Lyophilization process of lactobacillus plantarum

A technology of freeze-drying of Lactobacillus plantarum, applied in the field of freeze-drying process of Lactobacillus plantarum, to achieve the effect of improving the survival rate of freeze-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

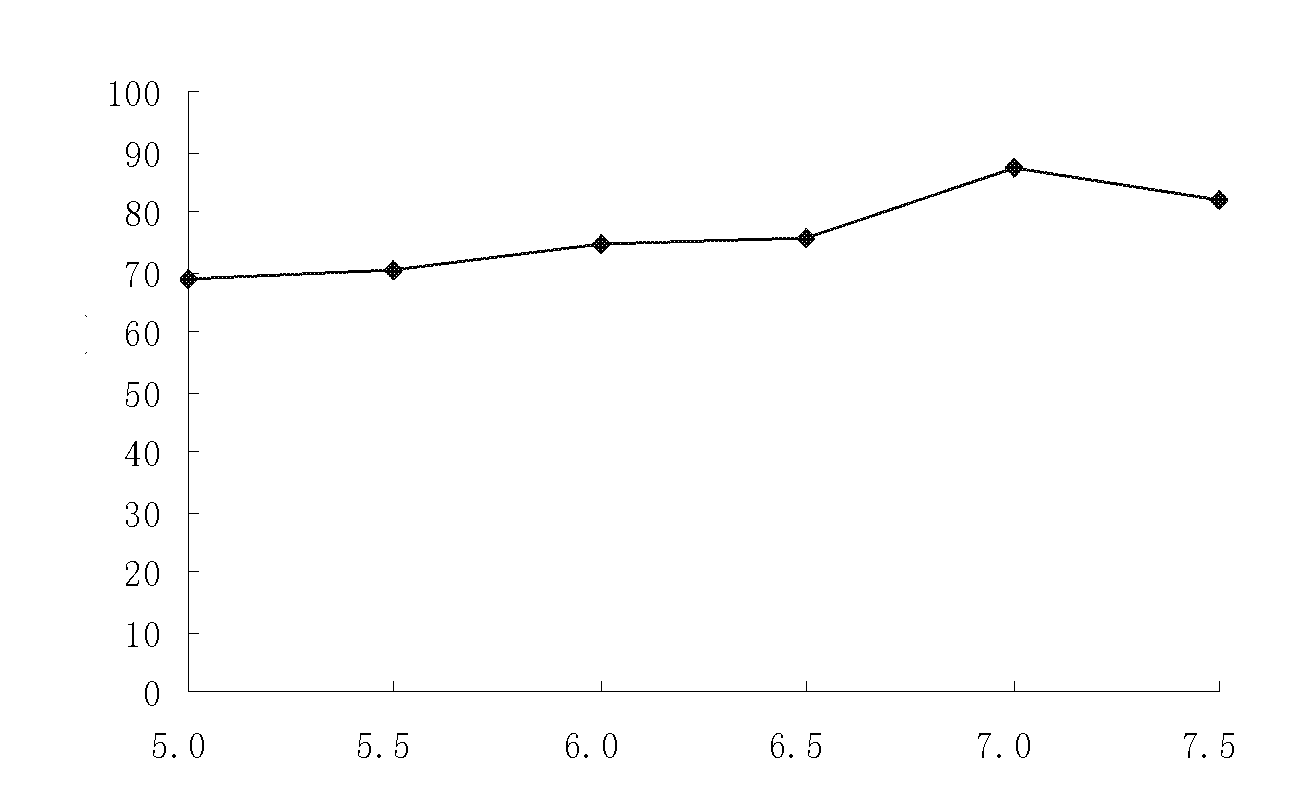

[0034] Embodiment 1 Protective agent pH comparison test.

[0035] 1.1 Materials

[0036] Lactobacillus plantarum, preserved by the Laboratory of Animal Nutrition and Breeding, Institute of Animal Husbandry and Veterinary Medicine, Beijing Academy of Agriculture and Forestry Sciences, was isolated from the cecal mucosa of 60-day-old weaned piglets, and was identified as Lactobacillus plantarum by the China Industrial Microbiology Collection Management Center .

[0037] Lyoprotectant: 14% skimmed milk powder + 2% glycerin + 4% sucrose + 0.15% sodium glutamate + 10% dextrin.

[0038] Counting medium (MRS medium): peptone 10.0g, beef extract 10.0g, yeast powder 5.0g, glucose 20.0g, anhydrous sodium acetate 5.0g, diammonium citrate 2.0g, Tween-801.0ml, dihydrogen phosphate Potassium 2.0g, magnesium sulfate 0.58g, manganese sulfate 0.19g, agar 15g, distilled water 1000ml, pH 6.5, sterilized at 121°C for 20min.

[0039] 1.2 Freeze-drying steps

[0040] The basic parameters of fre...

Embodiment 2

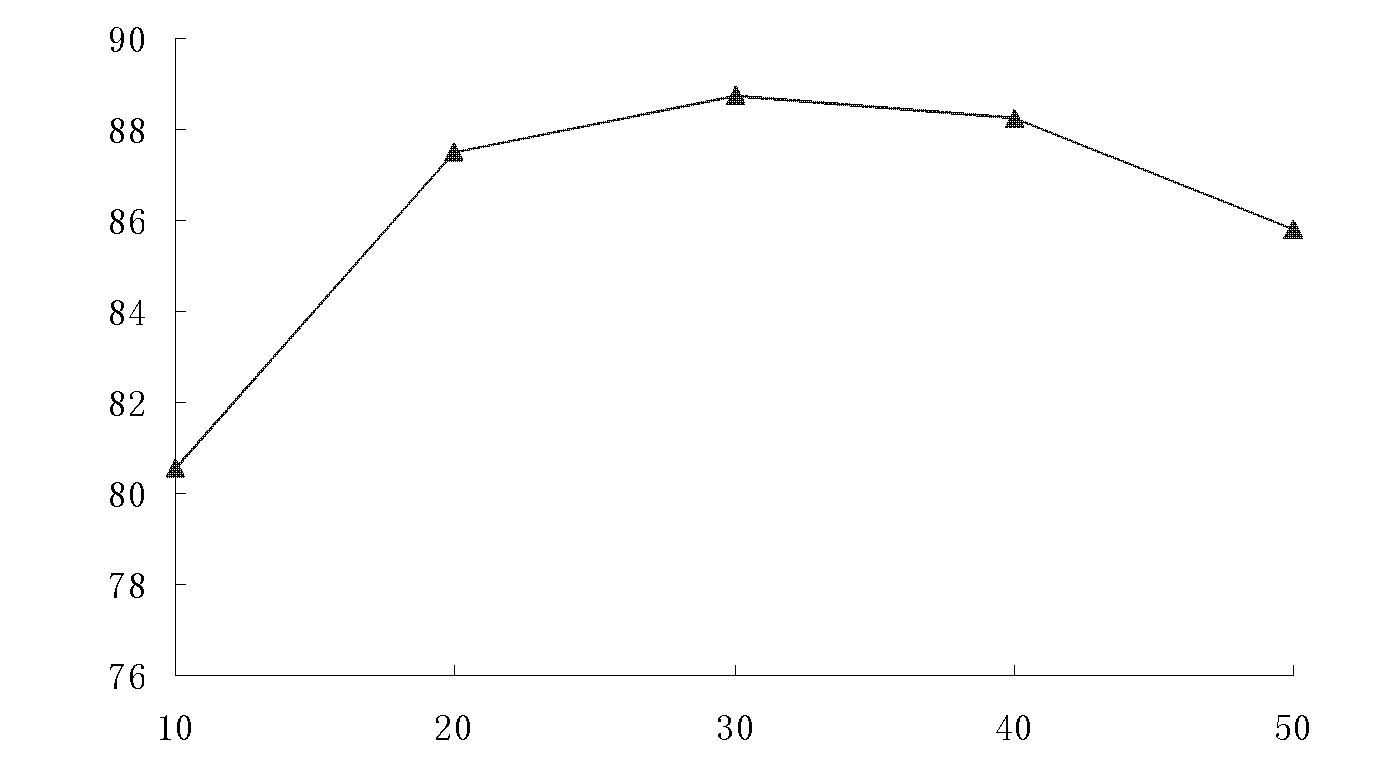

[0048] Embodiment 2. Effect of bacteria slime and protective agent equilibrium time on freeze-drying survival rate

[0049]Centrifuge the sludge and add it to the protective agent. Set 5 treatments. The equilibrium time between the sludge and the protective agent in the 5 treatments is 10, 20, 30, 40, and 50 minutes. Other parameters are the same as in Section 1.2, and then freeze-dried , measure the number of viable bacteria in the freeze-dried powder, and calculate the freeze-dried survival rate, the results are shown in Table 2.

[0050] Table 2 Effect of protective agent and bacteria slime equilibrium time on freeze-dried survival rate of Lactobacillus plantarum

[0051]

[0052] It can be seen from the results that the freeze-dried survival rate of Lactobacillus plantarum gradually increased with the prolongation of the balance time of the protective agent and the bacteria slime. When the balance time was 30 minutes, the freeze-dried survival rate of the bacteria reach...

Embodiment 3

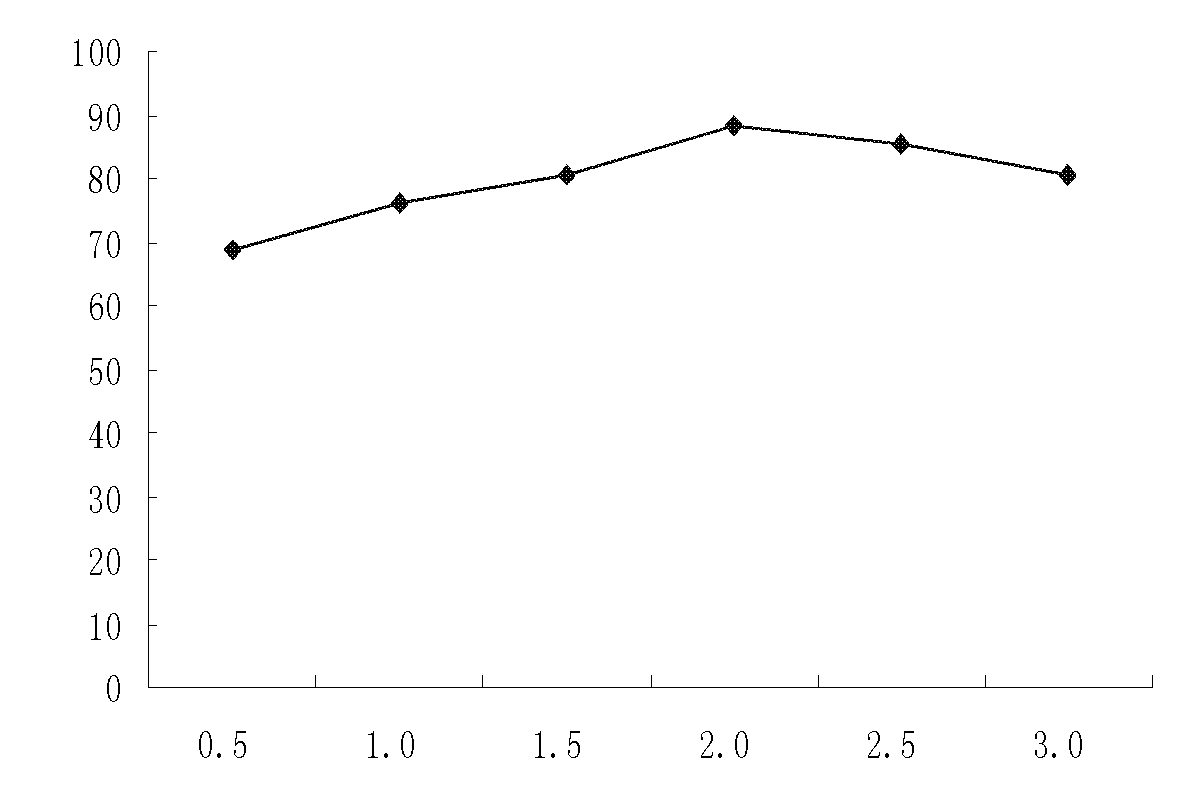

[0053] Embodiment 3. The impact of pre-freezing time on freeze-dried survival rate

[0054] Set up 6 treatments, mix the bacteria slime and protective agent, and take the pre-freezing time as 0.5, 1.0, 1.5, 2.0, 2.5, 3.0 hours respectively, other parameters are the same as section 1.2, measure the number of viable bacteria in the freeze-dried powder, and calculate the freeze-dried survival rate. The results found that when the pre-freezing time was short, the freeze-dried survival rate of Lactobacillus plantarum showed an upward trend, and the freeze-dried survival rate of the strains was the best when the pre-freezing time was 2.0 hours, and then as time went on, the freeze-dried survival rate of the strains increased. start to fall. Considering time efficiency and freeze-drying survival rate comprehensively, 1.5-2.5 hours is a relatively preferable parameter, as shown in Table 3.

[0055] Table 3 The influence of pre-freezing time on the freeze-dried survival rate of Lacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com