Freeze-drying protective agent and application thereof to freeze-dried lactobacillus reuteri

A technology of Lactobacillus reuteri and freeze-drying protective agent, which is applied in the field of microorganisms, can solve the problems of low viable count of Lactobacillus reuteri, destruction of pH dynamic balance, and decreased activity of Lactobacillus reuteri, so as to improve the efficiency of freeze-drying. The effect of stem survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

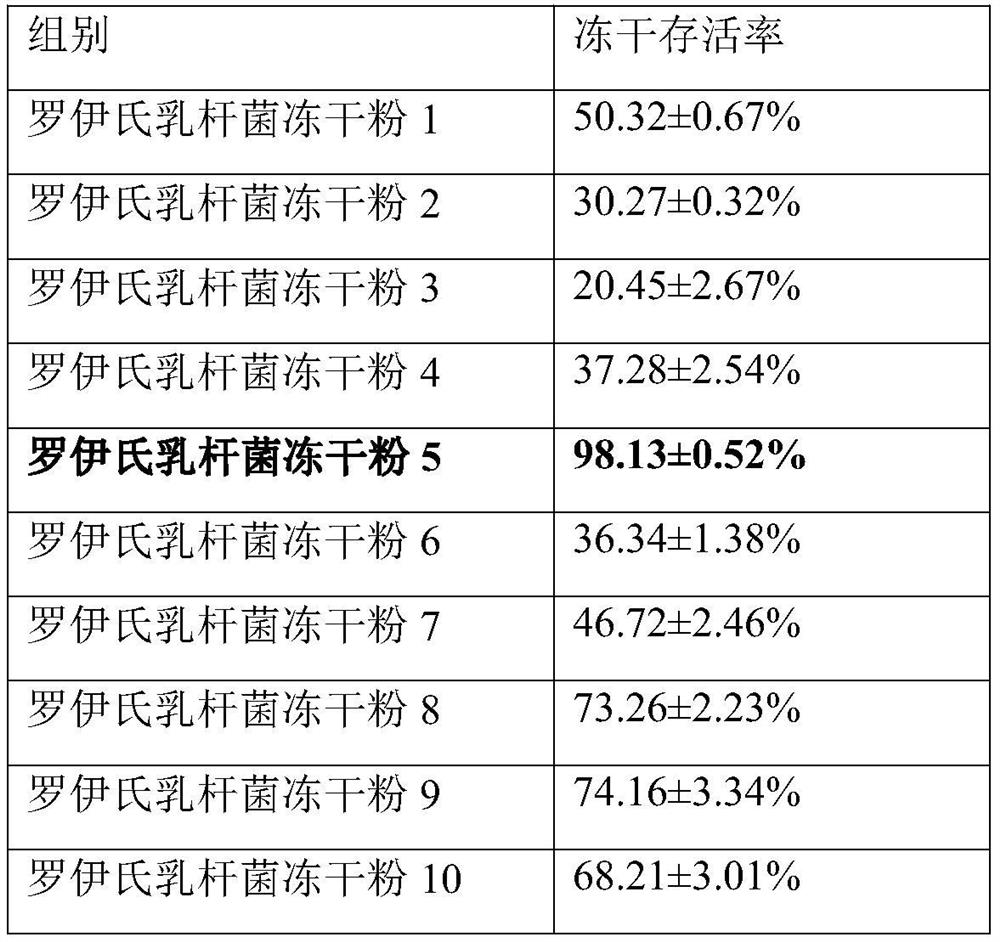

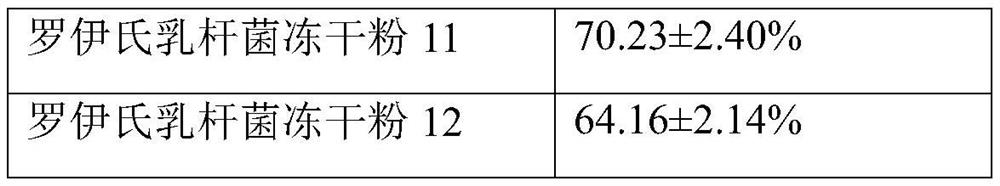

[0038] Embodiment 1: Preparation of Lactobacillus reuteri freeze-dried powder (Lactobacillus reuteri GDMCC No.60515)

[0039] Specific steps are as follows:

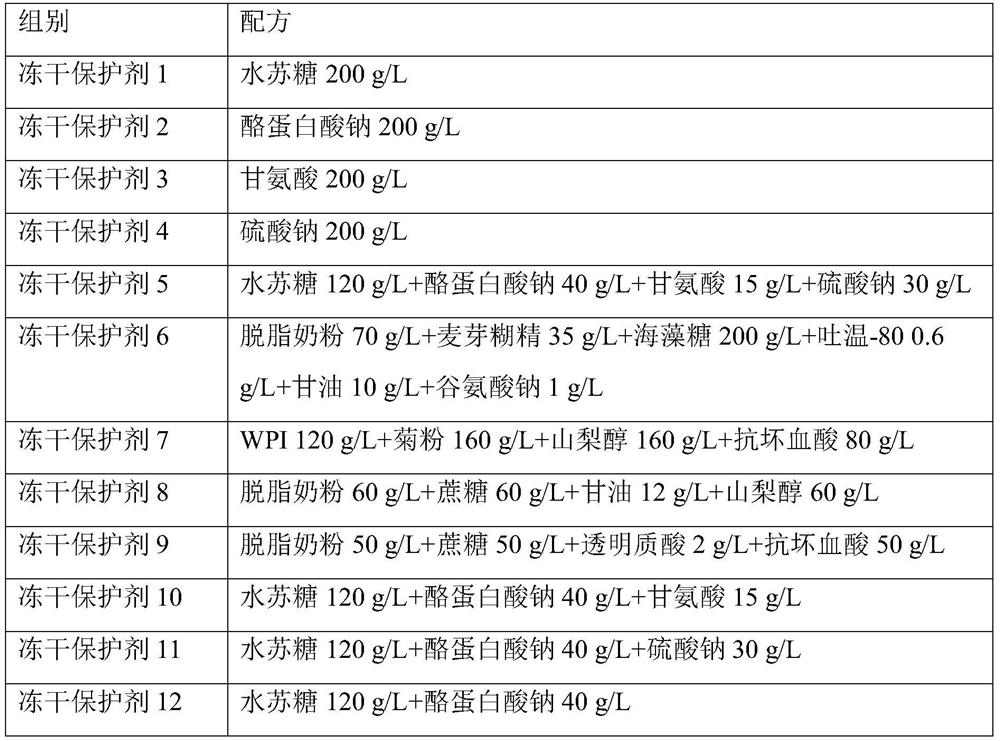

[0040](1) Configure freeze-drying protective agents 1-12 according to the formula in Table 1; among them, stachyose solution, sodium sulfate solution, maltodextrin solution, trehalose solution, Tween-80, glycerin solution, inulin solution, sorbic acid Alcohol solution and sucrose solution are sterilized at 115°C for 20 minutes, sodium caseinate solution is sterilized at 65°C for 30 minutes, glycine solution, hyaluronic acid solution, ascorbic acid solution, and sodium glutamate solution are sterilized through membrane, and skimmed milk powder solution is sterilized at 105°C Sterilize for 10 minutes, whey protein isolate (WPI) solution is sterilized at 85°C for 30 minutes;

[0041] (2) Dip the Lactobacillus reuteri GDMCC No.60515 bacterial solution in the bacteria preservation tube with an inoculation loop, streak it on ...

Embodiment 2

[0050] Embodiment 2: Preparation of Lactobacillus reuteri freeze-dried powder

[0051] Specific steps are as follows:

[0052] On the basis of Example 1, Lactobacillus reuteri GDMCC No.60515 was replaced with Lactobacillus reuteri CGMCC No.14394 to obtain Lactobacillus reuteri freeze-dried powder 13-24.

[0053] Detect the number of live bacteria of Lactobacillus reuteri in Lactobacillus reuteri freeze-dried powder 13~24, and calculate the freeze-dried survival rate of Lactobacillus reuteri in Lactobacillus reuteri freeze-dried powder 13~24 (detection The results are shown in Table 3).

[0054] As can be seen from Table 3, use the freeze-dried powder of Lactobacillus reuteri prepared by containing stachyose 120g / L, sodium caseinate 40g / L, glycine 15g / L and sodium sulfate 30g / L. The freeze-dried survival rate of Lactobacillus eiferii was the highest, as high as 104.42±2.47%.

[0055] The freeze-drying survival rate of Lactobacillus reuteri in table 3 Lactobacillus reuteri fr...

Embodiment 3

[0057] Embodiment 3: the preparation of Lactobacillus reuteri freeze-dried powder

[0058] Specific steps are as follows:

[0059] On the basis of Example 1, Lactobacillus reuteri GDMCC No.60515 was replaced with Lactobacillus reuteri GDMCC No.60735 to obtain Lactobacillus reuteri freeze-dried powder 25-36.

[0060] Detect the number of live bacteria of Lactobacillus reuteri in Lactobacillus reuteri freeze-dried powder 25~36, and calculate the freeze-dried survival rate of Lactobacillus reuteri in Lactobacillus reuteri freeze-dried powder 25~36 (detection The results are shown in Table 4).

[0061] As can be seen from Table 4, use the freeze-dried powder of Lactobacillus reuteri prepared by the freeze-dried powder containing stachyose 120g / L, sodium caseinate 40g / L, glycine 15g / L and sodium sulfate 30g / L. The freeze-dried survival rate of Lactobacillus eiferii was the highest, as high as 99.72±4.01%.

[0062] The freeze-drying survival rate of Lactobacillus reuteri in table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com