Patents

Literature

52results about How to "Improve freeze-drying survival rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

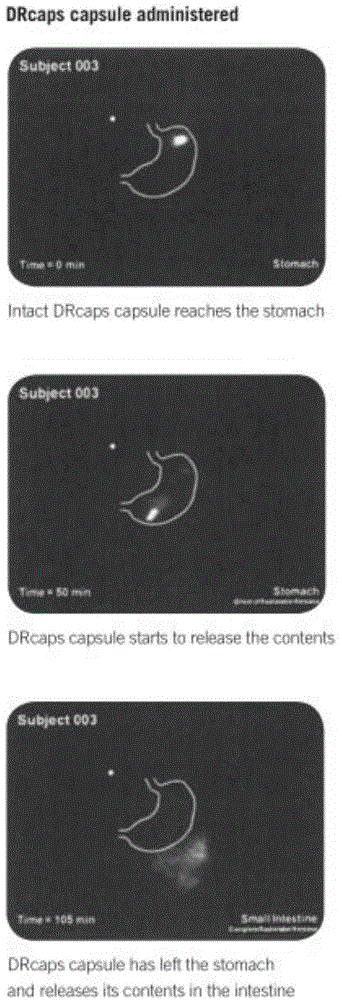

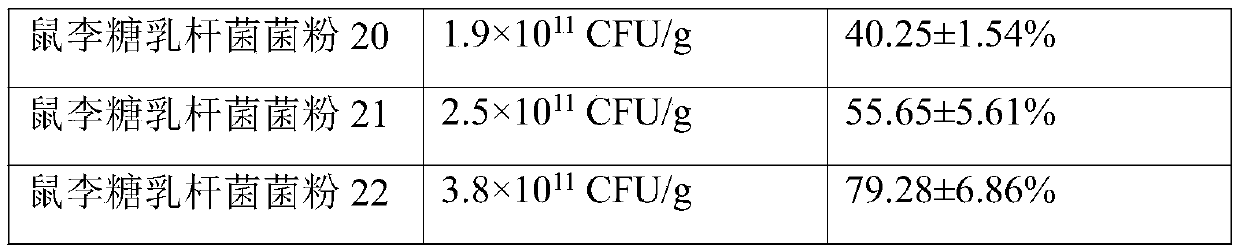

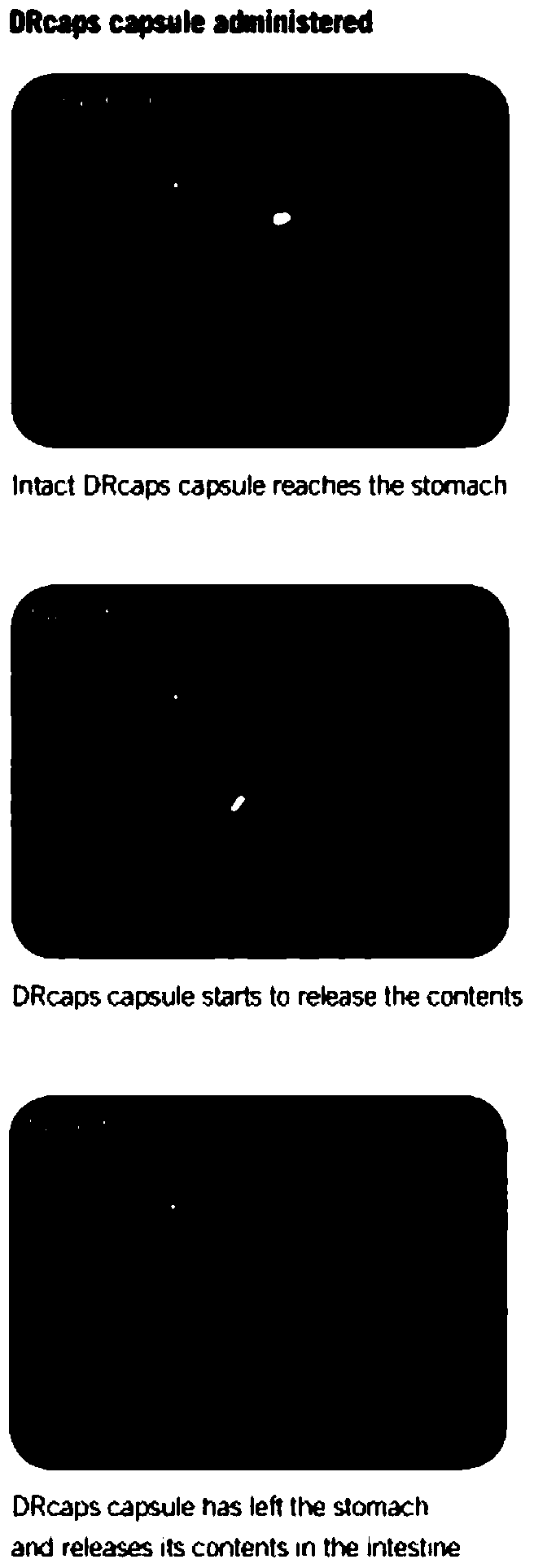

Fecal microbiota capsule, as well as preparation method and application thereof

The invention belongs to the technical field of fecal microbiota transplantation, and particularly relates to a fecal microbiota capsule, as well as a preparation method and application of the fecal microbiota capsule. The preparation method comprises the following steps: (1) a fecal microbiota solution is prepared; (2) the fecal microbiota solution, obtained in the step (1), is added with a freeze-drying protective additive, and freeze drying is performed to obtain fecal microbiota freeze-dried powder; (3) a capsule is filled with the fecal microbiota freeze-dried powder, obtained in the step (2), to obtain the fecal microbiota capsule. Through adoption of the fecal microbiota capsule, flora is enabled to be comparatively concentrated and can be preserved for a long time at a low temperature; implementation of flora transplantation is facilitated, and invasive implementation manners, such as a gastroscope, an enteroscope and a nasointestinal feeding tube, are not needed; when the fecal microbiota capsule is applied to weak patients, the safety is increased.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

Lyophilization process of lactobacillus plantarum

InactiveCN102220260AImprove freeze-drying survival rateImprove the best parametersBacteriaMicroorganism based processesMicrobial agentMicrobiologic agent

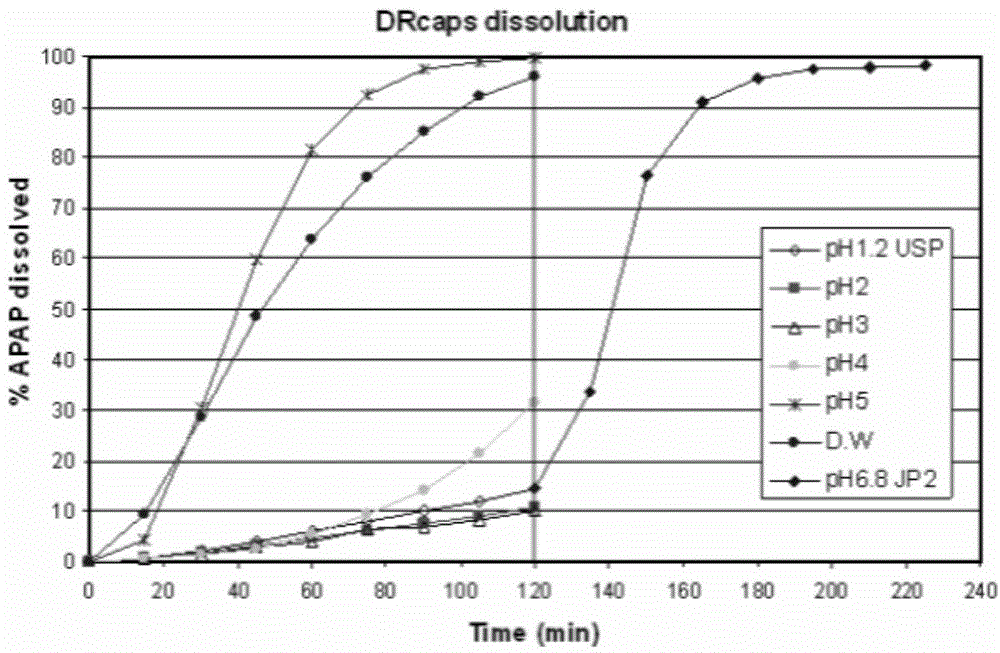

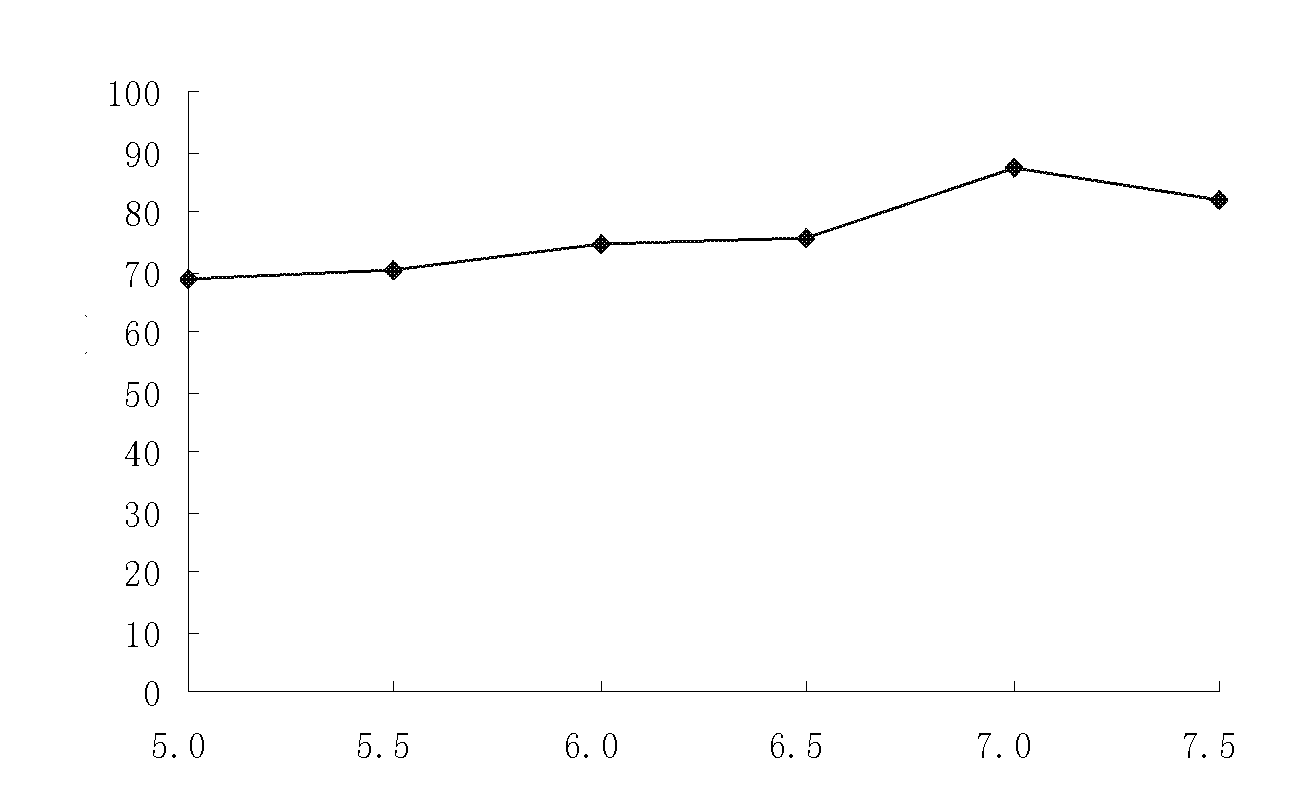

The invention relates to a lyophilization process of lactobacillus plantarum, and belongs to a microbial agent preparation process. In the lyophilization process of lactobacillus plantarum, the process parameters are that the pH of a lyophilization protective agent is 7.0-7.5, the balancing time of bacterium mire and the protective agent is 20-40minutes, pre-lyophilization is carried out for 2.0-2.5h under the condition of minus 80 DEG C, a phosphate buffer is adopted to prepare the protective agent, lyophilization livability can be up to over 90%, and the viable count can be up to over 4.0*1010cfu / g. Compared with the general method, the method disclosed by the invention has the advantages that the livability of the lactobacillus plantarum is improved remarkably.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Composite protective agent for increasing freeze-drying survival rate of lactobacillus plantarum and preparation method thereof

InactiveCN105420111AImprove freeze-drying survival rateThe survival rate is not easy to reduceMicroorganism based processesMicroorganism preservationFiltrationFreeze-drying

The invention provides a composite protective agent for increasing the freeze-drying survival rate of lactobacillus plantarum and a preparation method thereof. The protective agent is prepared from soybean polysaccharide, galactose, fructo-oligosaccharide, trehalose, skimmed milk, proline and distilled water. The preparation method includes the steps that the distilled water is divided into three parts, and soybean polysaccharide, galactose, fructo-oligosaccharide and trehalose are added to one part for dissolution and sterilization; the skimmed milk is added to another part of the distilled water for dissolution, and a skimmed milk solution is obtained and sterilized; proline is dissolved in the remaining distilled water, and membrane filtration sterilization is conducted; the three prepared solutions are evenly mixed under the sterile condition, and then the composite freeze-drying protective agent is obtained. According to the freeze-drying protective agent for lactobacillus plantarum, a freeze-drying protective additive is added in the fungus powder preparation process, the anti-freezing capacity of fungi can be improved, and therefore the freeze-drying survival rate of the fungus powder is increased, the storage period is long, and the survival rate is not likely to be reduced. The freeze-drying survival rate of the prepared fungus powder of lactobacillus plantarum ranges from 82.73% to 93.26%, and the viable count of the fungus powder ranges from 1.14*10<11> cfu / g to 1.98*10<11> cfu / g.

Owner:SHAANXI UNIV OF SCI & TECH

Probiotics microcapsule wall material and probiotics microcapsule preparation method

InactiveCN108323571AGuaranteed survivalImprove embedding yieldMilk preparationFood ingredient functionsFiberWater baths

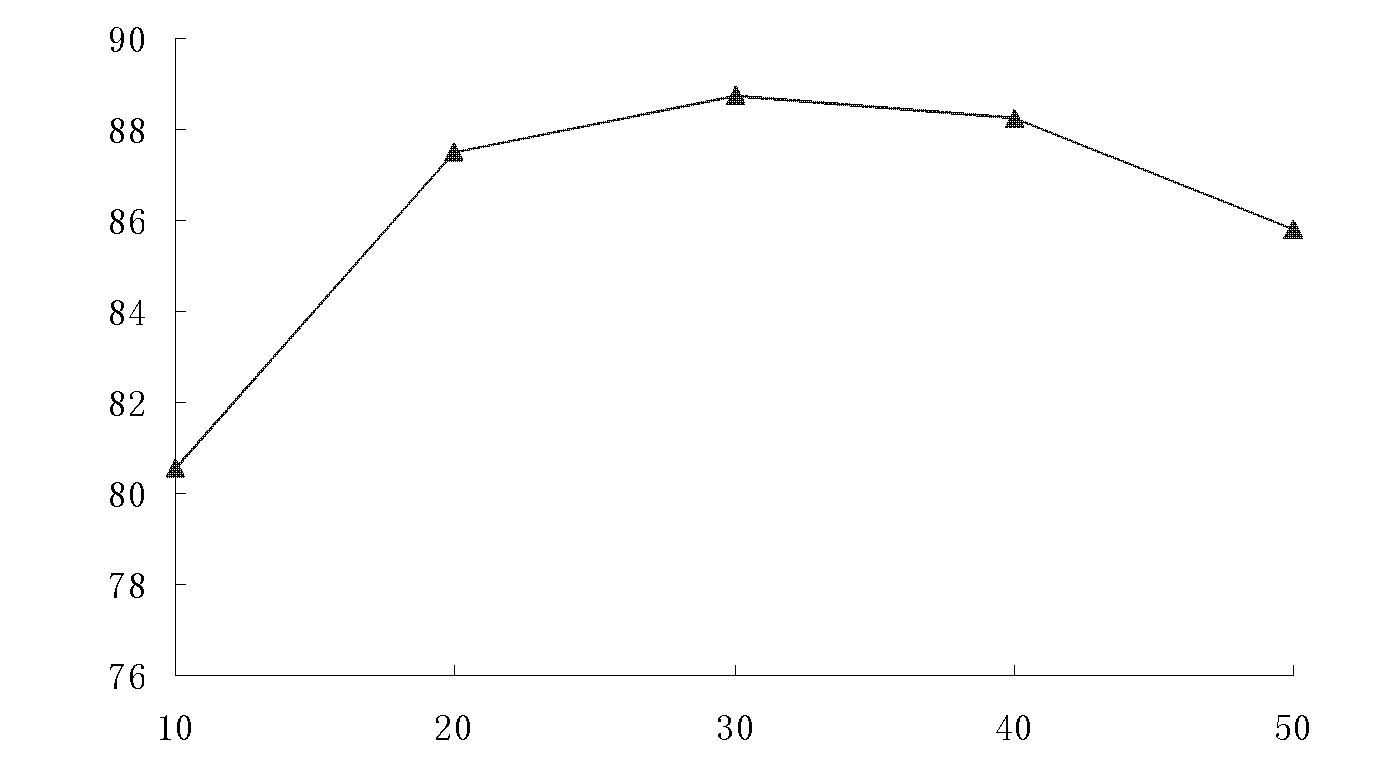

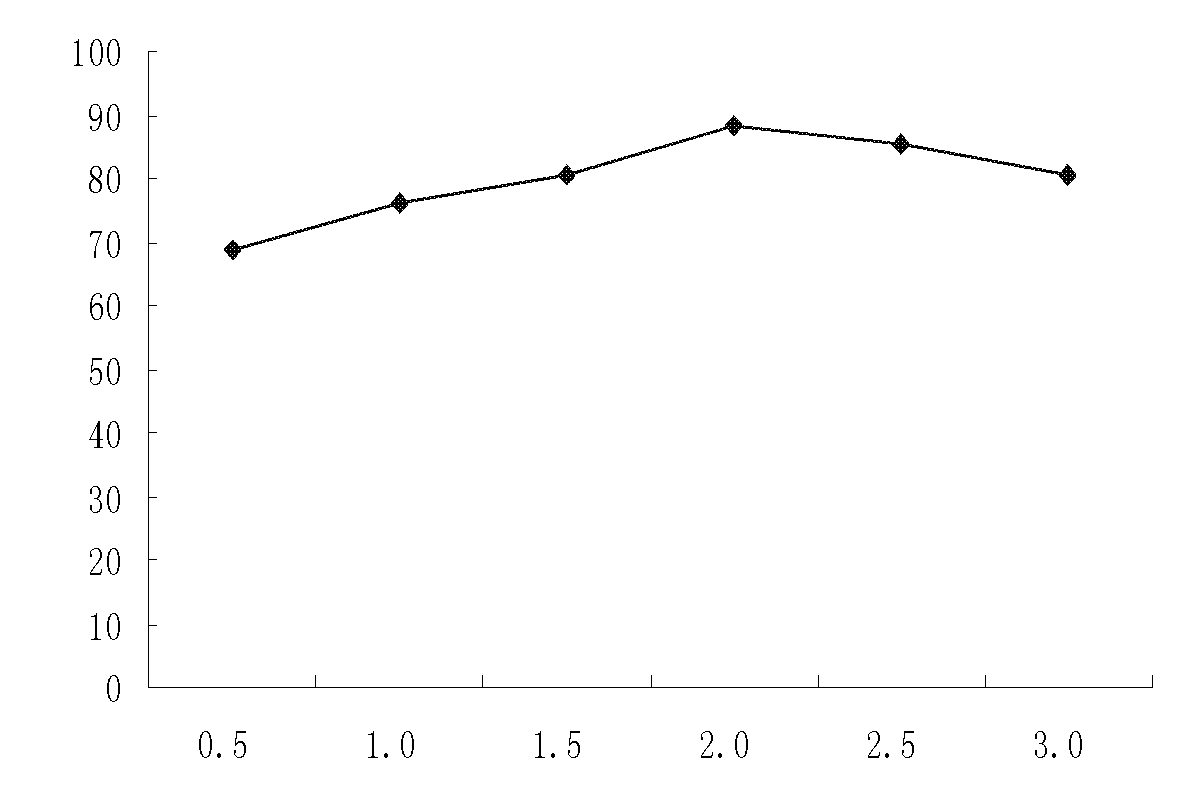

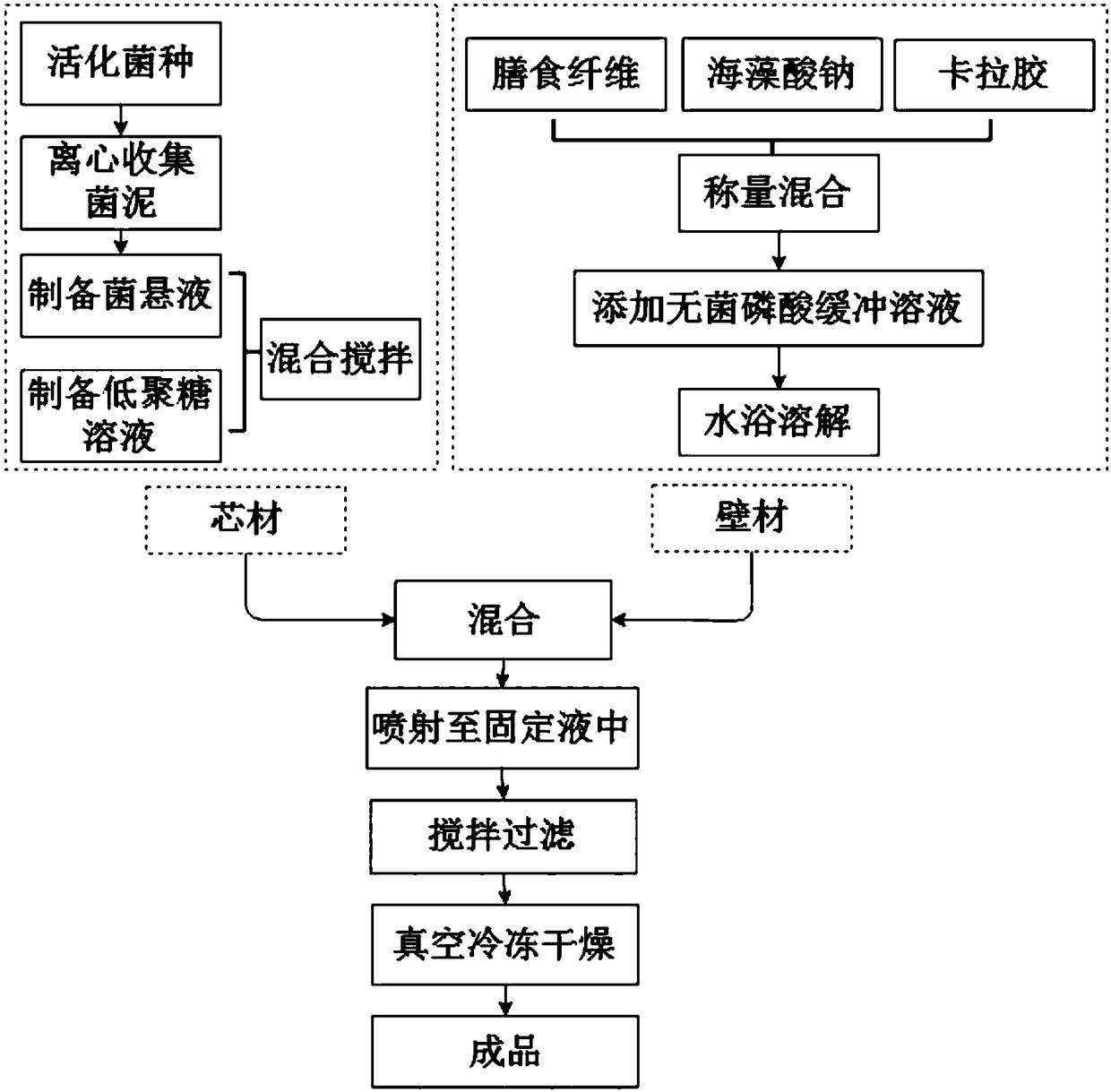

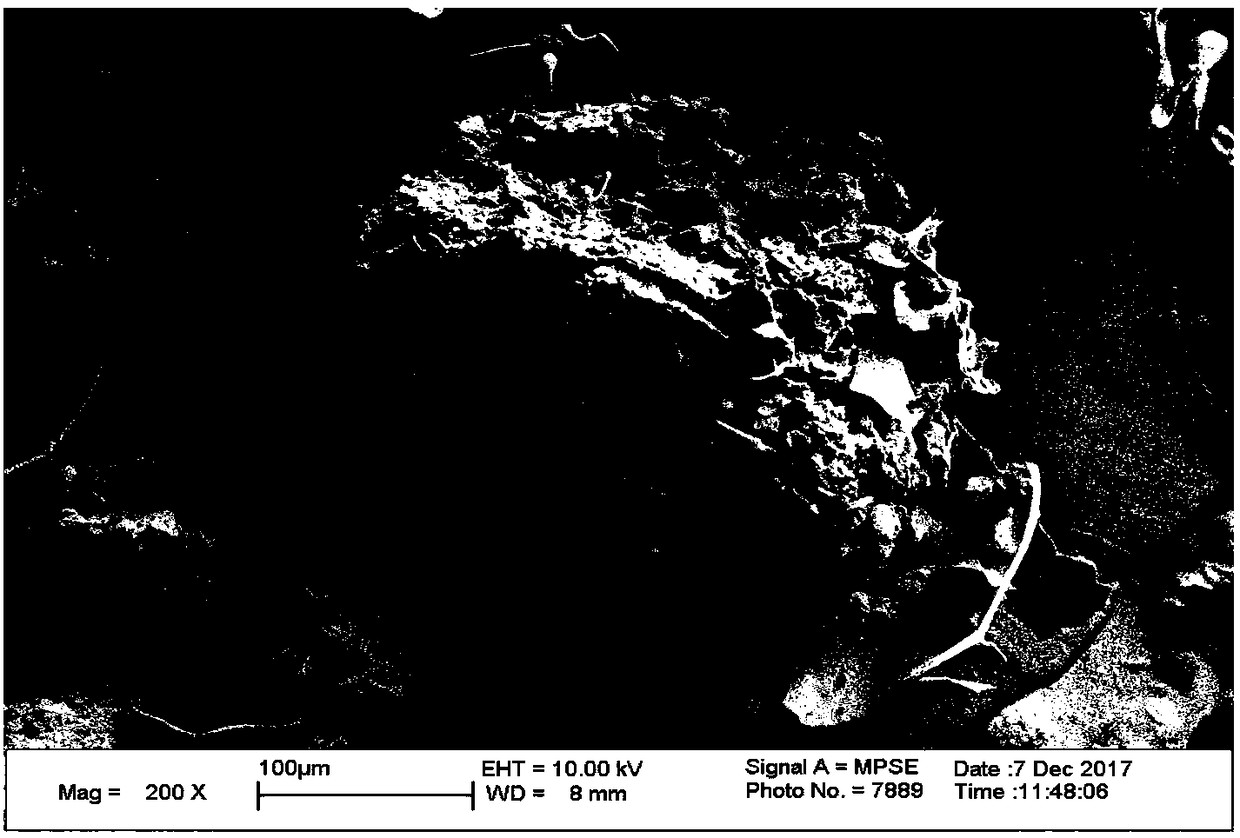

The invention discloses a probiotics microcapsule wall material preparation method. The probiotics microcapsule wall material preparation method comprises the following steps: mixing sodium alginate,carrageenan and meal fiber, performing ultraviolet lamp irradiation for 15-30 min, mixing a mixture with an aseptic phosphoric acid buffer solution with a pH value being with 6.8-7.4, performing water-bath dissolving at the temperature of 70-85 DEG C to prepare a wall material solution with mass concentration being 8.5-10.5%, wherein in the wall material solution, the mass concentration of the meal fiber is 1-5%, the mass concentration of sodium alginate is 2-4%, and the mass concentration of carrageenan is 4.5-6.5%. The invention also discloses the preparation method of the probiotics microcapsule, the volume ratio of an oligosaccharide solution (the mass concentration is 3-5%) to a probiotics suspension (greater than 5*107 CFU / mL) is 1:2-2:1. The probiotics microcapsule has the advantages of high embedding rate, high live bacteria number, high stress resistance, simple operation, economic performance, easy operation, and is suitable for industrial production.

Owner:GUANGZHOU MEDICAL UNIV

Lactobacillus freeze-dried product and preparation method of same

ActiveCN102978143AHigh viable countImprove stabilityBacteriaMicroorganism based processesBiotechnologyLactobacillus rhamnosus

The invention relates to a preparation method of a freeze-dried powder preparation of Lactobacillus acidophilus, Lactobacillus paracasei or lactobacillus rhamnosus, and provides a culture medium used in the freeze-drying process of Lactobacillus acidophilus, Lactobacillus paracasei or lactobacillus rhamnosus products. The inventor combines two critical factors influencing bacterial fermentation together, and creatively carries out fermentation in a high-density fermentation process by means of combination of two-sectional pH and three-sectional temperature variation, so that the relatively single form of the maximum cell biomass and the highest fermentation activity is improved remarkably, meanwhile, the obtained freeze-dried preparation is high in viable count and excellent in stability. The invention also provides an excellent freeze-drying protective additive.

Owner:中创益科(上海)生物科技有限公司

Method for producing freeze-drying bacterial powder of high-activity bifidobacterium and application

InactiveCN107868769AImprove freeze-drying survival rateImprove stress resistanceBacteriaMicroorganism based processesBiotechnologyFreeze-drying

The invention discloses a method for producing freeze-drying bacterial powder of high-activity bifidobacterium and application, belonging to the field of producing biological bacterium products. The method comprises the following steps of utilizing strong stress resistance of a bacterial thallus velum state to environmental stress, taking non-water-soluble dietary fiber, which is derived from grain flour, soya flour, vegetable powder, mushroom powder and the like, as a solid phase carrier to ferment and produce bifidobacterium velum thalluses; after fermentation, collecting bacterial sludge tomix with a freeze-drying protective additive, and performing vacuum freeze-drying to prepare the bacterial powder of bifidobacterium. By utilizing the method, the freeze-drying survival rate of the bifidobacterium is between 68% and 93% and is up to 5*1,010cfu / g or more, compared with the bifidobacterium in a non-velum state, the freeze-drying survival rate is improved by 200% or more and the storage stability is improved by 300% or more. By the method, the key common technical problem of developing the bacterial powder of the bifidobacterium with high activity and strong stress resistance issolved, and the prepared bacterial powder of the bifidobacterium can be applied to product forms such as leavening agents and solid beverage.

Owner:JIANGNAN UNIV

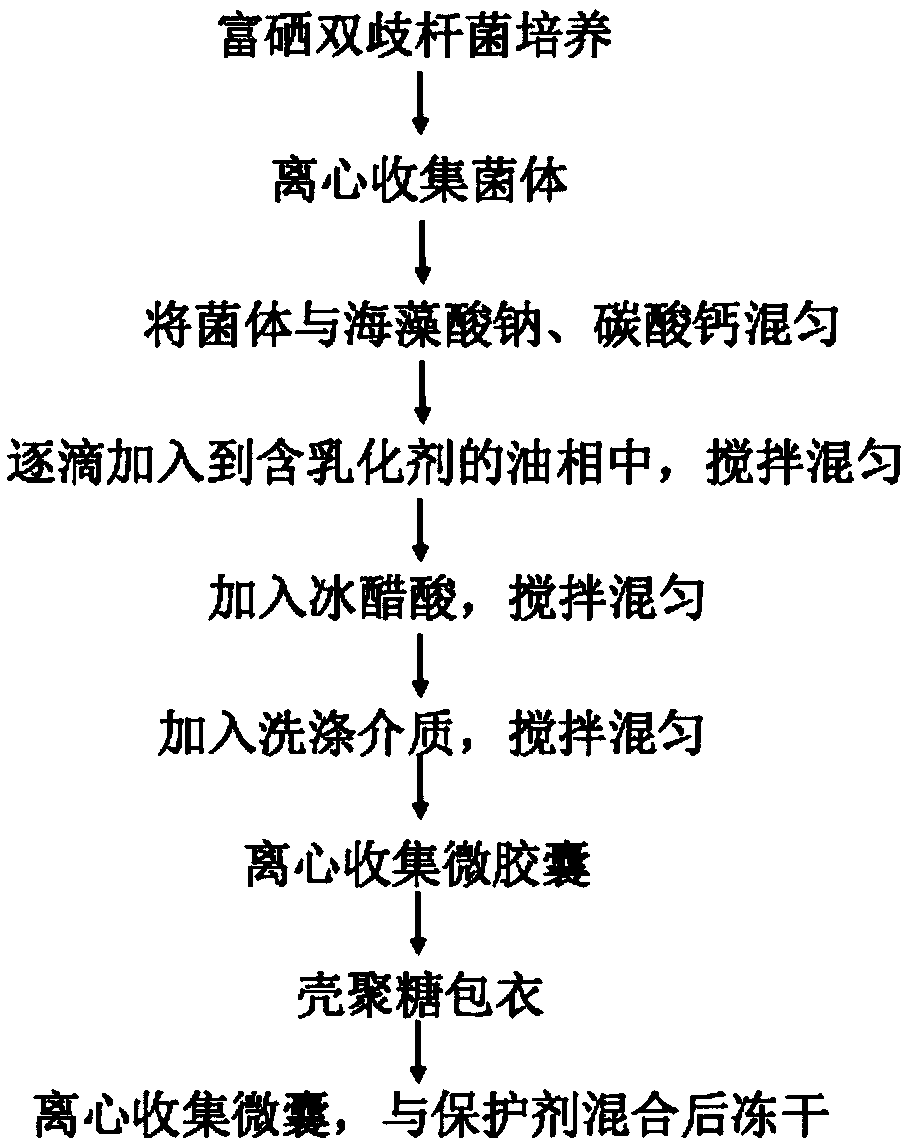

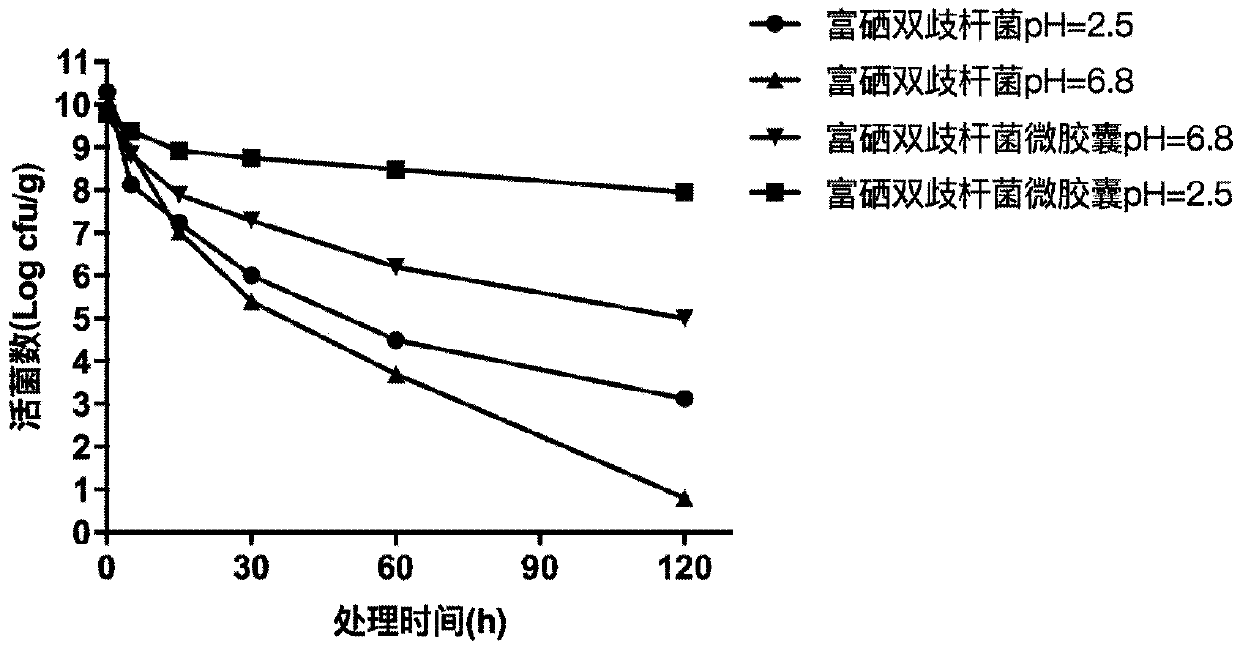

Selenium-enriched bacillus bifidus micro-capsules

InactiveCN109601811AHigh embedding rateImprove acid and bile salt resistance propertiesMilk preparationFood scienceVegetable oilFreeze-drying

The invention discloses selenium-enriched bacillus bifidus micro-capsules. The selenium-enriched bacillus bifidus micro-capsules are prepared by adopting a method comprising the following steps: uniformly mixing a sodium alginate solution with selenium-enriched bacillus bifidus thallus and calcium carbonate powder so as to obtain a mixture; dropwise adding the mixture into vegetable oil containingan emulsifier, and carrying out stirring so as to obtain an emulsion; sequentially adding vegetable oil containing glacial acetic acid and an emulsifier solution into the emulsion, carrying out stirring, and allowing standing; and then, separating oil phase so as to obtain aqueous phase, and centrifuging the aqueous phase so as to obtain the selenium-enriched bacillus bifidus micro-capsules. By screening reagents, materials and dosage ratio adopted in micro-capsule preparing, coating and freeze-drying processes, embedding rate of the selenium-enriched bacillus bifidus micro-capsules disclosedby the invention are improved. The embedding rate of the selenium-enriched bacillus bifidus micro-capsules is up to 98% while the particle size is smaller than 200 microns and the freeze-drying survival rate is up to 85%. According to normal-temperature stability results, viable number of the selenium-enriched bacillus bifidus micro-capsules is still about 10<8> cfu / g within 180 days.

Owner:JIANGSU DAYSEBIOTECH LTD +1

Method for improving freeze-drying survival rate of Lactobacillus acidophilus

InactiveCN102329759AImprove freeze-drying survival rateImprove the immunityBacteriaMicroorganism based processesFreeze-dryingSludge

The invention aims to provide a method for improving the freeze-drying survival rate of Lactobacillus acidophilus. The method comprises the following steps of: culturing the Lactobacillus acidophilus for 18h at the temperature of 37 DEG C, performing sublethal treatment on the Lactobacillus acidophilus, centrifuging for 10 to 15min at the temperature of 4 DEG C at the rotating speed of 7,000rpm, adding skimmed milk and a phosphate buffer solution into bacterial sludge of the Lactobacillus acidophilus, pre-freezing for 8 to 12h at the temperature of -40 DEG C, and putting into a freeze dryer and freeze-drying for 18 to 24h at the temperature of between -50 and -60 DEG C under the vacuum degree of between 4 and 6Pa to obtain bacterial powder of the Lactobacillus acidophilus. In the method for improving the freeze-drying survival rate of the Lactobacillus acidophilus, a Lactobacillus acidophilus culture solution is subjected to cold shock, heat shock or acid shock treatment first so as to ensure that the Lactobacillus acidophilus induces to synthesize cold shock protein and heat shock protein under adverse circumstances or changes the composition of fatty acid of cell membranes, so that the resistance of the Lactobacillus acidophilus in the subsequent freeze-drying process is improved, and the freeze-drying survival rate and the viable count of the bacterial powder are improved.

Owner:SHAANXI RES INST OF AGRI PRODS PROCESSING TECH +1

Preparation method of bdellovibrio bacteriovorus lyophilized powder

InactiveCN107213171AImprove freeze-drying survival rateGood dispersionAntibacterial agentsPowder deliveryFreeze-dryingHigh survival rate

The invention provides a preparation method of a powdery bdellovibrio bacteriovorus lyophilized preparation with high survival rate. The method comprises the steps of obtaining a bacteria solution or a bdellovibrio bacteriovorus bacterial suspension from which a harmful host is separated according to a conventional culture method of bdellovibrio bacteriovorus; preparing a protective agent solution; carrying out freeze drying on a to-be-lyophilized mixed solution, repeatedly vacuumizing and filling an inert gas to finally prepare the preparation into powder; and carrying out sealing packaging on the bdellovibrio bacteriovorus lyophilized preparation under a vacuum condition or under the condition of filling the inert gas to prepare a finished product, namely the bdellovibrio bacteriovorus lyophilized preparation. Through compounding of multiple lyophilized protective agents, the freeze-drying survival rate of bdellovibrio bacteriovorus is improved, the character of the bdellovibrio bacteriovorus lyophilized preparation is powder, and dispersion and compounding of the lyophilized preparation are facilitated.

Owner:XIAMEN CANCO BIOTECH CO LTD

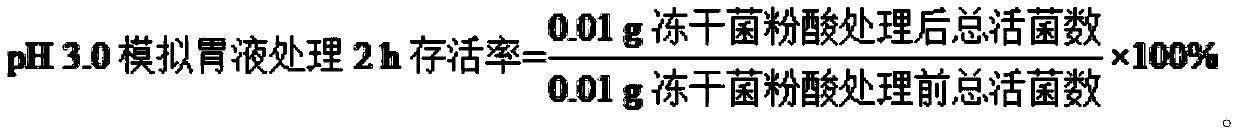

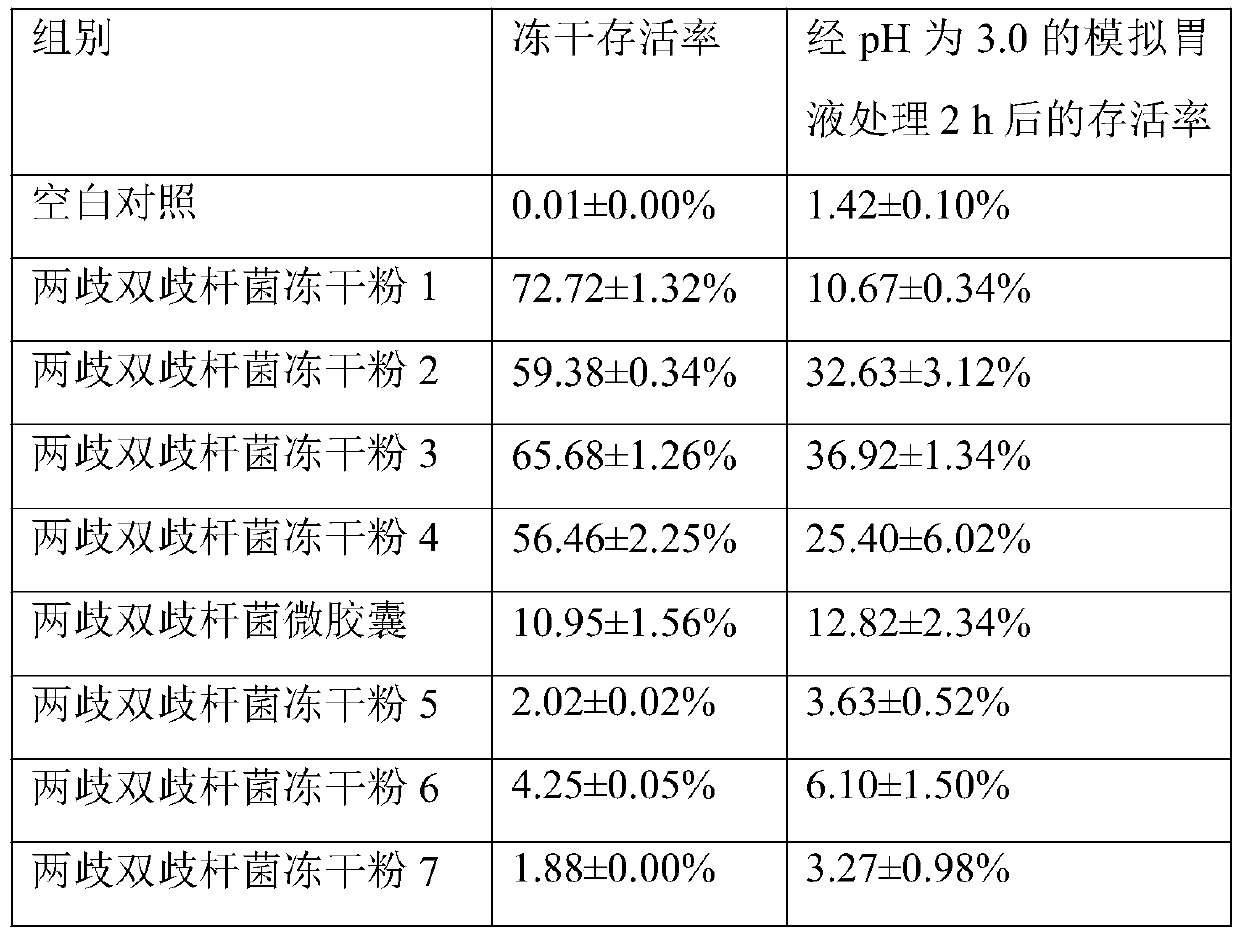

Freeze-drying protective agent capable of improving acid resistance of bifidobacteria and application of freeze-drying protective agent

ActiveCN111534435AImprove freeze-drying survival rateHigh activityBacteriaMicroorganism based processesBiotechnologyCellulose

The invention discloses a freeze-drying protective agent capable of improving the acid resistance of bifidobacteria and an application of the freeze-drying protective agent, and belongs to the technical field of microorganisms. The invention provides the freeze-drying protective agent capable of remarkably improving the freeze-drying survival rate and the acid resistance of the bifidobacterial. The freeze-drying protective agent comprises a component A and a component B, wherein the component A is one or more of sodium alginate, sodium caseinate and sodium carboxymethylcellulose, and the component B is one or more of rhamnose, xylose, arabinose, mannose, sorbitol and raffinose. When the freeze-drying protective agent is used for preparing bifidobacterium freeze-dried powder, the freeze-drying survival rate of the bifidobacteria is as high as 65.68%, and after the bifidobacterium freeze-dried powder prepared from the freeze-drying protective agent is treated with simulated gastric juicewith the pH value of 3.0 for 2 h, the survival rate of the bifidobacteria is as high as 36.92%.

Owner:JIANGNAN UNIV

Streptococcus thermophilus freeze-drying protective agent and preparation method thereof

ActiveCN102952771AImprove freeze-drying survival rateExtended shelf lifeBacteriaMicroorganism based processesFreeze-dryingDextran

The invention discloses a streptococcus thermophilus freeze-drying protective agent and a preparation method thereof. The streptococcus thermophilus freeze-drying protective agent comprises the following components in parts by mass: 10-20 parts of dried skim milk, 3-10 parts of raffinose, 4-10 parts of soybean oligosaccharides, 1.05-5.0 parts of dextran D40, 0.3-0.8 parts of sodium tripolyphosphate, 0.005-0.02 parts of propylgallate and 100 parts of distilled water, wherein the soybean oligosaccharides and the dextran D40 can both be purchased from LUOSHENBO science and technology Ltd.. The anti-freezing ability of thallus can be increased by adding a freeze-drying protective agent during a thallus powder preparing process, thus the freeze-drying survival rate of the thallus powder can be increased, the storage period can be longer, and the survival rate can not be easily lowered.

Owner:SHAANXI YATAI DAIRY CO LTD

Lactobacillus acidophilus anti-freeze culture medium and application method thereof

InactiveCN102408992AImprove freezing abilityImprove freeze-drying survival rateMicroorganism based processesMicroorganism preservationBetaineFreeze-drying

The invention provides a lactobacillus acidophilus anti-freeze culture medium and an application method thereof. The culture medium includes the following components by weight: 16-20 g of glucose, 0.4-0.8 g of fructus tribuli polysaccharide, 3-5 g of yeast extract, 4-6 g of sodium chloride, 0.3-0.5 g of mannitol, 0.8-1.2 g of sodium glutamate, 8-12 g of soybean peptone, 0.5-2.0 g of diammonium hydrogen citrate, 0.2-0.5 g of betaine, 1.0-2.5 g of dipotassium phosphate, 0.1-0.2 g of MgSO4, 0.5-1.0 ml of Tween-80 and 1,000 ml of distilled water. The culture medium has the advantages that: after lactobacillus acidophilus is cultured by using the anti-freeze culture medium, the freeze-dry survival rate of the lactobacillus acidophilus can reach up to 79.54 percent, and viable count of fungal powder reaches up to 4.09*10<11> cfu / g; and the lactobacillus acidophilus MRS (de Man, Rogosa and Sharp) broth is used for culture, so that the freeze-dry survival rate of the prepared fungal powder isonly 49.72 percent, and the viable count is only 1.24*10<11> cfu / g.

Owner:SHAANXI RES INST OF AGRI PRODS PROCESSING TECH +1

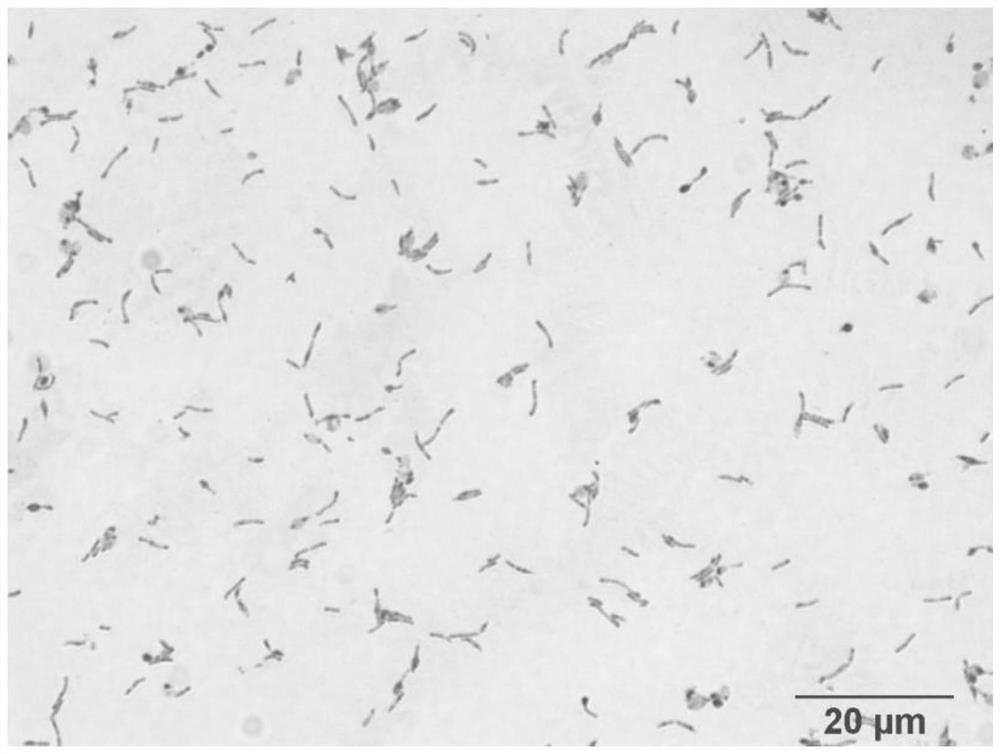

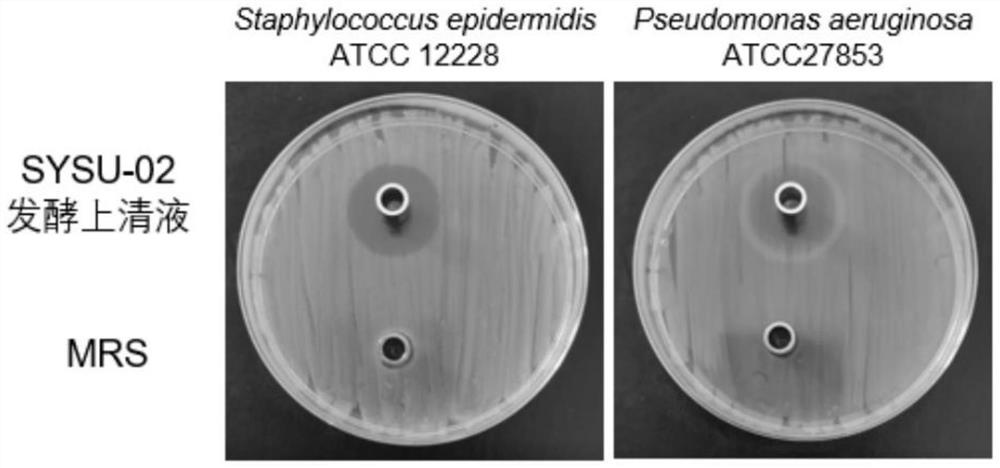

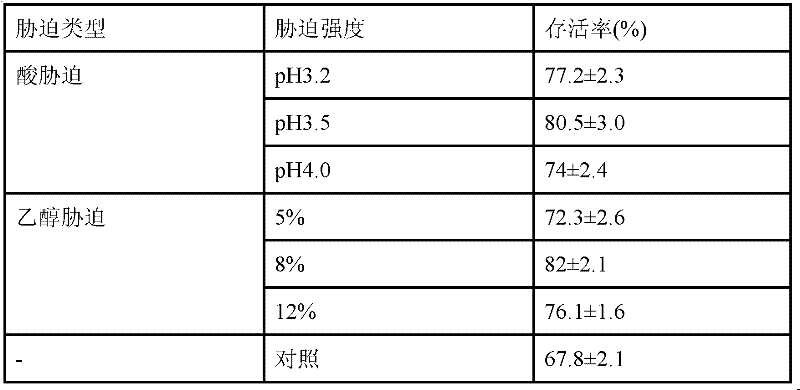

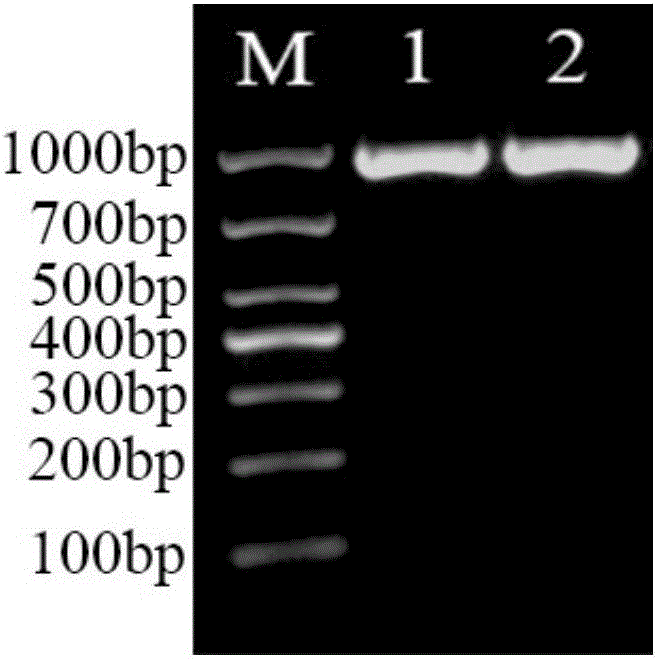

Bifidobacterium longum SYSU-02 and application thereof

ActiveCN114292781AGuaranteed survival rateReduce severityBacteriaDigestive systemBiotechnologyAcute ulcerative colitis

The invention belongs to the technical field of microorganism application, particularly relates to bifidobacterium longum SYSU-02 and application thereof, and discloses the bifidobacterium longum SYSU-02 with the preservation number of CGMCC (China General Microbiological Culture Collection Center) No.20651. The invention further discloses a preparation method of the bifidobacterium longum SYSU-02. An inhibition zone experiment and an MIC experiment show that the strain has an inhibition effect on pathogenic staphylococcus epidermidis and pseudomonas aeruginosa, and can be added into nasal cavity, oral cavity or skin cleaning products. Animal experiments prove that the strain can relieve the severity of acute ulcerative colitis and has a good protection effect on intestinal tracts. Meanwhile, the bifidobacterium longum-chitosan-inulin-calcium alginate microcapsule is constructed by adopting a microencapsulation technology and a freeze-drying technology, so that the stress resistance and the room-temperature storage stability of the strain are also improved on the basis of maintaining a relatively high freeze-drying survival rate; therefore, the survival rate of the bifidobacterium longum in the production, transportation and storage processes is ensured.

Owner:SUN YAT SEN UNIV

Bifidobacterium freeze drying preparation and special protection agent thereof

InactiveCN108546647AImprove freeze-drying survival rateMicroorganism based processesMicroorganism preservationXyloseBifidobacterium

The invention belongs to the field of microorganisms, and relates to a bifidobacterium freeze drying preparation and a special protection agent thereof. The bifidobacterium freeze drying preparation is characterized by being obtained through freeze drying after the protection agent is added into the bifidobacterium thalli. The special protection agent for the bifidobacterium freeze drying preparation is characterized by being prepared from the following ingredients in parts by weight: 3 to 5 parts of xylo-oligosaccharides, 4 to 8 parts of lactose, 0.5 to 1.5 parts of polyethyleneglycol, 1.5 to3 parts of lactamic acid, 0.5 to 1 part of lysine, 3 to 5 parts of skimmed milk powder, 2 to 4 parts of stachyose, 0.1 to 0.5 part of Jilin ginseng oligopeptides, 0.4 to 0.6 part of sodium bicarbonate, 0.7 to 1.2 parts of sodium ascorbate and 80 to 100 parts of water.

Owner:九江牧威利元科技中心(普通合伙)

Culture medium for improving freezing tolerance of Lactobacillus bulgaricus and application of culture medium

ActiveCN108018211AImprove frost resistanceIncrease the number of live bacteria in bacteria powderMicroorganism based processesMicroorganism preservationFreeze-dryingManganese

The invention provides a culture medium for improving the freezing tolerance of Lactobacillus bulgaricus and application of the culture medium. The culture medium contains the following components byweight: 12g-30g of mannose, 5g-10g of mycose, 3g-6g of casein peptone, 3g-6g of anhydrous sodium acetate, 5g-10g of beef extract powder, 3g-6g of potassium acetate, 1.5g-4.0g of anhydrous calcium chloride, 0.1g-0.8g of magnesium sulfate, 0.1g-0.5g of manganese sulfate, 0.1g-1g of L-cysteine hydrochloride, 0.6mL-1.2mL of Tween-80 and 1000mL of distilled water. By utilizing the freezing-resistant culture medium and particularly a freeze-drying protection method provided by the invention, relatively high freeze-drying survival rate of Lactobacillus bulgaricus can be realized, the preservation period is relatively long, and the survival rate is unlikely to be decreased.

Owner:内蒙古双奇药业股份有限公司

Method for improving lyophilized activity of Oenococcus oeni by utilizing stress pretreatment

InactiveCN102559500AImprove lyophilization activityImprove freeze-drying survival rateMicroorganism based processesWine preparationMonosodium glutamateAs Directed

The invention relates to a method for improving lyophilized activity of Oenococcus oeni by utilizing stress pretreatment, which comprises the following steps: performing enrichment culture of Oenococcus oeni strain to reach the stable period, centrifugally collecting the bacterial sludge, resuspending in the culture medium ATB containing the stress treatment fluid, standing at 25 DEG C for 2-3h, centrifuging, harvesting bacterial body, adding proper sodium pyruvate solution with mass concentration of 2-5% as the lyophilized protective agent and performing freeze drying to obtain lyophilized bacteria powder. The lyophilized bacteria powder prepared by the method of the invention can be used as direct Oenococcus oeni fermentation starter. The method of the invention introduces the idea of stress pretreatment, and uses sodium pyruvate as the lyophilized protective agent, which is the main component of the monosodium glutamate and is safe and no harm to human and poultry and has various health-care effects, the introduced idea can be used in the production process of direct edible fermentation starter.

Owner:NORTHWEST A & F UNIV

Overexpressed UGPase (UDP-glucose pyrophosphorylase) gene and method for constructing recombinant lactobacillus acidophilus thereof

ActiveCN106520794AImprove freeze-drying survival rateBacteriaMicroorganism based processesPhosphorylationLactobacillus acidophilus

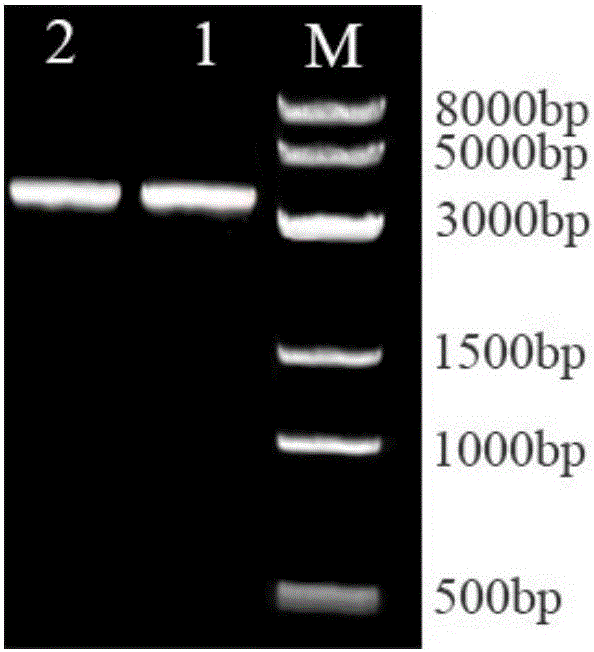

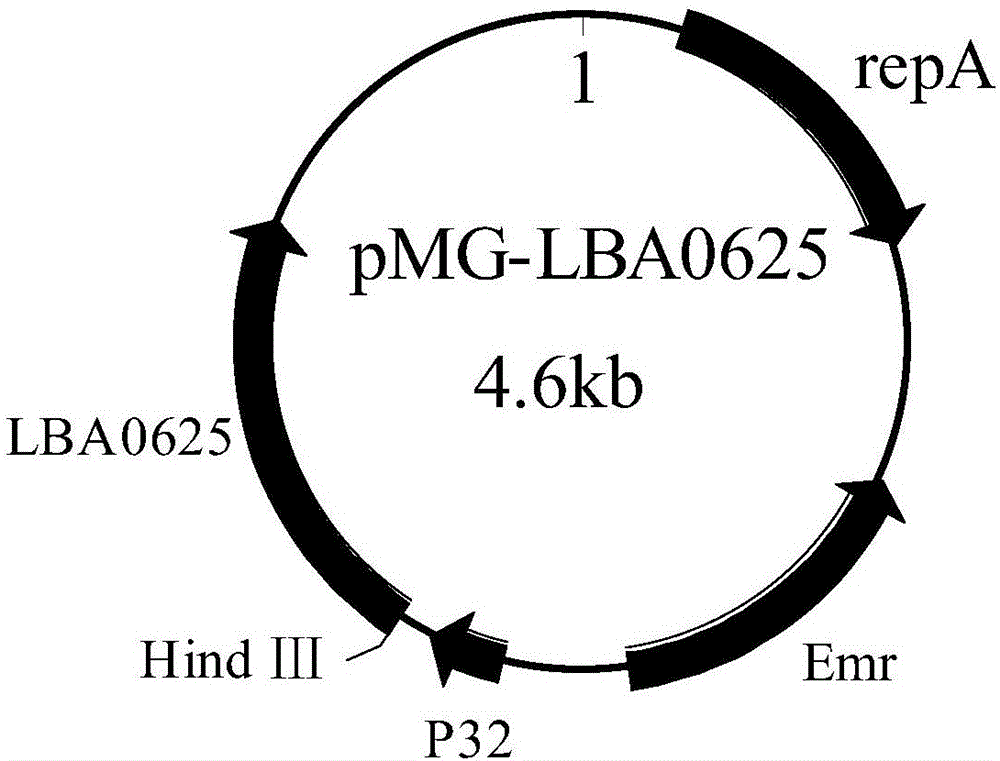

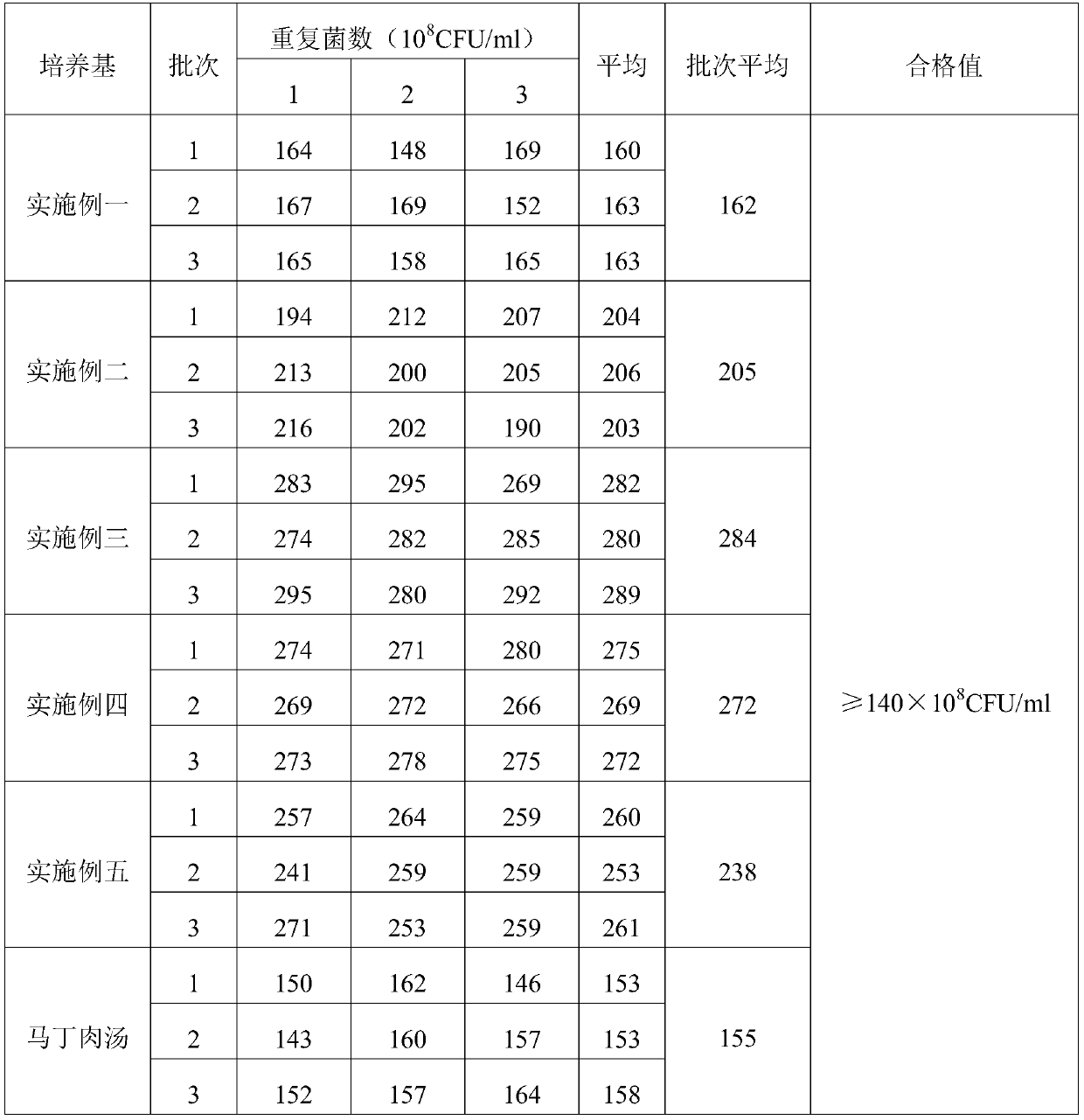

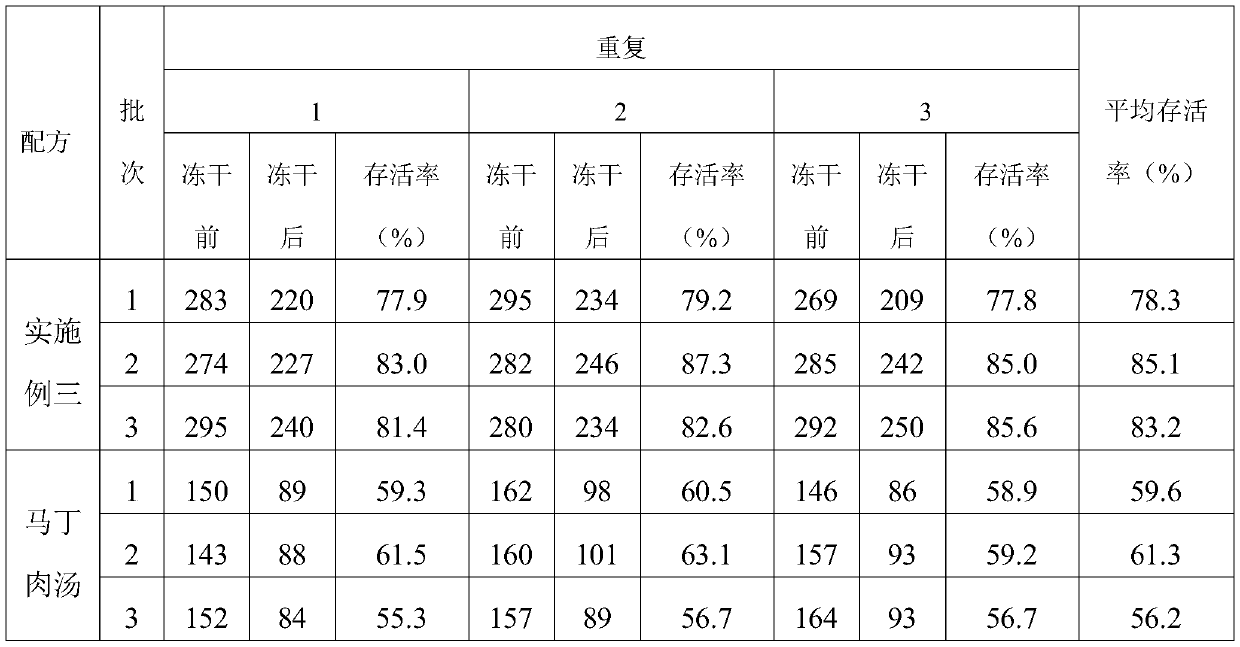

The invention discloses an overexpressed UGPase (UDP-glucose pyrophosphorylase) gene and a method for constructing recombinant lactobacillus acidophilus thereof. The method is characterized by comprising the specific steps as follows: (1) a UGPase gene LBA0625 is amplified with lactobacillus acidophilus genome DNA as a template; an expression vector pMG36e is subjected to single restriction digest with restriction enzyme Hind III, and after dephosphorylation and gel recovery are performed, a recombinant expression vector is constructed by inserting a PCR amplification product into the expression vector pMG36e; (2) an overexpression plasmid subjected to extraction and concentration is imported into lactobacillus acidophilus through electrotransformation, the lactobacillus acidophilus is resuscitated at 37 DEG C for 2 h, applied to an erythrocin resistant plate and cultured at 37 DEG C for 36 h for screening transformants; the transformants are subjected to PCR verification, and the recombinant lactobacillus acidophilus PLY127-1 of the overexpressed UGPase gene is obtained. The freeze-drying survival rate of the lactobacillus acidophilus can be increased substantially.

Owner:NINGBO UNIV

Method for extracting preserved bacteria solution from faeces

InactiveCN110540941AFor long-term storageEasy to transplantMicroorganism preservationOral medicationFreeze-drying

The invention relates to a method for extracting a preserved bacteria solution from faeces. The method comprises the following steps that (1) a faecal bacteria solution is prepared; (2) a freeze-drying protecting agent is added into the faecal bacteria solution obtained in the step (1), then the faecal bacteria solution is subjected to freeze drying, and thus faecal bacteria freeze-dried powder isobtained; (3) the faecal bacteria freeze-dried powder obtained in the step (2) is placed in a refrigerator at -80 DEG C to be preserved; and (4) when the faecal bacteria freeze-dried powder obtainedin the step (3) is taken and used, the faecal bacteria freeze-dried powder is restored to be liquid and then is taken and used. Compared with the prior art, according to the method, microflora is concentrated and can be preserved at the low temperature for a long term, the survival rate of faecal bacteria after being preserved for one week reaches 85.24%, microbiota transplantation is facilitatedthrough the mode of the faecal bacteria freeze-dried powder, and transplantation can be directly conducted through an oral administration feeding method.

Owner:SHANGHAI JIAO TONG UNIV

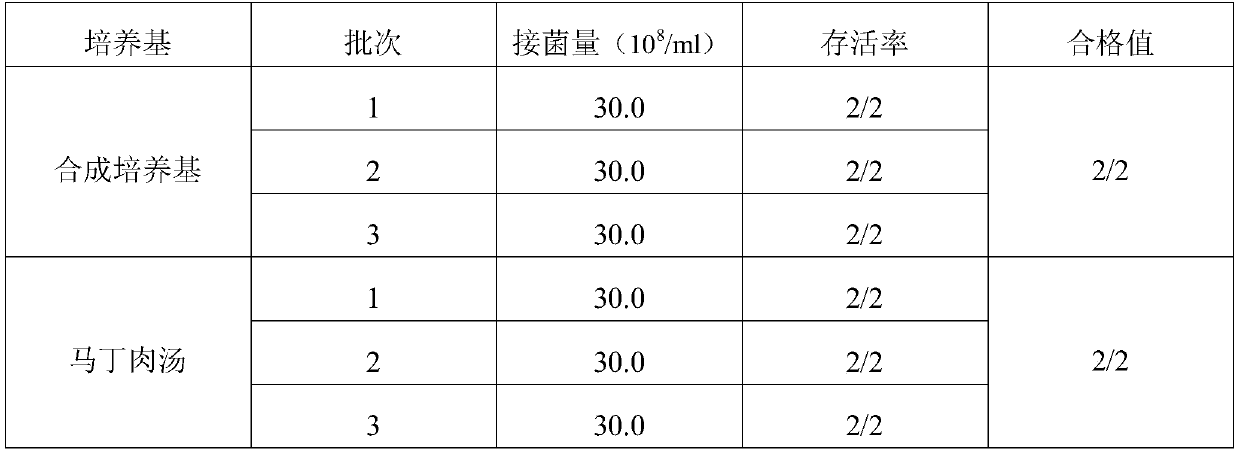

Swine pasteurellosis vaccine enrichment medium

PendingCN111040971APromote growth and reproductionRich in nutrientsBacteriaMicroorganism based processesBiotechnologyVaccine Production

The invention provides a swine pasteurellosis vaccine enrichment medium, and relates to the field of biology. The swine pasteurellosis vaccine enrichment medium is prepared from the following raw materials by weight: 20.0g of meat liver and stomach membrane digestive juice powder, 8.0g of bovine pancreas digestive juice, 10.0g of peptone, 5.0g of NaCl, 1.0g of a growth promoting factor, and purified water added to 1000ml. A preparation method of the swine pasteurellosis vaccine enrichment medium comprises the following steps: adding all the raw materials for preparing the swine pasteurellosisvaccine enrichment medium into purified water, fully dissolving the raw materials, and carrying out sterilization at 121 DEG C for 15 minutes for later use. The invention relates to an application ofa synthetic dry powder culture medium in swine pasteurellosis vaccine production. The synthetic dry powder culture medium has the beneficial effects that commercial raw materials can be selected, theculture medium is clear, the number of cultured bacteria is high, and the freeze-drying survival rate of the bacteria is increased.

Owner:青岛高科技工业园海博生物技术有限公司

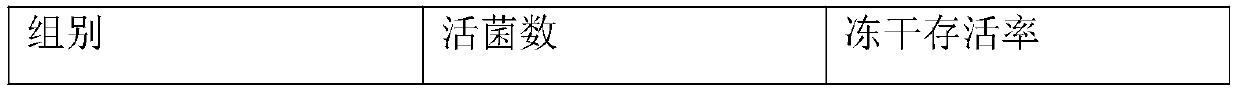

Lactobacillus freeze-dried product and preparation method of same

ActiveCN102978143BHigh viable countImprove stabilityBacteriaMicroorganism based processesBiotechnologyLactobacillus rhamnosus

The invention relates to a preparation method of a freeze-dried powder preparation of Lactobacillus acidophilus, Lactobacillus paracasei or lactobacillus rhamnosus, and provides a culture medium used in the freeze-drying process of Lactobacillus acidophilus, Lactobacillus paracasei or lactobacillus rhamnosus products. The inventor combines two critical factors influencing bacterial fermentation together, and creatively carries out fermentation in a high-density fermentation process by means of combination of two-sectional pH and three-sectional temperature variation, so that the relatively single form of the maximum cell biomass and the highest fermentation activity is improved remarkably, meanwhile, the obtained freeze-dried preparation is high in viable count and excellent in stability. The invention also provides an excellent freeze-drying protective additive.

Owner:中创益科(上海)生物科技有限公司

Method for reducing secretion amount of lactobacillus rhamnosus surface substance

ActiveCN111575223AReduce the difficulty of collectionReduce secretionBacteriaMicroorganism based processesBacilliArabinose

The invention discloses a method for reducing secretion amount of lactobacillus rhamnosus surface substance, and belongs to the technical field of microorganisms. The invention provides a method for reducing the secretion amount of the lactobacillus rhamnosus surface substances, which can obviously reduce the secretion amount of lactobacillus rhamnosus surface substances, thereby lowering the collection difficulty of lactobacillus rhamnosus thalli in a lactobacillus rhamnosus culture solution. According to the method, lactobacillus rhamnosus is inoculated into a culture medium containing arabinose, yeast extract powder, magnesium sulfate, manganese sulfate and Tween-80 to be cultured, so that the secretion amount of capsular polysaccharide on the surface of lactobacillus rhamnosus thallusis only 1.15 * 10 <-12 > mg / CFU; and the secretion amount of the surface protein is only 1.90 * 10 <-10 > mg / CFU.

Owner:JIANGNAN UNIV

Fecal bacteria capsule and its preparation and application

The invention belongs to the technical field of fecal microbiota transplantation, and particularly relates to a fecal microbiota capsule, as well as a preparation method and application of the fecal microbiota capsule. The preparation method comprises the following steps: (1) a fecal microbiota solution is prepared; (2) the fecal microbiota solution, obtained in the step (1), is added with a freeze-drying protective additive, and freeze drying is performed to obtain fecal microbiota freeze-dried powder; (3) a capsule is filled with the fecal microbiota freeze-dried powder, obtained in the step (2), to obtain the fecal microbiota capsule. Through adoption of the fecal microbiota capsule, flora is enabled to be comparatively concentrated and can be preserved for a long time at a low temperature; implementation of flora transplantation is facilitated, and invasive implementation manners, such as a gastroscope, an enteroscope and a nasointestinal feeding tube, are not needed; when the fecal microbiota capsule is applied to weak patients, the safety is increased.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

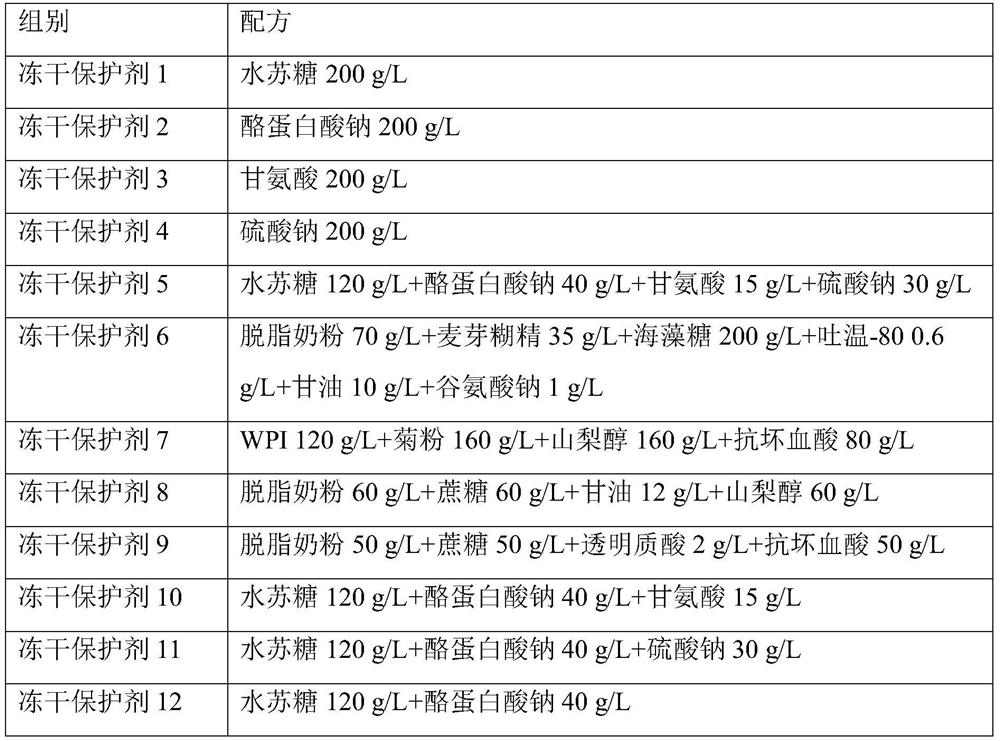

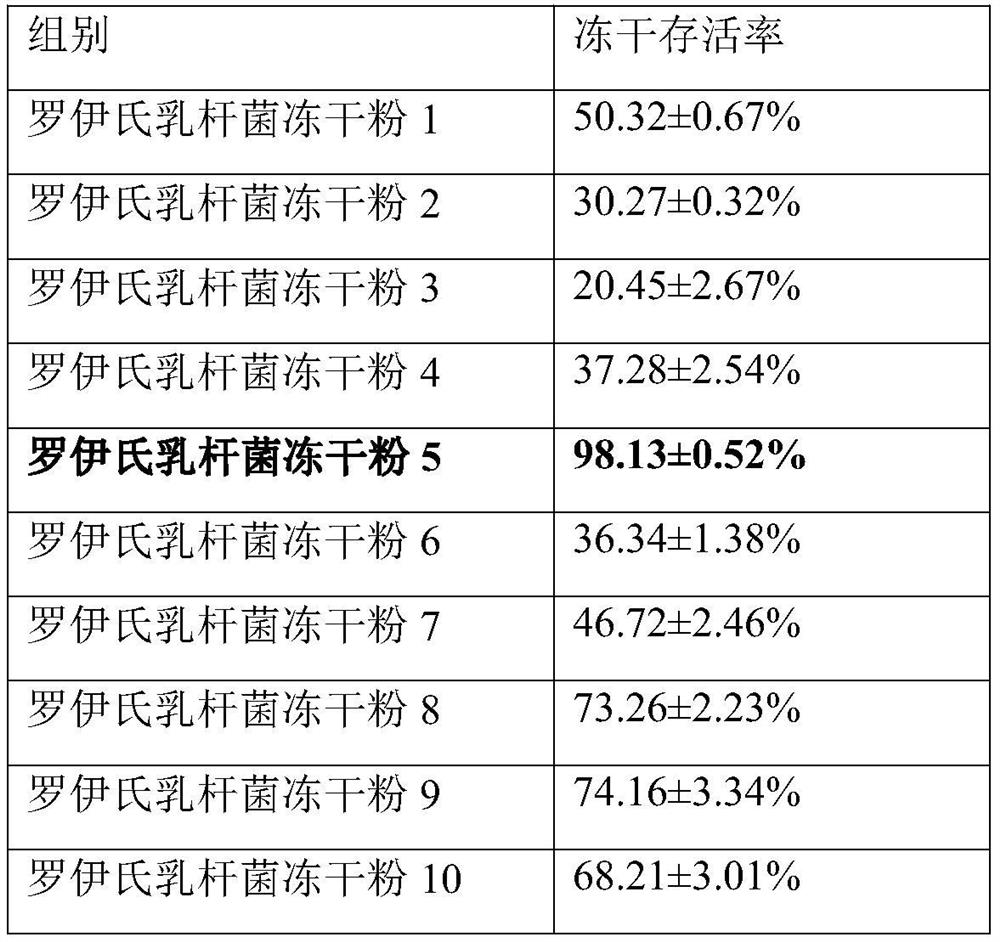

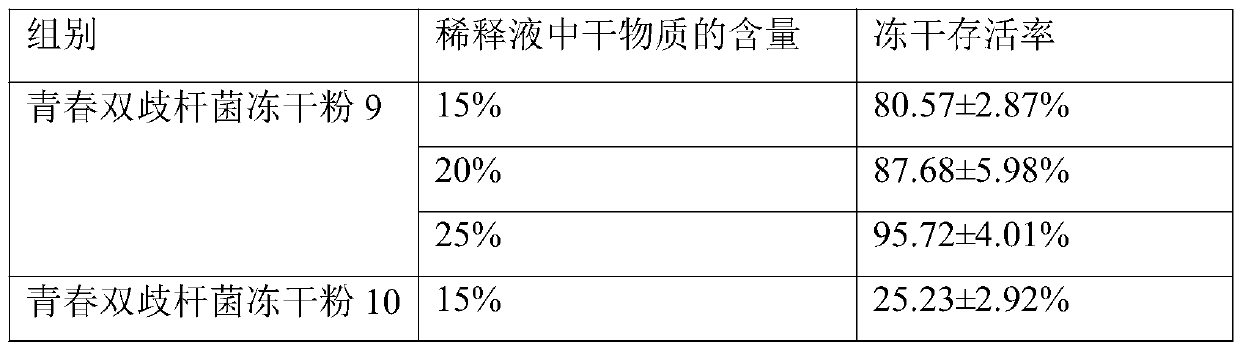

Freeze-drying protective agent and application thereof to freeze-dried lactobacillus reuteri

ActiveCN111621443AImprove freeze-drying survival rateBacteriaMicroorganism based processesStachyose hydrateBacilli

The invention discloses a freeze-drying protective agent and application thereof to freeze-dried lactobacillus reuteri, and belongs to the technical field of microorganisms. The invention provides a freeze-drying protective agent capable of obviously improving a freeze-drying survival rate of the lactobacillus reuteri. Ingredients of the freeze-drying protective agent comprise stachyose, sodium caseinate, glycine and sodium sulfate; and when lactobacillus reuteri freeze-dried powder is prepared by using the freeze-drying protective agent, the freeze-drying survival rate of the lactobacillus reuteri can reach 100%.

Owner:JIANGNAN UNIV

Freeze-drying protective agent and application thereof to freeze-drying of bifidobacterium adolescentis

ActiveCN111534434AImprove freeze-drying survival rateBacteriaMicroorganism based processesBiotechnologyMicroorganism

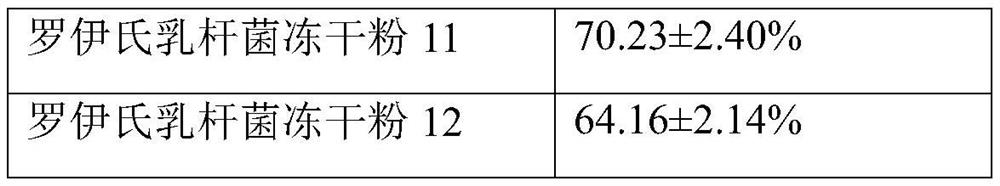

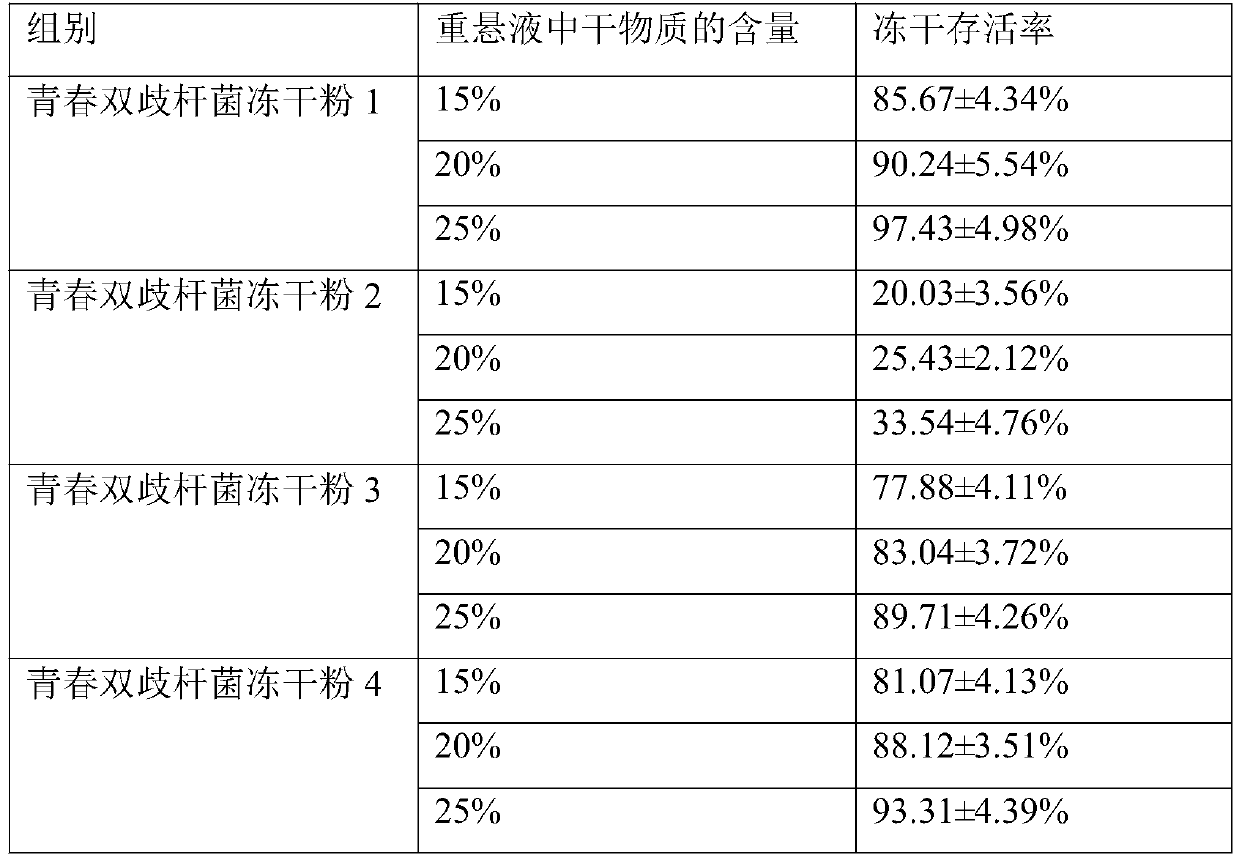

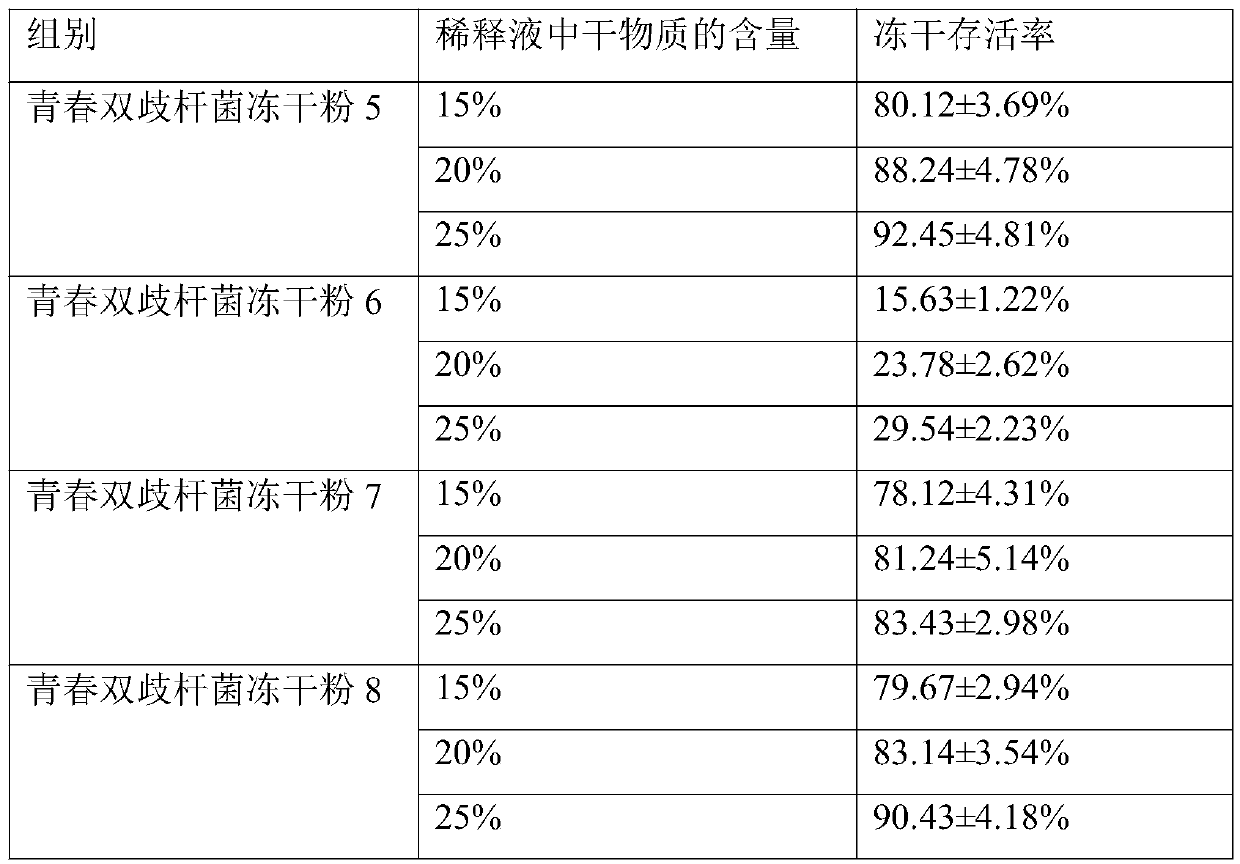

The invention discloses a freeze-drying protective agent and an application thereof to freeze-drying of bifidobacterium adolescentis, belongs to the technical field of microorganisms, and provides thefreeze-drying protective agent capable of obviously increasing the freeze-drying survival rate of the bifidobacterium adolescentis. The freeze-drying protective agent comprises the components of sorbitol, raffinose and whey protein; and when lyophilized powder of the bifidobacterium adolescentis is prepared by use of the freeze-drying protective agent, the freeze-dried survival rate of the bifidobacterium adolescentis is as high as 97.43 plus or minus 4.98%.

Owner:JIANGNAN UNIV

Novel thermophilic lactobacillus and application thererof in wet corn soaking process

ActiveCN109234186AImprove immersion efficiencyAvoid manual additionBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a novel thermophilic lactobacillus and the application thererof in the wet corn soaking process. The bacterial species preservation information of the thermophilic lactobacillus is as follows: name of preservation unit: Common Microbial Center of China Microbial Strain Collection Management Committee; Depository address: Institute of Microbiology, Chinese Academy of Sciences, No. 3 Academy, No. 1 Beichen West Road, Chaoyang District, Beijing; Date of deposit: 18 April 2018; Deposit No.: CGMCC No. 15623; Taxonomic name: Bacillus coagulans.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

Streptococcus thermophilus freeze-drying protective agent and preparation method thereof

ActiveCN102952771BImprove freeze-drying survival rateExtended shelf lifeBacteriaMicroorganism based processesFreeze-dryingDextran

Owner:SHAANXI YATAI DAIRY CO LTD

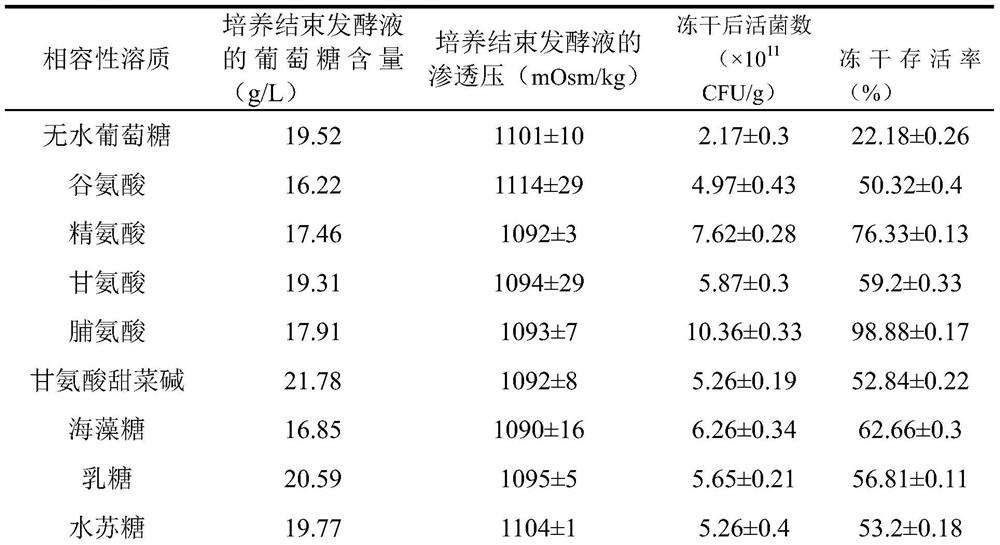

Culture method for improving freeze-drying stress resistance of bifidobacterium and application thereof

ActiveCN113234597AImprove survival rateImprove freeze-drying survival rateBacteriaMicroorganism based processesBacilliBifidobacterium

The invention discloses a culture method for improving freeze-drying stress resistance of bifidobacterium and application thereof, and belongs to the technical field of microorganisms and the technical field of fermentation and freeze-drying. The invention provides the method for increasing the freeze-drying survival rate of the bifidobacterium by adding the compatible solute into the culture medium for high-density fermentation of the bifidobacterium, the bifidobacterium is inoculated into the culture medium containing the compatible solute for high-density culture to a stable phase, the freeze-drying stress resistance of the bifidobacterium can be remarkably improved, and the freeze-drying survival rate of the bifidobacterium is maximally increased by 3.02 times (under the action of the same protective agent); according to the culture method, the freeze-drying survival rate of the bifidobacteria can be remarkably increased, and the freeze-drying survival rate of the bifidobacteria is increased from 10%-20% to 40%-60%.

Owner:JIANGNAN UNIV

Lactobacillus agent composition directly applied to corn soaking process

ActiveCN109234185AImprove immersion efficiencyAvoid manual additionBacteriaMicroorganism based processesMicroorganismMicrobial agent

The invention relates to a lactobacillus agent composition directly applied to the corn soaking process. The composition is composed of a microbial bacterial agent A and a microbial bacterial agent B.With a mass ratio of 1: 1.0-1.5; The microbial agent A is composed of thermophilic lactobacillus LAB 0 # and lyophilized protective agent; The microbial agent B is composed of thermophilic lactobacillus LAB 1 # and lyophilized protective agent.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

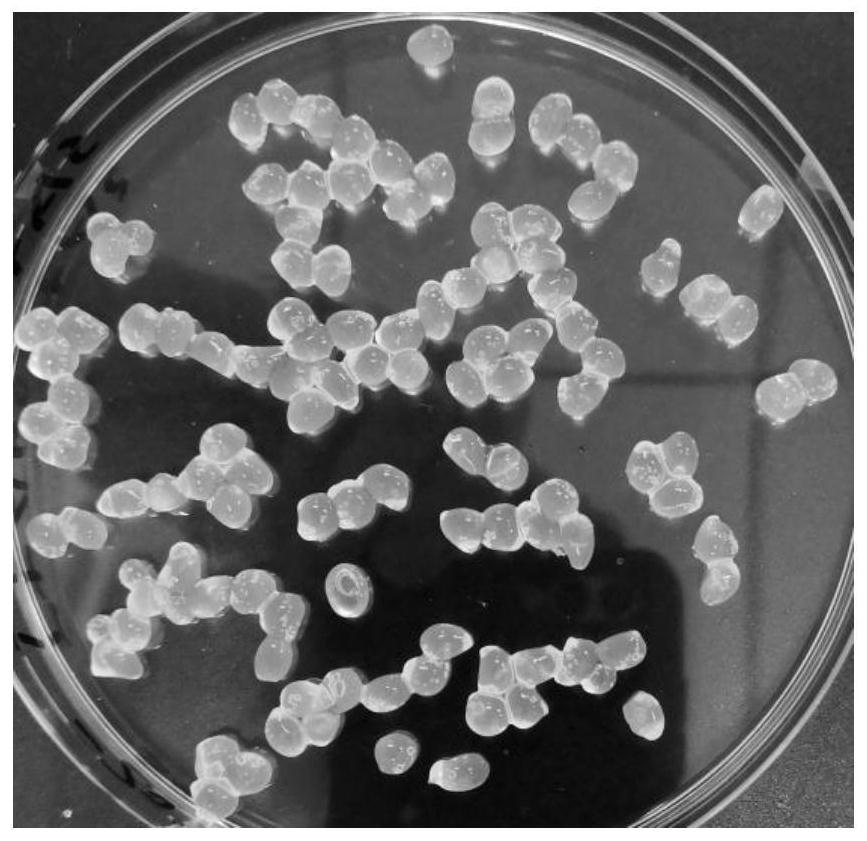

Micromolecular sugar/hyaluronic acid/calcium ion crosslinked polysaccharide gel bead and preparation method thereof

PendingCN113812632AImprove freeze-drying survival rateImprove survival rateSugar food ingredientsFood shapingSugarProbiotic bacteria

The invention discloses a micromolecular sugar / hyaluronic acid / calcium ion crosslinked polysaccharide gel bead and a preparation method thereof. The micromolecular sugar / hyaluronic acid / calcium ion crosslinked polysaccharide gel bead comprises the following components: micromolecular sugar, hyaluronic acid, calcium ions and polysaccharide. According to the finished product and the preparation method provided by the invention, the micromolecular sugar, hyaluronic acid with different molecular weights and calcium ion crosslinked polysaccharide are used as wall materials, and the gel bead loaded with probiotics is formed by adopting an extrusion method. The system can obviously improve the freeze-drying survival rate of probiotics, the survival rate during storage and the survival rate of gastrointestinal digestion.

Owner:JIANGNAN UNIV

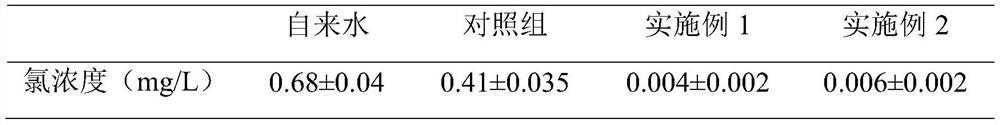

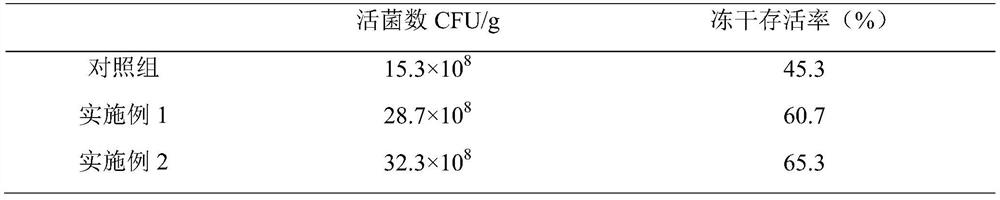

High-density fermentation culture medium of lactobacillus bulgaricus and fermentation process for high-density fermentation culture medium

ActiveCN112501074AIncrease the number of viable fermentation bacteriaSolve process problemsBacteriaMicroorganism based processesBiotechnologyLactobacillus

The invention belongs to the technical field of fermentation and particularly relates to a high-density fermentation culture medium of lactobacillus bulgaricus and a fermentation process for the high-density fermentation culture medium. Influence on thallus propagation and a subsequent fungus powder preparation process caused by inhibitors in drinking water employed in a fermentation process and lactic acid generated from metabolism is effectively solved. The lactobacillus bulgaricus is subjected to high-density culture by employing the high-density fermentation culture medium, and the viablecount and freeze-dried survival rate of fermentation liquor are increased remarkably. Therefore, application of this technology is beneficial to increase of production efficiency of Lactobacillus bulgaricus powder and reduction of production cost.

Owner:内蒙古双奇药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com