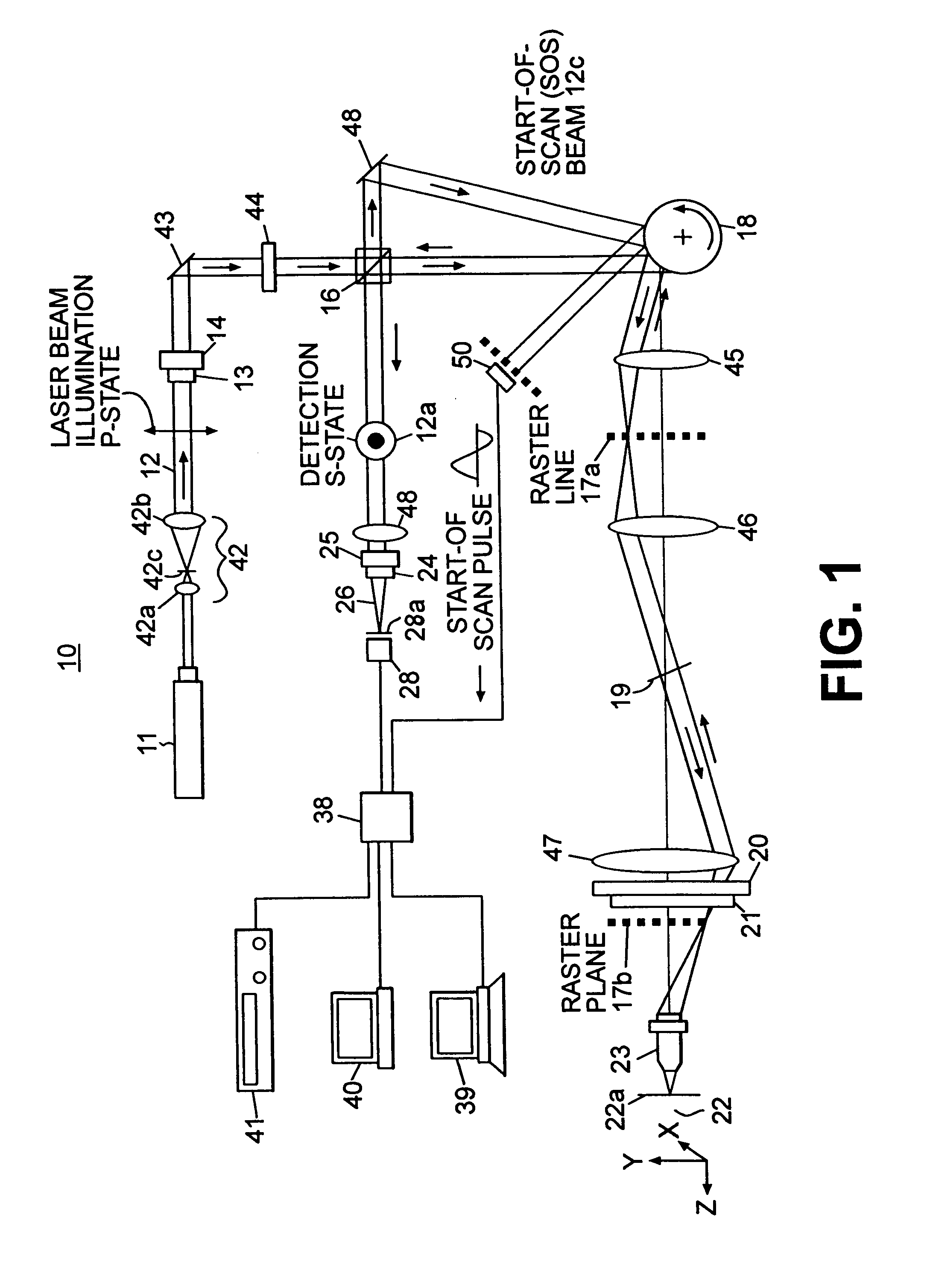

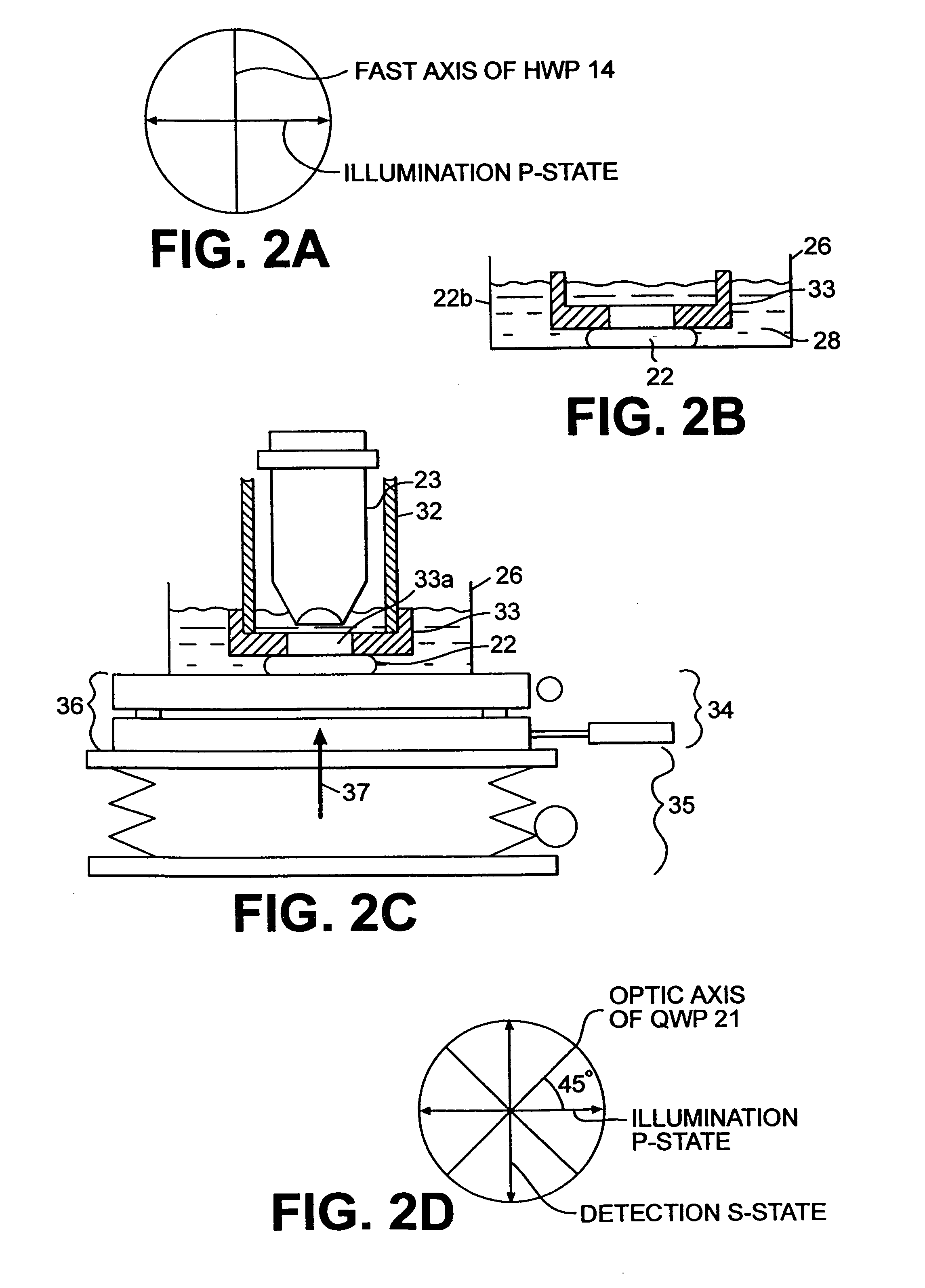

System and method for enhancing confocal reflectance images of tissue specimens

InactiveUS7139122B1Easy to observeImprove cell structureLuminescence/biological staining preparationMicroscopesMohs surgeryCross polarization

A system using cross polarization effects and an enhancement agent having citric or other similar alpha hydroxy acid to enhance confocal microscope reflectance images and particularly images of the nuclei of BCCs (basal cell carcinomas) and SCCs (squamous cell carcinomas) in the confocal reflectance images of excised tumor slices obtained during Mohs surgery by illuminating the tissue being imaged (a tumor slice) using polarized light. The reflected illumination is passed to a polarization analyzer, which passes the polarization component which is crossed with respect to the polarization of the illuminating light. The light from the analyzer is passed through the confocal aperture and detected. The section of the tissue either at the surface or within the tissue is scanned and the reflectance image is produced with enhanced visualization of the cellular or nuclear structure thereof thereby enabling determination of the extent of the tumor (cancerous cells) in the section. A method is also provided using the system for diagnosing cancerous cells in skin tissue.

Owner:CALIBER IMAGING & DIAGNOSTICS +1

Biomass-based polyurethane foam containing vegetable oil residue and preparation method of biomass-based polyurethane foam

The invention relates to biomass-based polyurethane foam containing vegetable oil residue, which is composed of a biomass liquification product, a catalyst, a foam stabilizer, vegetable oil residue and isocyanate. The invention also relates to a preparation method of the biomass-based polyurethane foam containing vegetable oil residue. The polyurethane foam provided by the invention has better degradation property, thus waste biomass is completely utilized and the pressure of petrochemical resources is reduced; the preparation cost is lower, and the raw materials are inexpensive, easily available and renewable; and the pore structure of the polyurethane foam material is improved and the compressive strength of the foam is improved.

Owner:CHINA AGRI UNIV

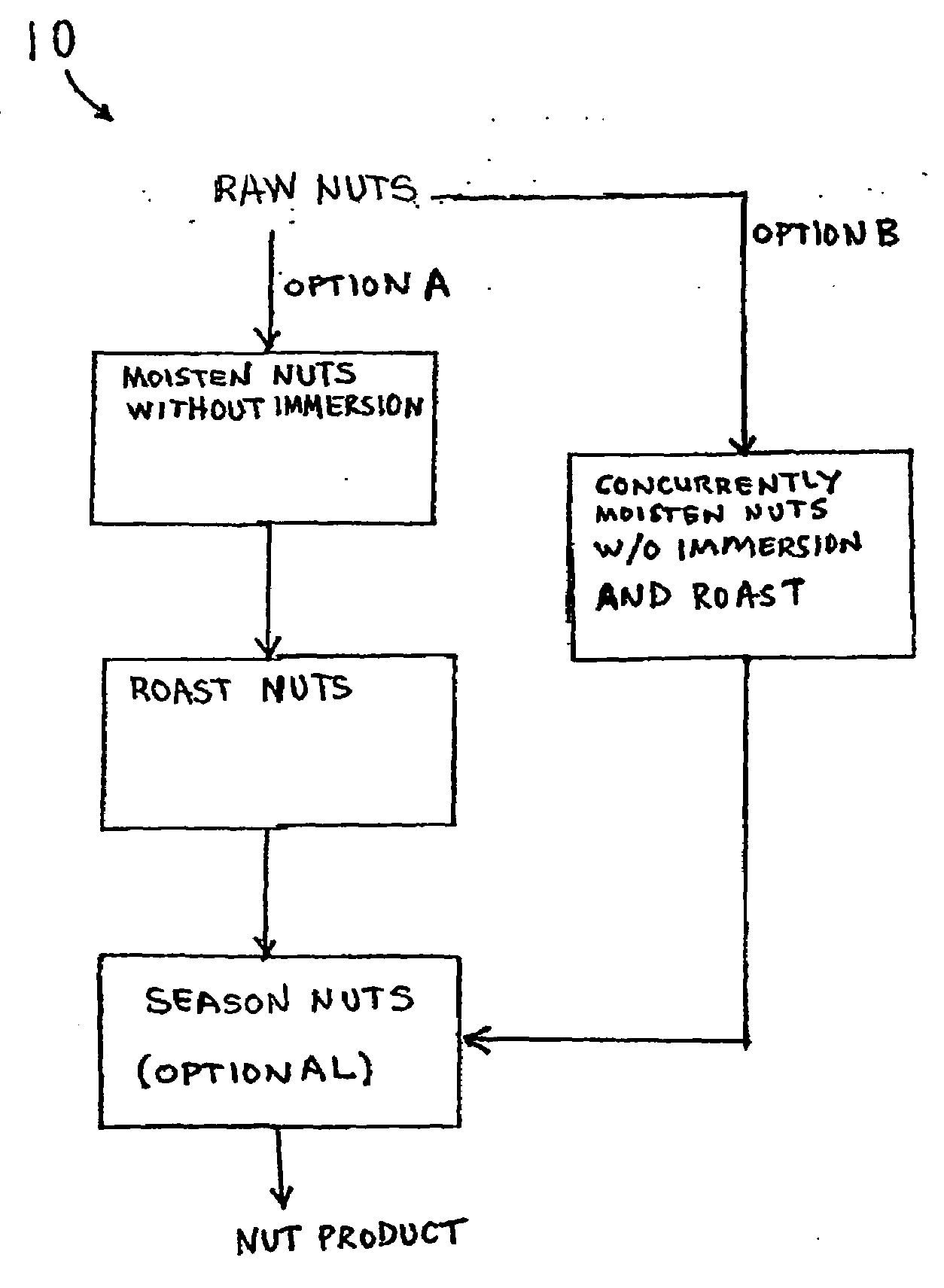

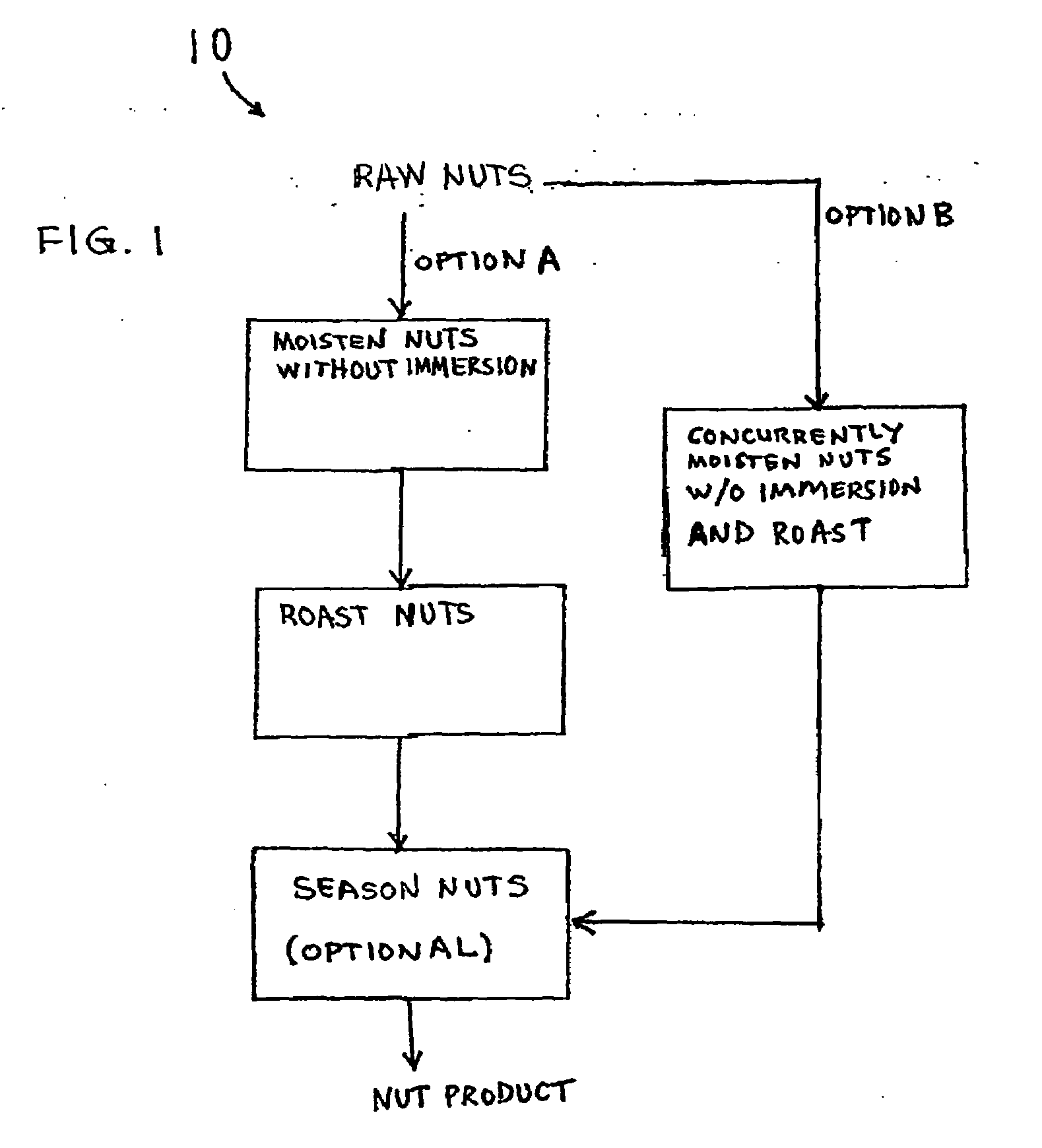

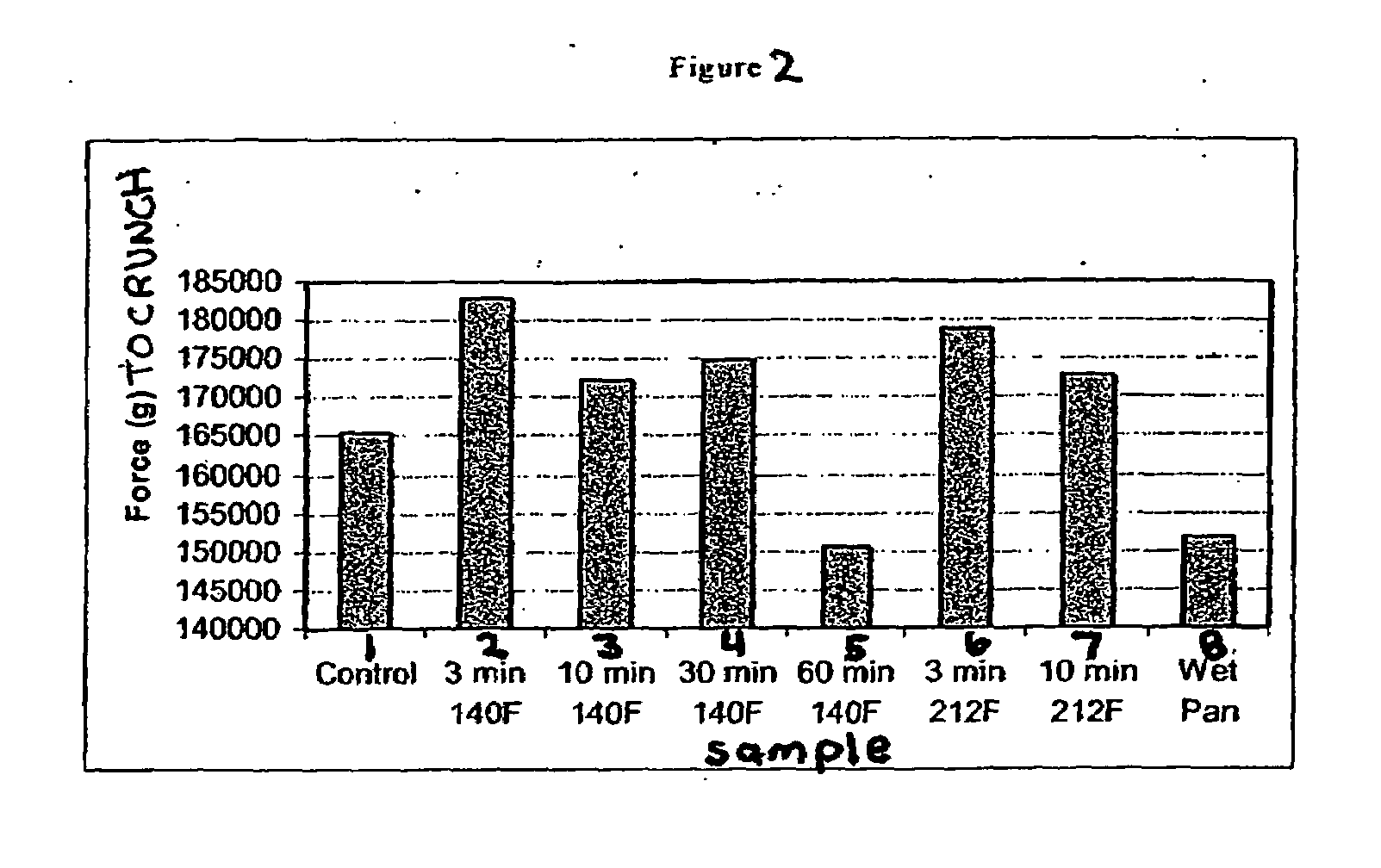

Process to enhance flavor of roasted nuts and products with modified texture

ActiveUS20080008803A1Improved nut productLow densityFood preparationGrain millingWater sourceFood flavor

Process for making crunchy flavorful nut products comprising contacting raw nuts with a water source effective to moisten the nuts without immersing the nuts in the water source, and roasting the moistened nuts. The nut products are crunchy and retain nut flavor when processed in this manner.

Owner:HORMEL FOODS

Room temperature crosslinked material

InactiveUS20090111902A1Safe disposalSafe installationPretreated surfacesCoatingsFoaming agentChemical compound

Materials and methods for providing building barriers are provided. The material may comprise a latex foam, which may include an A-side containing a functionalized latex and a B-side that contains a crosslinking agent and optionally a non-functionalized latex. The A- and / or B-side may contain a blowing agent package or components forming the blowing agent package. The blowing agent package may be the combination of two or more chemicals that when mixed together form a gas or a chemical compound that, when activated by heat or light, forms a gas. In an alternate embodiment, the latex foam includes a functionalized latex, an acid, and an encapsulated crosslinking agent and base. Alternatively, the spray latex may include a functionalized latex, a crosslinking agent, and an encapsulated dry acid and dry base. The encapsulating agent may be a protective, non-reactive shell that can be broken or melted at the time of application.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

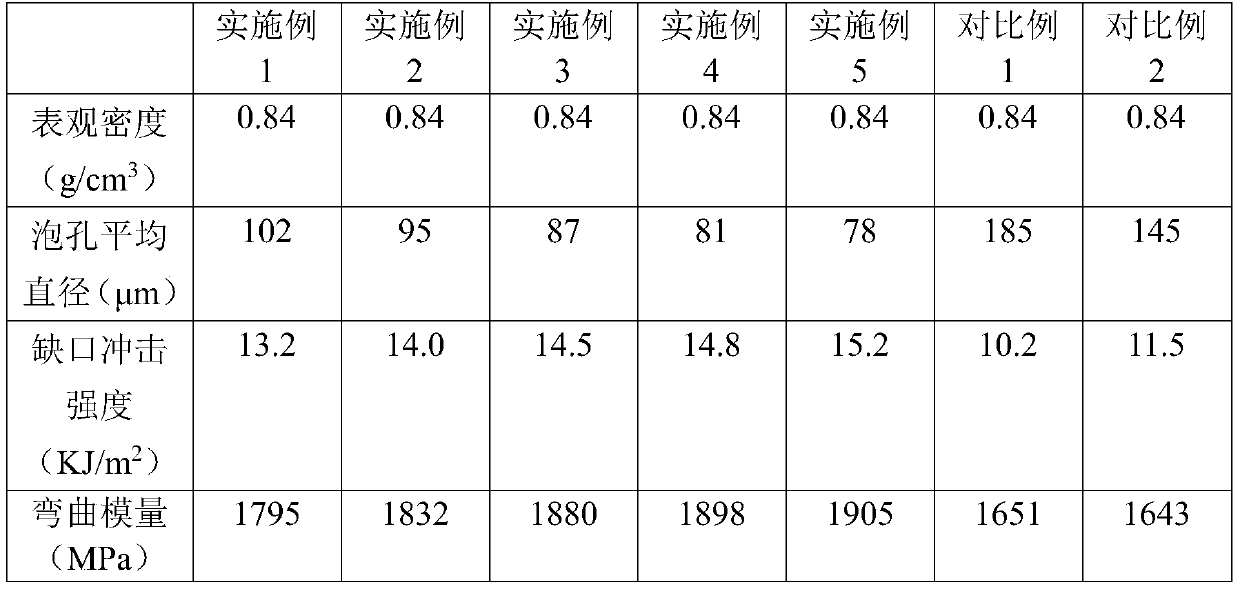

Injection molding grade polypropylene microcellular foam composite material and preparation method thereof

ActiveCN105504498AImprove melt strengthGood foaming effectSodium bicarbonatePolypropylene composites

The invention discloses an injection molding grade polypropylene microcellular foam composite material and a preparation method thereof. The preparation method comprises the step of carrying out microcellular injection molding foaming with an injection molding machine after uniformly mixing 90-99.9wt% of polypropylene composite material with 0.1-10wt% of foaming agent, wherein the polypropylene composite material is prepared from the following raw materials by weight percent: 42-95% of conventional polypropylene, 0.1-15% of micro-crosslinked polypropylene, 0.1-10% of polyethylene, 0.1-25% of talcum powder filler, 0.1-15% of toughening agent, 0.1-5% of antioxidant and 0-3% of other aids; the foaming agent is modified sodium bicarbonate. The polypropylene composite material has higher melt strength. The polypropylene microcellular foam material prepared from the polypropylene composite material is fine and uniform in pores, well maintains the original mechanical properties of the materials and also takes modified sodium bicarbonate as the foaming agent, thus preventing the obtained product from producing unpleasant odor.

Owner:SHANGHAI PRET COMPOSITES

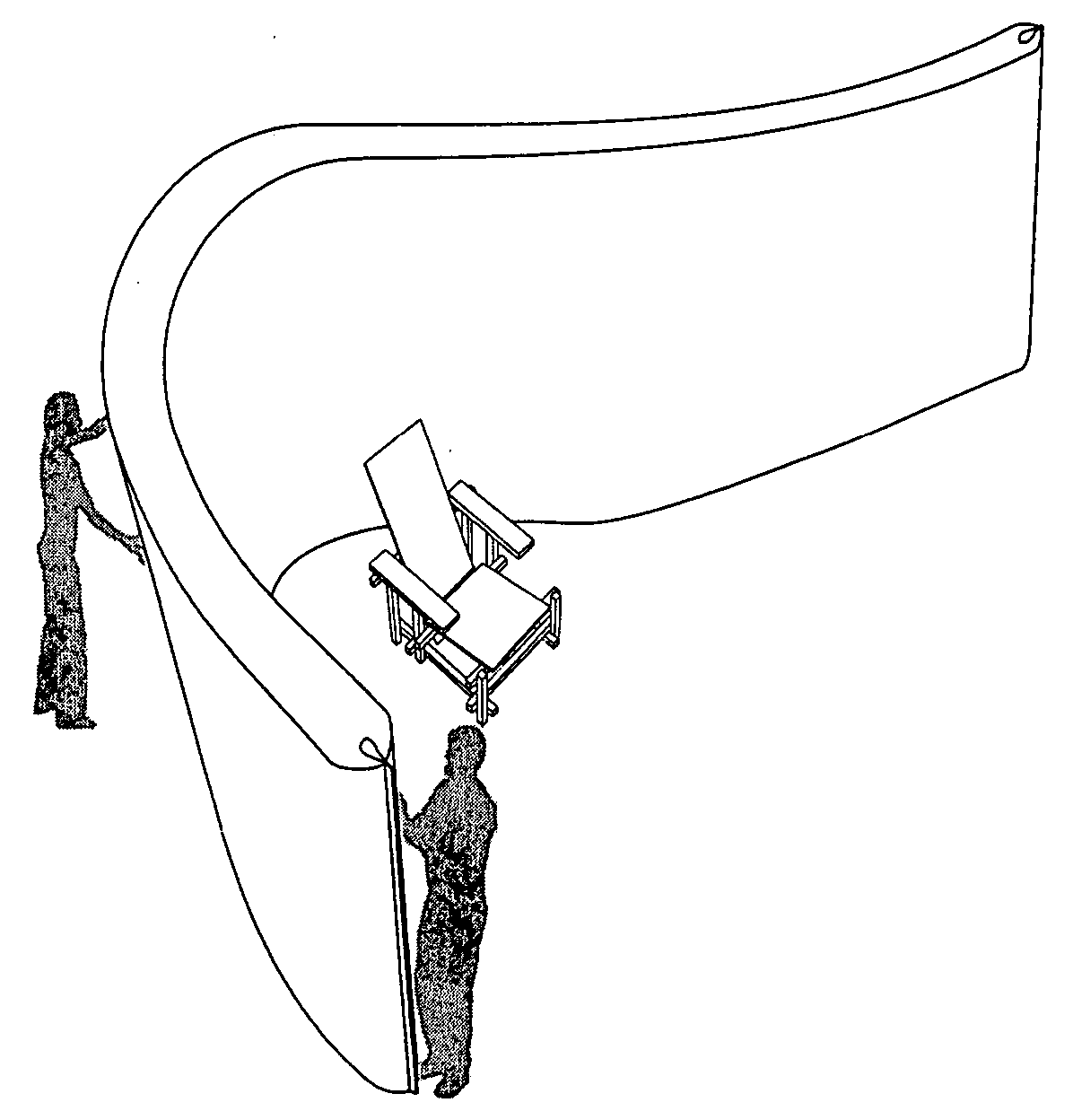

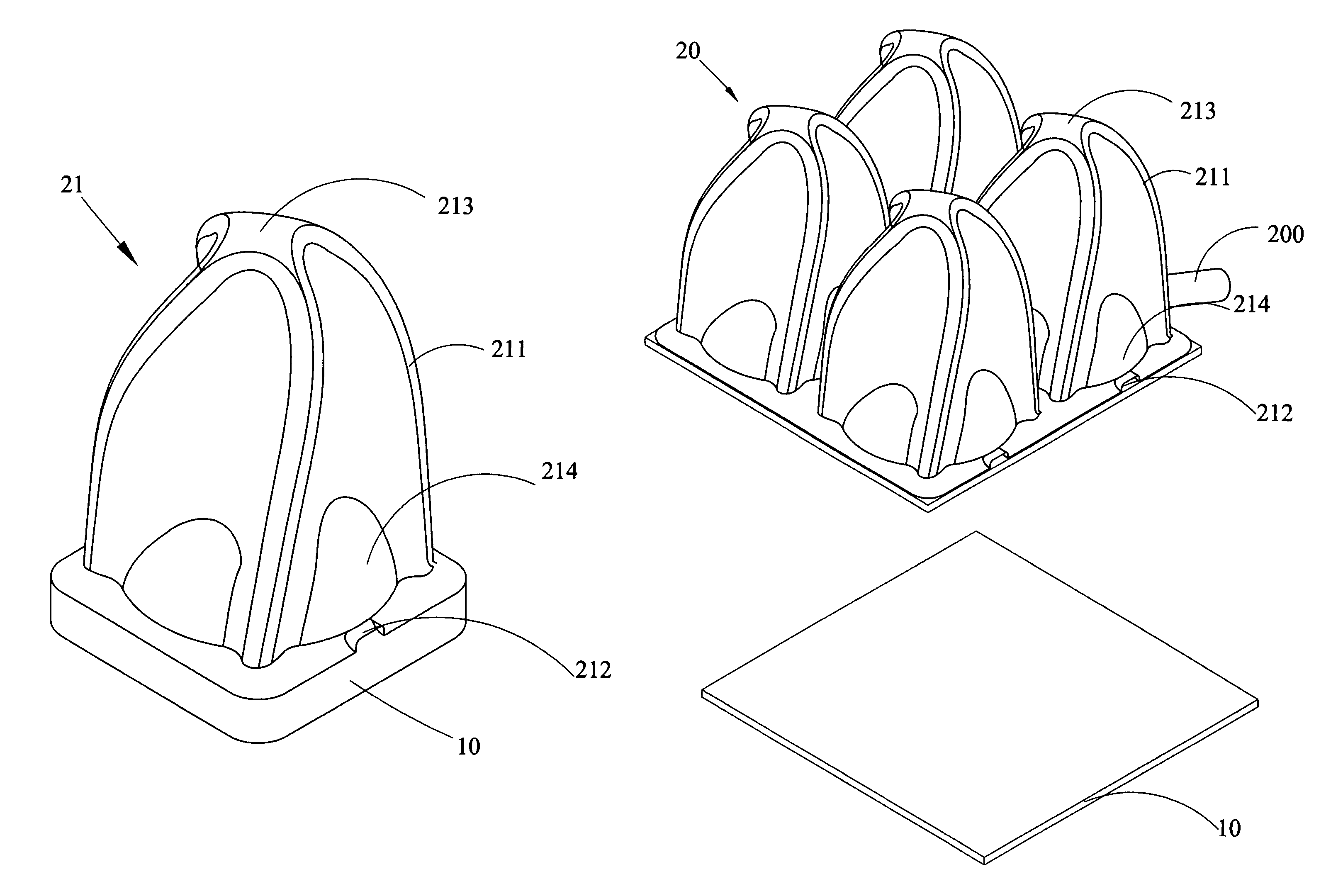

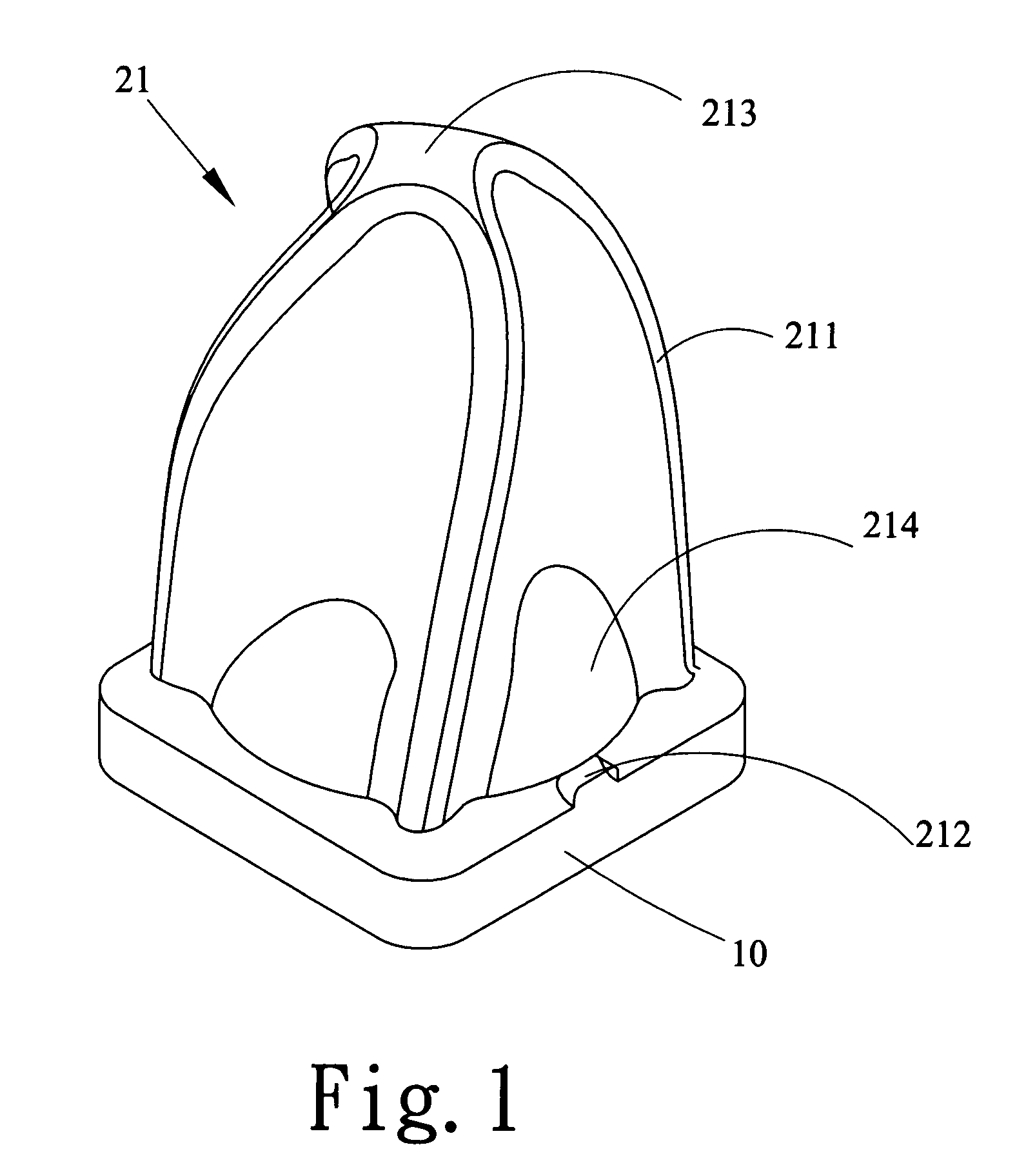

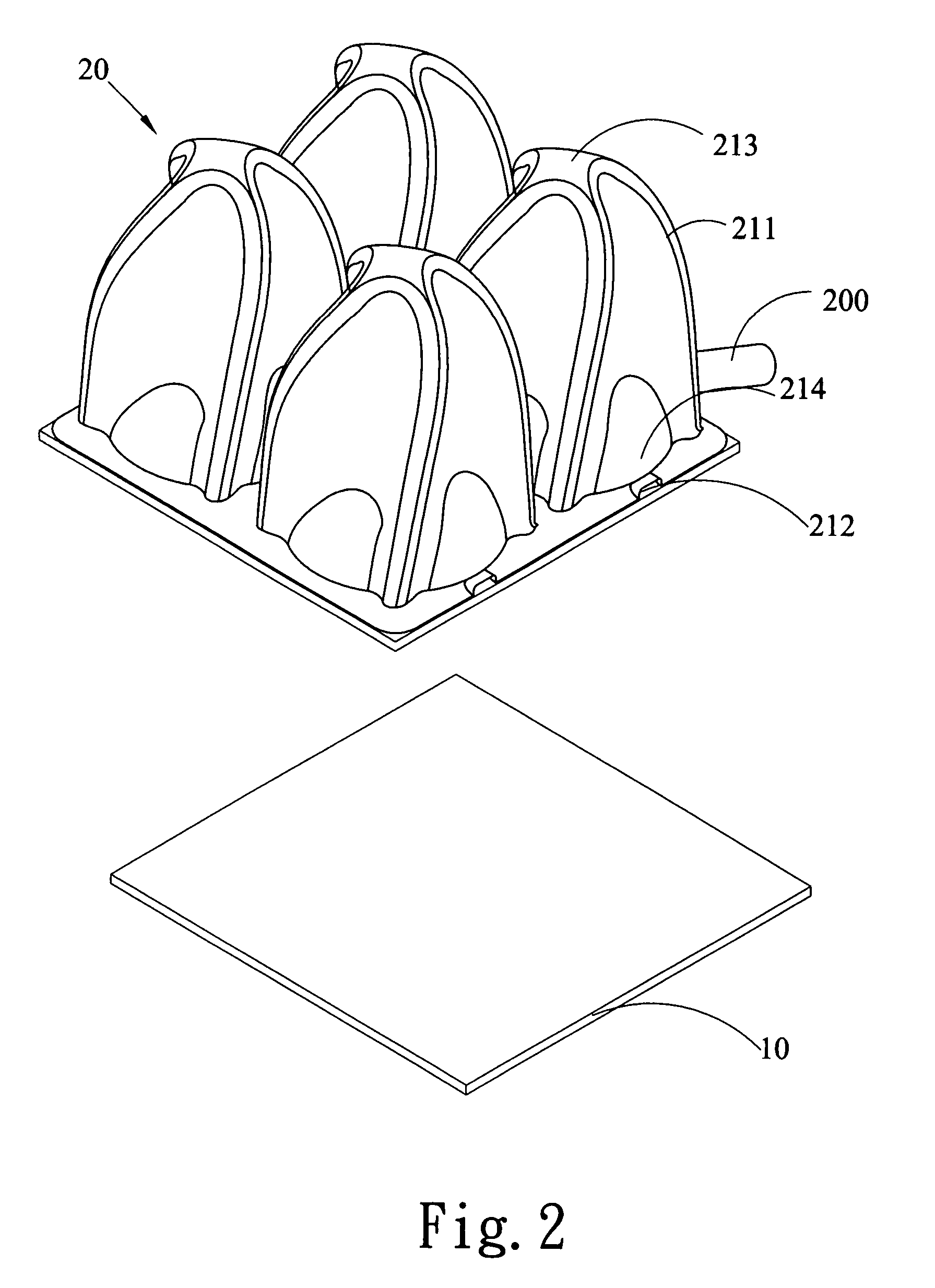

Flexible furniture system

ActiveUS20080023156A1Improve cell structureIncrease the lengthScreensDoor/window protective devicesEngineeringMechanical engineering

Owner:MOLO DESIGN

Fine cell flexible polyurethane foam

Owner:BRIDGESTONE CORP

Air inflation cushion with cells having helical edges

InactiveUS7406734B2Clean bodyHeat dissipationStuffed mattressesSpring mattressesHelical bladeEngineering

An air inflation cushion with cells having helical edges comprises a lower sheet; an upper cushion portion adhered upon the lower sheet; the upper cushion portion including at least one air inflation cell; each air inflation cell having an approximate rectangular cross section and being supported by four helical edges for enhancing the structure of the cell; upper ends of the helical edges being formed as rectangular upper planes; the four helical edges dividing the air inflation cell into four lateral surfaces; a lower portion of each lateral surface being formed with a convex cambered protrusion; and an air tap at one of the cells and extending from one of the helical edges. The air inflation cushion is made of black rubber. The cell is extended with a communication trench which causes two adjacent cells are communicated to one another.

Owner:MAI CHIN TIEN +1

Compression deformation resistant and high hardness foam silicone rubber material and preparation method thereof

The invention discloses a compression deformation resistant and high hardness foam silicone rubber material and preparation method thereof. The foam silicone rubber material is made of component A andcomponent B which are of equal mass, wherein the component A includes, by mass ratio, 100 parts of liquid silicone rubber, 0.5 to 2 parts of foaming agents, 15 to 45 parts of aids, 0.25 to 2 parts ofcatalysts, and 1 to 5 parts of colorants, and component B includes, by mass ratio, 100 parts of liquid silicone rubber, 0.5 to 2 parts of foaming agents, 25 to 55 parts of aids, 1 to 5 parts of crosslinking agents, and 0.5 to 2 parts of inhibitors. The compression deformation resistant and high hardness foam silicone rubber material has the advantages of having good thermal insulation, high hardness, delicate cells of a closed-cell structure and good compression set performance, being capable of not only providing a good cushioning effect when the device is impacted but also being used as aninsulating product to retard thermal diffusion, and reducing the risk in life.

Owner:浙江清优材料科技有限公司

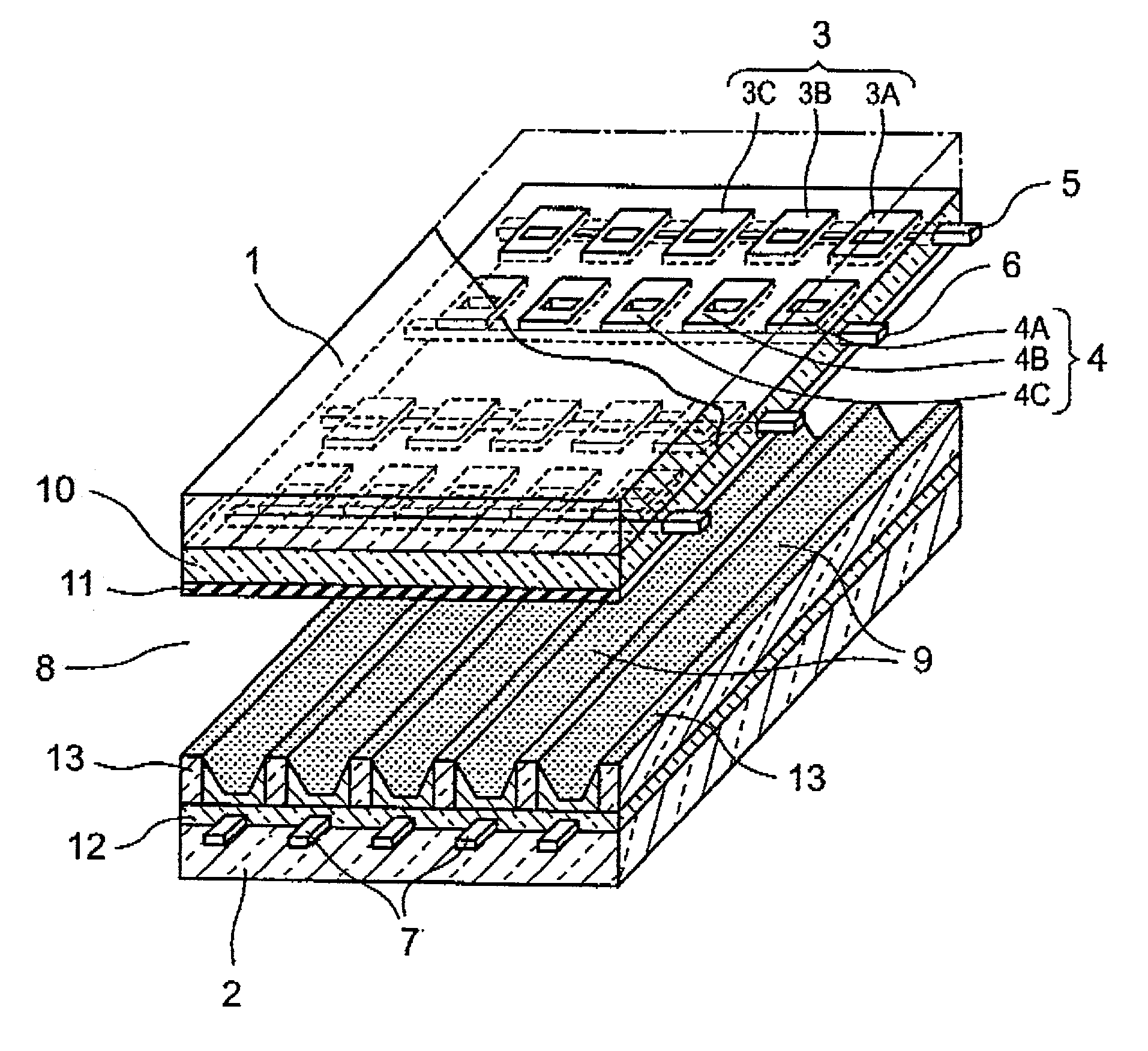

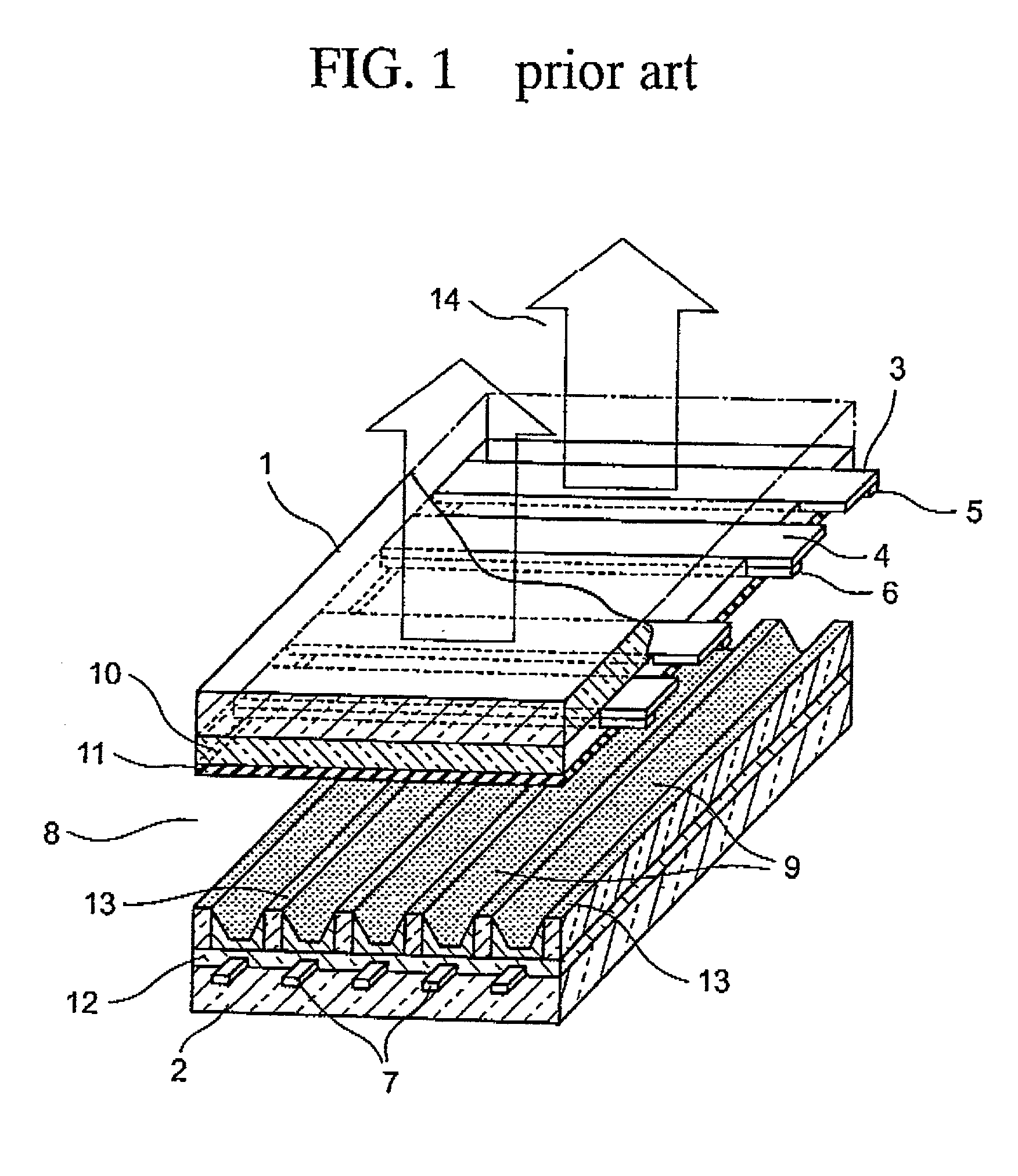

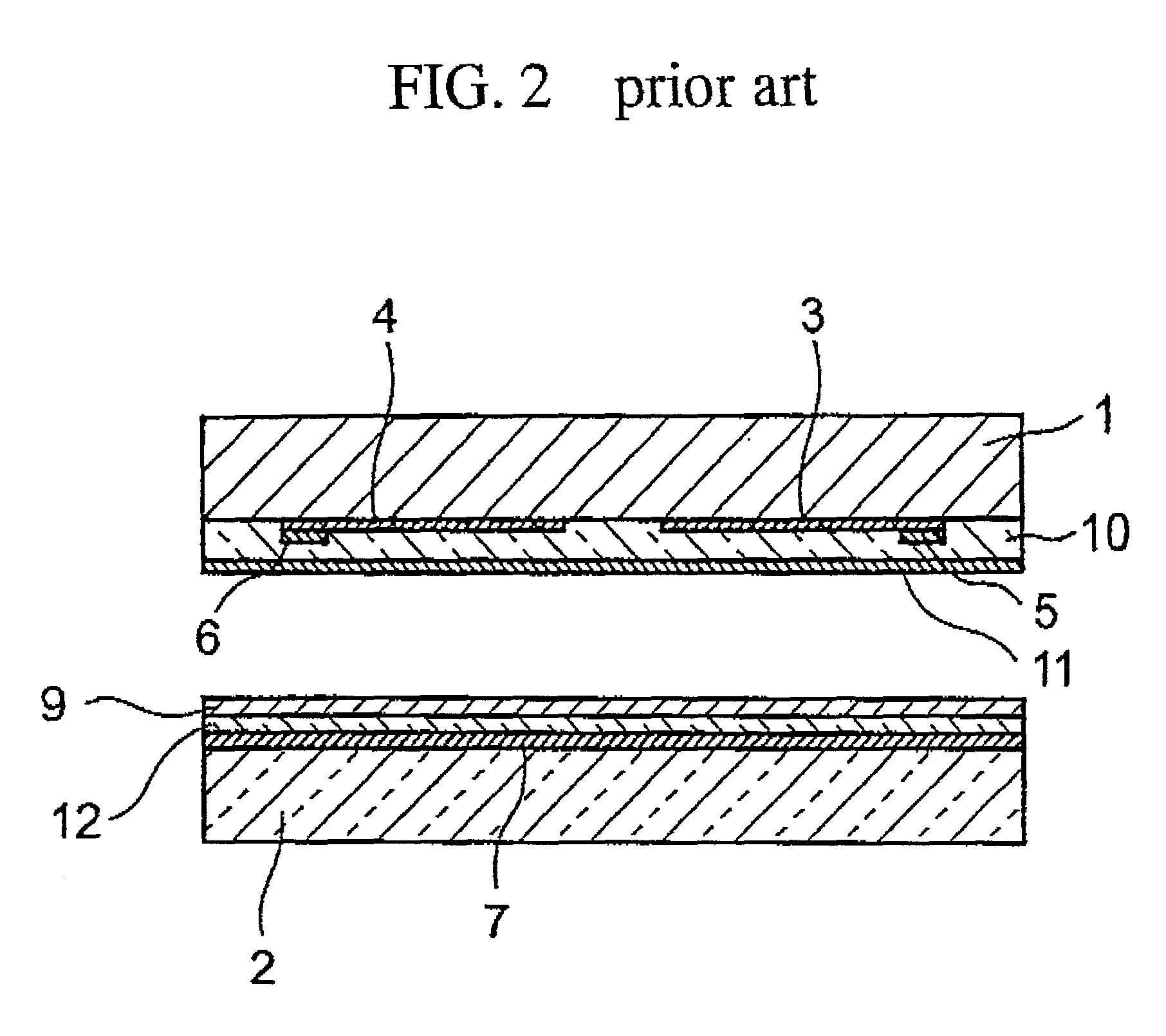

Plasma display panel with an improved electrode structure

InactiveUS20020130618A1Improve display qualityImprove cell structureAddress electrodesSustain/scan electrodesMolecular physicsPlasma display

A plasma display panel has an improved cell electrode structure including: a pair of sustaining and scanning electrodes which are approximately similar or equal in area to each other, and which are different from each other in pattern shape. Each of the scanning electrode alignments further includes a plurality of scanning electrodes. Adjacent two of the scanning electrodes are separated from each other by the separation wall. Each of the sustaining electrode alignments further includes a plurality of sustaining electrodes. Adjacent two of the sustaining electrodes are separated from each other by the separation wall.

Owner:PIONEER CORP

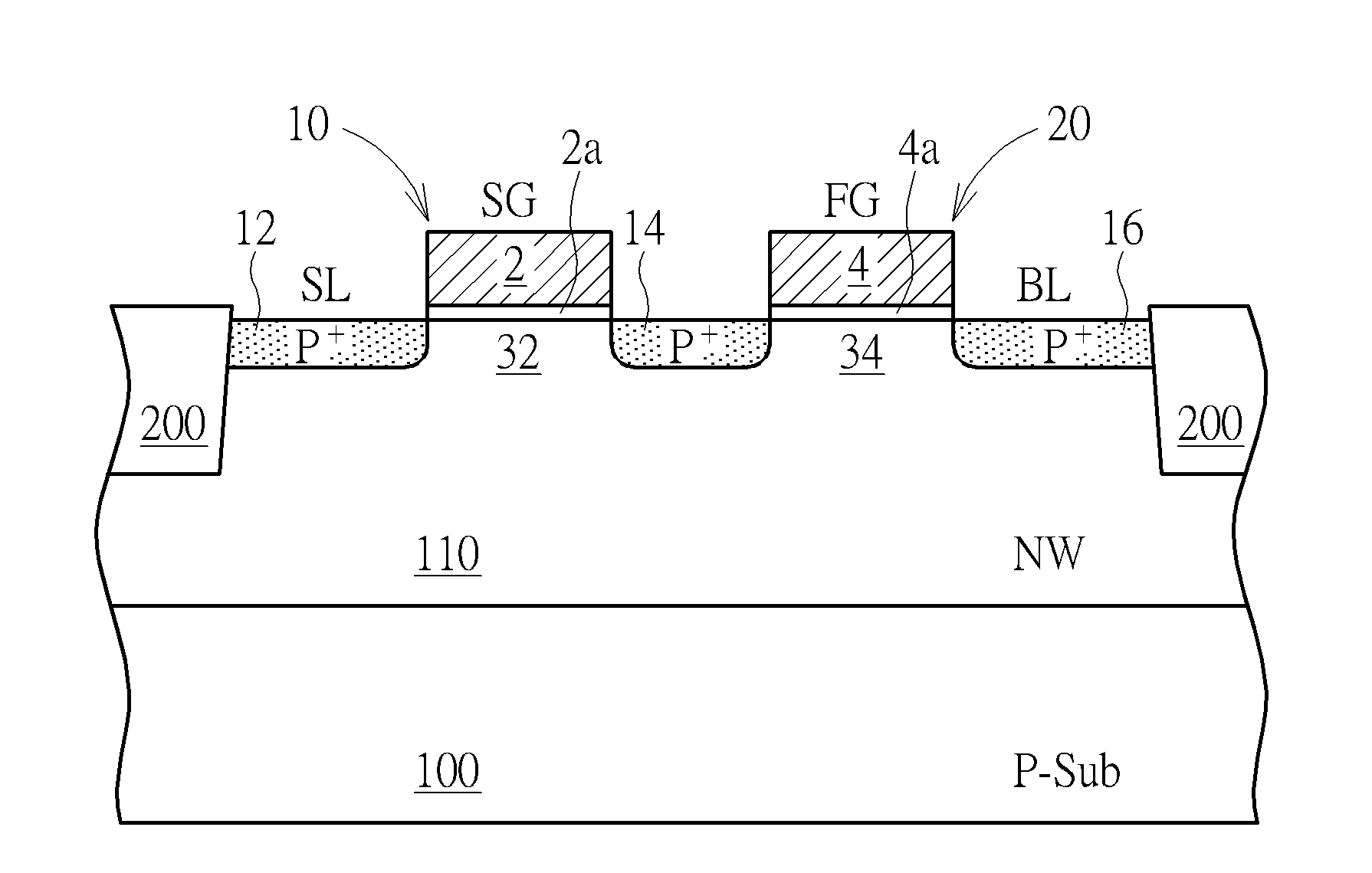

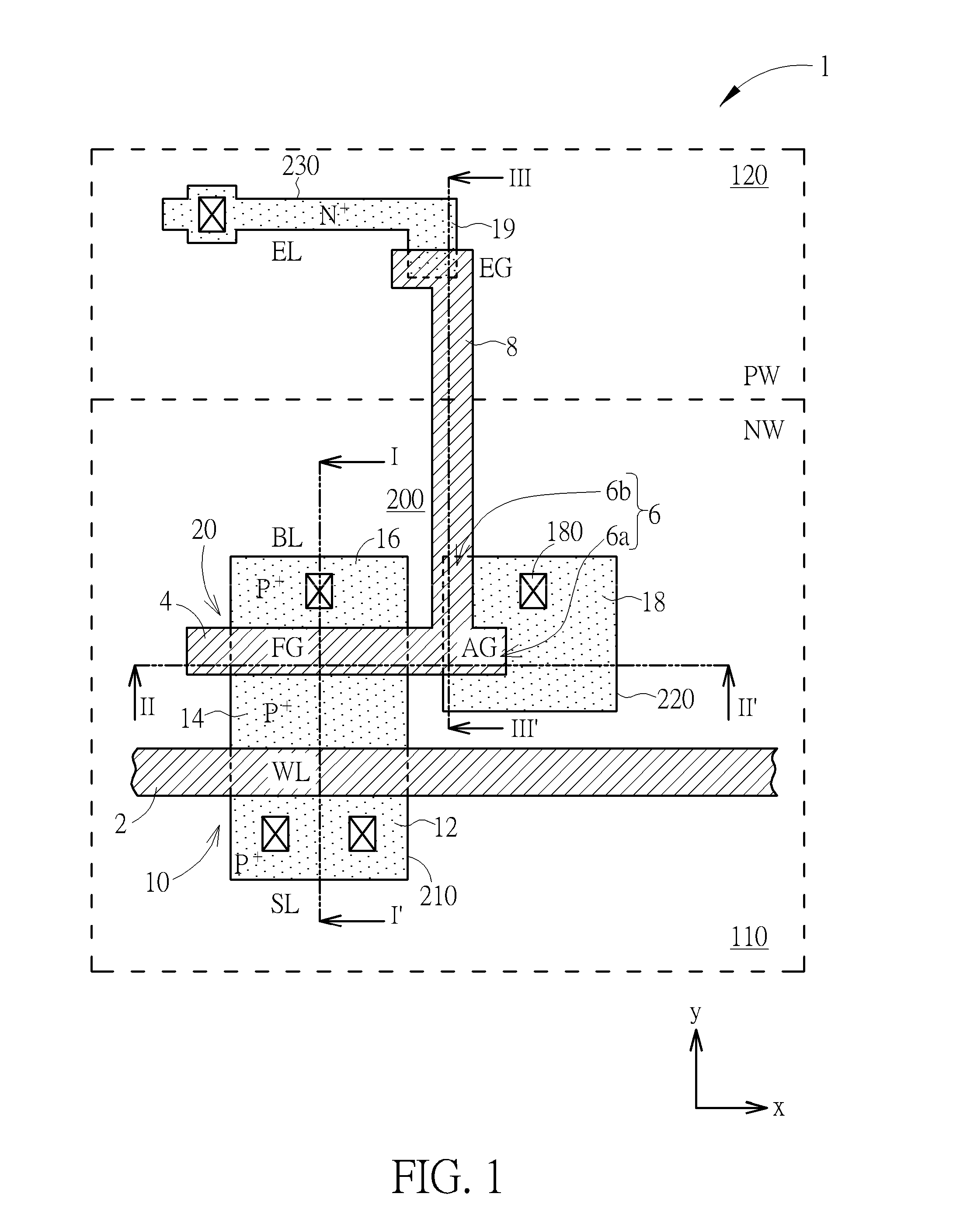

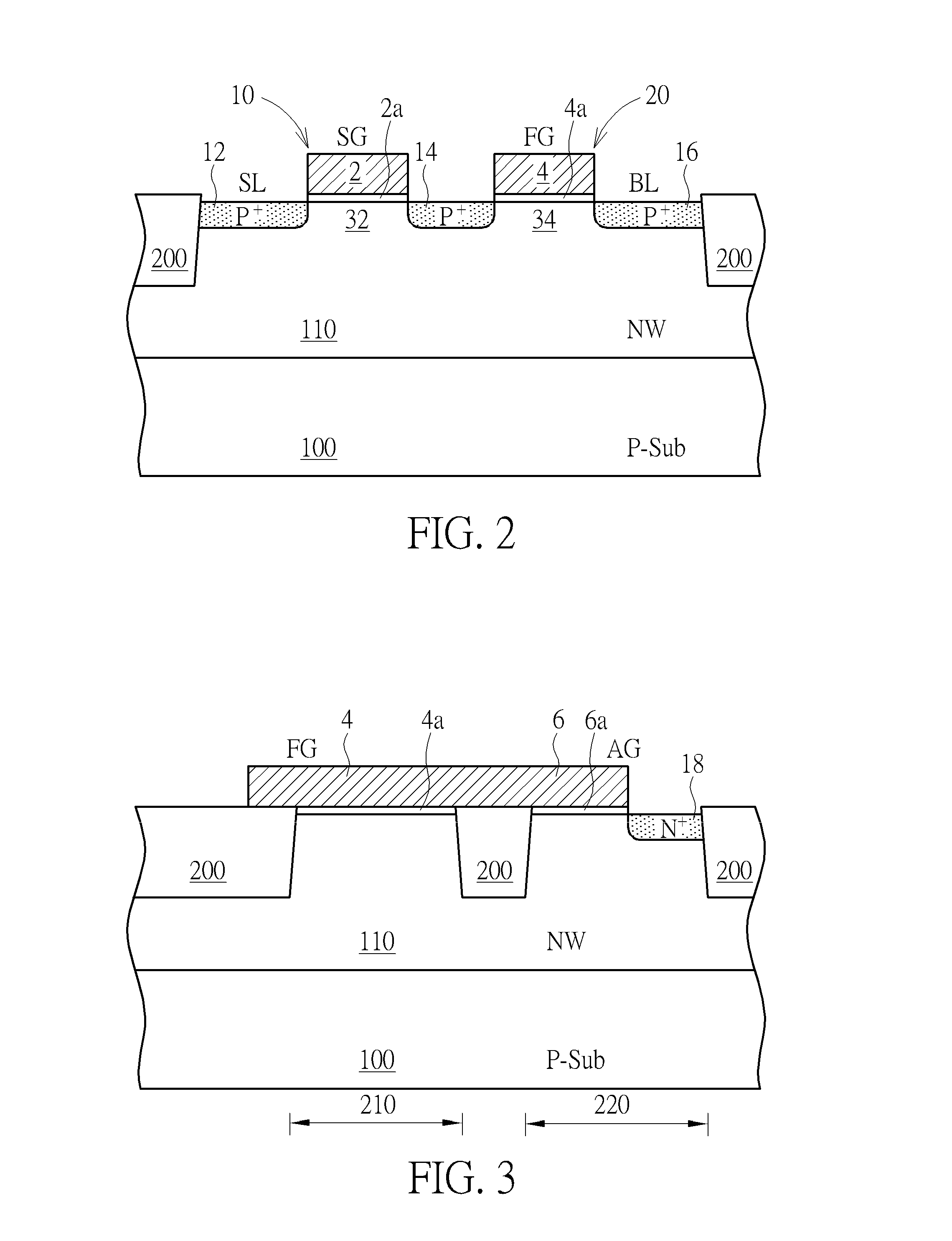

Nonvolatile memory cell structure with assistant gate

ActiveUS20150287732A1Improve cell structureImprove staminaSemiconductor/solid-state device detailsSolid-state devicesCapacitanceSemiconductor

A nonvolatile memory (NVM) cell includes a semiconductor substrate having therein an N well and a P well; a first OD region and a second OD region disposed within the N well; a PMOS select transistor disposed on the first OD region; a PMOS floating gate transistor serially connected to the select transistor and being disposed on the on the first OD region, wherein the PMOS floating gate transistor comprises a floating gate overlying the first OD region; and an assistant gate protruding from one distal end of the floating gate to one edge of the second OD region such that the assistant gate is capacitively coupled to the second OD region and the N well. The select transistor, the floating gate transistor and the assistant gate disposed on the same N well.

Owner:EMEMORY TECH INC

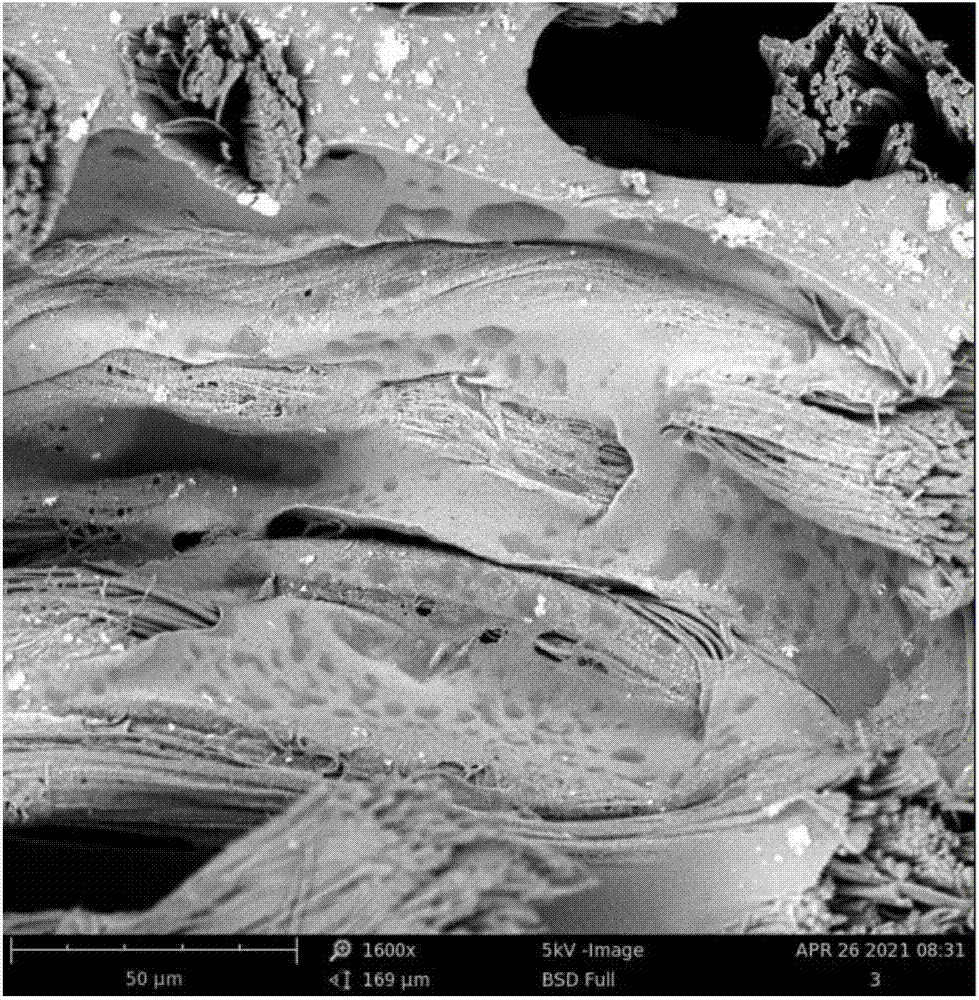

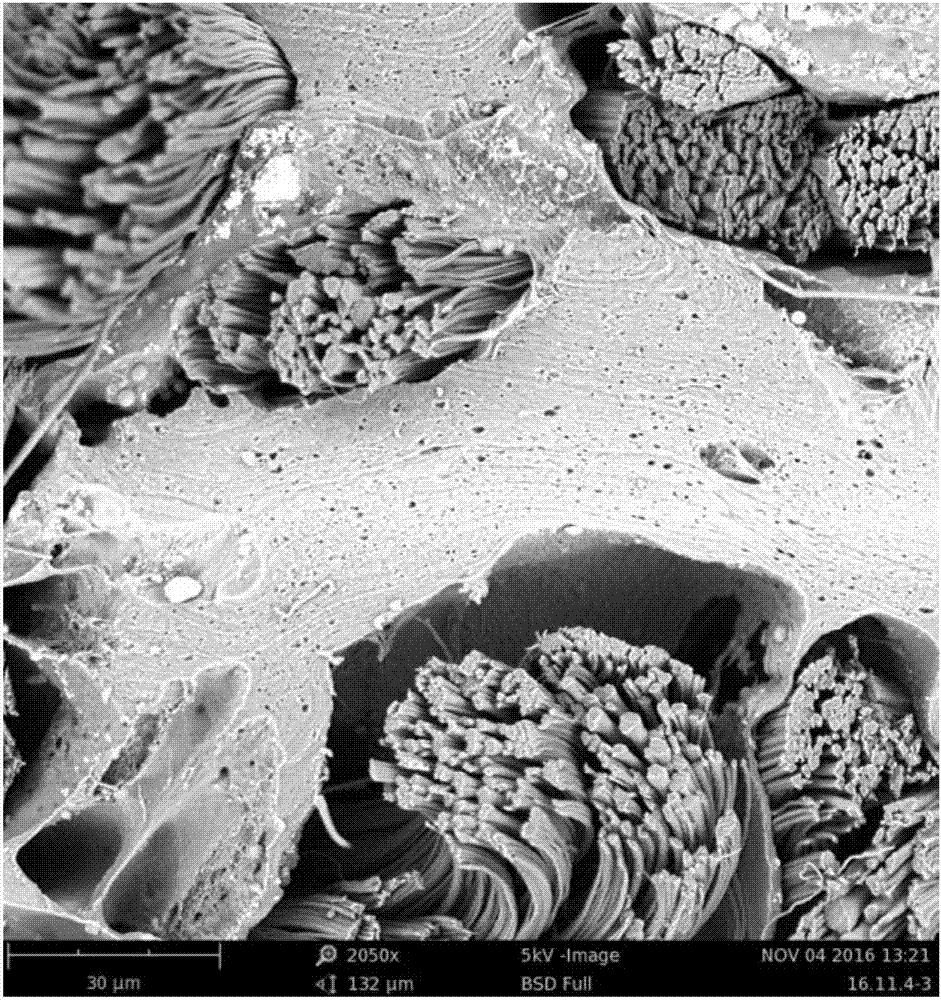

Waterborne impregnated resin, waterborne polyurethane superfine fiber synthetic leather and preparation method of waterborne polyurethane superfine fiber synthetic leather

The invention discloses waterborne impregnated resin, waterborne polyurethane superfine fiber synthetic leather and a preparation method of thewaterborne polyurethane superfine fiber synthetic leather. The waterborne impregnated resin is prepared from components in parts by weight as follows: 100 parts of a waterborne polyurethane emulsion, 5-30 parts of a water-soluble polymer, 0-100 parts of deionized water, 0.1-1 part of a wetting agent and 0-3 parts of a thickener. The preparation method of thewaterborne polyurethane superfine fiber synthetic leather comprises the following steps: sea-island non-woven fabric is impregnated in the waterborne impregnated resin and dried, and impregnated base cloth is obtained and fed into toluene for decrement; primary base cloth is obtained after washing and drying and is treated, and the waterborne polyurethane superfine fiber synthetic leather can be obtained. Environmental pollution is reduced greatly, part of soluble polymer granules are introduced, the release effect between fibers and resin is enhanced, and the obtained synthetic leather has a densercell structure.

Owner:HUAFON MICROFIBER SHANGHAI

Moisture barrier and energy absorbing cushion

InactiveUS20050079314A1Fine foamHigh strength to weight ratioSynthetic resin layered productsStoolsFiberEnergy absorption

A fabric reinforced closed cell foam composite having a textured or smooth surface which is substantially free of nodular surface irregularities. The fabric may be formed of woven fibers or of non-woven random fibers which are bonded together by resin or heat. The fabric is then coated to a suitable thickness with a foamed or unfoamed polymer formulation. The cushion has a high strength to weight ratio, is substantially impermeable to liquids, significantly dampens sound and absorbs energy. In addition, the cushion is non-slip, remaining substantially fixed in relation to the surface to which it is in contact by means of friction. Further, the surface of the cushion is relatively easily decorated with printed designs. Dyes could also be added to the foam formulation to produce a wide range of decorative colored cushions.

Owner:L & P PROPERTY MANAGEMENT CO

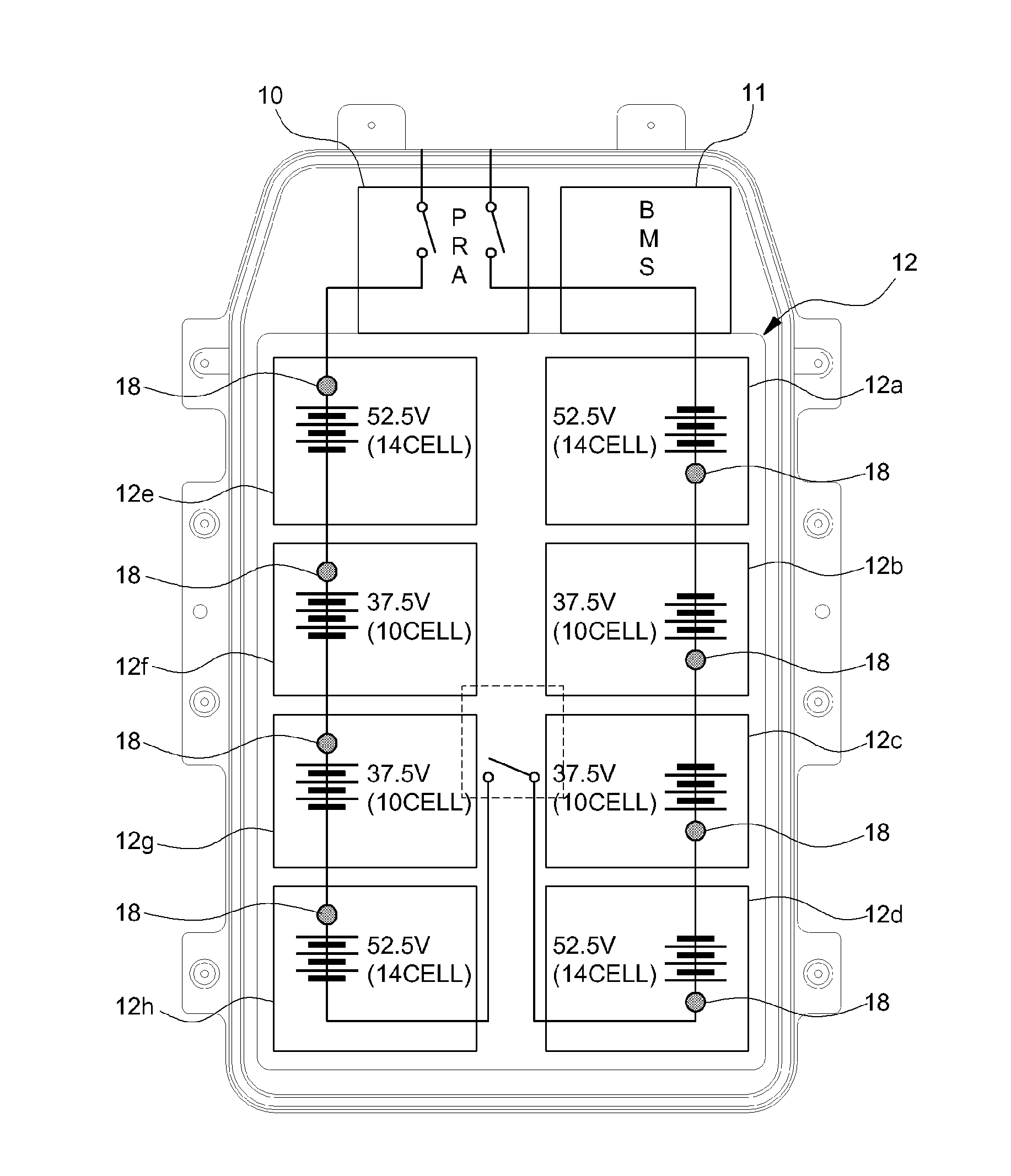

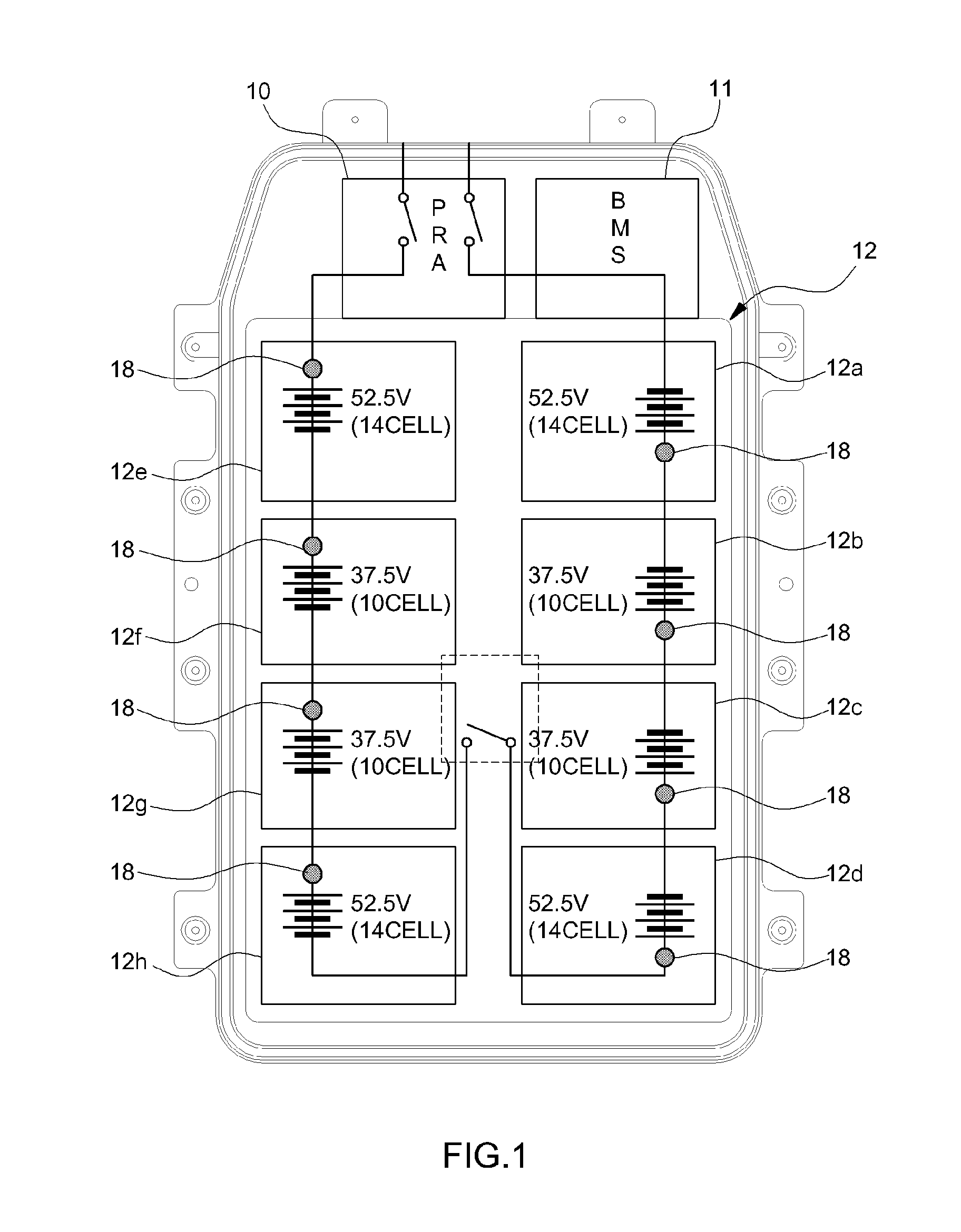

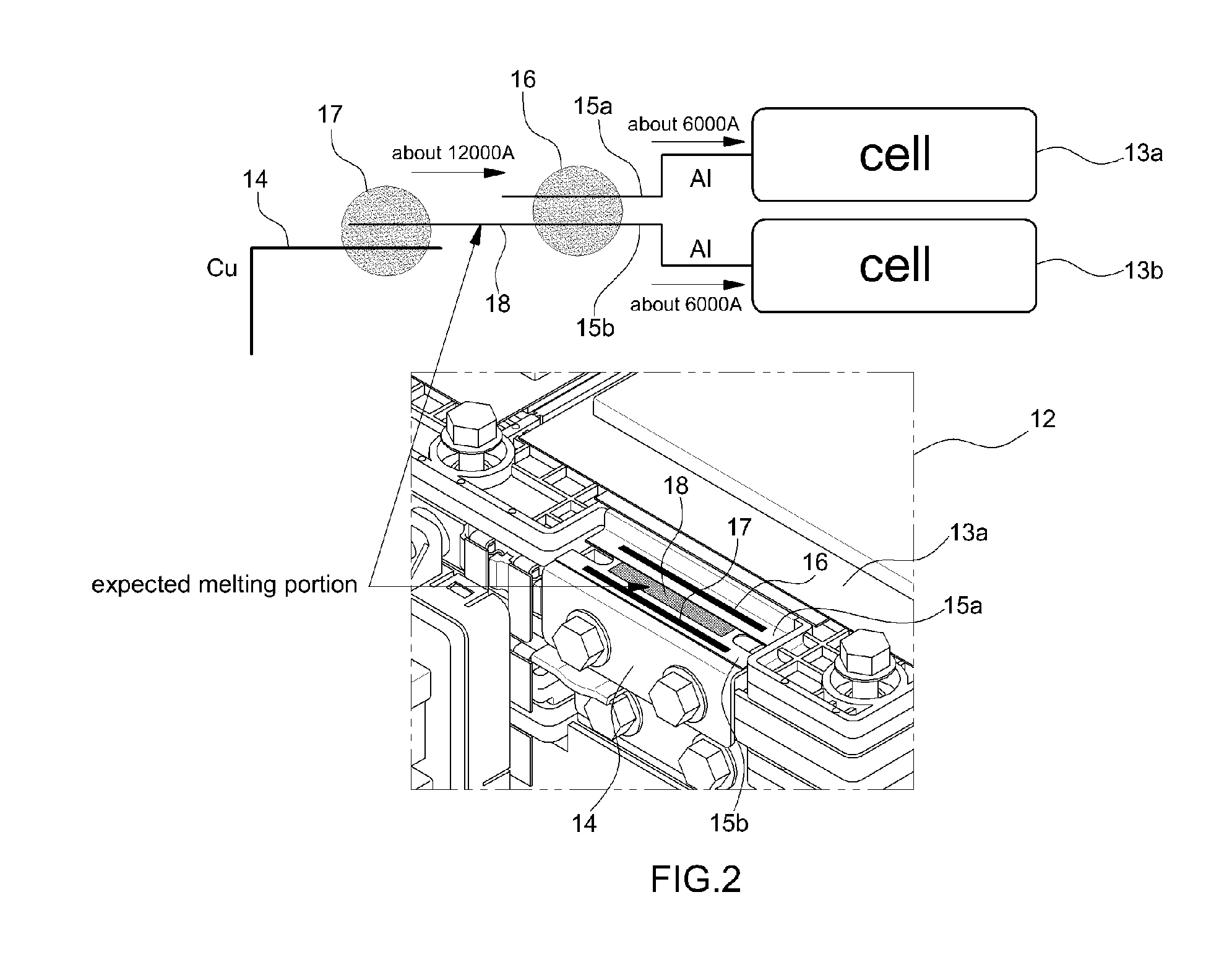

High voltage battery system for electric vehicle

InactiveUS20150165926A1Avoid injuryReduce the cross-sectional areaSafety/protection battery circuitsShort-circuit testingPower flowRoom temperature

A high-voltage battery system is provided that ensures fail safety against a room-temperature short circuit and a high-temperature short circuit in a high-voltage battery in an electric vehicle. The battery system prevents secondary injury due to fire in a vehicle collision or in maintenance while ensuring fail safety against a room-temperature short circuit and a high-temperature short circuit by implementing a type of safety element that ensures fail safety by improving the structure of a cell tap, that is, by partially reducing the cross-sectional area of a current path such that a conductive portion is rapidly melted by substantially high heat when a short circuit occurs in a battery.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com