High-strength polyurethane rigid foam as well as preparation method and application thereof

A technology of rigid foam plastics and polyurethane, applied in the field of high-strength polyurethane rigid foam plastics, can solve the problems of increased usage of flame retardant additives, foam release, poor strength, fluidity and other performance problems, and achieve flame retardancy Improved performance and heat resistance, good mold release and heat insulation performance, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

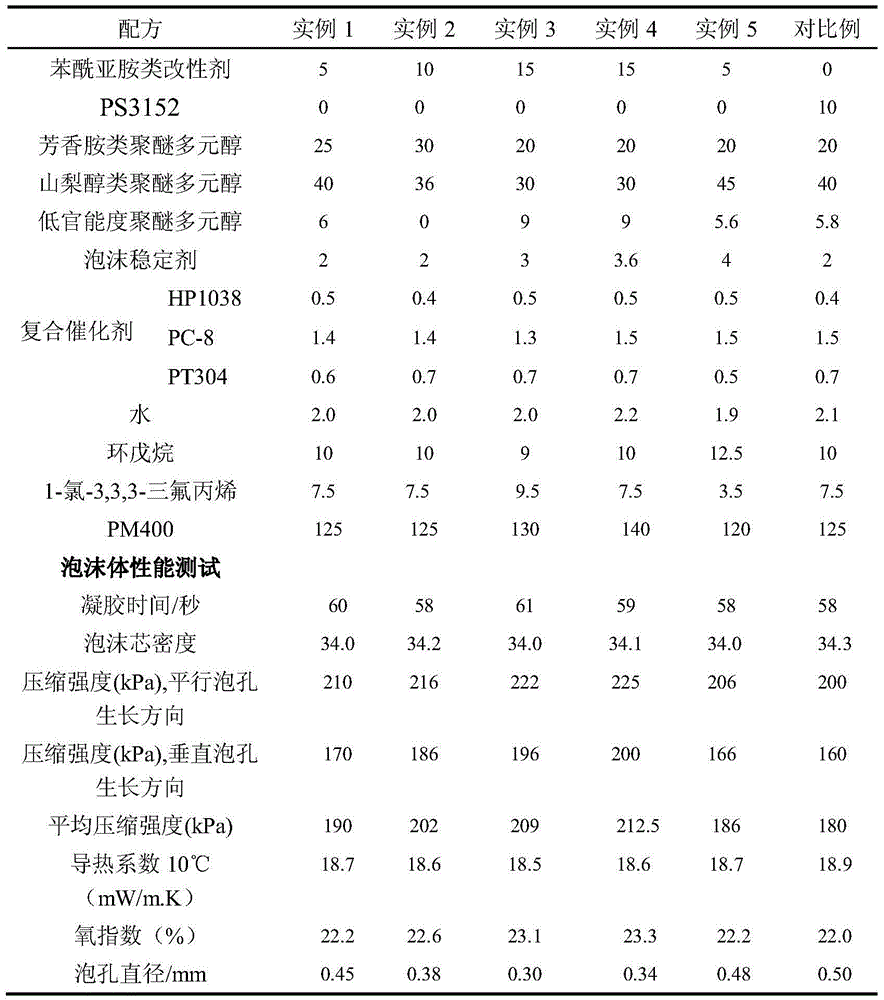

[0036] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

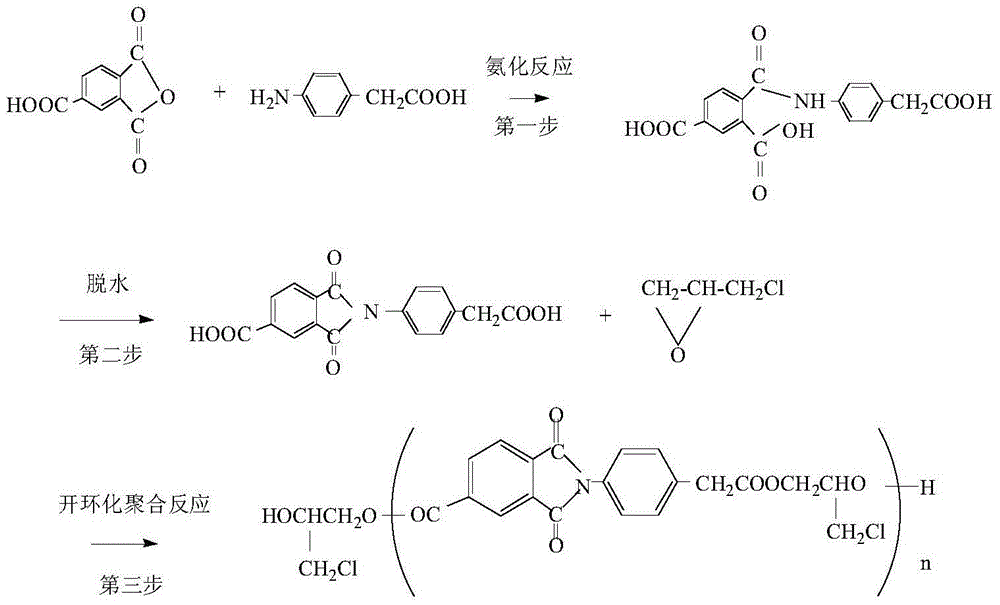

[0037] Benzene imide modifier:

[0038] Add trimellitic anhydride and p-aminophenylacetic acid and 300ml acetone solvent into the reaction kettle with a molar ratio of 1:1, and then add 2.0wt% catalyst based on trimellitic anhydride and p-aminophenylacetic acid total amount after completely dissolving Anhydrous sodium acetate was subjected to ammoniation dehydration cyclization reaction at 70°C for 3 hours to form a nitrogen-containing five-membered heterocyclic dicarboxylic acid. The dibasic acid is then reacted with epichlorohydrin (molar ratio=1:2.0) through the catalysis of 0.6wt% triphenylphosphine to obtain a hydroxyl value of 220±25mgKOH / g and a functionality of 2.

[0039] Preparation of aromatic amine polyether polyols:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com