Micromolecular sugar/hyaluronic acid/calcium ion crosslinked polysaccharide gel bead and preparation method thereof

A technology of calcium ion cross-linking and hyaluronic acid, which is applied in the field of popping beads to achieve the effect of improving the survival rate of freeze-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

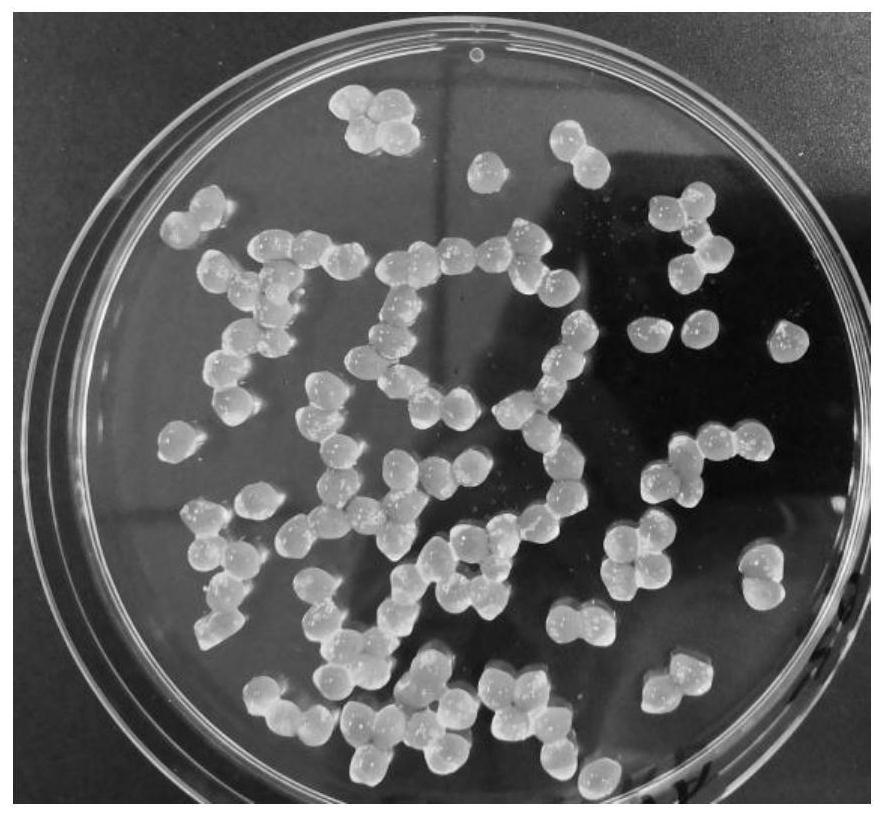

Embodiment 1

[0037] (1) Configure liquid medium, solid medium, 0.85% saline, and use an autoclave to sterilize at 115°C for 20 minutes together with other utensil materials;

[0038] (2) Take the frozen Lactobacillus rhamnosus LGG and inoculate it in a liquid medium for anaerobic culture for 24 hours, and centrifuge (4°C, 3500g, 10 minutes) to wash twice to make a bacterial suspension;

[0039] (3) Weigh trehalose in deionized water at a concentration of 5% (w / v), and stir until completely dissolved;

[0040] (4) Weigh 1,000,000 Da of hyaluronic acid into the solution of step (3) at a concentration of 0.5% (w / v), and stir until completely dissolved;

[0041] (5) Weigh sodium alginate in the solution of step (4), the concentration is 1.0% (w / v), stir until completely dissolved and degas;

[0042] (6) Weigh calcium chloride in deionized water with a concentration of 1.9% (w / v), and stir until completely dissolved;

[0043] (7) Get step (2) bacterium suspension and add the core material liq...

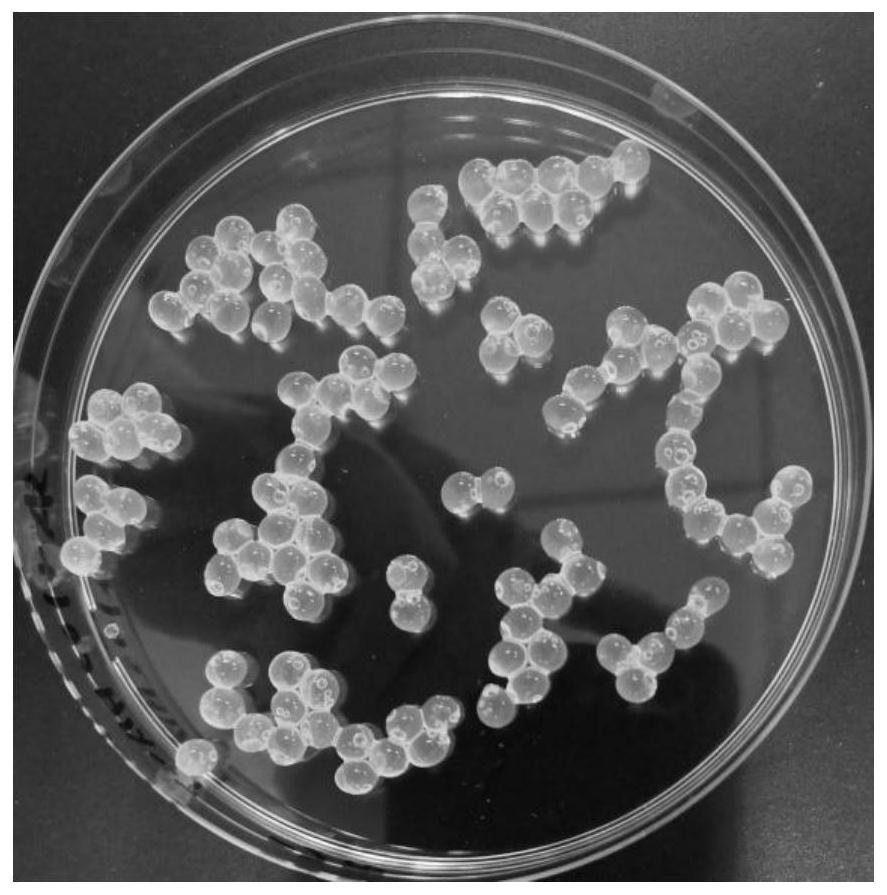

Embodiment 2

[0047] (1) Configure liquid medium, solid medium, 0.85% saline, and use an autoclave to sterilize at 115°C for 20 minutes together with other utensil materials;

[0048] (2) Take the frozen Lactobacillus rhamnosus LGG and inoculate it in a liquid medium for anaerobic culture for 24 hours, and centrifuge (4°C, 3500g, 10 minutes) to wash twice to make a bacterial suspension;

[0049] (3) Weigh trehalose in deionized water at a concentration of 5% (w / v), and stir until completely dissolved;

[0050] (4) Weigh 300,000 Da of hyaluronic acid in the solution of step (3) at a concentration of 0.5% (w / v), and stir until completely dissolved;

[0051] (5) Weigh sodium alginate in the solution of step (4), the concentration is 1.0% (w / v), stir until completely dissolved and degas;

[0052] (6) Weigh calcium chloride in deionized water with a concentration of 1.9% (w / v), and stir until completely dissolved;

[0053] (7) Get step (2) bacterium suspension and add the core material liquid ...

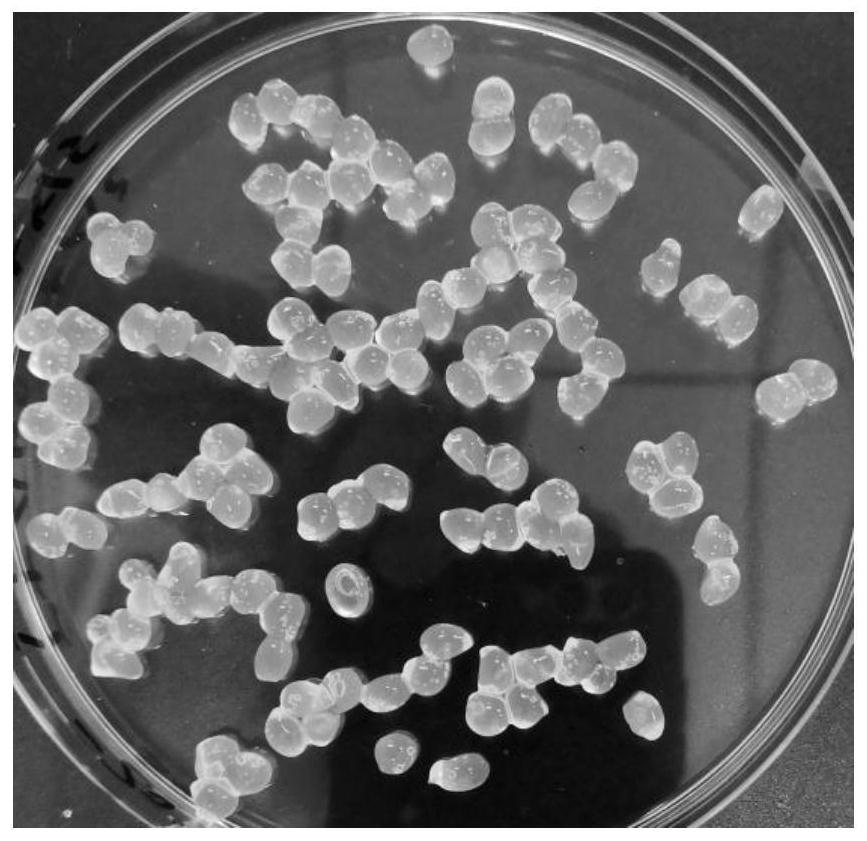

Embodiment 3

[0057] (1) Configure liquid medium, solid medium, 0.85% saline, and use an autoclave to sterilize at 115°C for 20 minutes together with other utensil materials;

[0058] (2) Take the frozen Lactobacillus rhamnosus LGG and inoculate it in a liquid medium for anaerobic culture for 24 hours, and centrifuge (4°C, 3500g, 10 minutes) to wash twice to make a bacterial suspension;

[0059] (3) Weigh trehalose in deionized water at a concentration of 2% (w / v), and stir until completely dissolved;

[0060] (4) Weigh 300,000 Da of hyaluronic acid in the solution of step (3) at a concentration of 0.5% (w / v), and stir until completely dissolved;

[0061] (5) Weigh sodium alginate in the solution of step (4), the concentration is 1.0% (w / v), stir until completely dissolved and degas;

[0062] (6) Weigh calcium chloride in deionized water with a concentration of 1.9% (w / v), and stir until completely dissolved;

[0063] (7) Get step (2) bacterium suspension and add the core material liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com