Method for improving lyophilized activity of Oenococcus oeni by utilizing stress pretreatment

An oenophilus and pretreatment technology, which is applied in microorganism-based methods, wine preparation, alcoholic beverage preparation, etc., can solve the problems of harsh and complex wine habitat, reduction of surviving bacteria, bacterial damage, etc., and achieve strong industrialization. Implementability, increase freeze-drying survival rate, increase the effect of taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

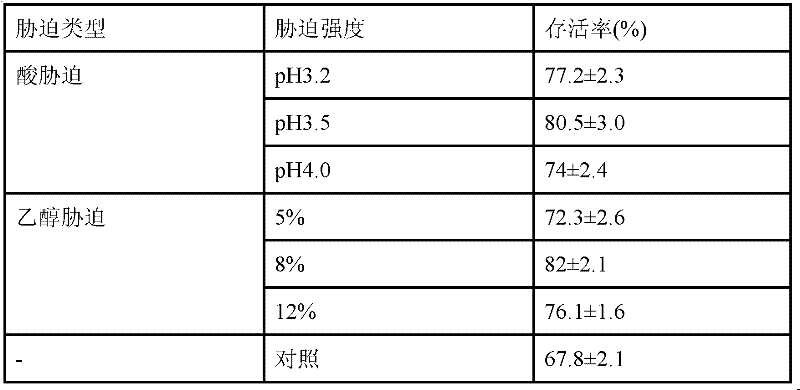

[0035] Centrifuge 1000ml of Oenococcus oeni cells grown to the stable stage at 6000×g for 10min at 4°C, discard the supernatant, wash with normal saline and collect the sludge, add 100ml of ATB medium to the sludge, Adjust the pH value of the ATB medium to 3.5 with hydrochloric acid, mix thoroughly, and let stand at 25°C for 2h.

[0036] After the stress-treated thalline was centrifuged under the same conditions, the bacteria sludge was collected after washing with normal saline, and 100ml of sodium glutamate solution with a mass concentration of 2.5% was added to the bacteria sludge, mixed evenly, and then placed at room temperature for 20 minutes Freeze-dry in a vacuum freeze-dryer for 28 hours to obtain freeze-dried bacterial powder.

[0037] After adding 100ml of ATB medium to the freeze-dried bacteria powder to rehydrate, count the number of live bacteria by plate colony counting method. In the freeze-dried bacteria powder after ordinary freeze-drying, the number of live ...

Embodiment 2

[0040] Centrifuge 1000ml of Oenococcus oeni thallus grown to the stable stage at 3000×g for 15min at 4°C, discard the supernatant, wash with normal saline and collect the sludge, add 100ml of ethanol with a concentration of 8% ATB medium, mix thoroughly, and stand at 25°C for 2.5h.

[0041] After the stress-treated thalline was centrifuged under the same conditions, the bacteria sludge was collected after washing with normal saline, and 50 ml of sodium glutamate solution with a mass concentration of 2.5% was added to the bacteria sludge, mixed evenly, and left to stand at room temperature for 30 minutes. Freeze-dry in a vacuum freeze-dryer for 25 hours to obtain freeze-dried bacterial powder.

[0042] After adding 50ml of ATB medium to the freeze-dried bacteria powder and rehydrating, count the number of live bacteria by plate colony counting method. 10 cfu / ml, and the number of live bacteria in the freeze-dried bacterial powder was 2.55×10 after the ATB medium stress of 8% e...

Embodiment 3

[0045] Centrifuge 500ml of Oenococcus oeni cells grown to the stable stage at 3000×g, 4°C for 10min, discard the supernatant, wash with normal saline and collect the sludge, add 100ml of ethanol concentration of 10% to the sludge ATB medium, mix thoroughly, and stand at 25°C for 2h.

[0046] Centrifuge the stress-treated bacteria under the same conditions, wash with normal saline, collect the bacteria sludge, add 50ml of 5% sodium glutamate solution, mix well, let stand at room temperature for 30min, and freeze in a vacuum freeze dryer. Dry for 25 hours to obtain freeze-dried bacteria powder.

[0047] After adding 50ml of ATB medium to the freeze-dried bacteria powder and rehydrating, the number of viable bacteria was counted by the plate colony counting method. 10 cfu / ml, the number of viable bacteria was 1.3×10 after 2 hours of stress in ATB medium with ethanol concentration of 10%. 10 cfu / ml.

[0048] Put the freeze-dried bacteria powder into 1000ml of wine after alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com