Culture method for improving freeze-drying stress resistance of bifidobacterium and application thereof

A technology of bifidobacteria and freeze-dried bacteria powder, which is applied in the field of fermentation, freeze-drying, and microorganisms, can solve the problems of single stress resistance method, insignificant effect, and reduce the growth rate, survival rate, and metabolic activity of lactic acid bacteria, and achieve Improve the survival rate of freeze-drying, the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: fermentation and freeze-drying process of bifidobacterium

[0060] Specific steps are as follows:

[0061] (1) Preparation of bifidobacterium seed liquid:

[0062] Streak the preserved bifidobacterium on the MRS solid medium, culture at 37°C for 36 hours to obtain a single colony; pick a single colony and inoculate it in the MRS liquid medium, culture at 37°C for 24 hours to obtain the seed solution;

[0063] (2) Inoculate the prepared seed solution into a Erlenmeyer flask containing MRS liquid medium at an inoculum size of 5% (v / v), and culture it anaerobically at 37° C. for 24 hours to obtain a culture solution;

[0064] (3) Preparation of fermentation medium containing compatible solutes

[0065] Yeast extract powder FM803 24g / L, anhydrous glucose 60g / L, Tween 80 1mL / L, cysteine hydrochloride 1g / L, MgSO 4 ·7H 2 O 0.35g / L, compatible solute of 10-30g / L; put the fermentation medium in a 5L fermenter, sterilize at 115°C for 15min, fill with nitrogen ...

Embodiment 2

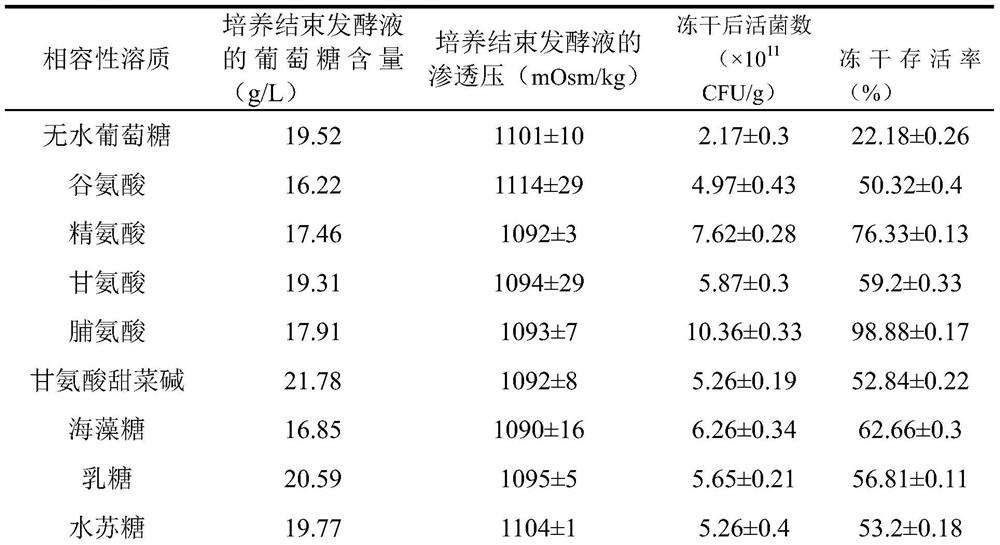

[0071] Embodiment 2: Fermentation and lyophilization of Bifidobacterium longum subsp.infantis CCFM 687

[0072] Specific steps are as follows:

[0073] Scheme 1: The specific implementation method is the same as in Example 1, the difference is that the compatible solute in step (3) is adjusted to 20g / L anhydrous glucose, and Bifidobacterium longum subsp.infantis CCFM 687 bacteria powder is prepared, and the bacteria harvested is detected Glucose content in culture medium, osmotic pressure value at the end of fermentation and freeze-dried survival rate.

[0074] Scheme two: the specific implementation method is the same as in Example 1, the difference is that the compatible solute in step (3) is adjusted to 20g / L of glutamic acid to prepare Bifidobacterium longum subsp.infantis CCFM 687 bacterial powder, and detect the fermentation Glucose content at the end point, osmotic pressure value at the end point of fermentation and freeze-drying survival rate.

[0075] Scheme three: ...

Embodiment 3

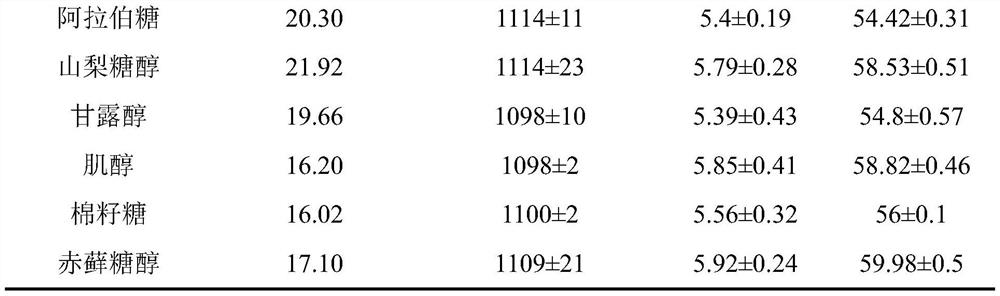

[0092] Embodiment 3: Fermentation and lyophilization of Bifidobacterium longum subsp.longum CCFM 1102

[0093] On the basis of Example 2, the Bifidobacterium longum subsp.infantis CCFM687 of Example 2 was replaced by Bifidobacterium longum subsp.longum CCFM 1102, and the experimental results are shown in Table 2.

[0094] Table 2: Bifidobacterium longum subsp.longum CCFM 1102 fermentation and freeze-drying results using the method of this example

[0095]

[0096]

[0097] The result shows that when the cultivation ends, the glucose content of the fermented liquid is all ≥ 16.00g / L, indicating that the glucose content in the fermentation medium of the present invention is sufficient; the osmotic pressure of the fermented liquid is all close to fully suppressing the osmotic pressure at the end of the fermentation; compared with the blank group, the experimental group After freeze-drying, the number of viable bacteria and the survival rate of freeze-drying were significant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com